Characterization and Analysis of the Main Factors of Brittleness of Shale Oil Reservoirs in the Liushagang Formation, X Depression, Beibuwan Basin

Abstract

:1. Introduction

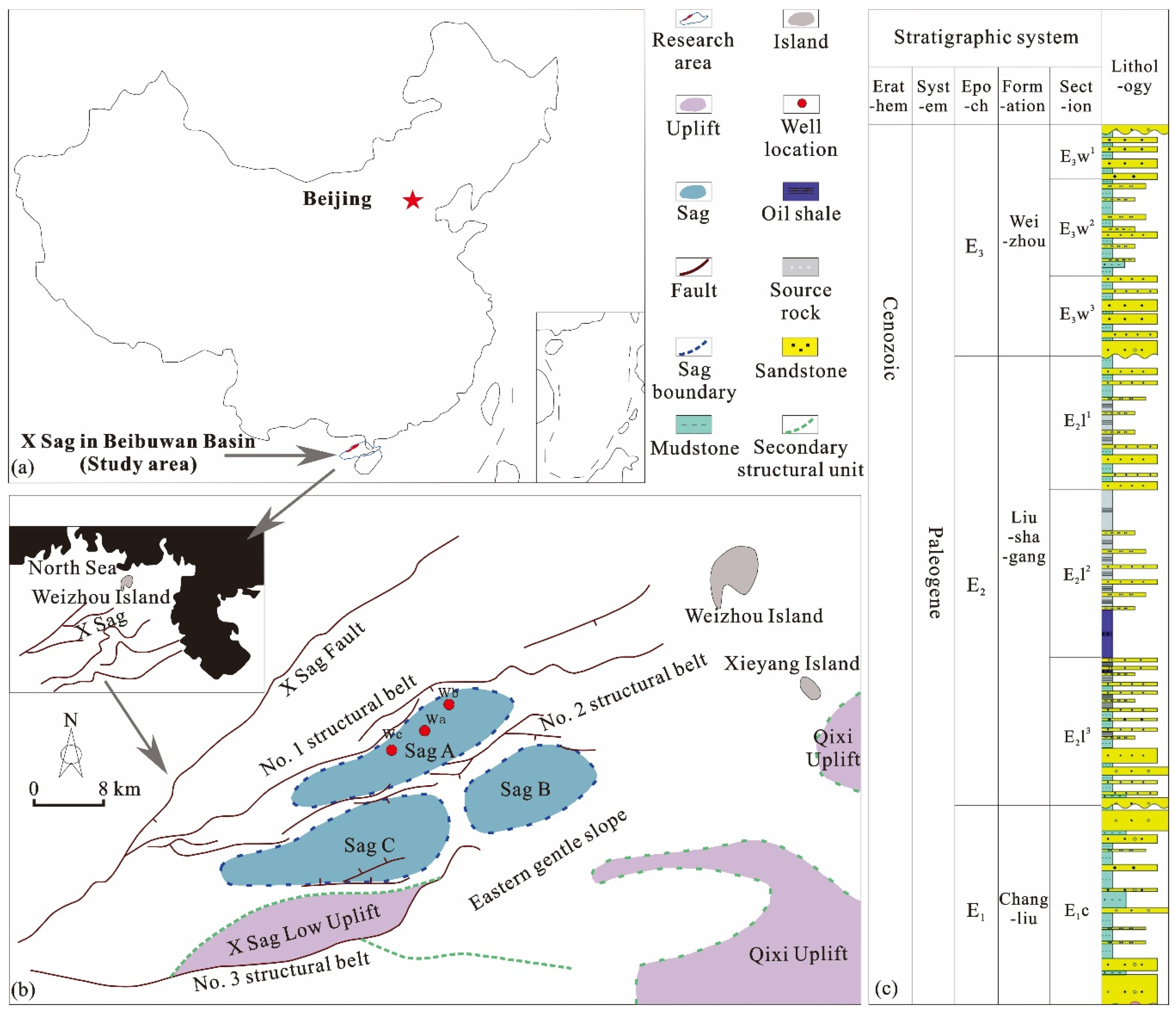

2. Geological Formation and Background

3. Samples and Methods

3.1. Experimental Methods

3.2. Characterization Methods of Reservoir Parameters

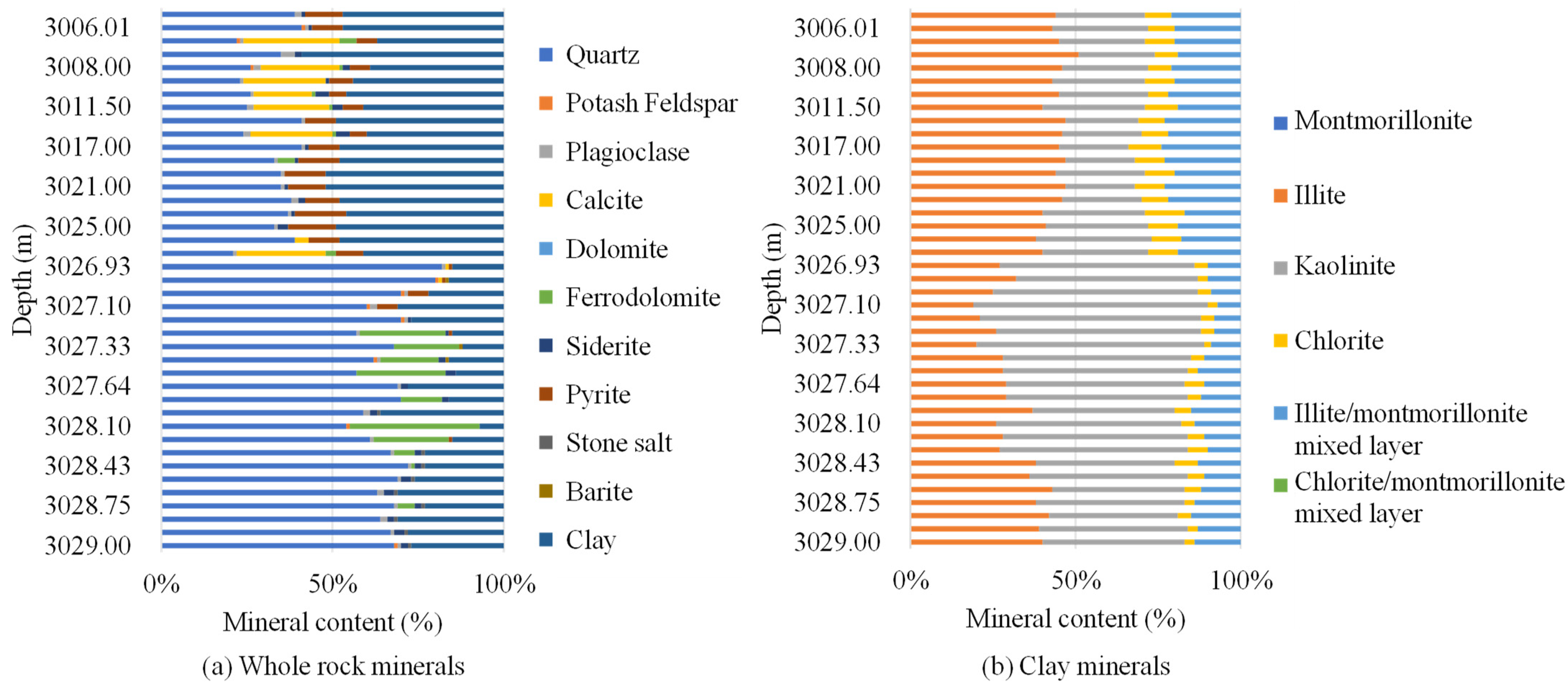

