Recent Advances and Developments in Phase Change Materials in High-Temperature Building Envelopes: A Review of Solutions and Challenges

Abstract

:1. Introduction

2. PCM Applications in Residential Construction

2.1. Studies Related to PCM in the Roof of Residual Buildings

2.2. Studies Related to PCMs in the Ceilings of Residual Buildings

2.3. Studies Related to the PCM in the Wall of Residual Buildings

3. Associated Challenges of Utilising PCMs in Buildings and Suggested Techniques for Improvement

- The thermal conductivity and latent heat storage capacity of PCMs are generally low, which reduces their ability to quickly collect or release heat. This limitation might make it more difficult for PCMs to react swiftly to temperature changes outside [97]

- PCMs are intended to function within specific temperature ranges. It is important to select the PCM with the right phase conversion temperature for the proposed use and climate. Specifically, choosing the right PCM for high temperatures is very challenging

- One consideration in the decision-making process may be the cost of premium PCMs. While long-term energy savings could offset the higher initial investment, cost concerns could still be problematic, particularly for initiatives with limited funding

- Integrating PCMs within roofs, ceilings, and walls could increase weight and volume in architectural constructions

- There may be compatibility problems if the PCMs are integrated with other building components, such as finishes and insulation

- Although PCMs have been used in a number of building sections, their cost prohibits their application in domestic home systems and residential units.

| Author [Reference] | Year | Geometry/Composition | Study Type | Studied Parameters | Results and Remarks |

|---|---|---|---|---|---|

| Plytaria et al. [67] | (2019) | Building radiant wall solar cooling system using phase change materials. | Numerical | Location of PCM layer. | South walls are optimal for PCM layers since they reduce the supplementary energy by 30%, improve solar coverage by 3.8%, and lower system costs by 3%. |

| Li et al. [68] | (2019) | The base wall comprised cement (3 cm), plaster (2 cm), and clay brick (15 cm). | Numerical | Impact of using phase change material. | The inside receives less heat because of the reduced PCM thermal conductivity. Increasing PCM thickness by two times reduces heat transmission by less than twofold. |

| Sun et al. [69] | (2019) | Three PCM walls with various assemblies. | Experimental | Impact and optimal PCM sphere placement. | Using the spheres of PCM in the top three layers resulted in yearly energy savings of 17.7%, 20.2%, and 23.1%, respectively. If applied annually, the spheres of PCM performed best in the third layer, during winter in the fourth, and during the summer in the third. |

