Making Aquaponics More Sustainable Using Worms and Water Replenishment Combined with a Sensing- and IoT-Based Monitoring System

Abstract

:1. Introduction

2. Related Work

3. Materials and Methods

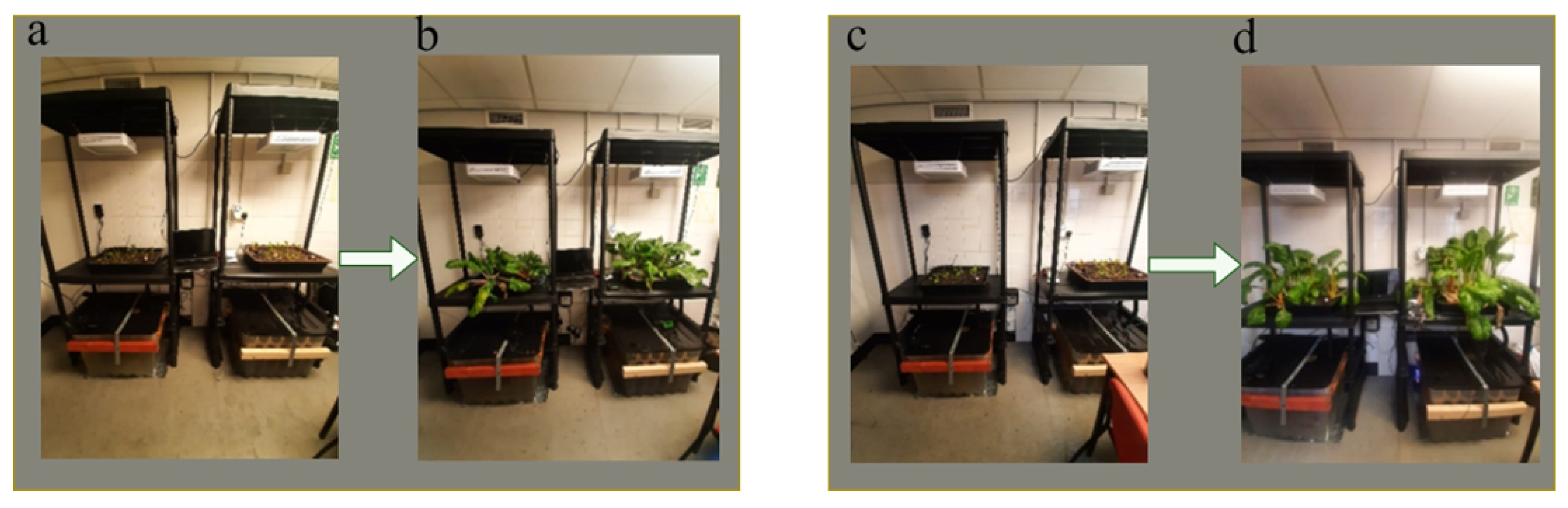

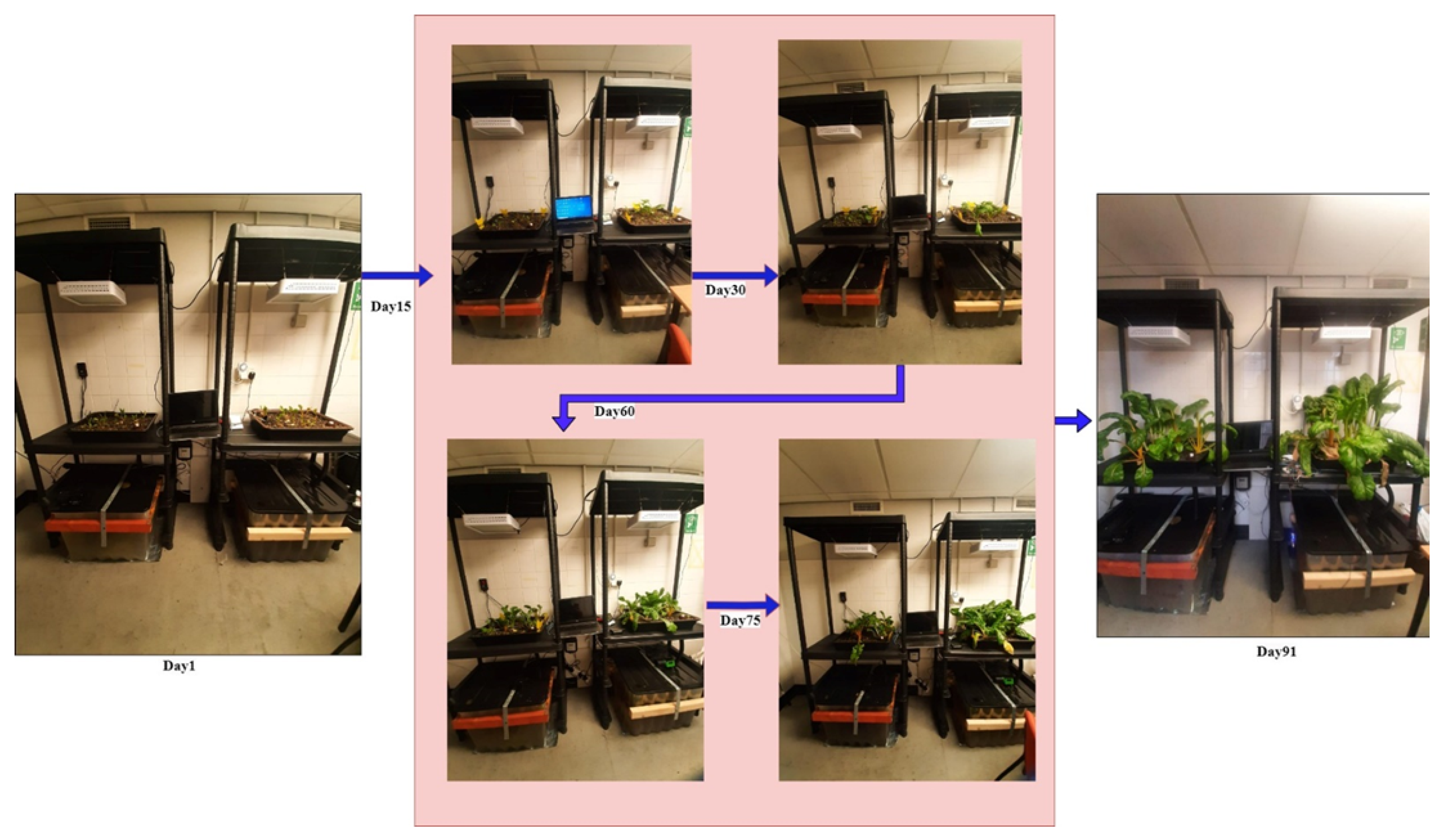

3.1. Experimental Design and Data Collection

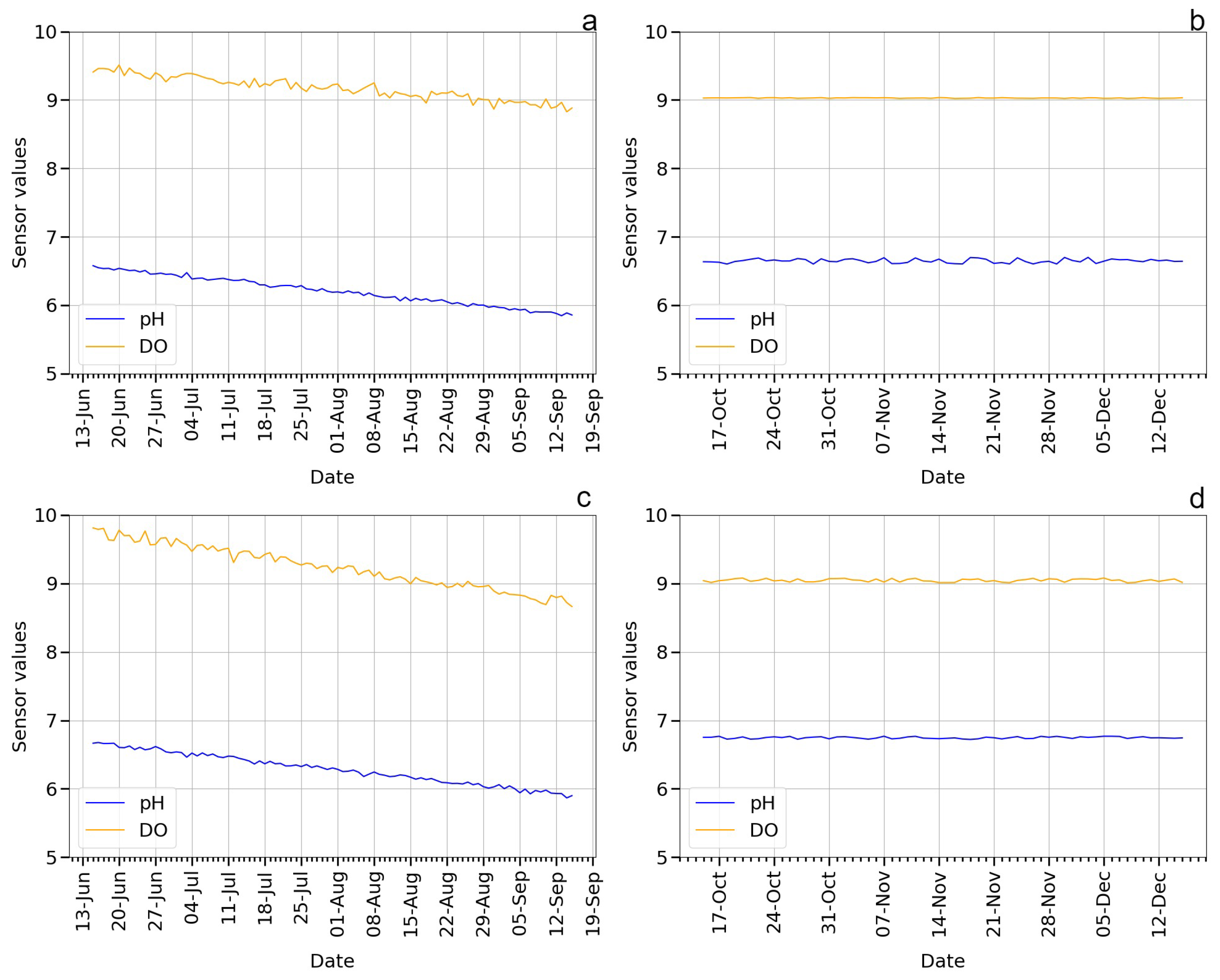

3.2. Sensors and IoT Devices

3.3. Algorithm Design

4. Results

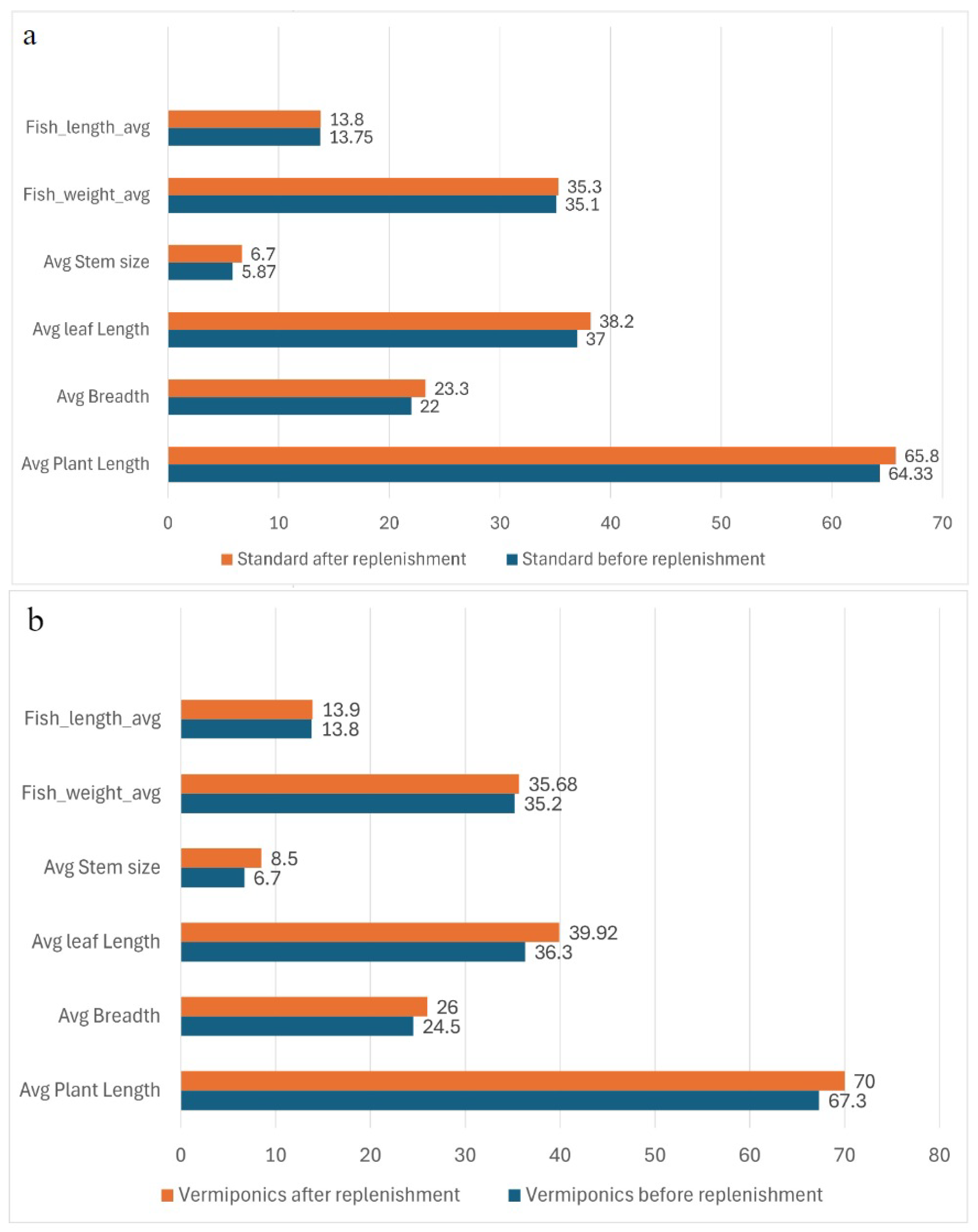

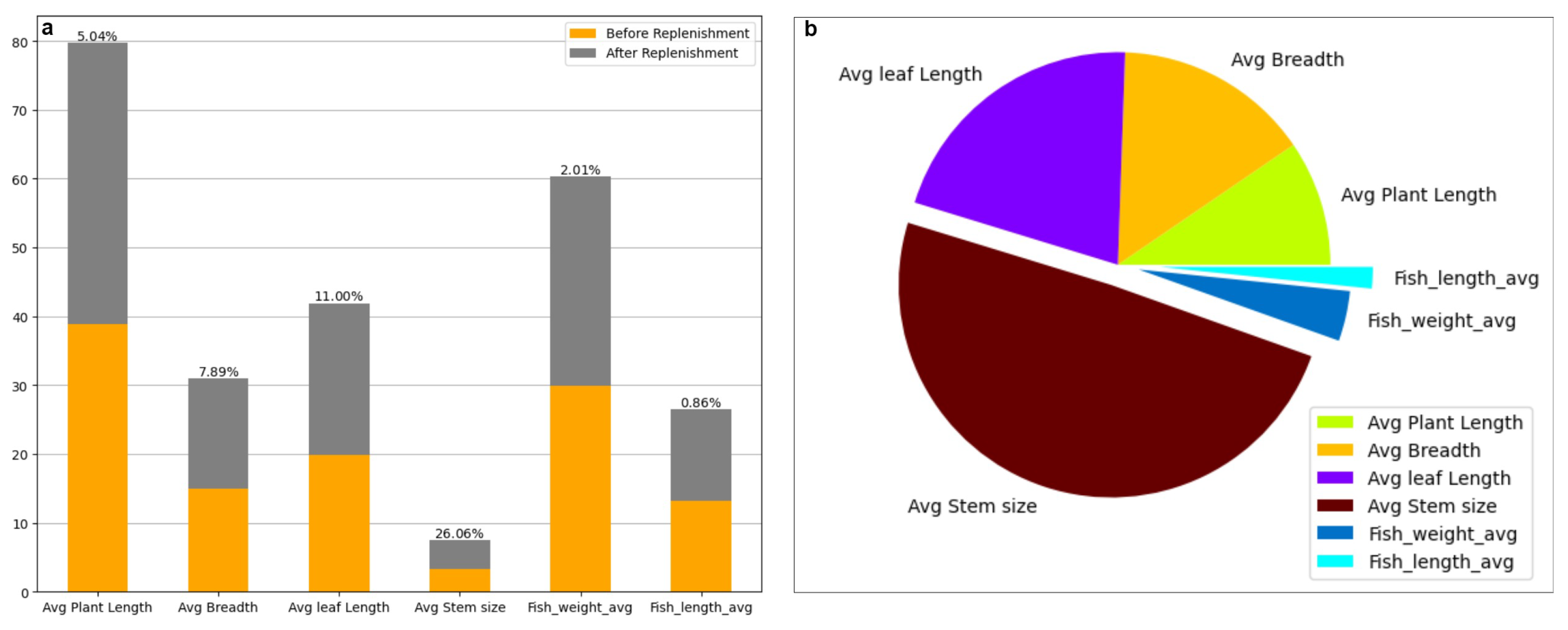

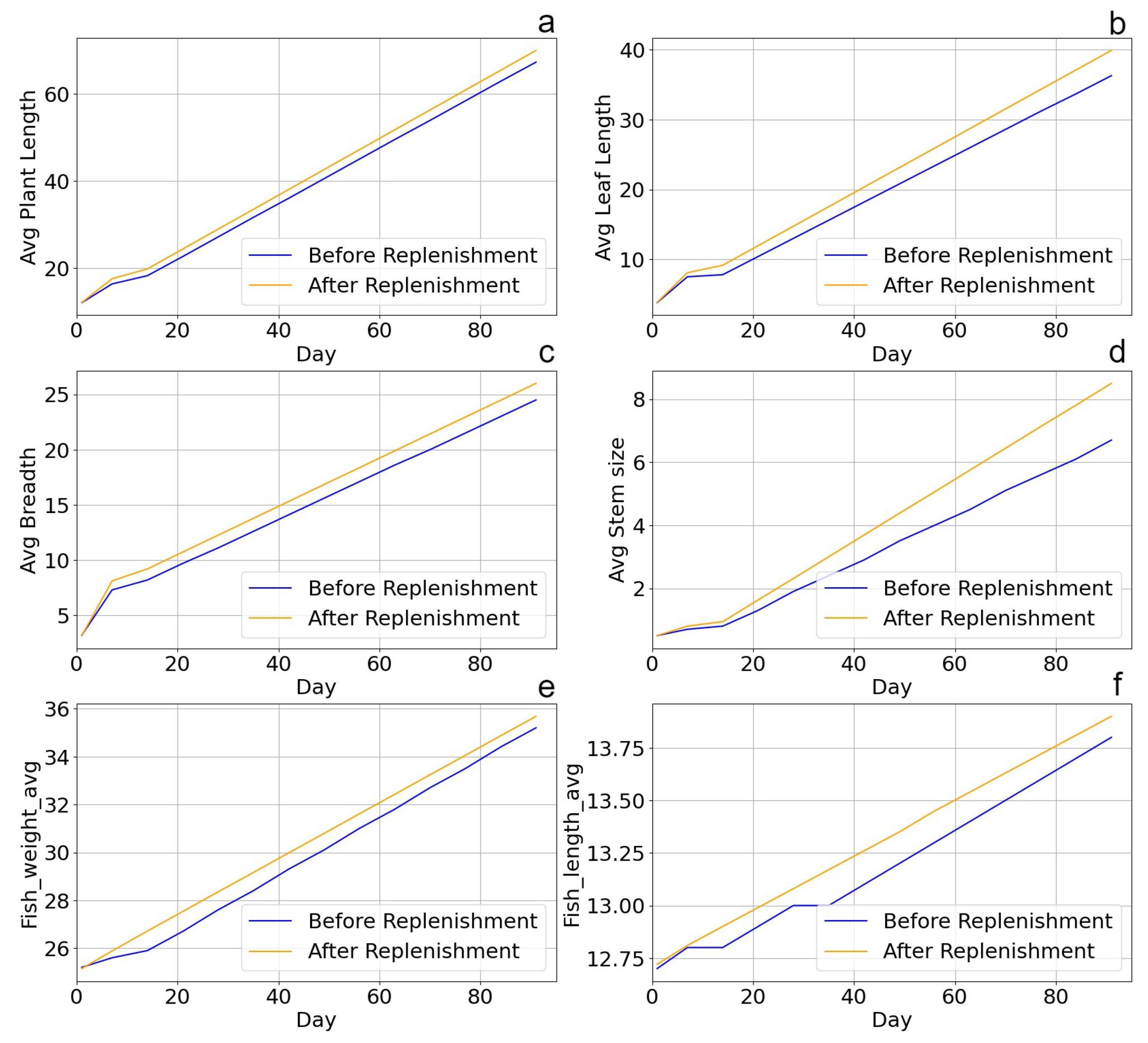

