Additively Manufactured Parametric Universal Clip-System: An Open Source Approach for Aiding Personal Exposure Measurement in the Breathing Zone

Abstract

:Featured Application

Abstract

1. Introduction

2. Materials and Methods

3. Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Appendix A

- Download the open source FreeCAD software from https://www.freecadweb.org/.

- Download the model files provided in the link above.

- Open the necessary FreeCAD [.FCstd] file using open source FreeCad Software.

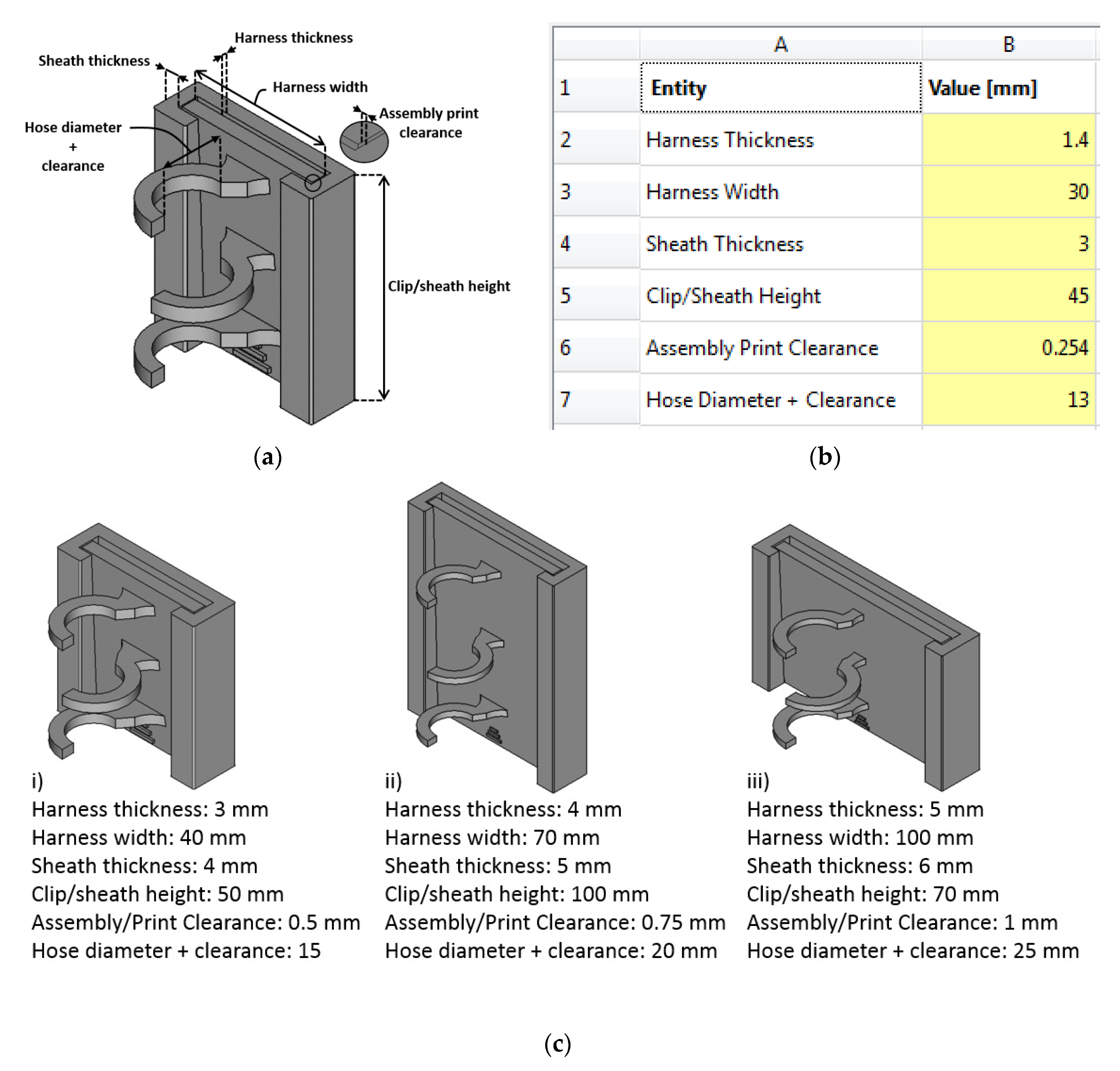

- To access parameters, double click the spreadsheet (left, under Model and labels and Attributes page). Depending of the printer, you may need to adjust assembly clearance and/or harness thickness.

