2. Materials and Methods

Recently, a new computational tool has been developed for simulating of the tribological interface between a brake pad and disc. The Abstract Cellular Automaton is based upon the same physical principles as the aforementioned cellular automata, but models the patches in a new way, and is structured differently from a programming perspective. This development was motivated by the facts that the individual tangential motion of patches can be essential to the NVH behavior of the entire pad [

12], and that the contour of the patches was not essential at any stage in the realization of the grid-based automaton. It follows that each patch can be modeled for simplicity as a rigid disc of constant thickness on an elastic matrix. The size dynamics of the patches require a locally-resolved wear particle flow, which is realized in the grid-based automata by local balance equations taking into account the friction properties and the patch coverage state of the brake pad. To integrate the principles of N-body simulations and classic grid-based cellular automata, we introduce an automaton with generalized neighborhood properties, where each patch is one cell. The result is a simulation software that produces global results comparable to those attained using the classic grid-based cellular automata simulations [

13]. Through its innovative structure and use of simplified algorithms, the Abstract Cellular Automaton implements the insights gained through the development and use of the classical grid-based cellular automata, while offering significant computational advantages compared to these predecessors and computing solutions of the entire pad-disc contact under realistic normal load distributions.

This work presents several functions and algorithms implemented in the Abstract Cellular Automaton. Many setting parameters are introduced, whose values are selected based on the results of complex validation simulations carried out on the Abstract Cellular Automaton as well as on classic grid-based automata, not all of which are shown in this work. These parameters () are defined and described within the body of this work and in the list of nomenclature. As the structures of the friction boundary layer (i.e., patch dynamics) in high-load contacts such as automotive brakes are a stable tribological effect, these parameters can be adjusted without significantly influencing the simulated phenomena. The used values aid in the fine-tuning of the simulation program to improve the performance for simulating semi-met brake pads. Another set of values would be implemented to simulate NAO brake pads, which differ from semi-met pads based on differing statistical parameters, not due to differing tribological mechanisms.

The Abstract Cellular Automaton was first documented in Ref. [

13], where its functionality was validated based on comparison studies with the grid-based cellular automata. It is a simulation tool developed with the intention of modeling the dynamic signature of the coefficient of friction at the tribological interface of an automotive braking system based on the theories of patch dynamics. The emergent simulated friction characteristics that come about through considerations of the patch dynamics can offer insights into true physical systems. In comparison to its predecessors (described above), the Abstract Cellular Automaton employs a reduction of fundamental physical parameters in the model. It strives to aid in the understanding of the dynamic processes relating to patch growth, birth, and collapse, as they interact with the fundamental tribological phenomena of the system. As the Abstract Cellular Automaton is capable of rapidly simulating the tribological interface between an entire brake pad and disc, up to 100,000 patches can be simulated simultaneously. Knowledge and insights gained through the development and implementation of the classic grid-based cellular automata were used towards the development of the Abstract Cellular Automaton. For example, the highly-detailed patch shape and location information attained using the grid-based cellular automata does not have a significant influence on the global macroscopic results. The Abstract Cellular Automaton therefore generalizes this type of information, simplifying computations without significant trade-offs in accuracy within its scope. The highly detailed, explicit simulations of the grid-based cellular automata are used towards the validation of the elementary processes of the Abstract Cellular Automaton.

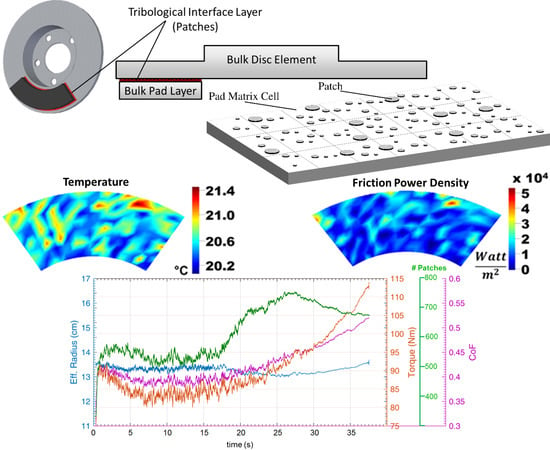

The benefits introduced by the Abstract Cellular Automaton come from its underlying structure. The task of analyzing the entire brake pad is carried out in two separate layers, as outlined

Figure 3.