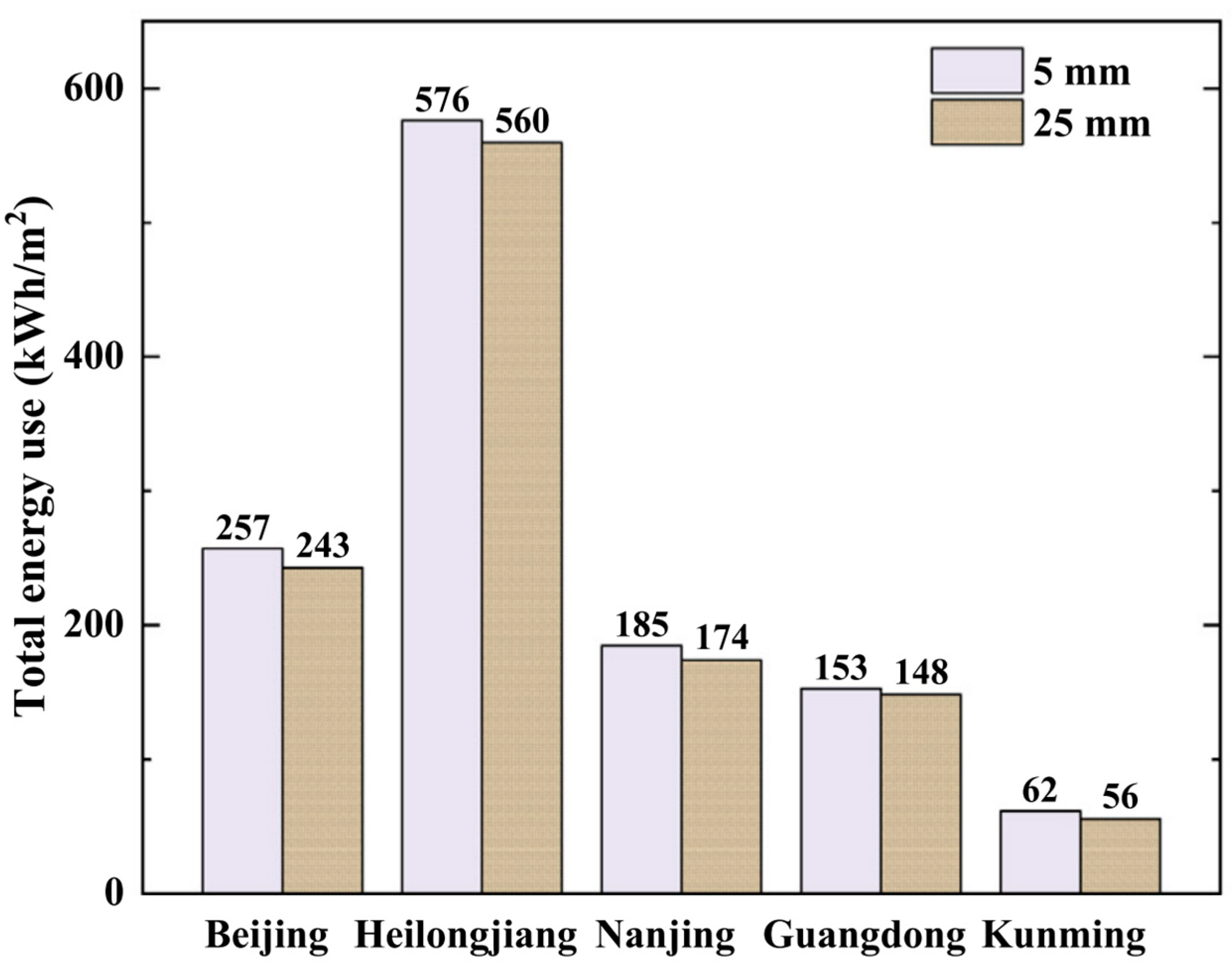

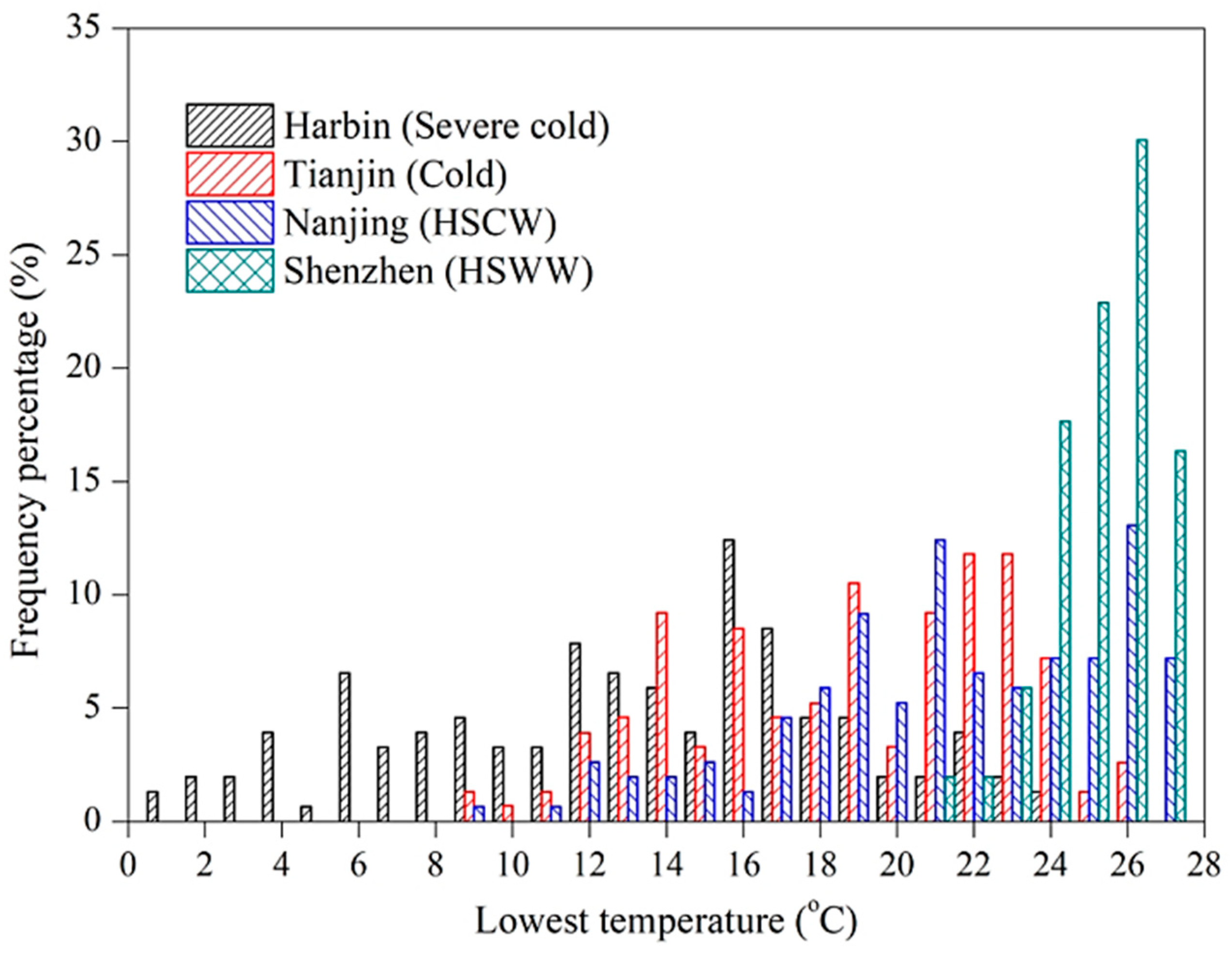

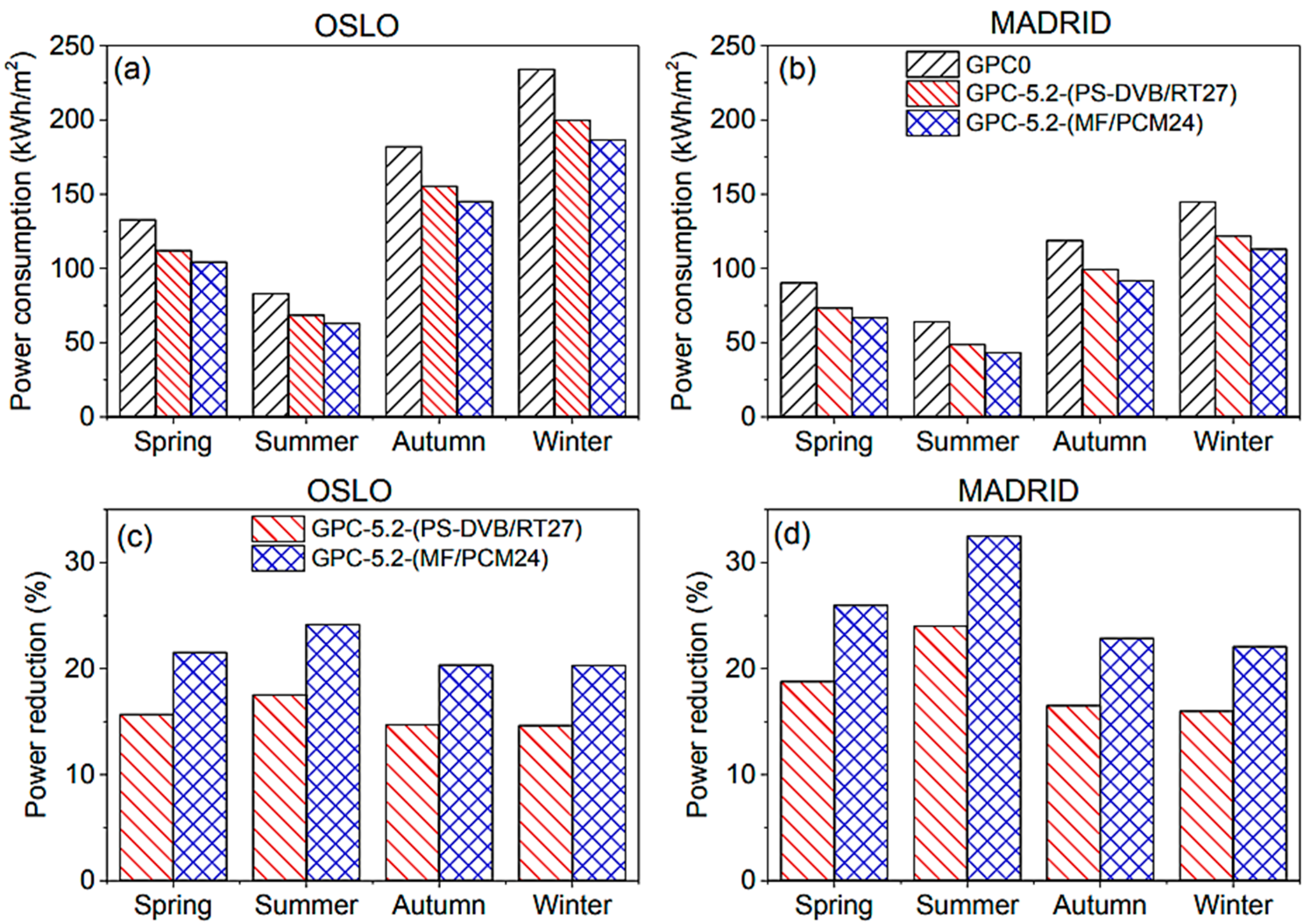

| Cao et al. [70] | (2019) | Geopolymer concrete (GPC) walls with micro-encapsulated phase transition. | Numerical | Impact of climate on MPCM design. | Building energy efficiency increased with greater MPCM levels and thicker concrete walls. |

| Cao et al. [71] | (2019) | Making multi-layer walls using a combination of micro-encapsulated PCMs and geopolymer concrete. | Experimental and Numerical | The micro-encapsulated PCMs’ effect on the geopolymer. | The PCM worked better near the outdoors. |

| Kant et al. [72] | (2020) | Wall made of PCMs. | Numerical | The PCM’s impact. | n-octadecane, RT-25, RT-26, and RT-28 phase change materials reduce heat transmission to the interior environment by 33.18%, 33.94%, 34.40%, and 37.13%, respectively, for three days. |

| Byon and Jeong [73] | (2020) | An integrated thermoelectric generator-based passive energy-harvesting system using PCMs. | Experimental and Numerical | Influence of PCMs. | Three–four energy-harvesting blocks might power contemporary digital circuits like sensors and controllers. |

| Vukadinović et al. [74] | (2020) | Wall constructed of concrete (20 cm thickness) including or not including a PCM for thermal storage. | Experimental | The impact of using PCMs. | For Zlatibor, Kopaonik, Novi Sad, and Belgrade, the energy needs for P3 are 0.91%, 1.77%, 1.79%, and 1.90% lower than P0, respectively. |

| Khan et al. [75] | (2020) | Building wall using PCMs. | Experimental | PCM’s impact upon the building wall heat transmission. | The bath of cold water (indoor state) has a lower temperature increase with the layer of PCM nearer to the source of heat than with the heat sink. |

| Yu et al. [76] | (2020) | PCMs for the major sun-facing wall’s interior. | Experimental and Numerical | Influence of using PCMs. | This application suits a 50-mm GH-37 PCM panel. |

| Arunkumar et al. [77] | (2020) | PCM-filled hollow block. | Experimental | Heat transmission from PCM-filled hollow block (wall). | Across the hollow block dimensions in the inside surface, the temperature decrease is 5.7%, and the gain decrease in heat is 33%. Surface temperatures are comparable. |

| Kishore et al. [78] | (2020) | Integration of PCM into building walls. | Numerical | PCM’s effect on building walls. | PCMs in building walls might increase energy usage if applied incorrectly. |

| Zaid et al. [79] | (2020) | Adding PCM to clay–straw walls. | Experimental | Effect of the PCM’s location. | The PCM-integrated wall has a 31.95% lower peak heat flow than the clay–straw wall with no PCMs. |

| Pirasaci [80] | (2020) | Residential building exterior PCM layer integration. | Numerical | Examine the PCM layer phase and heat storage. | PCM layer integration improves outcomes without phase change. |

| Ouhsaine et al. [81] | (2020) | PCMs on solar active walls. | Numerical | Impact of PCMs. | The PCM greatly improves indoor temperature stability and comfort. |

| Shen et al. [82] | (2020) | An innovative wall (RC-PCM). | Experimental and Numerical | Influence of using PCMs. | The RC-PCM inner surface temperature was inversely connected with wind speed and favourably correlated with emissivity. |

| Liu et al. [83] | (2021) | LBW integrated with PCM. | Numerical | Integrated PCM and LBW impact. | LBW thermal performance may be greatly improved with PCMs. |

| Rai [84] | (2021) | Brick-integrated PCM walls. | Numerical | PCM’s impact on masonry walls. | The PCM should have a melting temperature near the interior set-point and be fixed upon the wall inside with sufficient insulation for shielding it from outside conditions. |

| Kishore et al. [85] | (2021) | Innovative wall with PCMs between dynamic insulation and system layers. | Experimental | Effect of using a layer of PCM. | The PCM-DIMS-integrated wall might decrease yearly the heat input by 15–72% as well as the loss of heat by 7–38%. |

| Govindasamy and Panwar [86] | (2021) | Building walls include bio-phase change material (b-PCM). | Numerical | The effect of bio-phase change material thickness. | The lower thermal conductivity as well as the higher latent heat of the phase conversion helps b-PCMs reduce the heat transmission to the inner side room. |

| Hattan et al. [87] | (2021) | The traditional construction wall system uses shape-stabilized PCM (SSPCM) as TES. | Experimental | Shape-stabilized PCM benefits. | The mechanical testing of SSPCM-integrated mortars showed good outcomes for masonry wall-finishing plaster. |

| Zaid et al. [88] | (2021) | Adding a PCM to a clay–straw wall. | Experimental and Numerical | PCM’s impact in clay–straw walls. | In the clay–straw walls, PCM24 improved the density of internal heat flux by 33.33%. |

| Tian et al. [89] | (2021) | Brick walls had PCM layers on the exterior, centre (sandwiched), or interior. | Experimental | The impact of PCM on brick walls. | Exterior walls with PCM layers had the best insulation. |

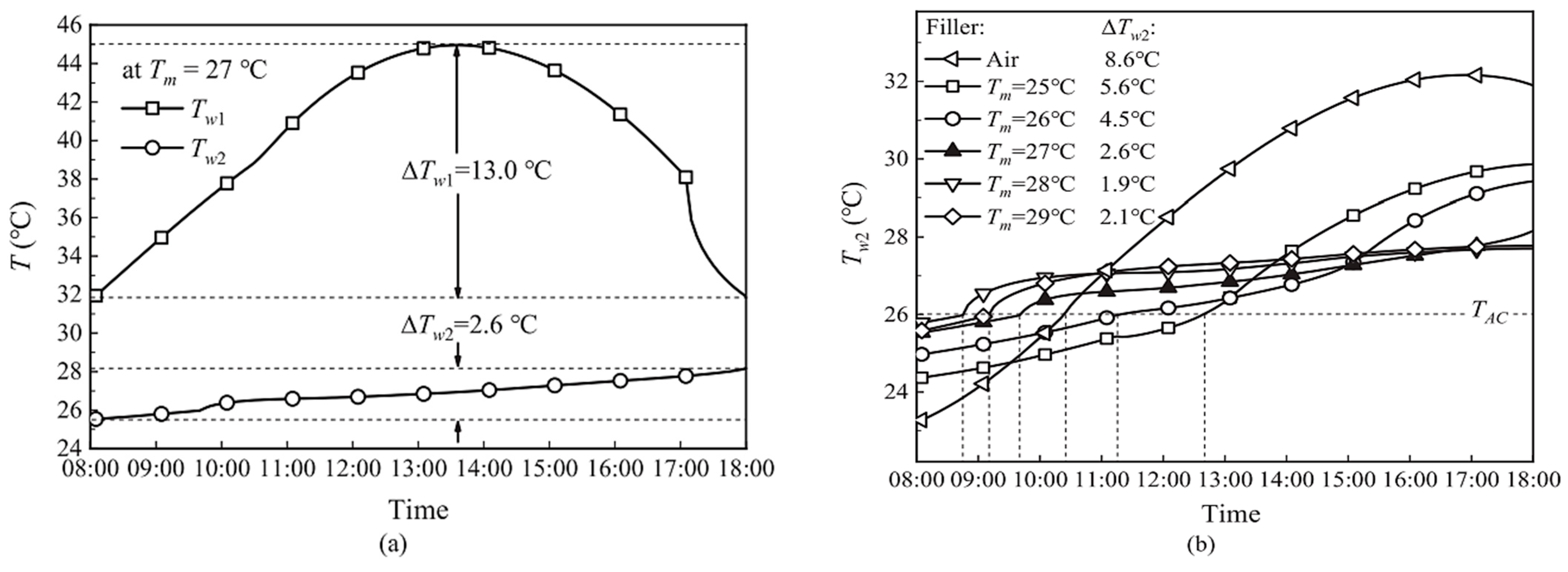

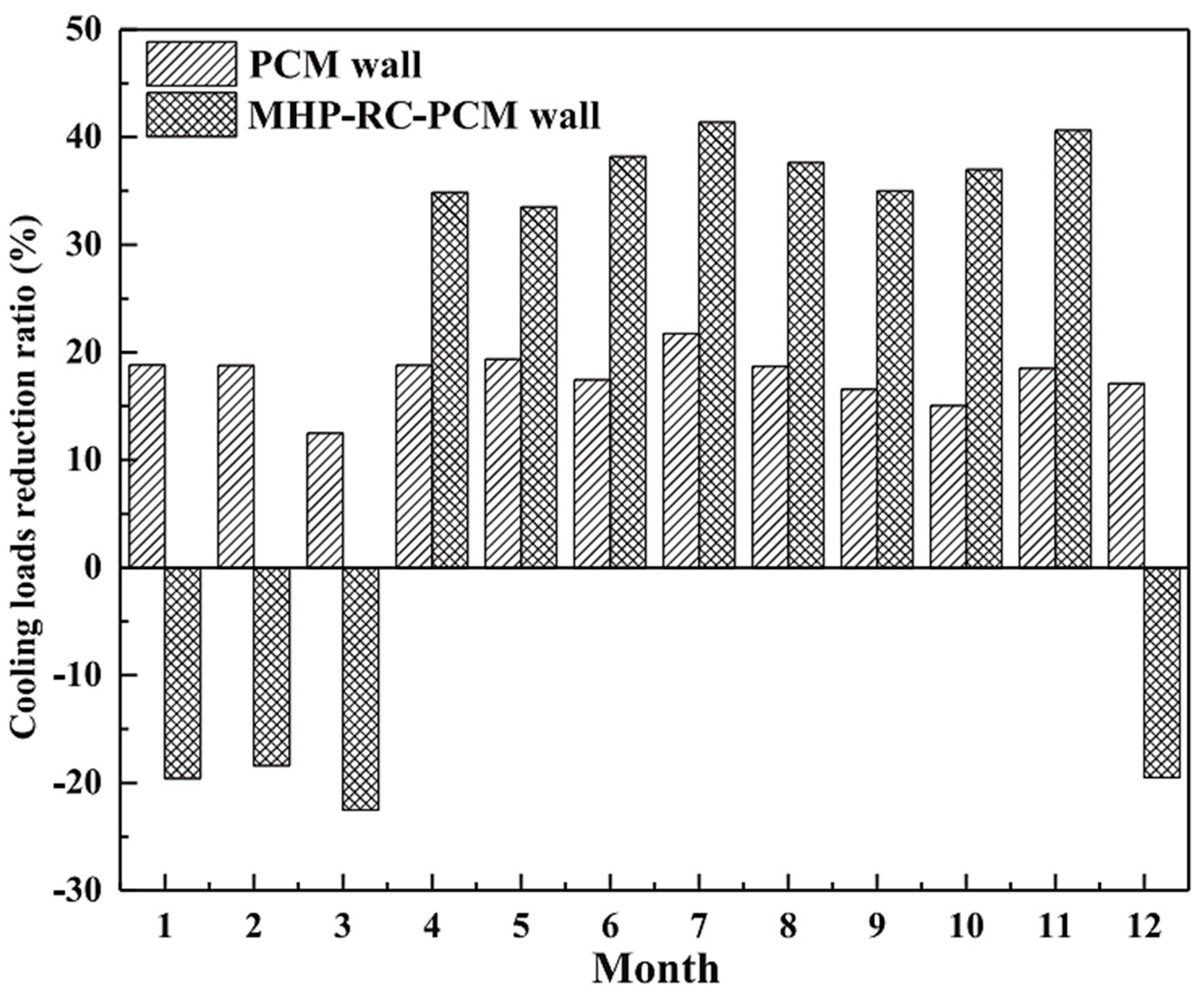

| Yu et al. [90] | (2021) | The PCM wall, micro-channel heat pipe, and sky radiative cooling. | Experimental and Numerical | Phase conversion temperature, MHPs, latent heat of PCM, and conduct of year-round heat. | The PCM phase conversion temperature had an effect on the percentage of liquid, decreasing the ratio of the cooling load and the MHP-RC-PCM wall’s inner surface temperature. |

