Enhancing Supply Chain Resilience in Prefabricated Buildings: The Role of Blockchain Technology in Volatile, Uncertain, Complex, and Ambiguous Environments

Abstract

:1. Introduction

2. Literature Review

2.1. Prefabricated Building Supply Chain

2.2. Supply Chain Resilience

2.3. Application of Blockchain Technology in Construction Supply Chain

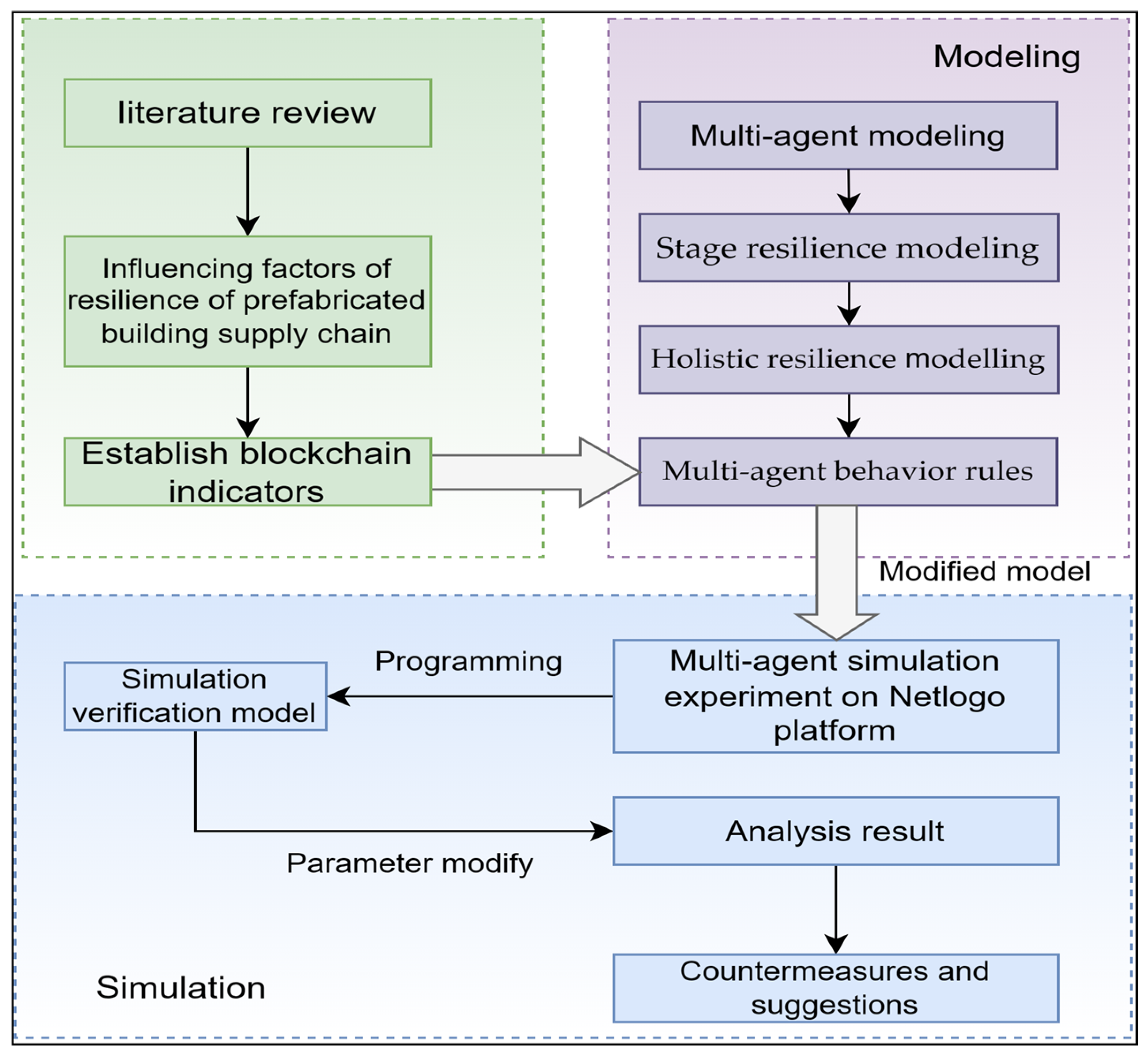

3. Materials and Methods

3.1. The Influence Factors System

3.2. Blockchain Technology’s Impact on the Resilience of Prefabricated Building Supply Chains

3.3. Resilience Measurement Modeling

3.3.1. Multi-Agent Modeling

3.3.2. Stage Resilience Modeling

3.3.3. Total Resilience Modeling

3.4. Multi-Agent Behavior Rules

- (1)

- General contractor

- (2)

- Design unit

- (3)

- Suppliers

- (4)

- Warehouse management unit

- (5)

- Producer

- (6)

- Logistics unit

- (7)

