Morphologies, Compatibilization and Properties of Immiscible PLA-Based Blends with Engineering Polymers: An Overview of Recent Works

Abstract

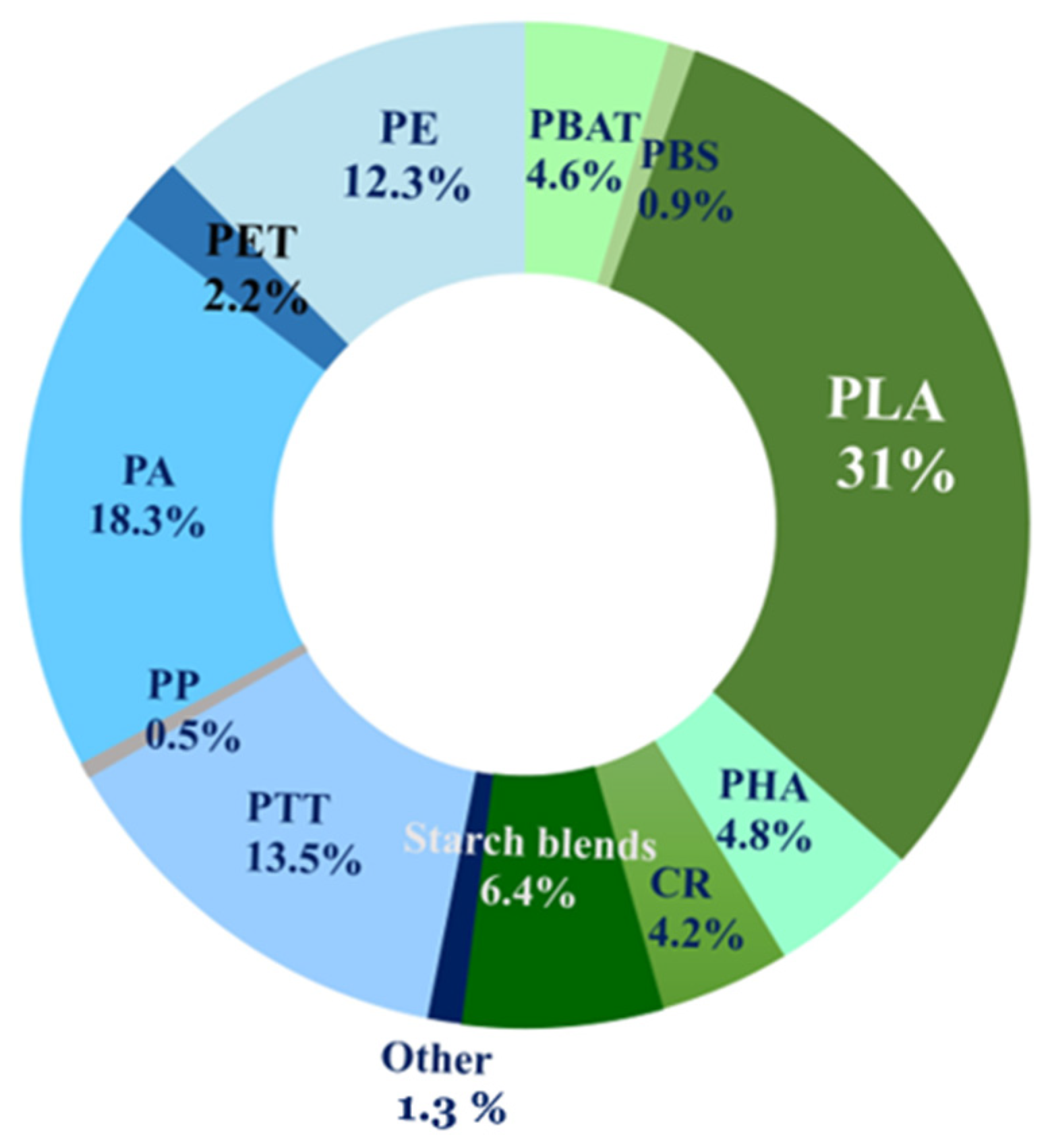

:1. Introduction: A Quest for High-Performance PLA-Based Materials

2. Fundamental Concepts Regarding Polymer Blends

2.1. Miscible Polymer Blends

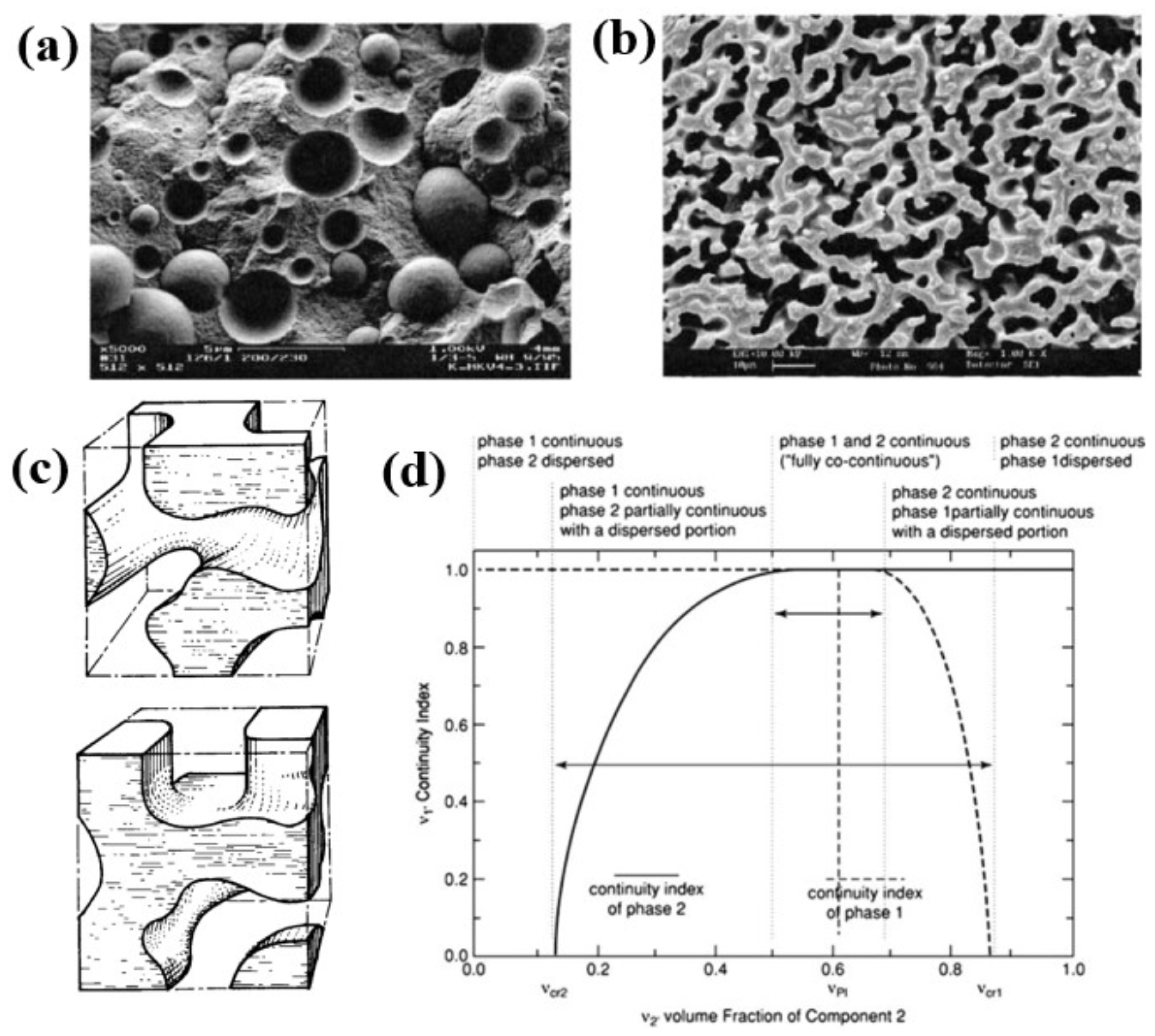

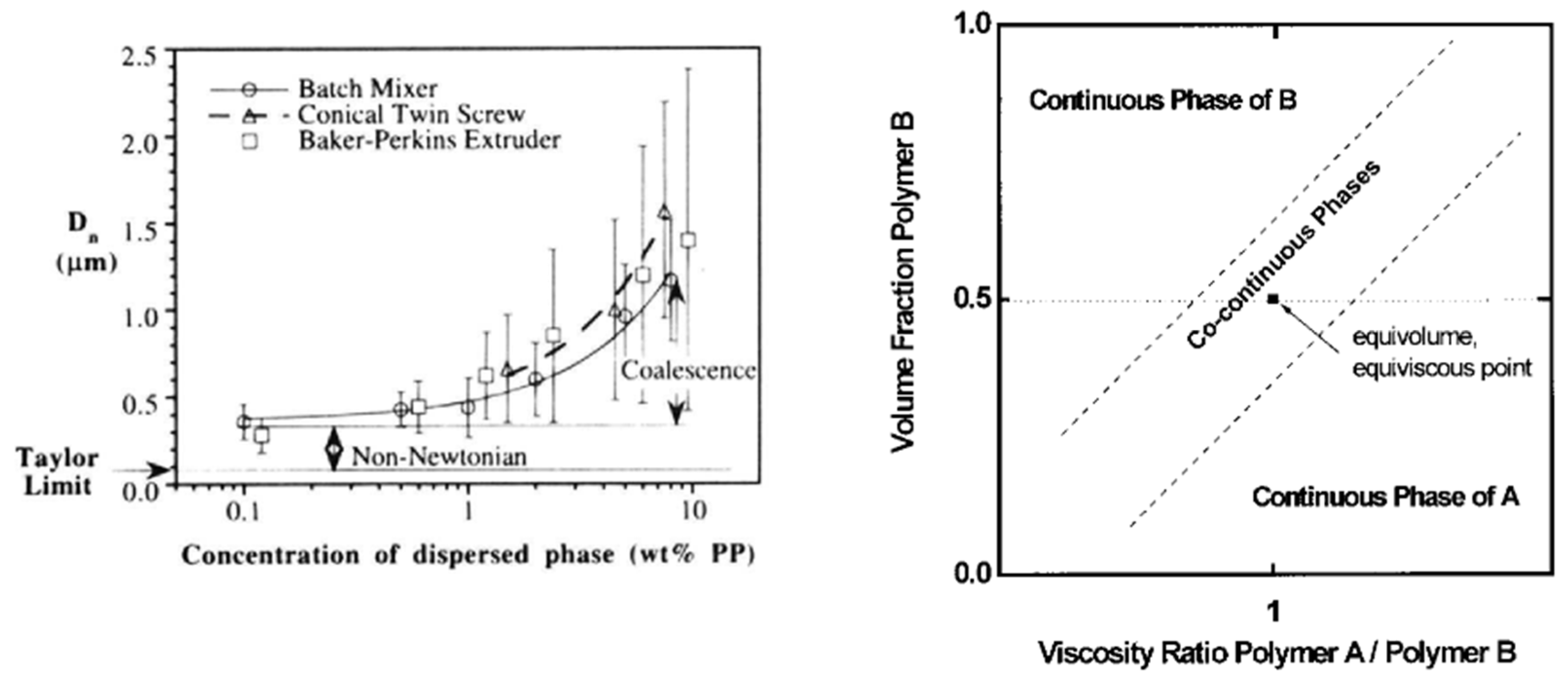

2.2. Immiscible Polymer Blends—Morphology

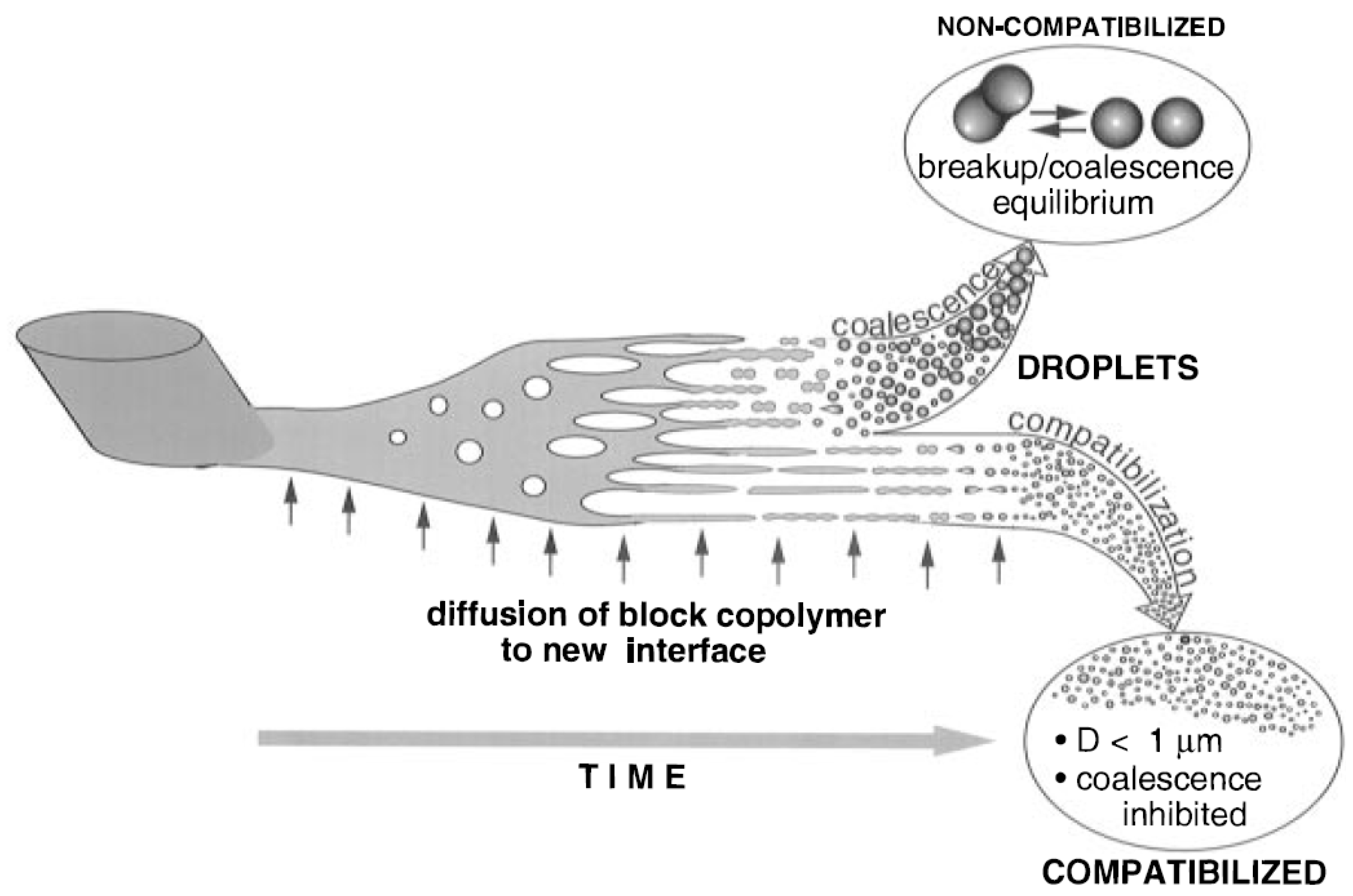

2.3. Compatibility in Immiscible Polymer Blends

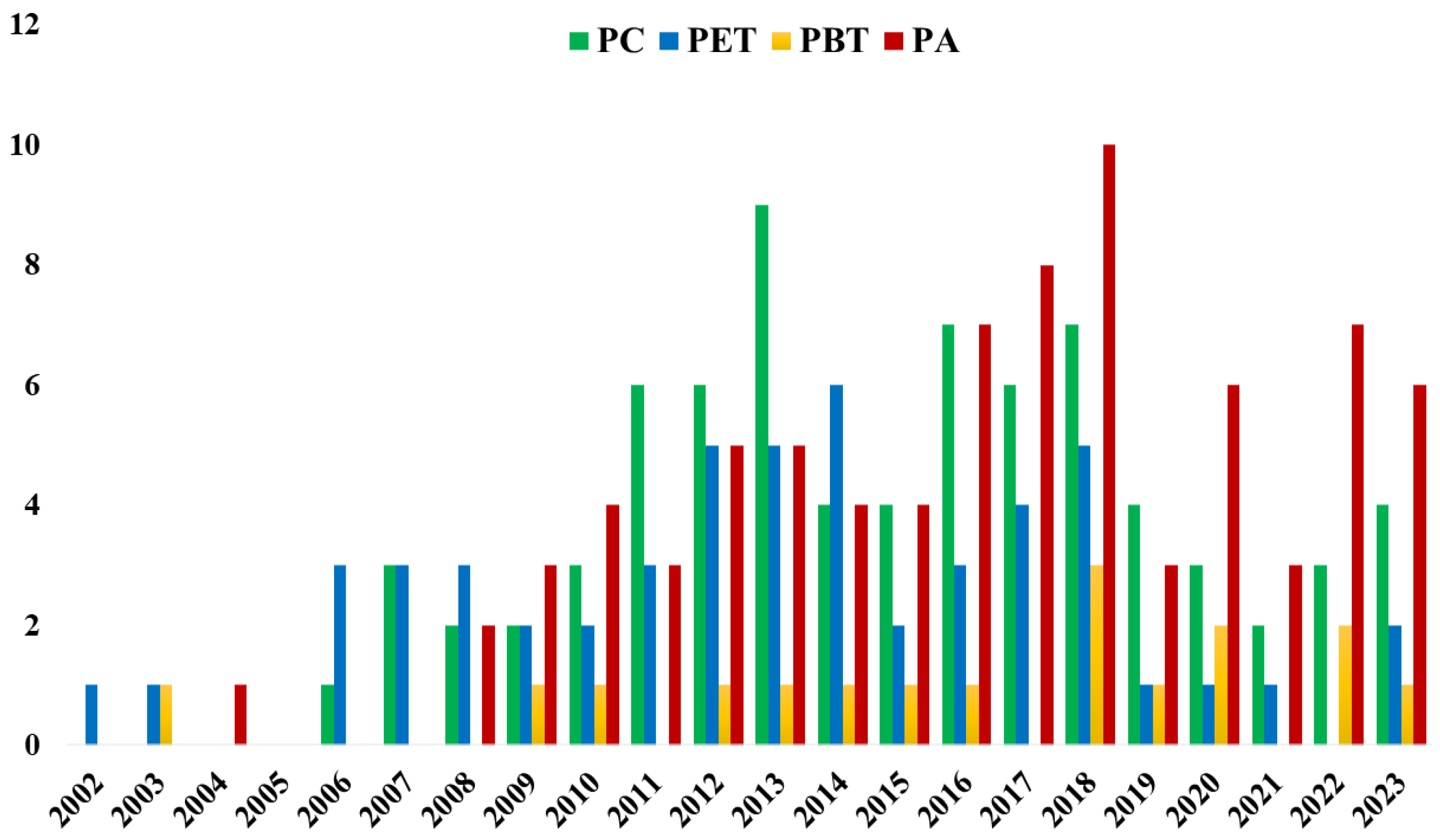

3. Overview of PLA-Based Blends with Engineering Polymers

3.1. General Considerations

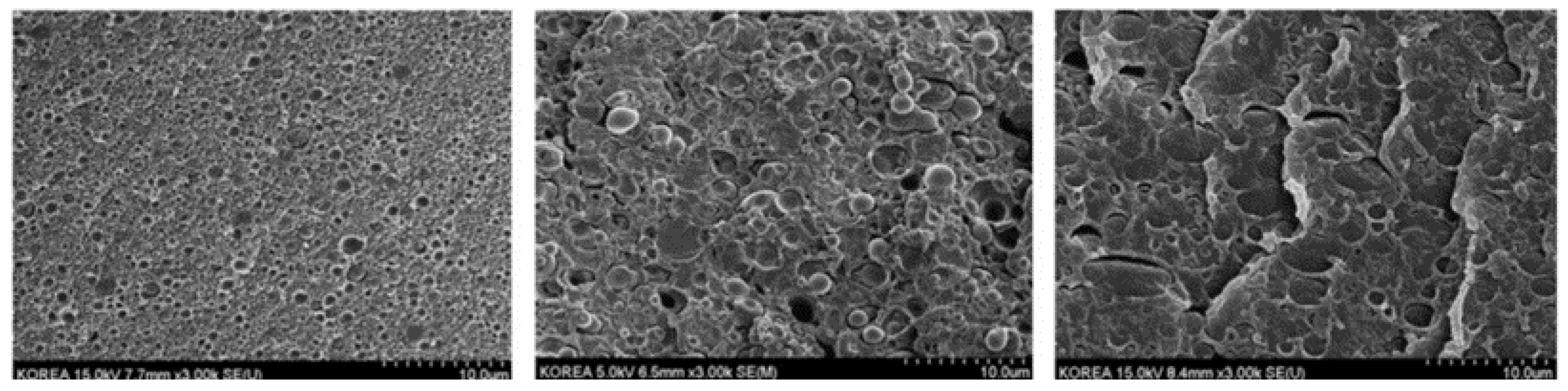

3.2. PLA-Based Blends with Poly(Carbonate) (PC)

| Compatibilizers | Achievements and Relevant Information | Ref. |

|---|---|---|

| None | Blends prepared by internal mixer at 190 °C Matrix/droplet morphologies for 10–30% PC into PLA with droplet size between 5 and 10 µm–poor interfacial adhesion; co-continuity observed for 50% PC with domain size > 10 µm–tensile strength 40–60 MPa, ductility 3–16%. | [98] |

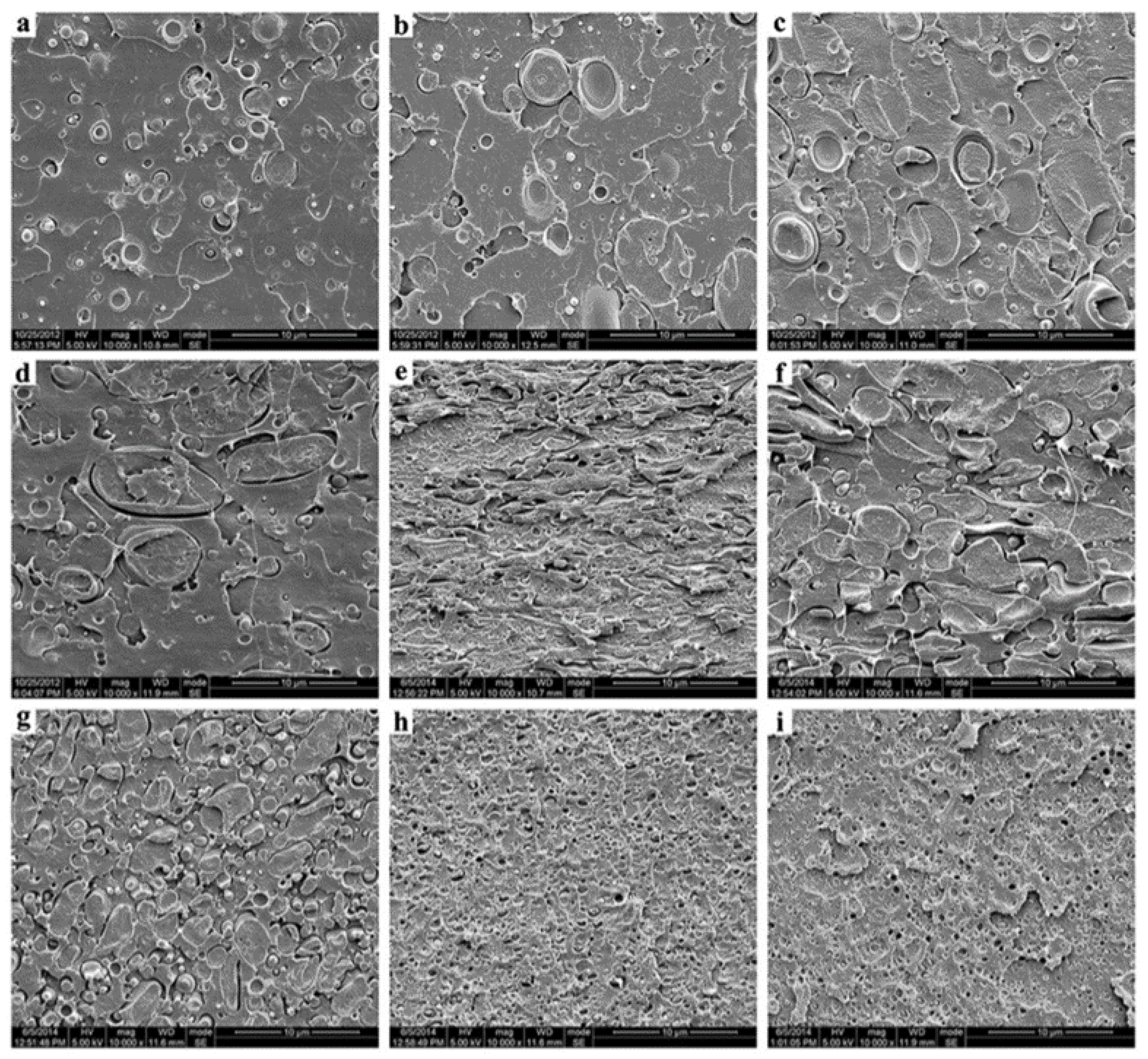

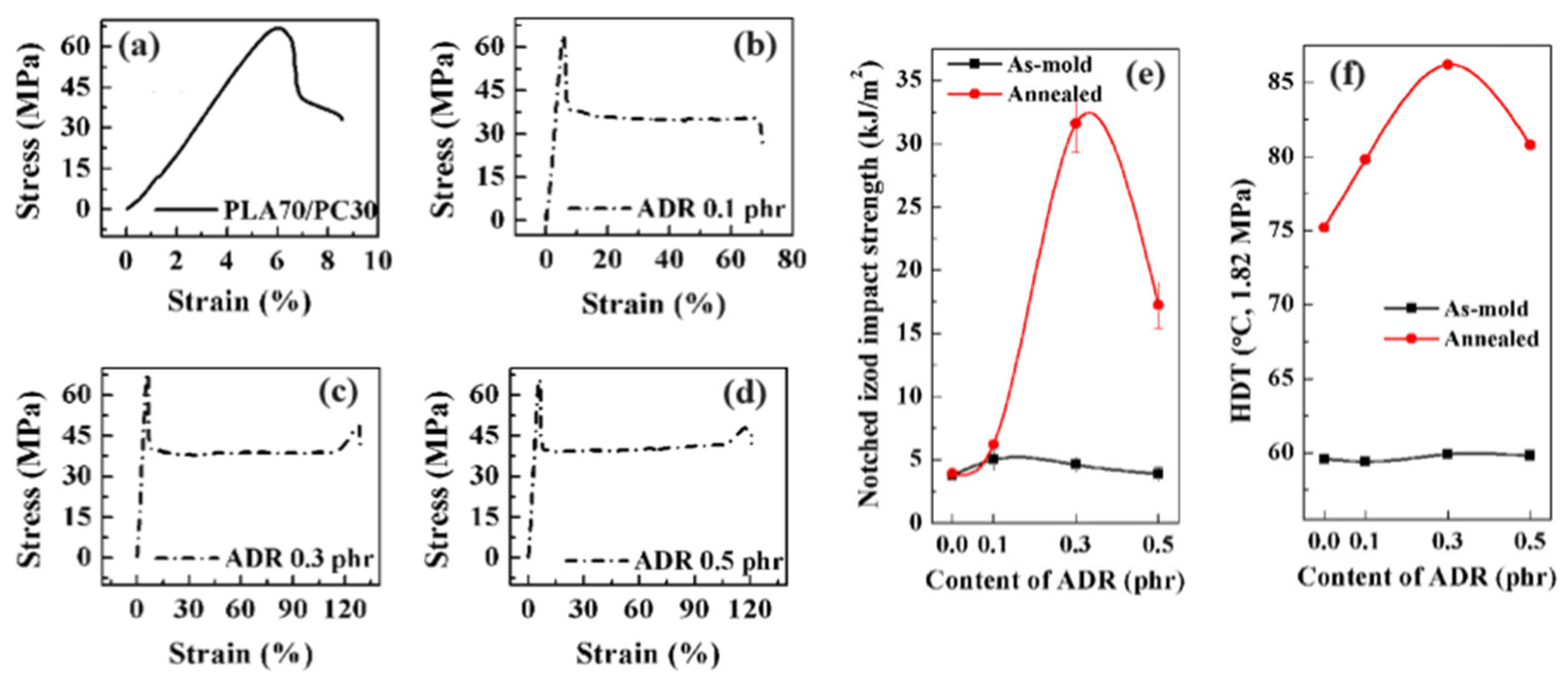

| Random styrene-glycidyl methacrylate copolymer (ADR) N,N,N’,N’-tetraglycidyl-4,4′-diaminodiphenyl methane (TGDDM) | Blends prepared by twin-screw extrusion at 190–230 °C Without compatibilizer—matrix/droplet morphologies for 10–30% PC into PLA, with droplet size between 2 and 5 µm—poor interfacial adhesion, tensile strength 60–65 MPa, ductility 5–10%, impact strength 5–10 kJ/m2, HDT 65–80 °C (after annealing). Without compatibilizer—co-continuity observed for 50% PC into PLA with domain size > 5 µm—tensile strength up to 65 MPa, ductility 70%, impact strength 12 kJ/m2, HDT up to 130 °C (after annealing). Best compatibilization efficiency of ADR (0.3 phr) with domain size down to 1 µm—strong morphological modifications observed with PC continuity at 30% PC—tensile strength 65 MPa, ductility 100%, impact strength 30 kJ/m2, HDT 85 °C (after annealing). | [90] |

| Styrene-acrylic multi-functional-epoxide oligomer (SAMFE, (Joncryl®) Styrene maleic anhydride copolymer (SMA, Joncryl®) | Blends prepared by twin-screw extrusion at 200 °C Without compatibilizer—matrix/droplet morphologies for 10–30% PC into PLA with droplet size close to 2 µm—tensile strength 55–60 MPa and ductility 30–70%. Best compatibilization efficiency of SAMFE (1%) with droplet size down to 1 µm—tensile strength 60–65 MPa and ductility 10%. | [89] |

