A Numerical Gear Rolling Test Method for Face-Hobbed Hypoid Gears

Abstract

:1. Introduction

2. Tooth Surface Measuring Points

3. Actual Tooth Surface Fitting

4. Numerical Gear Rolling Test Method

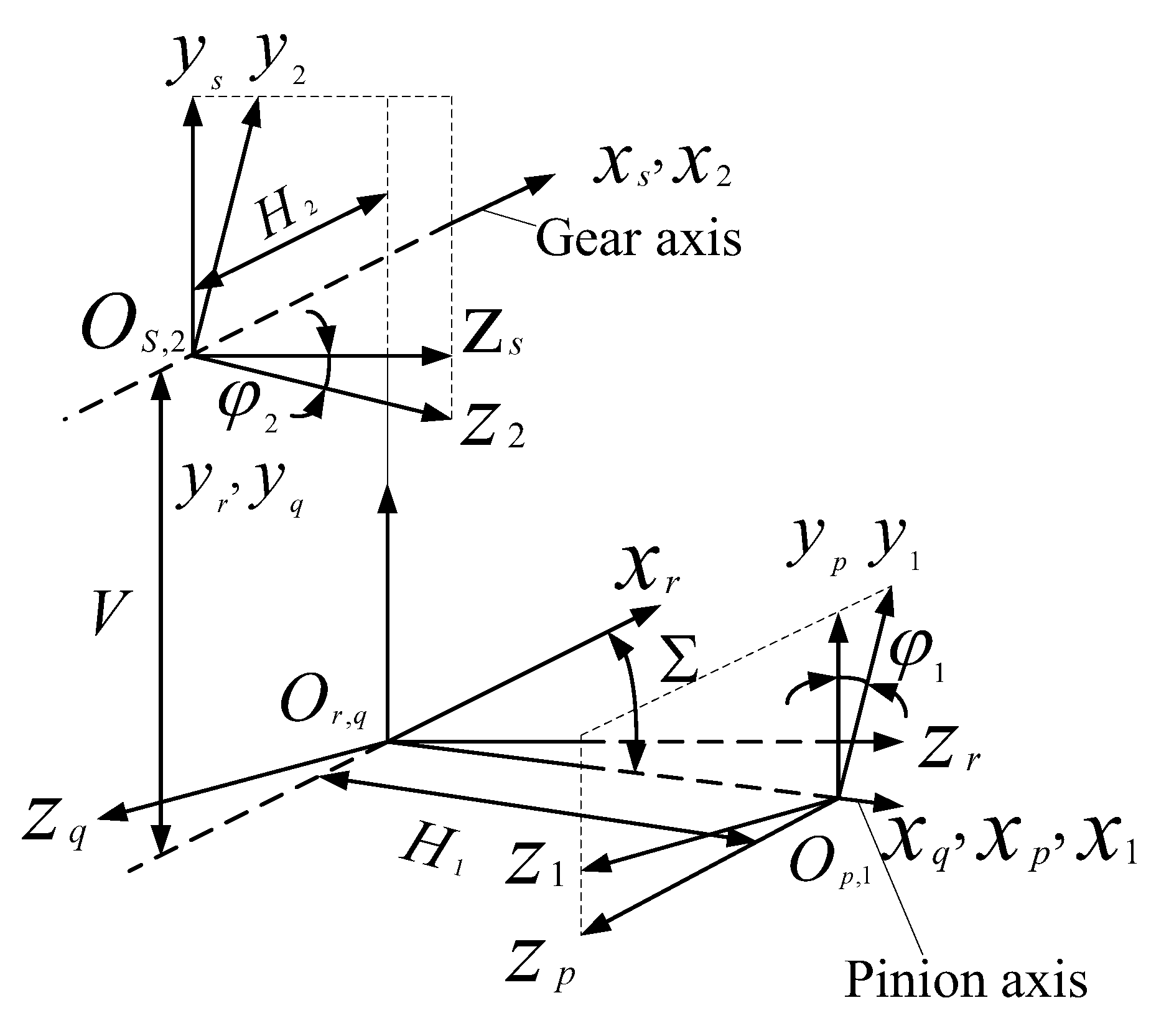

4.1. Coordinate Transformation

4.2. Calculation of Instant Meshing Point and Transmission Error

- (1)

- If the smallest value Dmin is less than 0.01 μm and other positions do not interfere, this point is considered to be the meshing point. Step 6 is performed.