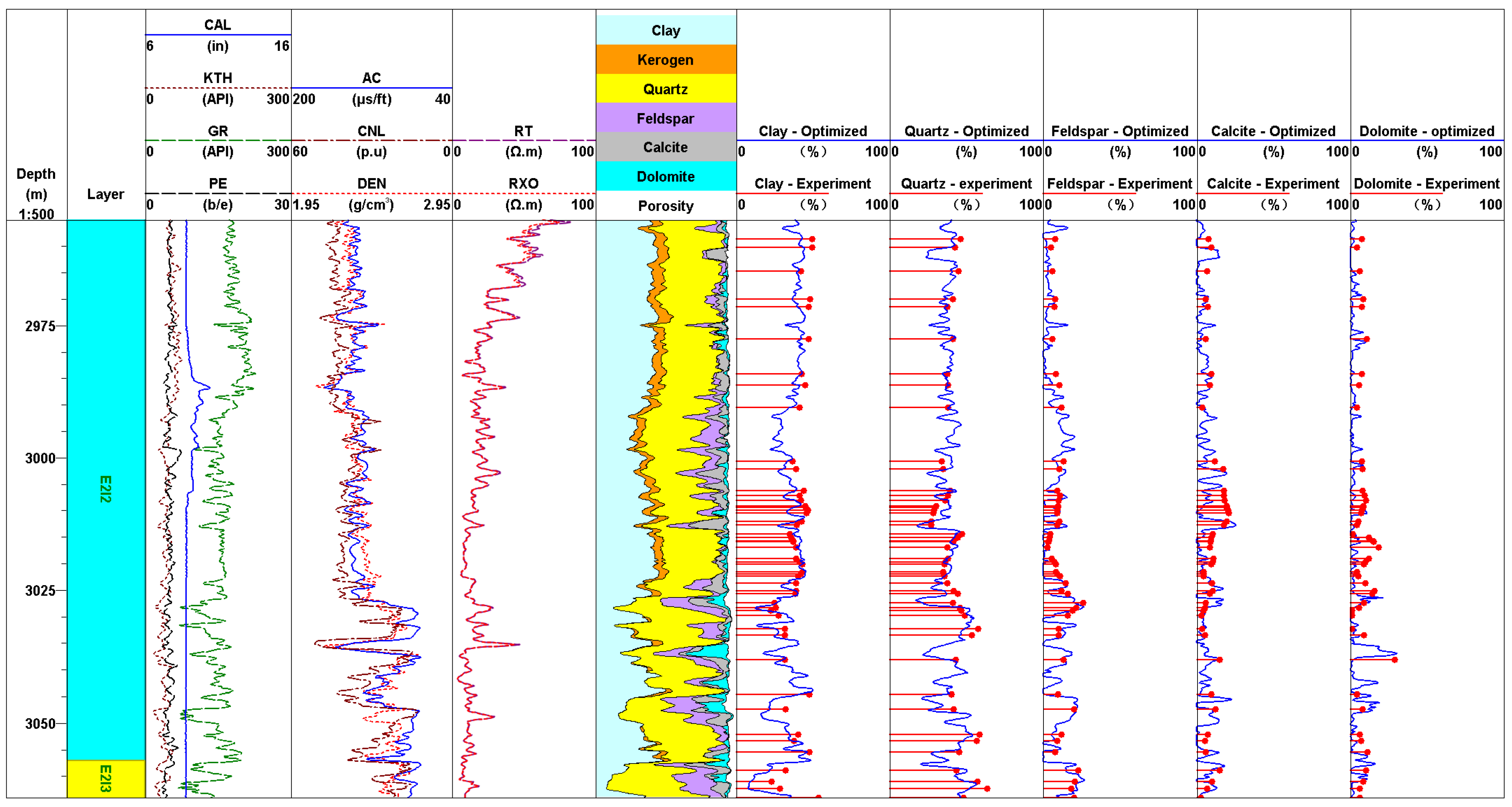

3.2.1. Calculation of Mineral Content

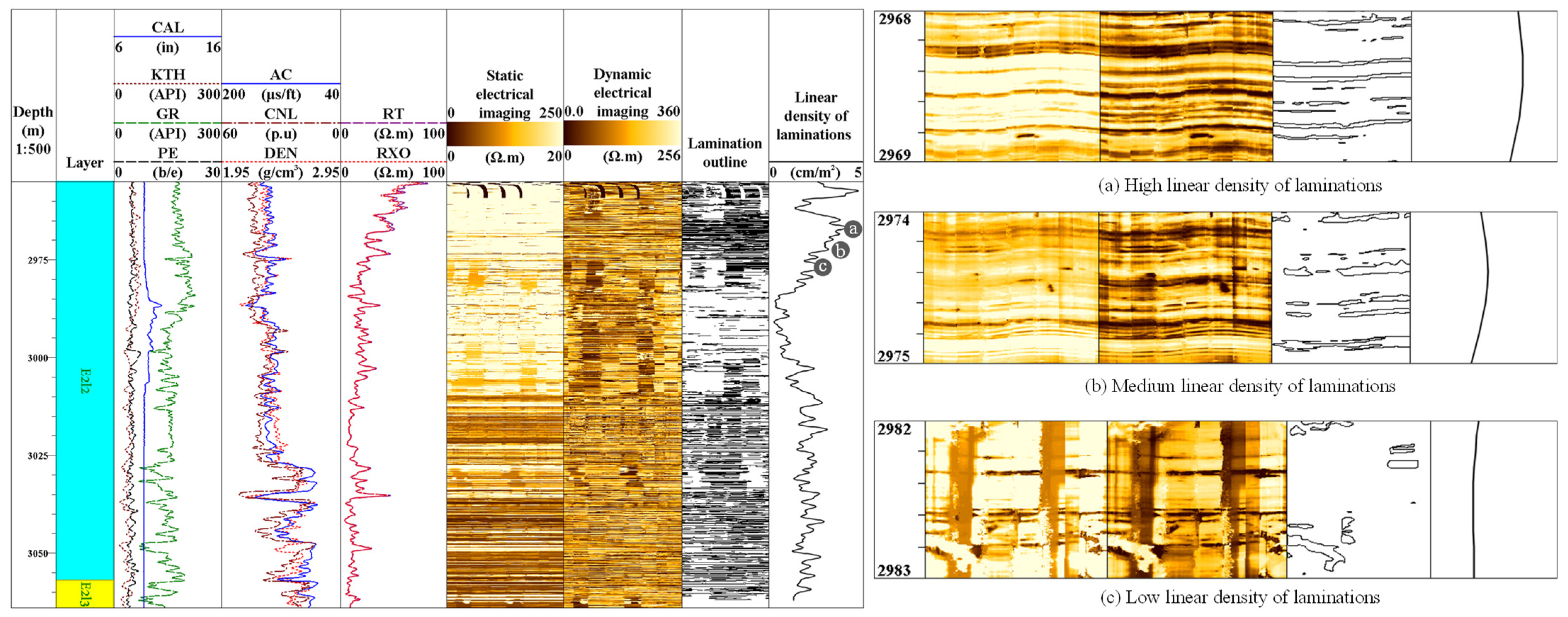

3.2.2. Calculation of Linear Density of Laminations

3.2.3. Calculation of Fracture Development Index with Logging Data

3.2.4. Calculation of the Maturity of Organic Matter

4. Results

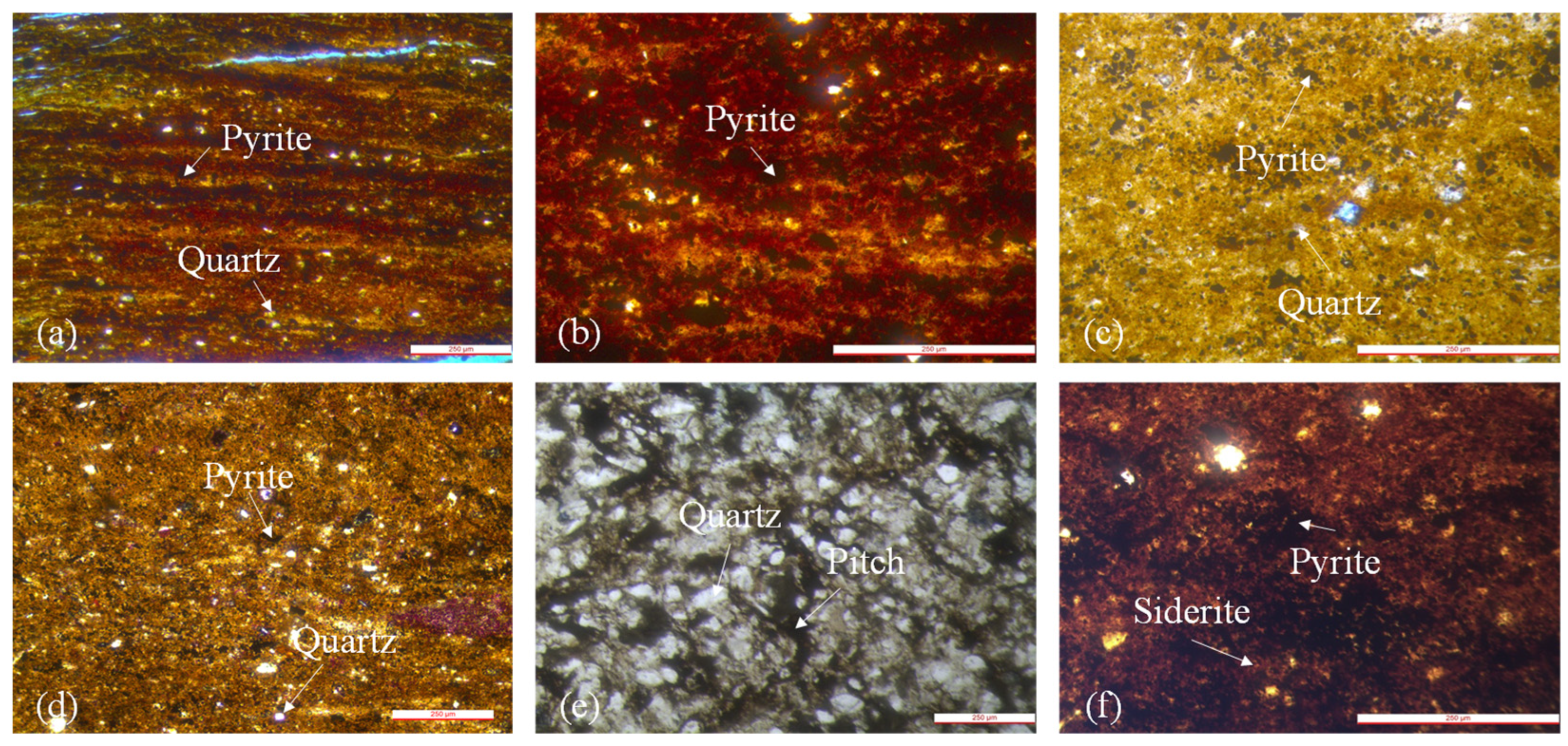

4.1. Experimental Analysis and Calculation Results of Mineral Contents