4.1. Standard Testbed Productivity Comparison

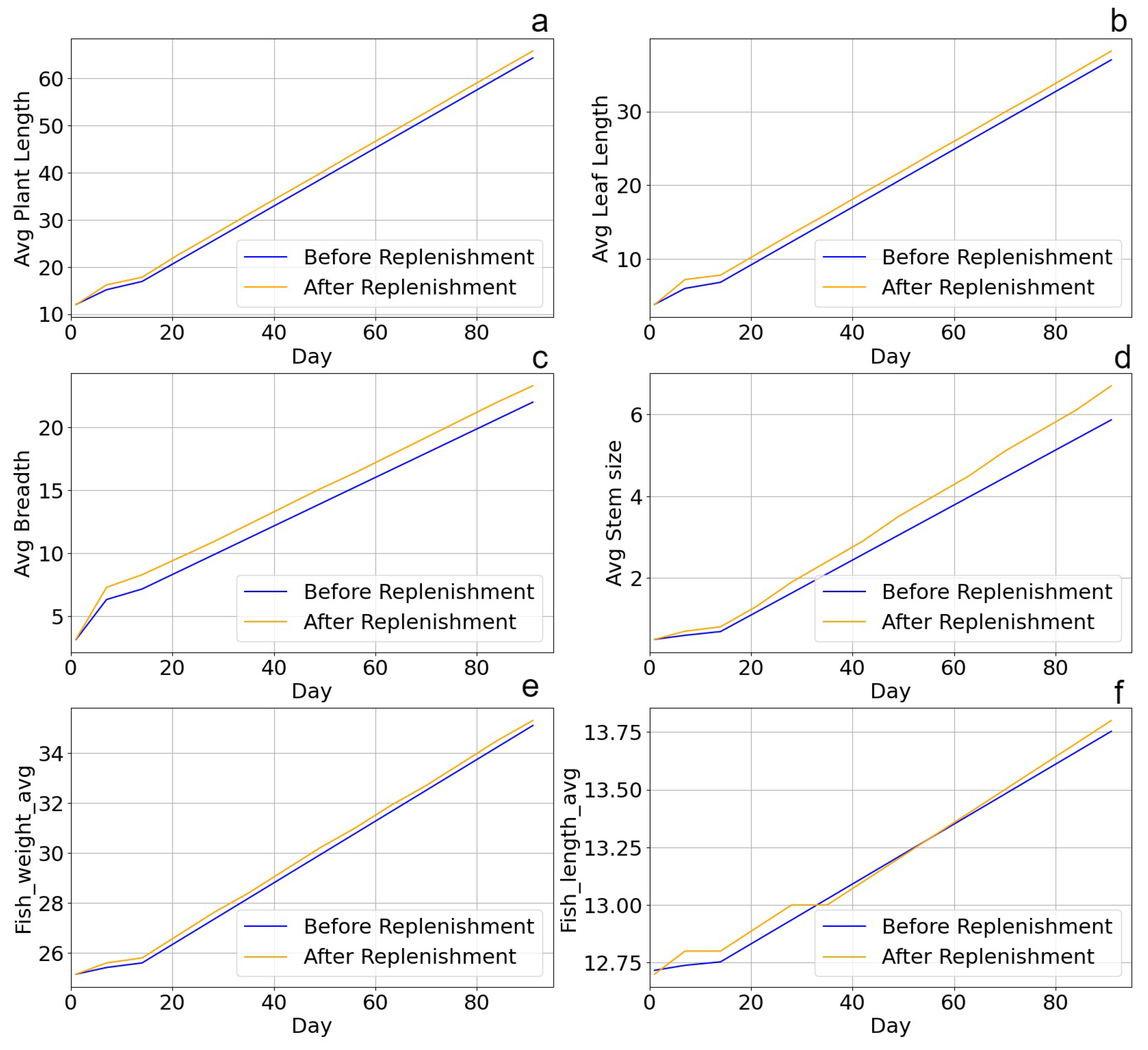

4.2. Vermiponics Testbed Productivity Comparison

5. Discussion

Limitation and Scope of the Project

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| IOT | Internet of Things |

| ML | Machine Learning |

| APS | Aquaponics Systems |

| TAN | Total Ammonia and Nitrogen |

| pH | Potential Hydrogen |

| TDSs | Total Dissolved Solids |

| DO | Dissolved Oxygen |

References