- (2)

- If the smallest value Dmin is less than 0.01 μm but there is interference, the rotary angle φ2 is too large and must be adjusted. Step 5 is done for detailed adjustment.

- (3)

- If the smallest value Dmin is not less than 0.01 μm, the grid is too sparse and the rotary angle φ2 is too small. Local grid refinement near the minimum value Dmin is performed on the gear, and the shortest distance dmin corresponding to all refined grid points and the minimum value Dmin are calculated again, as shown in Figure 9d. If the decrease in amplitude of Dmin is greater than 1%, the grid continues to be refined. If the decrease in amplitude of Dmin is lower than 1%, the rotary angle φ2 is rotated in a clockwise direction according to Equation (4), and Step 3 has to be carried out. The adjusted step length formula is

4.3. Calculation of Contact Ellipse and Contact Path

5. Numerical Examples

5.1. Actual Tooth Surface Modeling

5.2. Contact Pattern and Transmission Error

5.3. Finite Element Simulation of Contact Ellipse

6. Experimental Validation

7. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ding, H.; Tang, J.K.; Shao, W.; Zhou, Y.S.; Wang, G.X. Optimal modification of tooth flank form error considering measurement and compensation of cutter geometric errors for spiral bevel and hypoid gears. Mech. Mach. Theory 2017, 118, 14–37. [Google Scholar] [CrossRef]

- Artoni, A.; Gabiccini, M.; Kolivand, M. Ease-off based compensation of tooth surface deviations for spiral bevel and hypoid gears: Only the pinion needs corrections. Mech. Mach. Theory 2012, 61, 84–101. [Google Scholar] [CrossRef]

- Li, G.; Wang, Z.H.; Zhu, W.D. Prediction of surface wear of involute gears based on a modified fractal method. J. Tribol. 2019, 141, 031603. [Google Scholar] [CrossRef]

- Li, G.; Wang, Z.H.; Kubo, A. The modeling approach of digital real tooth surfaces of hypoid gears based on non-geometric-feature segmentation and interpolation algorithm. Int. J. Precis. Eng. Manuf. 2016, 17, 281–292. [Google Scholar] [CrossRef]

- Zhang, Y.; Litvin, F.L.; Maruyama, N.; Takeda, R.; Sugimoto, M. Computerized Analysis of Meshing and Contact of Gear Actual tooth surfaces. J. Mech. Des. 1994, 116, 677–682. [Google Scholar] [CrossRef]

- Li, G.; Wang, Z.H.; Kubo, A. Error-sensitivity Analysis for Hypoid Gears Using a Actual tooth surface Contact Mode. P. I. Mech. Eng. C-J. Mec. 2016, 231, 507–521. [Google Scholar] [CrossRef]

- Zhang, W.Q.; Guo, X.D.; Wang, Y.W.; Wen, Y.K.; Lin, C.C.; Lim, T.C. A CNC Tooth Grinding Method for Formate Face Hobbed Hypoid Gears. Mech. Mach. Theory 2020, 144, 103628. [Google Scholar] [CrossRef]

- Liu, G.L.; Li, D.G.; Wang, L.Y. Reconstruction of real tooth surfaces of Spiral Bevel Pinions with Modified Offset. Inverse Probl. Sci. En. 2015, 23, 214–234. [Google Scholar] [CrossRef]

- Du, J.F.; Fang, Z.D. An Active Tooth Surface Design Methodology for Face-hobbed Hypoid Gears Based on Measuring Coordinates. Mech. Mach. Theory 2016, 99, 140–154. [Google Scholar] [CrossRef]

- Ma, Z.Q.; Wang, X.C.; Shen, B. Real Tooth Contact Analysis of the Cylindrical Gears with Symmetrical Arcuate Tooth Trace. J. Xi’Jiaotong Univ. 2005, 39, 722–725. [Google Scholar]

- Lin, C.H.; Fong, Z.H. Numerical Tooth Contact Analysis of a Bevel Gear Set by Using Measured Tooth Geometry Data. Mech. Mach. Theory 2015, 84, 1–24. [Google Scholar] [CrossRef]

- Gosselin, C.; Shiono, Y.; Kagimoto, H.; Aoyama, N. Corrective Machine Settings of Spiral-bevel and Hypoid Gears with Profile Deviations. In Proceedings of the 4th World Congress on Gearing and Power Transmissions, Paris, France, 16–18 March 1999; pp. 543–555. [Google Scholar]

