Test Method for Mineral Spatial Distribution of BIF Ore by Imaging Spectrometer

Abstract

:1. Introduction

2. Materials and Methods

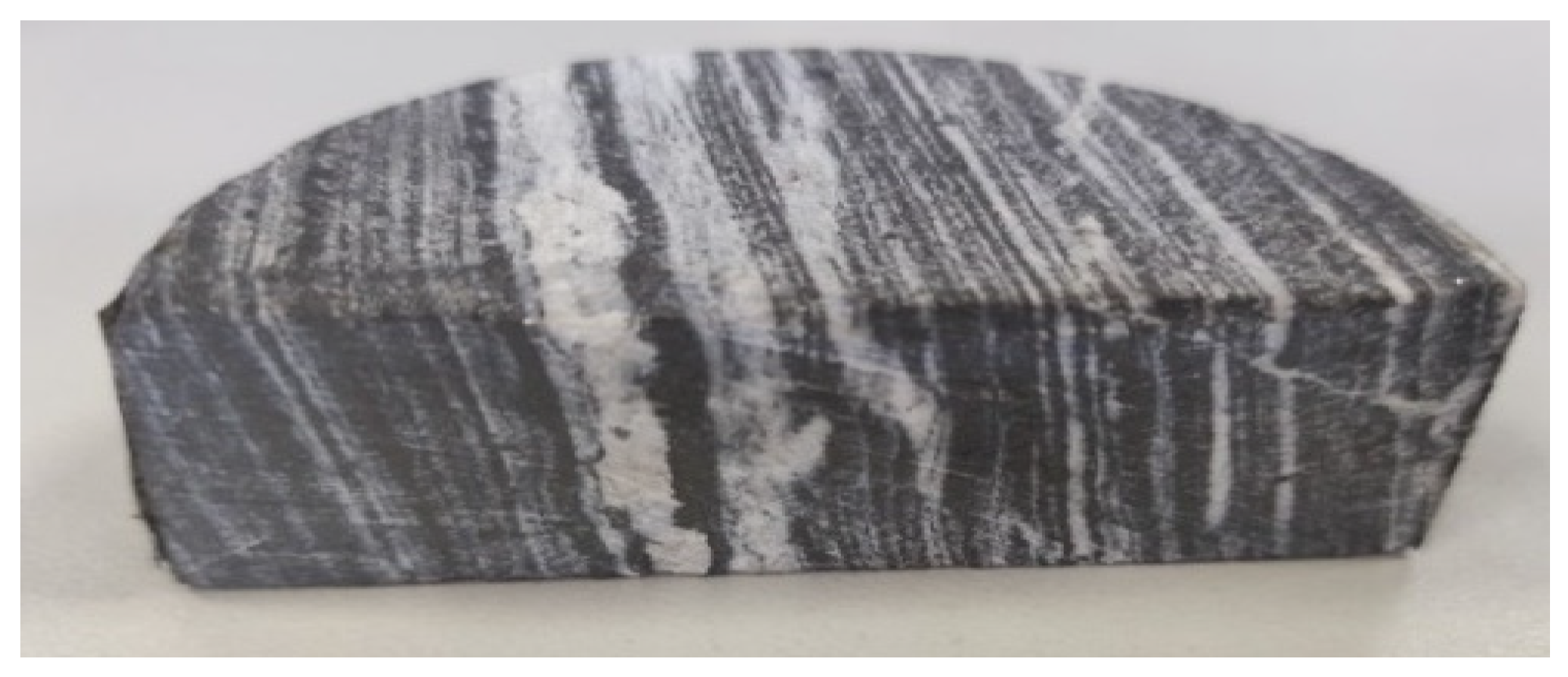

2.1. Iron Ore Sample Preparation

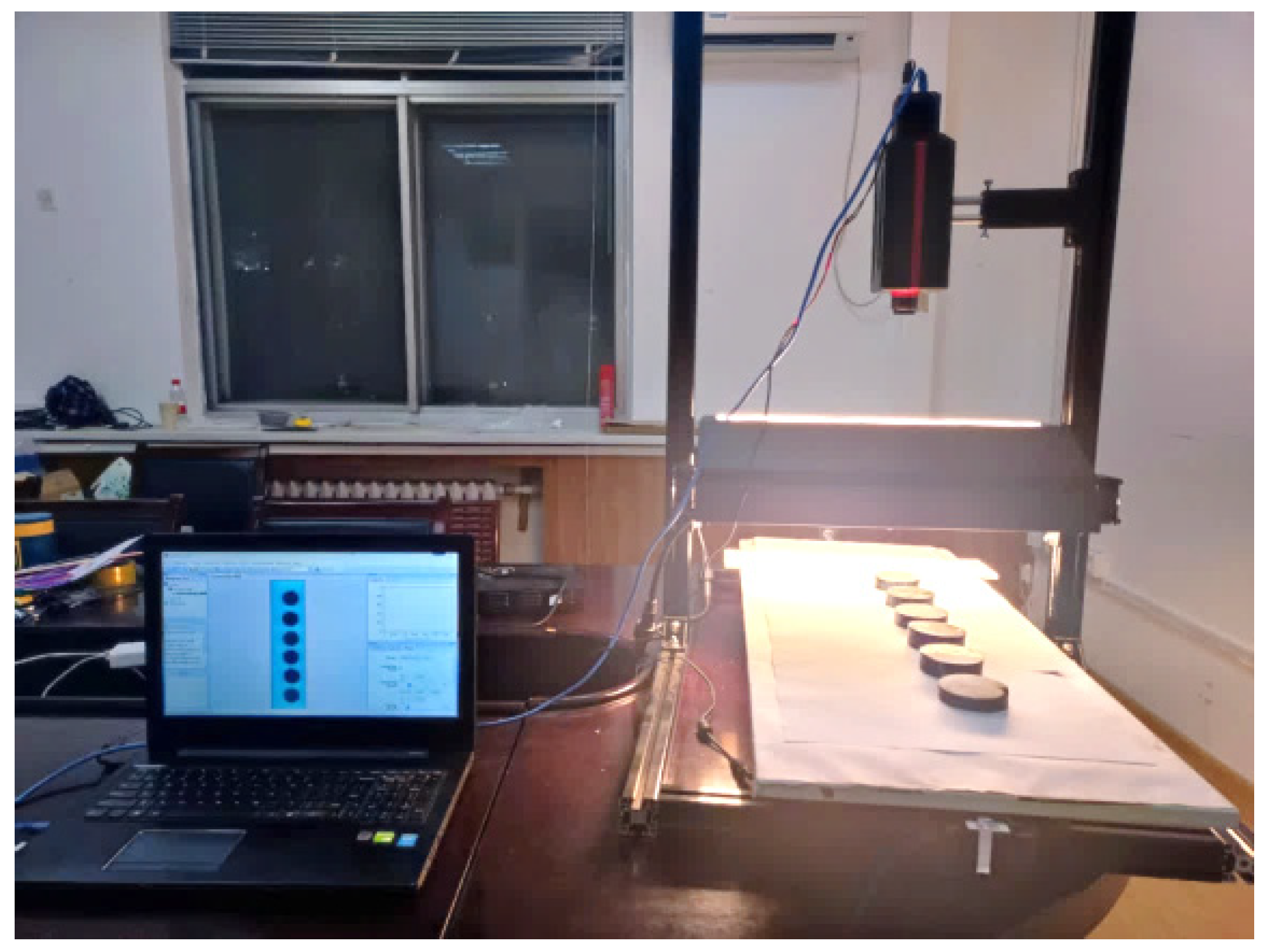

