Mechanism Analysis of Time-Dependent Characteristic of Dynamic Errors of Machine Tools

Abstract

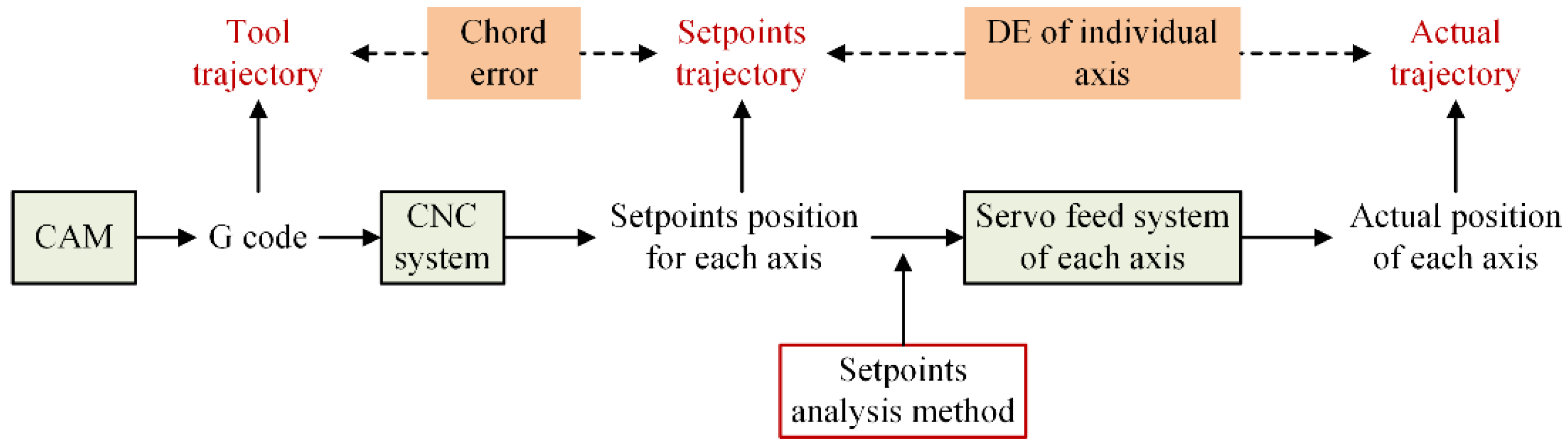

:1. Introduction

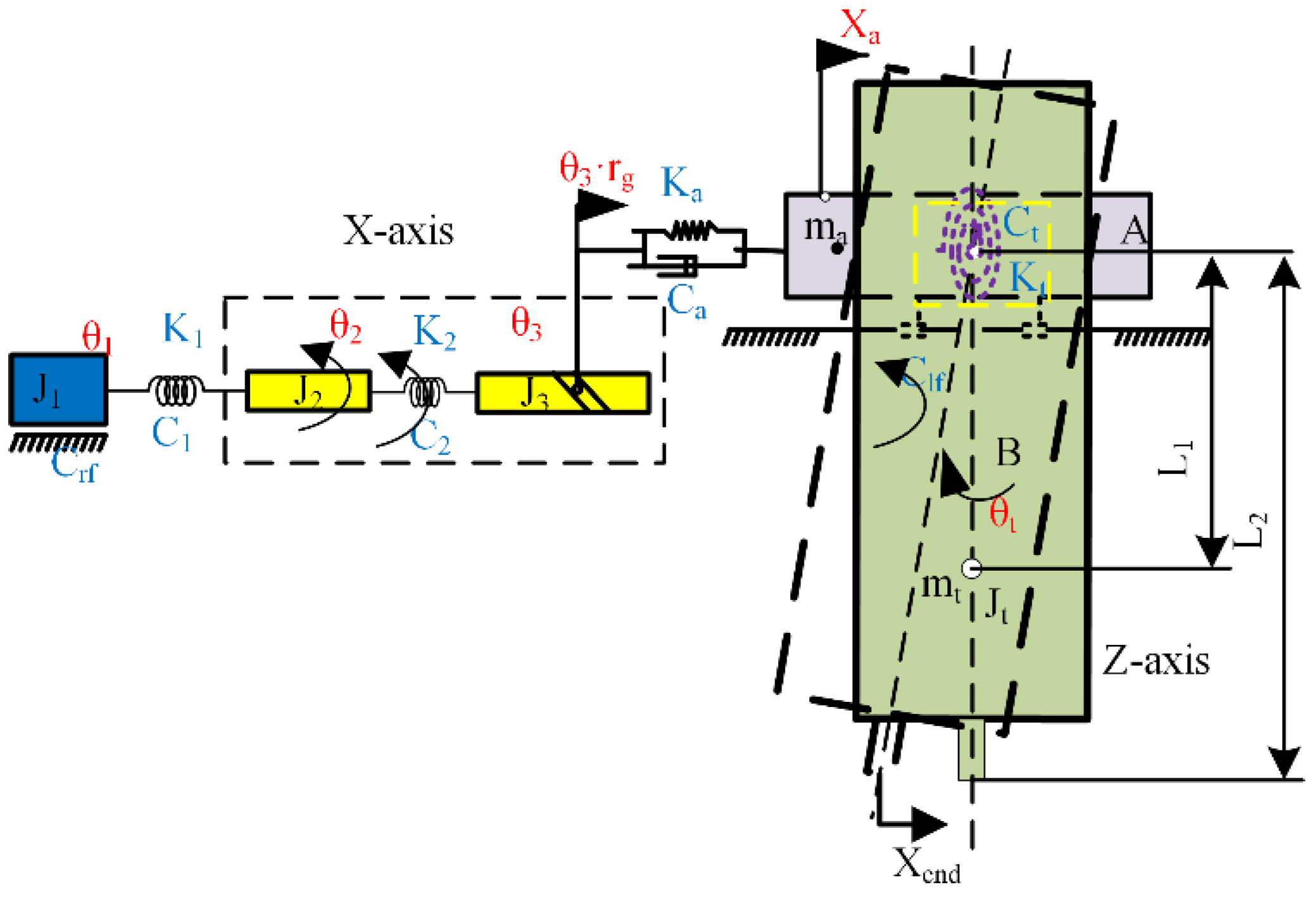

