Mechanical and Thermal Degradation-Related Performance of Recycled LDPE from Post-Consumer Waste

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Methods

2.2.1. Production of Test Specimens

- Temperatures on the screw: t1 = 200 °C; t2 = 220 °C; t3 = 224 °C; t4 = 220 °C; t5 = 230 °C

- Clamping force: 303 kN

- Maximum filling pressure: 90 bar

2.2.2. Testing of Mechanical Properties

Testing of Recycled LDPE from Post-Consumer Waste

Testing of Virgin LDPE

2.2.3. Statistical Evaluation of Measured Data

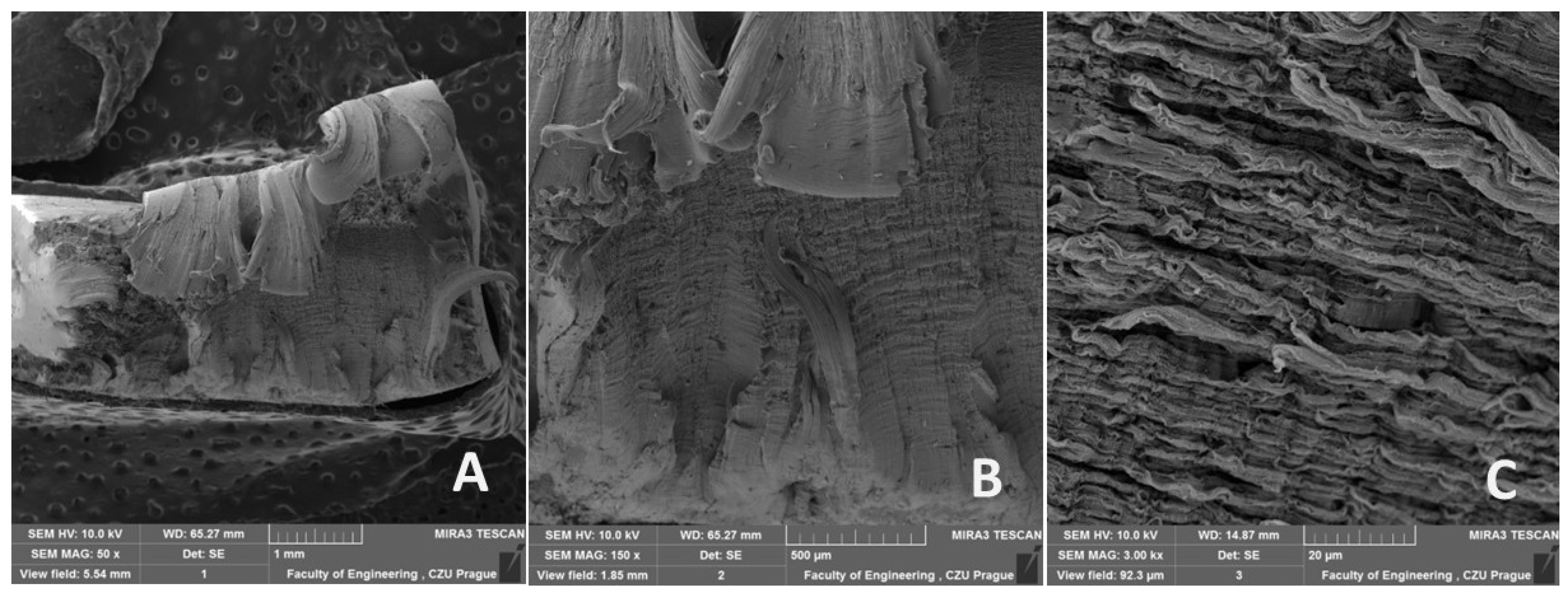

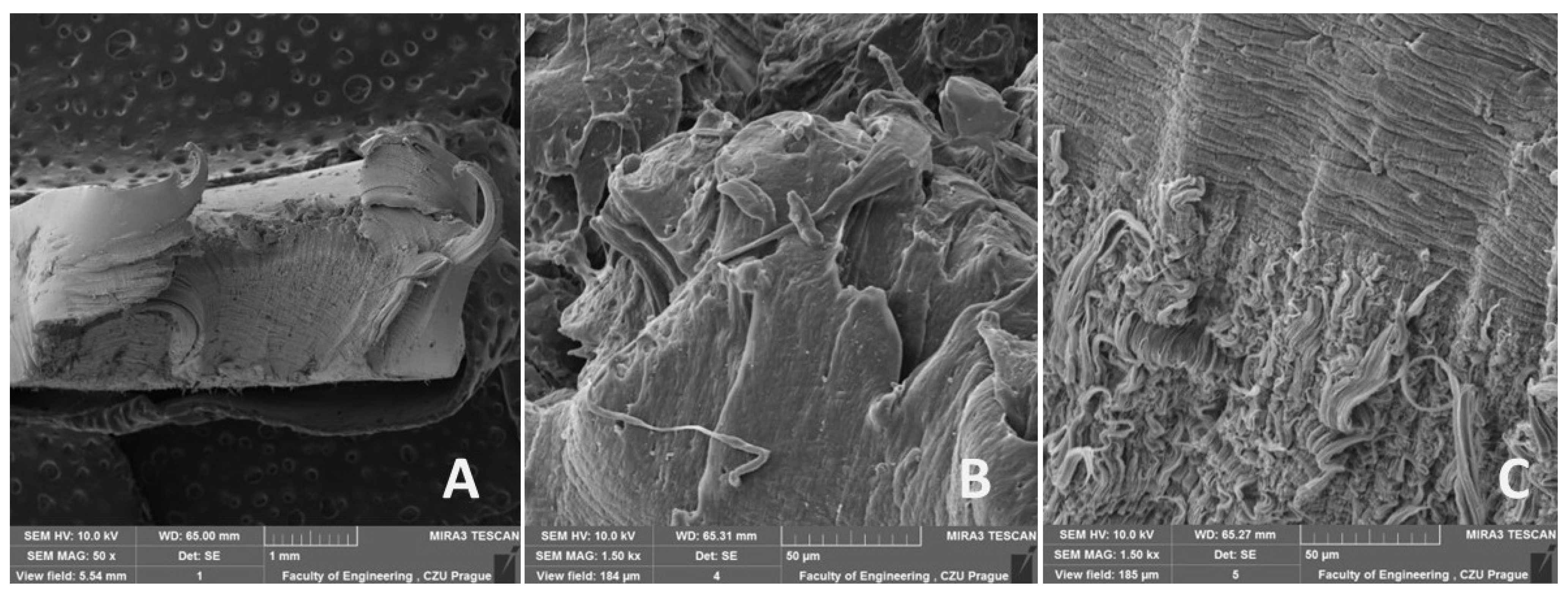

2.2.4. Scanning Electron Microscopy (SEM) Analysis

2.2.5. Fourier Transform Infrared Spectroscopy (FTIR)

2.2.6. Differential Scanning Calorimetry (DSC)

2.2.7. Dynamic Mechanical Analysis (DMA)

3. Results and Discussion

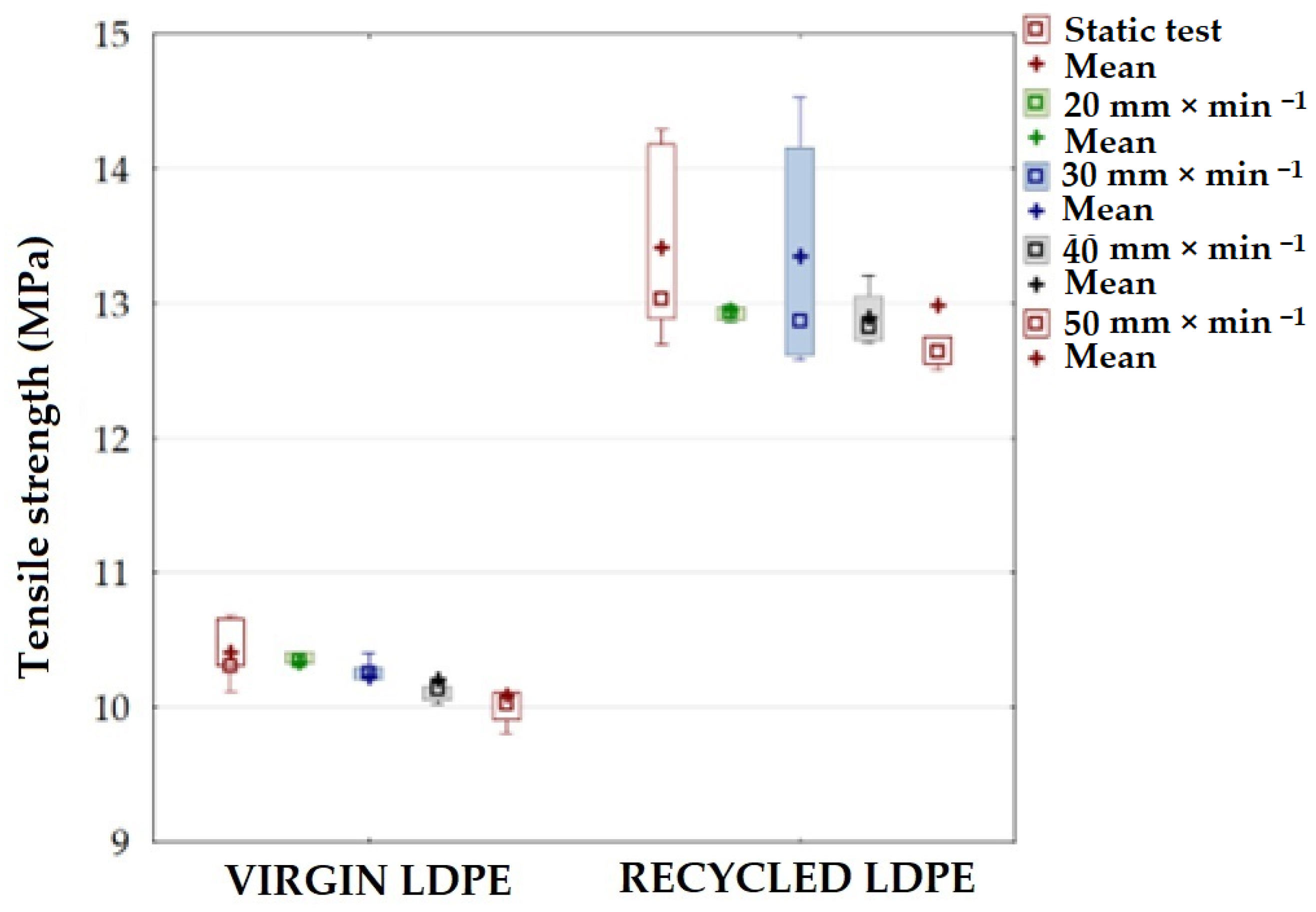

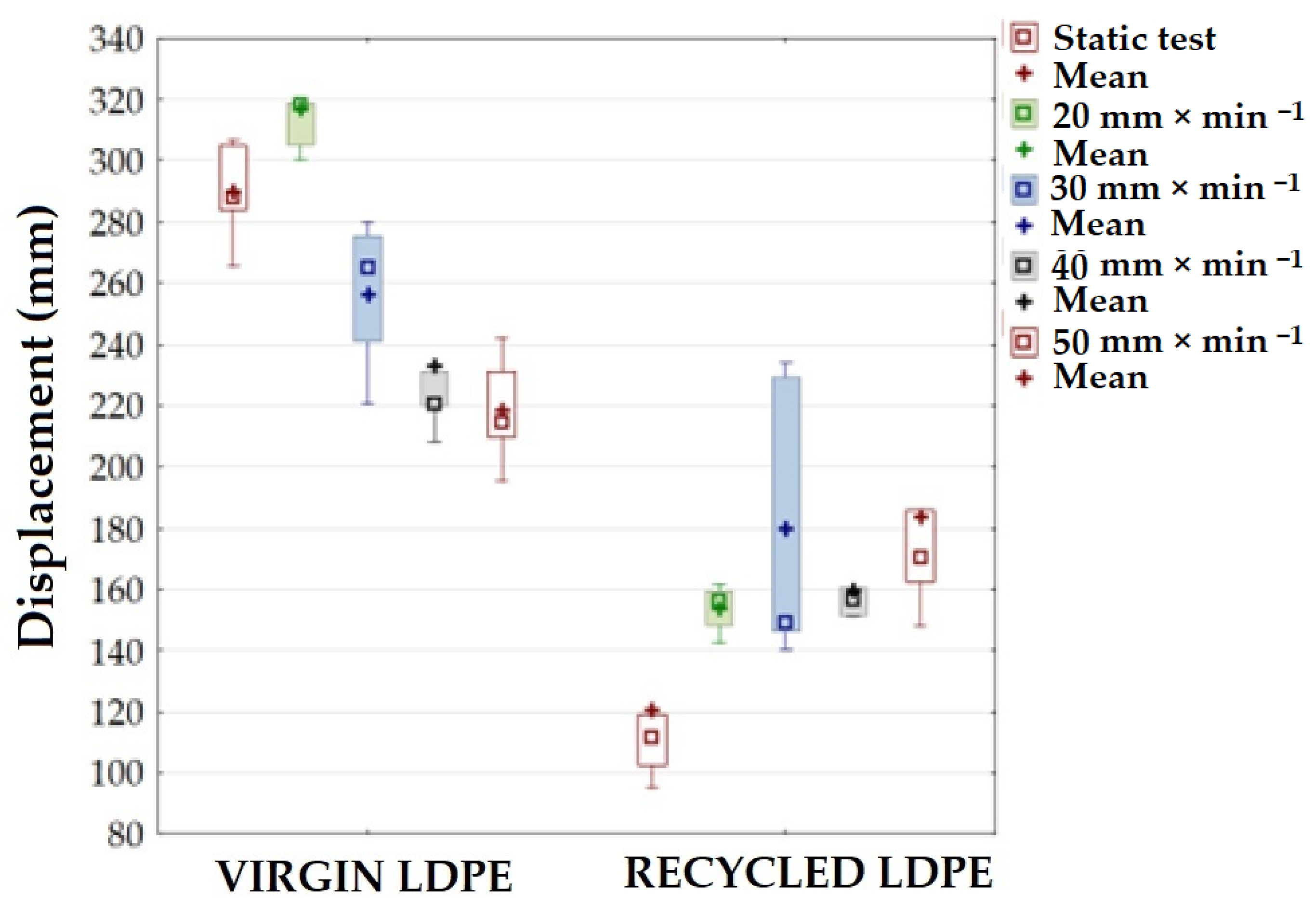

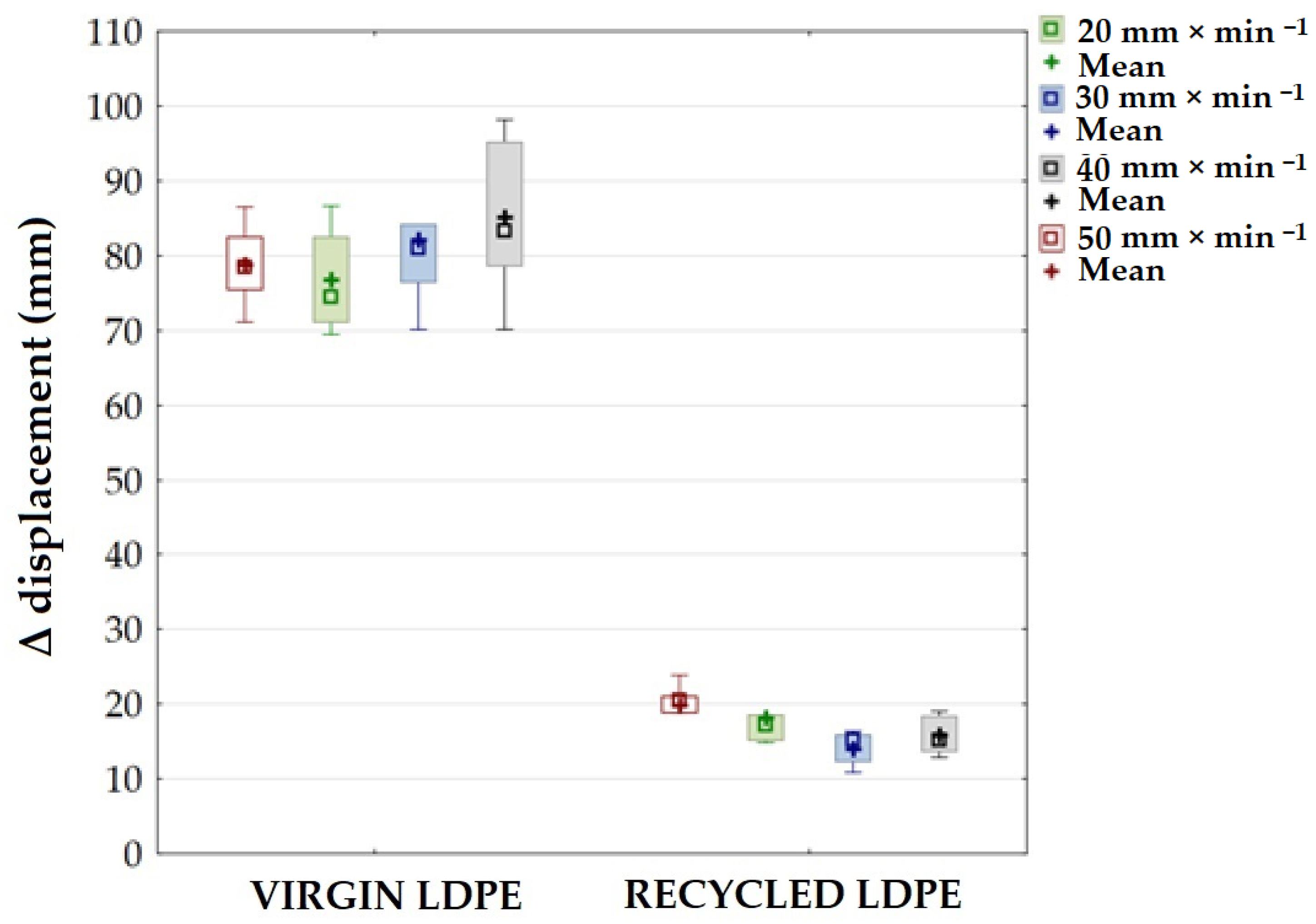

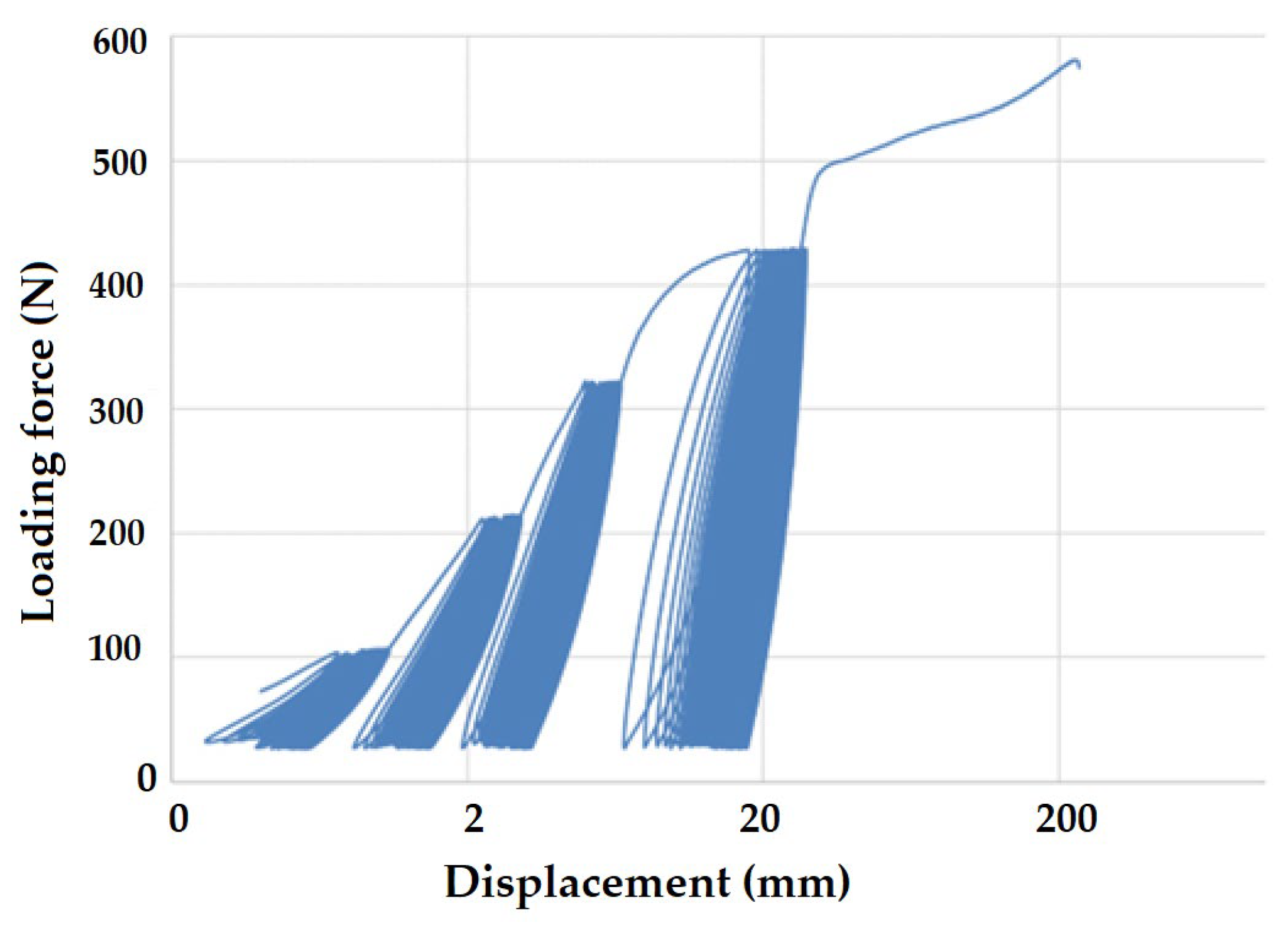

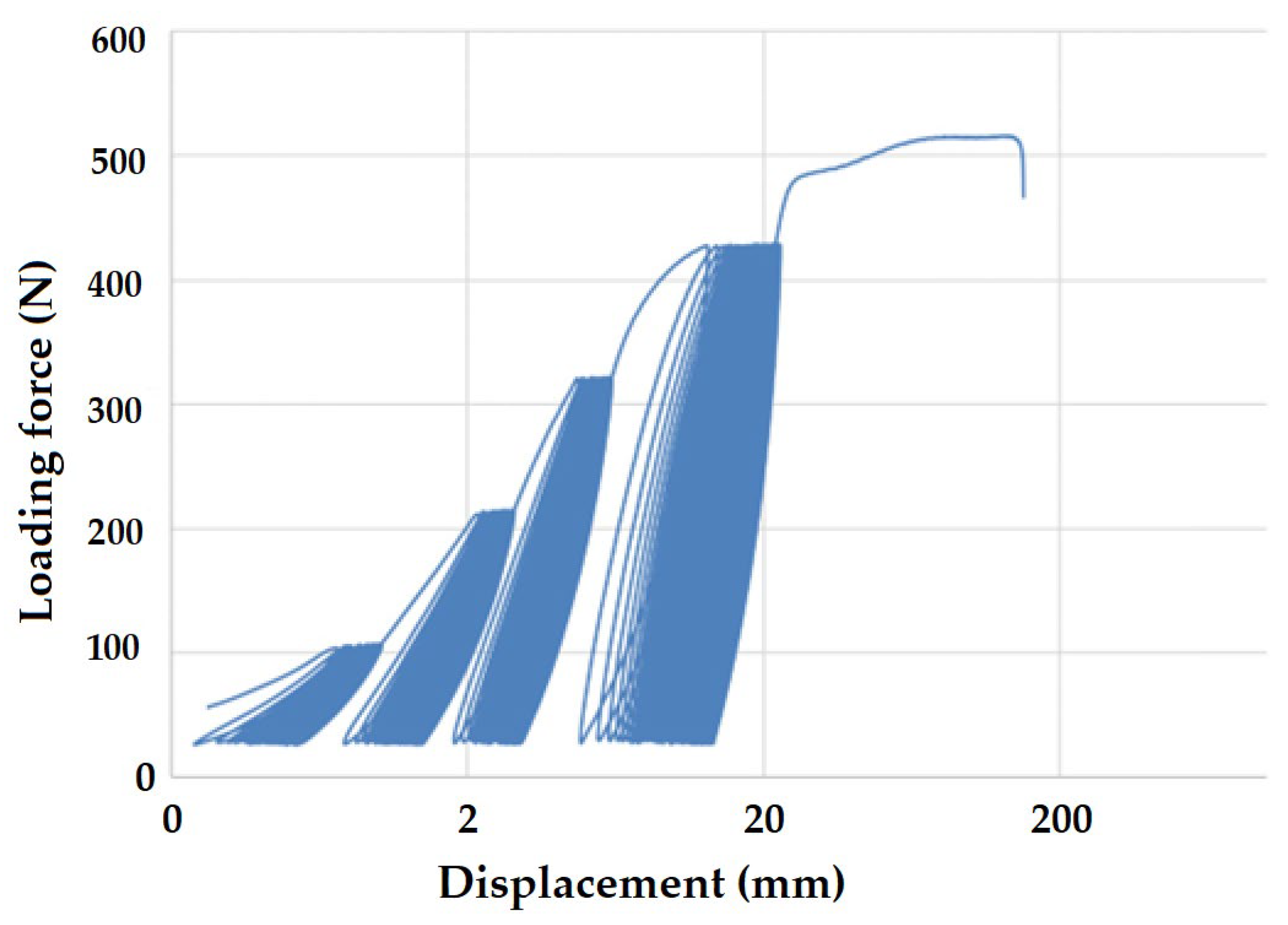

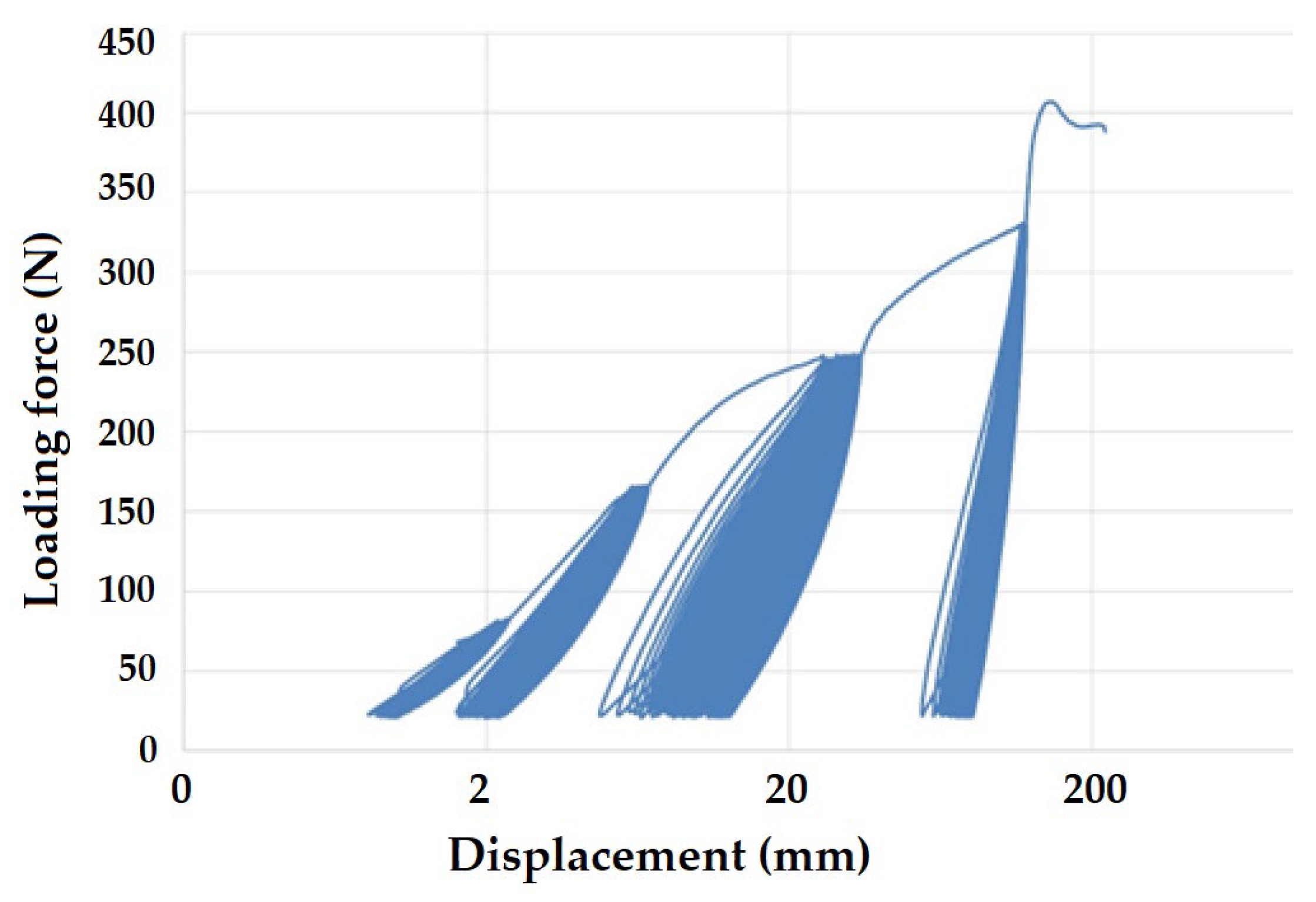

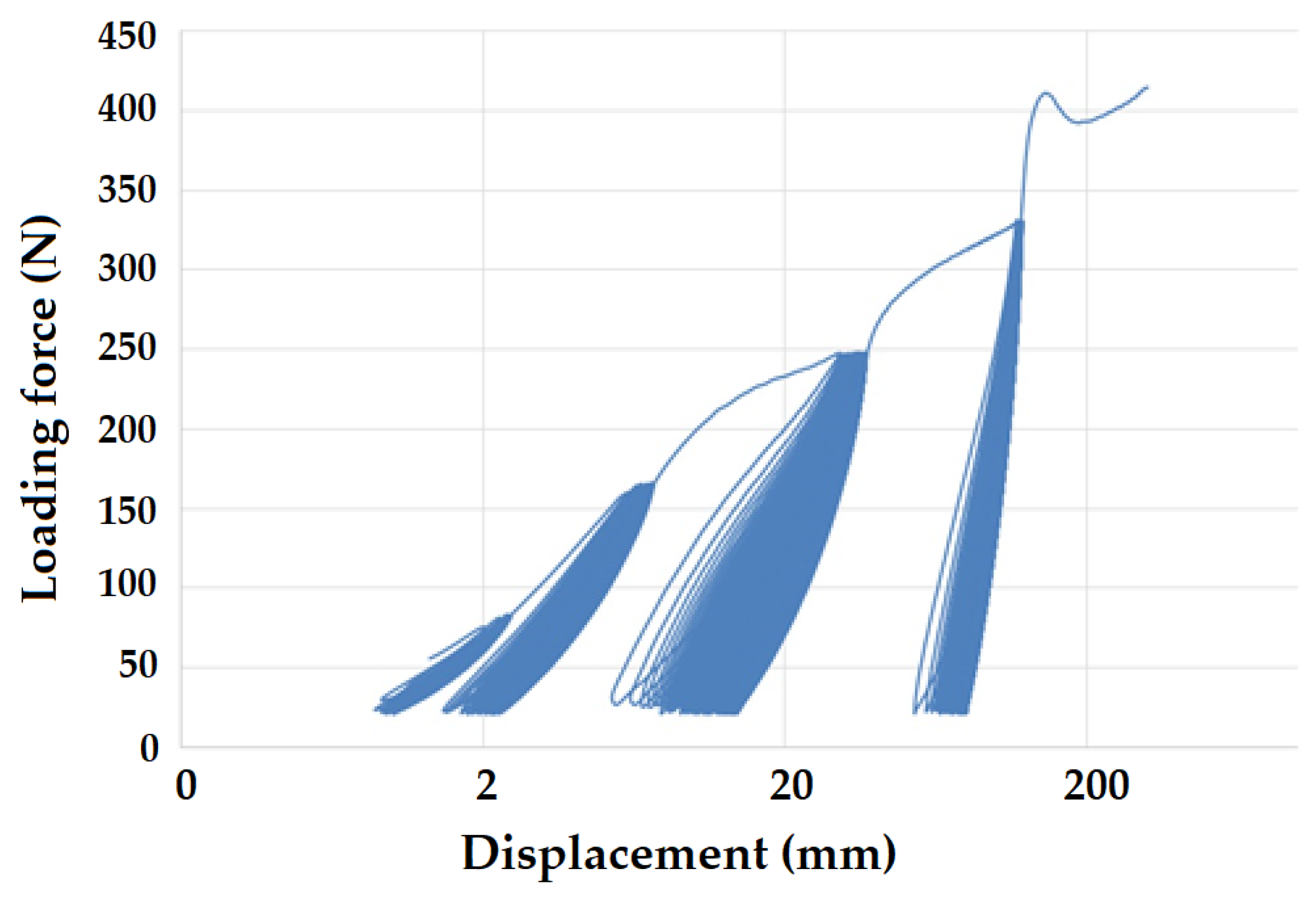