As the tribological interface between the pad and the disc has the most substantial influence on the friction behavior of the system, the computational effort is focused on this layer, which is modeled through an analysis of the contact patches in the interface. These computations are carried out using an approach similar to that of N-body simulations. A linked list containing pointers to all of the patches is implemented. At each time step, a series of functions are carried out at each individual patch. Here, the physics within the individual patches are computed, along with the following interactions: patch-pad (interaction between patches and the bulk matrix material of the brake pad; for example, thermal conduction), patch-disc (for example, friction), and patch-patch (interactions between neighboring patches). An example of a patch-patch interaction is the tangential elastic coupling between patches, which will be discussed below.

The bulk matrix material of the brake pad (pad matrix) is also considered in the analysis, albeit in a less detailed manner than the individual patches. For this portion of the simulation, it is assumed to be sufficient to consider the pad matrix in the form of a coarsely discretized grid. This is implemented using a classical grid-based cellular automaton approach, negligibly increasing the computational effort due to the relatively low number of pad matrix cells compared to the number of patch cells. The discretization size is chosen such that all relevant computations are numerically stable, and may be adjusted if higher resolution results are needed. Such adjustments do not affect the simulated tribological dynamics or mechanisms, although small numerical influences follow.

Figure 4 provides a general impression of how the linked list of patches is superimposed on the pad matrix.

In the pad matrix layer, the physics within each cell are computed, along with the following interactions: cell–disc (for example, friction between the pad matrix and the disc), cell-environment, and cell–cell (interactions between neighboring cells of the pad matrix). These interactions primarily concern heat transfer phenomena. The brake disc is currently modeled as a single, homogeneous element. The various interactions between the main simulation components are summarized in

Figure 5.

The prioritization of computational effort into the tribological interface, combined with the modeling techniques implemented, enable simulations to be run much faster than both common FEM studies and simulations from the classical cellular automaton programs.

Towards simulating friction in the tribological interface, the Abstract Cellular Automaton is capable of flexible implementation of various types of friction rules. For simple investigations, the assumption of constant Coulomb friction is a reasonable approximation. Here, a constant coefficient of friction is assigned to the contact between each patch and the disc. The contact between the pad matrix and the disc is generally assigned a lower friction value.

For more in-depth investigations, in which, for example, the patches are modeled as individual self-excited oscillators, it is reasonable to approximate friction as a function with a negative gradient with respect to the sliding speed. Further investigations require, for example, temperature-dependent friction states [

14].

The local friction coefficient can also be iteratively improved through the evaluation of the global coefficient of friction, by implementing the global result from one iteration as the local coefficient of friction in the following iteration, and so on. This will be presented in a future work. The use of the dynamic friction rules from Ref. [

8] is quite similar to such an optimization of the local friction formulation. Furthermore, different types of patches can be assigned different friction behavior characteristics based on, for example, the conditions under which the patches were formed. Between braking applications, the surfaces of the pad and disc can undergo oxidation effects. The influence of this on the friction behavior of the system is also implemented in the Abstract Cellular Automaton. Here, the difference between coated and non-coated patches is considered. The non-coated patches possess temporary friction characteristics, which can be modeled as the effects of self-locking of the wear particles.

The initial studies and tests performed using the Abstract Cellular Automaton, however, seek to implement relatively simple friction rules. As hundreds or thousands of patches (each exhibiting a simple friction behavior) undergo birth, growth, and collapse processes, interacting with one another and their surroundings, a global friction behavior of the system emerges that can be much more complex than the friction rules themselves.

The global coefficient of friction of the system is calculated as shown in Equation (1):

where

is the total number of patches in the system,

is the number of pad matrix cells,

is the friction force,

is the normal force,

is the coefficient of friction, and

and

are placeholders for iterating over the patches and matrix cells, respectively. Each of the individual friction forces are determined based on the individual normal force and friction rule on the given element.

The kinetic energy dissipated through friction and the associated friction power is primarily converted into heat. The resulting increase in temperature and further thermal effects are computed based on the methods described in Ref. [

14]. For further information on this, see the literature cited there. In this abstract automaton, the following effects are considered: heat generation due to friction, conduction between patches and their foundation pad cells, conduction between patches and the disc, conduction between the pad and the disc, conduction within the brake pad (between pad cells), and cooling from the environment through convection and radiation.