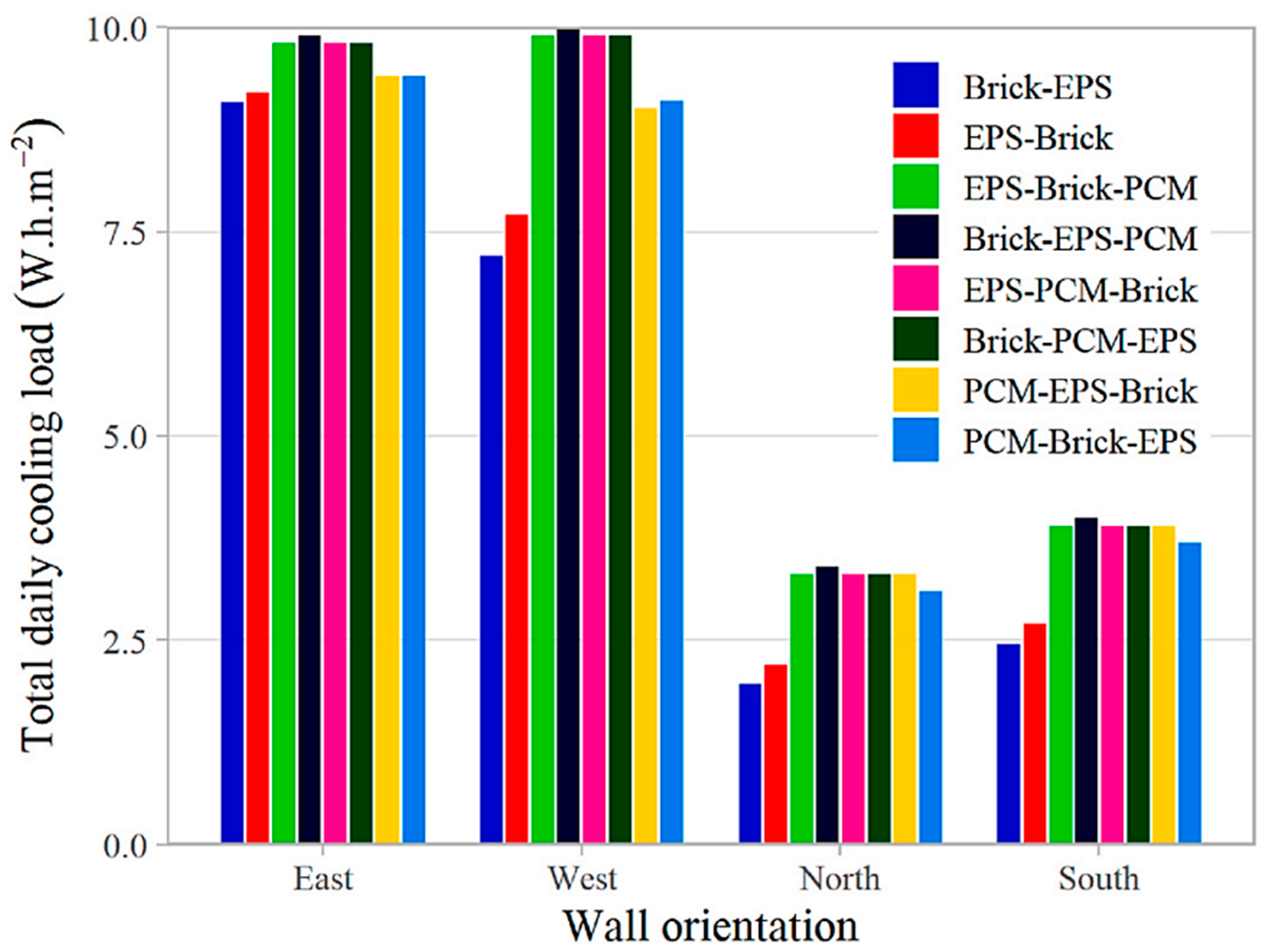

| Liu et al. [91] | (2022) | PCM integrated with LBW. | Experimental | PCM regulations and appropriateness affect LBW thermal performance in distinct ways. | The highest flow and mean flow of heat decreased by 62.8–66.4% and 28.2–29.5%, respectively, and the time of delay was raised by 5–5.34 h, in comparison with the reference wall. The east-, as well as west-facing walls, achieved the highest thermal performance gain at optimum PCM settings. |

| Alharbey et al. [92] | (2022) | Build PCM/bioPCM presence. | Experimental and Analytical | BioPCM and PCM effects. | When bioPCM M182/Q21 is used, the annual energy is reduced by 13%. It was discovered that bioPCM options Q21 and Q23 are particularly suitable, as they fully satisfy the building’s heating requirements while reducing energy consumption in the cooling section by 23.4% and 22.1%, respectively. |

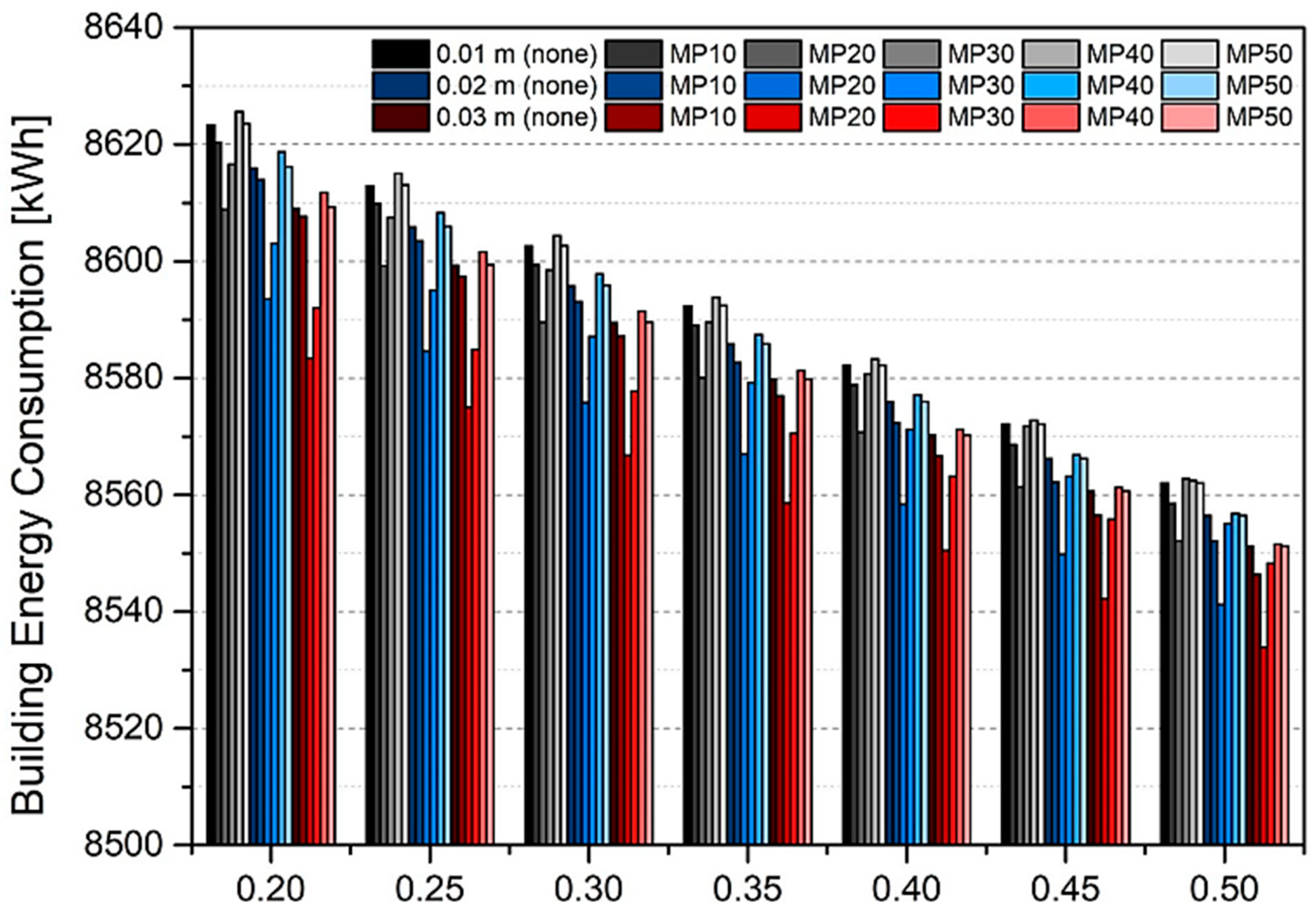

| Imafidon and Ting [93] | (2022) | Installing honeycomb PCM on modified building walls. | Numerical | Effect of honeycomb PCM on retrofitting building walls. | The increased thickness of the layer of PCM and the highest active heat capacity above 1 cm and 20 kJ/kg K do not enhance the performance further. |

| Nizovtsev and Sterlyagov [94] | (2023) | Lightweight construction outer-wall phase transition material. | Numerical | Effect of phase change layer. | PCMs at the wall’s centre reduced heat flow the most. |

| Allam et al. [95] | (2023) | Circular, square, and polygon brick cavities filled with PCMs. | Numerical | PCM type and cavity effects. | The PCM in brick walls reduces indoor heat transmission and raises the wall temperature to match the ambient temperature. |

| Gencel et al. [96] | (2023) | PCM-impregnated wallpapers are a new wall covering. | Experimental | Impact of PCM. | DDA case room temperature was colder for 9 h 53 min during the daytime. |

- PCM qualities like thermal conductivity must be improved for better outcomes

- Advanced PCM materials science research may allow for creative engineering solutions to incorporate PCMs into existing buildings, supporting the clean-energy agenda

- Combining PCMs with building components may be helpful, but sophisticated thermodynamic instruments like energy-economic and exergy-environmental methodologies must be used to examine the sustainable, financial, and ecological impacts of such units. Optimizing such materials via novel development approaches can also be beneficial

- Standards must be globally issued to identify suitable PCMs for different climates while maintaining optimal cycles and thermal efficiency

- Developing innovative PCM technologies like a dynamically adjustable and controlled phase change temperature is crucial

- Residential buildings use mostly commercial PCMs, such as paraffin-based PCMs. Further research is required to appraise the advantages of using other PCM kinds, like bio-based, inorganic, and eutectic PCMs

- To optimise thermal energy storage and release, mechanisms that improve the exchange of heat between the internal space and PCM must be designed

- In order to guarantee that the building’s structural integrity is maintained and added loads remain within reasonable bounds after the addition of PCMs in the roof, ceiling and walls, a specific set of design constraints should be acknowledged

- It is critical to evaluate PCM installations’ accessibility as well as any prospective maintenance or replacement difficulties

- It is essential to make sure PCMs do not negatively interact with nearby materials and that their effectiveness holds up over time

- To secure approvals and guarantee safety, specific research is necessary to ensure that PCM installations adhere to all applicable codes and standards

- It is crucial to design ventilation strategies that allow for heat exchange with PCMs while preserving the quality of the air within buildings after the addition of PCMs.