| Poly(styrene-g-acrylonitrile)-maleic anhydride (SAN-MAH) Poly(ethylene-co-octene) rubber-maleic anhydride (EOR-MAH) Poly(ethylene-co-glycidyl methacrylate) (EGMA) | Blends prepared by twin-screw extrusion at 240–260 °C Without compatibilizer—matrix/droplet morphologies for 30% PC into PLA with droplet size close to 2 µm—poor interfacial adhesion, tensile strength 55 MPa and impact strength 230 J/m. High compatibilization efficiency of SAN-MAH (5 phr) with droplet size down to 200 nm—reduced interfacial tension from 3.3 mN m−1 down to 0.1 mN/m, tensile strength 64 MPa and impact strength 400 J/m. | [89] |

| Epoxy-based additive (EP) Tetrabutylammonium bromide (TBAB) | Blends prepared by twin-screw extrusion at 220 °C Without compatibilizer—co-continuity observed at 50% PC into PLA with domain size > 10 µm—poor interfacial adhesion, impact strength 10 J/m and HDT 80 °C. High compatibilization efficiency of EP (10 phr) combined to TBAB (1 phr) with homogenous domain size down to 500 nm—impact strength 7 J/m and HDT up to 130 °C—improved toughness using PBSL but a reduction in HDT. | [92] |

| Poly(ethylene-n-butylene acrylate-glycidyl methacrylate) (EBA-GMA) | Blends prepared by twin-screw extrusion at 265 °C Without compatibilizer—PC-rich blends with 40% PLA—tensile strength 68 MPa, ductility 73%, impact strength 45 J/m and HDT 135 °C (after annealing). No compatibilization evidence for EBA-GMA (6%)—tensile strength 57 MPa, ductility 67%, impact strength 715 J/m and HDT 133 °C—similar value to PC/ABS blends. | [93] |

| Poly(ethylene-co-glycidyl methacrylate) (EGMA) | Blends prepared by twin-screw extrusion at 200 °C PLA/PC/SEBS/EGMA blends with complex morphologies—PC droplet or domain size < 1 µm—ductility 50–120%, impact strength up to 65 kJ/m2, HDT up to 95 °C—significant compatibilization efficiency of EGMA (5 phr) and improved impact strength using SEBS. | [94] |

| Zinc borate (BSX) Titanium pigment (TiO2) Tetrabutyl titanate (TT-01) Antimony trioxide (Sb2O3) | Blends prepared by internal mixer at 230 °C Without compatibilizer—matrix/droplet morphologies for 30% PC into PLA with heterogenous droplet size 5–20 µm—transesterification reactions observed at elevated mixing time. Best compatibilization efficiency of TT-01 with droplet size down to 2–5 µm—appearance of third phase attributed to PLA-PC copolymers formed at elevated mixing time. | [95] |

| Triacetin (TA) Tetrabutylammonium tetraphenylborate (TBATPB) | Blends prepared by twin-screw extrusion at 210–230 °C Without compatibilizer—matrix/droplet morphologies observed for 20—40% PC into PLA with droplet size 2—10 µm—poor interfacial adhesion, tensile strength 52–55 MPa, ductility 2–3%. Without compatibilizer—co-continuous morphologies observed at 60% PC into PLA—tensile strength 55 MPa, ductility up to 125%. Significant compatibilization efficiency of TA (5%) coupled to TBATPB (0.2%)—Strong morphological modifications observed with PC continuity at 40% PC—appearance of third phase attributed to PLA-PC copolymers—tensile strength 58–60 MPa, ductility 125%. | [96] |