As a simple friction law is often chosen, the global dynamics of the coefficient of friction largely result from the patch dynamics, or the cumulative effects of the simultaneous creation, growth, and collapse of hundreds or thousands of patches in the tribological interface. When constant friction coefficients are assumed for the patches and for the pad matrix, the global coefficient of friction is primarily influenced by the ratio of total patch surface area to the total pad area in the system. This can be expressed as shown in Equation (2).

where an increase in the total patch surface area is associated with a positive time derivative of the coefficient of friction [

8]. This coincides with the assumption that the coefficient of friction between the patches and the disc is greater than the friction coefficient between the pad matrix and the disc.

Figure 6,

Figure 7 and

Figure 8 show precisely how these dependencies affect the creation, growth, and destruction of patches, respectively. The patch birth algorithm is carried out once per simulation time step. The patch growth and collapse algorithms are each carried out once per patch per time step.

As shown in

Figure 6, the only conditions required for patch birth to take place are that the disc and pad need to be in contact, and that a sufficient volume of wear particles

is present in the tribological interface to create the respective patches. For simplicity, a single representative patch volume is considered toward determining if the latter condition is satisfied. It is taken into account that the patch density is greater than that of the pad material density (and likewise that of the wear particles). The parameter

is comprised of a pseudorandom component with a uniform distribution and deterministic components based on the brake pad material (NAO, low-met) and the simulation time step. For

, it can range between 0 and 84. The symbol

represents the function floor (

x), which returns the greatest integer less than or equal to

.

Once a patch already exists in the Abstract Cellular Automaton, it has the potential to increase in surface (and thereby contact) area. The algorithm employed is made explicit in

Figure 7. First, the magnitude of the increase in patch area

is determined. The square root of the current patch area is used as a factor in this step because new wear particles collect along the perimeter of the patch. The magnitude of patch growth is therefore directly proportional to the size of this perimeter. This value is then scaled according to reference values for the normal force and pad area. If the resulting value is nonzero, the patch is in contact with the disc, and sufficient wear particles are present to form the extra patch mass, growth can theoretically occur. If the patch is a “soft” or “white” patch, meaning that it consists of self-locked wear particles that have undergone no chemical change [

15], the conditions for patch growth are already fulfilled and growth occurs. If it is a “hard” or “black” patch, meaning it is coated with an oxide layer, an additional minimum temperature condition must also be fulfilled for growth to occur. When a patch grows, the amount of wear particles needed to create the additional patch mass are removed from the tribological boundary layer.

As seen in

Figure 7, the amount of area added on to a patch during growth is proportional to the average relative velocity between the patch and the disc, the time step, the square root of the patch’s surface area, and the normal force. This quantity is weighted with a constant factor to guarantee a realistic order of magnitude. The expression

represents updating the variable

through compound assignment as follows:

. An analogous compound assignment operation for addition (

) is referred to below.

By definition, “soft” patches are destroyed as soon as they are released from the brake disc and the self-locking mechanism is thus no longer in place. Regardless of patch type, other collapse mechanisms may occur. A patch collapses, for example, if its age exceeds its individual, non-constant lifetime factor (dependent on its load history), or if its size exceeds a fixed, global size limit (). Otherwise, a patch can also collapse as a result of various other effects, which in the Abstract Cellular Automaton are summarized in the form of a random variable . This value is scaled to the simulation time step, aiding the robustness of these simulations to the adjustment of . The term refers to a command that returns a pseudorandom integer within . When a patch collapses, it returns to the friction boundary layer in the form of free wear particles.

As seen in

Figure 6 and

Figure 7, the creation and growth of patches depend on the amount of wear particles present in the tribological interface. The wear of the brake pad is computed based on the Archard wear equation. The loss of wear particles to the environment is assumed to occur at the rate defined in Equation (3):

where

is the total volume of wear particles in the tribological interface,

is the simulation time step,

is the average sliding speed between the pad and the disc,

is the average width of the brake pad, and

is a constant model parameter. Based on the authors’ experience,

is assumed; the motion of the disc along the full width of the brake pad therefore results in a 25% loss of wear particles to the environment.

“In-stop” braking procedures can also be simulated using the Abstract Cellular Automaton. Early simulations implement this under the assumption that all eight pad-disc interfaces of the automobile undergo identical conditions and exhibit identical responses [

16].

A fundamental aspect of the Abstract Cellular Automaton’s functionality is the calculation of the normal force distribution on the patches and pad matrix. This problem is coupled with the computation of the deformation of the patches and bulk pad material. To attain this information, various potential system models can be implemented.