4. Conclusions

- The utilisation of PCMs in brick walls can reduce inside heat transmission and raise the internal wall temperature to match the indoor air temperature. In this regard, an outer layer of PCM can reduce the peak heat flow by 26.5% in a clay–straw wall. Intake heat flow averages 14.17 W/m2 via the PCM-integrated wall. Furthermore, moving the PCM layer in closer proximity to the source of heat decreases the relative rise in temperature within the cold-water bath compared to the heat sink

- Referring to the utilisation of PCMs in ceilings, an FSPCM in gypsum board ceilings can save 16.2% in cooling demand, making it economically viable. The best results for the roof structure’s time, decrement factor, melting and solidification cycle, and daily heat gain reduction are achieved with a PCM layer inclined at 2°

- The utilisation of PCMs in roofs has been shown to save 13%, 15%, and 17% more energy with TC, PCM, and TC/PCM roofs, respectively, compared to asphalt roofs. Additionally, a reduction of 7.37 °C in summer surface temperature can be achieved with the PCM/WPC roof module system. In addition, the MKR index can also be used to determine the optimum PCM and to assess the influence of different PCM properties across various climatic zones.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| Symbol | Definition |

| ATFR | Average temperature fluctuation reduction |

| DF | Decrement factor |

| DIMS | Dynamic insulation material and system |

| FOV | Finite volume method |

| FSPCM | Form-stable phase change material |

| FTD | Frequency of thermal discomfort |

| GPU | Graphical process unit |

| HDPE | High-density polyethylene |

| HFR | Heat flux reduction |

| LBM | Lattice Boltzmann method |

| MEP | Macro-encapsulated PCM panel |

| MHPs | Micro-channel heat pipes |

| MKR | Measure of Key Response |

| MPCM | Micro-encapsulated phase change material |

| MRT | Multiple-relaxation time |

| NTU | Number of transfer units |

| PCM | Phase change material |

| PCM FCR | PCM foamed cement roof |

| PCM-RCC | PCM-embedded radiant chilled ceiling |

| PCMC roof | Phase change material cool roof |

| Ra | Rayleigh numbers (-) |

| RC-PCM | Radiative cooling phase change materials |

| RCC | Reinforced cement concrete |

| RCP | Radiant ceiling panel |

| RMSE | Root mean square error |

| RMTR | Room maximum temperature reduction |

| SPCM | Shape-stabilized phase change material |

| SSPCM | Shape-stabilized PCM |

| TC | Thermochromic |

| TERCP | Thermoelectric radiant cooling panel |

| TES | Thermal energy storage |

| TL | Time lag |

| UDF | User-Defined Function |

| VR-MPCM | Ventilated roof composed of multiple phase change materials |

| WP | Wallpapers |

| WPC | Wood–plastic composite |

References

- Rashid, F.L.; Al-Obaidi, M.A.; Dulaimi, A.; Bernardo, L.F.A.; Eleiwi, M.A.; Mahood, H.B.; Hashim, A. A Review of Recent Improvements, Developments, Effects, and Challenges on Using Phase-Change Materials in Concrete for Thermal Energy Storage and Release. J. Compos. Sci. 2023, 7, 352. [Google Scholar] [CrossRef]

- De Gracia, A.; Cabeza, L.F. Phase Change Materials and Thermal Energy Storage for Buildings. Energy Build. 2015, 103, 414–419. [Google Scholar] [CrossRef]

- Demirbas, M.F. Thermal Energy Storage and Phase Change Materials: An Overview. Energy Sources Part B Econ. Plan. Policy 2006, 1, 85–95. [Google Scholar] [CrossRef]

- Berardi, U.; Gallardo, A.A. Properties of Concretes Enhanced with Phase Change Materials for Building Applications. Energy Build. 2019, 199, 402–414. [Google Scholar] [CrossRef]

- Zhang, Y.; Huang, J.; Fang, X.; Ling, Z.; Zhang, Z. Optimal Roof Structure with Multilayer Cooling Function Materials for Building Energy Saving. Int. J. Energy Res. 2020, 44, 1594–1606. [Google Scholar] [CrossRef]

- Kyriaki, E.; Konstantinidou, C.; Giama, E.; Papadopoulos, A.M. Life Cycle Analysis (LCA) and Life Cycle Cost Analysis (LCCA) of Phase Change Materials (PCM) for Thermal Applications: A Review. Int. J. Energy Res. 2018, 42, 3068–3077. [Google Scholar] [CrossRef]

- Baniassadi, A.; Sajadi, B.; Amidpour, M.; Noori, N. Economic Optimization of PCM and Insulation Layer Thickness in Residential Buildings. Sustain. Energy Technol. Assess. 2016, 14, 92–99. [Google Scholar] [CrossRef]

- Ascione, F. Energy Conservation and Renewable Technologies for Buildings to Face the Impact of the Climate Change and Minimize the Use of Cooling. Sol. Energy 2017, 154, 34–100. [Google Scholar] [CrossRef]

- Jacob, D.; Kotova, L.; Teichmann, C.; Sobolowski, S.P.; Vautard, R.; Donnelly, C.; Koutroulis, A.G.; Grillakis, M.G.; Tsanis, I.K.; Damm, A. Climate Impacts in Europe Under+ 1.5 C Global Warming. Earths Future 2018, 6, 264–285. [Google Scholar] [CrossRef]

- Santamouris, M. Cooling the Buildings–Past, Present and Future. Energy Build. 2016, 128, 617–638. [Google Scholar] [CrossRef]

- Kaboré, M.; Bozonnet, E.; Salagnac, P.; Abadie, M. Indexes for Passive Building Design in Urban Context–Indoor and Outdoor Cooling Potentials. Energy Build. 2018, 173, 315–325. [Google Scholar] [CrossRef]

- Akbari, H.; Matthews, H.D. Global Cooling Updates: Reflective Roofs and Pavements. Energy Build. 2012, 55, 2–6. [Google Scholar] [CrossRef]

- Akbari, H.; Cartalis, C.; Kolokotsa, D.; Muscio, A.; Pisello, A.L.; Rossi, F.; Santamouris, M.; Synnefa, A.; Wong, N.H.; Zinzi, M. Local Climate Change and Urban Heat Island Mitigation Techniques–the State of the Art. J. Civ. Eng. Manag. 2016, 22, 1–16. [Google Scholar] [CrossRef]

- Rosado, P.J.; Levinson, R. Potential Benefits of Cool Walls on Residential and Commercial Buildings across California and the United States: Conserving Energy, Saving Money, and Reducing Emission of Greenhouse Gases and Air Pollutants. Energy Build. 2019, 199, 588–607. [Google Scholar] [CrossRef]

- Zeng, R.; Wang, X.; Di, H.; Jiang, F.; Zhang, Y. New Concepts and Approach for Developing Energy Efficient Buildings: Ideal Specific Heat for Building Internal Thermal Mass. Energy Build. 2011, 43, 1081–1090. [Google Scholar] [CrossRef]

- Lu, S.; Chen, Y.; Liu, S.; Kong, X. Experimental Research on a Novel Energy Efficiency Roof Coupled with PCM and Cool Materials. Energy Build. 2016, 127, 159–169. [Google Scholar] [CrossRef]

- Pisello, A.L.; Fortunati, E.; Mattioli, S.; Cabeza, L.F.; Barreneche, C.; Kenny, J.M.; Cotana, F. Innovative Cool Roofing Membrane with Integrated Phase Change Materials: Experimental Characterization of Morphological, Thermal and Optic-Energy Behavior. Energy Build. 2016, 112, 40–48. [Google Scholar] [CrossRef]

- Li, D.; Zheng, Y.; Liu, C.; Wu, G. Numerical Analysis on Thermal Performance of Roof Contained PCM of a Single Residential Building. Energy Convers. Manag. 2015, 100, 147–156. [Google Scholar] [CrossRef]

- Pasupathy, A.; Velraj, R. Effect of Double Layer Phase Change Material in Building Roof for Year Round Thermal Management. Energy Build. 2008, 40, 193–203. [Google Scholar] [CrossRef]

- Cui, Y.; Xie, J.; Liu, J.; Wang, J.; Chen, S. A Review on Phase Change Material Application in Building. Adv. Mech. Eng. 2017, 9, 1687814017700828. [Google Scholar] [CrossRef]

- Akeiber, H.J.; Wahid, M.A.; Hussen, H.M.; Mohammad, A.T. Review of Development Survey of Phase Change Material Models in Building Applications. Sci. World J. 2014, 2014, 391690. [Google Scholar] [CrossRef] [PubMed]

- Song, M.; Niu, F.; Mao, N.; Hu, Y.; Deng, S. Review on Building Energy Performance Improvement Using Phase Change Materials. Energy Build. 2018, 158, 776–793. [Google Scholar] [CrossRef]

- Ahmed, M.; Meade, O.; Medina, M.A. Reducing Heat Transfer across the Insulated Walls of Refrigerated Truck Trailers by the Application of Phase Change Materials. Energy Convers. Manag. 2010, 51, 383–392. [Google Scholar] [CrossRef]

- Bhamare, D.K.; Rathod, M.K.; Banerjee, J. Numerical Model for Evaluating Thermal Performance of Residential Building Roof Integrated with Inclined Phase Change Material (PCM) Layer. J. Build. Eng. 2020, 28, 101018. [Google Scholar] [CrossRef]

- Bhamare, D.K.; Rathod, M.K.; Banerjee, J. Selection of Phase Change Material and Establishment of Thermophysical Properties of Phase Change Material Integrated with Roof of a Building Using Measure of Key Response Index: Proposal of a New Parameter. J. Energy Storage 2020, 32, 101812. [Google Scholar] [CrossRef]

- Luo, Z.; Xu, H.; Lou, Q.; Feng, L.; Ni, J. GPU-Accelerated Lattice Boltzmann Simulation of Heat Transfer Characteristics of Porous Brick Roof Filled with Phase Change Materials. Int. Commun. Heat. Mass. Transf. 2020, 119, 104911. [Google Scholar] [CrossRef]

- Hu, J.; Yu, X. (Bill) Adaptive Building Roof by Coupling Thermochromic Material and Phase Change Material: Energy Performance under Different Climate Conditions. Constr. Build. Mater. 2020, 262, 120481. [Google Scholar] [CrossRef]

- Triano-Juárez, J.; Macias-Melo, E.V.; Hernández-Pérez, I.; Aguilar-Castro, K.M.; Xamán, J. Thermal Behavior of a Phase Change Material in a Building Roof with and without Reflective Coating in a Warm Humid Zone. J. Build. Eng. 2020, 32, 101648. [Google Scholar] [CrossRef]

- Fabiani, C.; Piselli, C.; Pisello, A.L. Thermo-Optic Durability of Cool Roof Membranes: Effect of Shape Stabilized Phase Change Material Inclusion on Building Energy Efficiency. Energy Build. 2020, 207, 109592. [Google Scholar] [CrossRef]

- Li, H.; Li, J.; Xi, C.; Chen, W.; Kong, X. Experimental and Numerical Study on the Thermal Performance of Ventilated Roof Composed with Multiple Phase Change Material (VR-MPCM). Energy Convers. Manag. 2020, 213, 112836. [Google Scholar] [CrossRef]

- Chang, S.J.; Wi, S.; Cho, H.M.; Jeong, S.-G.; Kim, S. Numerical Analysis of Phase Change Materials/Wood–Plastic Composite Roof Module System for Improving Thermal Performance. J. Ind. Eng. Chem. 2020, 82, 413–423. [Google Scholar] [CrossRef]

- Boobalakrishnan, P.; Manoj Kumar, P.; Balaji, G.; Jenaris, D.S.; Kaarthik, S.; Jaya Prakash Babu, M.; Karthhik, K. Thermal Management of Metal Roof Building Using Phase Change Material (PCM). Mater. Today Proc. 2021, 47, 5052–5058. [Google Scholar] [CrossRef]