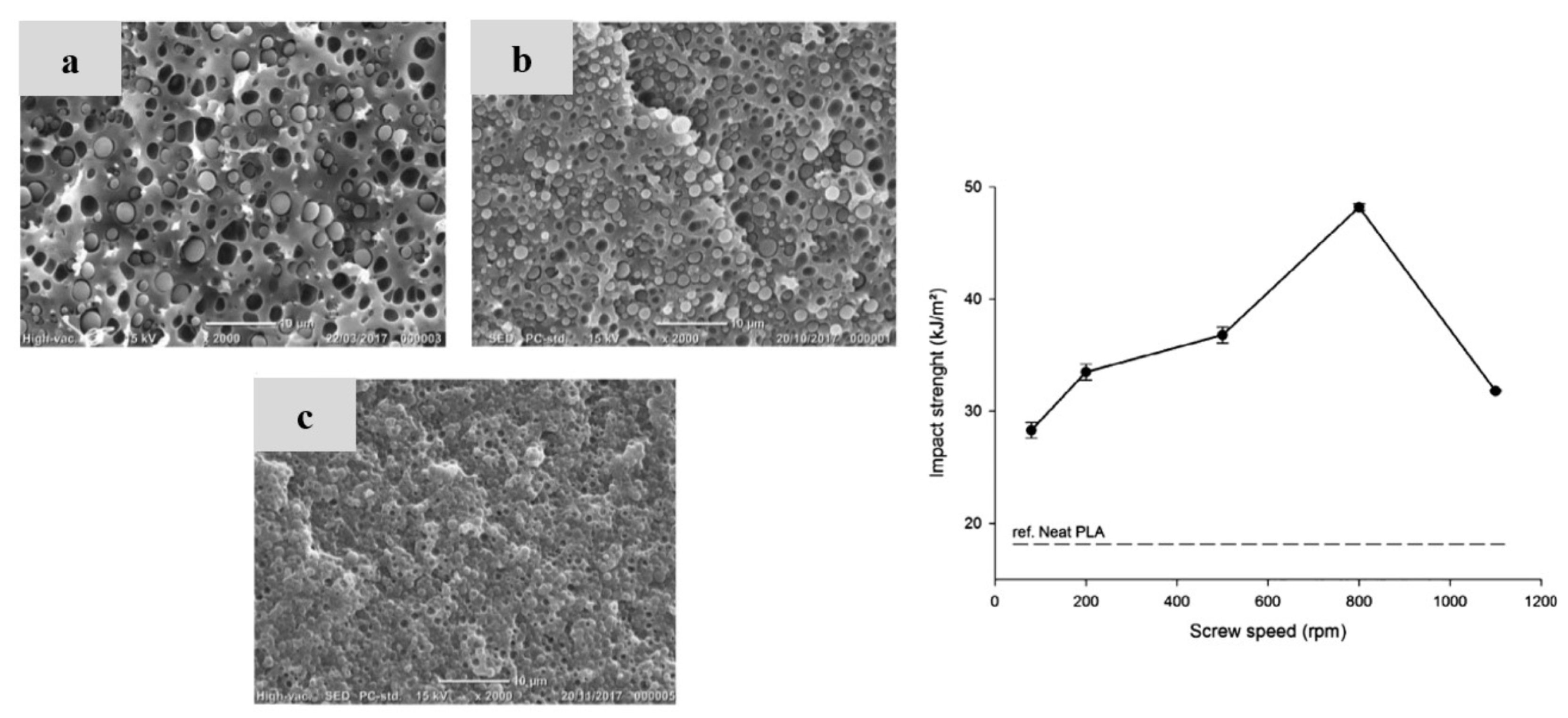

| Di-n-butyltin oxide (DBTO) | Blends prepared by twin-screw extrusion at 210–230 °C PC/PLA/TPU/DBTO blends with complex morphologies—PLA droplet or domain size between 2 and 5 µm—tensile strength 35–50 MPa, ductility 16%, impact strength 48 kJ/m2—slight compatibilization efficiency of DBTO (1%) and improved toughness using TPU. | [97] |

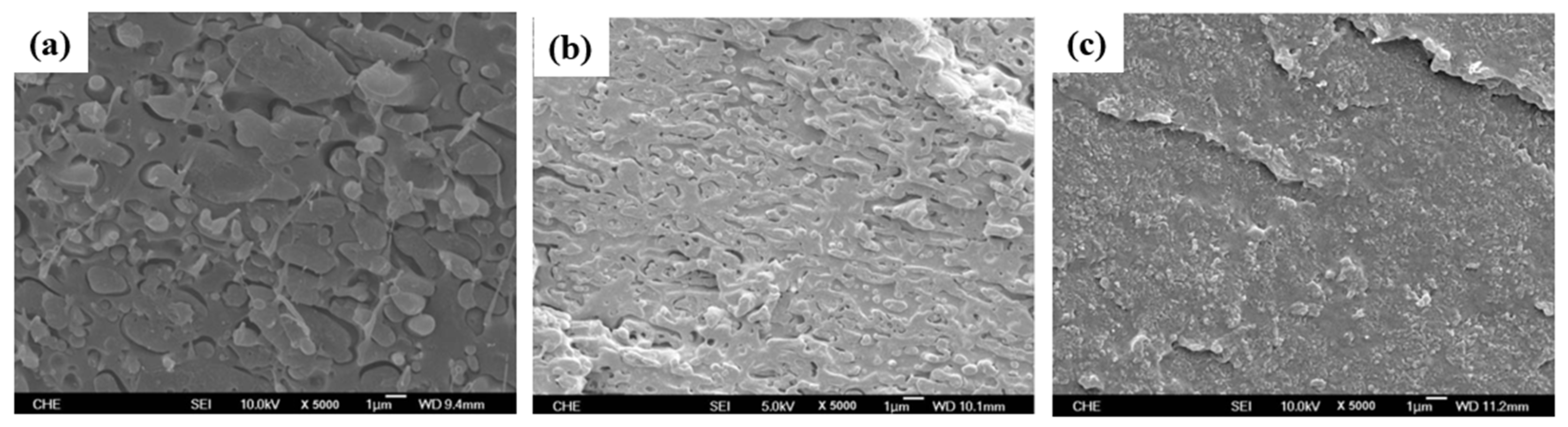

3.3. PLA-Based Blends with Poly(Ethylene Terephthalate) (PET) or Poly(Butylene Terephthalate) (PBT)

| Compatibilizers | Achievements and Relevant Information | Ref. |

|---|---|---|

| None | Blends prepared by single screw extrusion at 240–250 °C Matrix/droplet morphologies for 7.5% PLA into PET with droplet size close to 5 µm—good interfacial adhesion—tensile strength up to 68 MPa, ductility up to 80%, impact strength 10 J/m. | [104] |

| None | Blends prepared by injection molding at 265 °C Matrix/droplet morphologies for 20% PLA into PET with droplet size up to 5 µm—good interfacial adhesion—tensile strength 52 MPa, ductility between 50 and 200%, impact strength 35 kJ/m2. | [106] |

| None | Blends prepared by single-screw extrusion at 260 °C Matrix/droplet morphologies for 5–15% PLA into PET with droplet size between 0.5 and 1.9 µm–Good interfacial adhesion. | [103] |

| None | Blends prepared by internal mixer at 270 °C. Matrix/droplet morphologies for 1–5% PLA into PET with droplet size lower than 1 µm–good interfacial adhesion–tensile strength 34 MPa, ductility 400%. | [102] |

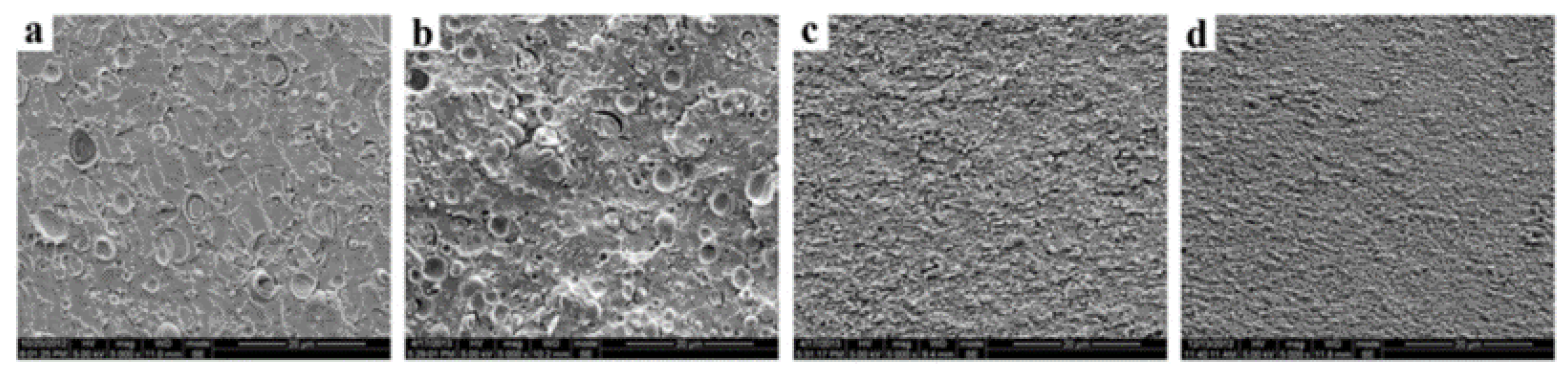

| Poly(ethylene-n-butylene-acrylate-co-glycidyl methacrylate) (EBA-GMA) Poly(styrene-acrylic-co-glycidyl methacrylate) (SA-GMA) | Blends prepared by twin-screw extrusion at 270 °C Without compatibilizers–matrix/droplet morphologies up to 30% PLA into PET with droplet size between 1.5 and 3.6 µm–good interfacial adhesion, tensile strength 71 MPa, ductility 5%, impact strength 7 J/m, HDT 62.3 °C. Best compatibilization efficiency of SA-GMA (0.7%)–co-continuous morphologies for 30% PLA into PET with domain size between 1 and 5 µm—tensile strength 70 MPa, ductility 110%, impact strength 30 J/m, HDT 68.3 °C. | [107] |

| Poly(Lactide-g-maleic anhydride) (PLA-g-MA) | Blends prepared by internal mixer at 190 °C Without compatibilizers—matrix/droplet morphologies up to 20% PETG into PLA with droplet size down to 0.48 µm—poor interfacial adhesion, interfacial tension 2 mN m−1, tensile strength 81 MPa, elongation at break 7%. Significant compatibilization efficiency of PLA-g-MA (5%)—matrix/droplet morphologies for 20% PETG with droplet size down to 230 nm—reduced interfacial tension from 2 mN m−1 down to 0.85 mN m−1, tensile strength 83 MPa, elongation at break 30%. | [111] |

| Compatibilizers | Achievements and Relevant Information | Ref. |

|---|---|---|

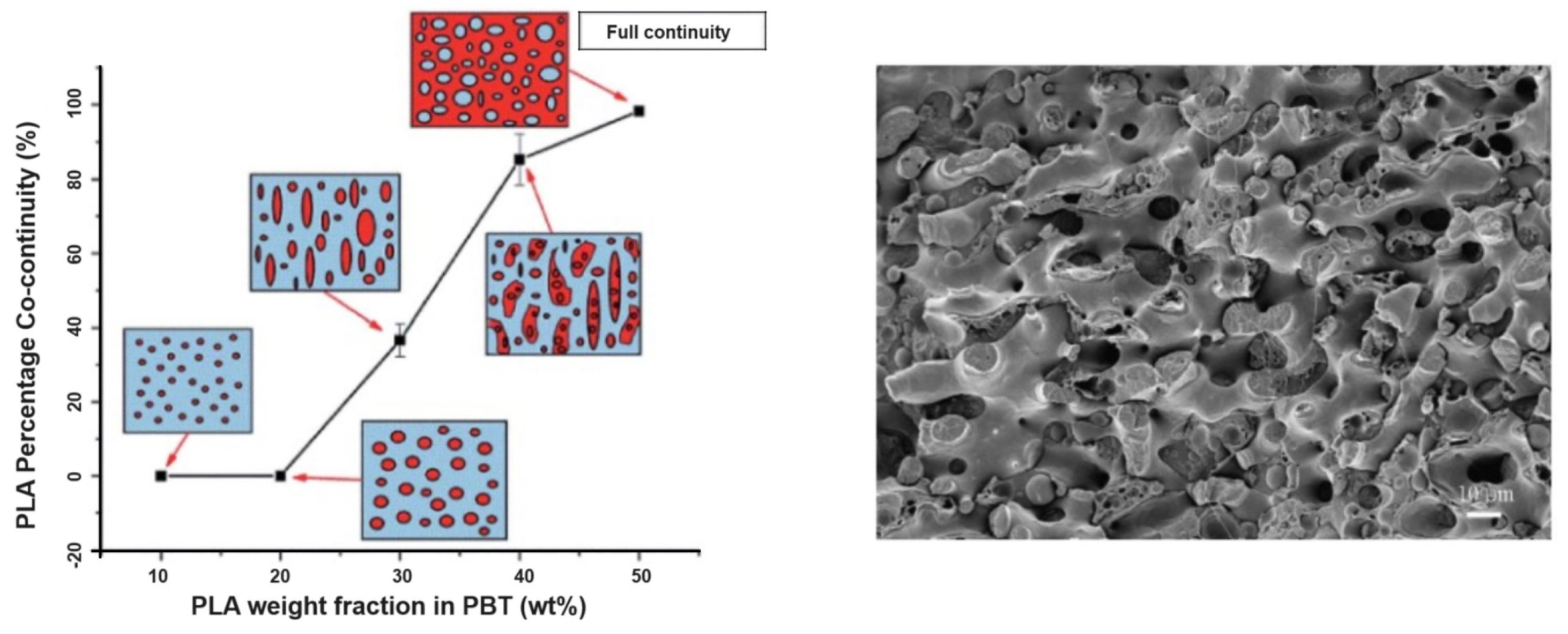

| None | Blends prepared by internal mixer at 250 °C Matrix/droplet morphologies up to 30% of PBT into PLA with droplet size ranging from 1 to 5 µm–fair interfacial adhesion; co-continuous morphologies with multi-level structures for 40% PBT–ductility close to 160%. | [112] |