2.2. Hyperspectral Imaging System

2.3. Hyperspectral Data Acquisition

2.4. Sample Mineral Composition Measurement

3. Inversion Model Construction

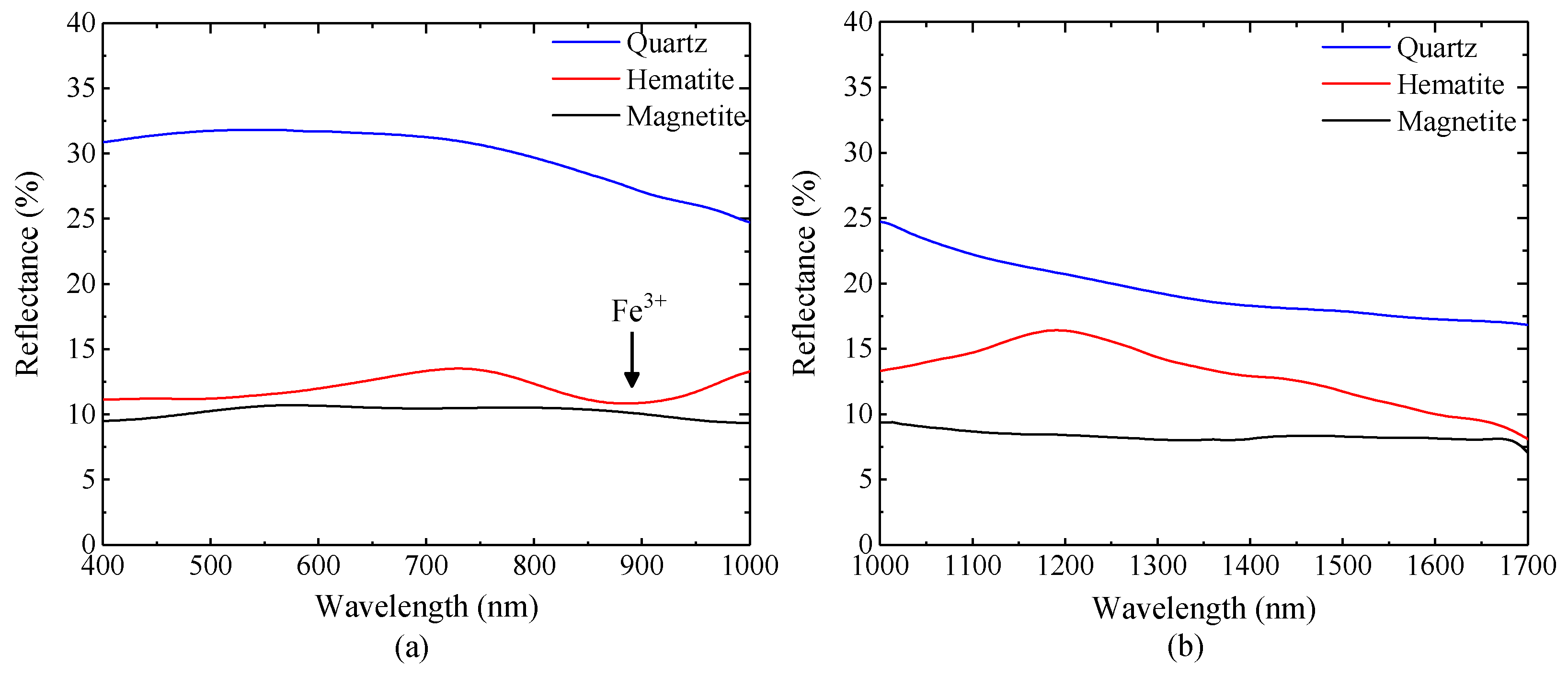

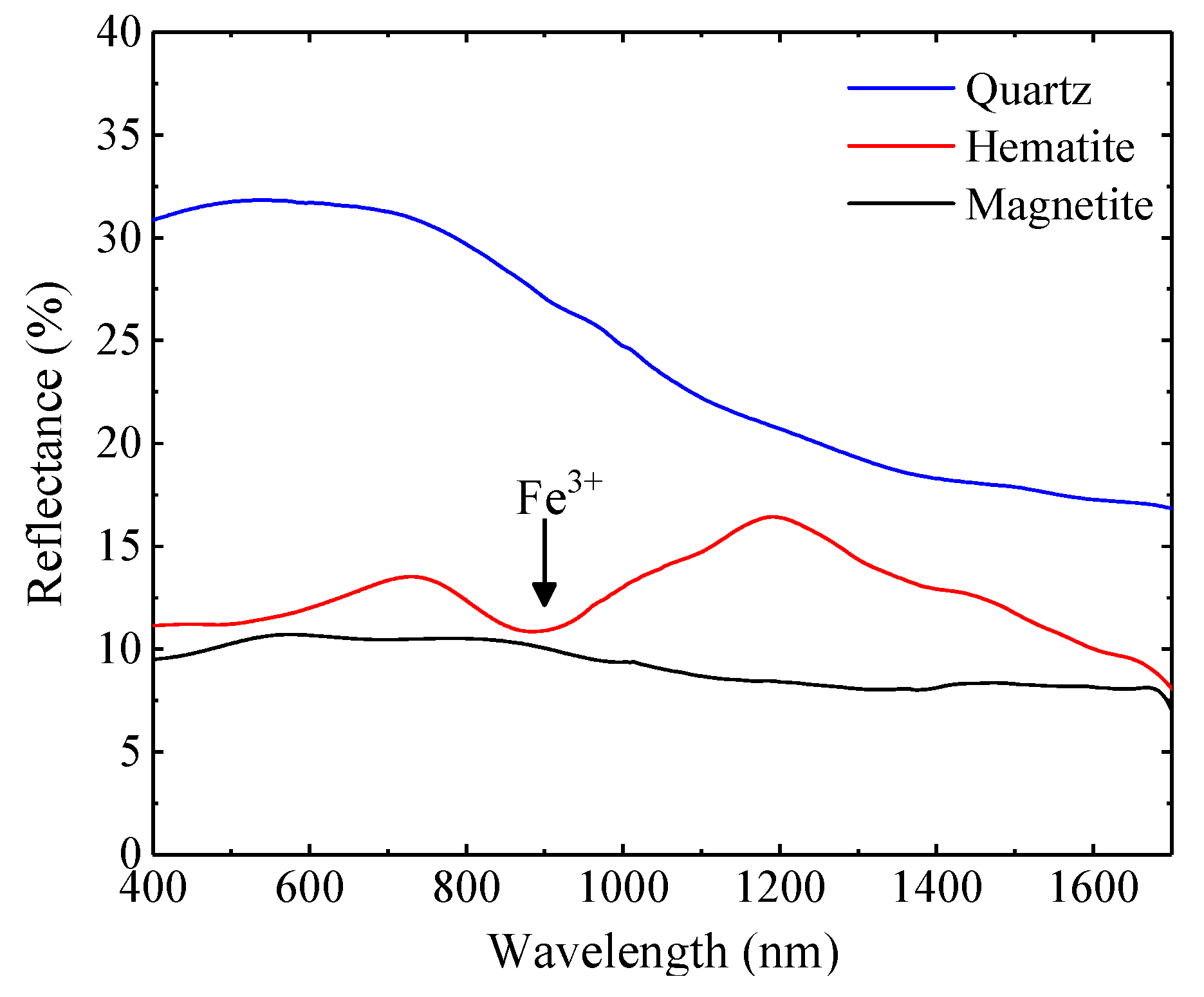