2. The DEs of an Individual Axis under To and Fro Motions

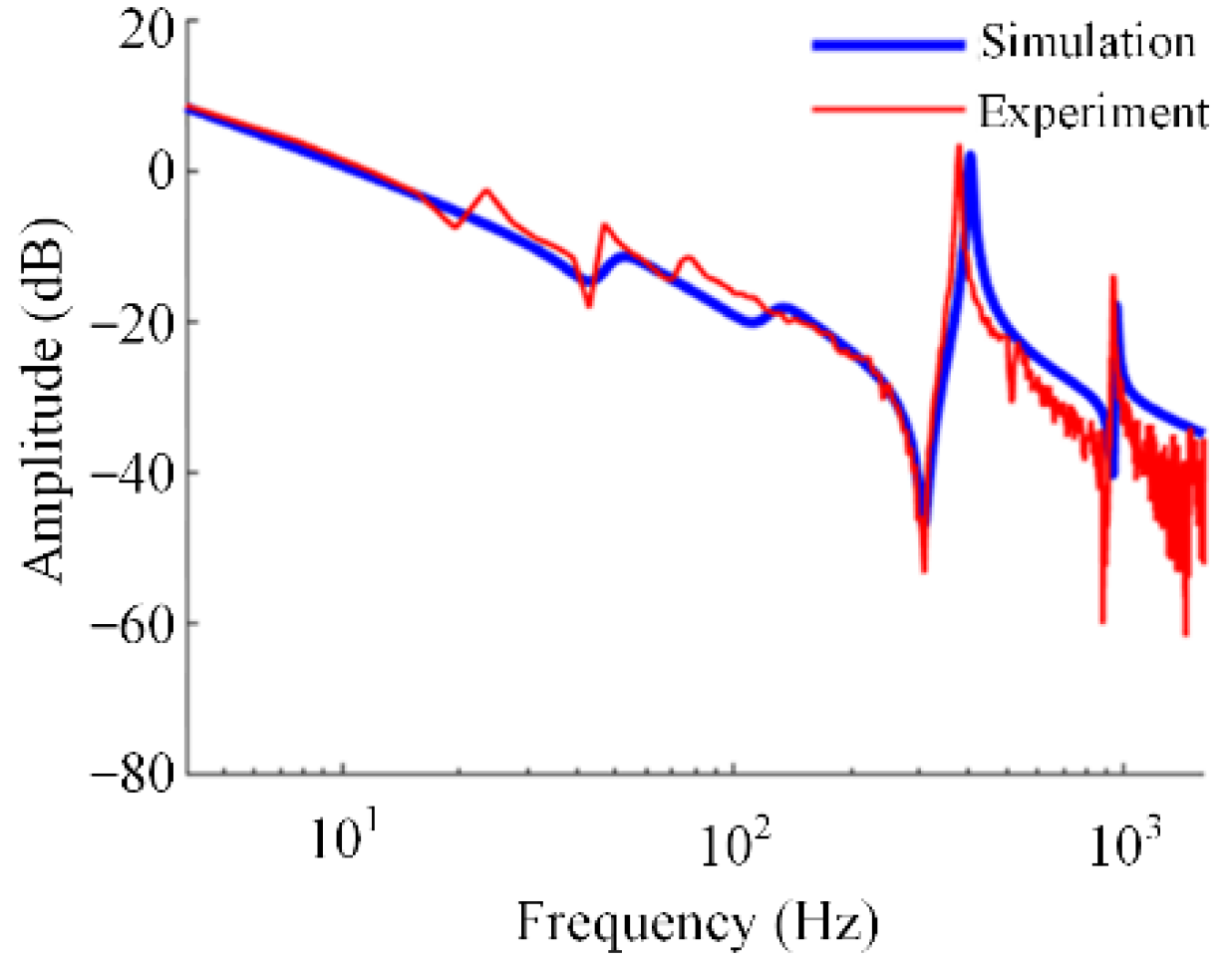

2.1. The Mechanical Dynamics and Servo Control Model of the Individual axis

2.2. The DEIS and DEOS

