Effect of Overaging on the Cyclic Deformation Behavior of an AA6061 Aluminum Alloy

Abstract

:1. Introduction

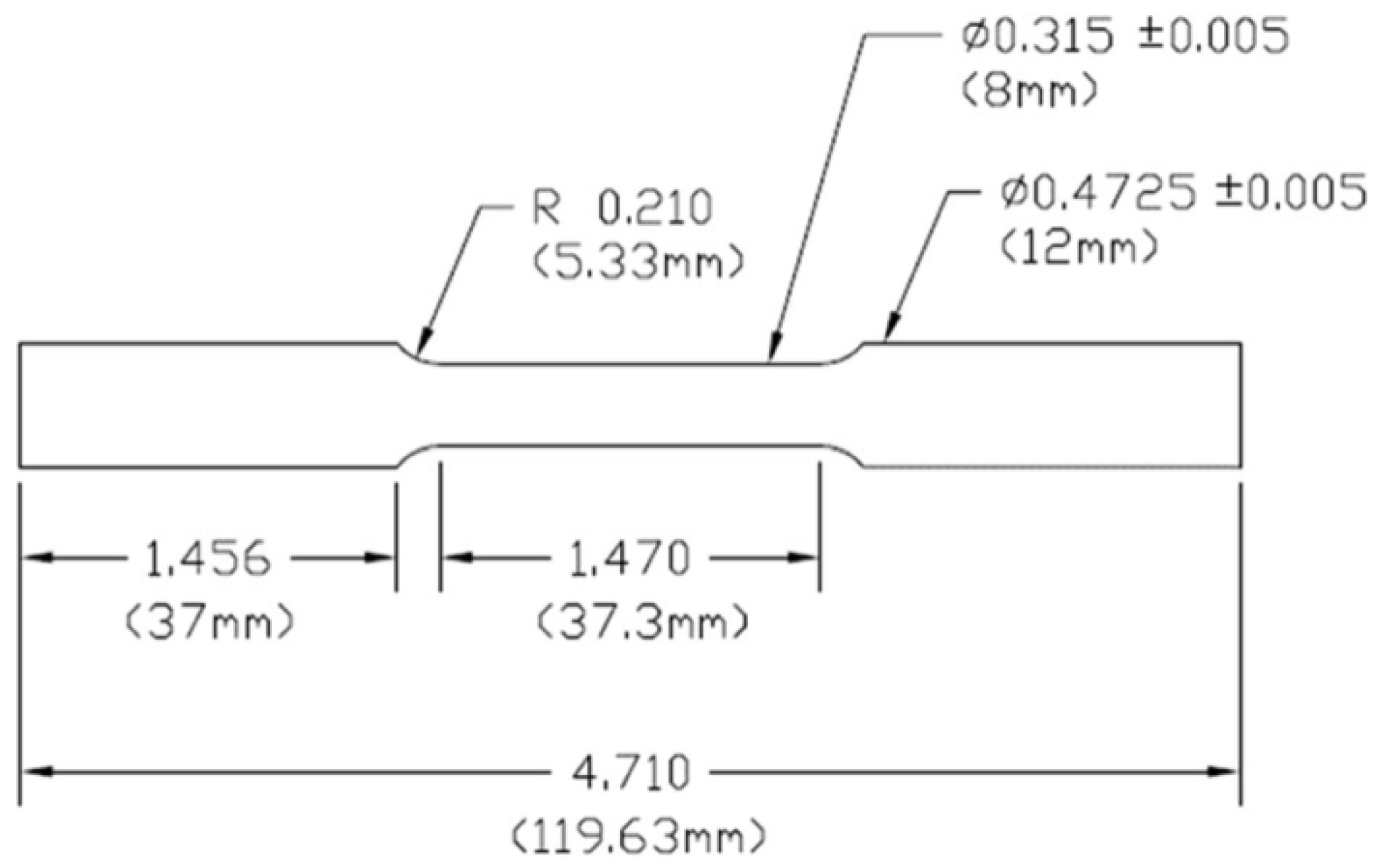

2. Materials and Experimental Procedure

3. Results and Discussion

3.1. Microstructure Evolution During Aging Treatment

3.2. Monotonic Tensile Properties under Various Aging Conditions

3.3. LCF Fatigue Behavior under Various Aging Conditions

3.3.1. Hysteresis Loops

3.3.2. Cyclic Stress and Strain Responses

3.3.3. Fatigue Life and Fatigue Fracture

3.3.4. Assessment of Fatigue Parameters

4. Conclusions

- (1)

- During the T7 aging treatment at 200 °C, no remarkable changes in the microstructure (Al-Fe-Si and Mg2Si intermetallics, and α-Al grain size) could be observed with increasing aging time. However, the size of precipitates increased from 60 nm under the T6 conditions to 220 nm after aging 48 h at 200 °C, leading to a decrease in the monotonic tensile strength.

- (2)

- The hysteresis loops of the first cycle after a long T7 aging time were moderately inflected compared to those under the T6 conditions, whereas nearly symmetrical loops were present during the mid-life cycle under all conditions tested. The peak stresses decreased and the plastic strain increased with increasing T7 aging time. Nearly ideal Masing behavior was exhibited under the T6 conditions, whereas it was lost under the overaging conditions.

- (3)

- Similar cyclic stress responses were found under all tested conditions: cyclic stabilization was present at low strain amplitudes (0.2–0.4%), whereas cyclic softening with initial hardening during the first few cycles occurred at middle-to-high strain amplitudes (0.6–1.2%). The softening rate increased gradually with increasing T7 aging time.

- (4)