3.1. Mineral Reference Spectroscopy

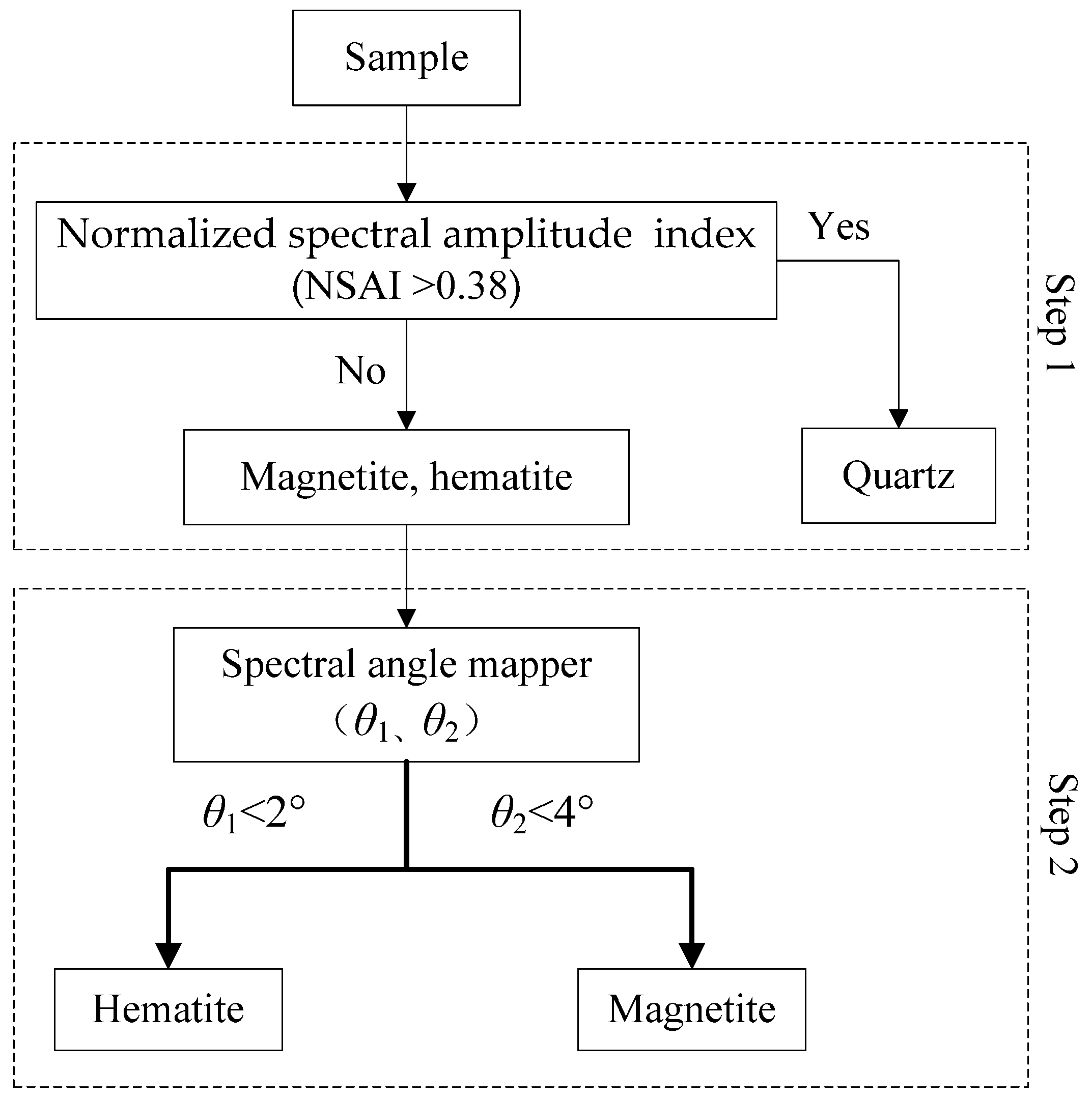

3.2. Model Construction

3.3. Model Evaluation Index

4. Model Validation and Discussion

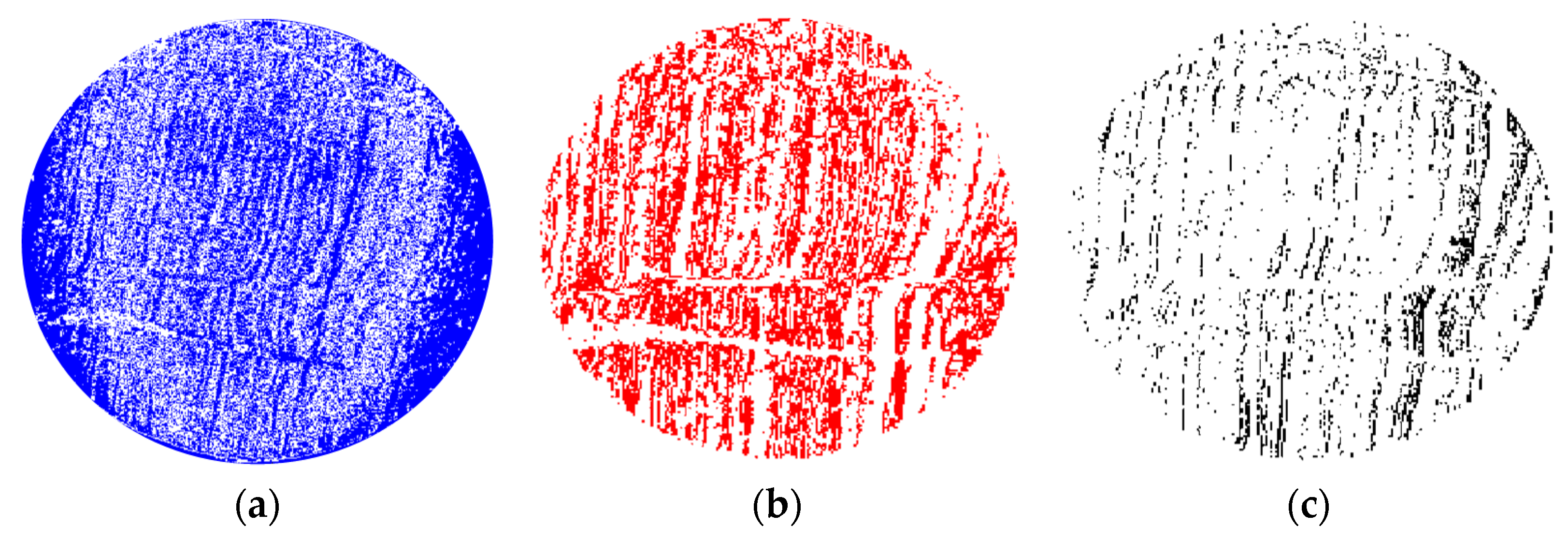

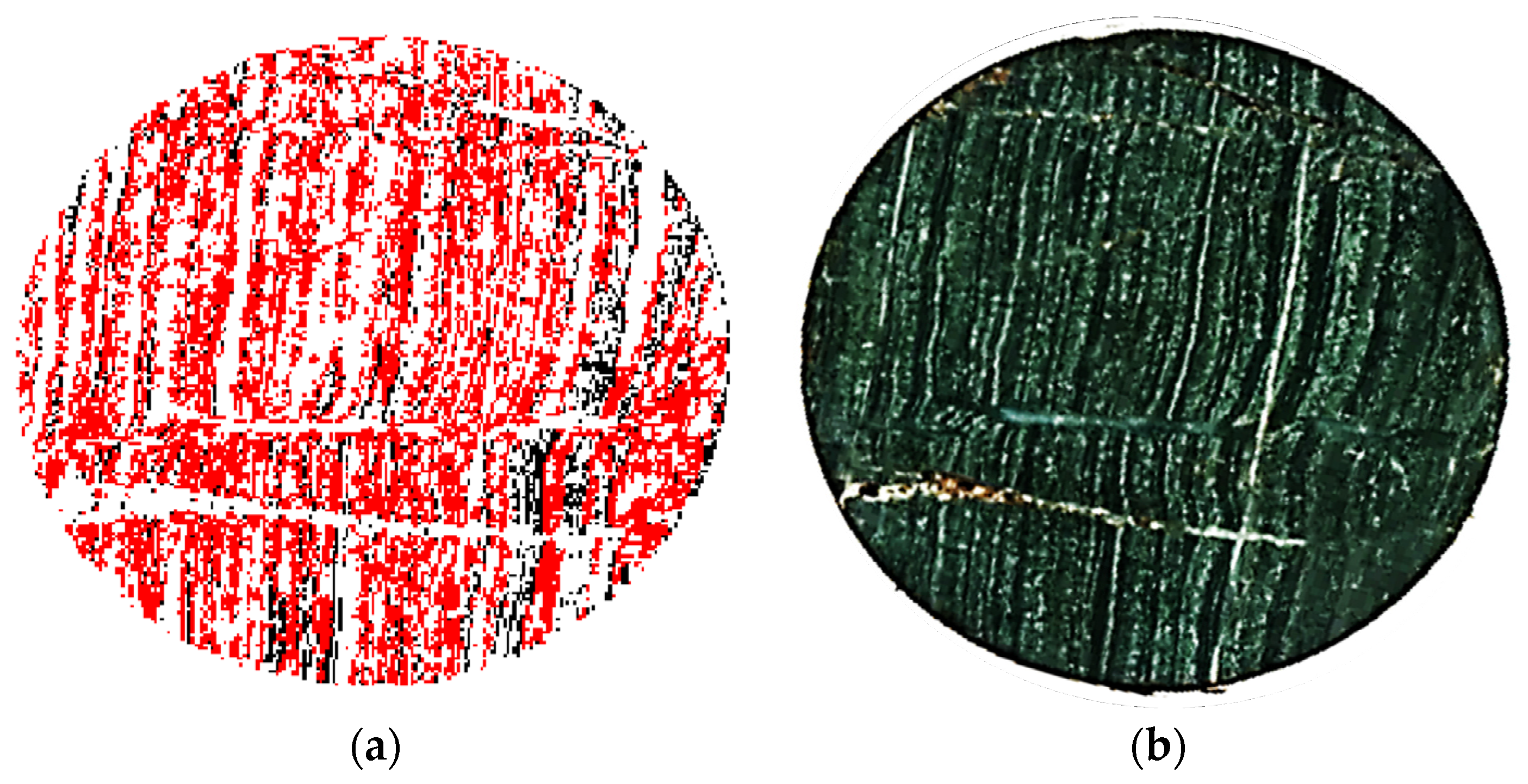