- Change the required parameters in the Spreadsheet. Please note that regeneration may take some time depending on your hardware specs.‘*’

- Export model as STL to print the model. (Files-> Export). Remember to click the model to activate it before exporting.

- Use STL file to print the model with (material extrusion) 3D printer. Depending on the printer, you may need to use the brim command to avoid bending. You may also consider printing the hose holder clip arrow downward to ensure good detail of the stopper mechanism.

- Remove the support structures. They can be removed by hand or with a sharp knife.

- Remove slider from sheath.

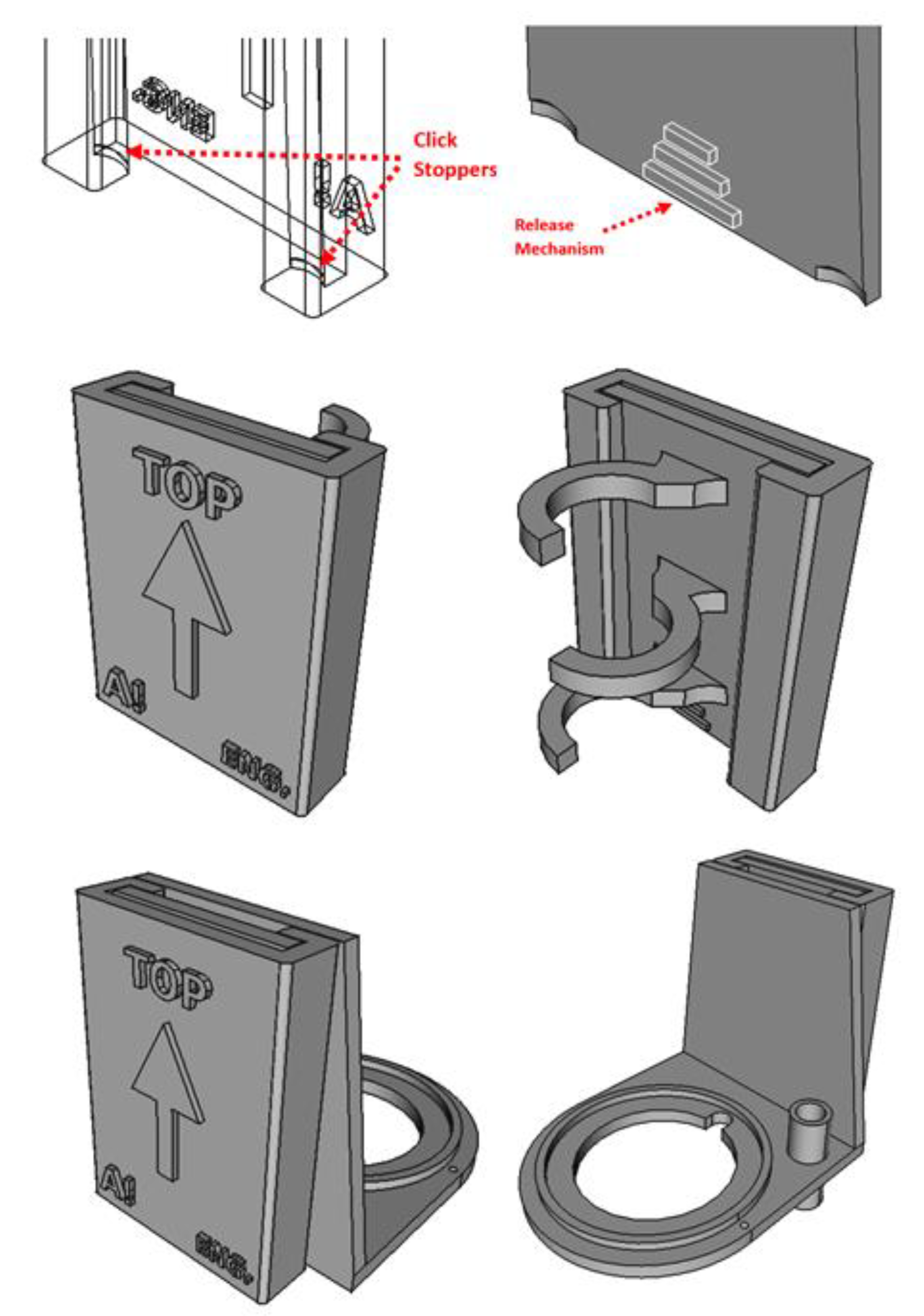

- Place the harness in the slot of the sheath through its open side. The open side will be the front of the harness and the back (arrow) side will be against the person.

- Slide the sheath on the harness to the needed position. Please note that arrow at the back of the sheath should be pointing up. When using in horizontal harness placement, that arrow points to the direction where slider will be inserted from.

- Insert the slider with the release mechanism first to the sheath.

- Push the slider until it clicks. It should be same level as the sheath.

- Push the release mechanism (segmented arrowhead) upwards to unlock the clip and to separate the components. Please do not push the hose holder or any other parts of tooling.

- Remove sheath from the harness.

References

- Vinson, R.; Volkwein, J.; McWilliams, L. Determining the Spatial Variability of Personal Sampler Inlet Locations. J. Occup. Environ. Hyg. 2007, 4, 708–714. [Google Scholar] [CrossRef]