- Delaide, B.; Delhaye, G.; Dermience, M.; Gott, J.; Soyeurt, H.; Jijakli, M.H. Plant and fish production performance, nutrient mass balances, energy and water use of the PAFF Box, a small-scale aquaponic system. Aquac. Eng. 2017, 78, 130–139. [Google Scholar] [CrossRef]

- Goddek, S.; Joyce, A.; Kotzen, B.; Dos-Santos, M. Aquaponics and Global Food Challenges. In Aquaponics Food Production Systems; Springer: Berlin/Heidelberg, Germany, 2019; pp. 3–17. [Google Scholar] [CrossRef]

- Ahmed, N.; Al-Mutairi, K.A. Earthworms effect on microbial population and soil fertility as well as their interaction with agriculture practices. Sustainability 2022, 14, 7803. [Google Scholar] [CrossRef]

- Sandell, L. Vermicompost for Reduction of Vegetable Waste-and a Possible Means to Produce Fish Feed in Aquaponic Systems; Swedish University of Agricultural Sciences: Uppsala, Sweden, 2014. [Google Scholar]

- Garczyńska, M.; Kostecka, J.; Pączka, G.; Mazur-Pączka, A.; Cebulak, T.; Butt, K.R. Chemical composition of earthworm (Dendrobaena veneta Rosa) biomass is suitable as an alternative protein source. Int. J. Environ. Res. Public Health 2023, 20, 3108. [Google Scholar] [CrossRef] [PubMed]