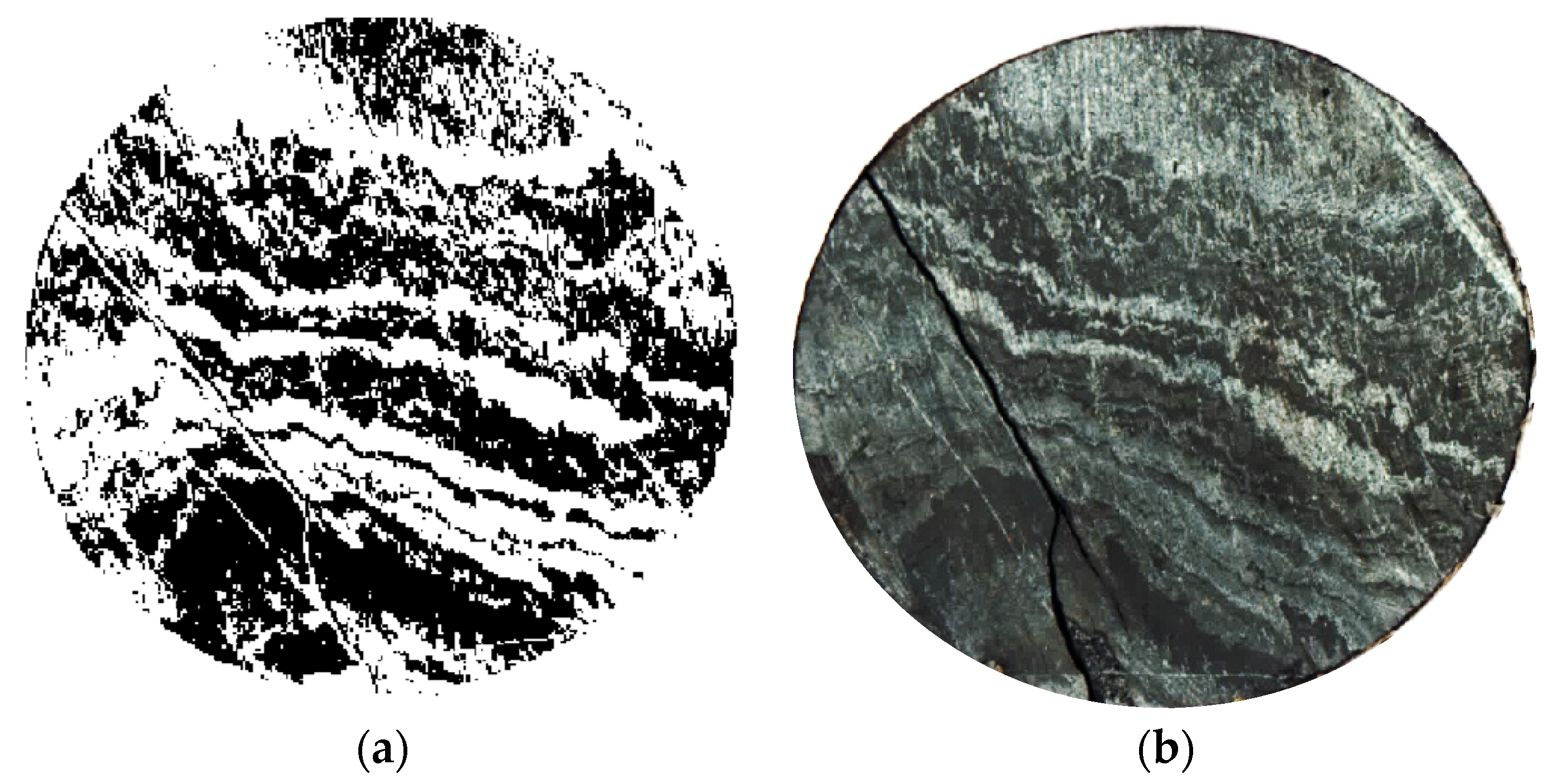

4.1. Identification Results of the Spatial Distribution of Iron Ore Components

4.2. Accuracy of Quantitative Inversion of Quartz, Hematite, and Magnetite

4.3. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Aftabi, A.; Atapour, H.; Mohseni, S.; Babaki, A. Geochemical discrimination among different types of banded iron formations (BIFs): A comparative review. Ore Geol. Rev. 2021, 136, 104244. [Google Scholar] [CrossRef]

