Applications and Prospects of Smooth Particle Hydrodynamics in Tunnel and Underground Engineering

Abstract

:1. Introduction

2. Characteristics, Principles, and a Case Study of SPH

2.1. Characteristics of SPH

- (1)

- Meshless: The problem domain is entirely represented by particles, which act as the fundamental computational units for estimating field variables. This particle-based approach removes the necessity for grid-based partitioning, thereby sidestepping the challenges related to mesh distortion and reconstruction.

- (2)

- Adaptive: The kernel approximation of the field function is recalculated at each time step using all particles within the continuous domain. This adaptability ensures that the SPH method maintains robustness and consistency, even with arbitrary variations in particle distribution over time.

- (3)

- Lagrangian Integration: The SPH method seamlessly integrates Lagrangian properties with particle characteristics. Through the application of particle approximation techniques to discrete partial differential equations formulated in the Lagrangian framework—encompassing essential variables like velocity, density, and energy—the method establishes a coherent and precise system for capturing fluid dynamics.

- (1)

- It is a mesh-free framework that demonstrates resilience to distortion and deformation.

- (2)

- It has high adaptability, making it suitable for scenarios with evolving boundaries.

- (3)

- The elimination of extensive element divisions effectively mitigates errors associated with local approximations found in finite element methods (FEMs).

- (4)

- There is continuity of the field function and its gradient within the solution domain, achieved through kernel function interpolation.

- (5)

- The resolution of governing equations is simplified, thereby easing the integration of chemical and thermodynamic effects.

2.2. Principles of SPH

2.2.1. Construction of SPH Basic Equation

- (1)

- Kernel approximation method.

- (1)

- The initial condition pertains to regularization, ensuring that the function adheres to a specific set of standards or norms.

- (2)

- The second is that when the degree of smoothness tends to zero, the properties of the Dirac function are as follows:

- (3)

- The third condition aims to strengthen the constraints, ensuring a tighter and more rigorous adherence to the specified requirements.

- (2)

- Particle approximation method.

2.2.2. Construction of Smooth Functions

- (1)

- Gaussian smooth function.

- (2)

- Cubic spline curve.

- (3)

- High-order spline curve.

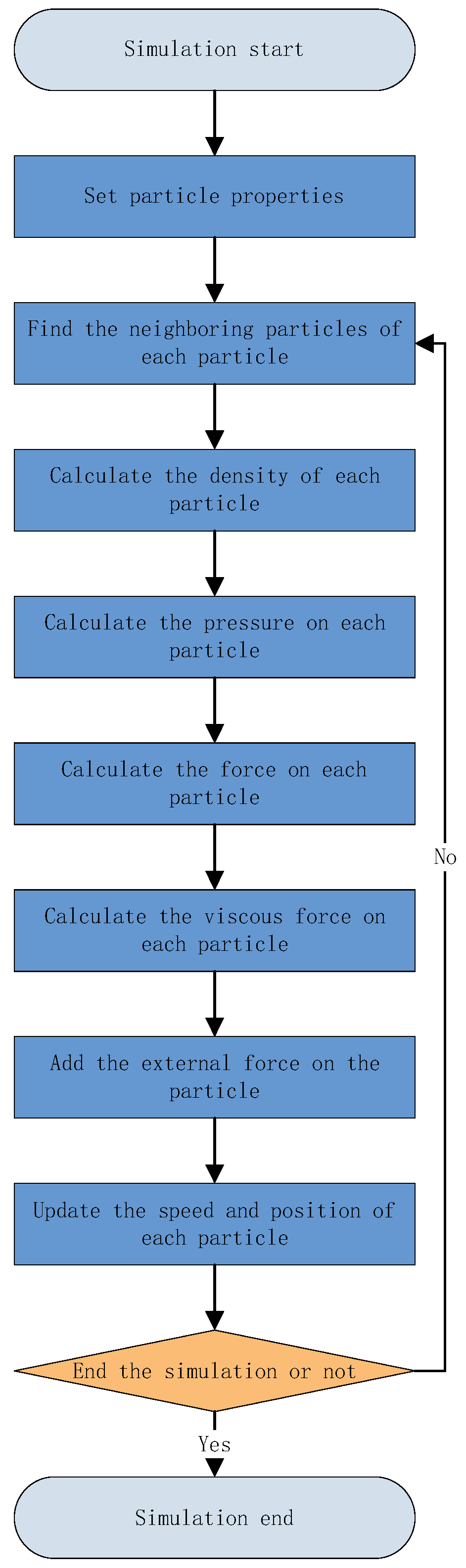

2.3. A Case Study of SPH

- (1)