- Wang, Z.H.; Li, G.; Kubo, A. Tooth Contact Analysis of Spiral Bevel Gears Based on Digital Actual tooth surfaces. Chin. J. Mech. Eng. 2014, 50, 1–11. [Google Scholar]

- Litvin, F.L. Applied Theory of Gearing: State of the Art. J. Vib. Acoust. 1995, 117, 128–134. [Google Scholar] [CrossRef]

- Wu, X.C.; Mao, S.M.; Wu, X.T. On Function-Oriented Design of Point-Contact Tooth Surface. Mech. Sci. Technol. 2000, 19, 347–349. [Google Scholar] [CrossRef]

- Du, J.F.; Wang, Z.R.; Liu, K. A Novel Tooth Contact Analysis Method Based on Value Iteration. Adv. Mech. Eng. 2020, 77, 162–169. [Google Scholar]

- Zhu, X.X. Free Curves and Surfaces Modeling Technology; Science Press: Beijing, China, 2000. [Google Scholar]

- Shi, F.Z. CAGD & NURBS; Higher Education Press: Beijing, China, 2001. [Google Scholar]

- Shih, Y.P.; Fong, Z.H.; Lin, J.C.Y. Mathematical Model for a Universal Face-Hobbing Hypoid Gear Generator. J. Mech. Des. 2007, 129, 38–47. [Google Scholar] [CrossRef]

- Wang, S.H.; Zhou, Y.S.; Tang, J.Y.; Tang, K.; Li, Z.M.Q. Digital Tooth Contact Analysis of Face Gear Drives with an Accurate Measurement Model of Face Gear Tooth Surface Inspected by CMMs. Mech. Mach. Theory 2022, 167, 104498. [Google Scholar] [CrossRef]

- Fan, Q. Enhanced Algorithms of Contact Simulation for Hypoid Gear Drives Produced by Face-milling and Face-hobbing Processes. J. Mech. Des. 2007, 129, 31–37. [Google Scholar] [CrossRef]

| Parameters | Symbols | Unit | Pinion | Gear |

|---|---|---|---|---|

| Shaft angle | Σ | deg | 90.0000 | |

| Hypoid offset | V | mm | 30.0000 | 30.0000 |

| Normal module | mn | mm | 7.6641 | 7.6641 |

| Number of teeth | Z | -- | 12 | 41 |

| Outer pitch diameter: gear | de2 | mm | -- | 452.0000 |

| Face width | F | mm | 80.4000 | 76.0000 |

| Whole depth | he | mm | 17.6603 | 17.6603 |

| Mean pitch cone diameter | dm | mm | 125.720 | 380.7530 |

| Pitch angle | δ | deg | 20.1596 | 69.6298 |

| Mean spiral angle | βm | deg | 42.9845 LH | 34.3833 RH |

| Nominal cutter radius | rw | mm | 175.0000 | 175.0000 |

| Nominal pressure angle: drive | αNv1 | deg | 22.5000 | 22.5000 |

| Nominal pressure angle: coast | αNx1 | deg | 22.5000 | 22.5000 |

| Outside diameter | dae | mm | 177.2915 | 453.8098 |

| Mean pitch cone distance | Rm | mm | 182.3948 | 203.0761 |

| Items | Results of Numerical Gear Rolling Test | Results of KIMoS5 | Relative Error |

|---|---|---|---|

| Drive side | −46.03 μrad | −48.2 μrad | 4.5% |

| Coast side | −45.05 μrad | −47.6 μrad | 5.3% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Du, J.; Mao, H.; Liu, Y.; Zhang, Q. A Numerical Gear Rolling Test Method for Face-Hobbed Hypoid Gears. Appl. Sci. 2023, 13, 10278. https://doi.org/10.3390/app131810278

Du J, Mao H, Liu Y, Zhang Q. A Numerical Gear Rolling Test Method for Face-Hobbed Hypoid Gears. Applied Sciences. 2023; 13(18):10278. https://doi.org/10.3390/app131810278

Chicago/Turabian StyleDu, Jinfu, Hong Mao, Yongxiang Liu, and Qunlin Zhang. 2023. "A Numerical Gear Rolling Test Method for Face-Hobbed Hypoid Gears" Applied Sciences 13, no. 18: 10278. https://doi.org/10.3390/app131810278