- Hassanzadeh, F.; Atapour, H.; Ranjbar, H. The Ediacaran metamorphosed banded iron formation (BIF) at Gohar Zamin mine (Gol-e-Gohar# 3 anomaly), Sirjan (southeastern Iran): Perspective from ore structures, bulk ore-rock geochemistry and OS-Pb isotopic signatures. Precambrian Res. 2023, 394, 107124. [Google Scholar]

- Lv, Z.; Cheng, H.; Wei, M.; Zhao, D.; Wu, D.; Liu, C. Mineralogical characteristic and beneficiation evaluation of a Ta-Nb-Li-Rb deposit. Minerals 2022, 12, 457. [Google Scholar] [CrossRef]

- Weibel, R.; Friis, H. Opaque minerals as keys for distinguishing oxidising and reducing diagenetic conditions in the Lower Triassic Bunter Sandstone, North German Basin. Sediment. Geol. 2004, 169, 129–149. [Google Scholar] [CrossRef]

- Pabiś-Mazgaj, E.; Gawenda, T.; Pichniarczyk, P.; Stempkowska, A. Mineral composition and structural characterization of the clinoptilolite powders obtained from zeolite-rich tuffs. Minerals 2021, 11, 1030. [Google Scholar] [CrossRef]

- Janovszky, P.; Jancsek, K.; Palásti, D.J.; Kopniczky, J.; Hopp, B.; Tóth, T.M.; Galbács, G. Classification of minerals and the assessment of lithium and beryllium content in granitoid rocks by laser-induced breakdown spectroscopy. J. Anal. At. Spectrom. 2021, 36, 813–823. [Google Scholar] [CrossRef]

- El-Desoky, H.M.; Shebl, A.; Abdel-Rahman, A.M.; Fahmy, W.; El-Awny, H.; El-Sherif, A.M.; El-Rahmany, M.M.; Csámer, Á. Multiscale mineralogical investigations for mineral potentiality mapping of Ras El-Kharit-Wadi Khashir district, Southern Eastern Desert, Egypt. Egypt. J. Remote Sens. Space Sci. 2022, 25, 941–960. [Google Scholar] [CrossRef]

- Xing, J.; Xian, H.; Yang, Y.; Chen, Q.; Xi, J.; Li, S.; He, H.; Zhu, J. Nanoscale Mineralogical Characterization of Terrestrial and Extraterrestrial Samples by Transmission Electron Microscopy: A Review. ACS Earth Space Chem. 2023, 7, 289–302. [Google Scholar] [CrossRef]

- Pirard, E. Multispectral imaging of ore minerals in optical microscopy. Mineral. Mag. 2004, 68, 323–333. [Google Scholar] [CrossRef]

- Tang, H.; Wang, H.; Wang, L.; Cao, C.; Nie, Y.; Liu, S. An Improved Mineral Image Recognition Method Based on Deep Learning. JOM 2023, 75, 2590–2602. [Google Scholar] [CrossRef]

- Kuczyńska-Zemła, D.; Sundell, G.; Zemła, M.; Andersson, M.; Garbacz, H. The distribution of O and N in the surface region of laser-patterned titanium revealed by atom probe tomography. Appl. Surf. Sci. 2021, 562, 150193. [Google Scholar] [CrossRef]

- Jeong, G.Y.; Nousiainen, T. TEM analysis of the internal structures and mineralogy of Asian dust particles and the implications for optical modeling. Atmos. Chem. Phys. 2014, 14, 7233–7254. [Google Scholar] [CrossRef]

- Li, Y.; Deng, F.; Hall, T.; Goldys, E. M CRISPR/Cas12a-powered immunosensor suitable for ultra-sensitive whole Cryptosporidium oocyst detection from water samples using a plate reader. Water Res. 2021, 203, 117553. [Google Scholar] [CrossRef]

- Abdullah; Ali, S.; Khan, Z.; Hussain, A.; Athar, A.; Kim, H.C. Computer vision based deep learning approach for the detection and classification of algae species using microscopic images. Water 2022, 14, 2219. [Google Scholar] [CrossRef]

- Jain, U.; Saxena, K.; Chauhan, N. Helicobacter pylori induced reactive oxygen Species: A new and developing platform for detection. Helicobacter 2021, 26, e12796. [Google Scholar] [CrossRef] [PubMed]

- Peyghambari, S.; Zhang, Y. Hyperspectral remote sensing in lithological mapping, mineral exploration, and environmental geology: An updated review. J. Appl. Remote Sens. 2021, 15, 031501. [Google Scholar] [CrossRef]

- Lobo, A.; Garcia, E.; Barroso, G.; Martí, D.; Fernandez-Turiel, J.L.; Ibáñez-Insa, J. Machine Learning for Mineral Identification and Ore Estimation from Hyperspectral Imagery in Tin–Tungsten Deposits: Simulation under Indoor Conditions. Remote Sens. 2021, 13, 3258. [Google Scholar] [CrossRef]

- Lorenz, S.; Ghamisi, P.; Kirsch, M.; Jackisch, R.; Rasti, B.; Gloaguen, R. Feature extraction for hyperspectral mineral domain mapping: A test of conventional and innovative methods. Remote Sens. Environ. 2021, 252, 112129. [Google Scholar] [CrossRef]

- Shaik, I.; Begum, S.K.; Nagamani, P.V.; Kayet, N. Characterization and mapping of hematite ore mineral classes using hyperspectral remote sensing technique: A case study from Bailadila iron ore mining region. SN Appl. Sci. 2021, 3, 1–13. [Google Scholar] [CrossRef]

- Duuring, P.; Hagemann, S.G.; Laukamp, C.; Chiarelli, L. Supergene modification of magnetite and hematite shear zones in banded iron-formation at Mt Richardson, Yilgarn Craton, Western Australia. Ore Geol. Rev. 2019, 111, 102995. [Google Scholar] [CrossRef]