- Wang, C.-H.; Chen, B.T.; Han, B.-C.; Liu, A.C.-Y.; Hung, P.-C.; Chen, C.-Y.; Chao, H.J. Field Evaluation of Personal Sampling Methods for Multiple Bioaerosols. PLoS ONE 2015, 10, e0120308. [Google Scholar] [CrossRef] [PubMed]

- Stephens, B.; Azimi, P.; El Orch, Z.; Ramos, T. Ultrafine particle emissions from desktop 3D printers. Atmos. Environ. 2013, 79, 334–339. [Google Scholar] [CrossRef]

- Ruzer, L.; Harley, N. Aerosols Handbook; CRC Press: Boca Raton, FL, USA, 2013; ISBN 9781439855195. [Google Scholar]

- Lidén, G. Evaluation of the SKC Personal Respirable Dust Sampling Cyclone. Appl. Occup. Environ. Hyg. 1993, 8, 178–190. [Google Scholar] [CrossRef]

- Haig, C.W.; Mackay, W.G.; Walker, J.T.; Williams, C. Bioaerosol sampling: Sampling mechanisms, bioefficiency and field studies. J. Hosp. Infect. 2016, 93, 242–255. [Google Scholar] [CrossRef] [PubMed]

- Asbach, C.; Alexander, C.; Clavaguera, S.; Dahmann, D.; Dozol, H.; Faure, B.; Fierz, M.; Fontana, L.; Iavicoli, I.; Kaminski, H.; et al. Review of measurement techniques and methods for assessing personal exposure to airborne nanomaterials in workplaces. Sci. Total Environ. 2017, 603–604, 793–806. [Google Scholar] [CrossRef]

- Vuorinen, V.; Aarnio, M.; Alava, M.; Alopaeus, V.; Atanasova, N.; Auvinen, M.; Balasubramanian, N.; Bordbar, H.; Erästö, P.; Grande, R.; et al. Modelling aerosol transport and virus exposure with numerical simulations in relation to SARS-CoV-2 transmission by inhalation indoors. Saf. Sci. 2020, 130, 104866. [Google Scholar] [CrossRef]