| Paraphenylene diisocyanate (PPDI) | Blends prepared by twin screw extrusion at 230–240 °C Without compatibilizers–co-continuous morphologies with multi-level structures for 50% PBT with domain sizes between 10 and 15 µm. Small compatibilization efficiency of PPDI (1%)—co-continuous morphologies with multi-level structures with domain sizes between 5 and 10 µm. | [118] |

| Ethylene-glycidyl methacrylate copolymer (Lotader AX 8840) | Blends prepared by twin screw extrusion at 220–240 °C Significant compatibilization efficiency of ethylene-glycidyl methacrylate copolymer—matrix/droplet morphology up to 10% of PBT into PLA with droplet size down to 200 nm—tensile strength between 50 and 55 MPa, ductility up to 25%, impact strength 200 J/m. | [119] |

| Epoxy styrene-acrylate copolymer (ESAC) Poly(ethylene-n-butyl-acrylate-co-glycidyl methacrylate) (EBA-GMA) | Blends prepared by twin screw micro-extrusion at 250 °C Without compatibilizers—matrix/droplet morphology up to 20% of PLA into PBT with droplet size approx. 1 µm–poor interfacial adhesion—co-continuous and multi-level structures observed for 40% PLA into PBT—tensile strength 50–55 MPa, ductility < 10%, impact strength 30 J/m. Strong compatibilization efficiency of ESAC (1%)—matrix/droplet morphology up to 40% of PLA into PBT with droplet size approx. 1 µm, tensile strength 60 MPa, ductility 160%, impact strength 30 J/m—combined effects of ESAC and EBA-GMA on impact strength. | [114] |

| Ethylene butyl acrylate copolymer grafted with maleic anhydride (EBA-g-MAH) | Blends prepared by twin screw extruder at 220–230 °C Without compatibilizer—matrix/droplet morphologies up to 15% PBT in PLA–tensile strength 64 MPa, ductility 2%, impact strength 2 kJ/m2. Very poor compatibilization efficiency of EBA-g-MAH—tensile strength 59 MPa, ductility 3%, impact strength 2.5 kJ/m2. | [113] |

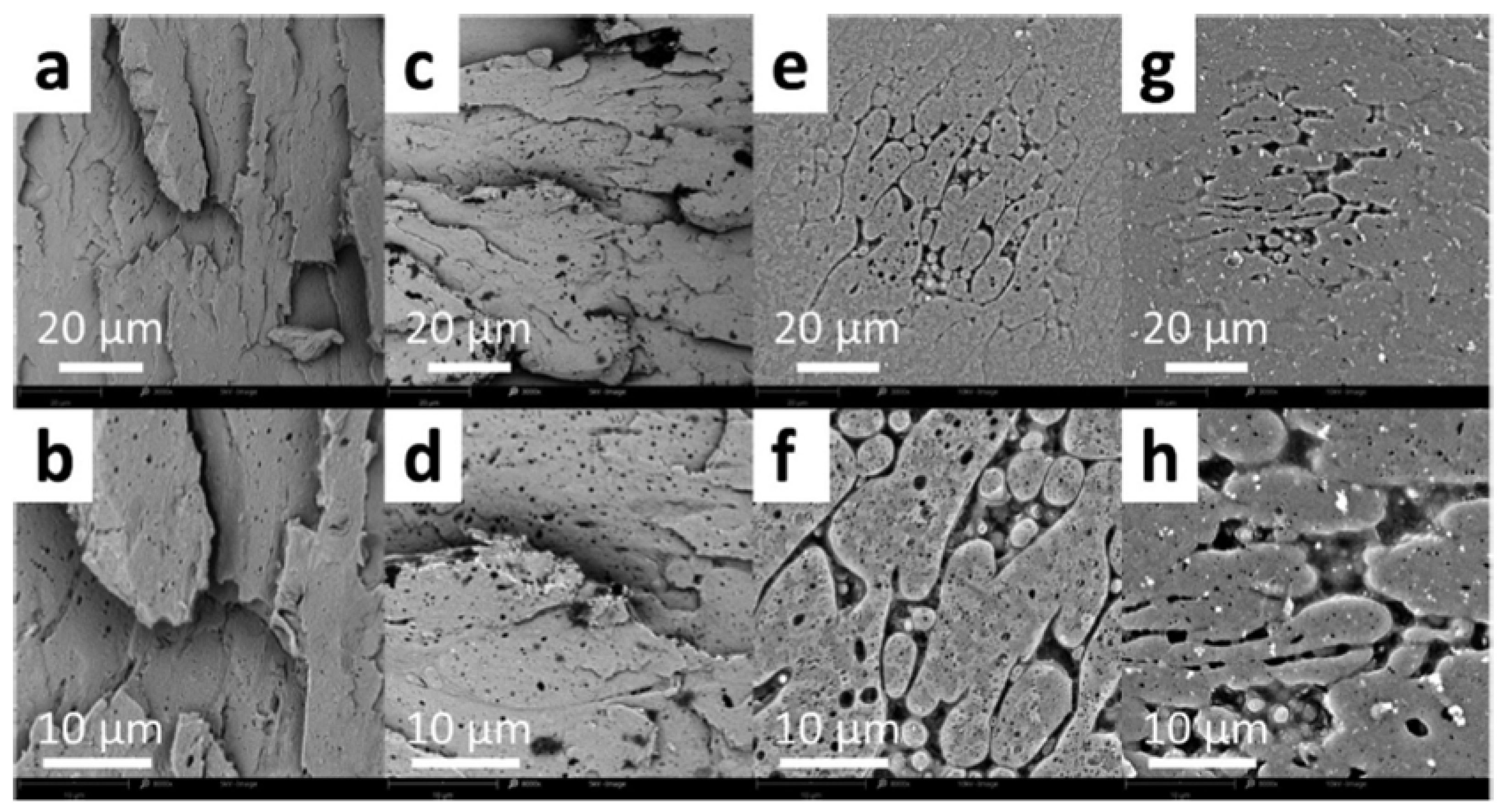

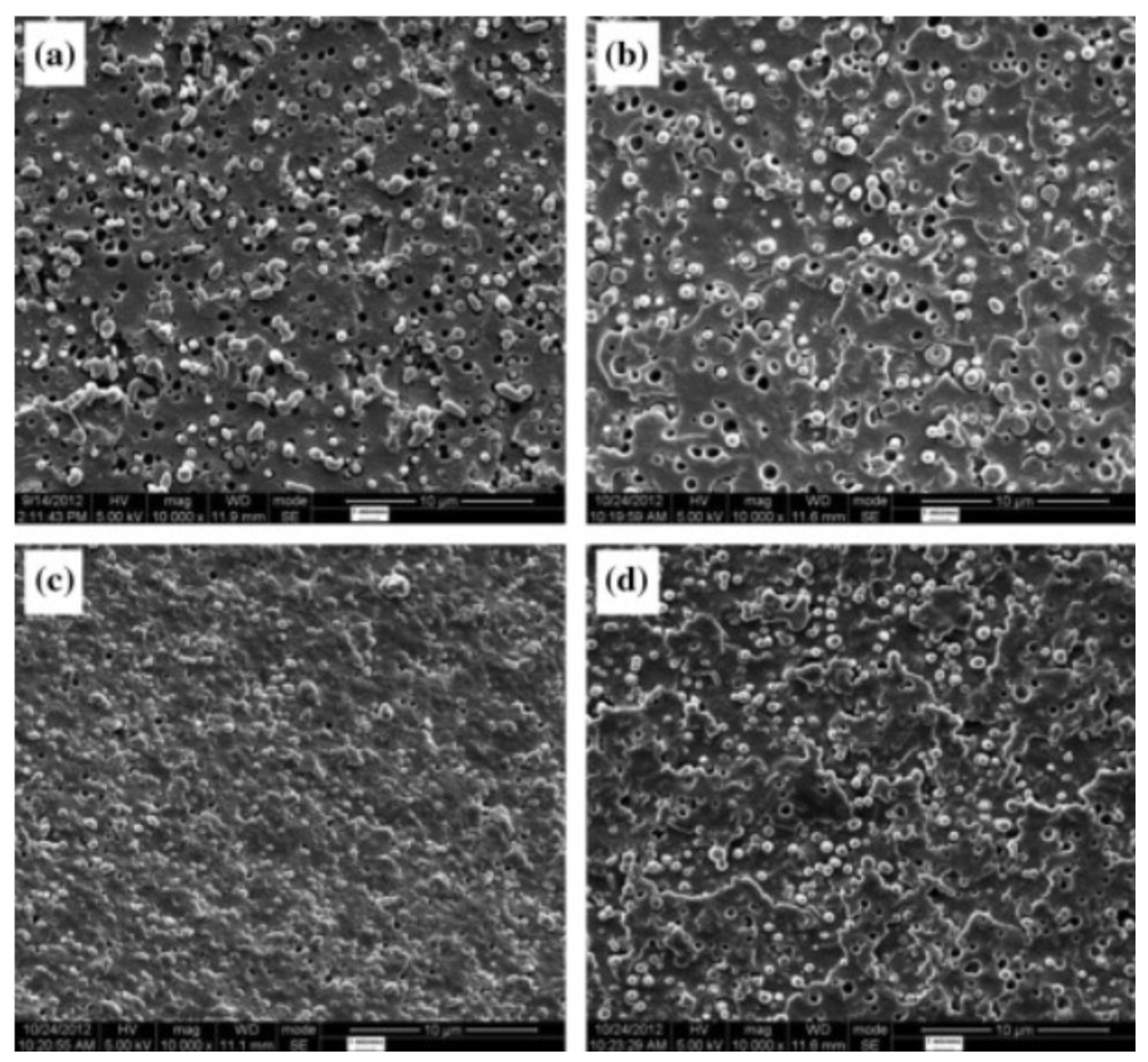

3.4. PLA-Based Blends with (Partly Biobased) Polyamides

| Blend Type and Compatibilizers | Achievements and Relevant Information | Ref. |

|---|---|---|

| PLA/PA6 blends | Blends prepared by twin screw extrusion at 210 °C Co-continuous morphologies for 40% PLA into PA6 with large domain size (>20 µm)—good interfacial adhesion—tensile strength between 47 and 57 MPa, impact strength close to 5 kJ/m2. | [126] |

| PLA/PA6 blends | Blends prepared by internal mixer at 235 °C Matrix/droplet morphologies up to 40% PLA into PA6 with droplet size between 2 and 10 µm—co-continuous morphologies for 50 and 60% PLA | [128] |

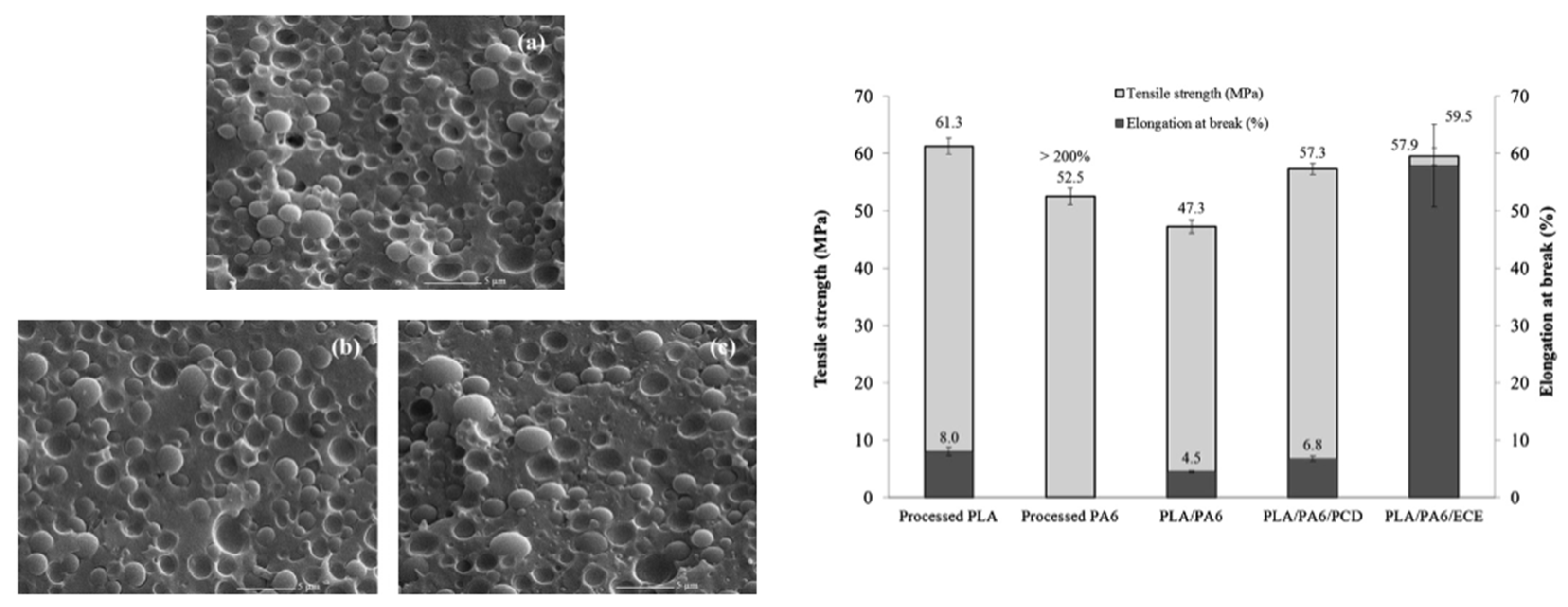

| PLA/PA6 blends Multifunctionnal epoxide chain extender (ECE, Joncryl 4368) Polycarbodiimide (PCD) | Blends prepared by twin screw extrusion at 250 °C Without compatibilizer—matrix/droplet morphology for 30% of PA6 with droplet size close to 2 µm—poor interfacial adhesion, tensile strength 47 MPa, ductility 4%, impact strength 2 kJ/m2. Slight compatibilization efficiency of ECE (0.5%)—similar matrix/droplet morphologies—tensile strength 59 MPa, ductility 57%, impact strength 5 kJ/m2. | [125] |

| PLA/PA6 blends Polyethylene-octene copolymer grafted with maleic anhydride (POE-g-MAH) | Blends prepared by twin screw extrusion at 220–240 °C Without compatibilizer—matrix/droplet morphologies for 30% PLA into PA6 with droplet size close to 2 µm—moderate interfacial adhesion, tensile strength 57 MPa, ductility 7%, impact strength 3 kJ/m2. Modest compatibilization efficiency of POE-g-MAH (10%)—slight reduction in droplet size down to 1 µm—improved interfacial adhesion, tensile strength 47 MPa, ductility 23%, impact strength 6 kJ/m2. | [127] |

| PLA/PA6 blends Alkenyl-succinide-anhydride-amide (ASAA) Alkenyl-succinic-anhydride-imide (ASAI) | Blends prepared by internal mixer at 235 °C Without compatibilizer—matrix/droplet morphologies for 20% PLA into PA6 with droplet size close to 1 µm—co-continuous morphologies for 40 and 50% PLA into PA6 with large domain size (>20 µm), tensile strength close to 50 MPa, ductility 6%, impact strength 2 kJ/m2. Significant compatibilization efficiency of ASAA or ASAI (1%)—significant reduction in droplet size down to 0.7 µm or continuous domain size below 10 µm—tensile strength up to 56 MPa, ductility 8%, impact strength 3 kJ/m2. | [124] |

