Strength and Mechanism of Granite Residual Soil Strengthened by Microbial-Induced Calcite Precipitation Technology

Abstract

:1. Introduction

2. Materials and methods

2.1. Materials

2.1.1. Soil

2.1.2. Preparation of the Bacterial Solution

2.2. Test Plan and Device

2.2.1. Test Plan

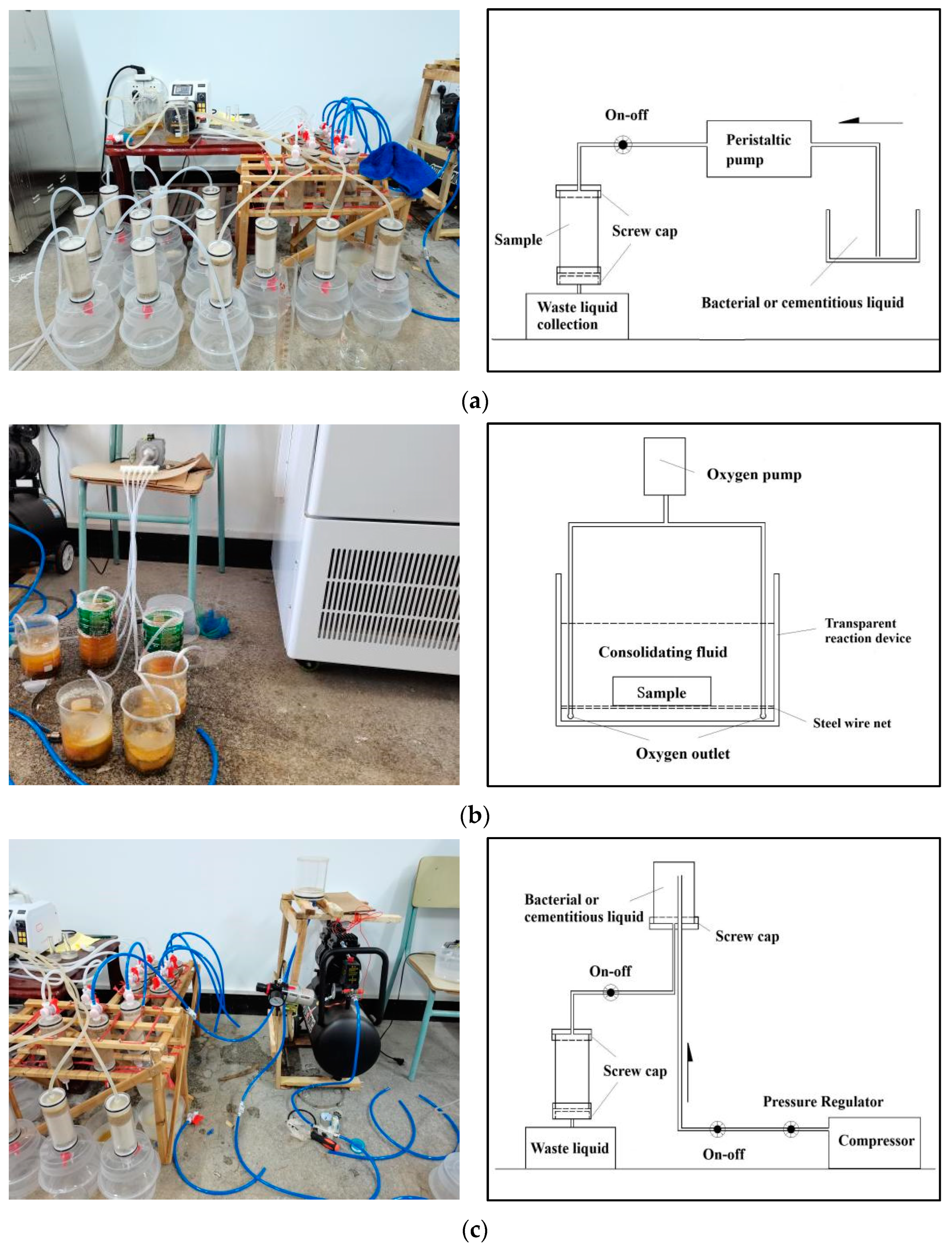

2.2.2. Test Mold and Device

2.3. Test Method

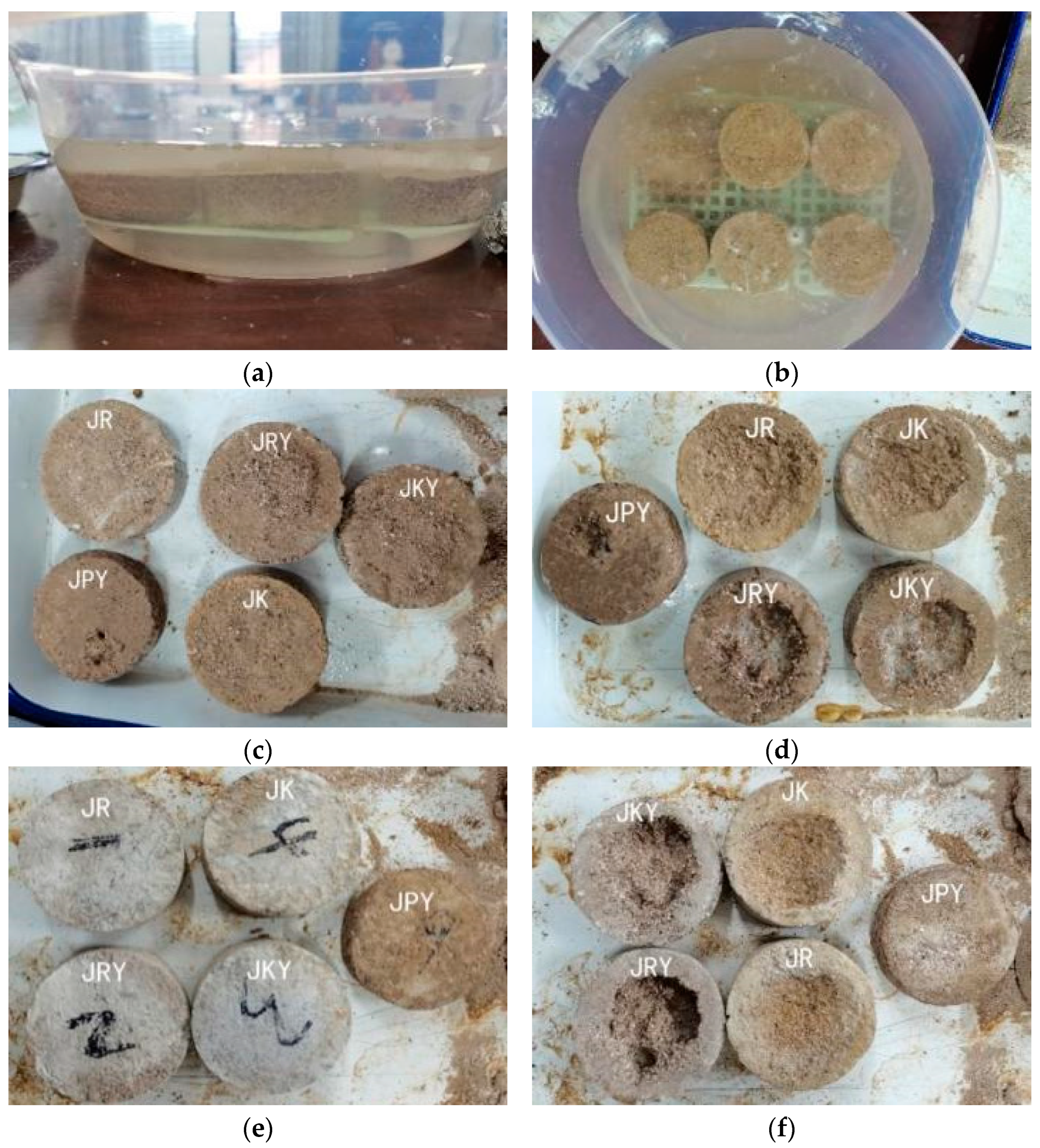

2.3.1. Disintegration Test

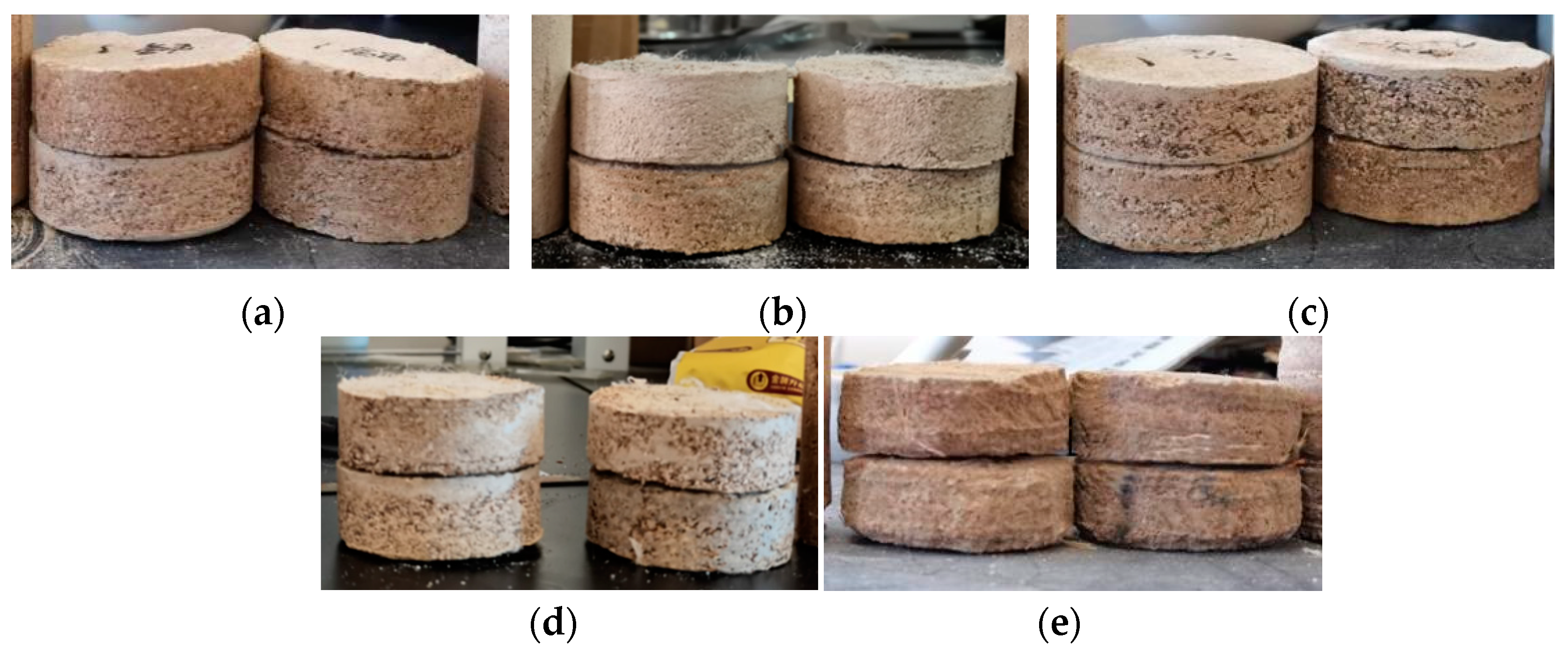

2.3.2. Unconfined Compressive Strength