- Compared to the T6 conditions, the fatigue life increased with increasing T7 aging time. The estimated fatigue parameters indicated that the fatigue ductility coefficient increased and the fatigue strength coefficient decreased with increasing T7 aging time.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Brammer, A.T.; Jordo, J.B.; Allison, P.G.; Barkey, M.E. Strain-controlled low-cycle fatigue properties of extruded 6061-T6 aluminum alloy. J. Mater. Eng. Perform. 2013, 22, 1348–1350. [Google Scholar] [CrossRef]

- Abood, A.N.; Saleh, A.H.; Abdullah, Z.W. Effect of heat treatment on strain life of aluminum alloy AA6061. J. Mater. Sci. Res. 2013, 2, 51–59. [Google Scholar]

- Yassar, R.S.; Field, D.P.; Weiland, H. Transmission electron microscopy and differential scanning calorimetry studies on the precipitation sequence in an Al-Mg-Si alloy: AA6022. J. Mater. Res. 2011, 20, 2705–2711. [Google Scholar] [CrossRef]

- Polat, A.; Avsar, M.; Ozturk, F. Effects of the artificial-aging temperature and time on the mechanical properties and springback behavior of AA6061. Mater. Technol. 2015, 49, 487–493. [Google Scholar] [CrossRef]

- Buha, J.; Lumley, R.N.; Crosky, A.G. Microstructural development and mechanical properties of interrupted aged Al-Mg-Si-Cu alloy. Metall. Mater. Trans. A 2006, 37, 3119–3130. [Google Scholar] [CrossRef]

- Haji, Z.N. Low cycle fatigue behavior of aluminum alloys AA2024-T6 and AA7020-T6. J. Eng. Sci. 2010, 22–23, 127–137. [Google Scholar]

- Sharma, V.; Rao, G.; Sharma, S.; George, K. Low cycle fatigue behavior of AA2219-T87 at room temperature. Mater. Perform. Charact. 2014, 3, 103–126. [Google Scholar] [CrossRef]

- Hidayetoglu, T.K.; Pica, P.N.; Haworth, W.L. Aging dependence of the bauschinger effect in aluminum alloy 2024. Mater. Sci. Eng. 1985, 73, 65–76. [Google Scholar] [CrossRef]