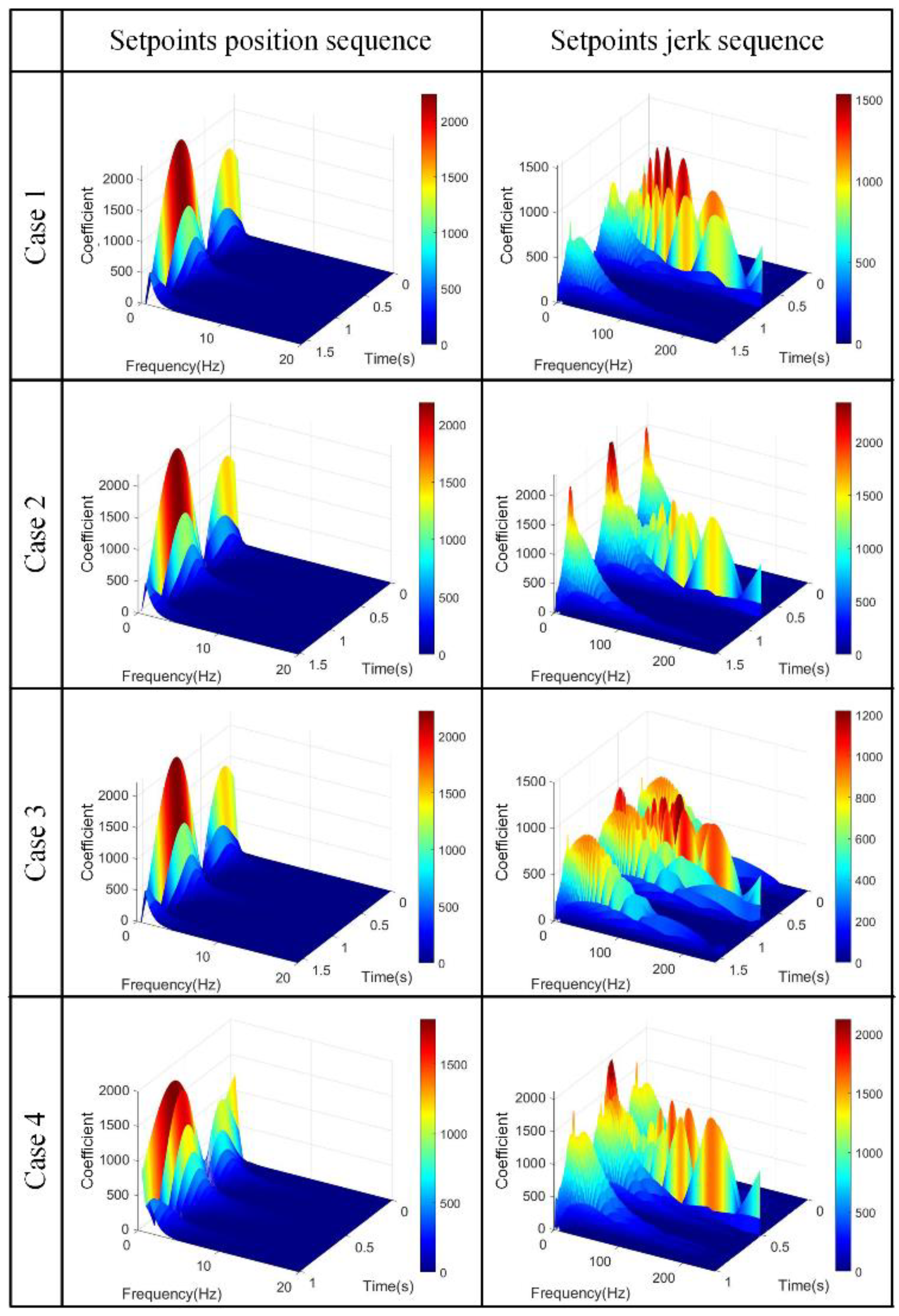

3. Setpoints Time–Frequency Analysis

3.1. Construction of the Setpoints Time–Frequency Diagrams

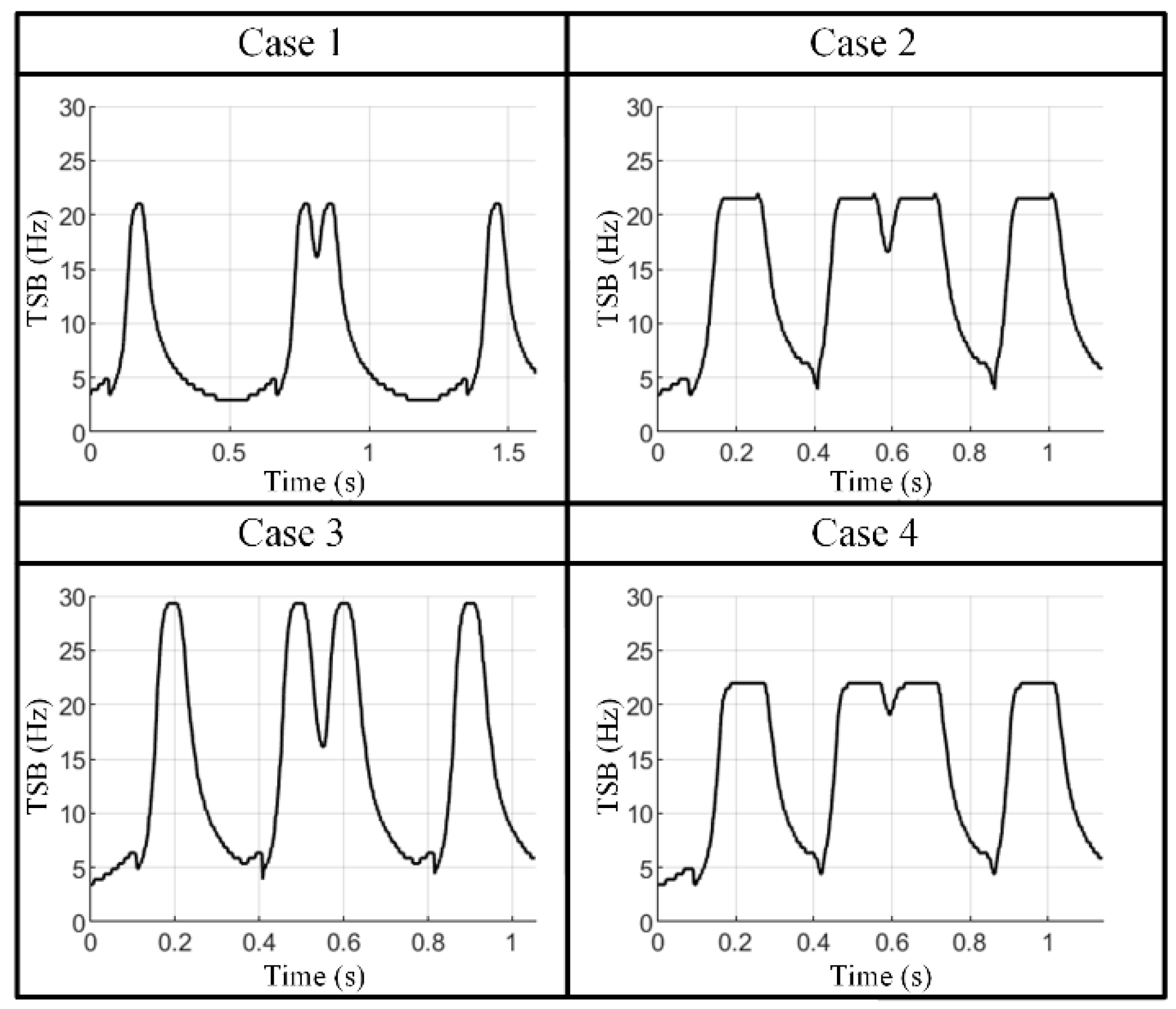