| PLA/PA6-10 blends Bisphenol-A type epoxy resin (BPAE) | Blends prepared by twin screw extrusion at 200–230 °C Without compatibilizer—matrix/droplet morphologies for 50% PA6-10 in PLA with high and heterogenous droplet size –tensile strength 51 MPa, ductility 3%, impact strength 11 J/m. Significant compatibilization efficiency of BPAE (3%)—matrix/droplet morphologies for 50% PA6-10 in PLA with lower droplet size –tensile strength 54 MPa, ductility 3%, impact strength 26 J/m. | [129] |

| PLA/PA10-10 | Blends prepared by twin screw extrusion at 205–215 °C Matrix/droplet morphologies up to 20–30% PA10-10 in PLA with droplet size close to 1.5 µm—poor interfacial adhesion, interfacial tension 9.0 mN/m; co-continuous morphologies for 40% PA10-10 in PLA—ductility 50%, impact strength 23 kJ/m2, HDT 110 °C (after annealing). | [116] |

| PLA/PA10-10 Styrene-acrylic multi-functional-epoxide oligomer (SAMFE, (Joncryl®) | Blends prepared by internal mixer at 210 °C Without compatibilizer—matrix/droplet morphologies up to 30% PA10-10 in PLA with droplet size between 2 and 5 µm—poor interfacial adhesion; co-continuous morphologies for 40–50% PA10-10 in PLA with domain size close to 10–20 µm—tensile strength 50 MPa, ductility 140%, impact strength 225 kJ/m2. Significant compatibilization efficiency of SAMFE (0.6%)—matrix/droplet morphologies up to 20% PA10-10 in PLA with droplet size below 500 nm—high interfacial adhesion; co-continuous morphologies for 30-40% PA10-10 in PLA with domain size down to 5 µm—tensile strength 50 MPa, ductility 170%, impact strength 300 kJ/m2. | [123] |

| PLA/PA10-10 Styrene-acrylic multi-functional-epoxide oligomer (SAMFE, (Joncryl®) | Blends prepared by twin screw extrusion at 205–215 °C Without compatibilizer—matrix/droplet morphologies for 30% PA10-10 in PLA with droplet size close to 1.5 µm Significant compatibilization efficiency of SAMFE (0.6%)—appearance of (nano)fibrillar morphologies with domain size down to 750 nm. | [130] |

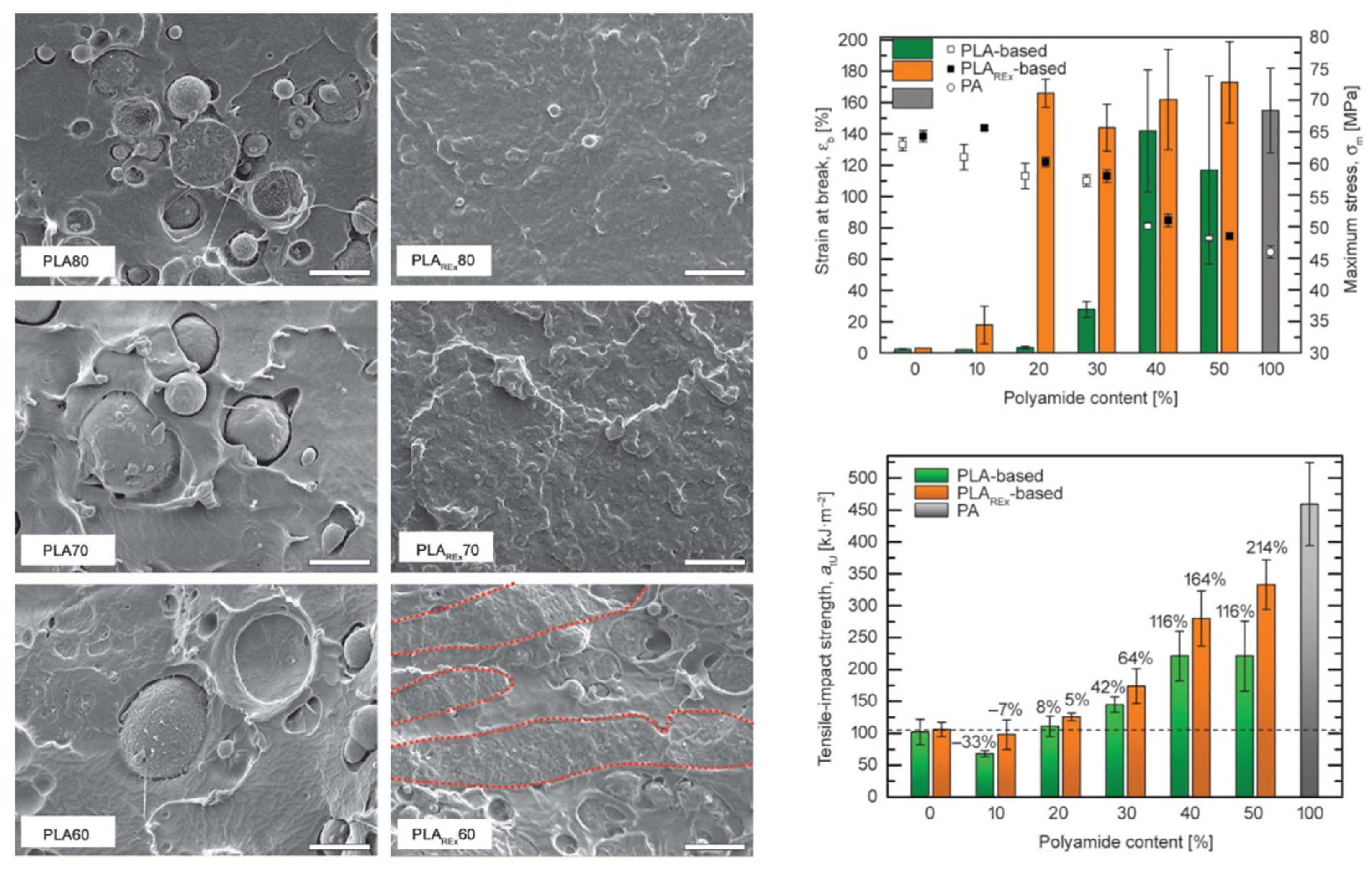

| PLA/PA11 | Blends prepared by twin screw extrusion at 220–235 °C Fibrillar morphologies for 20% PA11 in PLA with fiber diameter close to 1.5 µm—poor interfacial adhesion, tensile strength 53 MPa, ductility 80%, impact strength 19 kJ/m2 | [137] |

| PLA/PA11 | Blends prepared by twin screw extrusion at 205–215 °C Matrix/droplet morphologies up to 20–30% PA11 in PLA with droplet size close to 1.5 µm—poor interfacial adhesion, interfacial tension 4.9 mN/m; co-continuous morphologies for 40% PA11 in PLA—ductility 95%, impact strength 17 kJ/m2, HDT 130 °C (after annealing). | [116] |

| PLA/PA11 | Blends prepared by twin screw extrusion at 200 °C Matrix/droplet morphologies up to 20% PA11 in PLA with droplet size close to 2.5 µm—moderate interfacial adhesion; fibrillar morphologies for 30-40% PA11 with fiber diameter close to 2 µm; co-continuous morphologies for 50% PA11 in PLA—tensile strength 43 MPa, low ductility (<10%). | [132] |

| PLA/PA11 | Blends prepared by twin screw extrusion at 200 °C Matrix/droplet morphologies for 45% PA11 in PLLA with PLA droplet size between 1 and 5 µm—poor interfacial adhesion, tensile strength close to 46 MPa, ductility 5% and impact strength 47 kJ/m2—improved impact strength with an impact modifier. | [138] |

| PLA/PA11 | Blends prepared by twin screw extrusion at 215 °C Matrix/droplet morphologies up to 30% PA11 in PLA with droplet size between 1 and 5 µm—poor interfacial adhesion | [139] |

| PLA/PA11 | Blends prepared by internal mixer at 200 °C Matrix/droplet morphologies up to 20–30% PA11 in PLA with droplet size between 700 nm and 1.5 µm; fibrillar morphologies for 30–40% PA11 with fiber diameter between 2 and 5 µm—co-continuous morphologies for 50% PA11 with domain sizes around 10 µm—interfacial tension between 3.2 and 5.8 mN/m. | [131] |

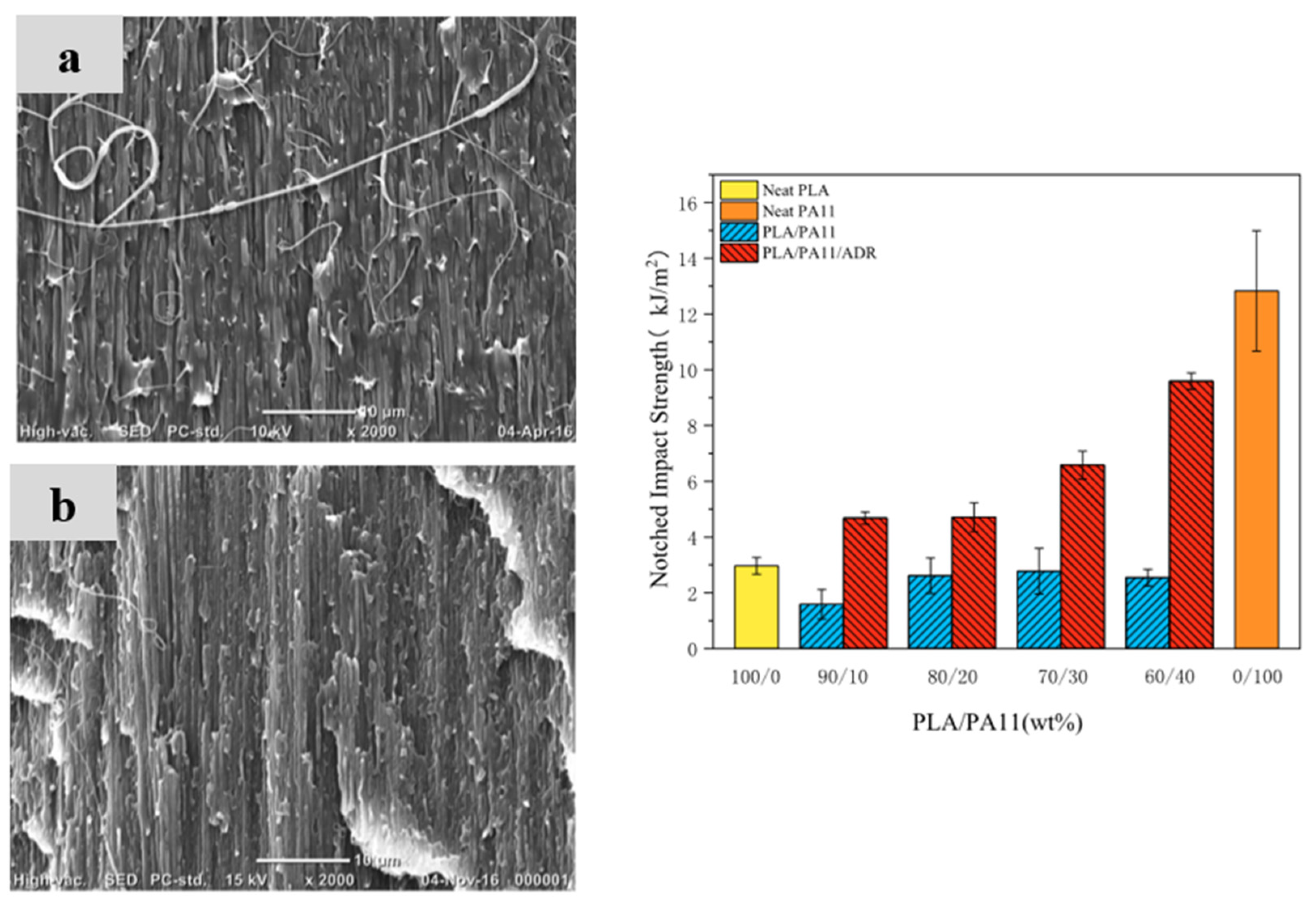

| PLA/PA11 Styrene-acrylic multi-functional-epoxide oligomer (SAMFE, (Joncryl®) | Blends prepared by twin screw extrusion at 200 °C Fibrillar morphologies for 20% PA11 in PLA with fiber diameter ranging from 300 nm to 500 nm—moderate interfacial adhesion, tensile strength between 57 and 64 MPa, ductility up to 250%. Modest compatibilization efficiency of SAMFE (1%)—fibrillar morphologies with fiber diameter of 300 nm—tensile strength 65 MPa, ductility 45%. | [53] |

| PLA/PA11 Styrene-acrylic multi-functional-epoxide oligomer (SAMFE, (Joncryl®) | Blends prepared by internal mixer at 220 °C Without compatibilizer—matrix/droplet morphologies up to 30% PA11 in PLA with droplet sizes from 800 nm to 2 µm—poor interfacial adhesion, tensile strength between 39 and 43 MPa, ductility 10% and impact strength 2.5 kJ/m2. Significant compatibilization efficiency of SAMFE (0.7%)—matrix/droplet morphologies for 30% PA11 in PLA with droplet size down to 300 nm—improved interfacial adhesion, tensile strength between 45 and 50 MPa, ductility higher than 250% and impact strength up to 10 kJ/m2. | [133] |

| PLA/PA11 p-Toluenesulfonic acid (TsOH) | Blends prepared by internal mixer and twin screw extrusion at 205 °C Without compatibilizer—co-continuous morphologies for 50% PA11 in PLA with domain sizes close to 2 µm—tensile strength close to 45 MPa and ductility between 40% and 75%. Moderate compatibilization efficiency of TsOH (0.5%)—co-continuous morphologies with domain sizes ranging from 2 to 10 µm—tensile strength close to 40 MPa and ductility above 100%. | [134] |

| PLA/PA11 Titanium(IV)isopropoxide (TIP) | Blends prepared by internal mixer at 205 °C Moderate compatibilization efficiency of TIP (0.05%)—matrix/droplet morphologies for 25% PA11 in PLA with PA11 droplet size between 500 nm and 1 µm—good interfacial adhesion; matrix/droplet morphologies for 50% PA11 in PLA with PLA droplet size between 2 and 3 µm—tensile strength between 40 and 45 MPa, ductility 3%, impact strength 30 J/m, HDT up to 70 °C. | [135] |

| PLA/PA12 | Blends prepared by twin screw extrusion at 205–215 °C Matrix/droplet morphologies up to 20–30% PA12 in PLA with droplet size from 700 nm to 1.5 µm—moderate interfacial adhesion, interfacial tension 2.0 mN/m; co-continuous morphologies for 40% PA12 in PLA—tensile strength 58 MPa, ductility 175%, impact strength 33 kJ/m2, HDT 115 °C (after annealing). | [116] |

| PLA/PA12 | Blends prepared by twin screw extrusion at 210 °C Fibrillar morphologies for 30% PA12 in PLA with fiber diameter close to 600 nm—good interfacial adhesion, tensile strength close to 58 MPa, ductility 220%, impact strength 48 kJ/m2, HDT 114 °C (after annealing). | [117] |

| PLA/PA12 Poly(L-Lactide) grafted with maleic anhydride (PLA-g-MA) | Blends prepared by twin screw extrusion at 210 °C Without compatibilizer—fibrillar morphologies for 30% PA12 in PLA with fiber diameter close to 1.4 µm—moderate interfacial adhesion, tensile strength close to 57 MPa, ductility 150%, impact strength 28 kJ/m2, HDT 95 °C (after annealing). Good compatibilization efficiency of PLA-g-MA (2%)—fibrillar morphologies with fiber diameter down to 800 nm—improved interfacial adhesion, tensile strength close to 54 MPa, ductility 280%, impact strength 47 kJ/m2, HDT 100 °C (after annealing). | [136] |