- Mass conservation:

- (2)

- Momentum conservation:

- (3)

- Energy conservation:

| Algorithm 1: Smoothed particle hydrodynamics simulation algorithm | |

| // Initialize particles | |

| 1: | for each particle i in fluid |

| 2: | initialize_position(particle i) |

| 3: | initialize_velocity(particle i) |

| 4: | initialize_mass(particle i) |

| 5: | initialize_other_properties(particle i) |

| 6: | end for |

| // Main simulation loop | |

| 7: | while time < end_time |

| 8: | // Compute density for each particle |

| 9: | for each particle i in fluid |

| 10: | rho_i = 0 |

| 11: | for each neighbor j of particle i |

| 12: | rho_i += mass(j) * W(position(i) − position(j), H) |

| 13: | end for |

| 14: | density(i) = rho_i |

| 15: | end for |

| 16: | // Compute pressure for each particle |

| 17: | for each particle i in fluid |

| 18: | pressure(i) = equation_of_state(density(i)) |

| 19: | end for |

| 20: | // Compute forces for each particle |

| 21: | for each particle i in fluid |

| 22: | force_i = 0 |

| 23: | for each neighbor j of particle i |

| 24: | force_i += -mass(i) * (pressure(i) + pressure(j))/(2 * density(j)) * gradW(position(i) − position(j), H) |