- On-site construction unit

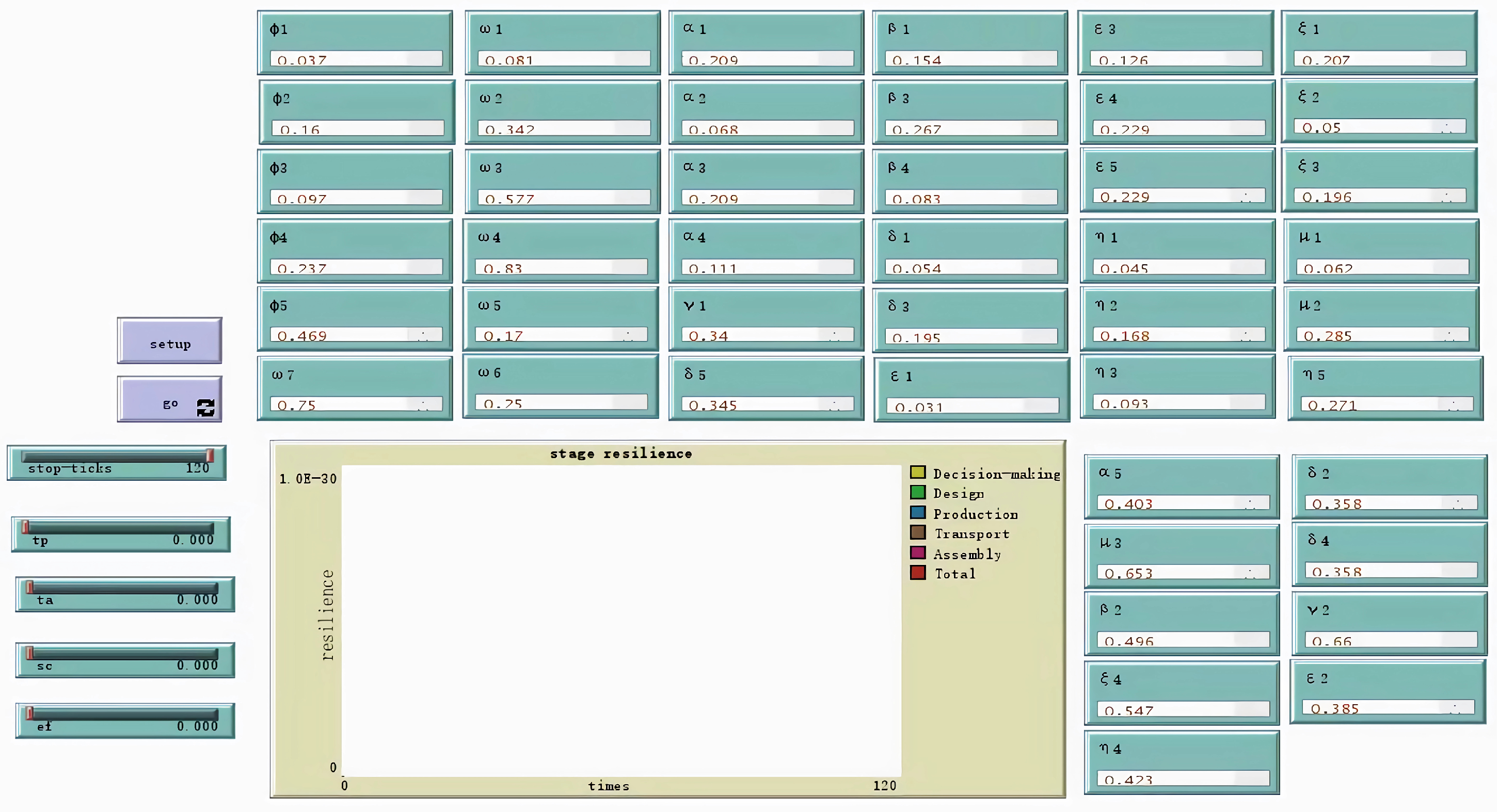

3.5. Multi-Agent Simulation Model Based on NetLogo

4. Data and Research Results

4.1. Analytic Hierarchy Process

4.2. Determination of Evaluation Index Weight

4.3. Initial Model Parameter Design

4.4. Model Simulation Results

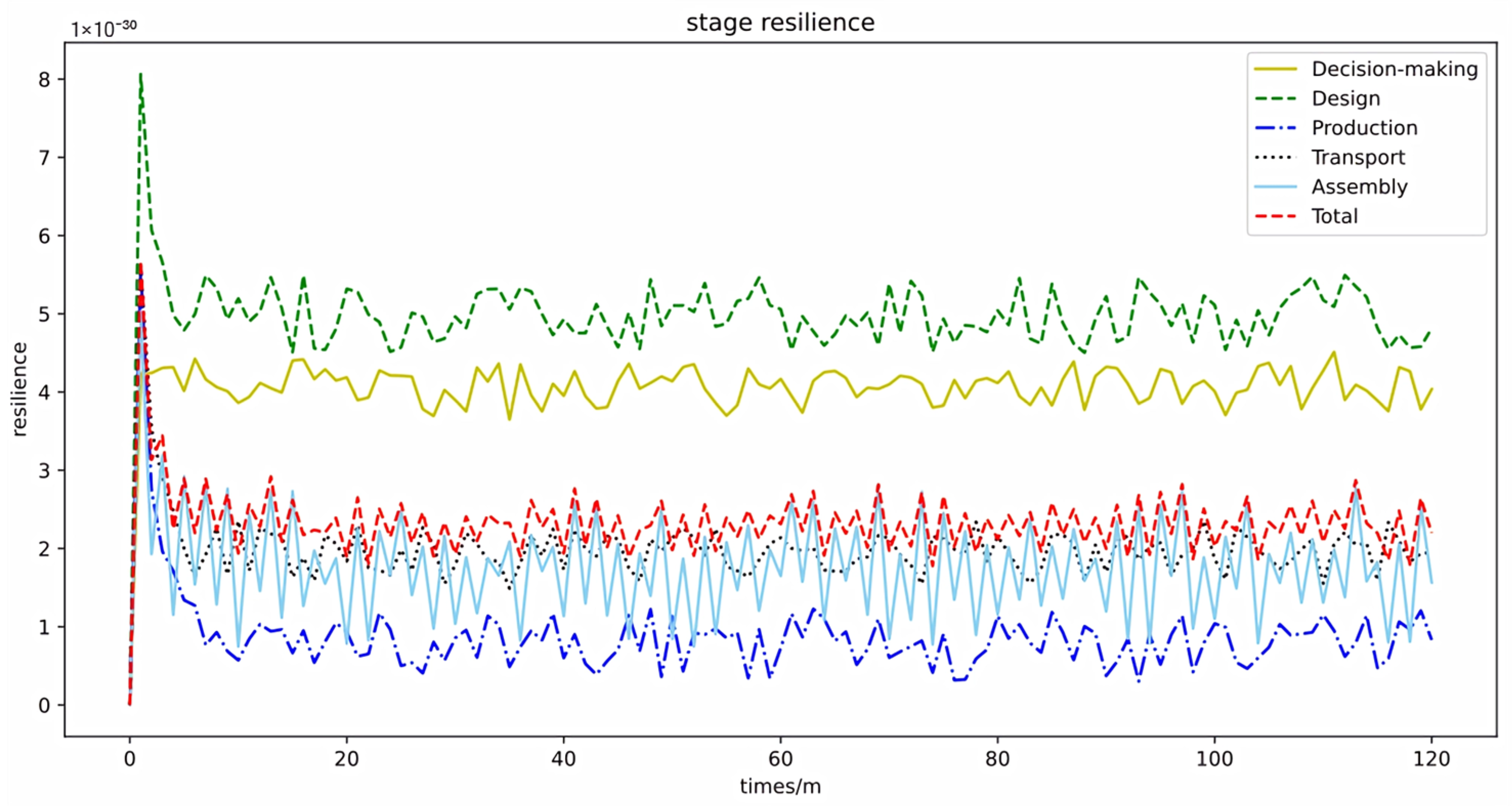

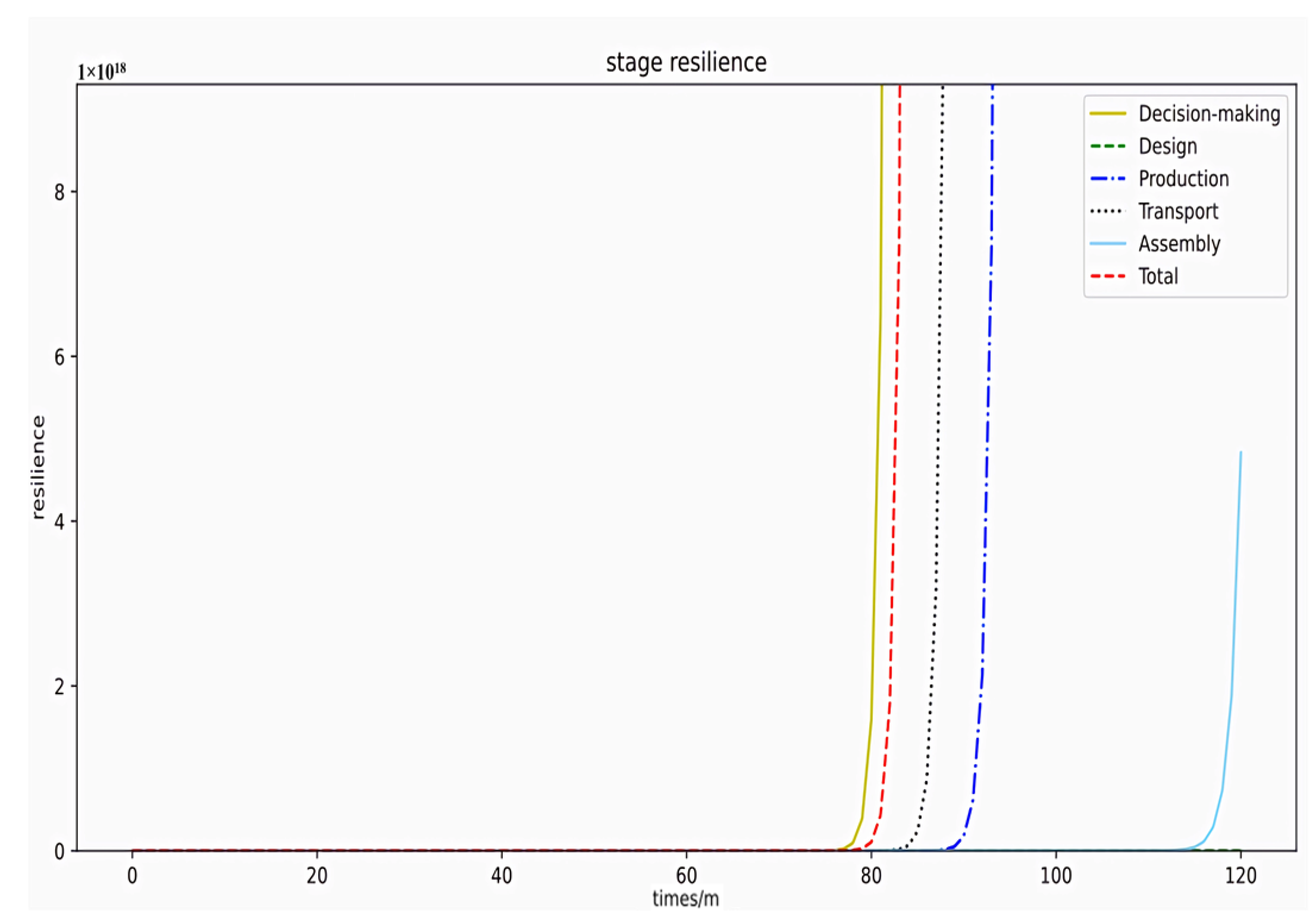

- (1)

- During the operation period set by the model, the development level of each stage and the overall resilience of the supply chain show a significant dynamic change trend. At the initial stage, the toughness performance was relatively good, and the peak value reached about 1 × 10-30. With the passage of time, the toughness showed a rapid and obvious decline and then began to maintain a low but still stable numerical range. The development of the model has experienced a process from high to low and then tends to be stable. It has not been continuously enhanced throughout the operating cycle, indicating that maintaining and improving supply chain resilience is a task that requires continuous attention and dynamic adjustment.

- (2)

- Resilience performance is best at the design stage, and as the supply chain process moves downstream, the level of resilience drops to the lowest point at the production stage. The reason is that the design phase often has higher flexibility and is forward-looking, can foresee and avoid some potential problems, and improves the system’s ability to resist risks through innovative design and redundancy planning. In the decision-making, production, transportation, and assembly stages of the supply chain, the complexity of the process is increasing. Subject to various practical problems such as equipment aging, operational errors, logistics delays, and information asymmetry, the level of resilience at each stage is gradually reduced.