- Musyoka, S.N.; Liti, D.M.; Ogello, E.; Waidbacher, H. Utilization of the earthworm, Eisenia fetida (Savigny, 1826) as an alternative protein source in fish feeds processing: A review. Aquac. Res. 2019, 50, 2301–2315. [Google Scholar] [CrossRef]

- Forchino, A.; Lourguioui, H.; Brigolin, D.; Pastres, R. Aquaponics and sustainability: The comparison of two different aquaponic techniques using the Life Cycle Assessment (LCA). Aquac. Eng. 2017, 77, 80–88. [Google Scholar] [CrossRef]

- Akazawa, S.i.; Badamkhatan, T.; Omiya, K.; Shimizu, Y.; Hasegawa, N.; Sakai, K.; Kamimura, K.; Takeuchi, A.; Murakami, Y. The Growth-Promoting Effect of Earthworm Vermiwash on House Tomato Plants. Sustainability 2023, 15, 10327. [Google Scholar] [CrossRef]

- Deepthi, M.P.; Nivethitha, S.; Saminathan, K.; Narendhirakannan, R.T.; Karmegam, N.; Kathireswari, P. Effect of vermiwash prepared from livestock biowaste as vermiponics medium on the growth and biochemical indices of Amaranthus viridis L. Environ. Technol. Innov. 2021, 21, 101300. [Google Scholar] [CrossRef]