3.1. Mechanical Properties

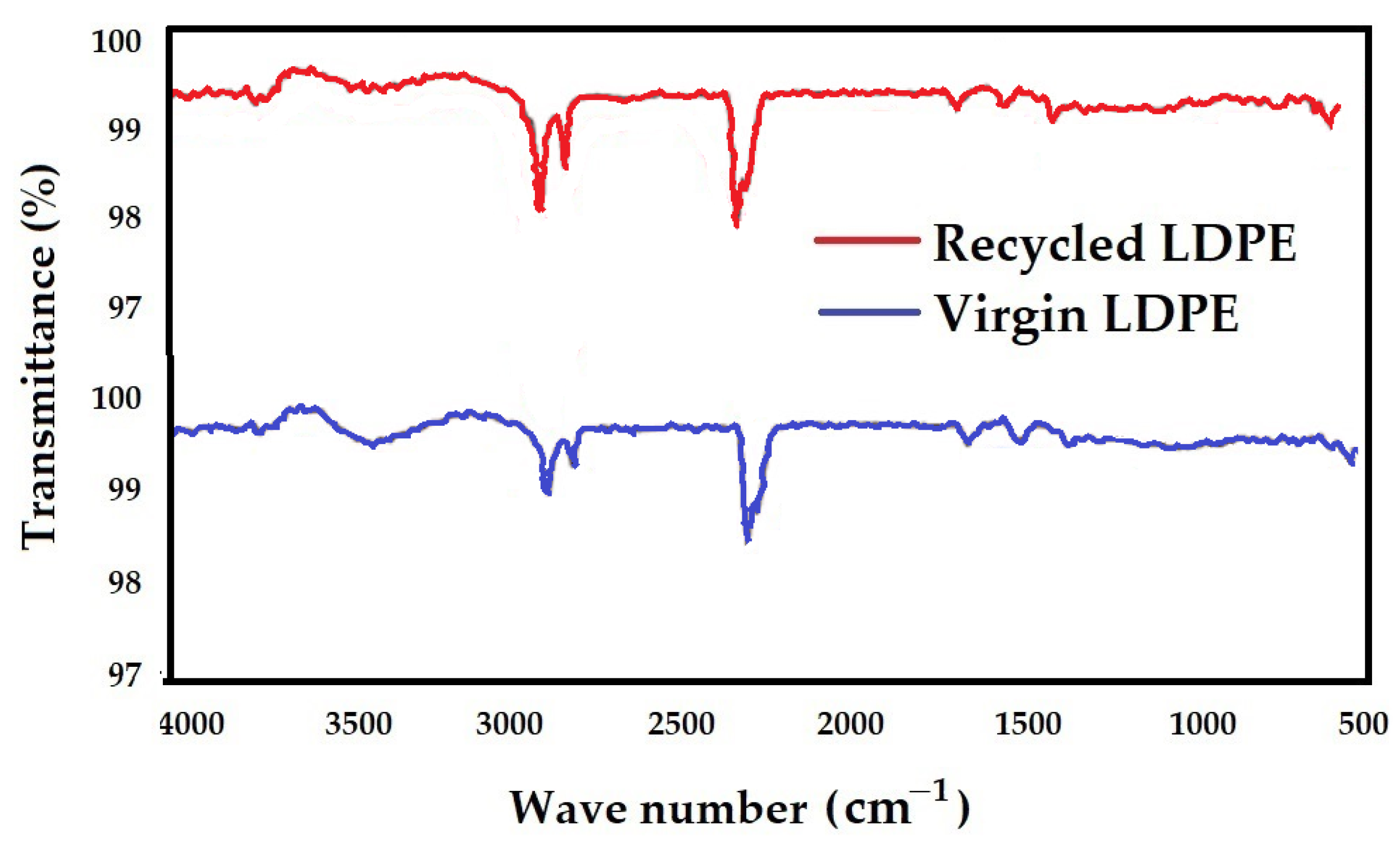

3.2. FTIR Analysis

3.3. Differential Scanning Calorimetry (DSC)

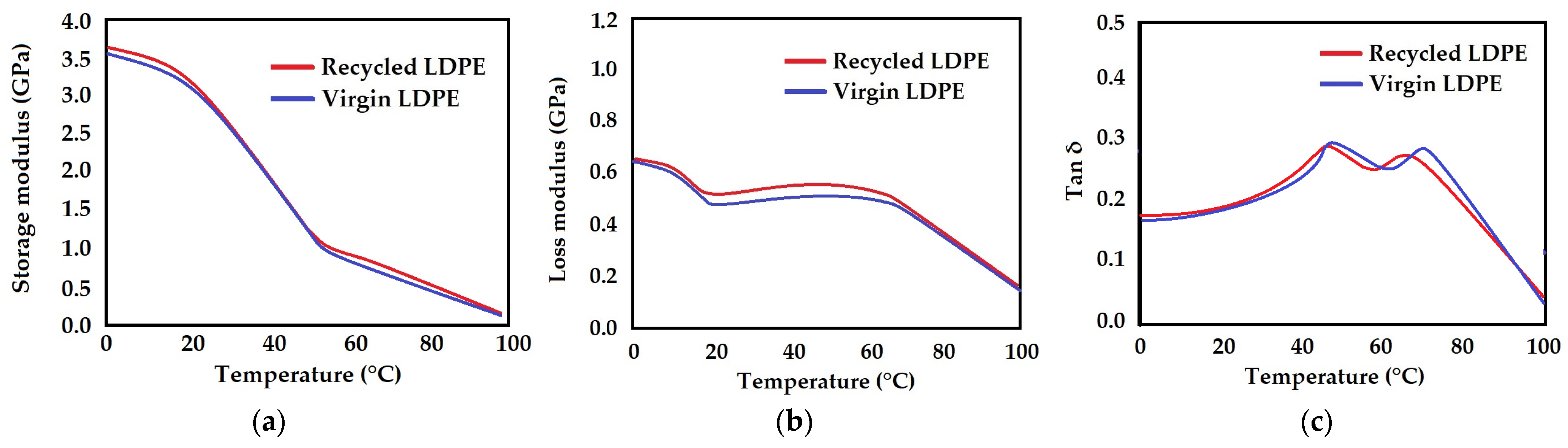

3.4. Dynamic Mechanical Analysis (DMA)

4. Conclusions

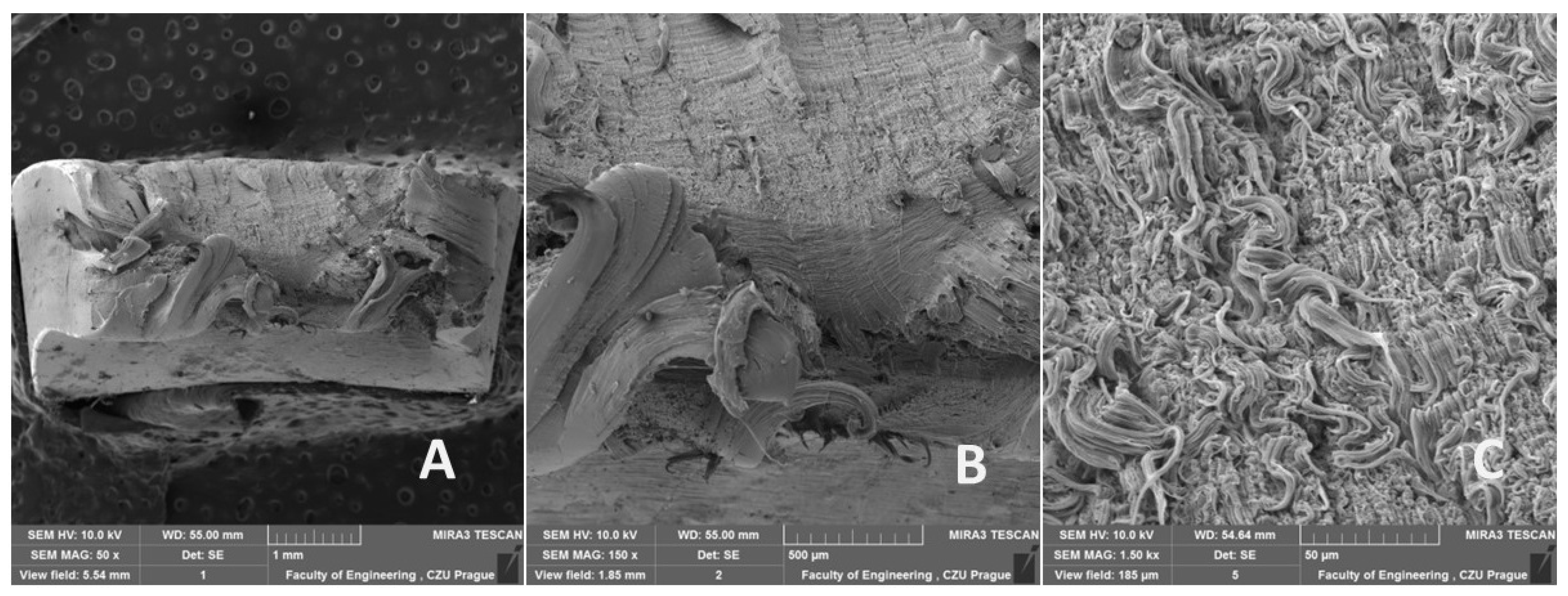

- The injection molding method achieved a smooth, non-porous structure with no obvious defects in the recycled LDPE from post-consumer waste material.

- Cyclic loading is one of the most common causes of the premature failure of polymeric materials. While using recycled material based on post-consumer wastes, the risk of violation is even more significant due to degradation processes. Research has shown that the recycled LDPE from post-consumer waste does not show deterioration in the mechanical or thermo-mechanical properties or their premature loss during the cyclic loading test. It was found that the mechanical properties of the recycled LDPE from post-consumer waste produced by the injection molding method are similar or even better than the original virgin material. The tested material did not undergo destruction due to cyclic fatigue tests taking place up to 80% of the maximum force during static testing.