- (3)

- Further analysis of the fluctuations in overall supply chain resilience and its stages during the operation of the model, it can be found that the resilience values of each stage fluctuate within their respective stable intervals except for the decline of resilience in the initial stage. This strongly proves that without the introduction of external technical interventions, the internal factors such as the initial state, management level, and resource allocation status of each participant in the supply chain will have a significant impact on the resilience of the supply chain in the short term. However, as the supply chain continues to operate, these short-term effects will gradually be digested and absorbed, and supply chain resilience will begin to return and remain in an inherently stable state based on existing conditions. This also shows that in the VUCA environment, only relying on the existing management mode and resource allocation, the good development of the prefabricated building supply chain will be subject to considerable limitations.

5. Discussion

5.1. Discussion of Multi-Agent Simulation Results

5.1.1. The Impact of Blockchain Technology on Parameter Changes

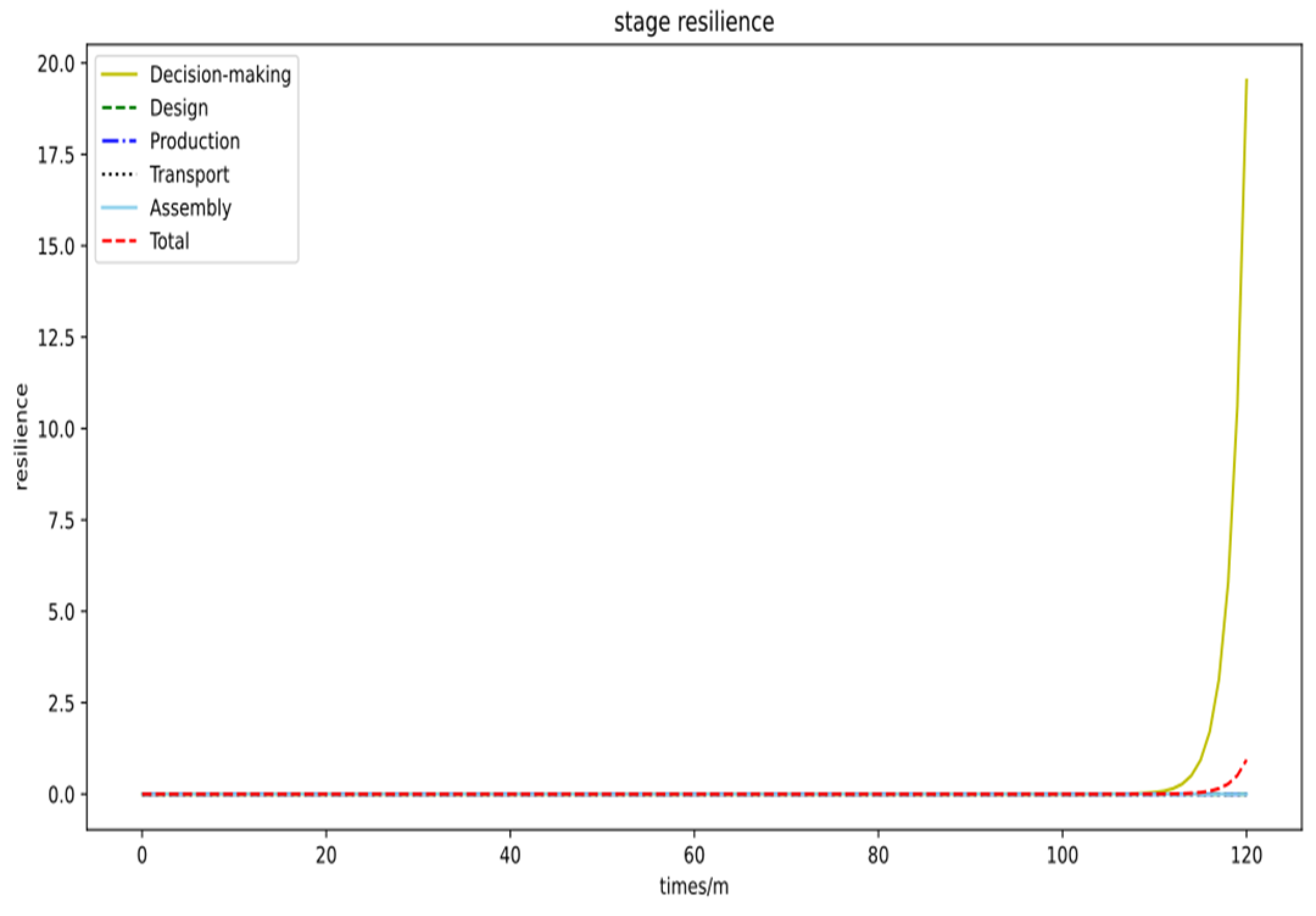

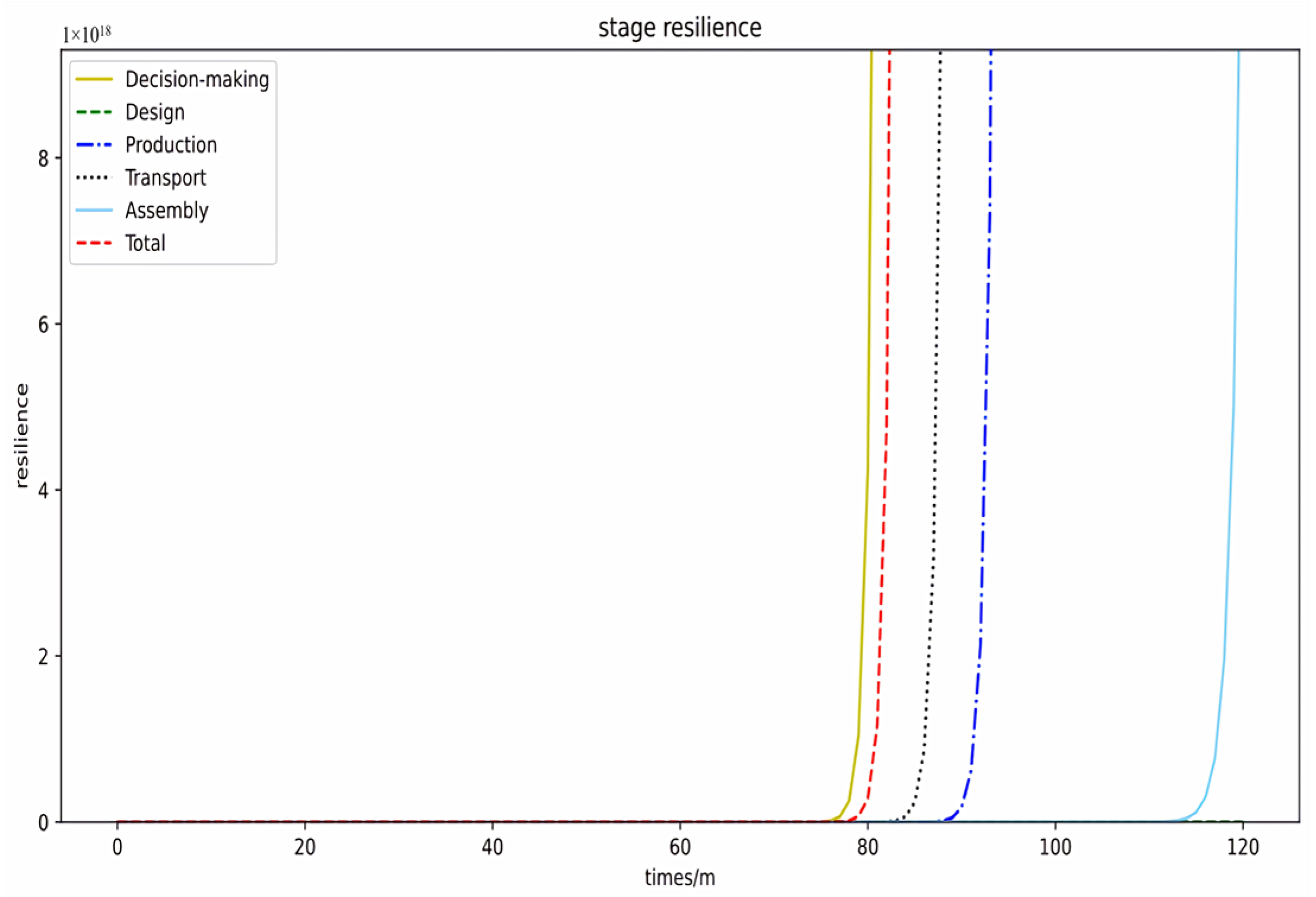

- (1)

- Compared with the simulation results of the initial model (Figure 4), after using the blockchain technology, even if the technology application is not mature, the resilience of the prefabricated building supply chain increases by multiple orders of magnitude, both in each stage and the overall resilience level. This is because blockchain technology reduces information asymmetry and improves decision-making efficiency by providing a decentralized and credible information-sharing platform. Therefore, after a long period of accumulation (i.e., after the seventh year), the improvement speed of each stage of the supply chain and the overall resilience has been significantly accelerated, even showing a nearly linear upward trend. Especially in the decision-making stage, because blockchain technology can transmit and track information instantly and accurately, the accuracy and timeliness of decision-making are greatly improved, and the resilience of this stage is improved most rapidly. This phenomenon is in stark contrast to the simulation results of the initial model.

- (2)

- Compared with the simulation results under the immature application of blockchain technology, the resilience of each stage and the overall resilience of the prefabricated building supply chain significantly improved when blockchain technology was fully applied. Not only did the resilience increase dramatically but the rate of improvement was also faster. This is attributed to the full utilization of blockchain technology in practice, which enhances its advantages in information processing, trust mechanisms, and risk prevention. The observed results also indicate that, under this condition, the development speed of resilience across the different stages and the overall supply chain follows a sequential order: decision-making stage, overall resilience, transportation stage, production stage, assembly stage, and design stage. This is in sharp contrast to the simulation results of the initial model.