| 25: | + viscosity_term |

| 26: | end for |

| 27: | force(i) = force_i |

| 28: | end for |

| 29: | // Integrate motion equations |

| 30: | for each particle i in fluid |

| 31: | velocity(i) += time_step * force(i)/density(i) |

| 32: | position(i) += time_step * velocity(i) |

| 33: | end for |

| 34: | // Handle boundary conditions |

| 35: | for each particle i in fluid |

| 36: | if position(i) is outside boundary |

| 37: | handle_boundary(position(i), velocity(i)) |

| 38: | end if |

| 39: | end for |

| 40: | // Advance time |

| 41: | time += time_step |

| 42: | end while |

3. Applications of Smooth Particle Hydrodynamics in Tunnel and Underground Engineering

3.1. Water and Mud Inrush during Tunnel Construction

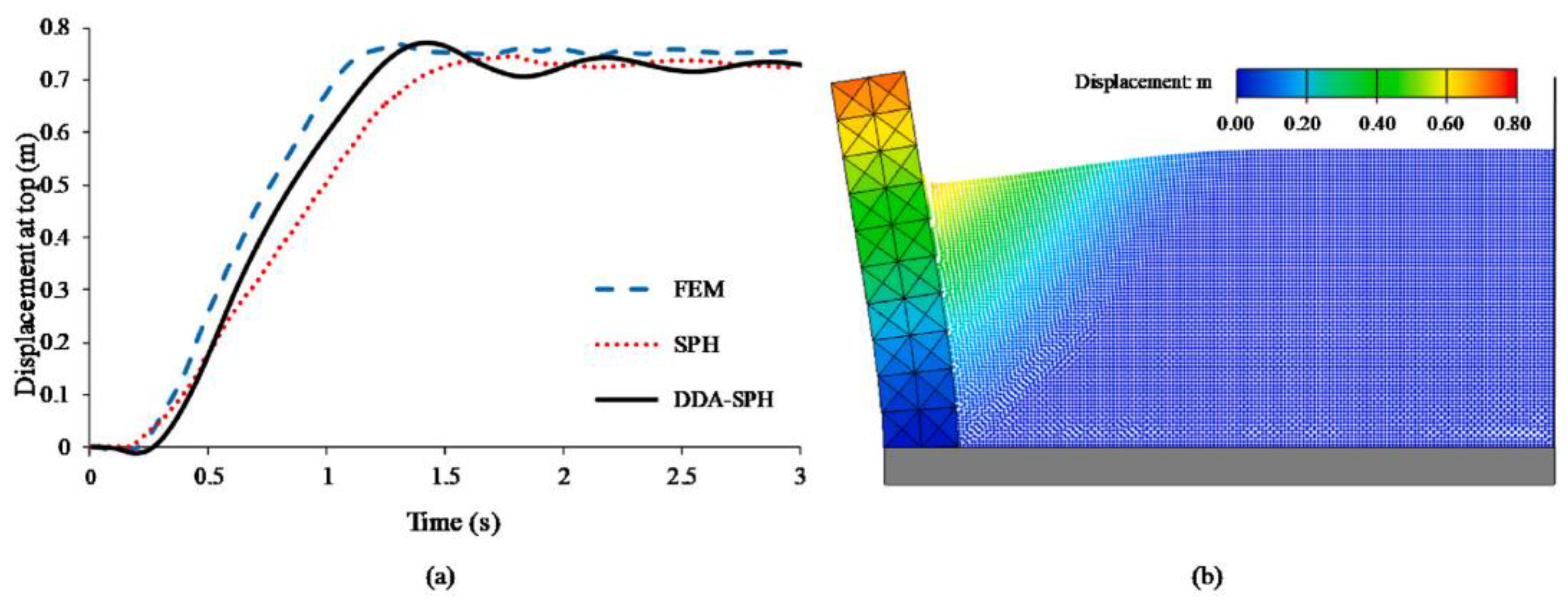

3.2. Interaction between Rock Structures and Soil

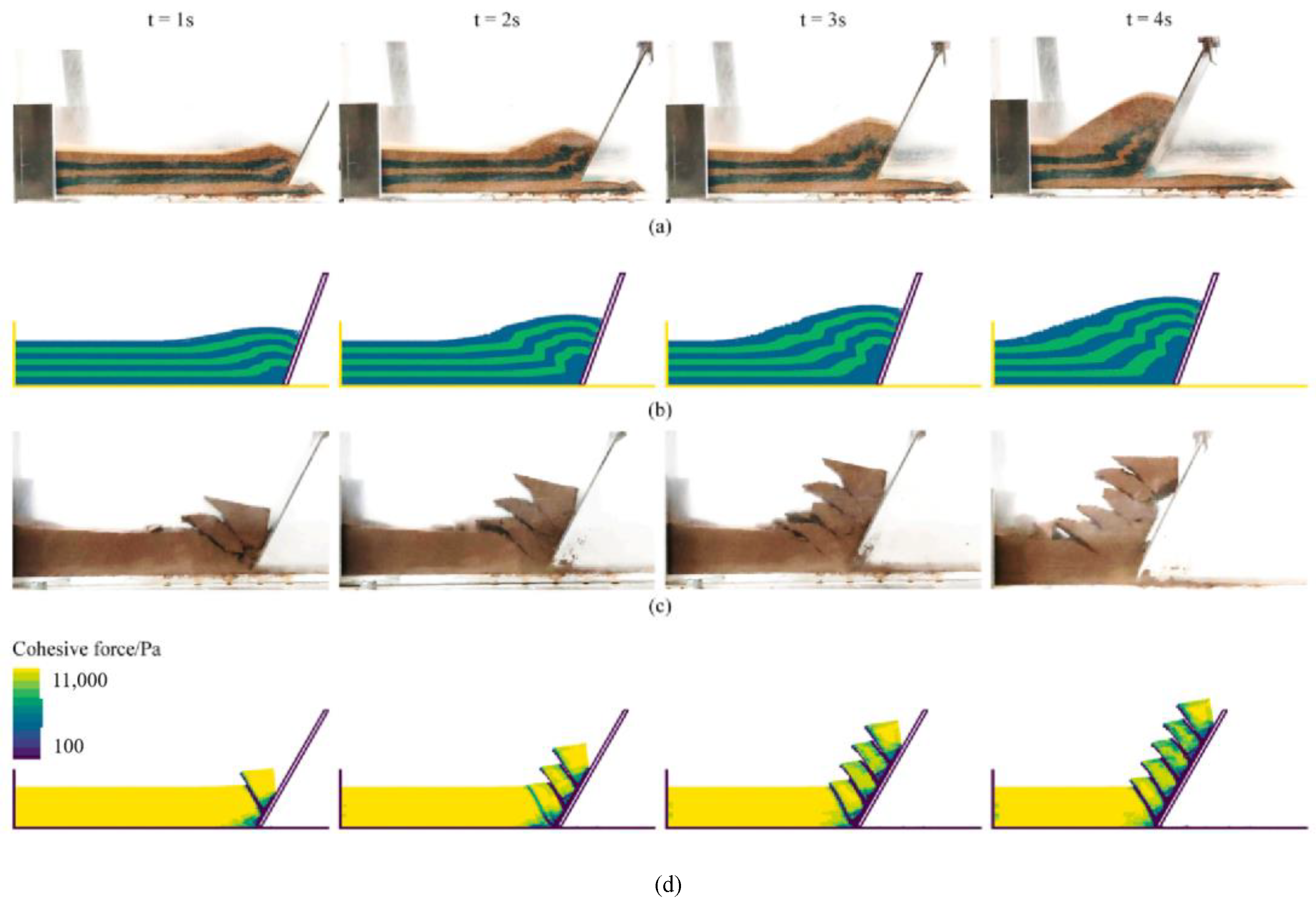

3.3. The Cutterhead Cuts Soil during Tunnel Construction