2.3.3. Determination of Calcium Carbonate Precipitation

2.3.4. Micro-Analysis

3. Test Results and Analysis

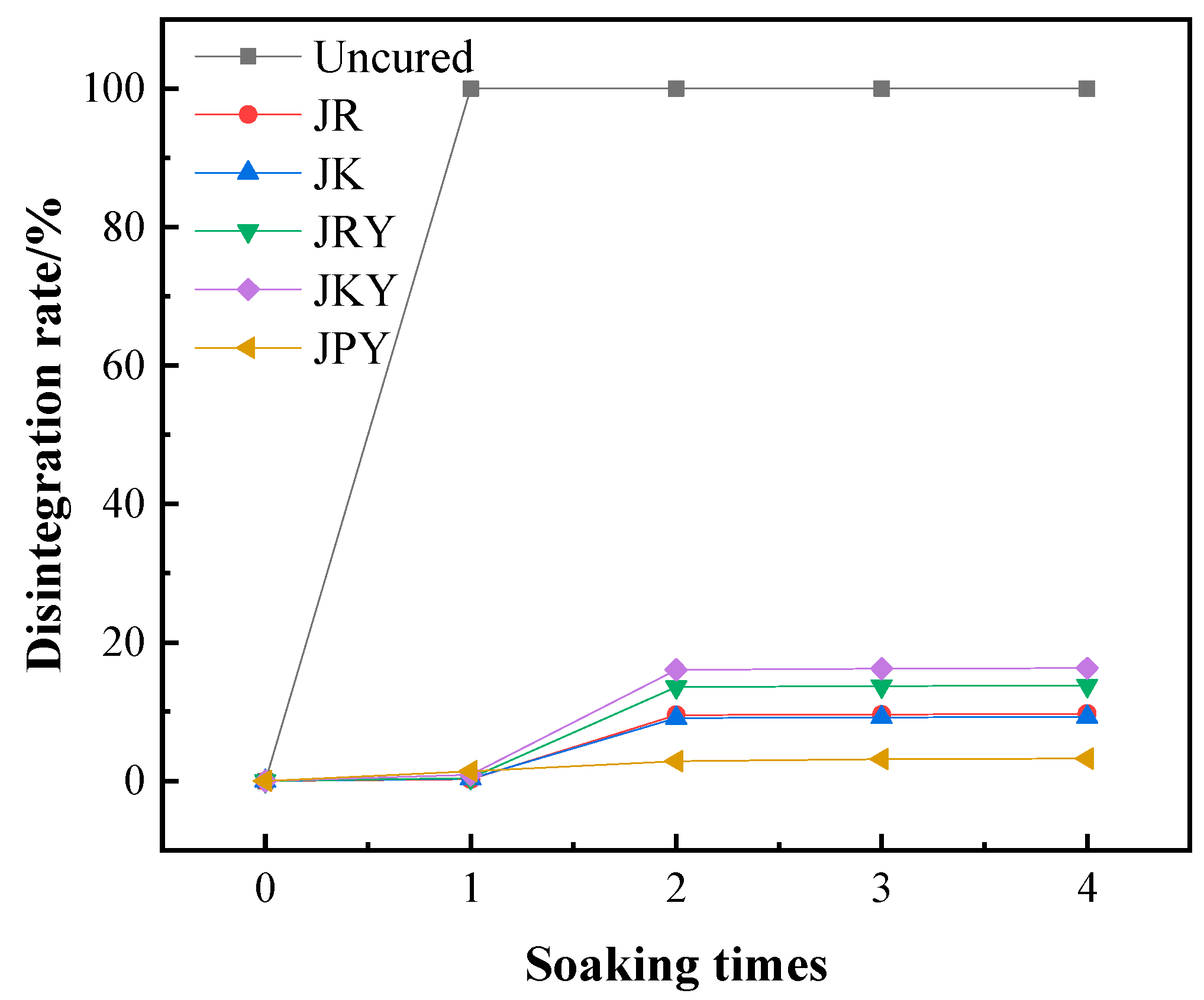

3.1. Disintegration Rate

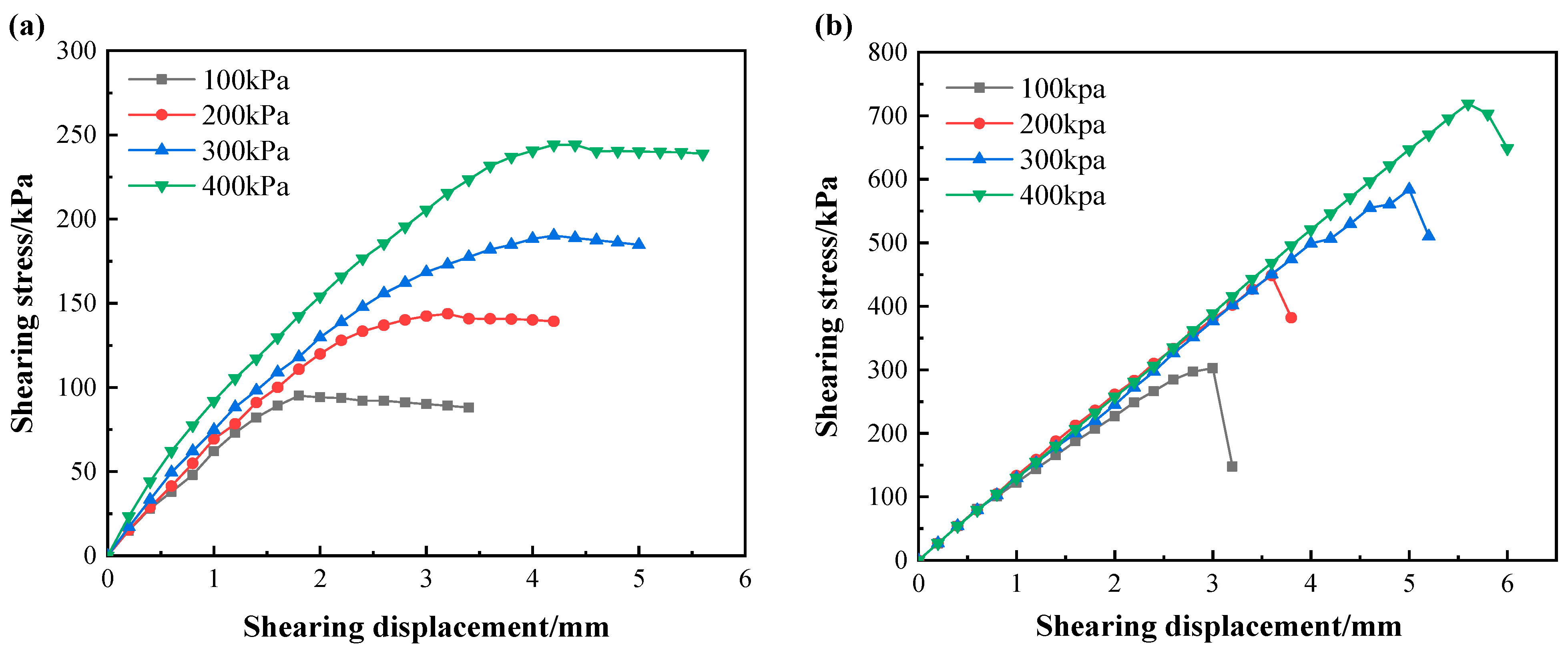

3.2. Shearing Strength