5.1.2. Changes in Key Influencing Factors of Each Agent

6. Conclusions

- (1)

- This study first reveals the practical challenges in the resilience development of prefabricated construction projects and examines the compatibility of blockchain technology in addressing these issues. By analyzing the difficulties faced in the resilient development of prefabricated construction projects, this paper explores the root causes of these challenges and how blockchain technology can potentially mitigate them.

- (2)

- This paper constructs a resilience measurement model for the prefabricated building supply chain based on blockchain technology. The model starts by assessing the resilience of key subjects (such as end-users, government agencies, general contractors, design units, etc.) and gradually extends to evaluate the resilience of various stages (e.g., project decision-making, engineering design, procurement, production) and the overall supply chain. In constructing the model, particular attention is given to the interaction behaviors between participants, their impact on supply chain resilience, and the quantified technical contributions of blockchain to supply chain resilience. Through a local-to-global analysis, this model reveals the transmission mechanisms of resilience under the ripple effect within the supply chain and comprehensively demonstrates the enhancement effect of blockchain technology on the resilience of the prefabricated building supply chain.

- (3)

- The improvement effect of blockchain technology on the resilience of the prefabricated building supply chain was verified through multi-agent simulation. To assess the application value of blockchain technology for enhancing the resilience of the prefabricated building supply chain, a multi-agent simulation was conducted using the NetLogo platform with nine key subjects. The simulation modeled the supply chain’s operations under varying levels of blockchain technology maturity, and the resulting changes in supply chain resilience were observed. The results clearly demonstrate the significant role of blockchain technology in enhancing the resilience of the prefabricated building supply chain. As the maturity of blockchain technology increases, both the extent and rate of improvement in local and overall supply chain resilience become more pronounced. These results strongly confirm the substantial potential and practical value of blockchain technology in enhancing the resilience of the prefabricated building supply chain.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Bowen, D. Incremenral Cost and Benefit Analysis of Prefabricated Buildings Based on System Dynamics. Master’s Thesis, Southwest Jiaotong University, Chengdu, China, 2022. [Google Scholar]

- Wenqing, S.; Zimin, W. Research on the impact of innovation capital factor flow on urban economic resilience. Product. Res. 2024, 3, 116–122. [Google Scholar]