- No decrease in tensile strength was observed for the recycled LDPE from the post-consumer waste material tested. No significant effect of the test speed was shown on the results of the static tensile test and the fatigue cyclic tests running up to 80% of the maximum load. Displacement increased significantly due to cyclic fatigue tests compared to static tensile test results. The cyclic fatigue tests at different test speeds resulted in permanent deformation between the 1st and 1000th cycles due to the fatigue behavior of the injection-molded recycled LDPE from post-consumer waste.

- Using SEM analysis, the fracture surface of the injection-molded recycled LDPE from post-consumer waste material was observed, which showed a homogeneous structure with parallel lines oriented in the loading direction and wavy regions in the transverse direction resulting from the shrinkage of the broken polymer chains.

- The FTIR spectra obtained for both virgin and recycled LDPE from post-consumer waste were quite similar. Further, the melting (endothermic) and crystallization (exothermic) peaks observed by DSC thermogram were similar for virgin and recycled LDPE from post-consumer waste. DMA thermograms showed similar results for the storage modulus, loss modulus and loss tangent (tan δ) for both virgin and recycled LDPE from post-consumer waste. The recycling did not cause much thermal damage to LDPE obtained from post-consumer waste.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Hundertmark, T.; Mayer, M.; McNally, C.; Simons, T.J.; Witte, C. Recycling and the Future of the Plastics Industry|McKinsey. Available online: https://www.mckinsey.com/industries/chemicals/our-insights/how-plastics-waste-recycling-could-transform-the-chemical-industry (accessed on 17 January 2024).

- Duque, J.V.F.; Martins, M.F.; Debenest, G.; Orlando, M.T.D.A. The Influence of the Recycling Stress History on LDPE Waste Pyrolysis. Polym. Test. 2020, 86, 106460. [Google Scholar] [CrossRef]

- Techawinyutham, L.; Tengsuthiwat, J.; Srisuk, R.; Techawinyutham, W.; Mavinkere Rangappa, S.; Siengchin, S. Recycled LDPE/PETG Blends and HDPE/PETG Blends: Mechanical, Thermal, and Rheological Properties. J. Mater. Res. Technol. 2021, 15, 2445–2458. [Google Scholar] [CrossRef]