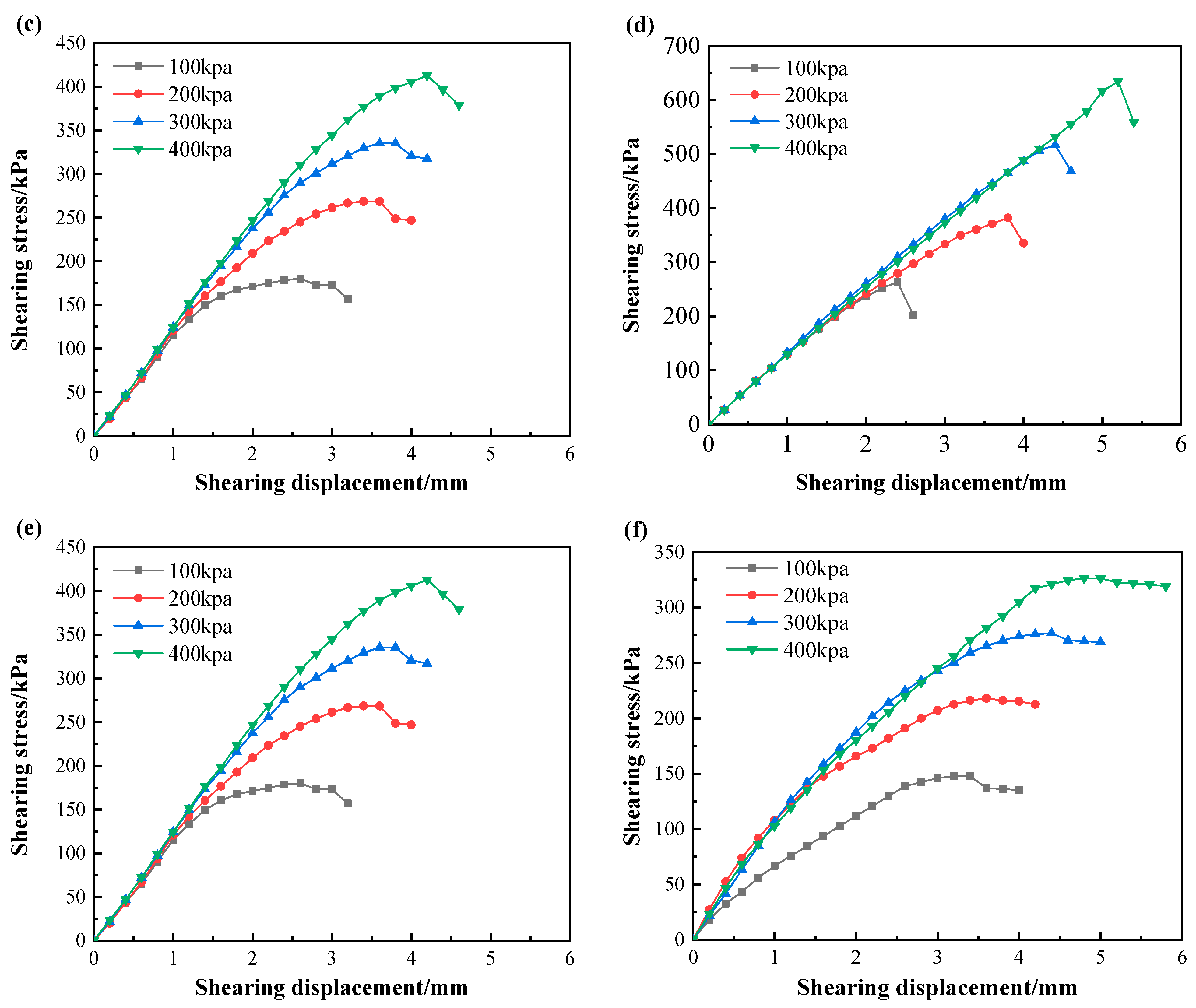

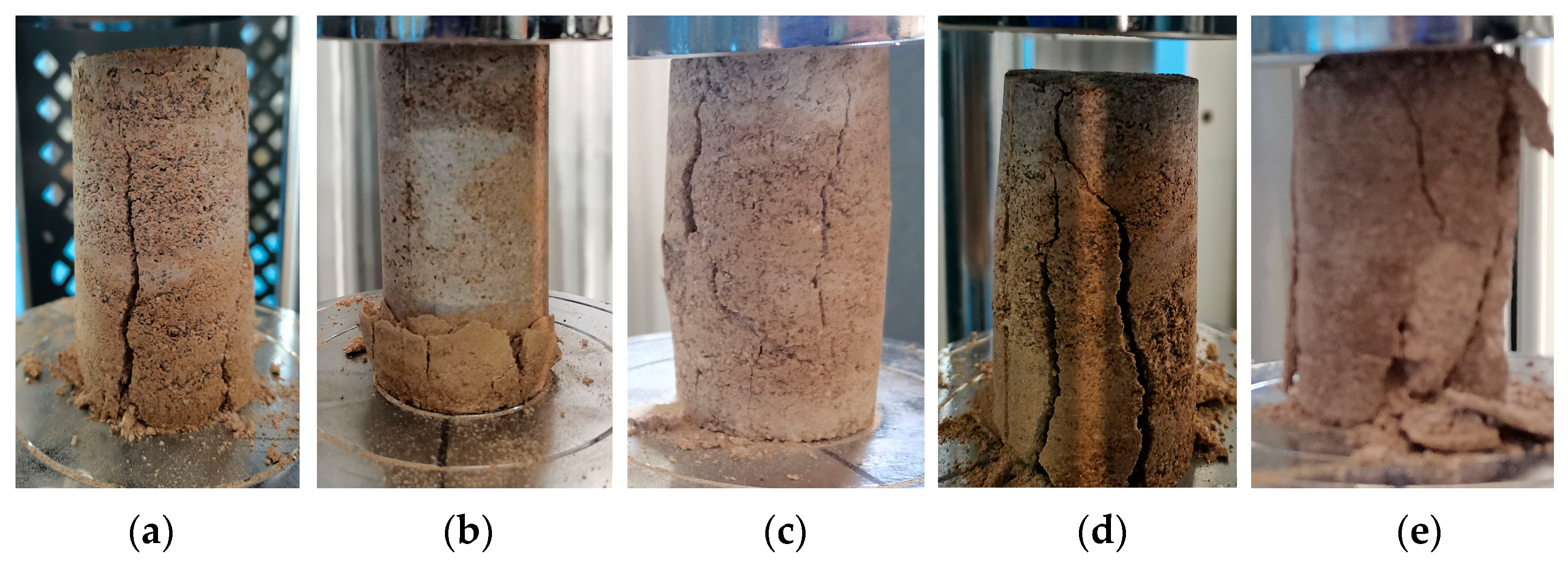

3.3. Unconfined Compressive Strength

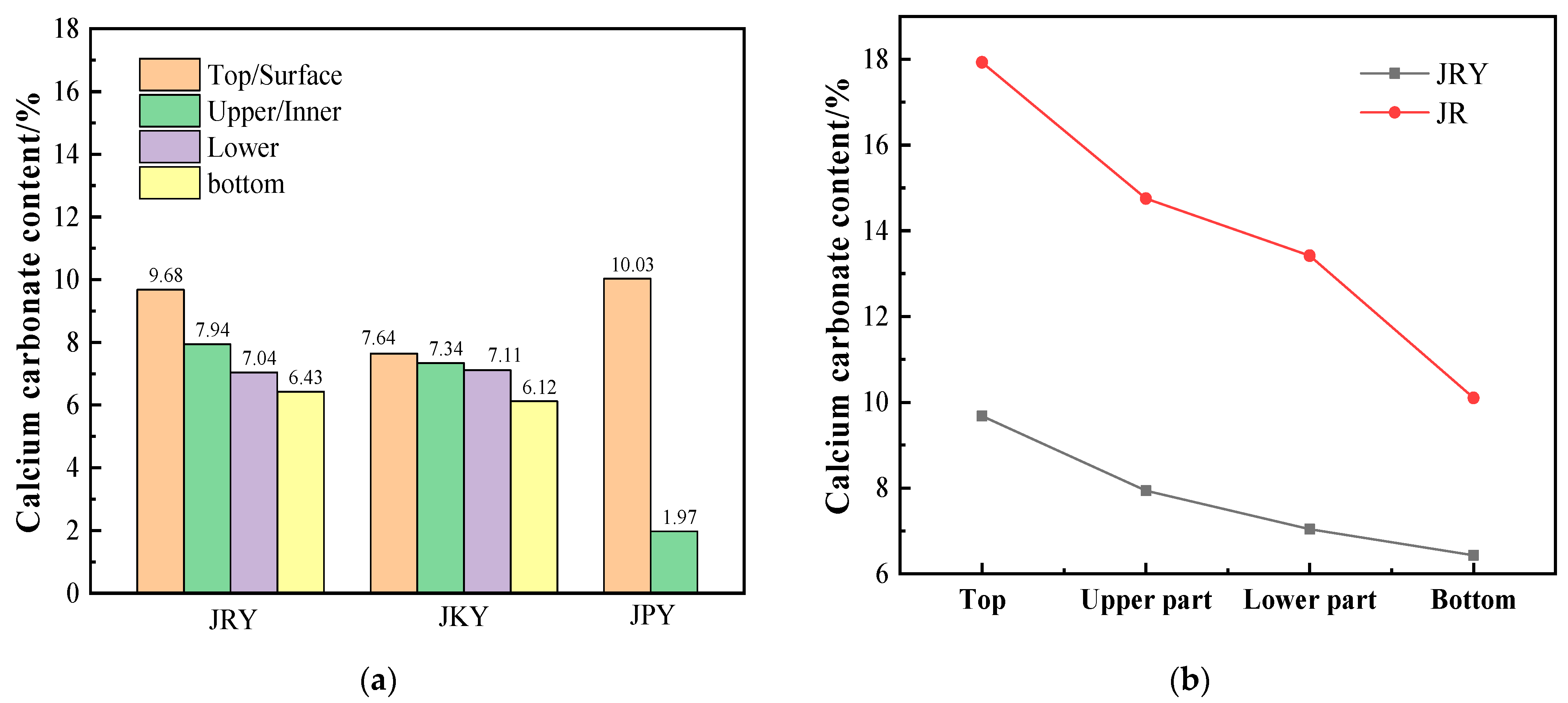

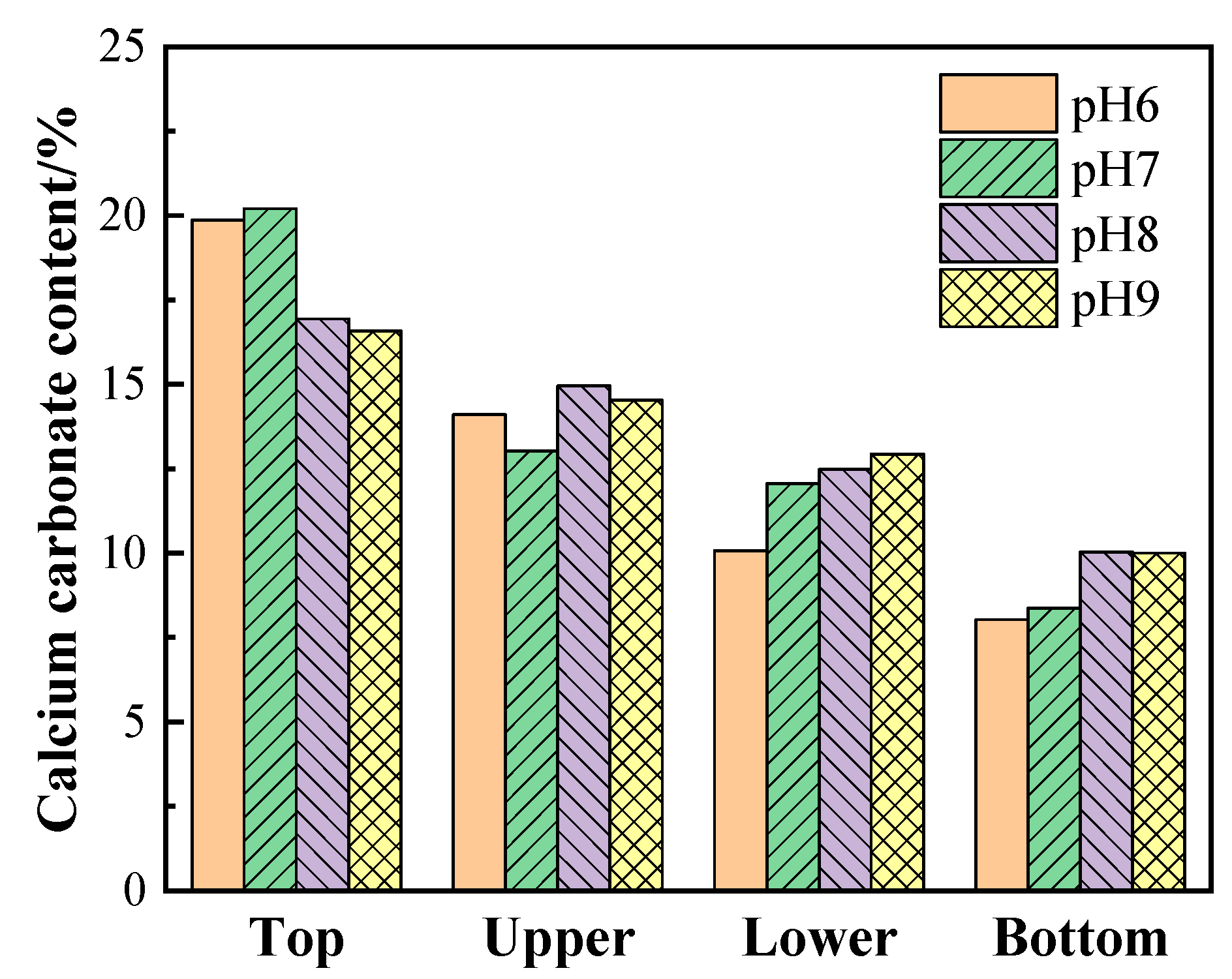

3.4. Homogeneity of Calcium Carbonate

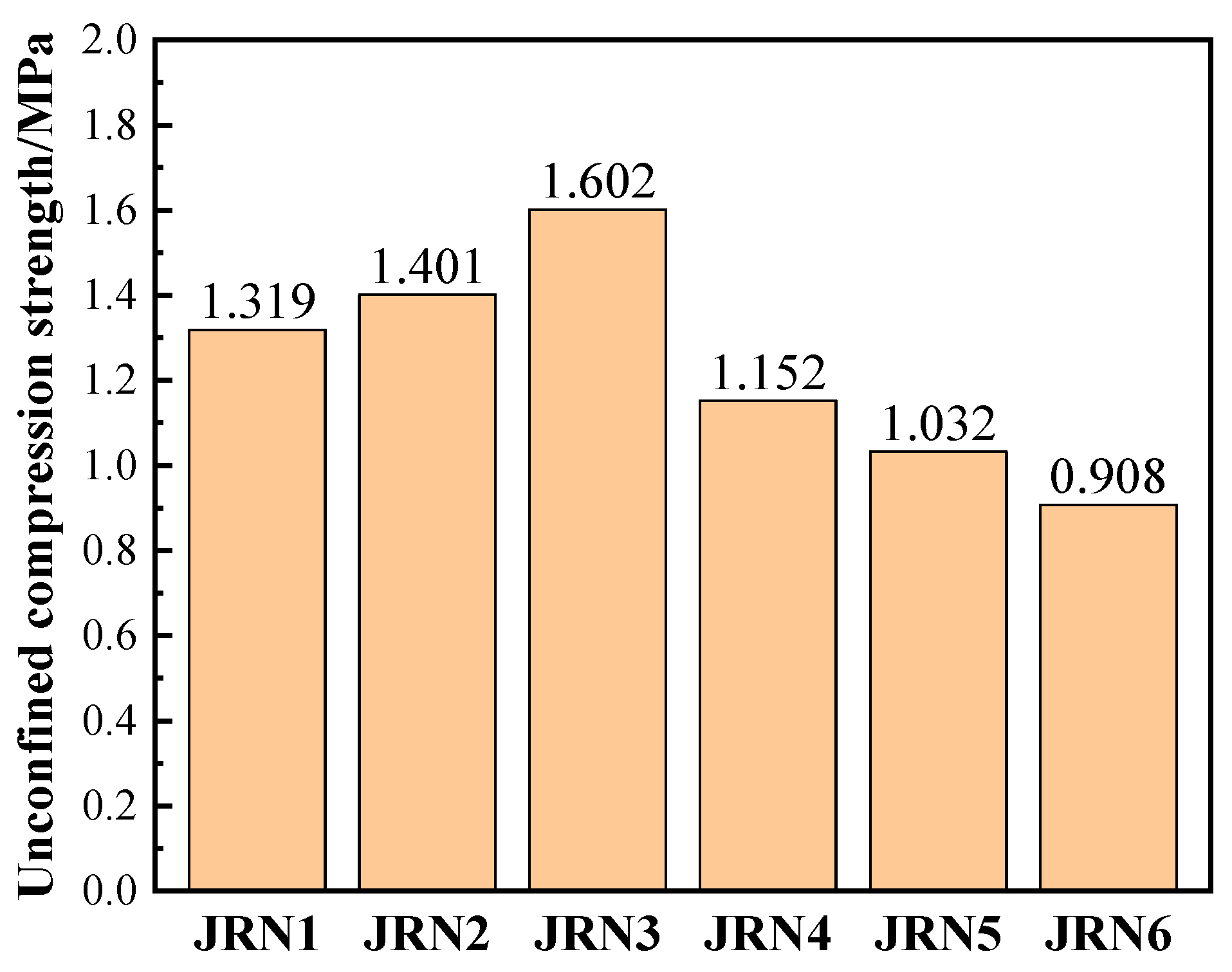