- Li, J.; Liang, L.; Dong, Y. Research Trend and Progress of Blockchain Enables Digital-intelligence Construction Based on CiteSpace. J. Civ. Eng. Manag. 2023, 40, 31–38. [Google Scholar]

- Lu, J.; Wang, J.; Song, Y.; Yuan, C.; He, J.; Chen, Z. Influencing Factors Analysis of Supply Chain Resilience of Prefabricated Buildings Based on PF-DEMATEL-ISM. Buildings 2022, 12, 1595. [Google Scholar] [CrossRef]

- Wang, H.; Xie, D.; Xin, J.; Dai, Z. Research on risk factors of prefabricated building supply chain. China Storage Transp. 2024, 3, 136–137. [Google Scholar]

- Zhang, M. Research on Risk of Prefabricated Building Supply Chain from the Perspective of Information Dissemination. Master’s Thesis, Tianjin University of Technology, Tianjing, China, 2021. [Google Scholar]

- Du, J.; Wang, W.; Hu, M. SEM and multi-agent simulation-based design change risk management in prefabricated construcation. J. Shanghai Univ. Nat. Sci. Ed. 2022, 28, 1038–1050. [Google Scholar]

- Sun, Y.; Tian, Y. Research on Key Risks of Prefabricated Building Supply Chain Based on Complex Network Theory. Constr. Econ. 2020, 41, 79–83. [Google Scholar]

- Luo, L.; Qiping Shen, G.; Xu, G.; Liu, Y.; Wang, Y. Stakeholder-associated supply chain risks and their interactions in a prefabricated building project in Hong Kong. J. Manag. Eng. 2019, 35, 5018015. [Google Scholar] [CrossRef]

- Baghdadi, A.; Heristchian, M.; Kloft, H. Connections placement optimization approach toward new prefabricated building systems. Eng. Struct. 2021, 233, 111648. [Google Scholar] [CrossRef]

- Zhang, Y.; Qu, F.; CHEN, C. Research on Performance Evaluation of Prefabricated Building Supply Chain Based on PCSCOR-FANP. Constr. Econ. 2021, 42 (Suppl. S1), 172–176. [Google Scholar]

- Zhao, S.; Wang, J.; Ye, M.; Huang, Q.; Si, X. An Evaluation of Supply Chain Performance of China’s Prefabricated Building from the Perspective of Sustainability. Sustainability 2022, 14, 1299. [Google Scholar] [CrossRef]

- Sholeh, M.N.; Nurdiana, A.; Dharmo, B.; Suharjono. Implementation of construction supply chain flow based on SCOR 12.0 performance standards. J. Phys. Conf. Ser. 2021, 1833, 012012. [Google Scholar] [CrossRef]

- Wang, S.; Mursalin, Y.; Lin, G.; Lin, C. Supply Chain Cost Prediction for Prefabricated Building Construction under Uncertainty. Math. Probl. Eng. Theory Methods Appl. 2018, 2018, 4580651. [Google Scholar] [CrossRef]

- Masood, R.; Lim, J.B.; Gonzalez, V.A. Performance of the supply chains for New Zealand prefabricated house-building. Sustain. Cities Soc. 2021, 64, 102537. [Google Scholar] [CrossRef]

- Sheffi, Y.; Rice, J.B.; Fleck, J.M.; Caniato, F. Supply Chain Response to Global Terrorism: A Situation Scan. In Proceedings of the EurOMA POMS Joint International Conference, Cernobbio, Italy, 17 June 2003; pp. 1–6. [Google Scholar]

- Christopher, M.; Peck, H. Building the Resilient Supply Chain. Int. J. Logist. Manag. 2004, 15, 1–13. [Google Scholar] [CrossRef]

- Zhu, L.; Chen, J.; Yuan, J. Research on Critical Factors Influencing the Resilience of Prefabricated Building Supply Chain Based on ISM. J. Civ. Eng. Manag. 2020, 37, 108–114. [Google Scholar]

- Cao, D.; He, Z.; Zhang, J.; Luo, J.; Liu, D. Research on the Resilience and Vulnerability of the Whole Industry China of Rail Transit Industry. J. Quant. Econ. 2020, 37, 16–26. [Google Scholar]

- Fan, X.; Lu, M. Influencing Factors and Evaluation of Auto Companies Supply Chain Resilience Under the COVID-19. J. Ind. Technol. Econ. 2020, 39, 21–28. [Google Scholar]

- Aggarwal, S.; Srivastava, M.K. A grey-based DEMATEL model for building collaborative resilience in supply chain. Int. J. Qual. Reliab. Ma 2019, 36, 1409–1437. [Google Scholar] [CrossRef]

- Riccardo, A.; Daria, B.; Dmitry, I. Increasing supply chain resilience through efficient redundancy allocation: A risk-averse mathematical model. Ifac-Pap. 2021, 54, 1011–1016. [Google Scholar] [CrossRef]

- Sahu, A.K.; Datta, S.; Mahapatra, S.S. Evaluation of performance index in resilient supply chain: A fuzzy-based approach. Benchmarking Int. J. 2017, 24, 118–142. [Google Scholar] [CrossRef]

- Cao, Y.; Su, Z.; Li, N. Research on System Architecture of the Information Sharing Management of Construction Supply Chain Based on Blockchain. Constr. Econ. 2019, 40, 69–74. [Google Scholar]

- Yao, Y.; Sun, E.; Zang, Y.; Li, M.; Zeng, T. Prefabricated Component Traceability System Based on RFID and Blockchain. Comput. Meas. Control 2020, 28, 221–225. [Google Scholar]

- Li, T.; Yan, X.; Wu, J. The Framework Construction of Engineering Construction Quality Management and Traceability System Based on Block-chain Technology. Constr. Econ. 2020, 41, 103–108. [Google Scholar]

- Yang, D.; Yue, A.; Yang, R. Research on Information Integration Management of Engineering Projects under Smart Construction: Based on the Application of Blockchain Technology. Constr. Econ. 2019, 40, 80–85. [Google Scholar]