4.2. Calculation Results of Linear Density of Laminations

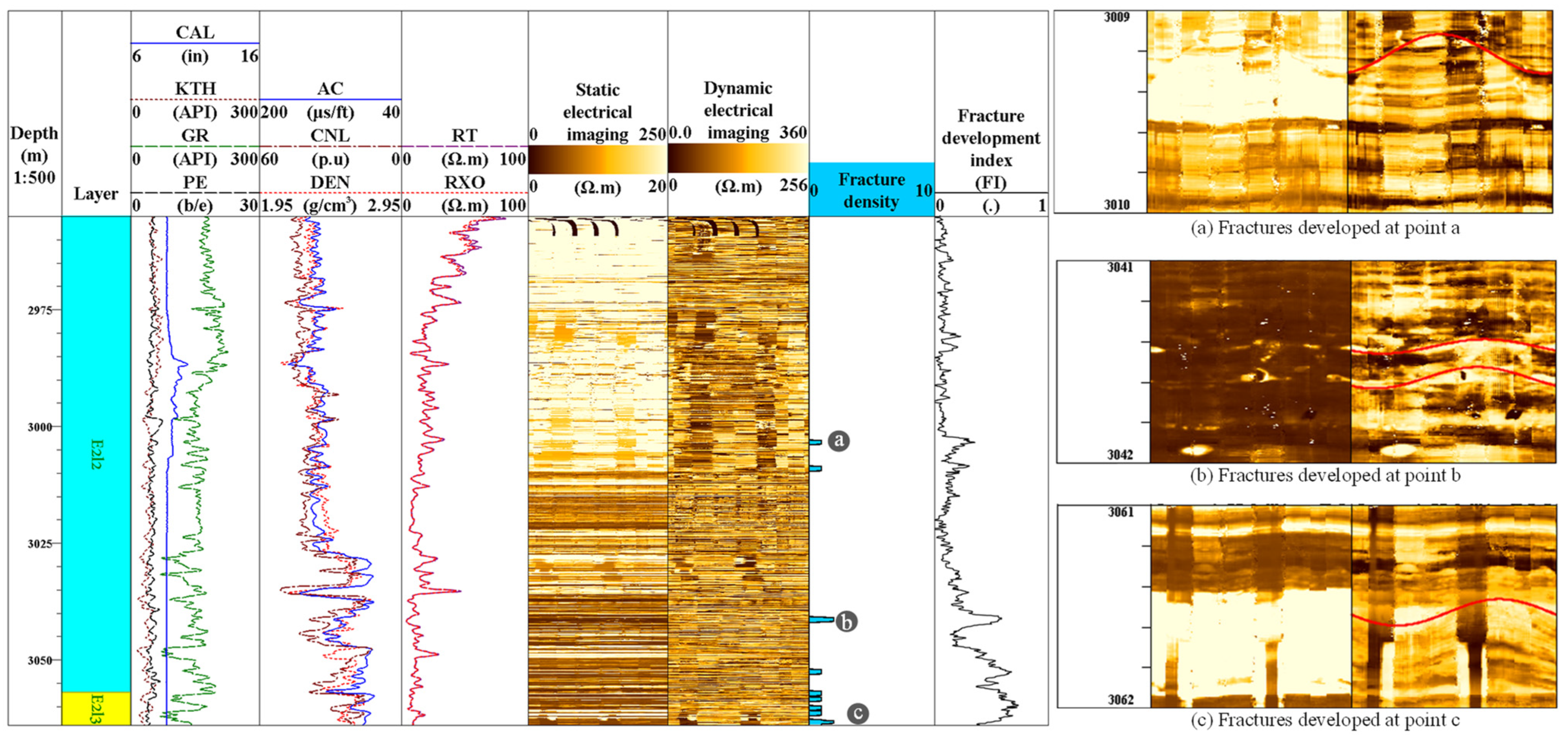

4.3. Calculation Results of Fracture Development Index Based on Logging Data

4.4. Calculation Results of Vitrinite Reflectance

4.5. Calculation Results of Horizontal Stress Difference

5. Discussion

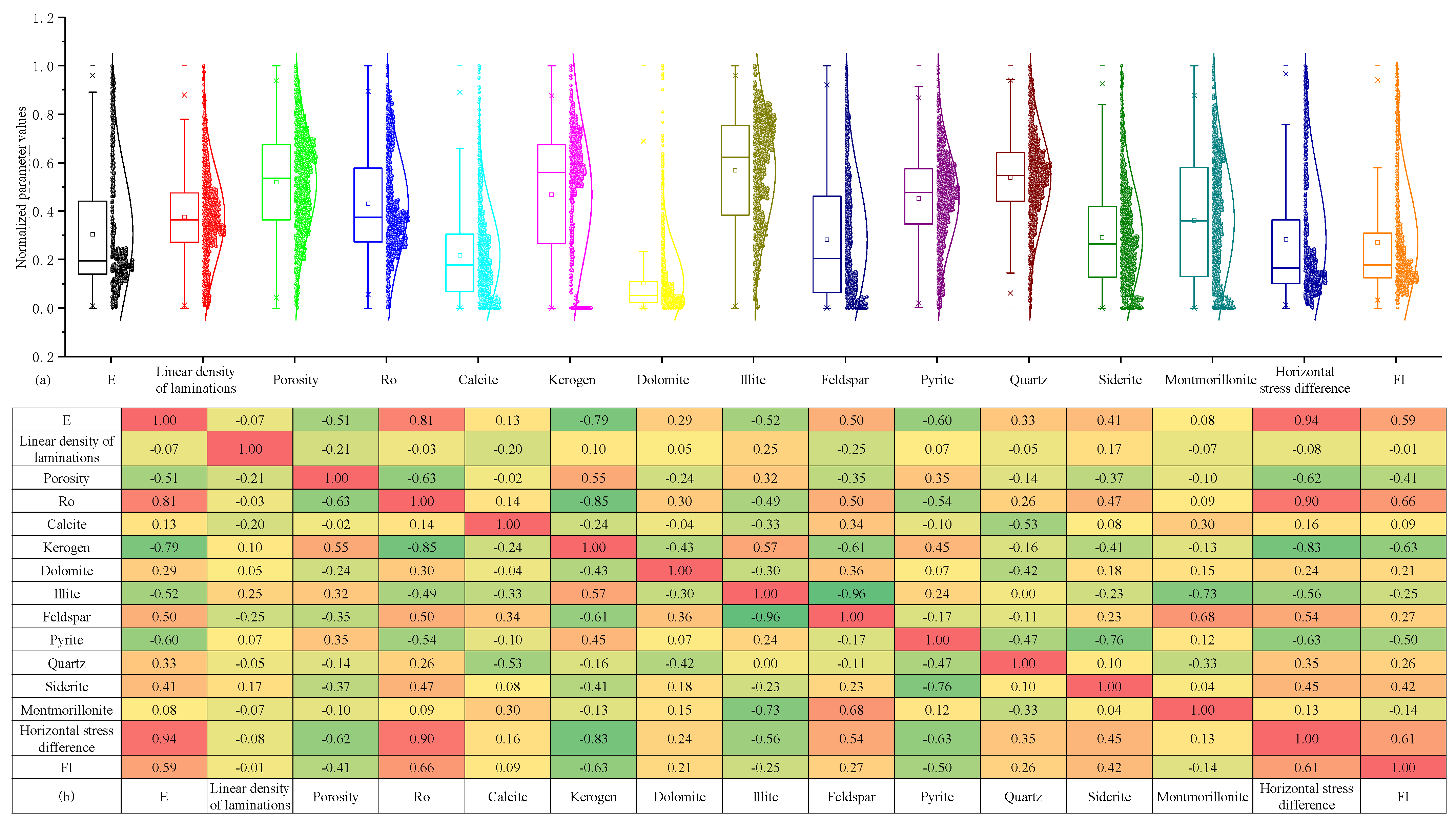

5.1. Correlation Analysis of the Main Factors and Brittleness

5.2. Analysis of the Main Factors of Brittleness

5.2.1. Brittle Minerals

5.2.2. Maturity of Organic Matter

5.2.3. Horizontal Stress Difference

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Lei, Q.; Weng, D.W.; Xiong, S.C.; Liu, H.B.; Guan, B.S.; Deng, Q.; Yan, X.M.; Liang, H.B.; Ma, Z.Y. Progress and development directions of shale oil reservoir stimulation technology of China National Petroleum Corporation. Pet. Explor. Dev. Online 2021, 48, 1198–1207. [Google Scholar] [CrossRef]

- Arfaoui, I.; Hamdi, O.; Boulvain, F. Geochemical and mineralogical characterizations of Silurian “Hot” shales: Implications for shale gas/oil reservoir potential in Jeffara basin-southeastern Tunisia, North Africa. J. Afr. Earth Sci. 2024, 212, 105213. [Google Scholar] [CrossRef]