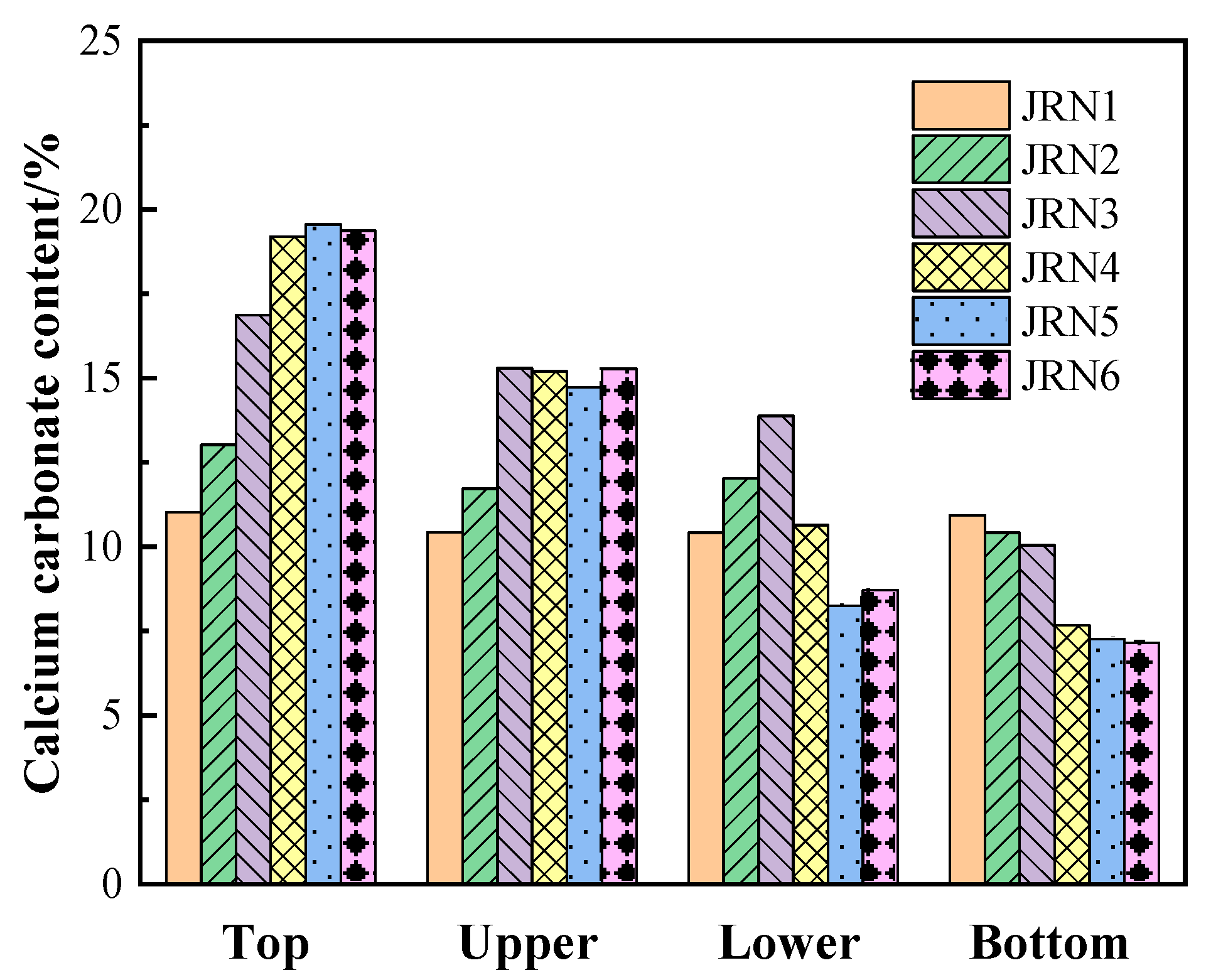

3.5. The Effect of Cementing Solution Concentration on Strengthening

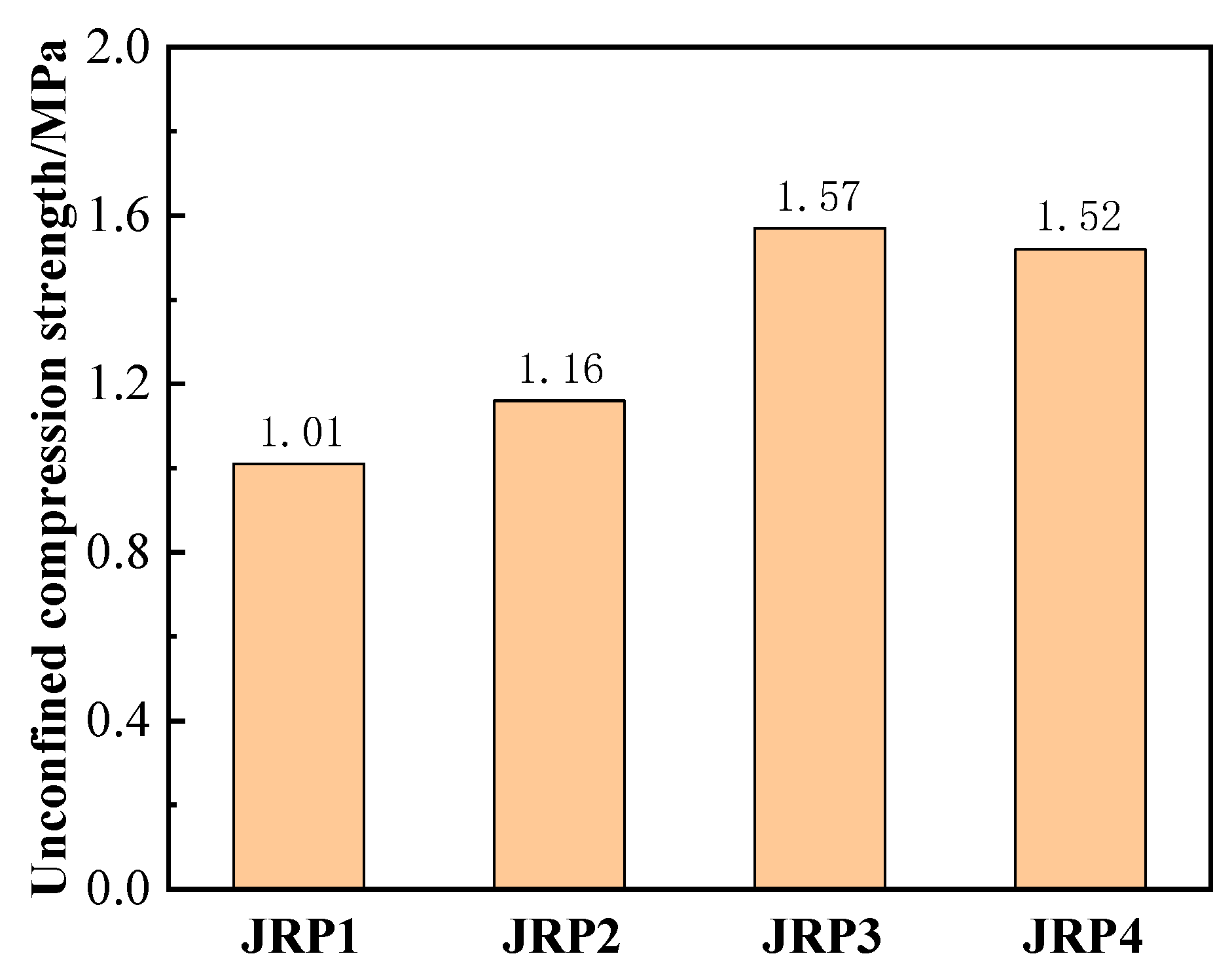

3.6. Effect of pH Value of Cementing Solution on Strengthening

3.7. Soil Strengthening Mechanism

3.7.1. XRD

3.7.2. SEM

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Basahel, H.; Mitri, H. Application of rock mass classification systems to rock slope stability assessment: A case study. J. Rock Mech. Geotech. Eng. 2017, 9, 993–1009. [Google Scholar] [CrossRef]