- Zhang, Z.; Wang, J.; Zhang, S.; Su, S.; Zhou, D.; Qi, H. Application Research on Blockchain Technology in Field of Building Engineering. Constr. Technol. 2020, 49, 1–5. [Google Scholar]

- Tezel, A.; Papadonikolaki, E.; Yitmen, I.; Hilletofth, P. Preparing construction supply chains for blockchain technology: An investigation of its potential and future directions. Front. Eng. Manag. 2020, 7, 547–563. [Google Scholar] [CrossRef]

- Yoon, J.H.P.P. State-of-the-Art Review of Blockchain-Enabled Construction Supply Chain. J. Constr. Eng. M. 2022, 148, 03121008. [Google Scholar] [CrossRef]

- Börekçi, D.Y.; Rofcanin, Y.; Heras, M.L.; Berber, A. Deconstructing organizational resilience: A multiple-case study. J. Manag. Organ. 2021, 27, 422–441. [Google Scholar] [CrossRef]

- Wang, Q.; Gong, Z.; Liu, C. Risk Network Evaluation of Prefabricated Building Projects in Underdeveloped Areas: A Case Study in Qinghai. Sustainability 2022, 14, 6355. [Google Scholar] [CrossRef]

- Yang, W. Study on the Evaluation of Supply Chain´s Resilience of Prefabricated Building under EPC Mode. Master’s Thesis, Xihua University, Chengdu, China, 2022. [Google Scholar]

- Yuan, M.; Li, Z.; Li, X.; Luo, X. Managing stakeholder-associated risks and their interactions in the life cycle of prefabricated building projects: A social network analysis approach. J. Clean. Prod. 2021, 323, 129102. [Google Scholar] [CrossRef]

- Huang, G.; Zang, C. Green Supply Chain of Prefabricated Buildings Based on SNA. J. Civ. Eng. Manag. 2020, 37, 41–49. [Google Scholar]

- Wang, H.; Chen, Y. Study on the Influence Factors of Resilience of the Prefabricated Construction Supply Chain Based on DEMATEL-ISM Model. J. Eng. Manag. 2023, 37, 13–18. [Google Scholar]

- Zhang, K.; Tsai, J. Identification of Critical Factors Influencing Prefabricated Construction Quality and Their Mutual Relationship. Sustainability 2021, 13, 11081. [Google Scholar] [CrossRef]

- Li, Z.; Zeng, J.; Wu, H. Research on Influencing Factors and Multi-Stage Transmission Relationships of Prefabricated Buildings Supply Chain Resilience. J. Eng. Manag. 2024, 38, 18–23. [Google Scholar]

- Zhang, S.; Li, Z.; Ma, S.; Li, L.; Yuan, M. Critical Factors Influencing Interface Management of Prefabricated Building Projects: Evidence from China. Sustainability 2022, 14, 5418. [Google Scholar] [CrossRef]

- Chen, Y. Research on Quality Information Sharing and Accountability of Prefabricated Building Based on Blockchain Technology. Master’s Thesis, Huazhong University of Science and Technology, Wuhan, China, 2021. [Google Scholar]

- Zhou, T.; Zhou, Y.; Guo, C. Multi-Dimensional Interpretation of Prefabricated Building IndustryChain and Evaluation of Influencing Factor of Supply Chain Autonomous Controllability. J. Archit. Civ. Eng. 2022, 39, 192–203. [Google Scholar]

- Zhang, M.; Liu, Y.; Ji, B. Influencing Factors of Resilience of PBSC Based on Empirical Analysis. Buildings 2021, 11, 467. [Google Scholar] [CrossRef]

- Zhang, C.; Zhang, W.; He, K.; Jin, T. Research on Profit Distribution of Prefabricated Building Green Supply Chain. Constr. Econ. 2023, 44, 79–87. [Google Scholar] [CrossRef]

| Related Agent | Factors | References |

|---|---|---|

| End user (UR) | Financing ability (u1) | [6,31,32] |

| Capital level (u2) | [32] | |

| Developer experience (u3) | [31,33] | |

| Knowledge of prefabrication techniques (u4) | [33,34] | |

| Scientific and reasonable maintenance (u5) | [31,33,34] | |

| Government agencies (GR) | Policy change and regulation (g1) | [31,35] |

| Support strength (g2) | [31,36] | |

| Completeness of Regulations and Standards (g3) | [31,34,36] | |

| efficiency of the approval process (g4) | [31,34] | |

| General contractor (CR) | Work experience (c1) | [31,34] |

| Incidence of safety accidents (c2) | [31,34] | |

| Engineering quality (c3) | [31,34] | |

| Design unit (DR) | Assembly design experience (d1) | [6,33,36,37] |

| Design change frequency (d2) | [17,33,34,36] | |

| Standardized design system (d3) | [31,38] | |

| Accuracy of design documents (d4) | [17,31,33,38] | |

| Information technology level (d5) | [39,40] | |

| Suppliers (SR) | Prefabricated component supply efficiency (s1) | [17,31,38] |

| Quality of components (s2) | [7,34,36,37] | |

| Producer (PR) | Personnel production skills (p1) | [17,33,35,41] |

| Quality of components (p2) | [7,17,37] | |

| Integration of components and degree of modularity (p3) | [17,34,41] | |

| Efficiency of prefabricated component delivery (p4) | [7,35] | |

| Efficiency of component production (p5) | [6,37] | |

| Warehouse management unit (WR) | Inventory management (w) | [31,41] |

| Logistics unit (LR) | transport capacity (l1) | [17,37,41] |

| Transport redundancy (l2) | [17,42] | |

| Transport efficiency (l3) | [6,17,33] | |

| Transport quality assurance (l4) | [7,37] | |

| On-site construction unit (AR) | Skilled labor (a1) | [6,37] |

| Reasonableness of the construction program (a2) | [31] | |

| Assembly capacity (a3) | [35,41] | |

| Quality of assembly (a4) | [43] | |

| Incidence of security incidents (a5) | [31,34] |

| Contract Agent | Contract Type | Contract Content |

|---|---|---|

| Government agencies | Document approval contracts | The general approval items are set through the smart contract. Once the electronic contract to be approved is uploaded, the system automatically approves. |