- Mauricio, T.F.; Adrián, M.; Wei, Y.; Jijun, M. Characterization of complex hydraulic fractures in Eagle Ford shale oil development through embedded discrete fracture modeling. Pet. Explor. Dev. Online 2021, 48, 713–720. [Google Scholar]

- Kubra, H.U.; Nukhet, D.; Hakan, M.B. Effects of US foreign and domestic shocks on US shale oil production across different basins. Resour. Policy 2022, 79, 102991. [Google Scholar]

- Stinchfield, B.T.; Auch, T.; Bratman, E. Energy Security, International Investment, and Democracy: The Case of the United States Shale Oil and Gas Industry. Democr. Secur. 2020, 16, 309–333. [Google Scholar] [CrossRef]

- Emad, K.; Taher, M.S.A.; Taghi, S.E.; Narges, S.; Alireza, P. Oil price shocks on shale oil supply and energy security: A case study of the United States. Int. J. Dev. Issues 2022, 21, 249–270. [Google Scholar]

- Zhao, W.Z.; Zhu, R.K.; Zhang, J.Y.; Yang, J.R. Classification, exploration and development status and development trend of continental shale oil in China. China Pet. Explor. 2023, 28, 1–13. [Google Scholar]

- Yang, Y.M.; Wen, L.; Wang, X.Z.; Hong, H.T.; Zhu, H.H.; Xiong, Y.; Li, M.Q.; Lu, J.G.; Zeng, D.; Yang, W. Geological characteristics and favorable exploration area selection of shale oil and gas of the Lower Jurassic Da’anzhai Member in the Sichuan Basin. Nat. Gas Ind. 2023, 43, 32–42. [Google Scholar]

- Sun, L.D.; Liu, H.; Zhu, R.K.; Cui, B.W.; Lei, Z.D.; Meng, S.W.; Tang, J.Z. Ten noteworthy issues on shale oil revolution in China. Acta Pet. Sin. 2023, 44, 2007–2019. [Google Scholar]

- Zou, C.N.; Lin, M.J.; Ma, F.; Liu, H.L.; Yang, Z.; Zhang, G.S.; Yang, Y.C.; Guan, C.X.; Liang, Y.B.; Wang, Y.; et al. Development, challenges and strategies of natural gas industry under carbon neutral target in China. Pet. Explor. Dev. 2024, 51, 418–435. [Google Scholar] [CrossRef]

- Lei, Q.; Weng, D.W.; Guan, B.S.; Shi, J.F.; Cai, B.; He, C.M.; Sun, Q.; Huang, R. Shale oil and gas exploitation in China: Technical comparison with US and development suggestions. Pet. Explor. Dev. Online 2023, 50, 944–954. [Google Scholar] [CrossRef]

- Xu, C.G.; Lai, W.C.; Zhang, X.T.; Zhang, J.W. New progress and future exploration thinking of CNO0C oil and gas exploration. China Offshore Oil Gas 2023, 35, 1–12. [Google Scholar]

- Zhang, J.H. Progress in Sinopec shale oil engineering technology. Pet. Reserv. Eval. Dev. 2023, 13, 1–8. [Google Scholar]

- Li, X.; Wu, K.Y.; Wang, J.G.; Yang, S.Y.; Zhang, Q.H.; Zhang, Q. Impact of Lithologic Heterogeneity on Brittleness of Cenozoic Unconventional Reservoirs (Fine-Grained) in Western Qaidam Basin. Minerals 2022, 12, 1443. [Google Scholar] [CrossRef]

- Liu, S.Y.; Cao, N.; Lou, Y.S.; Yuan, Y. A new approach for post-fracturing evaluation and productivity prediction based on a reservoir fracability index model in shale gas reservoirs. J. Pet. Explor. Prod. Technol. 2023, 13, 1807–1818. [Google Scholar] [CrossRef]

- Liu, Y.J.; Lai, F.Q.; Wang, R.Y.; Wu, Z.H.; Zhang, X.S.; Xu, H.; Li, J. Influencing Factors of the Brittleness of Continental Shales Containing Shell Limestone Interlayer. Minerals 2023, 13, 460. [Google Scholar] [CrossRef]

- Zhan, Y.; Lin, C.Y.; Ma, C.F.; Han, W.Z.; Ma, P.J.; Li, G. Lithofacies Characteristics and Sweet Spot Distribution of Lacustrine Shale Oil Reservoirs: A Case Study of the Second Member of the Kongdian Formation in the Cangdong Sag, Bohai Bay Basin. Minerals 2023, 13, 1391. [Google Scholar] [CrossRef]

- Ye, Y.P.; Tang, S.H.; Xi, Z.D.; Lu, R.Q.; Zhang, Z.Y.; Li, J.T. The Effects of Quartz Content, Particle Size and Distribution Mode on the Mechanical Properties and Fracturing of Shale. Nat. Resour. Res. 2023, 33, 239–262. [Google Scholar] [CrossRef]

- Sethi, C.; Hazra, B.; Ostadhassan, M.; Motra, B.H.; Dutta, A.; Pandey, J.K.; Kumar, S. Depositional environmental controls on mechanical stratigraphy of Barakar Shales in Rajmahal Basin, India. Int. J. Coal Geol. 2024, 285, 104477. [Google Scholar] [CrossRef]

- Zahrah, F.B.; Suhaili, M.I. The brittleness and ductility of shale from Setap shale, Miri, Sarawak. IOP Conf. Ser. Earth Environ. Sci. 2022, 1003, 012012. [Google Scholar]