4. Conclusions and Perspectives

Author Contributions

Funding

Conflicts of Interest

Abbreviations

| PLA | Poly(Lactide) or Poly(lactic acid) |

| ROP | Ring opening polymerization |

| PLLA | Poly(L-Lactide) |

| PDLA | Poly(D-Lactide) |

| PDLLA | Poly(D, L-Lactide) |

| PEG | Poly(ethylene glycol) |

| CL | ɛ-Caprolactone |

| P[CL-co-LA] | Poly(ɛ-caprolactone-co-lactic acid) |

| VL | δ Valerolactone |

| P[Cl-co-VA] | Poly(ɛ-caprolactone-co- δ valerolactone) |

| EBS | N,N’-ethylene bis-stearamide |

| CaCO3 | Calcium Carbonate |

| BH | Benzoyl hydrazide |

| OMBH | Octamethylene dicarboxylic dibenzoyl hydrazide |

| HDT | Heat deflection temperature |

| CNT | Carbon nanotubes |

| OMMT | Organo-Montmorillonite |

| PA | Poly(amide) |

| PS | Poly(styrene) |

| PBA | Poly(butyl acrylate) |

| PBSL | Poly(butylene succinate-co-l-lactate) |

| PBT | Poly(butylene terephthalate) |

| PC | Poly(carbonate) |

| PES | Poly(ethylene succinate) |

| PET | Poly(ethylene terephthalate) |

| PVDF | Poly(vinylidene fluoride) |

| PVP | poly(vinyl pyrrolidone) |

| PVPh | poly(vinyl phenol) |

| UCST | Upper critical solution temperature |

| SAN-g-MAH | Poly(styrene-co-acrylonitrile)-g-maleic anhydride |

| EOR-MAH | Poly(ethylene-co-octene) rubber maleic anhydride |

| EGMA | Poly(ethylene-co-glycidyl methacrylate) |

| T-POSS | Tetrasilanol phenyl polyhedral oligomeric silsesquioxane |

| G-POSS | Glycidyl iso-octyl polyhedral oligomeric silsesquioxane |

| ADR | random copolymer of styrene and glycidyl methacrylate |

| TGDDM | N,N,N′,N′-tetraglycidyl-4,4′-diamino diphenyl methane |

| SMA | Styrene maleic anhydride copolymer |

| PEBA-GMA | Poly(ethylene n-butylene acrylate glycidyl methacrylate) |

| PTT | Poly(trimethylene terephthalate) |

| ESAC | Epoxy-functionalized styrene-acrylate copolymer |

| PA6 | Poly(amide-6) |

| PA (6-10) | Poly(amide-6-10) |

| PA 11 | Poly(amide-11) |

| PA (10-10) | Poly(amide-10-10) |

| PA (6-6) | Poly(amide-6-6) |

| ASAA | Alkenyl-succinide-anhydride-amide |

| ASAI | Alkenyl-succinic-anhydride-imide |

| POE-g-MAH | Poly(ethylene octene) grafted maleic anhydride |

| TPU | Thermoplastic polyurethane |

| ECE | Multifunctional epoxies |

| PCD | Polycarbodiimide |

| BN | Boron nitride |

| TsOH | p-toluene sulfonic acid |

| PLArex | modified PLA with Joncryl-ADR-4300® epoxy-based resin |

| DMBH | Decamethylene dicarboxylic dibenzoyl hydrazide |

| Tg | Glass transition temperature |

| SEM | Scanning electron microscopy |

References

- Europeanbioplastics. Available online: https://www.european-bioplastics.org/bioplastics/materials/ (accessed on 8 April 2024).

- Garlotta, D. A Literature Review of Poly(Lactic Acid). J. Polym. Environ. 2001, 9, 63–84. [Google Scholar] [CrossRef]

- Nofar, M.; Sacligil, D.; Carreau, P.J.; Kamal, M.R.; Heuzey, M.-C. Poly (Lactic Acid) Blends: Processing, Properties and Applications. Int. J. Biol. Macromol. 2019, 125, 307–360. [Google Scholar] [CrossRef] [PubMed]

- Mehta, R.; Kumar, V.; Bhunia, H.; Upadhyay, S.N. Synthesis of Poly(Lactic Acid): A Review. J. Macromol. Sci. Part C Polym. Rev. 2005, 45, 325–349. [Google Scholar] [CrossRef]

- Madhavan Nampoothiri, K.; Nair, N.R.; John, R.P. An Overview of the Recent Developments in Polylactide (PLA) Research. Bioresour. Technol. 2010, 101, 8493–8501. [Google Scholar] [CrossRef] [PubMed]

- Cheng, Y.; Deng, S.; Chen, P.; Ruan, R. Polylactic Acid (PLA) Synthesis and Modifications: A Review. Front. Chem. China 2009, 4, 259–264. [Google Scholar] [CrossRef]

- Babu, R.P.; O’Connor, K.; Seeram, R. Current Progress on Bio-Based Polymers and Their Future Trends. Prog. Biomater. 2013, 2, 8. [Google Scholar] [CrossRef] [PubMed]

- Gandini, A.; Rodríguez, H.; Rahman, M.; Rogers, R.D.; Labidi, J.; Hedenqvist, M.S.; Celzard, A.; Tang, C.; Ralph, S.A.; Christensen, J.H.; et al. The Irruption of Polymers from Renewable Resources on the Scene of Macromolecular Science and Technology. Green Chem. 2011, 13, 1061–1083. [Google Scholar] [CrossRef]

- Nagarajan, V.; Mohanty, A.K.; Misra, M. Perspective on Polylactic Acid (PLA) Based Sustainable Materials for Durable Applications: Focus on Toughness and Heat Resistance. ACS Sustain. Chem. Eng. 2016, 4, 2899–2916. [Google Scholar] [CrossRef]

- Lasprilla, A.J.R.; Martinez, G.A.R.; Lunelli, B.H.; Jardini, A.L.; Filho, R.M. Poly-Lactic Acid Synthesis for Application in Biomedical Devices—A Review. Biotechnol. Adv. 2012, 30, 321–328. [Google Scholar] [CrossRef] [PubMed]

- Lopes, M.S.; Jardini, A.L.; Filho, R.M. Poly (Lactic Acid) Production for Tissue Engineering Applications. Procedia Eng. 2012, 42, 1402–1413. [Google Scholar] [CrossRef]

- Moran, J.M.; Pazzano, D.; Bonassar, L.J. Characterization of Polylactic Acid–Polyglycolic Acid Composites for Cartilage Tissue Engineering. Tissue Eng. 2003, 9, 63–70. [Google Scholar] [CrossRef] [PubMed]

- Tawakkal, I.S.M.A.; Cran, M.J.; Miltz, J.; Bigger, S.W. A Review of Poly(Lactic Acid)-Based Materials for Antimicrobial Packaging. J. Food Sci. 2014, 79, R1477–R1490. [Google Scholar] [CrossRef] [PubMed]

- Ahmed, J.; Varshney, S.K. Polylactides—Chemistry, Properties and Green Packaging Technology: A Review. Int. J. Food Prop. 2011, 14, 37–58. [Google Scholar] [CrossRef]

- Mihindukulasuriya, S.D.F.; Lim, L.-T. Nanotechnology Development in Food Packaging: A Review. Trends Food Sci. Technol. 2014, 40, 149–167. [Google Scholar] [CrossRef]

- Arora, A.; Padua, G.W. Review: Nanocomposites in Food Packaging. J. Food Sci. 2010, 75, R43–R49. [Google Scholar] [CrossRef] [PubMed]

- Kasirajan, S.; Ngouajio, M. Polyethylene and Biodegradable Mulches for Agricultural Applications: A Review. Agron. Sustain. Dev. 2012, 32, 501–529. [Google Scholar] [CrossRef]

- Avinc, O.; Khoddami, A. Overview of Poly(Lactic Acid) (PLA) Fibre I: Production, Properties, Performance, Environmental Impact, and End-Use Applications of Poly(Lactic Acid) Fibres. Fibre Chem. 2009, 41, 391–401. [Google Scholar] [CrossRef]

- Dugan, J.S. Novel Properties of PLA Fibers. Int. Nonwovens J. 2001, os-10, 29–33. [Google Scholar] [CrossRef]

- Ehrmann, G.; Ehrmann, A. Investigation of the Shape-Memory Properties of 3D Printed PLA Structures with Different Infills. Polymers 2021, 13, 164. [Google Scholar] [CrossRef] [PubMed]

- Samuel, C.; Barrau, S.; Lefebvre, J.-M.; Raquez, J.-M.; Dubois, P. Designing Multiple-Shape Memory Polymers with Miscible Polymer Blends: Evidence and Origins of a Triple-Shape Memory Effect for Miscible PLLA/PMMA Blends. Macromolecules 2014, 47, 6791–6803. [Google Scholar] [CrossRef]

- Liu, Z.; Wang, Y.; Wu, B.; Cui, C.; Guo, Y.; Yan, C. A Critical Review of Fused Deposition Modeling 3D Printing Technology in Manufacturing Polylactic Acid Parts. Int. J. Adv. Manuf. Technol. 2019, 102, 2877–2889. [Google Scholar] [CrossRef]

- Wasti Sanjita, A.S. Use of Biomaterials for 3D Printing by Fused Deposition Modeling Technique: A Review. Front. Chem. 2020, 8, 315. [Google Scholar] [CrossRef] [PubMed]

- Gong, S.; Zhang, B.; Zhang, J.; Wang, Z.L.; Ren, K. Biocompatible Poly(Lactic Acid)-Based Hybrid Piezoelectric and Electret Nanogenerator for Electronic Skin Applications. Adv. Funct. Mater. 2020, 30, 1908724. [Google Scholar] [CrossRef]

- Hamad, K.; Kaseem, M.; Ayyoob, M.; Joo, J.; Deri, F. Polylactic Acid Blends: The Future of Green, Light and Tough. Prog. Polym. Sci. 2018, 85, 83–127. [Google Scholar] [CrossRef]

- Pang, X.; Zhuang, X.; Tang, Z.; Chen, X. Polylactic Acid (PLA): Research, Development and Industrialization. Biotechnol. J. 2010, 5, 1125–1136. [Google Scholar] [CrossRef] [PubMed]

- Rasal, R.M.; Janorkar, A.V.; Hirt, D.E. Poly(Lactic Acid) Modifications. Prog. Polym. Sci. 2010, 35, 338–356. [Google Scholar] [CrossRef]

- Żenkiewicz, M.; Rytlewski, P.; Malinowski, R. Compositional, Physical and Chemical Modification of Polylactide. J. Achiev. Mater. Manuf. Eng. 2010, 43, 192–199. [Google Scholar]

- Bai, H.; Deng, S.; Bai, D.; Zhang, Q.; Fu, Q. Recent Advances in Processing of Stereocomplex-Type Polylactide. Macromol. Rapid Commun. 2017, 38, 1700454. [Google Scholar] [CrossRef] [PubMed]

- Odent, J.; Habibi, Y.; Raquez, J.-M.; Dubois, P. Ultra-Tough Polylactide-Based Materials Synergistically Designed in the Presence of Rubbery ε-Caprolactone-Based Copolyester and Silica Nanoparticles. Compos. Sci. Technol. 2013, 84, 86–91. [Google Scholar] [CrossRef]

- Tan, B.H.; Muiruri, J.K.; Li, Z.; He, C. Recent Progress in Using Stereocomplexation for Enhancement of Thermal and Mechanical Property of Polylactide. ACS Sustain. Chem. Eng. 2016, 4, 5370–5391. [Google Scholar] [CrossRef]

- Ljungberg, N.; Wesslén, B. Preparation and Properties of Plasticized Poly(Lactic Acid) Films. Biomacromolecules 2005, 6, 1789–1796. [Google Scholar] [CrossRef] [PubMed]

- Murariu, M.; Da Silva Ferreira, A.; Alexandre, M.; Dubois, P. Polylactide (PLA) Designed with Desired End-Use Properties: 1. PLA Compositions with Low Molecular Weight Ester-like Plasticizers and Related Performances. Polym. Adv. Technol. 2008, 19, 636–646. [Google Scholar] [CrossRef]

- Liu, H.; Zhang, J. Research Progress in Toughening Modification of Poly(Lactic Acid). J. Polym. Sci. B Polym. Phys. 2011, 49, 1051–1083. [Google Scholar] [CrossRef]

- Odent, J.; Raquez, J.-M.; Duquesne, E.; Dubois, P. Random Aliphatic Copolyesters as New Biodegradable Impact Modifiers for Polylactide Materials. Eur. Polym. J. 2012, 48, 331–340. [Google Scholar] [CrossRef]

- Kawamoto, N.; Sakai, A.; Horikoshi, T.; Urushihara, T.; Tobita, E. Physical and Mechanical Properties of Poly(L-Lactic Acid) Nucleated by Dibenzoylhydrazide Compound. J. Appl. Polym. Sci. 2007, 103, 244–250. [Google Scholar] [CrossRef]

- Kang, K.S.; Lee, S.I.; Lee, T.J.; Narayan, R.; Shin, B.Y. Effect of Biobased and Biodegradable Nucleating Agent on the Isothermal Crystallization of Poly(Lactic Acid). Korean J. Chem. Eng. 2008, 25, 599–608. [Google Scholar] [CrossRef]

- Adeosun, S.O.; Lawal, G.I.; Balogun, S.A.; Akpan, E.I. Review of Green Polymer Nanocomposites. J. Miner. Mater. Charact. Eng. 2012, 11, 385–416. [Google Scholar] [CrossRef]

- Raquez, J.-M.; Habibi, Y.; Murariu, M.; Dubois, P. Polylactide (PLA)-Based Nanocomposites. Prog. Polym. Sci. 2013, 38, 1504–1542. [Google Scholar] [CrossRef]

- Yang, Y.; Zhang, L.; Xiong, Z.; Tang, Z.; Zhang, R.; Zhu, J. Research Progress in the Heat Resistance, Toughening and Filling Modification of PLA. Sci. China Chem. 2016, 59, 1355–1368. [Google Scholar] [CrossRef]

- Li, Z.; Tan, B.H.; Lin, T.; He, C. Recent Advances in Stereocomplexation of Enantiomeric PLA-Based Copolymers and Applications. Prog. Polym. Sci. 2016, 62, 22–72. [Google Scholar] [CrossRef]

- Luo, F.; Fortenberry, A.; Ren, J.; Qiang, Z. Recent Progress in Enhancing Poly(Lactic Acid) Stereocomplex Formation for Material Property Improvement. Front. Chem. 2020, 8, 688. [Google Scholar] [CrossRef] [PubMed]

- Moser, K.; Schmitt, M.; Holzer, A.; Bergmann, B.; Diemert, J.; Elsner, P. Optimization of PLA Compounds Using Novel Nucleating Agents and Plasticizers. In Proceedings of the Regional Conference GRAZ 2015—Polymer Processing Society, Graz, Austria, 21–25 September 2015; AIP Publishing: Melville, NY, USA, 2016; p. 060006. [Google Scholar]

- Shi, X.; Zhang, G.; Phuong, T.; Lazzeri, A. Synergistic Effects of Nucleating Agents and Plasticizers on the Crystallization Behavior of Poly(Lactic Acid). Molecules 2015, 20, 1579–1593. [Google Scholar] [CrossRef] [PubMed]

- Anakabe, J.; Zaldua Huici, A.M.; Eceiza, A.; Arbelaiz, A.; Avérous, L. Combined Effect of Nucleating Agent and Plasticizer on the Crystallization Behaviour of Polylactide. Polym. Bull. 2017, 74, 4857–4886. [Google Scholar] [CrossRef]