- De la Rosa, R.; Khodadadzadeh, M.; Tusa, L.; Kirsch, M.; Gisbert, G.; Tornos, F.; Tolosana-Delgado, R.; Gloaguen, R. Mineral quantification at deposit scale using drill-core hyperspectral data: A case study in the Iberian Pyrite Belt. Ore Geol. Rev. 2021, 139, 104514. [Google Scholar] [CrossRef]

- Fouedjio, F.; Hill, E.J.; Laukamp, C. Geostatistical clustering as an aid for ore body domaining: Case study at the Rocklea Dome channel iron ore deposit, Western Australia. Appl. Earth Sci. 2018, 127, 15–29. [Google Scholar] [CrossRef]

- Haest, M.; Cudahy, T.; Laukamp, C.; Gregory, S. Quantitative mineralogy from infrared spectroscopic data, I.I. Three-dimensional mineralogical characterization of the Rocklea channel iron deposit, Western Australia. Econ. Geol. 2012, 107, 229–249. [Google Scholar] [CrossRef]

- Mathieu, M.; Roy, R.; Launeau, P.; Cathelineau, M.; Quirt, D. Alteration mapping on drill cores using a HySpex SWIR-320m hyperspectral camera: Application to the exploration of an unconformity-related uranium deposit (Saskatchewan, Canada). J. Geochem. Explor. 2017, 172, 71–88. [Google Scholar] [CrossRef]

- Ramanaidou, E.; Wells, M.; Lau, I.; Laukamp, C. Characterization of iron ore by visible and infrared reflectance and, Raman spectroscopies. In Iron Ore; Woodhead Publishing: Cambridge, UK, 2015; pp. 191–228. [Google Scholar]

- Zaini, N.; Van Der Meer, F.; Van Der Werff, H. Determination of Carbonate Rock Chemistry Using Laboratory-Based Hyperspectral Imagery. Remote Sens. 2014, 6, 4149–4172. [Google Scholar] [CrossRef]

- Booysen, R.; Lorenz, S.; Thiele, S.T.; Fuchsloch, W.C.; Marais, T.; Nex, P.A.; Gloaguen, R. Accurate hyperspectral imaging of mineralised outcrops: An example from lithium-bearing pegmatites at Uis, Namibia. Remote Sens. Environ. 2022, 269, 112790. [Google Scholar] [CrossRef]

- Hao, D.; Yao, Y.; Fu, J.; Michalski, J.R.; Song, K. The laboratory-based hyspex features of chlorite as the exploration tool for high-grade iron ore in Anshan-Benxi Area, Liaoning Province, Northeast China. Appl. Sci. 2020, 10, 7444. [Google Scholar] [CrossRef]

- Mao, Y.; Ma, B.; Liu, S.; Wu, L.; Zhang, X.; Yu, M. Study and validation of a remote sensing model for coal extraction based on reflectance spectrum features. Can. J. Remote Sens. 2014, 40, 327–335. [Google Scholar] [CrossRef]

- Kumar, C.; Chatterjee, S.; Oommen, T. Mapping hydrothermal alteration minerals using high-resolution AVIRIS-NG hyperspectral data in the Hutti-Maski gold deposit area, India. Int. J. Remote Sens. 2020, 41, 794–812. [Google Scholar] [CrossRef]

- Shi, C.; Wang, L. Incorporating spatial information in spectral unmixing: A review. Remote Sens. Environ. 2014, 149, 70–87. [Google Scholar] [CrossRef]

- Lussier, F.; Thibault, V.; Charron, B.; Wallace, G.Q.; Masson, J.F. Deep learning and artificial intelligence methods for Raman and surface-enhanced Raman scattering. TrAC Trends Anal. Chem. 2020, 124, 115796. [Google Scholar] [CrossRef]

- Khushboo; Bala, N.; Rawat, S.; Singh, S.; Arya, R. A Study of Spectral Data Processing with Emphasis on Spectral Similarity Measures for Hyperspectral Image Processing. In Soft Computing: Theories and Applications: Proceedings of SoCTA 2018; Springer: Singapore, 2020; pp. 859–868. [Google Scholar]

- Van der Meer, F. The effectiveness of spectral similarity measures for the analysis of hyperspectral imagery. Int. J. Appl. Earth Obs. Geoinf. 2006, 8, 3–17. [Google Scholar] [CrossRef]

- Bakker, W.H.; Schmidt, K.S. Hyperspectral edge filtering for measuring homogeneity of surface cover types. ISPRS J. Photogramm. Remote Sens. 2002, 56, 246–256. [Google Scholar] [CrossRef]

- Wang, K.; Yong, B.; Gu, X.; Xiao, P.; Zhang, X. Spectral similarity measure using frequency spectrum for hyperspectral image classification. IEEE Geosci. Remote Sens. Lett. 2014, 12, 130–134. [Google Scholar] [CrossRef]

- Li, H.; Zhang, Z.; Li, L.; Zhang, Z.; Chen, J.; Yao, T. Types and general characteristics of the BIF-related iron deposits in China. Ore Geol. Rev. 2014, 57, 264–287. [Google Scholar] [CrossRef]

- Noda, S.; Yamaguchi, Y. Estimation of surface iron oxide abundance with suppression of grain size and topography effects. Ore Geol. Rev. 2017, 83, 312–320. [Google Scholar] [CrossRef]

- Cudahy, T.J.; Ramanaidou, E.R. Measurement of the hematite: Goethite ratio using field visible and near-infrared reflectance spectrometry in channel iron deposits. West. Australia. Aust. J. Earth Sci. 1997, 44, 411–420. [Google Scholar] [CrossRef]

- Fisher, A.J.; Hayes, W.; Stoneham, A.M. Theory of the structure of the self-trapped exciton in quartz. J. Phys. Condens. Matter. 1990, 2, 6707. [Google Scholar] [CrossRef]

- Izawa MR, M.; Cloutis, E.A.; Rhind, T.; Mertzman, S.A.; Applin, D.M.; Stromberg, J.M.; Sherman, D.M. Spectral reflectance properties of magnetites: Implications for remote sensing. Icarus 2019, 319, 525–539. [Google Scholar] [CrossRef]