- National Institute for Occupational Safety Health Division of Physical Sciences Engineering. Manual of Analytical Methods; DHHS (NIOSH) Publication: Washington, DC, USA, 1994. [Google Scholar]

- Akmal, J.S.; Salmi, M.; Hemming, B.; Teir, L.; Suomalainen, A.; Kortesniemi, M.; Partanen, J.; Lassila, A. Cumulative Inaccuracies in Implementation of Additive Manufacturing Through Medical Imaging, 3D Thresholding, and 3D Modeling: A Case Study for an End-Use Implant. Appl. Sci. 2020, 10, 2968. [Google Scholar] [CrossRef]

- Tuomi, J.; Paloheimo, K.; Björkstrand, R.; Salmi, M.; Paloheimo, M.; Mäkitie, A.A. Medical applications of rapid prototyping—From applications to classification. Innov. Dev. Des. Manuf. 2010, 701–704. [Google Scholar] [CrossRef]

- Akmal, J.; Salmi, M.; Mäkitie, A.; Björkstrand, R.; Partanen, J. Implementation of Industrial Additive Manufacturing: Intelligent Implants and Drug Delivery Systems. J. Funct. Biomater. 2018, 9, 41. [Google Scholar] [CrossRef] [Green Version]

- Salmi, M.; Tuomi, J.; Sirkkanen, R.; Ingman, T.; Makitie, A. Rapid tooling method for soft customized removable oral appliances. Open Dent. J. 2012, 6, 85–89. [Google Scholar] [CrossRef] [PubMed]

- Wohlers, T. Wohlers Report 2020; Wohlers Associates, Inc.: Fort Collins, CO, USA, 2020. [Google Scholar]

- Khajavi, S.H.; Partanen, J.; Holmström, J. Additive manufacturing in the spare parts supply chain. Comput. Ind. 2014, 65, 50–63. [Google Scholar] [CrossRef]

- Totin, A.; Macdonald, E.; Conner, B. Additive manufacturing for aerospace maintenance and sustainment. DSIAC J. 2019, 6, 4–11. [Google Scholar]

- Salmi, M.; Partanen, J.; Tuomi, J.; Chekurov, S.; Björkstrand, R.; Huotilainen, E.; Kukko, K.; Kretzschmar, N.; Akmal, J.; Jalava, K.; et al. Digital Spare Parts. Aalto University. 2018. Available online: http://urn.fi/URN:ISBN:978-952-60-3746-2 (accessed on 22 September 2020).

- Ullah, R.; Akmal, J.S.; Laakso SV, A.; Niemi, E. Anisotropy of additively manufactured 18Ni-300 maraging steel: Threads and surface characteristics. Procedia CIRP 2020, 93C, 66–76. [Google Scholar] [CrossRef]

- Jalava, K.; Salmi, M.; Kukko, K.; Orkas, J. Multi-scale topologically optimized components made by casting and additive manufacturing. In Proceedings of the 73rd World Foundry Congress, Congress Proceedings, Krakow, Poland, 23–27 September 2018; pp. 141–142. [Google Scholar]

- Akmal, J. Digital Unique Component Manufacturing Through Direct and Indirect Additive Manufacturing. Aalto University 2017. Available online: http://urn.fi/URN:NBN:fi:aalto-201710307355 (accessed on 22 September 2020).

- Salmi, M.; Akmal, J.S.; Pei, E.; Wolff, J.; Jaribion, A.; Khajavi, S.H. 3D Printing in COVID-19: Productivity Estimation of the Most Promising Open Source Solutions in Emergency Situations. Appl. Sci. 2020, 10, 4004. [Google Scholar] [CrossRef]

- Jones, R.; Haufe, P.; Sells, E.; Iravani, P.; Olliver, V.; Palmer, C.; Bowyer, A. RepRap: The replicating rapid prototyper. Robotica 2011, 29, 177–191. [Google Scholar] [CrossRef] [Green Version]