- Yokota, S.; Iwamatsu, A. Weathering distribution in a steep slope of soft pyroclastic rocks as an indicator of slope instability. Eng. Geol. 2000, 55, 57–68. [Google Scholar] [CrossRef]

- Liu, X.Y.; Zhang, X.W.; Kong, L.W.; Wang, G.; Liu, H.H. Formation mechanism of collapsing gully in southern China and the relationship with granite residual soil: A geotechnical perspective. Catena 2022, 210, 105890. [Google Scholar] [CrossRef]

- Liu, W.P.; Song, X.Q.; Luo, J.; Hu, L.N. The processes and mechanisms of collapsing erosion for granite residual soil in southern China. J. Soils Sediments 2020, 20, 992–1002. [Google Scholar] [CrossRef]

- Li, C.S.; Kong, L.W.; Shu, R.J.; An, R.; Zhang, X.W. Disintegration characteristics in granite residual soil and their relationship with the collapsing gully in South China. Open Geosci. 2020, 12, 1116–1126. [Google Scholar] [CrossRef]

- Yuan, B.; Chen, W.; Zhao, J.; Li, L.; Liu, F.; Guo, Y.; Zhang, B. Addition of alkaline solutions and fibers for the reinforcement of kaolinite-containing granite residual soil. Appl. Clay Sci. 2022, 228, 106644. [Google Scholar] [CrossRef]

- Liu, X.Y.; Zhang, X.W.; Kong, L.W.; Wang, G.; Lu, J.F. Disintegration of granite residual soils with varying degrees of weathering. Eng. Geol. 2022, 305, 106723. [Google Scholar] [CrossRef]

- Yuan, B.X.; Chen, W.J.; Zhao, J.; Yang, F.; Luo, Q.Z.; Chen, T.Y. The Effect of organic and inorganic modifiers on the physical properties of granite residual soil. Adv. Mater. Sci. Eng. 2022, 2022, 9542258. [Google Scholar] [CrossRef]

- Chehlafi, A.; Kchikach, A.; Derradji, A.; Mequedade, N. Highway cutting slopes with high rainfall erosion in Morocco: Evaluation of soil losses and erosion control using concrete arches. Eng. Geol. 2019, 260, 105200. [Google Scholar] [CrossRef]

- Lian, J.F.; Wu, J.J.; Luo, Q. Theoretical analysis and optimization of frame protection to control shallow slope stability and soil erosion. Transp. Geotech. 2022, 33, 100724. [Google Scholar] [CrossRef]

- Fan, J.W.; Yang, S.J.; Deng, B.; Sun, B.; Liu, T.Y. A New Technique of Lattice Beam Construction with Pre-Anchoring for Strengthening Cut Slope: A Numerical Analysis of Temporary Stability during Excavation. Buildings 2022, 12, 1930. [Google Scholar] [CrossRef]

- Chen, J.; Lei, X.W.; Zhang, H.L.; Lin, Z.; Wang, H.; Hu, W. Laboratory model test study of the hydrological effect on granite residual soil slopes considering different vegetation types. Sci. Rep. 2021, 11, 14668. [Google Scholar] [CrossRef]

- DeJong, J.T.; Mortensen, B.M.; Martinez, B.C.; Nelson, D.C. Bio-mediated soil improvement. Ecol. Eng. 2010, 36, 197–210. [Google Scholar] [CrossRef]

- Yu, T.; Souli, H.; Pechaud, Y.; Fleureau, J.M. Review on engineering properties of MICP-treated soils. Geomech. Eng. 2021, 27, 13–30. [Google Scholar]

- Harkes, M.P.; van Paassen, L.A.; Booster, J.L.; Whiffin, V.S.; van Loosdrecht, M.C.M. Fixation and distribution of bacterial activity in sand to induce carbonate precipitation for ground reinforcement. Ecol. Eng. 2010, 36, 112–117. [Google Scholar] [CrossRef]

- VWhiffin, S.; van Paassen, L.A.; Harkes, M.P. Microbial carbonate precipitation as a soil improvement technique. Geomicrobiol. J. 2007, 24, 417–423. [Google Scholar] [CrossRef]

- Wang, Y.Z.; Konstantinou, C.; Soga, K.; Biscontin, G.; Kabla, A.J. Use of microfluidic experiments to optimize MICP treatment protocols for effective strength enhancement of MICP-treated sandy soils. Acta Geotech. 2022, 17, 3817–3838. [Google Scholar] [CrossRef]

- Chek, A.; Crowley, R.; Ellis, T.N.; Durnin, M.; Wingender, B. Evaluation of Factors Affecting Erodibility Improvement for MICP-Treated Beach Sand. J. Geotech. Geoenviron. Eng. 2021, 147, 4021001. [Google Scholar] [CrossRef]

- Tang, C.S.; Yin, L.Y.; Jiang, N.J.; Zhu, C.; Zeng, H.; Li, H.; Shi, B. Factors affecting the performance of microbial-induced carbonate precipitation (MICP) treated soil: A review. Environ. Earth Sci. 2020, 79, 94. [Google Scholar] [CrossRef]

- Murugan, R.; Suraishkumar, G.K.; Mukherjee, A.; Dhami, N.K. Insights into the influence of cell concentration in design and development of microbially induced calcium carbonate precipitation (MICP) process. PLoS ONE 2021, 16, e0254536. [Google Scholar] [CrossRef] [PubMed]

- Hang, L.; Yang, F.; Xu, J.; Zhao, Z.H.; Xiao, W.; He, J. Experimental Study on the Effective Production of Biocement for Soil Solidification and Wind Erosion Control. Sustainability 2023, 15, 5402. [Google Scholar] [CrossRef]

- Karimian, A.; Hassanlourad, M. Mechanical behaviour of MICP-treated silty sand. Bull. Eng. Geol. Environ. 2022, 81, 285. [Google Scholar] [CrossRef]

- Yu, X.P.; Xiao, H.B.; Li, Z.Y.; Qian, J.F.; Luo, S.P.; Su, H.Y. Experimental study on microstructure of unsaturated expansive soil improved by MICP method. Appl. Sci. 2022, 12, 342. [Google Scholar] [CrossRef]

- Li, J.; Tian, L.; Xu, Y.; Tian, Z.; Zhang, Z. Study on the solidification effect of dredger fill by microbial-induced calcium precipitation (MICP). Materials 2022, 15, 7891. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.-N.; Li, S.-K.; Li, Z.-Y.; Garg, A. Exploring the application of the MICP technique for the suppression of erosion in granite residual soil in Shantou using a rainfall erosion simulator. Acta Geotech. 2023, 18, 3273–3285. [Google Scholar] [CrossRef]