- Hunt, G.R. Visible and near-infrared spectra of minerals and rocks: III. Oxides and hydro-oxides. Mod. Geol. 1971, 2, 195–205. [Google Scholar]

- Mao, Y.; Wang, D.; Liu, S.; Song, L.; Wang, Y.; Zhao, Z. Research and verification of a remote sensing BIF model based on spectral reflectance characteristics. J. Indian Soc. Remote Sens. 2019, 47, 1051–1061. [Google Scholar] [CrossRef]

- Sinaice, B.B.; Owada, N.; Ikeda, H.; Toriya, H.; Bagai, Z.; Shemang, E.; Adachi, T.; Kawamura, Y. Spectral angle mapping and AI methods applied in automatic identification of Placer deposit magnetite using multispectral camera mounted on UAV. Minerals 2022, 12, 268. [Google Scholar] [CrossRef]

- Zhang, H.; Zhang, P.; Zhou, F.; Lu, M. Application of multi-stage dynamic magnetizing roasting technology on the utilization of cryptocrystalline oolitic hematite: A review. Int. J. Min. Sci. Technol. 2022, 32, 865–876. [Google Scholar] [CrossRef]

- Zhu, D.; Jiang, Y.; Pan, J.; Yang, C. Study of Mineralogy and Metallurgical Properties of Lump Ores. Metals 2022, 12, 1805. [Google Scholar] [CrossRef]

- Song, L.; Liu, S.J.; Yu, M.L.; Mao, Y.C.; Wu, L.X. A classification method based on the combination of visible, near-infrared and thermal infrared spectrum for coal and gangue distinguishment. Guang Pu Xue Yu Guang Pu Fen Xi = Guang Pu. 2017, 37, 416–422. [Google Scholar]

- Moon, I.; Lee, I.; Seo, J.H.; Yang, X. Geochemical studies of banded iron formations (BIFs) in the North China Craton: A review. Geosci. J. 2017, 21, 971–983. [Google Scholar] [CrossRef]

| Parameters | PIka L | PIka NIR-320 |

|---|---|---|

| Spectral range (nm) | 400–1000 | 900–1700 |

| Spectral resolution (nm) | 2.1 | 4.9 |

| Sampling interval (nm) | 1.07 | 4.9 |

| Spectral channels | 561 | 164 |

| Spatial channels | 900 | 320 |

| Pixel size (µm) | 5.86 | 30 |

| Sample ID | SiO2 (%) | Fe3O4 (%) | Fe2O3 (%) | Total (%) |

|---|---|---|---|---|

| 1 | 46.33 | 51.2 | 2.08 | 99.61 |

| 2 | 51.89 | 13.92 | 33.13 | 98.94 |

| 3 | 54.05 | 6.40 | 38.18 | 98.63 |

| 4 | 55.05 | 1.03 | 43.81 | 99.89 |

| 5 | 55.11 | 0.50 | 43.08 | 98.69 |

| 6 | 57.28 | 4.67 | 37.23 | 99.18 |

| 7 | 62.29 | 7.41 | 29.85 | 99.55 |

| 8 | 62.28 | 1.10 | 36.15 | 99.53 |

| 9 | 64.02 | 4.99 | 30.16 | 99.17 |

| 10 | 64.80 | 0.87 | 32.11 | 98.78 |

| 11 | 53.27 | 12.04 | 34.46 | 99.77 |

| Sample ID | Quartz(%) | Magnetite (%) | Hematite (%) | ||||||

|---|---|---|---|---|---|---|---|---|---|

| True Value | Identified Value | Error | True Value | Identified Value | Error | True Value | Identified Value | Error | |

| 1 | 46.33 | 41.41 | 4.92 | 51.20 | 49.30 | 1.90 | 2.08 | 0.01 | 2.07 |

| 2 | 51.89 | 53.88 | 1.99 | 13.92 | 9.33 | 4.59 | 33.13 | 35.93 | 2.80 |

| 3 | 54.05 | 53.32 | 0.73 | 6.40 | 6.64 | 0.24 | 38.18 | 38.40 | 0.22 |

| 4 | 55.05 | 53.29 | 1.76 | 1.03 | 0.27 | 0.76 | 43.81 | 41.62 | 2.19 |

| 5 | 55.11 | 54.64 | 0.47 | 0.50 | 0.13 | 0.37 | 43.08 | 42.12 | 0.96 |

| 6 | 57.28 | 62.29 | 4.41 | 4.67 | 0.54 | 4.13 | 37.23 | 37.45 | 0.22 |

| 7 | 62.29 | 63.95 | 1.66 | 7.41 | 7.57 | 0.16 | 29.85 | 27.12 | 2.73 |

| 8 | 62.28 | 58.59 | 3.69 | 1.10 | 0.37 | 0.73 | 36.15 | 34.95 | 1.20 |

| 9 | 64.02 | 63.99 | 0.03 | 4.99 | 5.13 | 0.14 | 30.16 | 27.48 | 2.68 |

| 10 | 64.80 | 65.44 | 0.64 | 0.87 | 1.48 | 0.39 | 32.11 | 31.66 | 0.45 |

| 11 | 53.27 | 57.20 | 3.93 | 12.04 | 0.01 | 12.03 | 34.46 | 48.23 | 13.77 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yi, W.; Liu, S.; Ding, R.; Yue, H.; Wang, H.; Wang, J. Test Method for Mineral Spatial Distribution of BIF Ore by Imaging Spectrometer. Minerals 2024, 14, 959. https://doi.org/10.3390/min14090959

Yi W, Liu S, Ding R, Yue H, Wang H, Wang J. Test Method for Mineral Spatial Distribution of BIF Ore by Imaging Spectrometer. Minerals. 2024; 14(9):959. https://doi.org/10.3390/min14090959

Chicago/Turabian StyleYi, Wenhua, Shanjun Liu, Ruibo Ding, Heng Yue, Haoran Wang, and Jingli Wang. 2024. "Test Method for Mineral Spatial Distribution of BIF Ore by Imaging Spectrometer" Minerals 14, no. 9: 959. https://doi.org/10.3390/min14090959