- Wong, W.A.; Bucci, R.J.; Stentz, R.H.; Conway, J.B. Tensile and Strain-Controlled Fatigue Data for Certain Aluminum Alloys for Application in the Transportation Industry; SAE International: Warrendale, PA, USA, 1987. [Google Scholar]

- Srivatsan, T.S.; Kolar, D.; Magnusen, P. Influence of temperature on cyclic stress response, strain resistance, and fracture behavior of aluminum alloy 2524. Mater. Sci. Eng. A 2001, 314, 118–130. [Google Scholar] [CrossRef]

- Borrego, L.P.; Abreu, L.M.; Costa, J.M.; Ferreira, J.M. Analysis of low cycle fatigue in almgsi aluminium alloys. Eng. Fail. Anal. 2004, 11, 715–725. [Google Scholar] [CrossRef]

- Lapovok, R.; Loader, C.; Torre, F.H.D.; Semiatin, S.L. Microstructure evolution and fatigue behavior of 2124 aluminum processed by ECAE with back pressure. Mater. Sci. Eng. A 2006, 425, 36–46. [Google Scholar] [CrossRef]

- Jogi, B.F.; Brahmankar, P.K.; Nanda, V.S.; Prasad, R.C. Some studies on fatigue crack growth rate of aluminum alloy 6061. J. Mater. Process. Technol. 2008, 201, 380–384. [Google Scholar] [CrossRef]

- Tsuyoshi, T.; Sasaki, K. Low cycle thermal fatigue of aluminum alloy cylinder head in consideration of changing metrology microstructure. Procedia Eng. 2010, 2, 767–776. [Google Scholar] [CrossRef]

- Zhu, M.; Jian, Z.; Yang, G.; Zhou, Y. Effects of T6 heat treatment on the microstructure, tensile properties, and fracture behavior of the modified A356 alloys. Mater. Des. 2012, 36, 243–249. [Google Scholar] [CrossRef]

- Fan, K.L.; He, G.Q.; Liu, X.S.; Liu, B.; She, M.; Yuan, Y.L.; Yang, Y.; Lu, Q. Tensile and fatigue properties of gravity casting aluminum alloys for engine cylinder heads. Mater. Sci. Eng. A 2013, 586, 78–85. [Google Scholar] [CrossRef]

- Nandy, S.; Sekhar, A.P.; Kar, T.; Ray, K.K.; Das, D. Influence of ageing on the low cycle fatigue behaviour of an Al–Mg–Si alloy. Philos. Mag. 2017, 97, 1978–2003. [Google Scholar] [CrossRef]

- Su, L.; Lu, C.; Deng, G.; Tieu, A.K.; Sun, X. Microstructure and mechanical properties of 1050/6061 laminated composite processed by accumulative roll bonding. Rev. Adv. Mater. Sci. 2013, 33, 33–37. [Google Scholar]

- Osten, J.; Milkereit, B.; Schick, C.; Kessler, O. Dissolution and precipitation behaviour during continuous heating of Al–Mg–Si alloys in a wide range of heating rates. Materials 2015, 8, 2830–2848. [Google Scholar] [CrossRef]

- Edwards, G.A.; Stiller, K.; Dunlop, G.L.; Couper, M.J. The precipitation sequence in Al–Mg–Si alloys. Acta Mater. 1998, 46, 3893–3904. [Google Scholar] [CrossRef]

- Ozturk, F.; Sisman, A.; Toros, S.; Kilic, S.; Picu, R.C. Influence of aging treatment on mechanical properties of 6061 aluminum alloy. Mater. Des. 2010, 31, 972–975. [Google Scholar] [CrossRef]

- Liu, K.; Chen, X.G. Development of Al-Mn-Mg 3004 alloy for applications at elevated temperature via dispersoid strengthening. Mater. Des. 2015, 84, 340–350. [Google Scholar] [CrossRef]