- Pötschke, P.; Paul, D.R. Formation of Co-Continuous Structures in Melt-Mixed Immiscible Polymer Blends. J. Macromol. Sci. Part C Polym. Rev. 2003, 43, 87–141. [Google Scholar] [CrossRef]

- Horák, Z.; Fortelný, I.; Kolařík, J.; Hlavatá, D.; Sikora, A. Polymer blends, Encyclopedia of Polymer Science and Technology; John Wiley and Sons: New York, NY, USA, 2005; pp. 1–59. ISBN 9780471440260. [Google Scholar] [CrossRef]

- Ajji, A.; Utracki, L.A. Interphase and Compatibilization of Polymer Blends. Polym. Eng. Sci. 1996, 36, 1574–1585. [Google Scholar] [CrossRef]

- Samuel, C.; Raquez, J.-M.; Dubois, P. PLLA/PMMA Blends: A Shear-Induced Miscibility with Tunable Morphologies and Properties. Polymer 2013, 54, 3931–3939. [Google Scholar] [CrossRef]

- Faverjon, C.; Yousfi, M.; Parajua-sejil, C.; Truchot, V.; Duchet-Rumeau, J. Elongational flow mixing: A novel innovative approach to elaborate high-performance SBR-based elastomer compounds. Appl. Rheol. 2023, 33, 20230105. [Google Scholar] [CrossRef]

- Grace, H.P. Dispersion Phenomena in High Viscosity Immiscible Fluid Systems and Application of Static Mixers as Dispersion Devices in Such Systems. Chem. Eng. Commun. 1982, 14, 225–277. [Google Scholar] [CrossRef]

- Sundararaj, U.; Macosko, C.W. Drop Breakup and Coalescence in Polymer Blends: The Effects of Concentration and Compatibilization. Macromolecules 1995, 28, 2647–2657. [Google Scholar] [CrossRef]

- Yousfi, M.; Dadouche, T.; Chomat, D.; Samuel, C.; Soulestin, J.; Lacrampe, M.-F.; Krawczak, P. Development of Nanofibrillar Morphologies in Poly(l-Lactide)/Poly(Amide) Blends: Role of the Matrix Elasticity and Identification of the Critical Shear Rate for the Nodular/Fibrillar Transition. RSC Adv. 2018, 8, 22023–22041. [Google Scholar] [CrossRef] [PubMed]

- Galloway, J.A.; Koester, K.J.; Paasch, B.J.; Macosko, C.W. Effect of Sample Size on Solvent Extraction for Detecting Cocontinuity in Polymer Blends. Polymer 2004, 45, 423–428. [Google Scholar] [CrossRef]

- Prochazka, F.; Barbier, D.; Castro, M. Evolution de Morphologie Pendant Le Processus de Mélanges Des Polymères Incompatibles. In Rhéologie et Procédés de Transformation (GFR 2005); Groupe Français de Rhéologie: Paris, France, 2005; 337p + 1CD-Rom. [Google Scholar]

- Willemse, R.C.; Posthuma de Boer, A.; van Dam, J.; Gotsis, A.D. Co-Continuous Morphologies in Polymer Blends: A New Model. Polymer 1998, 39, 5879–5887. [Google Scholar] [CrossRef]

- Chaput, S.; Carrot, C.; Castro, M.; Prochazka, F. Co-Continuity Interval in Immiscible Polymer Blends by Dynamic Mechanical Spectroscopy in the Molten and Solid State. Rheol. Acta 2004, 43, 417–426. [Google Scholar] [CrossRef]

- Miles, I.S.; Zurek, A. Preparation, Structure, and Properties of Two-Phase Co-Continuous Polymer Blends. Polym. Eng. Sci. 1988, 28, 796–805. [Google Scholar] [CrossRef]

- Souza, A.M.C.; Demarquette, N.R. Influence of Coalescence and Interfacial Tension on the Morphology of PP/HDPE Compatibilized Blends. Polymer 2002, 43, 3959–3967. [Google Scholar] [CrossRef]

- Samuel, C.; Parpaite, T.; Lacrampe, M.-F.; Soulestin, J.; Lhost, O. Melt Compatibility between Polyolefins: Evaluation and Reliability of Interfacial/Surface Tensions Obtained by Various Techniques. Polym. Test. 2019, 78, 105995. [Google Scholar] [CrossRef]

- Wu, S. Polymer Interface and Adhesion; Marcel Dekker: New York, NY, USA, 1982; ISBN 9780203742860. [Google Scholar]

- Koning, C.; Van Duin, M.; Pagnoulle, C.; Jerome, R. Strategies for Compatibilization of Polymer Blends. Prog. Polym. Sci. 1998, 23, 707–757. [Google Scholar] [CrossRef]

- Macosko, C.W.; Guégan, P.; Khandpur, A.K.; Nakayama, A.; Marechal, P.; Inoue, T. Compatibilizers for Melt Blending: Premade Block Copolymers. Macromolecules 1996, 29, 5590–5598. [Google Scholar] [CrossRef]

- Xanthos, M.; Dagli, S.S. Compatibilization of Polymer Blends by Reactive Processing. Polym. Eng. Sci. 1991, 31, 929–935. [Google Scholar] [CrossRef]

- Chang, K.; Macosko, C.W.; Morse, D.C. Ultralow Interfacial Tensions of Polymer/Polymer Interfaces with Diblock Copolymer Surfactants. Macromolecules 2007, 40, 3819–3830. [Google Scholar] [CrossRef]

- Lyu, S.P.; Bates, F.S.; Macosko, C.W. Competitive Roles of Block Copolymer during Polymer Blending: Suppression of Coalescence and Reduction of Interfacial Tension; American Chemical Society: Washington, DC, USA, 1999; pp. 1016–1017. [Google Scholar]

- Van Hemelrijck, E.; Van Puyvelde, P.; Velankar, S.; Macosko, C.W.; Moldenaers, P. Interfacial Elasticity and Coalescence Suppression in Compatibilized Polymer Blends. J. Rheol. 2003, 48, 143. [Google Scholar] [CrossRef]

- Macaúbas, P.H.P.; Demarquette, N.R. Morphologies and Interfacial Tensions of Immiscible Polypropylene/Polystyrene Blends Modified with Triblock Copolymers. Polymer 2001, 42, 2543–2554. [Google Scholar] [CrossRef]

- Garmabi, H.; Demarquette, N.R.; Kamal, M.R. Effect of Temperature and Compatibilizer on Interfacial Tension of PE/PA-6 and PP/EVOH. Int. Polym. Process. 1998, 13, 183–191. [Google Scholar] [CrossRef]

- Lyu, S.; Jones, T.D.; Bates, F.S.; Macosko, C.W. Role of Block Copolymers on Suppression of Droplet Coalescence. Macromolecules 2002, 35, 7845–7855. [Google Scholar] [CrossRef]

- Martinez Villadiego, K.; Arias Tapia, M.J.; Useche, J.; Escobar Macías, D. Thermoplastic Starch (TPS)/Polylactic Acid (PLA) Blending Methodologies: A Review. J. Polym. Environ. 2021, 30, 75–91. [Google Scholar] [CrossRef]

- Delgado-Aguilar, M.; Puig, R.; Sazdovski, I.; Fullana-i-Palmer, P. Polylactic Acid/Polycaprolactone Blends: On the Path to Circular Economy, Substituting Single-Use Commodity Plastic Products. Materials 2020, 13, 2655. [Google Scholar] [CrossRef] [PubMed]

- Naser, A.Z.; Deiab, I.; Darras, B.M. Poly(Lactic Acid) (PLA) and Polyhydroxyalkanoates (PHAs), Green Alternatives to Petroleum-Based Plastics: A Review. RSC Adv. 2021, 11, 17151–17196. [Google Scholar] [CrossRef] [PubMed]

- Su, S.; Kopitzky, R.; Tolga, S.; Kabasci, S. Polylactide (PLA) and its blends with poly (butylene succinate)(PBS): A brief review. Polymers 2019, 11, 1193. [Google Scholar] [CrossRef] [PubMed]

- Di Lorenzo, M.L. Poly(l-Lactic Acid)/Poly(Butylene Succinate) Biobased Biodegradable Blends. Polym. Rev. 2020, 61, 457–492. [Google Scholar] [CrossRef]

- Gigante, V.; Canesi, I.; Cinelli, P.; Coltelli, M.B.; Lazzeri, A. Rubber Toughening of Polylactic Acid (PLA) with Poly(Butylene Adipate-Co-Terephthalate) (PBAT): Mechanical Properties, Fracture Mechanics and Analysis of Ductile-to-Brittle Behavior While Varying Temperature and Test Speed. Eur. Polym. J. 2019, 115, 125–137. [Google Scholar] [CrossRef]

- Arrieta, M.P.; Samper, M.D.; Aldas, M.; López, J. On the Use of PLA-PHB Blends for Sustainable Food Packaging Applications. Materials 2017, 10, 1008. [Google Scholar] [CrossRef] [PubMed]

- Zembouai, I.; Kaci, M.; Bruzaud, S.; Benhamida, A.; Corre, Y.M.; Grohens, Y. A Study of Morphological, Thermal, Rheological and Barrier Properties of Poly(3-Hydroxybutyrate-Co-3-Hydroxyvalerate)/Polylactide Blends Prepared by Melt Mixing. Polym. Test. 2013, 32, 842–851. [Google Scholar] [CrossRef]

- Vrsaljko, D.; Macut, D.; Kovačevic, V. Potential Role of Nanofillers as Compatibilizers in Immiscible PLA/LDPE Blends. J. Appl. Polym. Sci. 2015, 132, 41414. [Google Scholar] [CrossRef]

- Quitadamo, A.; Massardier, V.; Santulli, C.; Valente, M. Optimization of thermoplastic blend matrix HDPE/PLA with different types and levels of coupling agents. Materials 2018, 11, 2527. [Google Scholar] [CrossRef] [PubMed]

- Rajan, K.P.; Thomas, S.P.; Gopanna, A.; Al-Ghamdi, A.; Chavali, M. Polyblends and Composites of Poly (Lactic Acid) (PLA): A Review on the State of the Art. J. Polym. Sci. Eng. 2018, 1, 1–15. [Google Scholar] [CrossRef]

- Hamad, K.; Kaseem, M.; Yang, H.W.; Deri, F.; Ko, Y.G. Properties and medical applications of polylactic acid: A review. Express Polym. Lett. 2015, 9, 435–455. [Google Scholar] [CrossRef]

- Sookprasert, P.; Hinchiranan, N. Morphology, Mechanical and Thermal Properties of Poly(Lactic Acid) (PLA)/Natural Rubber (NR) Blends Compatibilized by NR-Graft-PLA. J. Mater. Res. 2017, 32, 788–800. [Google Scholar] [CrossRef]

- Phattarateera, S.; Pattamaprom, C. Comparative Performance of Functional Rubbers on Toughness and Thermal Property Improvement of Polylactic Acid. Mater. Today Commun. 2019, 19, 374–382. [Google Scholar] [CrossRef]

- Yang, J.; Nie, S.; Zhu, J. A Comparative Study on Different Rubbery Modifiers: Effect on Morphologies, Mechanical, and Thermal Properties of PLA Blends. J. Appl. Polym. Sci. 2016, 133, 43340. [Google Scholar] [CrossRef]

- Rodolfo, M.G.; Costa, L.C.; Marini, J. Toughened Poly(Lactic Acid)/Thermoplastic Polyurethane Uncompatibilized Blends. J. Polym. Eng. 2022, 42, 214–222. [Google Scholar]

- Samuel, C.; Raquez, J.M.; Dubois, P. Biobased Poly(Lactides)/Poly(Methyl Methacrylate) Blends: A Perfect Association for Durable and Smart Applications? In Proceedings of the PPS-30: The 30th International Conference of the Polymer Processing Society, Cleveland, OH, USA, 6–12 June 2014; AIP Publishing LLC: Long Island, NY, USA, 2015; Volume 1664, p. 030005. [Google Scholar]

- Bouzouita, A.; Samuel, C.; Notta-Cuvier, D.; Odent, J.; Lauro, F.; Dubois, P.; Raquez, J.-M. Design of Highly Tough Poly(l-Lactide)-Based Ternary Blends for Automotive Applications. J. Appl. Polym. Sci. 2016, 133, 43402. [Google Scholar] [CrossRef]

- Lee, J.B.; Lee, Y.K.; Choi, G.D.; Na, S.W.; Park, T.S.; Kim, W.N. Compatibilizing Effects for Improving Mechanical Properties of Biodegradable Poly (Lactic Acid) and Polycarbonate Blends. Polym. Degrad. Stab. 2011, 96, 553–560. [Google Scholar] [CrossRef]

- Lin, L.; Deng, C.; Wang, Y.Z. Improving the Impact Property and Heat-Resistance of PLA/PC Blends through Coupling Molecular Chains at the Interface. Polym. Adv. Technol. 2015, 26, 1247–1258. [Google Scholar] [CrossRef]

- Yemisci, F.; Aytac, A. Compatibilization of Poly(Lactic Acid)/Polycarbonate Blends by Different Coupling Agents. Fibers Polym. 2017, 18, 1445–1451. [Google Scholar] [CrossRef]

- Wang, Y.; Chiao, S.M.; Hung, T.-F.; Yang, S.-Y. Improvement in Toughness and Heat Resistance of Poly(Lactic Acid)/Polycarbonate Blend through Twin-Screw Blending: Influence of Compatibilizer Type. J. Appl. Polym. Sci. 2012, 125, E402–E412. [Google Scholar] [CrossRef]

- Yuryev, Y.; Mohanty, A.K.; Misra, M. Hydrolytic Stability of Polycarbonate/Poly(Lactic Acid) Blends and Its Evaluation via Poly(Lactic) Acid Median Melting Point Depression. Polym. Degrad. Stab. 2016, 134, 227–236. [Google Scholar] [CrossRef]

- Hashima, K.; Nishitsuji, S.; Inoue, T. Structure-Properties of Super-Tough PLA Alloy with Excellent Heat Resistance. Polymer 2010, 51, 3934–3939. [Google Scholar] [CrossRef]

- Liu, C.; Lin, S.; Zhou, C.; Yu, W. Influence of Catalyst on Transesterification between Poly(Lactic Acid) and Polycarbonate under Flow Field. Polymer 2013, 54, 310–319. [Google Scholar] [CrossRef]

- Phuong, V.T.; Coltelli, M.B.; Cinelli, P.; Cifelli, M.; Verstichel, S.; Lazzeri, A. Compatibilization and Property Enhancement of Poly(Lactic Acid)/Polycarbonate Blends through Triacetin-Mediated Interchange Reactions in the Melt. Polymer 2014, 55, 4498–4513. [Google Scholar] [CrossRef]

- Zhou, Y.; Luo, L.; Liu, W.; Zeng, G.; Chen, Y. Preparation and Characteristic of PC/PLA/TPU Blends by Reactive Extrusion. Adv. Mater. Sci. Eng. 2015, 2015, 1–9. [Google Scholar] [CrossRef]

- Imre, B.; Renner, K.; Pukanszky, B. Interactions, Structure and Properties in Poly(Lactic Acid)/Thermoplastic Polymer Blends. Express Polym. Lett. 2014, 8, 2–14. [Google Scholar] [CrossRef]

- Yeh, J.-T.; Fan-Chiang, C.-C.; Yang, S.-S. Effects of Composition of Modified Polyamide on Barrier Properties of Polyethylene/Modified Polyamide Blends. J. Appl. Polym. Sci. 1997, 64, 1531–1540. [Google Scholar] [CrossRef]

- Girija, B.G.; Sailaja, R.R.N.; Madras, G. Thermal Degradation and Mechanical Properties of PET Blends. Polym. Degrad. Stab. 2005, 90, 147–153. [Google Scholar] [CrossRef]