- Al-Yasiri, Q.; Szabó, M. Case Study on the Optimal Thickness of Phase Change Material Incorporated Composite Roof under Hot Climate Conditions. Case Stud. Constr. Mater. 2021, 14, e00522. [Google Scholar] [CrossRef]

- Al-Yasiri, Q.; Szabó, M. Experimental Evaluation of the Optimal Position of a Macroencapsulated Phase Change Material Incorporated Composite Roof under Hot Climate Conditions. Sustain. Energy Technol. Assess. 2021, 45, 101121. [Google Scholar] [CrossRef]

- Elawady, N.; Bekheit, M.; Sultan, A.A.; Radwan, A. Energy Assessment of a Roof-Integrated Phase Change Materials, Long-Term Numerical Analysis with Experimental Validation. Appl. Therm. Eng. 2022, 202, 117773. [Google Scholar] [CrossRef]

- Rangel, C.G.; Rivera-Solorio, C.I.; Gijón-Rivera, M.; Mousavi, S. The Effect on Thermal Comfort and Heat Transfer in Naturally Ventilated Roofs with PCM in a Semi-Arid Climate: An Experimental Research. Energy Build. 2022, 274, 112453. [Google Scholar] [CrossRef]

- Wang, P.; Liu, Z.; Zhang, X.; Zhang, H.; Chen, X.; Zhang, L. Adaptive Building Roof Combining Variable Transparency Shape-Stabilized Phase Change Material: Application Potential and Adaptability in Different Climate Zones. Build. Environ. 2022, 222, 109436. [Google Scholar] [CrossRef]

- Meng, E.; Yang, J.; Zhou, B.; Wang, C.; Li, J. Preparation and Thermal Performance of Phase Change Material (PCM) Foamed Cement Used for the Roof. J. Build. Eng. 2022, 53, 104579. [Google Scholar] [CrossRef]

- Rahi, M.F.; Arıcı, M.; Abdulateef, A.M.; Niyas, H. Numerical Investigation and Optimization of Macro-Encapsulated Phase Change Material Capsules in Building Roof Slab. J. Energy Storage 2023, 68, 107806. [Google Scholar] [CrossRef]

- Sedaghat, A.; Salem, H.; Hussam, W.K.; Mahdizadeh, A.; Al-Khiami, M.I.; Malayer, M.A.; Soleimani, S.M.; Sabati, M.; Narayanan, R.; Rasul, M.; et al. Exploring Energy-Efficient Building Solutions in Hot Regions: A Study on Bio-Phase Change Materials and Cool Roof Coatings. J. Build. Eng. 2023, 76, 107258. [Google Scholar] [CrossRef]

- Jiang, L.; Gao, Y.; Zhuang, C.; Feng, C.; Zhang, X.; Guan, J.; Dong, S. Experimental and Numerical Study on Thermal Performance of Phase-Change-Material Cool Roofs in Summer. Sustain. Cities Soc. 2023, 99, 104936. [Google Scholar] [CrossRef]

- Nguyen, L.; Alshuraiaan, B.; Hajjar, A.; Izadi, M.; El Idi, M.M. Assessment of the Thermal Resistance of Novel Roof Structures Incorporating Nano-Phase Change Materials Capsules under the Influence of an External Magnetic Field. J. Build. Eng. 2023, 79, 107851. [Google Scholar] [CrossRef]

- Yu, J.; Qian, C.; Yang, Q.; Xu, T.; Zhao, J.; Xu, X. The Energy Saving Potential of a New Ventilation Roof with Stabilized Phase Change Material in Hot Summer Region. Renew. Energy 2023, 212, 111–127. [Google Scholar] [CrossRef]

- Nguyen, L.; Hajjar, A.; Izadi, M.; Sheremet, M.A.; Ben Hamida, M.B. Numerical Study on Thermal Resistance of PCMs Incorporated in Novel Roof Structures against Energy Loss. J. Energy Storage 2023, 74, 109506. [Google Scholar] [CrossRef]

- Nguyen, L.; Alshuraiaan, B.; Hajjar, A.; Izadi, M.; El Idi, M.M. Controlling Energy Loss from Roof Structures Equipped by Round-Corner Double Semi-Hexagonal Ferro- Phase Change Material Layer Using Magnetic Field. J. Clean. Prod. 2023, 428, 139335. [Google Scholar] [CrossRef]

- Luo, Z.; Liu, X.; Yang, Q.; Qu, Z.; Xu, H.; Xu, D. Numerical Study on Performance of Porous Brick Roof Using Phase Change Material with Night Ventilation. Energy Build. 2023, 286, 112972. [Google Scholar] [CrossRef]

- Staffell, I.; Pfenninger, S.; Johnson, N. A Global Model of Hourly Space Heating and Cooling Demand at Multiple Spatial Scales. Nat. Energy 2023, 8, 1328–1344. [Google Scholar] [CrossRef]

- Basher, H.O.; Hasan, M.I.; Shdhan, A.O. Numerical Investigation of Phase Change Materials for Insulation of Residential Buildings in Hot Regions in Iraqi Cities. Wasit J. Eng. Sci. 2018, 6, 1–20. [Google Scholar] [CrossRef]

- Yasin, M.; Scheidemantel, E.; Klinker, F.; Weinläder, H.; Weismann, S. Generation of a Simulation Model for Chilled PCM Ceilings in TRNSYS and Validation with Real Scale Building Data. J. Build. Eng. 2019, 22, 372–382. [Google Scholar] [CrossRef]

- Abden, M.J.; Tao, Z.; Pan, Z.; George, L.; Wuhrer, R. Inclusion of Methyl Stearate/Diatomite Composite in Gypsum Board Ceiling for Building Energy Conservation. Appl. Energy 2020, 259, 114113. [Google Scholar] [CrossRef]

- Lim, H.; Kang, Y.-K.; Jeong, J.-W. Application of a Phase Change Material to a Thermoelectric Ceiling Radiant Cooling Panel as a Heat Storage Layer. J. Build. Eng. 2020, 32, 101787. [Google Scholar] [CrossRef]

- Yan, W.-M.; Ho, C.J.; Tseng, Y.-T.; Qin, C.; Rashidi, S. Numerical Study on Convective Heat Transfer of Nanofluid in a Minichannel Heat Sink with Micro-Encapsulated PCM-Cooled Ceiling. Int. J. Heat. Mass. Transf. 2020, 153, 119589. [Google Scholar] [CrossRef]

- Velasco-Carrasco, M.; Chen, Z.; Aguilar-Santana, J.L.; Riffat, S. Experimental Evaluation of Thermal Energy Storage (TES) with Phase Change Materials (PCM) for Ceiling Tile Applications. Future Cities Environ. 2020, 6, 1–11. [Google Scholar] [CrossRef]

- Bogatu, D.-I.; Kazanci, O.B.; Olesen, B.W. An Experimental Study of the Active Cooling Performance of a Novel Radiant Ceiling Panel Containing Phase Change Material (PCM). Energy Build. 2021, 243, 110981. [Google Scholar] [CrossRef]

- Gallardo, A.; Berardi, U. Design and Control of Radiant Ceiling Panels Incorporating Phase Change Materials for Cooling Applications. Appl. Energy 2021, 304, 117736. [Google Scholar] [CrossRef]

- Sinacka, J.; Szczechowiak, E. An Experimental Study of a Thermally Activated Ceiling Containing Phase Change Material for Different Cooling Load Profiles. Energies 2021, 14, 7363. [Google Scholar] [CrossRef]

- Skovajsa, J.; Drabek, P.; Sehnalek, S.; Zalesak, M. Design and Experimental Evaluation of Phase Change Material Based Cooling Ceiling System. Appl. Therm. Eng. 2022, 205, 118011. [Google Scholar] [CrossRef]

- Mousavi, S.; Rismanchi, B.; Brey, S.; Aye, L. Lessons Learned from PCM Embedded Radiant Chilled Ceiling Experiments in Melbourne. Energy Rep. 2022, 8, 54–61. [Google Scholar] [CrossRef]

- ISO 7730; Ergonomics of the Thermal Environment-Analytical Determination and Interpretation of Thermal Comfort Using Calculation of the PMV and PPD Indices and Local Thermal Comfort Criteria. ISO: Geneva, Switzerland, 2006.

- Gallardo, A.; Berardi, U. Experimental Evaluation of the Cooling Performance of Radiant Ceiling Panels with Thermal Energy Storage. Energy Build. 2022, 262, 112021. [Google Scholar] [CrossRef]

- Mustafa, J.; Alqaed, S.; Sharifpur, M. PCM Embedded Radiant Chilled Ceiling as a Solution to Shift the Cooling Peak Load-Focusing on Solidification Process Acceleration. J. Build. Eng. 2022, 57, 104894. [Google Scholar] [CrossRef]

- Khattari, Y.; Arid, A.; El Ouali, A.; Kousksou, T.; Janajreh, I.; Mahjoub Ben Ghoulam, E. CFD Study on the Validity of Using PCM in a Controlled Cooling Ceiling Integrated in a Ventilated Room. Dev. Built Environ. 2022, 9, 100066. [Google Scholar] [CrossRef]

- Yang, S.; Zhang, Y.; Zhao, Y.; Torres, J.F.; Wang, X. PCM-Based Ceiling Panels for Passive Cooling in Buildings: A CFD Modelling. Energy Build. 2023, 285, 112898. [Google Scholar] [CrossRef]

- Hlanze, P.; Jiang, Z.; Cai, J.; Shen, B. Model-Based Predictive Control of Multi-Stage Air-Source Heat Pumps Integrated with Phase Change Material-Embedded Ceilings. Appl. Energy 2023, 336, 120796. [Google Scholar] [CrossRef]

- Arivazhagan, R.; Geetha, N.B.; Pandiyarajan, R. Experimental and Numerical Investigation of PCMS on Ceilings for Thermal Management. J. Eng. Res. 2023; in press. [Google Scholar] [CrossRef]

- Mousavi, S.; Rismanchi, B.; Brey, S.; Aye, L. Thermal and Energy Performance Evaluation of a Full-Scale Test Cabin Equipped with PCM Embedded Radiant Chilled Ceiling. Build. Environ. 2023, 237, 110348. [Google Scholar] [CrossRef]

- Plytaria, M.T.; Bellos, E.; Tzivanidis, C.; Antonopoulos, K.A. Numerical Simulation of a Solar Cooling System with and without Phase Change Materials in Radiant Walls of a Building. Energy Convers. Manag. 2019, 188, 40–53. [Google Scholar] [CrossRef]

- Li, Z.X.; Al-Rashed, A.A.A.A.; Rostamzadeh, M.; Kalbasi, R.; Shahsavar, A.; Afrand, M. Heat Transfer Reduction in Buildings by Embedding Phase Change Material in Multi-Layer Walls: Effects of Repositioning, Thermophysical Properties and Thickness of PCM. Energy Convers. Manag. 2019, 195, 43–56. [Google Scholar] [CrossRef]

- Sun, X.; Jovanovic, J.; Zhang, Y.; Fan, S.; Chu, Y.; Mo, Y.; Liao, S. Use of Encapsulated Phase Change Materials in Lightweight Building Walls for Annual Thermal Regulation. Energy 2019, 180, 858–872. [Google Scholar] [CrossRef]

- Cao, V.D.; Pilehvar, S.; Salas-Bringas, C.; Szczotok, A.M.; Bui, T.Q.; Carmona, M.; Rodriguez, J.F.; Kjøniksen, A.-L. Thermal Analysis of Geopolymer Concrete Walls Containing Microencapsulated Phase Change Materials for Building Applications. Sol. Energy 2019, 178, 295–307. [Google Scholar] [CrossRef]

- Cao, V.D.; Bui, T.Q.; Kjøniksen, A.-L. Thermal Analysis of Multi-Layer Walls Containing Geopolymer Concrete and Phase Change Materials for Building Applications. Energy 2019, 186, 115792. [Google Scholar] [CrossRef]

- Kant, K.; Shukla, A.; Sharma, A. Numerical Simulation of Building Wall Incorporating Phase Change Material for Cooling Load Reduction. Energy Clim. Change 2020, 1, 100008. [Google Scholar] [CrossRef]