- Müller, M.; Chotěborský, R.; Valášek, P.; Hloch, S. Unusual Possibility of Wear Resistance Increase Research in the Sphere of Soil Cultivation. Teh. Vjesn. 2013, 20, 641–646. [Google Scholar]

- Schulte, A.; Velarde, P.Á.S.; Marbach, L.; Mörbitz, P. Measuring the Circularity Potential of Recycled LDPE Based on Quantity and Quality Conservation—A Functional Requirement Matrix Approach. Resour. Conserv. Recycl. Adv. 2023, 17, 200127. [Google Scholar] [CrossRef]

- Mleziva, J. Polymery—Výroba, Struktura, Vlastnosti a Použití, 2nd ed.; Sobotáles: Praha, Czech Republic, 2000; ISBN 80-859-2072-7. [Google Scholar]

- Přikrylová, J. Aplikační Potenciál LDPE. LLDPE, HDPE a Jejich Směsí. Bachelor’s Thesis, Tomas Bata University in Zlín, Zlín, Czech Republic, 2017. [Google Scholar]

- Bertin, S.; Robin, J.J. Study and Characterization of Virgin and Recycled LDPE/PP Blends. Eur. Polym. J. 2002, 38, 2255–2264. [Google Scholar] [CrossRef]

- Núñez, S.S.; Conesa, J.A.; Moltó, J.; Fullana, A. Decontamination of Recycled LDPE Using Different Washing Methods. Resour. Conserv. Recycl. 2023, 195, 107017. [Google Scholar] [CrossRef]