- Chandramenon, P.; Gascoyne, A.; Tchuenbou-Magaia, F. IoT and machine learning approach for the determination of optimal freshwater replenishment rate in aquaponics system. Front. Sustain. Resour. Manag. 2024, 3, 1363914. [Google Scholar] [CrossRef]

- Endut, A.; Jusoh, A.; Ali, N.; Nik, W.W.; Hassan, A. A study on the optimal hydraulic loading rate and plant ratios in recirculation aquaponic system. Bioresour. Technol. 2010, 101, 1511–1517. [Google Scholar] [CrossRef] [PubMed]

- Franco, I.; Faustino, E.; Mota, A.; Bernardino, R. Sustainable nutrients: Vermicompost, a tool to additivate aquaponic systems. Front. Mar. Sci. 2018, 5. [Google Scholar] [CrossRef]

- Das, B.; Islam, S.M.; Nag, S.K.; Vatsos, I.N.; Siddik, M.A. Earthworm, Perionyx excavatus as an alternate protein source for Nile tilapia: Effects on growth performance, blood biochemistry, erythrocyte morphology and intestinal health. Aquac. Int. 2024, 1–23. [Google Scholar] [CrossRef]

- Ingram, G. Substances involved in the natural resistance of fish to infection—A review. J. Fish Biol. 1980, 16, 23–60. [Google Scholar] [CrossRef]

- Falahatkar, B. Nutritional requirements of the Siberian sturgeon: An updated synthesis. In The Siberian Sturgeon (Acipenser baerii, Brandt, 1869) Volume 1-Biology; Springer: Cham, Switzerland, 2018; pp. 207–228. [Google Scholar]

- Rico-García, E.; Esteban Ortega-Torres, A.; Sabino Herrera-Matallana, T. Vermiliquer as a biostimulant and antioxidant in hydroponic lettuce (Lactuca sativa). Production 2023, 50, 25–31. [Google Scholar]

- Kasozi, N.; Wilhelmi, B.; Kaiser, H. The effect of the addition of a probiotic mixture of two Bacillus species to a coupled aquaponics system on water quality, growth and digestive enzyme activity of Mozambique tilapia, Oreochromis mossambicus. J. Appl. Aquac. 2021, 35, 510–528. [Google Scholar] [CrossRef]

- Karimanzira, D.; Rauschenbach, T. Enhancing aquaponics management with IoT-based Predictive Analytics for efficient information utilization. Inf. Process. Agric. 2019, 6, 375–385. [Google Scholar] [CrossRef]

- Okoye, K.; Hosseini, S. T-test Statistics in R: Independent Samples, Paired Sample, and One Sample T-tests. In R Programming: Statistical Data Analysis in Research; Springer: Berlin/Heidelberg, Germany, 2024; pp. 159–186. [Google Scholar]

- Sallenave, R. Important Water Quality Parameters in Aquaponics Systems; College of Agricultural, Consumer and Environmental Sciences: Urbana, IL, USA, 2016. [Google Scholar]

- Fox, B.K.; Tamaru, C.S.; Radovich, T.; Klinger-Bowen, R.; McGovern-Hopkins, K.; Bright, L.; Pant, A.; Gurr, I.; Sugano, J.; Sipes, B.; et al. Beneficial Use of Vermicompost in Aquaponic Vegetable Production; Hānai ‘Ai/the Food Provider: Hawai, HI, USA, 2011; pp. 1–5. [Google Scholar]

- Pant, A.P.; Radovich, T.J.; Hue, N.V.; Talcott, S.T.; Krenek, K.A. Vermicompost extracts influence growth, mineral nutrients, phytonutrients and antioxidant activity in pak choi (Brassica rapa cv. Bonsai, Chinensis group) grown under vermicompost and chemical fertiliser. J. Sci. Food Agric. 2009, 89, 2383–2392. [Google Scholar] [CrossRef]

- Kasozi, N.; Abraham, B.; Kaiser, H.; Wilhelmi, B. The complex microbiome in aquaponics: Significance of the bacterial ecosystem. Ann. Microbiol. 2021, 71, 1. [Google Scholar] [CrossRef]