3.2. Extraction of Time-Dependent Setpoint Bandwidth (TDSB)

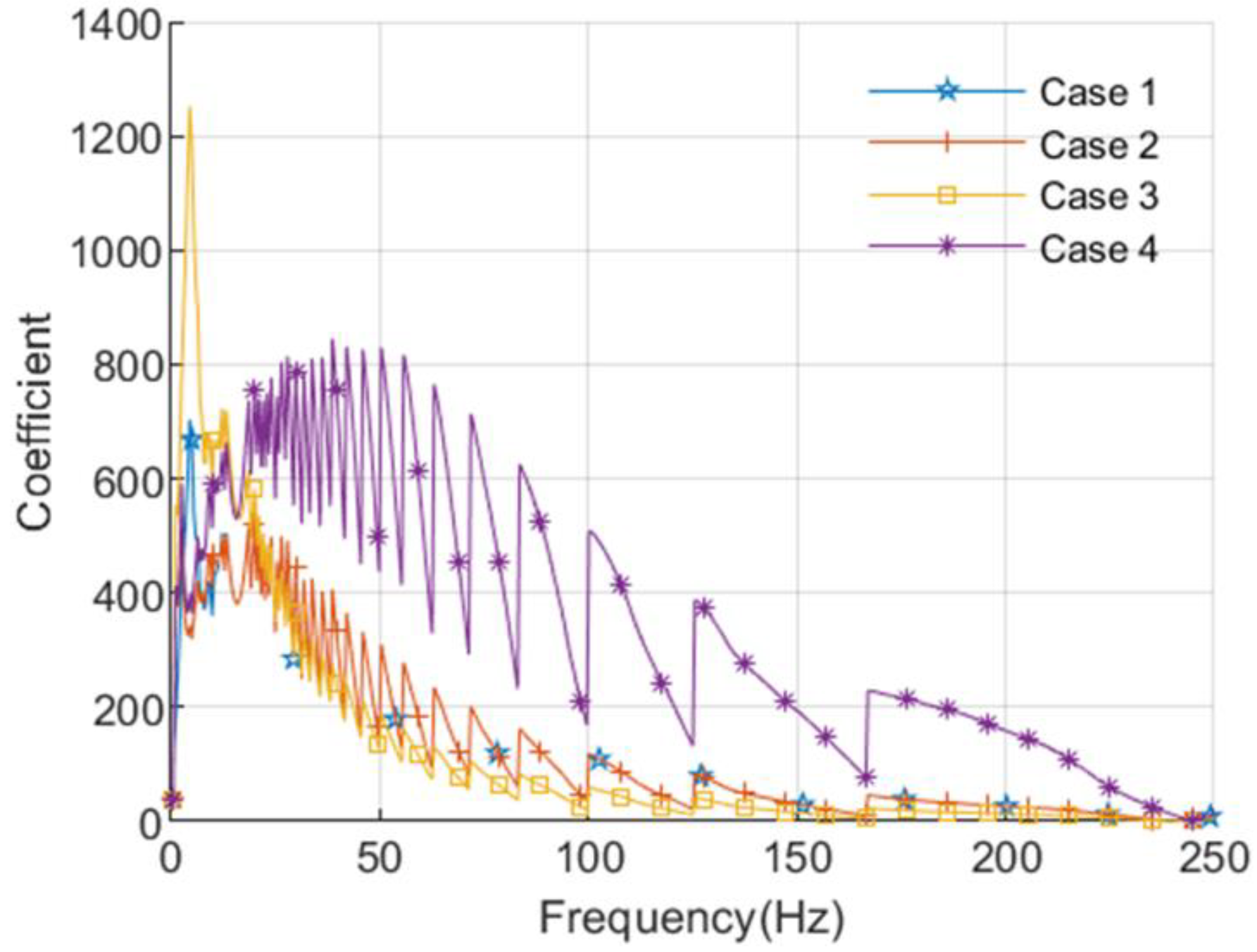

3.3. Extraction of Time-Dependent Potential Excitation (TDPE)

4. Mechanism Analysis