- Gao, P.; Krantz, J.; Ferki, O.; Nieduzak, Z.; Perry, S.; Sobkowicz, M.J.; Masato, D. Thermo-Mechanical Recycling via Ultrahigh-Speed Extrusion of Film-Grade Recycled LDPE and Injection Molding. Sustain. Mater. Technol. 2023, 38, e00719. [Google Scholar] [CrossRef]

- Moreno, D.D.P.; Hirayama, D.; Saron, C. Accelerated Aging of Pine Wood Waste/Recycled LDPE Composite. Polym. Degrad. Stab. 2018, 149, 39–44. [Google Scholar] [CrossRef]

- Gomes, D.A.C.; de Novais Miranda, E.H.; de Araújo Veloso, M.C.R.; da Silva, M.G.; Ferreira, G.C.; Mendes, L.M.; Júnior, J.B.G. Production and Characterization of Recycled Low-Density Polyethylene/Amazon Palm Fiber Composites. Ind. Crop. Prod. 2023, 201, 116833. [Google Scholar] [CrossRef]

- Kibirkštis, E.; Mayik, V.; Zatserkovna, R.; Vaitasius, K.; Stepanenko, A.; Kandrotaitė-Janutienė, R.; Venytė, I.; Danilovas, P.P. Study of Physical and Mechanical Properties of Partially Biodegradable LDPE Polymeric Films and Their Application for Printing and Packaging. Polym. Test. 2022, 112, 107646. [Google Scholar] [CrossRef]