In early versions of the classical grid-based cellular automata, broad approximations were used to calculate the normal force on the patches and pad matrix cells focused on developing models based on the local discretization of a continuous half-space [

7]. This resulted in rather precise results for the normal force and deformations of all cells in the cellular automata, but was associated with significant computational costs. Therefore, instead of a half-space, a Winkler dynamic bedding modulus is assumed, which is achieved without unacceptable accuracy losses. This model is illustrated in

Figure 9. For the computation of the normal force distribution, the materials of the patches and pad matrix are considered separately. Here, each matrix cell is represented by an individual spring, and each patch cell is modeled as a second spring, serially connected to the corresponding matrix cell. Known material parameters are implemented for modeling the spring stiffnesses of the pad matrix. The patches are generally considered to be significantly denser and harder than the pad matrix, and are therefore modeled with comparably high spring stiffnesses. Such a model allows for the simple implementation of patches of varying height.

In the Abstract Cellular Automaton, each patch is represented by a single spring, so it necessarily experiences a uniform normal force distribution and deformation. This is a closer representation of the notion that a patch is a hard, flat, surface structure. The implementation of this model is schematically represented

Figure 9d.

It is evident in this figure that the Abstract Cellular Automaton offers an advanced class of simplicity, improving performance without sacrificing informational value. Here, it is important to note that the pad matrix element is not directly coupled to the springs of the patches. The pad matrix spring element is first engaged when the deformation of the patches is sufficient for the disc to contact the pad matrix.

While all patches are modeled in the Abstract Cellular Automaton as having the same thickness, or depth

, contributing to their volume and lumped mass, they have varying unloaded spring lengths, or heights

, as seen in

Figure 10a. Thus, the surface roughness of the brake pad material is accounted for.

On a real brake pad, the tangential motion of one patch

(along the direction of the disc’s motion) is related to the deformation of the pad material near that patch. The motion of a neighboring patch

is coupled to the motion of

through this deformation. In the Abstract Cellular Automaton, this coupling is accounted for using a lumped element model based on Ref. [

12], as shown in

Figure 10b. Here, the coupled vibrations of patches in the friction boundary layer are simulated under the assumption that the patches act as coupled stick–slip oscillators. The tangential coupling of an individual patch to the matrix of the brake pad is simplified through a single, linear spring.

The spring stiffnesses, represented by

, are chosen for simplicity based on results from an FEM study on deformations of flat cylindrical structures on the face of a quasi-half-space, as shown in

Figure 11.

Here, the spring stiffnesses of an individual patch, , in the normal (, into the pad material) and tangential (, the sliding direction of the disc) directions are shown as functions of the patch’s surface area, .

Figure 11 shows that the stiffnesses of the patches in both the normal and tangential directions can be closely approximated as proportional to the square root of the patch’s area. The resulting functions used are given in Equations (4) and (5):

with the constants

and

. The tangential stiffness coupling two neighboring patches

and

is assumed to be described by:

This relationship ensures that the elastic coupling of the patches is approximately proportional to the reciprocal of their initial distance from one another,

, as described in Ref. [

17]. The relationship shown in Equation (6) and the value for the constant

were chosen based on results of FEM parameter studies. This relationship is only considered for any two given circular patches with a maximum distance of

from one another. The elastic coupling between patches greater than this distance is neglected. There is no explicit limit for the number of neighboring patches that can be elastically coupled with any given patch.

Although not shown in

Figure 10, calculations of friction-induced vibrations are carried out considering the elastic connection of patches with several of their neighbors (for example, the spring connecting patches

and

). Naturally, the patches are elastically coupled to one another along a two-dimensional elastic grid, although displacements and forces perpendicular to the motion of the disc (in the radial direction) are neglected. For simplicity, the vertical elastic coupling of the patches with one another is also neglected. The brake disc imposes a kinematic constraint, however, directly coupling the vertical position of all patches that make contact with the disc (i.e., all patches with a nonzero normal force which contribute to the friction behavior of the system).

The positions of each patch cell within the linked list is arbitrary with regard to its location on the surface of the pad. For some physical analyses, it is beneficial to rapidly analyze the interaction of a patch with several of its closest neighboring patches. This is important, for example, in high-frequency analyses of the friction-induced vibrations of the patches (discussed below). In order to systematically implement the elastic coupling of the patches, each patch is fitted with an array of pointers to its neighboring patches. This is carried out based on a predefined maximum distance between patches. The elastic coupling between two patches and is neglected if the two patches are further apart than a defined maximum distance . The implementation and investigation of the associated phenomena will be discussed in another work, which will focus on simulations of the high-frequency vibrations of patches.