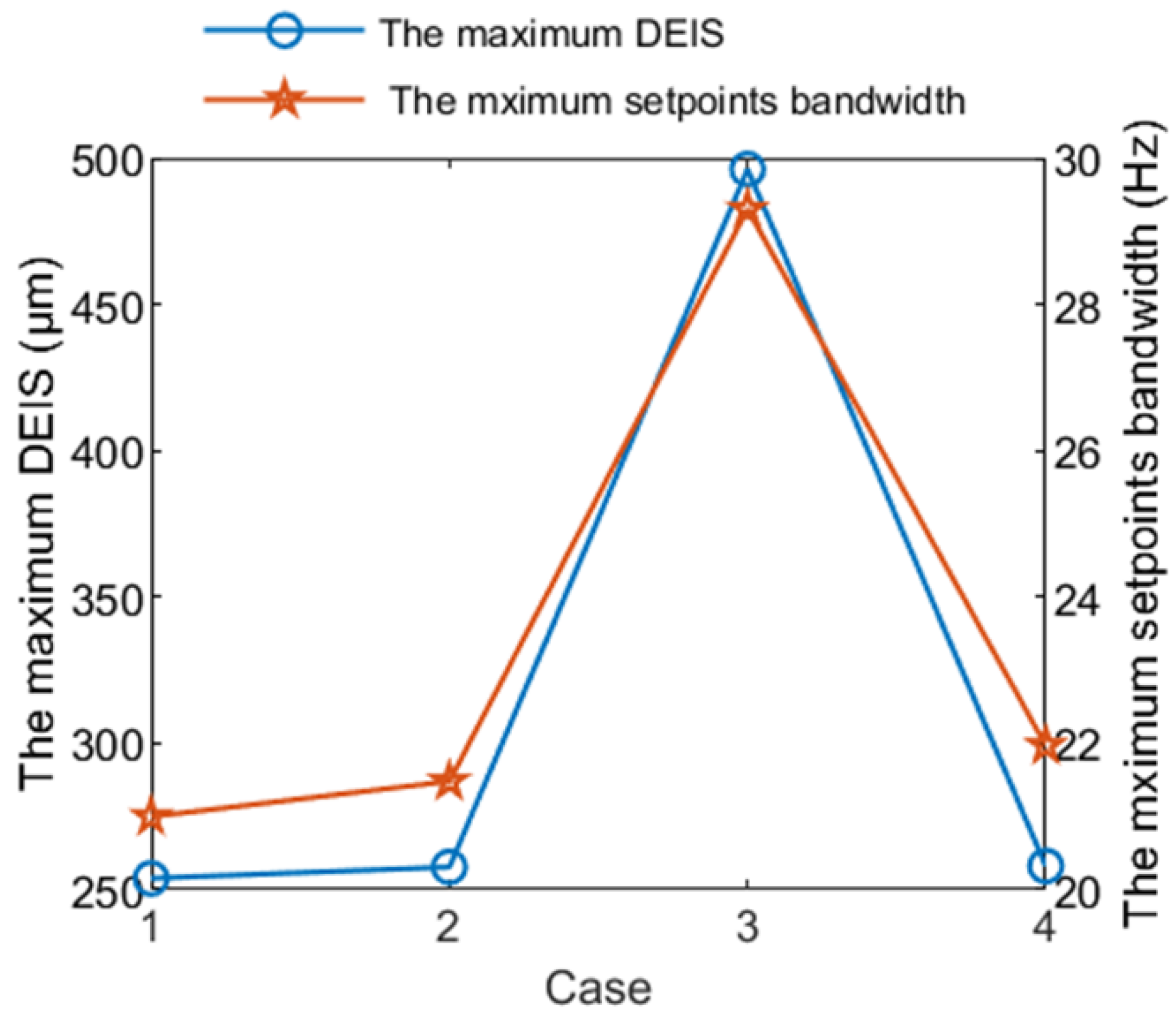

4.1. The Correlation between TDSBs and the DEIS

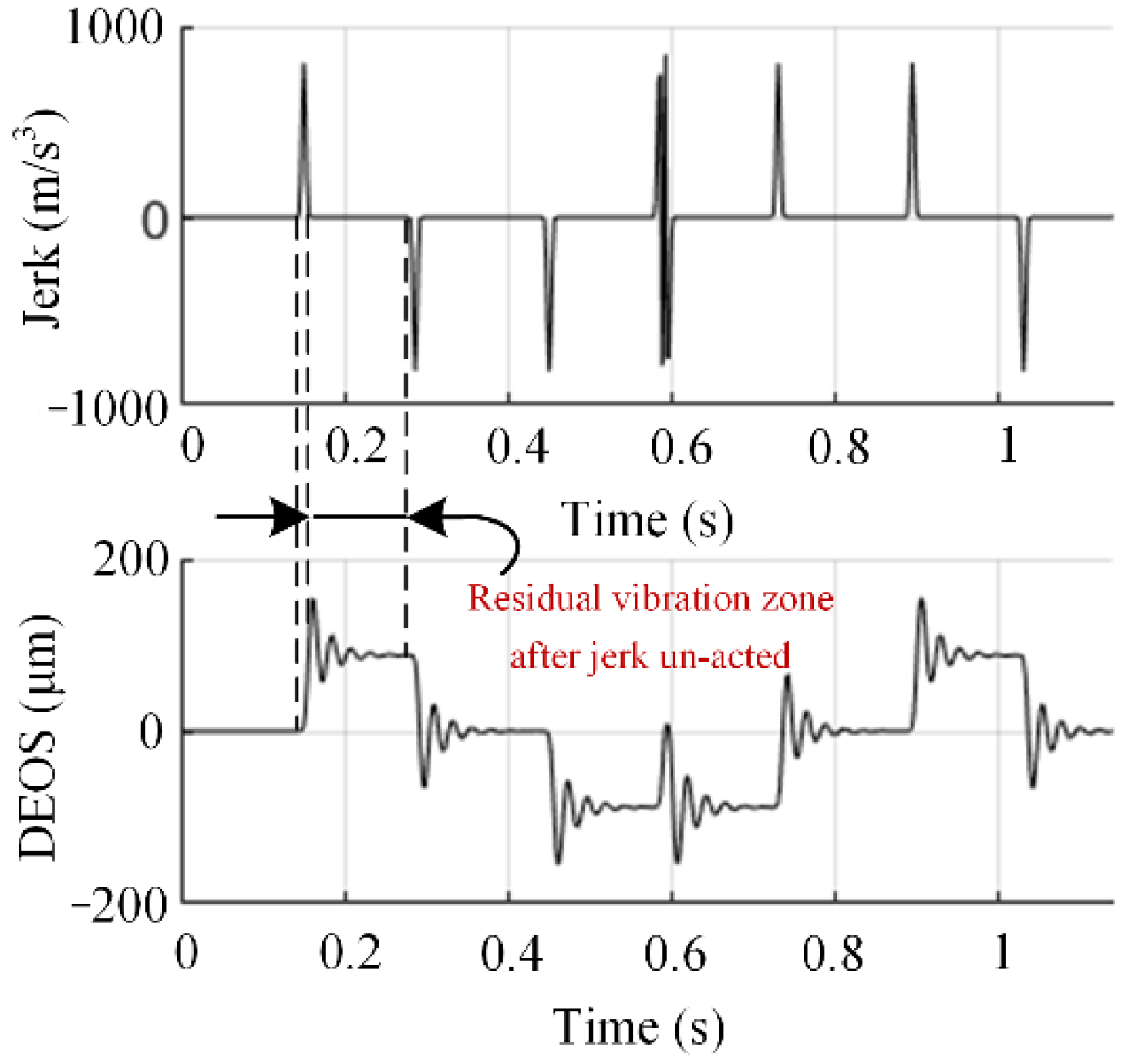

4.2. The Correlation between TDPEs and the DEOS

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Lyu, D.; Liu, Q.; Liu, H.; Zhao, W. Dynamic error of CNC machine tools: A state-of-the-art review. Int. J. Adv. Manuf. Technol. 2020, 106, 1869–1891. [Google Scholar] [CrossRef]