- Fu, Y.; Liao, L.; Yang, L.; Lan, Y.; Mei, L.; Liu, Y.; Hu, S. Molecular Dynamics and Dissipative Particle Dynamics Simulations for Prediction of Miscibility in Polyethylene Terephthalate/Polylactide Blends. Mol. Simul. 2013, 39, 415–422. [Google Scholar] [CrossRef]

- La Mantia, F.P.; Botta, L.; Morreale, M.; Scaffaro, R. Effect of Small Amounts of Poly(Lactic Acid) on the Recycling of Poly(Ethylene Terephthalate) Bottles. Polym. Degrad. Stab. 2012, 97, 21–24. [Google Scholar] [CrossRef]

- Torres-Huerta, A.M.; Palma-Ramírez, D.; Domínguez-Crespo, M.A.; Del Angel-López, D.; de la Fuente, D. Comparative Assessment of Miscibility and Degradability on PET/PLA and PET/Chitosan Blends. Eur. Polym. J. 2014, 61, 285–299. [Google Scholar] [CrossRef]

- Torres-Huerta, A.M.; Del Angel-López, D.; Domínguez-Crespo, M.A.; Palma-Ramírez, D.; Perales-Castro, M.E.; Flores-Vela, A. Morphological and Mechanical Properties Dependence of PLA Amount in PET Matrix Processed by Single-Screw Extrusion. Polym. Plast. Technol. Eng. 2016, 55, 672–683. [Google Scholar] [CrossRef]

- Topkanlo, H.A.; Ahmadi, Z.; Taromi, F.A. An In-Depth Study on Crystallization Kinetics of PET/PLA Blends. Iran. Polym. J. 2018, 27, 13–22. [Google Scholar] [CrossRef]

- McLauchlin, A.R.; Ghita, O.R. Studies on the Thermal and Mechanical Behavior of PLA-PET Blends. J. Appl. Polym. Sci. 2016, 133, 44147. [Google Scholar] [CrossRef]

- You, X.; Snowdon, M.R.; Misra, M.; Mohanty, A.K. Biobased Poly(Ethylene Terephthalate)/Poly(Lactic Acid) Blends Tailored with Epoxide Compatibilizers. ACS Omega 2018, 3, 11759–11769. [Google Scholar] [PubMed]

- Yahyaee, N.; Javadi, A.; Garmabi, H.; Khaki, A. Effect of Two-Step Chain Extension Using Joncryl and PMDA on the Rheological Properties of Poly (Lactic Acid). Macromol. Mater. Eng. 2020, 305, 1900423. [Google Scholar] [CrossRef]

- Yousfi, M.; Samuel, C.; Dadouche, T.; Mincheva, R.; Lacrampe, M.F. Long-Chain Branched Poly(Butylene Succinate-Co-Terephthalate) Copolyesters: Impact of (Reactive) Synthesis Strategies on Melt Strength Properties. Express Polym. Lett. 2023, 17, 300–316. [Google Scholar] [CrossRef]

- Al-Itry, R.; Lamnawar, K.; Maazouz, A. Rheological, Morphological, and Interfacial Properties of Compatibilized PLA/PBAT Blends. Rheol. Acta 2014, 53, 501–517. [Google Scholar]

- Jiang, W.-R.; Bao, R.-Y.; Yang, W.; Liu, Z.-Y.; Xie, B.-H.; Yang, M.-B. Morphology, Interfacial and Mechanical Properties of Polylactide/Poly(Ethylene Terephthalate Glycol) Blends Compatibilized by Polylactide-g-Maleic Anhydride. Mater. Des. 2014, 59, 524–531. [Google Scholar] [CrossRef]

- Di Lorenzo, M.L.; Rubino, P.; Cocca, M. Miscibility and Properties of Poly(l-Lactic Acid)/Poly(Butylene Terephthalate) Blends. Eur. Polym. J. 2013, 49, 3309–3317. [Google Scholar] [CrossRef]

- Kuru, Z.; Kaya, M.A. Improving the Properties of Biodegradable PLA via Blending with Polyesters for Industrial Applications. Eur. J. Res. Dev. 2022, 2, 299–318. [Google Scholar] [CrossRef]

- Chang, B.P.; Mohanty, A.K.; Misra, M. Tuning the Compatibility to Achieve Toughened Biobased Poly(Lactic Acid)/Poly(Butylene Terephthalate) Blends. RSC Adv. 2018, 8, 27709–27724. [Google Scholar] [CrossRef] [PubMed]

- Yousfi, M.; Samuel, C.; Soulestin, J.; Lacrampe, M.-F.; Orús, J.E.; Yousfi, M.; Samuel, C.; Soulestin, J.; Lacrampe, M.-F. Rheological Considerations in Processing Self-Reinforced Thermoplastic Polymer Nanocomposites: A Review. Polymers 2022, 14, 637. [Google Scholar] [CrossRef] [PubMed]

- Raj, A.; Prashantha, K.; Samuel, C. Compatibility in Biobased Poly(L-lactide)/Polyamide Binary Blends: From Melt-state Interfacial Tensions to (Thermo)Mechanical Properties. J. Appl. Polym. Sci. 2019, 137, 48440. [Google Scholar] [CrossRef]

- Raj, A.; Samuel, C.; Malladi, N.; Prashantha, K. Enhanced (Thermo)Mechanical Properties in Biobased Poly(Lactide)/Poly(Amide-12) Blends Using High Shear Extrusion Processing without Compatibilizers. Polym. Eng. Sci. 2020, 60, 1902–1916. [Google Scholar] [CrossRef]

- Kim, M.W.; Hong, S.M.; Lee, D.; Park, K.; Kang, T.J.; Youn, J.R. Chain Extension Effects of Para-Phenylene Diisocyanate on Crystallization Behavior and Biodegradability of Poly(Lactic Acid)/Poly(Butylene Terephthalate) Blends. Adv. Compos. Mater. 2010, 19, 331–348. [Google Scholar] [CrossRef]

- Santos, L.G.; Costa, L.C.; Pessan, L.A. Development of Biodegradable PLA/PBT Nanoblends. J. Appl. Polym. Sci. 2018, 135, 45951. [Google Scholar] [CrossRef]

- Mark, J.E. Polymer Data Handbook; Oxford University Press: Oxford, UK, 2009; ISBN 9780195181012. [Google Scholar]

- Farah, S.; Anderson, D.G. Physical and Mechanical Properties of PLA, and Their Functions in Widespread Applications—A Comprehensive Review. Adv. Drug Deliv. Rev. 2016, 107, 367–392. [Google Scholar] [CrossRef] [PubMed]

- Van de Velde, K.; Kiekens, P. Biopolymers: Overview of Several Properties and Consequences on Their Applications. Polym. Test. 2002, 21, 433–442. [Google Scholar] [CrossRef]

- Cailloux, J.; Abt, T.; Santana, O.; Carrasco, F. Effect of the Viscosity Ratio on the PLA/PA10. 10 Bioblends Morphology and Mechanical Properties. Express Polym. Lett. 2018, 12, 569–582. [Google Scholar] [CrossRef]

- Kucharczyk, P.; Sedlarik, V.; Miskolczi, N.; Szakacs, H.; Kitano, T. Properties Enhancement of Partially Biodegradable Polyamide/Polylactide Blends through Compatibilization with Novel Polyalkenyl-Poly-Maleic-Anhydride-Amide/Imide-Based Additives. J. Reinf. Plast. Compos. 2012, 31, 189–202. [Google Scholar] [CrossRef]

- Khankrua, R.; Pivsa-Art, S.; Hiroyuki, H.; Suttiruengwong, S. Effect of Chain Extenders on Thermal and Mechanical Properties of Poly(Lactic Acid) at High Processing Temperatures: Potential Application in PLA/Polyamide 6 Blend. Polym. Degrad. Stab. 2014, 108, 232–240. [Google Scholar] [CrossRef]

- Chen, Y.; Xu, W.J.; Zeng, G.S.; Zeng, X.H.; Liu, W.Y.; Huang, Y.G. Preparation and Properties Research of PA6/PLA Blends Toughening Modified by TPU. Appl. Mech. Mater. 2012, 200, 278–281. [Google Scholar] [CrossRef]

- Wang, Y.-L.; Hu, X.; Li, H.; Ji, X.; Li, Z.-M. Polyamide-6/Poly(Lactic Acid) Blends Compatibilized by the Maleic Anhydride Grafted Polyethylene-Octene Elastomer. Polym. Plast. Technol. Eng. 2010, 49, 1241–1246. [Google Scholar] [CrossRef]

- Sedlarik, V.; Otgonzul, O.; Kitano, T.; Gregorova, A.; Hrabalova, M.; Junkar, I.; Cvelbar, U.; Mozetic, M.; Saha, P. Effect of Phase Arrangement on Solid State Mechanical and Thermal Properties of Polyamide 6/Polylactide Based Co-Polyester Blends. J. Macromol. Sci. Part B 2012, 51, 982–1001. [Google Scholar] [CrossRef]

- Pai, F.-C.; Lai, S.-M.; Chu, H.-H. Characterization and Properties of Reactive Poly(Lactic Acid)/Polyamide 610 Biomass Blends. J. Appl. Polym. Sci. 2013, 130, 2563–2571. [Google Scholar] [CrossRef]

- García-Masabet, V.; Pérez, O.S.; Cailloux, J.; Abt, T.; Sánchez-Soto, M.; Carrasco, F.; Maspoch, M.L. PLA/PA Bio-Blends: Induced Morphology by Extrusion. Polymers 2019, 12, 10. [Google Scholar] [CrossRef] [PubMed]

- Heshmati, V.; Zolali, A.M.; Favis, B.D. Morphology Development in Poly (Lactic Acid)/Polyamide11 Biobased Blends: Chain Mobility and Interfacial Interactions. Polymer 2017, 120, 197–208. [Google Scholar] [CrossRef]

- Stoclet, G.; Seguela, R.; Lefebvre, J.-M. Morphology, Thermal Behavior and Mechanical Properties of Binary Blends of Compatible Biosourced Polymers: Polylactide/Polyamide11. Polymer 2011, 52, 1417–1425. [Google Scholar] [CrossRef]

- Yu, X.; Wang, X.; Zhang, Z.; Peng, S.; Chen, H.; Zhao, X. High-Performance Fully Bio-Based Poly(Lactic Acid)/Polyamide11 (PLA/PA11) Blends by Reactive Blending with Multi-Functionalized Epoxy. Polym. Test. 2019, 78, 105980. [Google Scholar] [CrossRef]

- Gug, J.; Sobkowicz, M.J. Improvement of the Mechanical Behavior of Bioplastic Poly(Lactic Acid)/Polyamide Blends by Reactive Compatibilization. J. Appl. Polym. Sci. 2016, 133, 43350. [Google Scholar] [CrossRef]

- Patel, R.; Ruehle, D.A.; Dorgan, J.R.; Halley, P.; Martin, D. Biorenewable Blends of Polyamide-11 and Polylactide. Polym. Eng. Sci. 2014, 54, 1523–1532. [Google Scholar] [CrossRef]

- Raj, A.; Samuel, C.; Prashantha, K. Role of Compatibilizer in Improving the Properties of PLA/PA12 Blends. Front. Mater. 2020, 7, 193. [Google Scholar] [CrossRef]

- Rashmi, B.J.; Prashantha, K.; Lacrampe, M.-F.; Krawczak, P. Toughening of Poly(Lactic Acid) without Sacrificing Stiffness and Strength by Melt-Blending with Polyamide 11 and Selective Localization of Halloysite Nanotubes. Express Polym. Lett. 2015, 9, 721–735. [Google Scholar] [CrossRef]

- Dong, W.; Cao, X.; Li, Y. High-Performance Biosourced Poly(Lactic Acid)/Polyamide 11 Blends with Controlled Salami Structure. Polym. Int. 2014, 63, 1094–1100. [Google Scholar] [CrossRef]

- Nuzzo, A.; Bilotti, E.; Peijs, T.; Acierno, D.; Filippone, G. Nanoparticle-Induced Co-Continuity in Immiscible Polymer Blends—A Comparative Study on Bio-Based PLA-PA11 Blends Filled with Organoclay, Sepiolite, and Carbon Nanotubes. Polymer 2014, 55, 4908–4919. [Google Scholar] [CrossRef]

| Properties | PLA | PC | PET | PBT |

|---|---|---|---|---|

| Tensile Strength (MPa) | 50–60 | 60–70 | 50–80 | 50–60 |

| Young’s Modulus (GPa) | 3.4–3.7 | 2.2–2.5 | 2.5–2.8 | 2.6–2.8 |

| Elongation at break (%) | 2.5–10 | >50 | >50 | >50 |

| Unnotched Charpy impact strength (kJ/m2) | 20–25 | Unbreak | Unbreak | Unbreak |

| Notched Charpy impact strength (kJ/m2) | <5 | 70 | 3 | 5 |

| IZOD notched impact strength (J/m) | 5–30 | 600–800 | 20–30 | 40–50 |

| Tg (°C) | 45–65 | 145–150 | 65–70 | 30–50 |

| Melting temperature (°C) | 150–175 | Amorphous | 255–265 | 220–230 |

| HDT (°C)—Method B @ 0.45 MPa | 60 | 138 | 115 | 165 |

| HDT (°C)—Method A @ 1.8 MPa | 50 | 125 | 80 | 55 |

| (Potential) biobased content at the commercial level | 100% | 0% (up to a 10–20 percent with biobased diphenyl carbonate) | 0% (up to 30–35% with biobased ethylene glycol) | 0% (up to 30–35% with biobased 1,4-butanediol) |

| Properties | PA6 | PA6-10 | PA10-10 | PA11 |

|---|---|---|---|---|

| Tensile Strength (MPa) | 79 | 83 | 52 | 70 |

| Young’s Modulus (GPa) | 2.9 | 1–2 | 1.5 | 1.2 |

| Elongation at break (%) | 70 | 120–300 | 150–170 | 160 |

| Unnotched/Notched Charpy impact strength (kJ/m2) | 50/42 | 100/15 | No break/10 | No break/8 |

| Notched IZOD impact strength (J/m) | 53 | 50 | 40 | 27 |

| Tg (°C) | 47–57 | 67 | 50 | 42 |

| Melting temperature (°C) | 220 | 220 | 200–205 | 185 |

| HDTA (°C) | 150–190 | 150–175 | 120 | 145–175 |

| HDTB (°C) | 60–80 | 55–85 | 50 | 50–160 |

| (Potential) biobased content at the commercial level | - | 60 | 100 | 100 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Raj, A.; Yousfi, M.; Prashantha, K.; Samuel, C. Morphologies, Compatibilization and Properties of Immiscible PLA-Based Blends with Engineering Polymers: An Overview of Recent Works. Polymers 2024, 16, 1776. https://doi.org/10.3390/polym16131776

Raj A, Yousfi M, Prashantha K, Samuel C. Morphologies, Compatibilization and Properties of Immiscible PLA-Based Blends with Engineering Polymers: An Overview of Recent Works. Polymers. 2024; 16(13):1776. https://doi.org/10.3390/polym16131776

Chicago/Turabian StyleRaj, Amulya, Mohamed Yousfi, Kalappa Prashantha, and Cédric Samuel. 2024. "Morphologies, Compatibilization and Properties of Immiscible PLA-Based Blends with Engineering Polymers: An Overview of Recent Works" Polymers 16, no. 13: 1776. https://doi.org/10.3390/polym16131776

APA StyleRaj, A., Yousfi, M., Prashantha, K., & Samuel, C. (2024). Morphologies, Compatibilization and Properties of Immiscible PLA-Based Blends with Engineering Polymers: An Overview of Recent Works. Polymers, 16(13), 1776. https://doi.org/10.3390/polym16131776