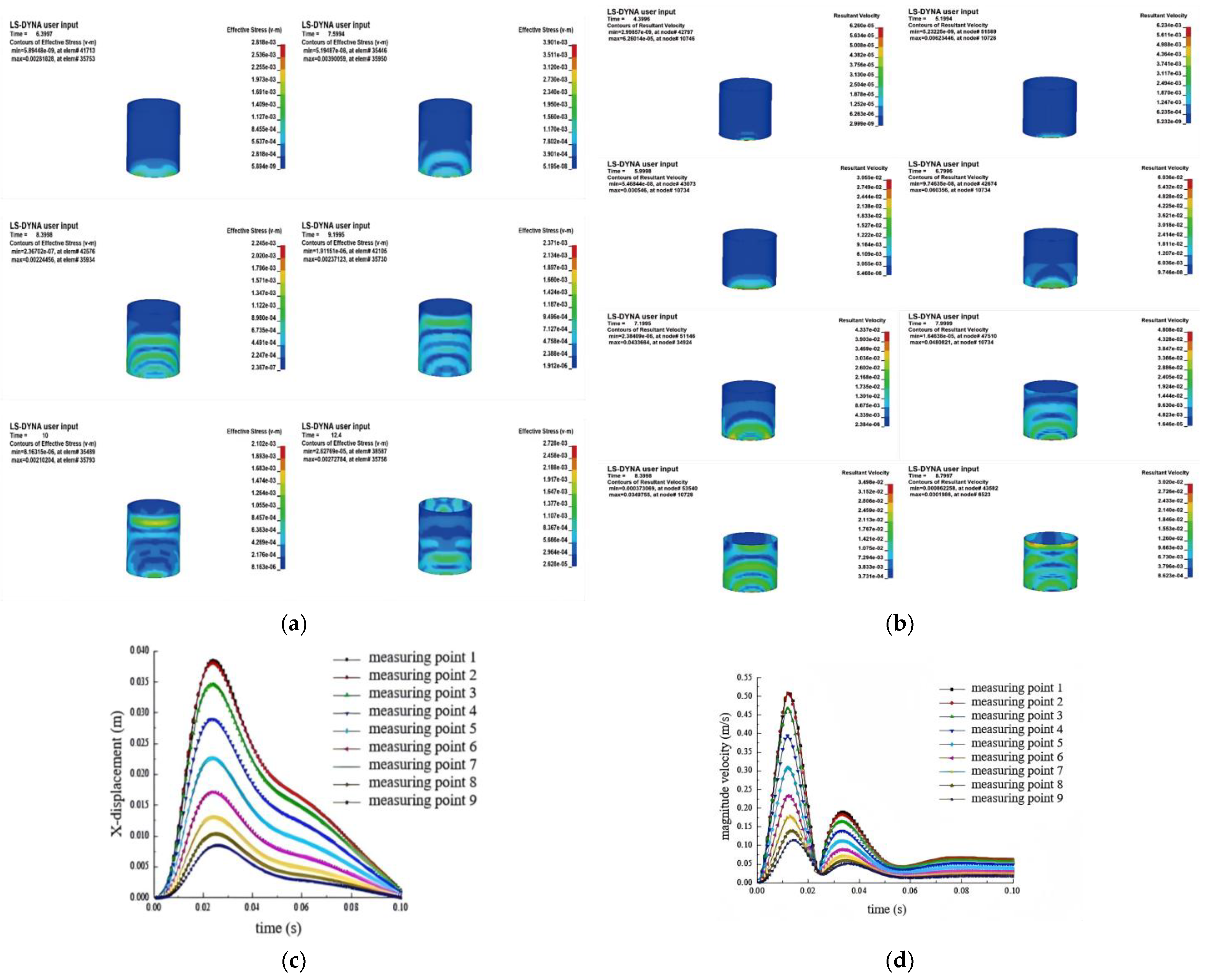

4. Example Simulation and Analysis of SPH in Tunnel and Underground Engineering

4.1. Engineering Background

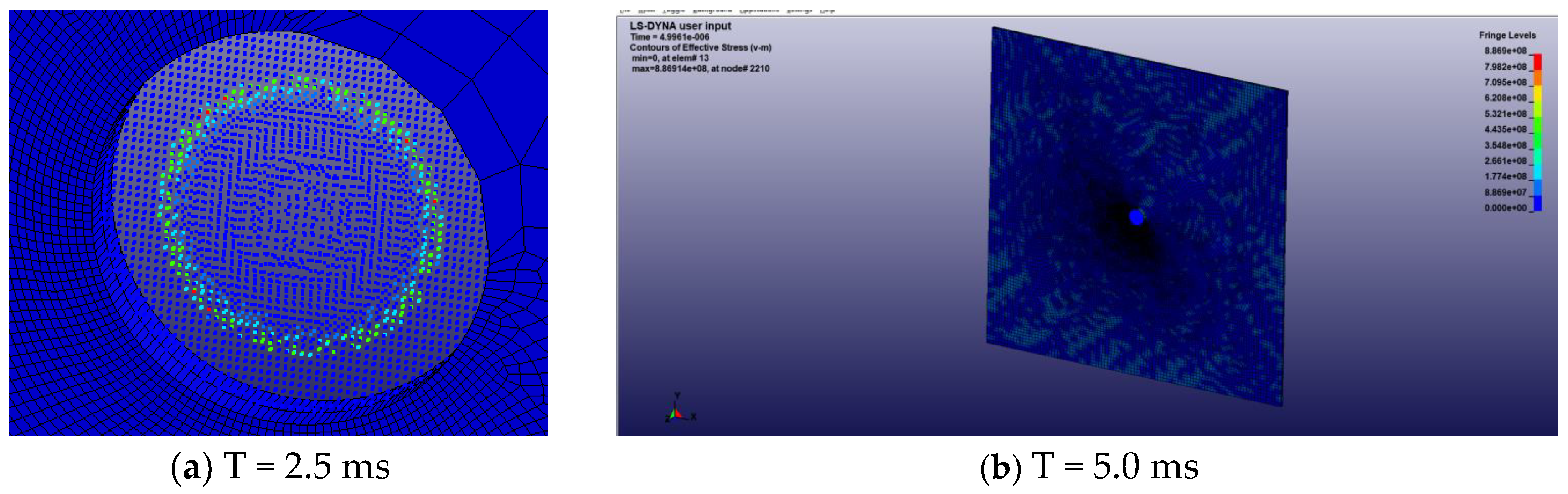

4.2. Establishment of Numerical Simulation Model

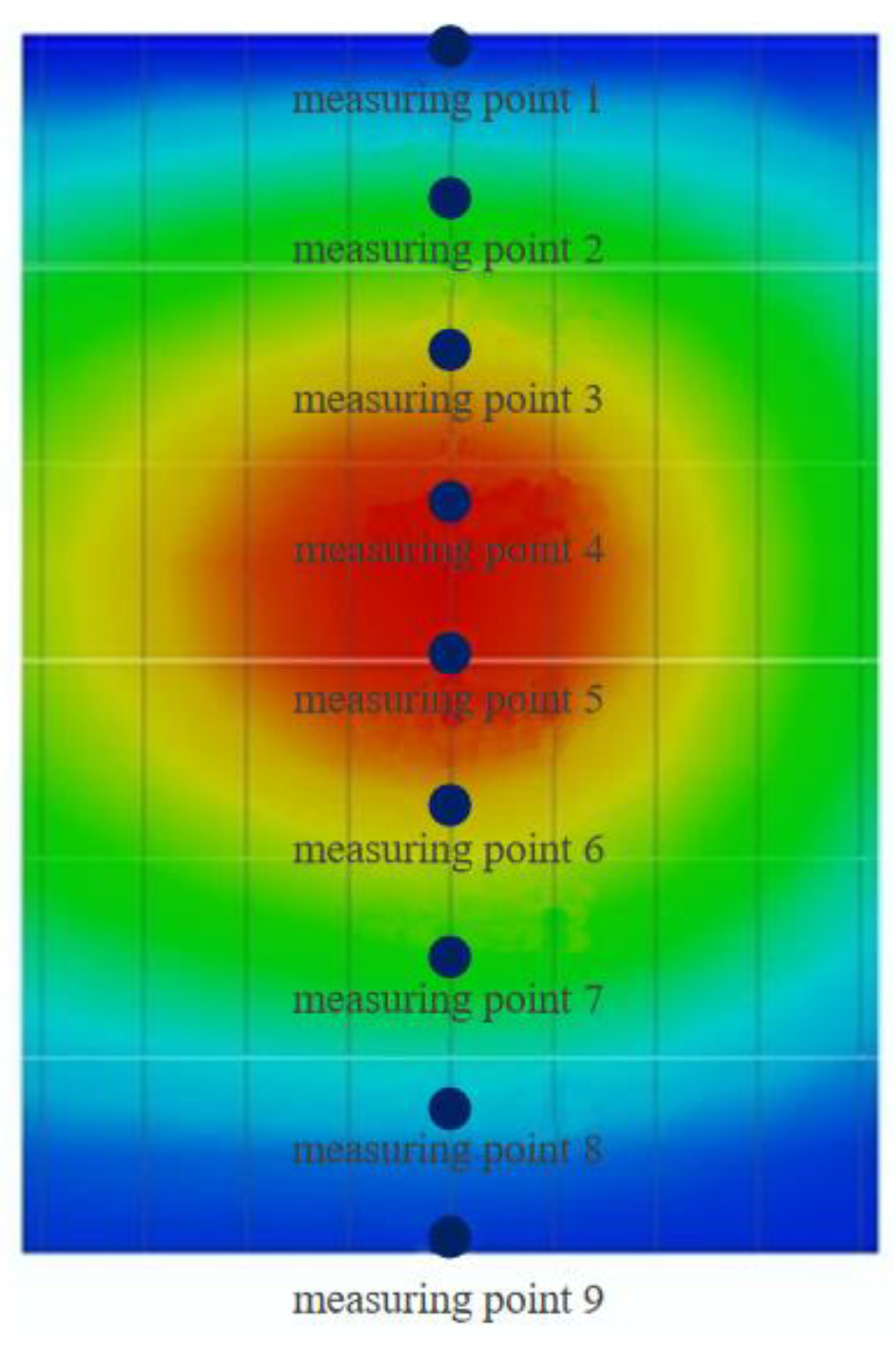

4.3. Numerical Simulation Results Analysis

5. Conclusions

- (1)

- This study provides a comprehensive examination of the application and future prospects of smoothed particle hydrodynamics (SPH) in tunnel and underground engineering. It thoroughly reviews the defining characteristics and theoretical foundations of the SPH method, supplemented with examples derived from the Navier–Stokes (N-S) equations. The discussion highlights SPH’s distinctive advantages in addressing complex flow dynamics and large deformation challenges. As a meshless technique, SPH demonstrates significant efficiency in managing dynamic boundaries, fluid–solid interactions, and multi-field coupling conditions.