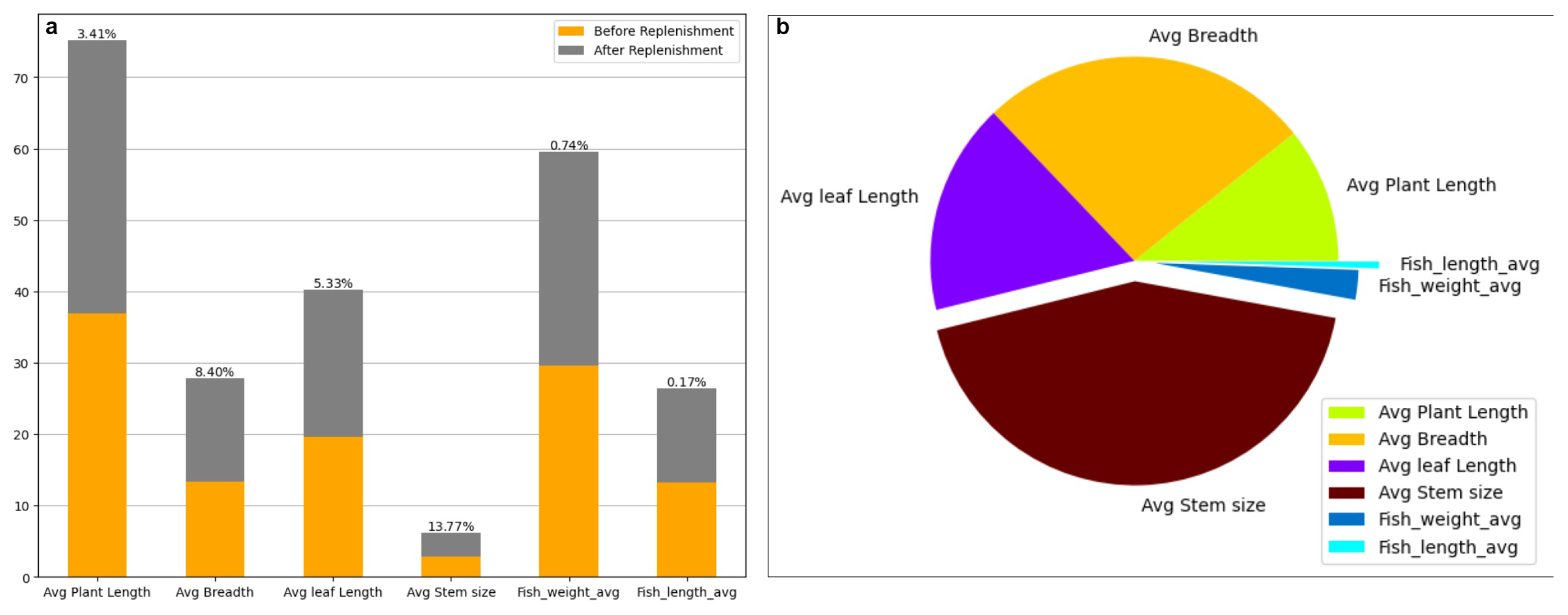

| Attributes | Mean Productivity before Replenishment | Mean Productivity after Replenishment | % of Productivity Difference |

|---|---|---|---|

| Avg plant length | 36.92 | 38.18 | 3.42 |

| Avg breadth | 13.31 | 14.42 | 8.41 |

| Avg leaf length | 19.58 | 20.63 | 5.33 |

| Avg stem size | 2.89 | 3.29 | 13.78 |

| Fish weight avg | 29.64 | 29.86 | 0.75 |

| Fish length avg | 13.17 | 13.20 | 0.17 |

| Attributes | Mean Productivity before Replenishment | Mean Productivity after Replenishment | % of Productivity Difference |

|---|---|---|---|

| Avg plant length | 38.86 | 40.82 | 5.04 |

| Avg breadth | 14.91 | 16.09 | 7.89 |

| Avg leaf length | 19.86 | 22.05 | 11.01 |

| Avg stem size | 3.29 | 4.15 | 26.06 |

| Fish weight avg | 29.83 | 30.43 | 2.02 |

| Fish length avg | 13.20 | 13.31 | 0.86 |

| Attributes | p-Value (Aquaponics) | p-Value (Vermiponics) |

|---|---|---|

| Avg Plant Length | ||

| Avg Breadth | ||

| Avg leaf Length | ||

| Avg Stem size | ||

| Fish weight avg | ||

| Fish length avg |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chandramenon, P.; Gascoyne, A.; Naughton, L.; Tchuenbou-Magaia, F. Making Aquaponics More Sustainable Using Worms and Water Replenishment Combined with a Sensing- and IoT-Based Monitoring System. Appl. Sci. 2024, 14, 8516. https://doi.org/10.3390/app14188516

Chandramenon P, Gascoyne A, Naughton L, Tchuenbou-Magaia F. Making Aquaponics More Sustainable Using Worms and Water Replenishment Combined with a Sensing- and IoT-Based Monitoring System. Applied Sciences. 2024; 14(18):8516. https://doi.org/10.3390/app14188516

Chicago/Turabian StyleChandramenon, Praveen, Andrew Gascoyne, Liam Naughton, and Fideline Tchuenbou-Magaia. 2024. "Making Aquaponics More Sustainable Using Worms and Water Replenishment Combined with a Sensing- and IoT-Based Monitoring System" Applied Sciences 14, no. 18: 8516. https://doi.org/10.3390/app14188516