- Ebrahimi, R.; Pardis, N. Determination of strain-hardening exponent using double compression test. Mater. Sci. Eng. A 2009, 518, 56–60. [Google Scholar] [CrossRef]

- Abu-Haiba, M.S.; Fatemi, A.; Zoroufi, M. Creep deformation and monotonic stress-strain behavior of haynes alloy 556 at elevated temperatures. J. Mater. Sci. 2002, 37, 2899–2907. [Google Scholar] [CrossRef]

- Suresh, S. Fatigue of Materials; Cambridge University Press: Cambridge, UK, 2006. [Google Scholar]

- Wang, Z.; Laird, C. Relationship between loading process and masing behavior in cyclic deformation. Mater. Sci. Eng. A 1988, 101, L1–L5. [Google Scholar] [CrossRef]

- Christ, H.J.; Mughrabi, H. Cyclic stress-strain response and microstructure under variable amplitude loading. Fatigue Fract. Eng. Mater. Struct. 1996, 19, 335–348. [Google Scholar] [CrossRef]

- Mirza, F.A.; Chen, D.L.; Li, D.J.; Zeng, X.Q. Low cycle fatigue of an extruded Mg-3Nd-0.2Zn-0.5Zr magnesium alloy. Mater. Des. 2014, 64, 63–73. [Google Scholar] [CrossRef]

- Xue, L. A unified expression for low cycle fatigue and extremely low cycle fatigue and its implication for monotonic loading. Int. J. Fatigue 2008, 30, 1691–1698. [Google Scholar] [CrossRef]

- Lam, P.C.; Srivatsan, T.S.; Hotton, B.; Al-Hajri, M. Cyclic stress response characteristics of an aluminum-magnesium-silicon alloy. Mater. Lett. 2000, 45, 186–190. [Google Scholar] [CrossRef]

- Calabrese, C.; Laird, C. Cyclic stress—Strain response of two-phase alloys Part I. Microstructures containing particles penetrable by dislocations. Mater. Sci. Eng. 1974, 13, 141–157. [Google Scholar] [CrossRef]

- Bhat, S.P.; Laird, C. High temperature cyclic deformation of precipitation hardened alloy—I. Partially coherent precipitates. Acta Metall. 1979, 27, 1861–1871. [Google Scholar] [CrossRef]

- Song, M.S.; Ran, M.W.; Kong, Y.Y.; Yan, D.Y. Low cycle fatigue behavior of cast A356 aluminum alloys. Chin. J. Nonferr. Met. 2011, 21, 538–545. [Google Scholar]

- Tian, D.D.; Liu, X.S.; He, G.Q.; Shen, Y.; Lv, S.Q.; Wang, Q.G. Low cycle fatigue behavior of casting A319 alloy under two different aging conditions. Mater. Sci. Eng. A 2016, 654, 60–68. [Google Scholar] [CrossRef]

- Mirza, F.A.; Chen, D.L. Fatigue of magnesium alloys. In Aerospace Materials Handbook; Zhang, S., Zhao, D.L., Eds.; CRC Press: Boca Raton, FL, USA; Taylor& Francis: New York, NY, USA, 2013; pp. 647–698. [Google Scholar]

- Begum, S.; Chen, D.L.; Xu, S.; Luo, A.A. Strain-controlled low-cycle fatigue properties of a newly developed extruded magnesium alloy. Metall. Mater. Trans. A 2008, 39, 3014–3026. [Google Scholar] [CrossRef]

| Material | Mn | Si | Cu | Cr | Mg | Fe | Al |

|---|---|---|---|---|---|---|---|

| 6061 | 0.045 | 0.63 | 0.26 | 0.05 | 0.85 | 0.25 | Balance |

| Condition | Yield Strength YS (MPa) | Ultimate Strength UTS (MPa) | UTS/YS | Elongation El (%) | n, Strain-Hardening Exponent | K/MPa, Monotonic Strength Coefficient |