- Pedroso, A.G.; Rosa, D.S. Mechanical, Thermal and Morphological Characterization of Recycled LDPE/Corn Starch Blends. Carbohydr. Polym. 2005, 59, 1–9. [Google Scholar] [CrossRef]

- Scott, G. ‘Green’ Polymers. Polym. Degrad. Stab. 2000, 68, 1–7. [Google Scholar] [CrossRef]

- Conesa, J.A.; Nuñez, S.S.; Ortuño, N.; Moltó, J. Pah and Pop Presence in Plastic Waste and Recyclates: State of the Art. Energies 2021, 14, 3451. [Google Scholar] [CrossRef]

- Santagata, C.; Iaquaniello, G.; Salladini, A.; Agostini, E.; Capocelli, M.; De Falco, M. Production of Low-Density Poly-Ethylene (LDPE) from Chemical Recycling of Plastic Waste: Process Analysis. J. Clean. Prod. 2020, 253, 119837. [Google Scholar] [CrossRef]

- Müller, M.; Rudawska, A.; Tichý, M.; Kolář, V.; Hromasová, M. Research on Wear Resistance of Polymeric Composite Materials Based on Microparticles from Tyre Recyclation Process. Manuf. Technol. 2020, 20, 223–228. [Google Scholar] [CrossRef]

- Maris, J.; Bourdon, S.; Brossard, J.M.; Cauret, L.; Fontaine, L.; Montembault, V. Mechanical Recycling: Compatibilization of Mixed Thermoplastic Wastes. Polym. Degrad. Stab. 2018, 147, 245–266. [Google Scholar] [CrossRef]

- Oblak, P.; Gonzalez-Gutierrez, J.; Zupančič, B.; Aulova, A.; Emri, I. Processability and Mechanical Properties of Extensively Recycled High Density Polyethylene. Polym. Degrad. Stab. 2015, 114, 133–145. [Google Scholar] [CrossRef]

- Vera-Sorroche, J.; Kelly, A.; Brown, E.; Coates, P.; Karnachi, N.; Harkin-Jones, E.; Li, K.; Deng, J. Thermal Optimisation of Polymer Extrusion Using In-Process Monitoring Techniques. Appl. Therm. Eng. 2013, 53, 405–413. [Google Scholar] [CrossRef]

- Gryn’ova, G.; Hodgson, J.L.; Coote, M.L. Revising the Mechanism of Polymer Autooxidation. Org. Biomol. Chem. 2011, 9, 480–490. [Google Scholar] [CrossRef]

- Luzuriaga, S.; Kovářová, J.; Fortelný, I. Degradation of Pre-Aged Polymers Exposed to Simulated Recycling: Properties and Thermal Stability. Polym. Degrad. Stab. 2006, 91, 1226–1232. [Google Scholar] [CrossRef]

- Vilaplana, F.; Karlsson, S. Quality Concepts for the Improved Use of Recycled Polymeric Materials: A Review. Macromol. Mater. Eng. 2008, 293, 274–297. [Google Scholar] [CrossRef]

- Awaja, F.; Zhang, S.; Tripathi, M.; Nikiforov, A.; Pugno, N. Cracks, Microcracks and Fracture in Polymer Structures: Formation, Detection, Autonomic Repair. Prog. Mater. Sci. 2016, 83, 536–573. [Google Scholar] [CrossRef]

- Barbosa, S.E.; Capiati, N.J.; Kenny, J.M. Processability and Mechanical Properties of Ternary Composites PP/EPDM/GF. Polym. Compos. 2000, 21, 377–386. [Google Scholar] [CrossRef]

- Katz, H.S.; Milewski, J. Handbook of Fillers and Reinforcements for Plastics; Van Nostrand Reinhold Co.: New York, NY, USA, 2003; ISBN 1859573827. [Google Scholar]

- Zhang, L.; Liu, Z.; Wu, D.; Zhang, H.; Zhu, P. Fast and Synergetic Fatigue Life Prediction of Short Fiber Reinforced Polymer Composites from Monotonic and Cyclic Loading Behavior. Compos. Sci. Technol. 2023, 241, 110121. [Google Scholar] [CrossRef]

- Durjava, A.; Nagode, M.; Šeruga, D. Applicability of Memory Rules during Cyclic Stress–Strain Response of Polymers PA6 and PA66 GF30. Mater. Today Commun. 2023, 35, 106342. [Google Scholar] [CrossRef]

- Baradaran, S.; Rahimi, J.; Ameri, M.; Maleki, A. Mechanical Performance of Asphalt Mixture Containing Eco-Friendly Additive by Recycling PET. Case Stud. Constr. Mater. 2024, 20, e02740. [Google Scholar] [CrossRef]

- Saleh, M.; Anwar, S.; AlFaify, A.Y.; Al-Ahmari, A.M.; Abd Elgawad, A.E.E. Development of PLA/Recycled-Desized Carbon Fiber Composites for 3D Printing: Thermal, Mechanical, and Morphological Analyses. J. Mater. Res. Technol. 2024, 29, 2768–2780. [Google Scholar] [CrossRef]

- Di, L.; Yang, Y.; Wang, S. Additive Manufacturing Thermoplastic Recycling: Profit-Driven Planning and Optimization. J. Clean. Prod. 2024, 436, 140598. [Google Scholar] [CrossRef]

- ISO 527-2:2012; Plastics—Determination of Tensile Properties Part 2: Test Conditions for Moulding and Extrusion Plastics. ISO: Geneva, Switzerland, 2012.

- Kolář, V.; Hrabě, P.; Müller, M.; Hromasová, M.; Herák, D.; Sutanto, H. Influence of Alkali Treatment of Jatropha curcas L. Filler on the Service Life of Hybrid Adhesive Bonds under Low Cycle Loading. Polymers 2023, 15, 395. [Google Scholar] [CrossRef]

- Ahmed, T.; Mamat, O. The Development and Characteriza-tion of HDPE-silica Sand Nanoparticles Composites. In Proceedings of the 2011 IEEE Colloquium on Humanities, Science and Engineering, Penang, Malaysia, 5–6 December 2011; Volume 21, pp. 6–11. [Google Scholar]

- Alapati, S.; Meledath, J.T.; Karmarkar, A. Effect of Morpholo-gy on Electrical Treeing in Low Density Polyethylene Nanocomposites. IET Sci. Meas. Technol. 2014, 8, 60–68. [Google Scholar] [CrossRef]

- Zaharescu, T.; Râpă, M.; Blanco, I.; Borbath, T.; Borbath, I. Durability of LDPE/UHMWPE Composites under Accelerated Degradation. Polymers 2020, 12, 1241. [Google Scholar] [CrossRef] [PubMed]

- Li, D.; Zhou, L.; Wang, X.; He, L.; Yang, X. Effect of Crystallinity of Polyethylene with Different Densities on Breakdown Strength and Conductance Property. Materials 2019, 12, 1746. [Google Scholar] [CrossRef] [PubMed]

- Moreno, D.D.P.; Saron, C. Influence of Compatibilizer on the Properties of Low-Density Polyethylene/Polyamide 6 Blends Obtained by Mechanical Recycling of Multilayer Film Waste. Waste Manag. Res. 2018, 36, 729–736. [Google Scholar] [CrossRef] [PubMed]

- Yang, J.; Kang, G.; Liu, Y.; Chen, K.; Kan, Q. Life Prediction for Rate-Dependent Low-Cycle Fatigue of PA6 Polymer Considering Ratchetting: Semi-Empirical Model and Neural Network Based Approach. Int. J. Fatigue 2020, 136, 105619. [Google Scholar] [CrossRef]

- Yang, J.; Kang, G.; Chen, K.; Kan, Q.; Liu, Y. Experimental Study on Rate-Dependent Uniaxial Whole-Life Ratchetting and Fatigue Behavior of Polyamide 6. Int. J. Fatigue 2020, 132, 105402. [Google Scholar] [CrossRef]

- Eftekhari, M.; Fatemi, A. On the Strengthening Effect of Increasing Cycling Frequency on Fatigue Behavior of Some Polymers and Their Composites: Experiments and Modeling. Int. J. Fatigue 2016, 87, 153–166. [Google Scholar] [CrossRef]