- Bowyer, A. 3D printing and humanity’s first imperfect replicator. 3d Print Addit. Manuf. 2014, 1, 4–5. [Google Scholar] [CrossRef]

- ISO/TC 261 ISO/ASTM 52900:2015(E). Additive Manufacturing-General Principles-Terminology, 2nd ed.; ISO/ASTM International: Vernier, Switzerland, 2015. [Google Scholar]

- Pearce, J.M. Building Research Equipment with Free, Open-Source Hardware. Science 2012, 337, 1303–1304. [Google Scholar] [CrossRef]

- Pearce, J.M. Open-Source Lab.: How to Build. Your Own Hardware and Reduce Research Costs; Elsevier: Amsterdam, The Netherlands, 2014. [Google Scholar]

- Baden, T.; Chagas, A.M.; Gage, G.; Marzullo, T.; Prieto-Godino, L.L.; Euler, T. Open labware: 3-D printing your own lab equipment. PloS Biol. 2015, 13, e1002086. [Google Scholar] [CrossRef]

- Coakley, M.; Hurt, D.E. 3D printing in the laboratory: Maximize time and funds with customized and open-source labware. J. Lab. Autom. 2016, 21, 489–495. [Google Scholar] [CrossRef] [Green Version]

- Khajavi, S.; Holmström, J.; Partanen, J. Additive manufacturing in the spare parts supply chain: Hub configuration and technology maturity. Rapid Prototype J. 2018, 65, 50–63. [Google Scholar] [CrossRef] [Green Version]

- Chekurov, S.; Kajaste, J.; Saari, K.; Kauranne, H.; Pietola, M.; Partanen, J. Additively manufactured high-performance counterflow heat exchanger. Prog. Addit. Manuf. 2019, 4, 55–61. [Google Scholar] [CrossRef] [Green Version]

- Thompson, M.K.; Moroni, G.; Vaneker, T.; Fadel, G.; Campbell, R.I.; Gibson, I.; Bernard, A.; Schulz, J.; Graf, P.; Ahuja, B.; et al. Design for Additive Manufacturing: Trends, opportunities, considerations, and constraints. Cirp. Ann. 2016, 65, 737–760. [Google Scholar] [CrossRef]

- Best Practices for Open-Source Hardware 1.0. Available online: https://www.oshwa.org/sharing-bestpractices/ (accessed on 10 September 2020).

- Gibb, A. Building Open Source Hardware: DIY Manufacturing for Hackers and Makers; Pearson Education: London, UK, 2014. [Google Scholar]

- Oberloier, S.; Pearce, J.M. General Design Procedure for Free and Open-Source Hardware for Scientific Equipment. Designs 2017, 2, 2. [Google Scholar] [CrossRef] [Green Version]

- ISO. ISO 14644-1:2015; Cleanrooms and Associated Controlled Environments. Part. 1: Classification of Air Cleanliness By Particle Concentration; ISO: Geneva, Switzerland, 2015. [Google Scholar]

- FreeCAD: An Open-Source Parametric 3D CAD Modeler. Available online: https://www.freecadweb.org/ (accessed on 24 May 2018).

- Akmal, J.S.; Kukko, K.; Pearce, J.M. Additively Manufactured Parametric Universal-Clip-System. 2019. Available online: https://osf.io/6u3zr/ (accessed on 22 September 2020).

- Stratasys Direct, Inc. Fused Deposition Modeling (FDM) Design Guidelines. 2015. Available online: https://www.stratasysdirect.com/resources/design-guidelines/fused-deposition-modeling (accessed on 22 September 2020).

- Stratasys Direct, Inc. ABSplus-P430: Production-Grade Thermoplastic for 3D Printers. 2017. Available online: https://www.stratasys.com/materials/search/absplus (accessed on 22 September 2020).