|---|---|---|---|---|---|---|

| T6 | 286 (5.2) * | 319 (6.7) | 1.12 | 14.6 (2.3) | 0.10 | 439 |

| T7-5 | 275 (4.8) | 305 (6.1) | 1.11 | 15.5 (1.5) | 0.10 | 424 |

| T7-24 | 208 (4.1) | 244 (5.8) | 1.17 | 17.9 (2.3) | 0.12 | 365 |

| T7-48 | 188 (4.5) | 228 (5.2) | 1.21 | 19.6 (2.8) | 0.14 | 356 |

| 6061-T6 [2] | 300 | 338 | 1.13 | 13 | N/A | 480 |

| Strain Amplitude (%) | Condition | First Cycle | Mid-Life Cycle | ||||

|---|---|---|---|---|---|---|---|

| Δσmax (MPa) | Δσmin (MPa) | Δεp (%) | Δσmax (MPa) | Δσmin (MPa) | Δεp (%) | ||

| 0.4 | T7-5 | −8.91 | 0.67 | 0.26 | −21.27 | −12.58 | 0.10 |

| T7-24 | −36.97 | 30.03 | −0.19 | −61.39 | 27.60 | 0.09 | |

| T7-48 | −65.82 | 50.60 | 0.12 | −83.76 | 46.48 | 0.11 | |

| 0.8 | T7-5 | −14.15 | 18.70 | 0.08 | −32.39 | 34.79 | 0.05 |

| T7-24 | −42.67 | 53.12 | 0.10 | −64.08 | 67.48 | 0.07 | |

| T7-48 | −50.68 | 66.07 | 0.13 | −90.90 | 90.84 | 0.11 | |

| 1.2 | T7-5 | −2.14 | 9.79 | −0.10 | −21.54 | 21.93 | −0.11 |

| T7-24 | −40.87 | 43.40 | −0.01 | −56.92 | 59.71 | 0.05 | |

| T7-48 | −63.02 | 65.37 | 0.04 | −83.15 | 79.09 | 0.09 | |

| Low-Cycle Fatigue Parameters | T6 | T7-5 | T7-24 | T7-48 | T6 [1] | T6 [8] |

|---|---|---|---|---|---|---|

| Cyclic strain-hardening exponent, n’ | 0.14 | 0.12 | 0.15 | 0.18 | 0.078 | 0.24 |

| Cyclic strength coefficient, K’ (MPa) | 636 | 621 | 552 | 478 | 268 | 372 |

| Fatigue strength coefficient, σ’f (MPa) | 872 | 613 | 602 | 458 | 705 | 593 |

| Fatigue strength exponent, b | −0.087 | −0.110 | −0.110 | −0.214 | −0.11 | −0.093 |

| Fatigue ductility coefficient, ε’f | 0.70 | 0.90 | 1.80 | 4.49 | 2.40 | 5.39 |

| Fatigue ductility exponent, c | −1.10 | −0.87 | −0.80 | −0.79 | −0.98 | −1.10 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, K.; Mirza, F.A.; Chen, X.G. Effect of Overaging on the Cyclic Deformation Behavior of an AA6061 Aluminum Alloy. Metals 2018, 8, 528. https://doi.org/10.3390/met8070528

Liu K, Mirza FA, Chen XG. Effect of Overaging on the Cyclic Deformation Behavior of an AA6061 Aluminum Alloy. Metals. 2018; 8(7):528. https://doi.org/10.3390/met8070528

Chicago/Turabian StyleLiu, Kun, Foisal Ahmed Mirza, and Xiao Grant Chen. 2018. "Effect of Overaging on the Cyclic Deformation Behavior of an AA6061 Aluminum Alloy" Metals 8, no. 7: 528. https://doi.org/10.3390/met8070528