- Altintas, Y.; Verl, A.; Brecher, C.; Uriarte, L.; Pritschow, G. Machine tool feed drives. CIRP Ann. Manuf. Technol. 2011, 60, 779–796. [Google Scholar] [CrossRef]

- Huo, F.; Poo, A.-N. Precision contouring control of machine tools. Int. J. Adv. Manuf. Technol. 2013, 64, 319–333. [Google Scholar] [CrossRef]

- Tang, L.; Landers, R.G. Multiaxis Contour Control—the State of the Art. IEEE Trans. Control. Syst. Technol. 2013, 21, 1997–2010. [Google Scholar] [CrossRef]

- Uriarte, L.; Zatarain, M.; Axinte, D.; Yagüe-Fabra, J.; Ihlenfeldt, S.; Eguia, J.; Olarra, A. Machine tools for large parts. CIRP Ann. 2013, 62, 731–750. [Google Scholar] [CrossRef]

- Oomen, T. Advanced Motion Control for Precision Mechatronics: Control, Identification, and Learning of Complex Systems. IEEJ J. Ind. Appl. 2018, 7, 127–140. [Google Scholar] [CrossRef] [Green Version]

- Yuan, M.; Manzie, C.; Good, M.; Shames, I.; Gan, L.; Keynejad, F.; Robinette, T. A review of industrial tracking control algorithms. Control. Eng. Pract. 2020, 102, 104536. [Google Scholar] [CrossRef]

- Tajima, S.; Sencer, B. Global tool-path smoothing for CNC machine tools with uninterrupted acceleration. Int. J. Mach. Tools Manuf. 2017, 121, 81–95. [Google Scholar] [CrossRef]

- Jia, Z.-Y.; Song, D.-N.; Ma, J.-W.; Hu, G.-Q.; Su, W.-W. A NURBS interpolator with constant speed at feedrate-sensitive regions under drive and contour-error constraints. Int. J. Mach. Tools Manuf. 2017, 116, 1–17. [Google Scholar] [CrossRef]

- Erkorkmaz, K.; Chen, Q.-G.; Zhao, M.-Y.; Beudaert, X.; Gao, X.-S. Linear programming and windowing based feedrate optimization for spline toolpaths. CIRP Ann. 2017, 66, 393–396. [Google Scholar] [CrossRef]

- Wang, Y.S.; Yang, D.S.; Gai, R.L.; Wang, S.H.; Sun, S.J. Design of trigonometric velocity scheduling algorithm based on pre-interpolation and look-ahead interpolation. Int. J. Mach. Tools Manuf. 2015, 96, 94–105. [Google Scholar] [CrossRef]

- Tulsyan, S.; Altintas, Y. Local toolpath smoothing for five-axis machine tools. Int. J. Mach. Tools Manuf. 2015, 96, 15–26. [Google Scholar] [CrossRef]

- Sencer, B.; Ishizaki, K.; Shamoto, E. A curvature optimal sharp corner smoothing algorithm for high-speed feed motion generation of NC systems along linear tool paths. Int. J. Adv. Manuf. Technol. 2015, 76, 1977–1992. [Google Scholar] [CrossRef]

- Nam, S.-H.; Yang, M.-Y. A study on a generalized parametric interpolator with real-time jerk-limited acceleration. Comput. Aided Des. 2004, 36, 27–36. [Google Scholar] [CrossRef]

- Smith., D.A. Wide Bandwidth Control of High-Speed Milling Machine Feed Drives; University of Florida: Gainesville, FL, USA, 1999. [Google Scholar]

- Rotariu, I.; Ellenbroek, R.; Steinbuch, M. Time-Frequency Analysis of a Motion System with Learning Control. In Proceedings of the American Control Conference, Denver, CO, USA, 4–6 June 2003. [Google Scholar]

- Hennen, B.; Rotariu, I.; Steinbuch, M. Time-frequency analysis of position-dependent dynamics in a Motion System with ILC. In Proceedings of the American Control Conference, ACC ‘07, New York, NY, USA, 11–13 July 2007. [Google Scholar]

- Rotariu, I.; Steinbuch, M.; Ellenbroek, R. Adaptive iterative learning control for high precision motion systems. IEEE Trans. Control. Syst. Technol. 2008, 16, 1075–1082. [Google Scholar] [CrossRef]

- Alkafafi, L. Time and Frequency Optimal Motion Control of CNC Machine Tools; Technische Universität Hamburg: Hamburg, Germany, 2013. [Google Scholar]

- GNC62. Available online: https://www.dlkede.com/plus/view.php?aid=11 (accessed on 13 January 2022).