- Qi, Z.; Lu, L.; Doan, L.; Thota, B.; Zeng, D.; Su, X. Frequency Effects on High-Density Polyethylene Failure under Cyclic Loading. In Proceedings of the WCX™ 17: SAE World Congress Experience 2017, Detroit, MI, USA, 4–6 April 2017; SAE International: Warrendale, PA, USA, 2017. [Google Scholar]

- Premanand, A.; Rienks, M.; Balle, F. Accelerated Estimation of the Very High Cycle Fatigue Strength and Life of Polymer Composites under Ultrasonic Cyclic Three-Point Bending. Mater. Des. 2024, 240, 112872. [Google Scholar] [CrossRef]

- Suresh, S. Fatigue of Materials; Cambridge University Press: Cambridge, UK, 1998; ISBN 9780521570466. [Google Scholar]

- Senatov, F.S.; Niaza, K.V.; Stepashkin, A.A.; Kaloshkin, S.D. Low-Cycle Fatigue Behavior of 3d-Printed PLA-Based Porous Scaffolds. Compos. Part B Eng. 2016, 97, 193–200. [Google Scholar] [CrossRef]

- Tao, G.; Xia, Z. A Non-Contact Real-Time Strain Measurement and Control System for Multiaxial Cyclic/Fatigue Tests of Polymer Materials by Digital Image Correlation Method. Polym. Test. 2005, 24, 844–855. [Google Scholar] [CrossRef]

- Tao, G.; Xia, Z. Ratcheting Behavior of an Epoxy Polymer and Its Effect on Fatigue Life. Polym. Test. 2007, 26, 451–460. [Google Scholar] [CrossRef]

- Müller, M.; Šleger, V.; Kolář, V.; Hromasová, M.; Piš, D.; Mishra, R.K. Low-Cycle Fatigue Behavior of 3D-Printed PLA Reinforced with Natural Filler. Polymers 2022, 14, 1301. [Google Scholar] [CrossRef] [PubMed]

- Xia, Z.; Shen, X.; Ellyin, F. Biaxial Cyclic Deformation of an Epoxy Resin: Experiments and Constitutive Modeling. J. Mater. Sci. 2005, 40, 643–654. [Google Scholar] [CrossRef]

- Chen, Y.; Smith, L.V. Ratcheting and Recovery of Adhesively Bonded Joints under Tensile Cyclic Loading. Mech. Time-Depend. Mater. 2021, 27, 59–78. [Google Scholar] [CrossRef]

- Zhang, J.; Li, H.; Li, H.Y.; Wei, X.L. Uniaxial Ratchetting and Low-Cycle Fatigue Failure Behaviors of Adhesively Bonded Butt-Joints under Cyclic Tension Deformation. Int. J. Adhes. Adhes. 2019, 95, 102399. [Google Scholar] [CrossRef]

- Benaarbia, A.; Chrysochoos, A.; Robert, G. Thermomechanical Behavior of PA6.6 Composites Subjected to Low Cycle Fatigue. Compos. Part B Eng. 2015, 76, 52–64. [Google Scholar] [CrossRef]

- Kovács, R.L.; Csontos, M.; Gyöngyösi, S.; Elek, J.; Parditka, B.; Deák, G.; Kuki, Á.; Kéki, S.; Erdélyi, Z. Surface characterization of plasma-modified low density polyethylene by attenuated total reflectance fourier-transform infrared (ATR-FTIR) spectroscopy combined with chemometrics. Polym. Test. 2021, 96, 107080. [Google Scholar] [CrossRef]

- Jebashalomi, V.; Charles, P.; Rajaram, R. Microbial degradation of low-density polyethylene (LDPE) and polystyrene using Bacillus cereus (OR268710) isolated from plastic-polluted tropical coastal environment. Sci. Total Environ. 2024, 924, 171580. [Google Scholar] [CrossRef]

- Tao, L.; Ma, X.; Ye, L.; Jia, J.; Wang, L.; Ma, P.; Liu, J. Interactions of lignin and LDPE during catalytic co-pyrolysis: Thermal behavior and kinetics study by TG-FTIR. J. Anal. Appl. Pyrol. 2021, 158, 105267. [Google Scholar] [CrossRef]

- Silva, D.; Wiebeck, H. Using PLS, iPLS and siPLS linear regressions to determine the composition of LDPE/HDPE blends: A comparison between confocal Raman and ATR-FTIR spectroscopies. Vib. Spectrosc. 2017, 92, 259–266. [Google Scholar] [CrossRef]

- Moez, A.; Aly, S.; Elshaer, Y. Effect of gamma radiation on low density polyethylene (LDPE) films: Optical, dielectric and FTIR studies. Spectrochim. Acta Part A Mol. Biomol. Spectrosc. 2012, 93, 203–207. [Google Scholar] [CrossRef]

- Doğan, O.; Kayacan, I. Pyrolysis of Low and High Density Polyethylene. Part II: Analysis of Liquid Products Using FTIR and NMR Spectroscopy. Energy Sources Part A Recovery Util. Environ. Eff. 2008, 30, 392–400. [Google Scholar] [CrossRef]

- Khonakdar, H. Dynamic mechanical analysis and thermal properties of LLDPE/EVA/modified silica nanocomposites. Compos. Part B Eng. 2015, 76, 343–353. [Google Scholar] [CrossRef]

- Awad, S.A. Mechanical and thermal characterisations of low-density polyethylene/nanoclay composites. Polym. Polym. Compos. 2021, 29, 1325–1332. [Google Scholar] [CrossRef]

- Mohagheghian, I.; McShane, G.; Stronge, W. Impact perforation of monolithic polyethylene plates: Projectile nose shape dependence. Int. J. Impact Eng. 2015, 80, 162–176. [Google Scholar] [CrossRef]

- Bashir, M.A. Use of Dynamic Mechanical Analysis (DMA) for Characterizing Interfacial Interactions in Filled Polymers. Solids 2021, 2, 108–120. [Google Scholar] [CrossRef]

| Lower Amplitude Limit | Upper Limit of Amplitude | Number of Cycles within the Amplitude |

|---|---|---|

| 27 N | 107 N | 250 |

| 27 N | 215 N | 250 |

| 27 N | 322 N | 250 |

| 27 N | 429 N | 250 |

| Lower Amplitude Limit | Upper Limit of Amplitude | Number of Cycles within the Amplitude |

|---|---|---|

| 21 N | 83 N | 250 |

| 21 N | 166 N | 250 |

| 21 N | 248 N | 250 |

| 21 N | 331 N | 250 |

| Functional Group | Wave Number Band | % in Virgin LDPE | % in Recycled LDPE from Post-Consumer Waste |

|---|---|---|---|

| (=CH−) | 2900–4000 | 34.4 | 34.6 |

| (−CH3) | 2840–2860 | 22.2 | 22.7 |

| (C-C) | 2340–2370 | 8.7 | 8.4 |

| (C=O) | 1810–1820 | 0.7 | 0.6 |

| (C=C) | 1640–1650 | 1.5 | 1.2 |

| (−COOH) | 1370–1380 | 2.6 | 3.4 |

| (−OH) | 3250–3580 | 4.4 | 4.8 |

| (=CH2) | 1450–1470 | 16.9 | 16.5 |

| Others | 710–910 | 8.6 | 7.8 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Müller, M.; Kolář, V.; Mishra, R.K. Mechanical and Thermal Degradation-Related Performance of Recycled LDPE from Post-Consumer Waste. Polymers 2024, 16, 2863. https://doi.org/10.3390/polym16202863

Müller M, Kolář V, Mishra RK. Mechanical and Thermal Degradation-Related Performance of Recycled LDPE from Post-Consumer Waste. Polymers. 2024; 16(20):2863. https://doi.org/10.3390/polym16202863

Chicago/Turabian StyleMüller, Miroslav, Viktor Kolář, and Rajesh Kumar Mishra. 2024. "Mechanical and Thermal Degradation-Related Performance of Recycled LDPE from Post-Consumer Waste" Polymers 16, no. 20: 2863. https://doi.org/10.3390/polym16202863

APA StyleMüller, M., Kolář, V., & Mishra, R. K. (2024). Mechanical and Thermal Degradation-Related Performance of Recycled LDPE from Post-Consumer Waste. Polymers, 16(20), 2863. https://doi.org/10.3390/polym16202863