- Byon, Y.-S.; Jeong, J.-W. Annual Energy Harvesting Performance of a Phase Change Material-Integrated Thermoelectric Power Generation Block in Building Walls. Energy Build. 2020, 228, 110470. [Google Scholar] [CrossRef]

- Vukadinović, A.; Radosavljević, J.; Đorđević, A. Energy Performance Impact of Using Phase-Change Materials in Thermal Storage Walls of Detached Residential Buildings with a Sunspace. Sol. Energy 2020, 206, 228–244. [Google Scholar] [CrossRef]

- Khan, R.J.; Bhuiyan, M.Z.H.; Ahmed, D.H. Investigation of Heat Transfer of a Building Wall in the Presence of Phase Change Material (PCM). Energy Built Environ. 2020, 1, 199–206. [Google Scholar] [CrossRef]

- Yu, N.; Chen, C.; Mahkamov, K.; Han, F.; Zhao, C.; Lin, J.; Jiang, L.; Li, Y. Selection of a Phase Change Material and Its Thickness for Application in Walls of Buildings for Solar-Assisted Steam Curing of Precast Concrete. Renew. Energy 2020, 150, 808–820. [Google Scholar] [CrossRef]

- Arunkumar, D.; Ramu, M.; Murugan, R.; Kannan, S.; Arun, S.; Baskar, S. Investigation of Heat Transfer of Wall with and without Using Phase Change Material. Mater. Today Proc. 2020, 33, 2646–2650. [Google Scholar] [CrossRef]

- Kishore, R.A.; Bianchi, M.V.A.; Booten, C.; Vidal, J.; Jackson, R. Optimizing PCM-Integrated Walls for Potential Energy Savings in U.S. Buildings. Energy Build. 2020, 226, 110355. [Google Scholar] [CrossRef]

- Zaid, Z.B.; Tilioua, A.; Lamaamar, I.; Ansari, O.; Souli, H.; Hamdi Alaoui, M.A. An Experimental Study of the Efficacy of Integrating a Phase Change Material into a Clay-Straw Wall in the Drâa-Tafilalet Region (Errachidia Province), Morocco. J. Build. Eng. 2020, 32, 101670. [Google Scholar] [CrossRef]

- Pirasaci, T. Investigation of Phase State and Heat Storage Form of the Phase Change Material (PCM) Layer Integrated into the Exterior Walls of the Residential-Apartment during Heating Season. Energy 2020, 207, 118176. [Google Scholar] [CrossRef]

- Ouhsaine, L.; Ramenah, H.; El Ganaoui, M.; Mimet, A. Dynamic State-Space Model and Performance Analysis for Solar Active Walls Embedded Phase Change Material. Sustain. Energy Grids Netw. 2020, 24, 100401. [Google Scholar] [CrossRef]

- Shen, D.; Yu, C.; Wang, W. Investigation on the Thermal Performance of the Novel Phase Change Materials Wall with Radiative Cooling. Appl. Therm. Eng. 2020, 176, 115479. [Google Scholar] [CrossRef]

- Liu, Z.; Hou, J.; Meng, X.; Dewancker, B.J. A Numerical Study on the Effect of Phase-Change Material (PCM) Parameters on the Thermal Performance of Lightweight Building Walls. Case Stud. Constr. Mater. 2021, 15, e00758. [Google Scholar] [CrossRef]

- Rai, A.C. Energy Performance of Phase Change Materials Integrated into Brick Masonry Walls for Cooling Load Management in Residential Buildings. Build. Environ. 2021, 199, 107930. [Google Scholar] [CrossRef]

- Kishore, R.A.; Bianchi, M.V.A.; Booten, C.; Vidal, J.; Jackson, R. Enhancing Building Energy Performance by Effectively Using Phase Change Material and Dynamic Insulation in Walls. Appl. Energy 2021, 283, 116306. [Google Scholar] [CrossRef]

- Govindasamy, D.; Panwar, V. Effect of Variation in Thickness of Phase Change Material on Temperature across the Composite Building Wall. Mater. Today Proc. 2021, 46, 10221–10226. [Google Scholar] [CrossRef]

- Hattan, H.A.; Madhkhan, M.; Marani, A. Thermal and Mechanical Properties of Building External Walls Plastered with Cement Mortar Incorporating Shape-Stabilized Phase Change Materials (SSPCMs). Constr. Build. Mater. 2021, 270, 121385. [Google Scholar] [CrossRef]

- Zaid, Z.B.; Tilioua, A.; Lamaamar, I.; Ansari, O.; Hamdi Alaoui, M.A. Thermal Performance of Clay-Straw Wall Incorporating Phase Change Materials in Errachidia City (South Eastern Morocco): A Simulation Approach. Case Stud. Constr. Mater. 2021, 15, e00786. [Google Scholar]

- Tian, G.; Lv, H.; Huang, J.; Liu, P.; Feng, W. Experimental Study on the Heat Transfer Characteristics of Different Walls with Phase Change Materials in Summer. J. Build. Eng. 2021, 44, 103354. [Google Scholar] [CrossRef]

- Yu, C.; Shen, D.; He, W.; Hu, Z.; Zhang, S.; Chu, W. Parametric Analysis of the Phase Change Material Wall Combining with Micro-Channel Heat Pipe and Sky Radiative Cooling Technology. Renew. Energy 2021, 178, 1057–1069. [Google Scholar] [CrossRef]

- Liu, Z.; Hou, J.; Wei, D.; Meng, X.; Dewancker, B.J. Thermal Performance Analysis of Lightweight Building Walls in Different Directions Integrated with Phase Change Materials (PCM). Case Stud. Therm. Eng. 2022, 40, 102536. [Google Scholar] [CrossRef]

- Alharbey, R.A.; Daqrouq, K.O.; Alkhateeb, A. Energy Exchange of Inserting Eco-Friendly Bio Phase Change Material into the Vertical Walls to Make the Buildings Energy-Efficient. J. Build. Eng. 2022, 56, 104777. [Google Scholar] [CrossRef]

- Imafidon, O.J.; Ting, D.S.-K. Energy Consumption of a Building with Phase Change Material Walls—The Effect of Phase Change Material Properties. J. Energy Storage 2022, 52, 105080. [Google Scholar] [CrossRef]

- Nizovtsev, M.I.; Sterlyagov, A.N. Effect of Phase Change Material (PCM) on Thermal Inertia of Walls in Lightweight Buildings. J. Build. Eng. 2024, 82, 107912. [Google Scholar] [CrossRef]

- Allam, B.; Nehari, T.; Benlekkam, M.L. Building Brick Wall Thermal Management Optimization and Temperature Control Based on Phase Change Materials Integration. Case Study of the City of Bechar, Algeria. J. Energy Storage 2023, 73, 109043. [Google Scholar] [CrossRef]

- Gencel, O.; Ustaoglu, A.; Sarı, A.; Hekimoğlu, G.; Sutcu, M.; Tozluoglu, A.; Tutus, A.; Cicekler, M.; Veer Tyagi, V. Developing Wallpaper/Dodecyl Alcohol Composite Phase Change Materials as New Kind of Wall Covering Elements for Building Interior Thermoregulation. Therm. Sci. Eng. Prog. 2023, 46, 102183. [Google Scholar] [CrossRef]

- Rashid, F.L.; Al-Obaidi, M.A.; Dulaimi, A.; Mahmood, D.M.N.; Sopian, K. A Review of Recent Improvements, Developments, and Effects of Using Phase-Change Materials in Buildings to Store Thermal Energy. Designs 2023, 7, 90. [Google Scholar] [CrossRef]

| Author [Reference] | Year | Geometry | Study Type | Studied Parameters | Results and Remarks |

|---|---|---|---|---|---|

| Bhamare et al. [24] | (2020) | Inclined PCM layer on residential roof. | Numerical | Roofing PCM layer tilt. | Inclining the roofing PCM layer reduced the daily heat gain significantly. When it comes to time, the parameter of decrement, cycle of melting and solidification, daily heat gain savings for the structure of the roof, and the PCM layer inclined at 2° offer the best performance. |

| Bhamare et al. [25] | (2020) | PCM-integrated roof. | Experimental and Numerical | PCM thermophysics influences. | PCM thermal conductivity and melting temperature affect PCM choices and building thermal performance. |

| Luo et al. [26] | (2020) | Porous phase change brick roof. | Numerical | Phase shift material-filled porous brick roof impact. | A normal porous-brick roof filled with air performed poorly, lowering the heat flow to 67.8 kJ/m2. In contrast, a roof packed with the PCM at a temperature of 27 °C reduced the heat flow by 73.4%. |

| Hu et al. [27] | (2020) | A roof that has been coated with thermochromic or has a PCM applied to it. | Numerical | Effect of TC/PCM coatings. | TC, PCM, and TC/PCM roofs save 13%, 15%, and 17% more energy than asphalt roofs, respectively. |

| Triano-Juárez et al. [28] | (2020) | PCM-intermediary concrete roof. | Numerical | The PCM impact upon the concrete roof. | A 2 cm layer of PCM at the grey roof’s inner surface reduced the interior surface temperature by 6.4 °C and the heat gain by 22.2%. |

| Fabiani et al. [29] | (2020) | A shape-stabilized composite that stores heat better. | Numerical | Clarify whether PCM addition might improve membrane behaviour over time. | The addition of 25% PCM in weight enhanced the prototype’s surface finishing and decreased thermal-induced deterioration and leakage. |

| Li et al. [30] | (2020) | Innovative ventilated roof made of various phase transition materials. | Experimental and Numerical | Influence of VR-MPCM. | Compared to typical vented roofs, a VR-MPCM reduces the interior highest temperature by 16.9–18.8% and delays the occurrence of the highest temperature by 30–50 min. |

| Chang et al. [31] | (2020) | WPC roof module system with a phase change material. | Experimental | Impact of PCM/WPC roof. | The surface temperatures were decreased by 7.37 °C, thanks to the PCM/WPC roof module system. |

| Boobalakrishnan et al. [32] | (2021) | The single-story metal roof used paraffin-based phase shifting material. | Experimental | Impact of metal roof PCM encapsulation. | A significant reduction in external, interior, and thermal comfort was achieved by encasing the PCM in the metal roof of the one-story building. |