- Ahn, S.-H.; Montero, M.; Odell, D.; Roundy, S.; Wright, P.K. Anisotropic material properties of fused deposition modeling ABS. Rapid Prototype J. 2002, 8, 248–257. [Google Scholar] [CrossRef] [Green Version]

- Croccolo, D.; De Agostinis, M.; Olmi, G. Experimental characterization and analytical modelling of the mechanical behaviour of fused deposition processed parts made of ABS-M30. Comput. Mater. Sci. 2013, 79, 506–518. [Google Scholar] [CrossRef]

- Tymrak, B.M.; Kreiger, M.; Pearce, J.M. Mechanical properties of components fabricated with open-source 3-D printers under realistic environmental conditions. Mater. Des. 2014, 58, 242–246. [Google Scholar] [CrossRef]

- Letcher, T.; Rankouhi, B.; Javadpour, S. Experimental study of mechanical properties of additively manufactured ABS plastic as a function of layer parameters. In Proceedings of the ASME International Mechanical Engineering Congress and Exposition, Houston, TX, USA, 13–19 November 2015; Volume 57359, p. V02AT02A018. [Google Scholar]

- Rankouhi, B.; Javadpour, S.; Delfanian, F.; Letcher, T. Failure analysis and mechanical characterization of 3D printed ABS with respect to layer thickness and orientation. J. Fail. Anal. Prev. 2016, 16, 467–481. [Google Scholar] [CrossRef]

- Tanikella, N.G.; Wittbrodt, B.; Pearce, J.M. Tensile strength of commercial polymer materials for fused filament fabrication 3D printing. Addit. Manuf. 2017, 15, 40–47. [Google Scholar] [CrossRef] [Green Version]

- Lee, C.S.; Kim, S.G.; Kim, H.J.; Ahn, S.H. Measurement of anisotropic compressive strength of rapid prototyping parts. J. Mater. Process. Technol. 2007, 187–188, 627–630. [Google Scholar] [CrossRef]

- Tanikella, N.G.; Savonen, B.; Gershenson, J.; Pearce, J.M. Viability of distributed manufacturing of bicycle components with 3-D printing: CEN standardized polylactic acid pedal testing. J. Hum. Eng. 2017, 5, 1. [Google Scholar]

- Rankin, T.M.; Giovinco, N.A.; Cucher, D.J.; Watts, G.; Hurwitz, B.; Armstrong, D.G. Three-dimensional printing surgical instruments: Are we there yet? J. Surg. Res. 2014, 189, 193–197. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- ASTM. ASTM D3039-76, Test. Method for Tensile Properties of Polymer Matrix Composite Materials; ASTM: West Conshohocken, PA, USA, 1976. [Google Scholar]

- ASTM. ASTM D638-97, Test. Method for Tensile Properties of Plastics; ASTM: West Conshohocken, PA, USA, 1997. [Google Scholar]

- Padzi, M.M.; Bazin, M.M.; Muhamad, W.M.W. Fatigue Characteristics of 3D Printed Acrylonitrile Butadiene Styrene (ABS). IOP Seri. Mater. Sci. Eng. 2017, 269, 012060. [Google Scholar] [CrossRef]

- Lee, J.; Huang, A. Fatigue analysis of FDM materials. Rapid Prototype J. 2013, 19, 291–299. [Google Scholar] [CrossRef]

- Michaels, R.E.; Pearce, J.M. 3-D printing open-source click-MUAC bands for identification of malnutrition. Public Health Nutr. 2017, 20, 2063–2066. [Google Scholar] [CrossRef] [Green Version]

- 3D HUBS: Network of Manufacturing Hubs. Available online: https://www.3dhubs.com/ (accessed on 15 March 2019).

- CraftCloud: Service Provider. Available online: https://craftcloud.all3dp.com/ (accessed on 15 March 2019).

- SD3D: Service Provider. Available online: https://www.sd3d.com/ (accessed on 15 March 2019).

- iMaterialise: Service Provider. Available online: https://i.materialise.com/ (accessed on 8 March 2019).