- Kivi, R.I.; Ameri, M.; Molladavoodi, H. Shale brittleness evaluation based on energy balance analysis of stress-strain curves. J. Pet. Sci. Eng. 2018, 167, 1–19. [Google Scholar] [CrossRef]

- Iyare, U.; Blake, O.; Ramsook, R. Brittleness evaluation of Naparima Hill mudstones. J. Pet. Sci. Eng. 2021, 196, 107737. [Google Scholar] [CrossRef]

- Ye, Y.P.; Tang, S.H.; Xi, Z.D.; Jiang, D.X.; Duan, Y. Quartz types in the Wufeng-Longmaxi Formations in southern China: Implications for porosity evolution and shale brittleness. Mar. Pet. Geol. 2022, 137, 105479. [Google Scholar] [CrossRef]

- Tan, M.J.; Wu, H.L.; Wang, S.Y.; Du, G.H.; Bai, Y.; Wang, Q. Progress and development direction of log interpretation technology for marine shale gas in China. Acta Pet. Sin. 2024, 45, 241–260. [Google Scholar]

- Wang, Q.; Li, H.; Liu, T.; Li, Z.G.; Dong, Y.J.; Jiang, B.K. Characterization method and main controlling factors of shale brittleness. Fault-Block Oil Gas Field 2020, 27, 458–463. [Google Scholar]

- Bobaru, F.; Zhang, G. Why do cracks branch? A peridynamic investigation of dynamic brittle fracture. Int. J. Fract. 2015, 196, 59–98. [Google Scholar] [CrossRef]

- Florin, B.; Ugo, G.; Ziguang, C. Introduction to the special issue on nonlocal models in fracture and damage. Int. J. Fract. 2024, 245, 115–120. [Google Scholar]

- Wang, L.Y.; Golfier, F.; Tinet, A.; Chen, W.Z.; Vuik, C. An efficient adaptive implicit scheme with equivalent continuum approach for two-phase flow in fractured vuggy porous media. Adv. Water Resour. 2022, 163, 104186. [Google Scholar] [CrossRef]

- Wang, L.Y.; Yin, Z.Y.; Chen, W.Z. Characteristics of crack growth in brittle solids with the effects of material heterogeneity and multi-crack interaction. Int. J. Fract. 2024, 246, 77–99. [Google Scholar] [CrossRef]

- Mews, S.K.; Alhubail, M.M.; Barati, G.R. A Review of Brittleness Index Correlations for Unconventional Tight and Ultra-Tight Reservoirs. Geosciences 2019, 9, 319. [Google Scholar] [CrossRef]

- Zhang, B.T.; Tang, J.Y.; Wang, W.J.; Yin, C.L. Characteristics of tectonic sedimentary evolution in northern depression of beibuwan basin. Offshore Oil 2014, 34, 7–12. [Google Scholar]

- Xu, J.J.; Jin, Q.; Xu, X.D.; Cheng, F.Q.; Hu, C.H.; Wang, B.; Chen, T. Factors controlling organic-rich shale development in the Liushagang Formation, Weixinan Sag, Beibu Gulf Basin: Implications of structural activity and the depositional environment. Pet. Sci. 2024, 18, 1011–1020. [Google Scholar] [CrossRef]

- Deng, Y.; Hu, D.S.; Zhu, J.T.; Liu, G.H.; Chen, K.; Tong, C.X.; Zhang, D.J.; Xu, X.D.; Man, Y.; You, J.J.; et al. Hydrocarbon accumulation regularities, new fields and new types of exploration, and resource potentials in Beibuwan Basin. Acta Pet. Sin. 2024, 45, 202–225. [Google Scholar]

- GB/T 19145-2003; Petroleum. Determination of Total Organic Carbon in Sedimentary Rock. Petroleum Industry Press: Beijing, China, 2003.

- SY/T 5124-1995; Geology Exploration. Method for Determination of Vitrinite Reflectance in Sedimentary Rocks. Petroleum Industry Press: Beijing, China, 1995.

- Lohr, C.D.; Hackley, P.C. Relating Tmax and hydrogen index to vitrinite and solid bitumen reflectance in hydrous pyrolysis residues: Comparisons to natural thermal indices. Int. J. Coal Geol. 2021, 242, 103768. [Google Scholar] [CrossRef]

- SY/T 5163-2010; Geology Exploration. Analysis Method for Clay Minerals and Ordinary Non-Clay Minerals in Sedimentary Rocks by the X-ray Diffraction. Petroleum Industry Press: Beijing, China, 2010.

- SY/T 5368-2000; Geology Exploration. Thin Section Examination of Rock. Petroleum Industry Press: Beijing, China, 2000.

- Shubhangi, K.; Javaregowda, D.; Sanjukta, D.; Abdul, M.R. Multiproxy geochemical characterization of Kommugudem Formation, Krishna Godavari Basin, India: Implication on hydrocarbon potential and shale brittleness. Geol. J. 2021, 57, 1373–1390. [Google Scholar]

- Owolabi, L.L.; Mohamed, M.; Abdulrauf, A.; Abdulrauf, A.; Abdullah, S. Brittleness and Microcracks: A New Approach of Brittleness Characterization for Shale Fracking. J. Nat. Gas Sci. Eng. 2020, 87, 103793. [Google Scholar]

- Wang, R.Y.; Liu, Y.J.; Li, Z.; Wang, D.H.; Wang, G.P.; Lai, F.Q.; Li, Z.H.; He, J.H. Microscopic pore structure characteristics and controlling factors of marine shale: A case study of Lower Cambrian shales in the Southeastern Guizhou, Upper Yangtze Platform, South China. Front. Earth Sci. 2024, 12, 1368326. [Google Scholar] [CrossRef]