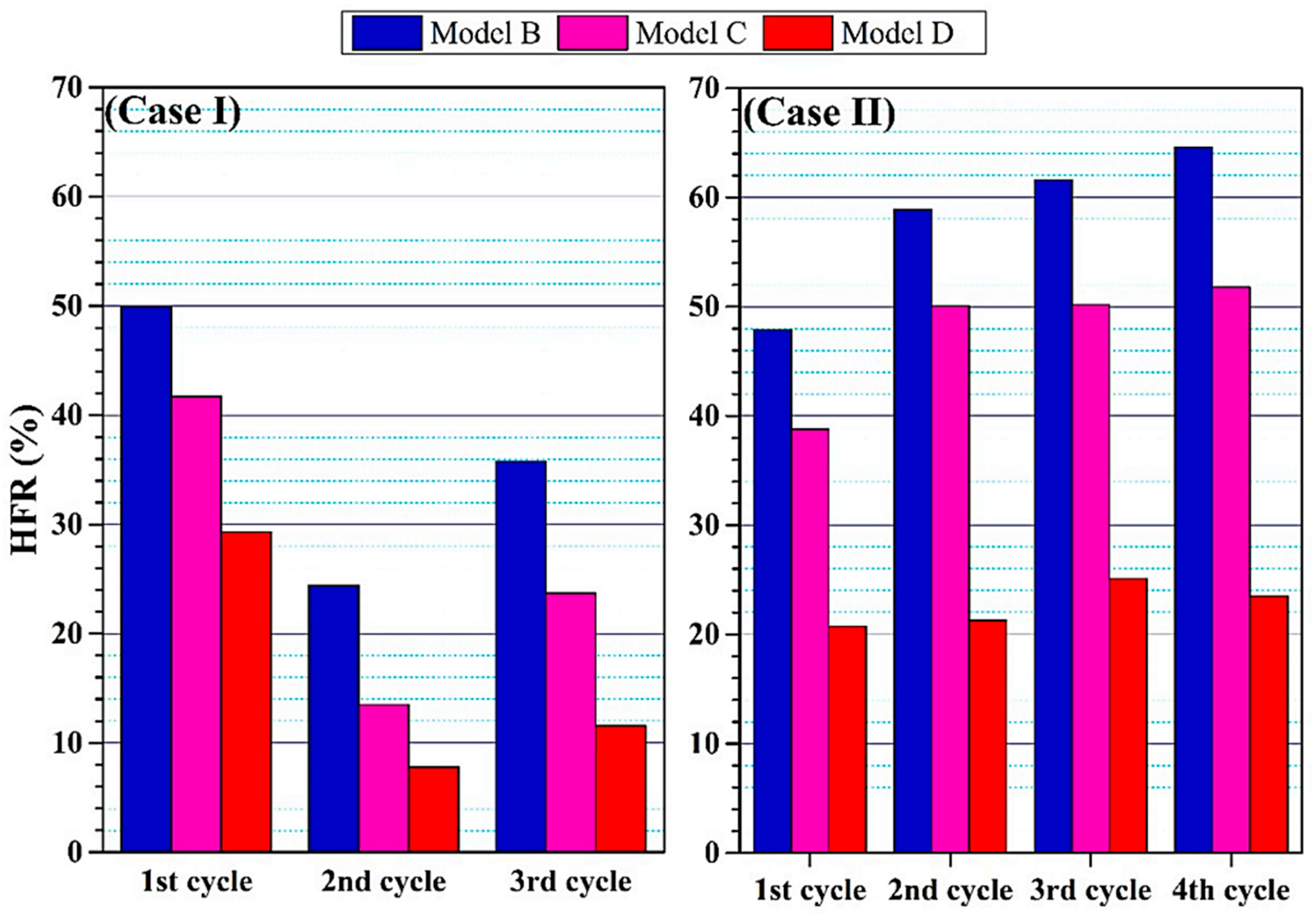

| Al-Yasiri et al. [33] | (2021) | Composite roof with a PCM layer in extreme temperatures. | Experimental | Effect of PCM-layered composite roof. | The 20 mm composite roof outperformed the reference instance in terms of thermal performance, outperforming it by 13.9% in RMTR, 10.74 °C in ATFR, 44.7% in DF, and 190 min in TL. |

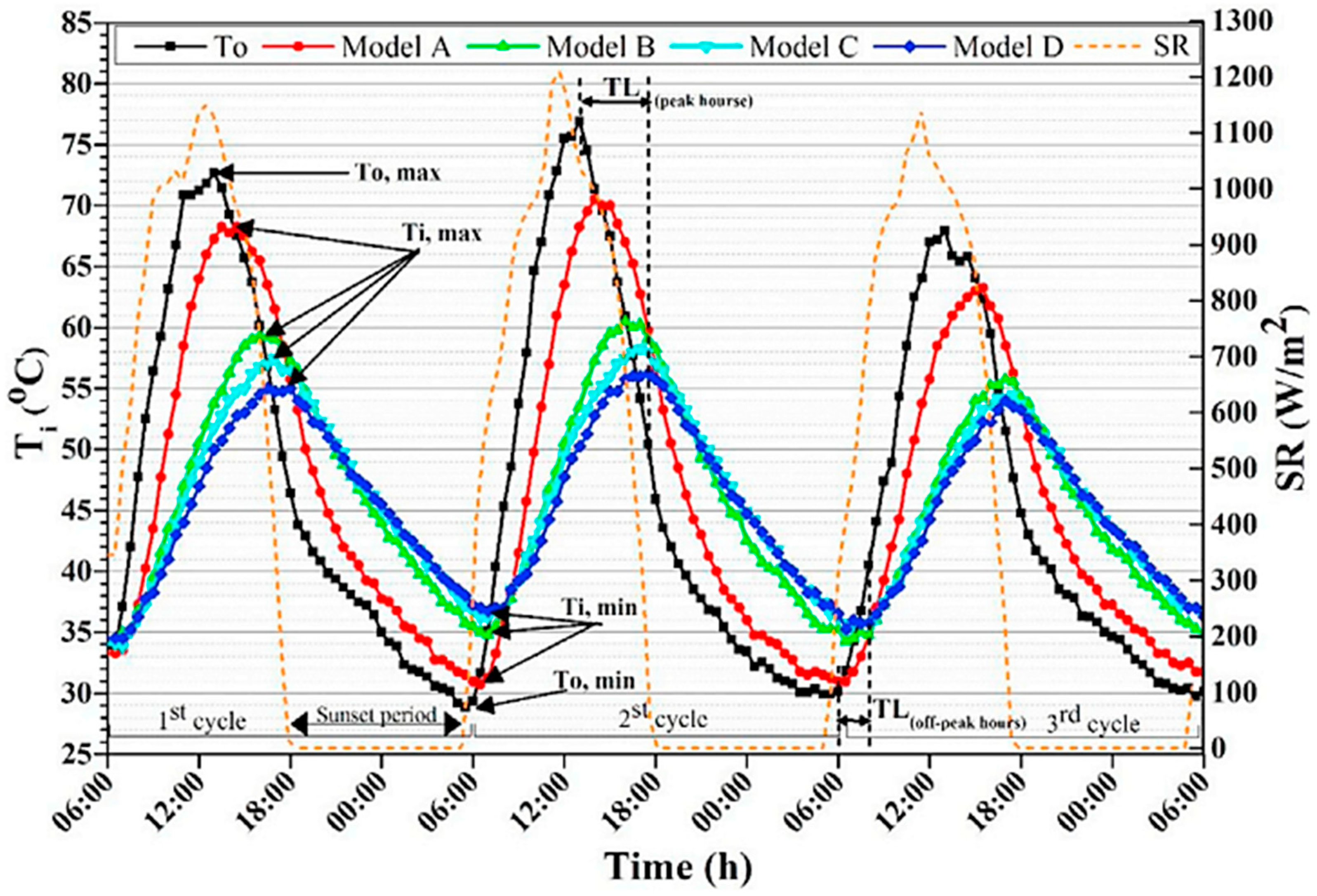

| Al-Yasiri et al. [34] | (2021) | PCM-clad composite roof. | Experimental | Effect of PCM-incorporated composite roof. | At high temperatures, the PCM performed well. The maximum room temperature for PCM models was 9 °C lower than that of the reference model. |

| Elawady et al. [35] | (2022) | Building roof with PCMs. | Numerical | Influence of PCM layer. | Insulating the roof with PCMs lowers the internal heat loss and brings the temperature of the inside wall to the required temperature of the air. |

| Rangel et al. [36] | (2022) | Phase change material on semi-arid roofs. | Experimental | The PCM’s impact on naturally ventilated roof thermal comfort. | A peak lag time of −10 to 70 min and an interior air temperature reduction ranging from 3.94% to 7.02% are characteristics of configurations that use PCMs. |

| Wang et al. [37] | (2022) | Building a roof using a shape-stabilized phase change material’s changeable transparency. | Numerical | Impact of phase change material melting temperature, thickness, and extinction coefficient. | The recommended PCM temperature of melting as well as the thickness are 24 °C and 8 mm for Beijing, 24 °C and 4 mm for Changsha and Guangzhou, and 21 °C and 5 mm for Urumqi, respectively. |

| Meng et al. [38] | (2022) | PCM foamed cement with varying rates. | Experimental | Impact of the rate of foaming. | Roof interior surface temperatures can be reduced by 2 °C and 1.1 °C, and by 2.9 °C and 2.5 °C in different cases, via PCM FCRs and FCRs. |

| Rahi et al. [39] | (2023) | RCC roof slab with macro-encapsulated PCMs. | Numerical | Shape, thermal shading, and area of heat transmission all have an impact when using the same PCM. | Increased heat transfer area improves thermal performance and provides the best scenario, reducing peak and average temperatures by 3.2 and 1.2 °C. |

| Sedaghat et al. [40] | (2023) | BioPCMs and cool roof coatings save energy in three hot climates. | Experimental and Numerical | BioPCMs and cool roof coatings’ potential. | BioPCMs at three wall and roof places saved 53%, 22%, and 23% of energy in India, Kuwait, and Australia, respectively. |

| Jiang et al. [41] | (2023) | PCMC cool roof. | Experimental and Numerical | Roof heat transfer and energy savings. | With the PCMC cool roof, the real-time temperatures of the outside and inside of the roof were decreased by 30.0 °C and 6.4 °C, respectively, and the flow of heat from the roof’s inside was reduced by 33.3% to 66.7%. |

| Nguyen et al. [42] | (2023) | Six roof configurations with PCM capsules in various places and orientations are studied. | Numerical | The effects of a PCM with an angled magnetic field. | Because capsules are tiny, the magnetic field has little influence on thermal behaviour. |

| Yu et al. [43] | (2023) | New shape-stabilized phase change ventilation roof. | Experimental and Analytical | Impact of PCM and nocturnal ventilation. | PCM and night ventilation save energy well. |

| Nguyen et al. [44] | (2023) | Variations on roof PCM integration. | Numerical | Impact of PCM configurations. | At a low Rayleigh number, the highest thermal resistance is achieved when a single PCM block is positioned at the top of the cavity, separated from the hot source by a layer of brick. |

| Nguyen et al. [45] | (2023) | Roof with Ferro-phase change materials and nanoparticles exposed to a magnetic field. | Numerical | Impact of Hartmann number and magnetic field inclination. | Vertically oriented Ferro-PCM blocks have 30% lower thermal resistance than horizontal ones without magnetic fields. |

| Luo et al. [46] | (2023) | Paraffin wax-filled porous bricks with high diurnal temperature fluctuations. | Numerical | Effect of paraffin wax on permeable brickwork. | Paraffin waxes that had the temperatures of phase transition: 28, 26, 24, and 28 °C worked admirably on the porous brick roofs in Xining, Shanghai, Harbin, Hohhot, and Urumqi. |

| Author [Reference] | Year | Geometry | Study Type | Studied Parameters | Results and Remarks |

|---|---|---|---|---|---|

| Basher et al. [48] | (2018) | Adding PCM to building walls and ceilings. | Numerical | PCM’s impact on thermal performance and comfort. | PCM insulation lowers zones’ interior temperature, cooling load, and power usage. |

| Yasin et al. [49] | (2019) | A new PCM-chilled ceiling room model. | Experimental and Numerical | Impact of PCM. | An RMSE of ±0.3 °C and ±0.6 °C was found for the simulated as well as observed temperature deviation for the operational and PCM temperatures, respectively. |

| Abden et al. [50] | (2020) | Composite FSPCM for gypsum board. | Experimental | Impact of using FSPCM. | FSPCM in gypsum board ceilings saves 16.2% cooling demand, making it economically viable. |

| Lim et al. [51] | (2020) | An integrated thermoelectric radiant cooling panel made of PCM. | Experimental and Numerical | The impact of employing PCM. | The supreme option of PCM-TERCP for conditioned space utilisation is a layer of PCM with a 10 mm thickness over the panel’s five heat fins per unit length of the panel. |

| Yan et al. [52] | (2020) | Micro-encapsulated PCM covers the mini-channel ceiling. | Numerical | Effect of micro-encapsulated PCMs. | Using micro-encapsulated PCMs reduces the heat flow of the ceiling in the heating section. Additionally, MEPCM melts quicker at lower Reynolds numbers. |

| Velasco-Carrasco et al. [53] | (2020) | Keep room temperatures up using PCM ceiling tiles. | Experimental | Effect of applying PCMs. | The S23 panel can safely encapsulate the PCM and enhance heat exchange with the thermal environment, making it ideal for building inclusion. |