| Supplier | Cash on delivery contract | The manufacturer scans the code to confirm the receipt of the smart contract to achieve automatic checkout. |

| Warehouse management unit | Warehouse control contract | Real-time tracking of product storage dynamics, and automatic execution of default penalties to deal with timeout or out-of-stock situations. |

| Logistics unit | Transport Control Contract | Real-time monitoring of the transportation process, such as the occurrence of delivery timeouts, automatically triggers a penalty contract. |

| On-site construction unit | Delivery delay contract | Automatic triggering of penalty contracts in the event of a delay in the arrival of products for delivery. |

| Indicator | Function |

|---|---|

| Transparency index (tp) | Quantifying the level of information transparency enabled by blockchain technology. |

| Traceability index (ta) | Quantify the ability of blockchain technology to track and trace materials throughout the supply chain. |

| Security index (sc) | Quantifying the level of data security enabled by blockchain technology. |

| Efficiency index (ef) | Quantifying the efficiency of data sharing and transaction processing enabled by blockchain technology. |

| Agent | Resilience Model |

|---|---|

| End user (UR) | |

| Government agencies (GR) | |

| General contractor (CR) | |

| Design unit (DR) | |

| Suppliers (SR) | |

| Producer (PR) | |

| Warehouse management unit (WR) | |

| Logistics unit (LR) | |

| On-site construction unit (AR) |

| Stage | Agent Involved | Resilience Model |

|---|---|---|

| Decision-making stage | UR | |

| CR | ||

| GR | ||

| Design stage | DR | |

| Procurement production stage | SR | |

| PR | ||

| Transportation stage | LR | |

| WR | ||

| Assembly stage | AR |

| Stage | Weight | Agent | Weight | Factors | Weight |

|---|---|---|---|---|---|

| Decision-making stage | 0.037 | End user (UR) | 0.081 | u1 | 0.209 |

| u2 | 0.068 | ||||

| u3 | 0.209 | ||||

| u4 | 0.111 | ||||

| u5 | 0.403 | ||||

| Government agencies (GR) | 0.577 | g1 | 0.154 | ||

| g2 | 0.496 | ||||

| g3 | 0.267 | ||||

| g4 | 0.083 | ||||

| General contractor (CR) | 0.342 | c1 | 0.062 | ||

| c2 | 0.285 | ||||

| c3 | 0.653 | ||||

| Design stage | 0.160 | Design unit (DR) | 1 | d1 | 0.054 |

| d2 | 0.358 | ||||

| d3 | 0.195 | ||||

| d4 | 0.358 | ||||

| d5 | 0.345 | ||||

| Procurement production stage | 0.097 | Suppliers (SR) | 0.830 | s1 | 0.34 |

| s2 | 0.66 | ||||

| Producer (PR | 0.170 | p1 | 0.031 | ||

| p2 | 0.350 | ||||

| p3 | 0.126 | ||||

| p4 | 0.229 | ||||

| p5 | 0.229 | ||||

| Transportation stage | 0.237 | Warehouse management unit (WR) | 0.25 | w | 1 |

| Logistics unit (LR) | 0.75 | l1 | 0.207 | ||

| l2 | 0.050 | ||||

| l3 | 0.196 | ||||

| l4 | 0.547 | ||||

| Assembly stage | 0.469 | On-site construction unit (AR) | 1 | a1 | 0.045 |

| a2 | 0.168 | ||||

| a3 | 0.093 | ||||

| a4 | 0.423 | ||||

| a5 | 0.271 |

| Agent | Factors | Initial Value |

|---|---|---|

| End user (UR) | u1 | 0.5 |

| u2 | 0.8 | |

| u3 | 0.3 | |

| u4 | 0.5 | |

| u5 | 0.3 | |

| Government agencies (GR) | g1 | 0.5 |

| g2 | 0.3 | |

| g3 | 0.5 | |

| g4 | 0.6 | |

| General contractor (CR) | c1 | 0.8 |

| c2 | 0.2 | |

| c3 | 0.3 | |

| Design unit (DR) | d1 | 0.7 |

| d2 | 0.8 | |

| d3 | 0.5 | |

| d4 | 0.3 | |

| d5 | 0.6 | |

| Suppliers (SR) | s1 | 0.8 |

| s2 | 0.3 | |

| Producer (PR | p1 | 0.6 |

| p2 | 0.3 | |

| p3 | 0.5 | |

| p4 | 0.8 | |

| p5 | 0.7 | |

| Warehouse management unit (WR) | w | 0.7 |

| Logistics unit (LR) | l1 | 0.6 |

| l2 | 0.6 | |

| l3 | 0.7 | |

| l4 | 0.3 | |

| On-site construction unit (AR) | a1 | 0.7 |

| a2 | 0.7 | |

| a3 | 0.8 | |

| a4 | 0.3 | |

| a5 | 0.3 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, J.; Yuan, P.; Liang, L.; Cao, J. Enhancing Supply Chain Resilience in Prefabricated Buildings: The Role of Blockchain Technology in Volatile, Uncertain, Complex, and Ambiguous Environments. Buildings 2024, 14, 3006. https://doi.org/10.3390/buildings14093006

Li J, Yuan P, Liang L, Cao J. Enhancing Supply Chain Resilience in Prefabricated Buildings: The Role of Blockchain Technology in Volatile, Uncertain, Complex, and Ambiguous Environments. Buildings. 2024; 14(9):3006. https://doi.org/10.3390/buildings14093006

Chicago/Turabian StyleLi, Junting, Peizhuo Yuan, Lili Liang, and Jinfeng Cao. 2024. "Enhancing Supply Chain Resilience in Prefabricated Buildings: The Role of Blockchain Technology in Volatile, Uncertain, Complex, and Ambiguous Environments" Buildings 14, no. 9: 3006. https://doi.org/10.3390/buildings14093006