- Erkorkmaz, K.; Kamalzadeh, A. Compensation of axial vibrations in ball screw drives. CIRP Ann. Manuf. Technol. 2007, 56, 373–378. [Google Scholar]

- Okwudire, C.; Altintas, Y. Minimum tracking error control of flexible ball screw drives using a discrete-time sliding mode controller. ASME Trans. J. Dyn. Syst. Meas. Control. 2009, 131, 051006. [Google Scholar] [CrossRef]

- Sun, Z.; Zahn, P.; Verl, A.; Lechler, A. A new control principle to increase the bandwidth of feed drives with large inertia ratio. Int. J. Adv. Manuf. Technol. 2017, 91, 1747–1752. [Google Scholar] [CrossRef]

- Sencer, B.; Dumanli, A. Optimal control of flexible drives with load side feedback. CIRP Ann. Manuf. Technol. 2017, 66, 357–360. [Google Scholar] [CrossRef]

- Liu, H.; Zhang, J.; Zhao, W. An Intelligent Non-Collocated Control Strategy for Ball-Screw Feed Drives with Dynamic Variations. Engineering 2017, 3, 641–647. [Google Scholar] [CrossRef]

- Erkorkmaz, K.; Kamalzadeh, A. High bandwidth control of ball screw drives. CIRP Ann. Manuf. Technol. 2006, 55, 393–398. [Google Scholar] [CrossRef]

- Bringmann, B.; Maglie, P. A method for direct evaluation of the dynamic 3D path accuracy of NC machine tools. CIRP Ann. Manuf. Technol. 2009, 58, 343–346. [Google Scholar] [CrossRef]

- Knapp, W.; Weikert, S. Testing the Contouring Performance in 6 Degrees of Freedom. Ann. CIRP 1999, 48, 433–436. [Google Scholar] [CrossRef]

- Matsubara, A.; Nagaoka, K.; Fujita, T. Model-reference feedforward controller design for high-accuracy contouring control of machine tool axes. CIRP Ann. 2011, 60, 415–418. [Google Scholar] [CrossRef]

- Denkena, B.; Overmeyer, L.; Litwinski, K.M.; Peters, R. Compensation of geometrical deviations via model based-observers. Int. J. Adv. Manuf. Technol. 2014, 73, 989–998. [Google Scholar] [CrossRef]

- Steinlin, M.; Weikert, S.; Wegener, K. Open loop inertial cross-talk compensation based on measurement data. In Proceedings of the 25th Annual Meeting of the American Society for Precision Engineering, ASPE 2010, Atlanta, GA, USA, 31 October–4 November 2010; pp. 101–104. [Google Scholar]

- Ansoategui, I.; Campa, F.J.; López, C.; Díez, M. Influence of the machine tool compliance on the dynamic performance of the servo drives. Int. J. Adv. Manuf. Technol. 2017, 90, 2849–2861. [Google Scholar] [CrossRef]

- Dong, J.; Ferreira, P.M.; Stori, J.A. Feed-rate optimization with jerk constraints for generating minimum-time trajectories. Int. J. Mach. Tools Manuf. 2007, 47, 1941–1955. [Google Scholar] [CrossRef]

- Erkorkmaz, K.; Altintas, Y. High speed CNC system design. Part I: Jerk limited trajectory generation and quintic spline interpolation. Int. J. Mach. Tools Manuf. 2001, 41, 1323–1345. [Google Scholar] [CrossRef]

- Barre, P.-J.; Bearee, R.; Borne, P.; Dumetz, E. Influence of a Jerk Controlled Movement Law on the Vibratory Behaviour of High-Dynamics Systems. J. Intell. Robot. Syst. 2005, 42, 275–293. [Google Scholar] [CrossRef]

| Case | The Max. Velocity (mm/min) | The Max. Acceleration (g) | The Max. Acceleration Establishment Time (ms) | The Jerk at the First Peak (m/s3) |

|---|---|---|---|---|

| 1 | 20,000 | 0.5 | 20 | 432.8 |

| 2 | 40,000 | 0.5 | 20 | 432.8 |

| 3 | 40,000 | 1.0 | 40 | 461.4 |

| 4 | 40,000 | 0.5 | 10 | 820.8 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lyu, D.; Zhao, Y.; Song, Y.; Liu, H.; Wang, D. Mechanism Analysis of Time-Dependent Characteristic of Dynamic Errors of Machine Tools. Machines 2022, 10, 160. https://doi.org/10.3390/machines10020160

Lyu D, Zhao Y, Song Y, Liu H, Wang D. Mechanism Analysis of Time-Dependent Characteristic of Dynamic Errors of Machine Tools. Machines. 2022; 10(2):160. https://doi.org/10.3390/machines10020160

Chicago/Turabian StyleLyu, Dun, Yanchao Zhao, Yanhong Song, Hui Liu, and Dawei Wang. 2022. "Mechanism Analysis of Time-Dependent Characteristic of Dynamic Errors of Machine Tools" Machines 10, no. 2: 160. https://doi.org/10.3390/machines10020160

APA StyleLyu, D., Zhao, Y., Song, Y., Liu, H., & Wang, D. (2022). Mechanism Analysis of Time-Dependent Characteristic of Dynamic Errors of Machine Tools. Machines, 10(2), 160. https://doi.org/10.3390/machines10020160