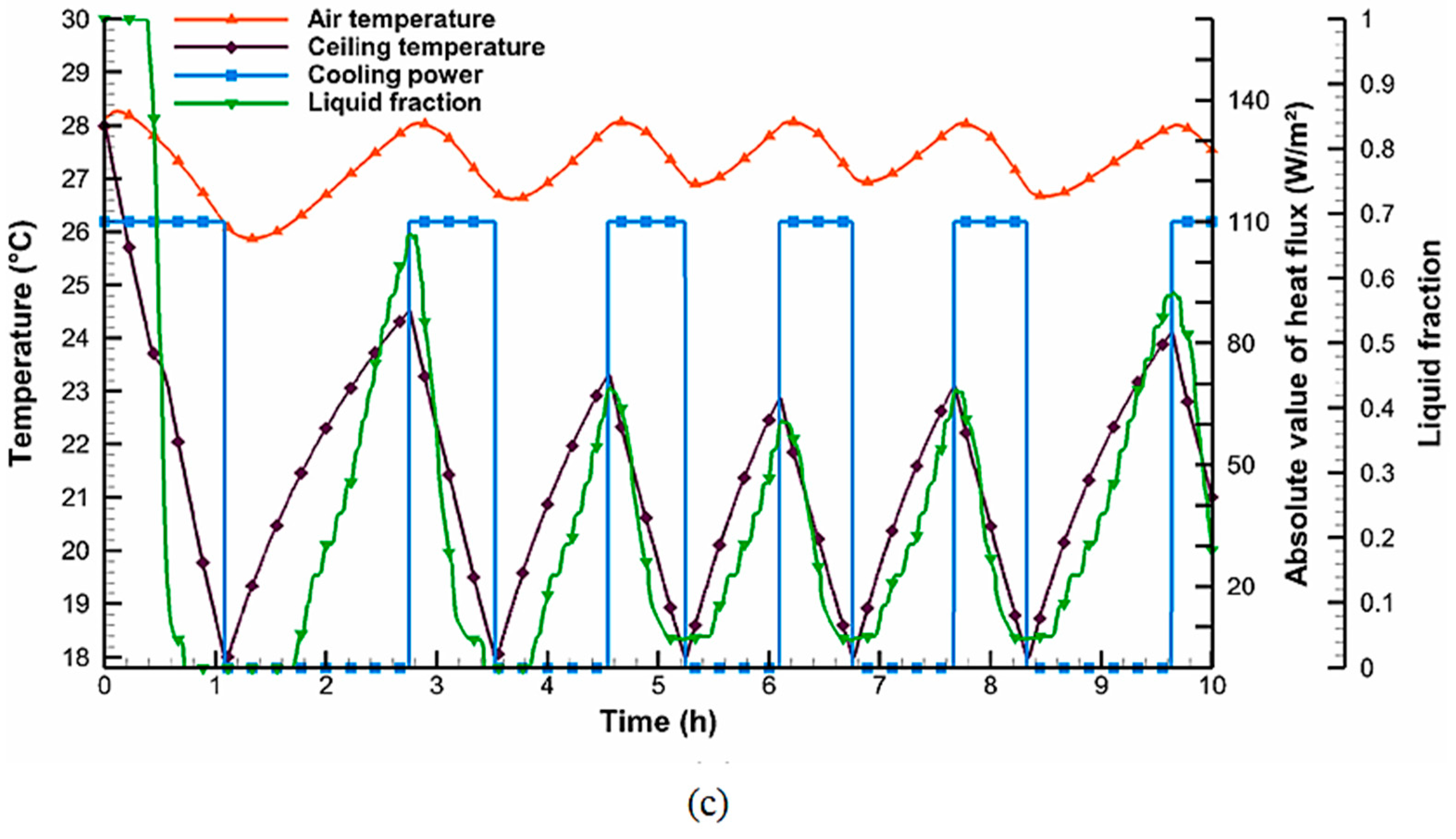

| Bogatu et al. [54] | (2021) | Innovative macro-encapsulated PCM panel for the effective cooling of the ceiling, including integrated pipes. | Experimental | Effect of innovative macro-encapsulated PCM panel. | If the PCM is entirely drained, the heat storage capacity may shift the cooling demand to off-peak hours. |

| Gallardo and Berardi [55] | (2021) | RCP-PCM system by Adiant. | Experimental and Numerical | Adant ceiling panel (RCP)-PCM system effect. | An RCP-PCM system has the potential to save 22% more energy than an all-air system in areas with high temperatures and humidity. |

| Sinacka and Szczechowiak [56] | (2021) | A 60% paraffin-filled chamber with hanging thermally actuated ceiling panels. | Experimental | Phase shift material and energy supply. | Unsteady state assessments are needed because the thermally triggered ceiling and PCM integration complicate energy audits, designs, and control plan creation. |

| Skovajsa et al. [57] | (2022) | Ceiling cooling using PCMs. | Experimental and Numerical | PCMs’ impact on ceiling cooling. | Relying upon the change rate of air, the suggested cooling ceiling system can minimise temperature peaks by 3.2 °C and save 27% of energy. |

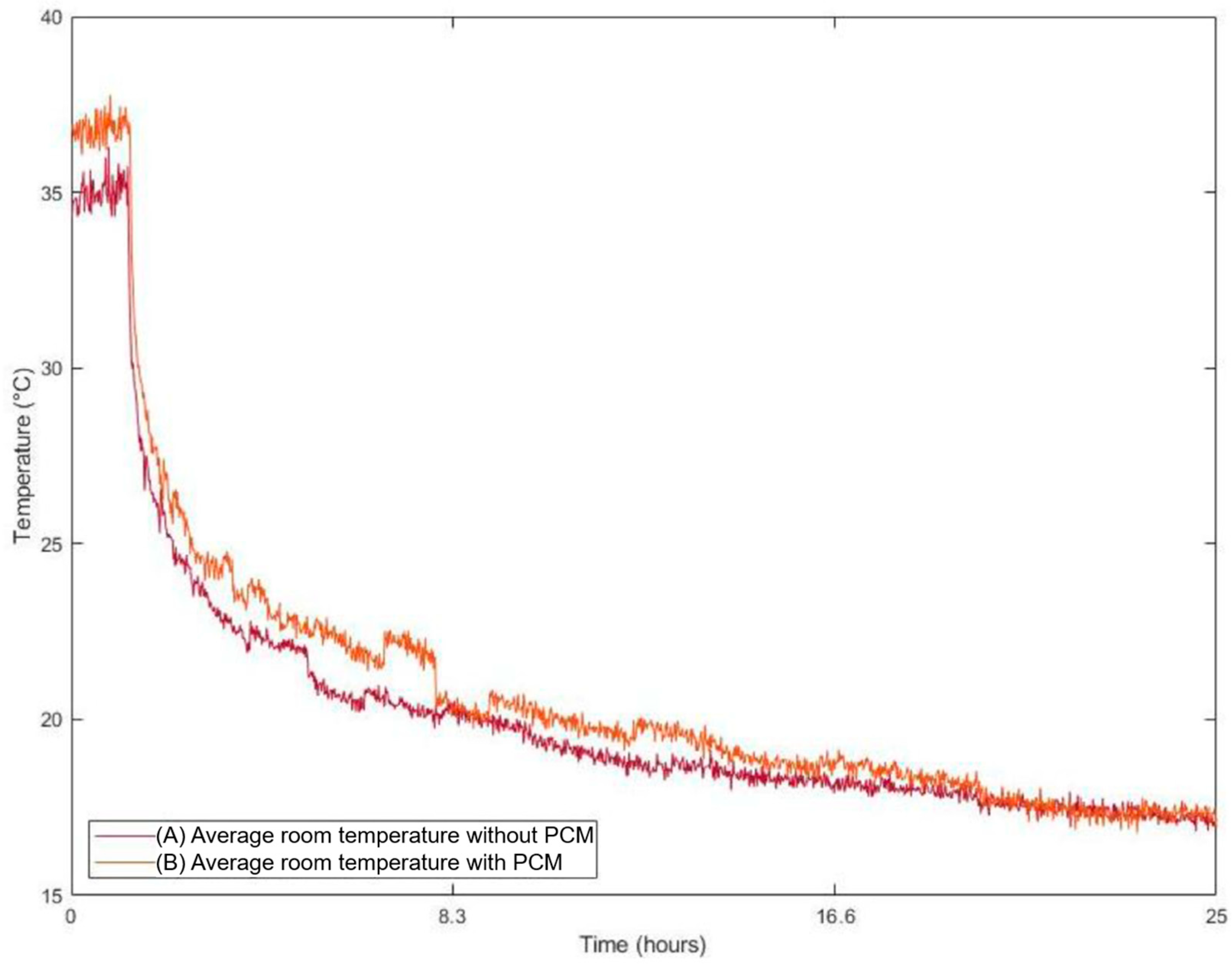

| Mousavi et al. [58] | (2022) | A standalone cabin with a fresh PCM-integrated radiant chilled ceiling (PCM-RCC). | Experimental | Impact of using PCM. | Design must consider numerous variables to maximize PCM recharge overnight efficiency. If the battery does not overheat before midnight, 6–8 h should be plenty of time. |

| Gallardo and Berardi [60] | (2022) | The macro-encapsulated phase change materials are concealed by the serpentine copper coil of standard radiant ceiling panels (RCPs). | Experimental | Influence of the RCP-PCM system. | By redistributing cooling loads to off-peak hours, the RCP-PCM system can keep workers comfortable from 8:00 to 18:00 in the workday. |

| Mustafa et al. [61] | (2022) | PCM improves RCC. | Numerical | Impact of PCM. | When the cold airflow goes into the internal ventilation, it can cut electricity consumption by 26.1% in April and 25.3% in October, but not in July and August. |

| Khattari et al. [62] | (2022) | A ventilated room with a governed cooling ceiling system using PCMs. | Numerical | Impact of using PCMs. | Paraffin C13 as a PCM in cooling ceilings saved 17.07% and 16.30% in Fez and Ifrane climates. |

| Yang et al. [63] | (2023) | A ceiling-mounted thin-shell container containing lauric, capric, and oleic acids as PCMs. | Numerical | Impact of panel volume, starting PCM–air temperature differential, and shell thickness. | Thermal performance is better for pyramid array panels than tetrahedral panels, with an average melting rate 20.8% greater at 250 mL. |

| Hlanze et al. [64] | (2023) | A multi-stage air-source heat pump with PCM ceiling panels. | Numerical | Impact of PCM ceiling panels. | Beneath a time-of-use rate tariff, the suggested governing approach for the PCM-integrated heat pump may reduce the energy costs by (27.1%), whereas a rule-based control strategy with fine-tuning might reduce them by 20.4%. |

| Arivazhagan et al. [65] | (2023) | Ceiling-integrated PCM. | Experimental | Phase-change material impact. | The difference in temperature between the PCM and the inside air after installation was 8.77 °C, 1.55 °C, 1 °C, and 0.44 °C, correspondingly, due to a 1.69 °C, 5.79 °C, 2.26 °C, and −2.87 °C reduction in the air temperature. |

| Mousavi et al. [66] | (2023) | The system of PCM-RCC in a full-scale examination cabin with PCM panels. | Experimental | Impact of PCM-RCC on PCM panels. | PCM panels were completely recharged after 4–5 h of the chilled water movement overnight. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rashid, F.L.; Dulaimi, A.; Hatem, W.A.; Al-Obaidi, M.A.; Ameen, A.; Eleiwi, M.A.; Jawad, S.A.; Bernardo, L.F.A.; Hu, J.W. Recent Advances and Developments in Phase Change Materials in High-Temperature Building Envelopes: A Review of Solutions and Challenges. Buildings 2024, 14, 1582. https://doi.org/10.3390/buildings14061582

Rashid FL, Dulaimi A, Hatem WA, Al-Obaidi MA, Ameen A, Eleiwi MA, Jawad SA, Bernardo LFA, Hu JW. Recent Advances and Developments in Phase Change Materials in High-Temperature Building Envelopes: A Review of Solutions and Challenges. Buildings. 2024; 14(6):1582. https://doi.org/10.3390/buildings14061582

Chicago/Turabian StyleRashid, Farhan Lafta, Anmar Dulaimi, Wadhah Amer Hatem, Mudhar A. Al-Obaidi, Arman Ameen, Muhammad Asmail Eleiwi, Sarah Abbas Jawad, Luís Filipe Almeida Bernardo, and Jong Wan Hu. 2024. "Recent Advances and Developments in Phase Change Materials in High-Temperature Building Envelopes: A Review of Solutions and Challenges" Buildings 14, no. 6: 1582. https://doi.org/10.3390/buildings14061582