- Liang, S.H.; Xiao, X.L.; Fang, C.X.; Feng, D.L.; Wang, Y.X. Experimental study on the mechanical properties and disintegration resistance of microbially solidified granite residual soil. Crystals 2022, 12, 132. [Google Scholar] [CrossRef]

- Zhu, W.X.; Deng, H.F.; Li, J.L.; Xiong, Y.X.Y.; Cheng, L. Effect of calcium lignosulfonate on mechanical properties of fully weathered granite solidified by microorganism. China Civ. Eng. J. 2023. [Google Scholar] [CrossRef]

- GB/T 50123-2019; Engineering Classification of Soils. National Quality Supervision Bureau: Beijing, China, 2019. (In Chinese)

- Cui, Z.J.; Yang, J.G.; Chen, Y.X. The type and evolution of the granite landforms in China. Acta Geogr. Sin. 2007, 62, 675–690. [Google Scholar]

- Sun, Y.; Liu, Q.; Xu, H.; Wang, Y.; Tang, L. Influences of different modifiers on the disintegration of improved granite residual soil under wet and dry cycles. Int. J. Min. Sci. Technol. 2022, 32, 831–845. [Google Scholar] [CrossRef]

- Su, F.; Yang, Y.; Qi, Y.; Zhang, H. Combining microbially induced calcite precipitation (MICP) with zeolite: A new technique to reduce ammonia emission and enhance soil treatment ability of MICP technology. J. Environ. Chem. Eng. 2022, 10, 107770. [Google Scholar] [CrossRef]

- Wang, Y.; Wang, G.; Wan, Y.; Yu, X.; Zhao, J.; Shao, J. Recycling of dredged river silt reinforced by an eco-friendly technology as microbial induced calcium carbonate precipitation (MICP). Soils Found. 2022, 62, 101216. [Google Scholar] [CrossRef]

- Fu, T.; Saracho, A.C.; Haigh, S.K. Microbially induced carbonate precipitation (MICP) for soil strengthening: A comprehensive review. Biogeotechnics 2023, 1, 100002. [Google Scholar] [CrossRef]

- Mohapatra, S.S.; Pradhan, S.P.; Pradhan, P.K.; Pattnaik, P.; Jena, B.; Malla, S.K. Experimental study on mechanical properties of coarse graded soil incorporation with MICP process. Mater. Today Proc. 2022, 65, 3887–3892. [Google Scholar] [CrossRef]

- Chen, L.; Song, Y.; Fang, H.; Feng, Q.; Lai, C.; Song, X. Systematic optimization of a novel, cost-effective fermentation medium of Sporosarcina pasteurii for microbially induced calcite precipitation (MICP). Constr. Build. Mater. 2022, 348, 128632. [Google Scholar] [CrossRef]

- Fouladi, A.S.; Arulrajah, A.; Chu, J.; Horpibulsuk, S. Application of Microbially Induced Calcite Precipitation (MICP) technology in construction materials: A comprehensive review of waste stream contributions. Constr. Build. Mater. 2023, 388, 131546. [Google Scholar] [CrossRef]

- Al Qabany, A.; Soga, K.; Santamarina, C. Factors Affecting Efficiency of Microbially Induced Calcite Precipitation. J. Geotech. Geoenviron. Eng. 2012, 138, 992–1001. [Google Scholar] [CrossRef]

| Granularity Division | Coarse Sand (<2 mm) | Medium Sand (<1 mm) | Fine Sand (<0.5 mm) | Silt (<0.075 mm) | Clay (<0.005 mm) |

|---|---|---|---|---|---|

| Content (%) | 100 | 80.78 | 56.92 | 24.5 | 6.86 |

| Wet Density (g/cm3) | Dry Density (g/cm3) | Rate of Water Content (%) | Plastic Limit (%) | Liquid Limit (%) | Plasticity Index | Specific Gravity (g/cm3) | Optimum Water Content (%) |

|---|---|---|---|---|---|---|---|

| 1.438 | 1.289 | 11.6 | 24.07 | 37.21 | 13.14 | 2.62 | 15.06 |

| Group | Grouting Method | Number of Grouting | Cementitious Liquid Component Content | |

|---|---|---|---|---|

| Bacteria | Cementation Solution | |||

| JRY | Peristaltic pump | 1 | 15 | Urea: 30 g/L; Calcium chloride: 55.5 g/L |

| JR | 5 | 15 | ||

| JKY | Air compressor | 1 | 15 | |

| JK | 5 | 15 | ||

| JPY | Soak | 1 | 15 | |

| Group | Cementitious Liquid Concentration | ||

|---|---|---|---|

| Urea (mol/L) | Anhydrous Calcium Chloride (mol/L) | Cementitious Liquid pH | |

| JRN1 | 0.25 | 0.25 | 8.5 |

| JRN2 | 0.5 | 0.25 | |

| JRN3 | 0.5 | 0.5 | |

| JRN4 | 1.0 | 0.5 | |

| JRN5 | 1.0 | 1.0 | |

| JRN6 | 2.0 | 1.0 | |

| JRP1 | 0.5 | 0.5 | 6 |

| JRP2 | 7 | ||

| JRP3 | 8 | ||

| JRP4 | 9 | ||

| Method | Test Group | Shear Strength under Different Vertical Pressures (kPa) | |||

|---|---|---|---|---|---|

| 100 kPa | 200 kPa | 300 kPa | 400 kPa | ||

| / | Uncured | 95.11 | 143.71 | 190.11 | 244.17 |

| Peristaltic pump grouting | JR | 302.74 | 448.698 | 583.848 | 718.998 |

| JRY | 180.2 | 273.5 | 325.17 | 412.66 | |

| Air compressor grouting | JK | 263.09 | 382.02 | 517.17 | 634.3 |

| JKY | 163.98 | 220.46 | 268.12 | 364.18 | |

| Soaking method | JPY | 147.76 | 218.04 | 276.61 | 326.16 |

| Curing Method | Test Group | Cohesion (kPa) | Internal Friction Angle (°) |

|---|---|---|---|

| / | Uncured | 42.11 | 26.84 |

| Peristaltic pump grouting | JR | 167.59 | 54.15 |

| JRY | 108.1 | 37.38 | |

| Air compressor grouting | JK | 136.95 | 51.32 |

| JKY | 101.6 | 33.38 | |

| Soaking method | JPY | 93.7 | 30.71 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, R.; Li, H.; Chen, Z.; Liu, F.; Wei, M.; Liu, F.; Wang, Q.; Hu, C. Strength and Mechanism of Granite Residual Soil Strengthened by Microbial-Induced Calcite Precipitation Technology. Appl. Sci. 2023, 13, 8863. https://doi.org/10.3390/app13158863

Wang R, Li H, Chen Z, Liu F, Wei M, Liu F, Wang Q, Hu C. Strength and Mechanism of Granite Residual Soil Strengthened by Microbial-Induced Calcite Precipitation Technology. Applied Sciences. 2023; 13(15):8863. https://doi.org/10.3390/app13158863

Chicago/Turabian StyleWang, Rong, Huawei Li, Zichuang Chen, Fang Liu, Muwang Wei, Feiyu Liu, Qian Wang, and Changbin Hu. 2023. "Strength and Mechanism of Granite Residual Soil Strengthened by Microbial-Induced Calcite Precipitation Technology" Applied Sciences 13, no. 15: 8863. https://doi.org/10.3390/app13158863