- Mazouz, H.E.; Hamimed, M.; Yahiaoui, A.; Benzagouta, S.M.; Khodja, M.; Achi, N.; Duplay, J. An integrated approach for the identification of lithofacies and clay mineralogy through Neuro-Fuzzy, cross plot, and statistical analyses, from well log data. J. Earth Syst. Sci. Publ. Indian Acad. Sci. 2020, 129, 117–127. [Google Scholar]

- Lai, F.Q.; Li, S.C.; Wang, M.; Liu, Y.J.; Zhong, L.L.; Huang, Z.H.; Wang, H.T. Optimal Retrieval Method for Mineral Constituents of Shale Oil Reservoirs in Jiyang Sag. Spec. Oil Gas Reserv. 2022, 29, 16–23. [Google Scholar]

- Zhao, L.; Mao, R.; Deng, X.; Feng, Z.Y.; Chen, J.K.; Zong, X.H.; Feng, C. Research on Inversion Log Evaluation Method of Special Mineral in Alkali Lake Shale Oil Reservoir—A Case Study of the Fengcheng Formation in the Mahu Sag, China. Processes 2024, 12, 105. [Google Scholar] [CrossRef]

- Liu, Y.J.; Lai, F.Q.; Zhang, H.J.; Tan, Z.J.; Wang, Y.F.; Zhao, X.T.; Tan, X.F. A novel mineral composition inversion method of deep shale gas reservoir in Western Chongqing. J. Pet. Sci. Eng. 2021, 202, 108528. [Google Scholar]

- Lai, F.Q.; Zhang, G.T.; Huang, Z.H.; Wang, H.T.; Zhu, Z.X.; Zhong, L.L.; Xia, X.X. A Method for Extracting Sand Lamination Parameters of Shale Oil and Gas Reservoir. Patent CN202010855000.5, 12 March 2021. [Google Scholar]

- Ding, W.L.; Wang, Y.; Wang, S.H.; Liu, T.F.; Zhang, Z.Y.; Gou, T.; Zhang, M.Y.; He, X. Research progress and insight on non-tectonic fractures in shale reservoirs. Earth Sci. Front. 2024, 31, 297–314. [Google Scholar]

- Li, C.H.; Zhao, L.; Liu, B.; Li, J.X.; Chen, Y.F.; Zhang, Y. Research status and development trend of fractures in carbonate reservoir. Bull. Geol. Sci. Technol. 2021, 40, 31–48. [Google Scholar]

- He, S.B.; Meng, K.; Wang, C.; Chen, Y.B.; Zhao, H.; Wang, H.Y.; Yu, H.Y. Fracture Identification Using Conventional Logs in Ultra-Low Permeability Sandstone Reservoirs: A Case Study of the Chang 6 Member of the Ordos Basin, China. Minerals 2023, 13, 297. [Google Scholar] [CrossRef]

- Brave, M.; Renatus, K.; Habibu, M.; Habibu, M.; Simon, G.C. The organic geochemistry of Permian high latitude sediments in two boreholes in the southern Sydney Basin, New South Wales, Australia. Mar. Pet. Geol. 2023, 154, 1063116. [Google Scholar]

- Ejeh, I.O.; Etobro, A.A.I.; Perleros, K.; Ogala, J.E.; Ehinola, A.O.; Christanis, k.; Kalaitzidis, S. Hydrocarbon generation potential of Campano-Maastrichtian to Paleogene shales in the Benin Flank of the Anambra Basin, SW Nigeria. Energy Geosci. 2024, 5, 100286. [Google Scholar] [CrossRef]

- Farouk, S.; Arafat, M.; Fagelnour, S.M.; Kahtany, K.A.; Gentzis, T. Petroleum system assessment of the Beni Suef Basin, Western Desert, Egypt. J. Afr. Earth Sci. 2024, 217, 105345. [Google Scholar] [CrossRef]

- Rickman, R.; Mullen, M.; Petre, E.; Grieser, B.; Kundert, D. A practical use of shale petrophysics for stimulation design optimization: All shale plays are not clones of the Barnett Shale. In Proceedings of the SPE Annual Technical Conference and Exhibition, Denver, CO, USA, 21–24 September 2008; Volume 2, pp. 840–850. [Google Scholar]

- Okiongbo, K.S.; Aplin, A.C.; Larter, S.R. Changes in type II kerogen density as a function of maturity: Evidence from the Kimmeridge Clay Formation. Energy Fuels 2005, 19, 2495–2499. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lai, F.; Liu, Y.; Tang, M.; Zeng, C.; Wang, R. Characterization and Analysis of the Main Factors of Brittleness of Shale Oil Reservoirs in the Liushagang Formation, X Depression, Beibuwan Basin. Minerals 2024, 14, 958. https://doi.org/10.3390/min14090958

Lai F, Liu Y, Tang M, Zeng C, Wang R. Characterization and Analysis of the Main Factors of Brittleness of Shale Oil Reservoirs in the Liushagang Formation, X Depression, Beibuwan Basin. Minerals. 2024; 14(9):958. https://doi.org/10.3390/min14090958

Chicago/Turabian StyleLai, Fuqiang, Yuejiao Liu, Mingzheng Tang, Chengxiang Zeng, and Ruyue Wang. 2024. "Characterization and Analysis of the Main Factors of Brittleness of Shale Oil Reservoirs in the Liushagang Formation, X Depression, Beibuwan Basin" Minerals 14, no. 9: 958. https://doi.org/10.3390/min14090958