- Wittbrodt, B.T.; Glover, A.G.; Laureto, J.; Anzalone, G.C.; Oppliger, D.; Irwin, J.L.; Pearce, J.M. Life-cycle economic analysis of distributed manufacturing with open-source 3-D printers. Mechatronics 2013, 23, 713–726. [Google Scholar] [CrossRef] [Green Version]

- Heikkinen IT, S.; Kauppinen, C.; Liu, Z.; Asikainen, S.M.; Spoljaric, S.; Seppälä, J.V.; Savin, H.; Pearce, J.M. Chemical Compatibility of Fused Filament Fabrication -based 3-D Printed Components with Solutions Commonly Used in Semiconductor Wet Processing. Addit. Manuf. 2018, 23, 99–107. [Google Scholar] [CrossRef] [Green Version]

| Clip Properties | ||||||

| Clip Variant | ABS Mass [g] | Support Mass [g] | Print Time (Lulzbot Mini) | Print Time (uPrint) | Printer Operating Cost (Lulzbot Mini) [€/h] | Printer Operating Cost (Uprint) [€/h] |

| (1) hose | 12.2946 | 5.1068 | 2 h 44 min | 3.56 | ||

| (2) hose | 13.7139 | 2.6949 | 1h 47 min | 0.73 | ||

| (3) cyclone | 25.1874 | 11.1652 | 4 h 13 min | 3.56 | ||

| In House | ||||||

| Clip Variant | Generic Filament Cost [€/clip] | Proprietary Filament Cost [€/clip] | Printer Operating Cost (Lulzbot mini) [€/clip] | Printer Operating Cost (uPrint) [€/clip] | Cost [€/clip] (Lulzbot + generic filament) | Cost [€/clip] (Uprint + proprietary filament) |

| (1) hose | 5.38 | 9.72 | 15.10 € | |||

| (2) hose | 0.33 | 1.31 | 1.64 € | |||

| (3) cyclone | 11.20 | 14.99 | 26.19 € | |||

| Service Providers | ||||||

| Clip Variant | SD3D Cost [€/clip] (Sd3d.com) | Craftcloud [€/clip] (craftcloud.all3dp.com) | iMaterialise Cost [€/clip] (i.Materialise.com) | 3Dhubs Cost [€/clip] (3dhubs.com) | ||

| (1) hose | 21.94 | 21.67 | 73.5 | 100 | ||

| (3) cyclone | 32.38 | 27.05 | 86.8 | 100 | ||

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kukko, K.; Akmal, J.S.; Kangas, A.; Salmi, M.; Björkstrand, R.; Viitanen, A.-K.; Partanen, J.; Pearce, J.M. Additively Manufactured Parametric Universal Clip-System: An Open Source Approach for Aiding Personal Exposure Measurement in the Breathing Zone. Appl. Sci. 2020, 10, 6671. https://doi.org/10.3390/app10196671

Kukko K, Akmal JS, Kangas A, Salmi M, Björkstrand R, Viitanen A-K, Partanen J, Pearce JM. Additively Manufactured Parametric Universal Clip-System: An Open Source Approach for Aiding Personal Exposure Measurement in the Breathing Zone. Applied Sciences. 2020; 10(19):6671. https://doi.org/10.3390/app10196671

Chicago/Turabian StyleKukko, Kirsi, Jan Sher Akmal, Anneli Kangas, Mika Salmi, Roy Björkstrand, Anna-Kaisa Viitanen, Jouni Partanen, and Joshua M. Pearce. 2020. "Additively Manufactured Parametric Universal Clip-System: An Open Source Approach for Aiding Personal Exposure Measurement in the Breathing Zone" Applied Sciences 10, no. 19: 6671. https://doi.org/10.3390/app10196671

APA StyleKukko, K., Akmal, J. S., Kangas, A., Salmi, M., Björkstrand, R., Viitanen, A. -K., Partanen, J., & Pearce, J. M. (2020). Additively Manufactured Parametric Universal Clip-System: An Open Source Approach for Aiding Personal Exposure Measurement in the Breathing Zone. Applied Sciences, 10(19), 6671. https://doi.org/10.3390/app10196671