- (2)

- As a meshless technique, smoothed particle hydrodynamics (SPH) offers distinct advantages for simulating fluid–solid interactions and multi-field coupling conditions, particularly in the dynamic environments of tunnel construction involving water and mud flows. SPH has demonstrated its versatility across a range of fields, including astrophysics, fluid dynamics, and solid mechanics. Its effectiveness in addressing various physical phenomena and incorporating material properties underscores its ability to enhance the accuracy of simulation results. The applicability of SPH is further validated through simulations of water and mud behavior during tunnel construction, the interaction between rock and soil structures, and the failure mechanisms of brittle materials.

- (3)

- This paper provides an in-depth examination of the theoretical foundations of smoothed particle hydrodynamics (SPH) and its potential applications in tunnel excavation and underground engineering. SPH has proven effective in simulating fluid dynamics and soil deformation during tunnel blasting, with simulation outcomes aligning closely with actual monitoring data. This validates the method’s feasibility and effectiveness for practical engineering applications. Despite its notable performance in managing large deformations in soft rocks and the mechanical cutting of hard rocks, SPH faces significant challenges. These include the complexity of constitutive models for surrounding rock masses, the rheological characteristics of tunnel structures, and the inherent spatiotemporal effects during excavation. Additionally, the fundamental theory of SPH requires further development, particularly in multi-field coupling scenarios. As computational resources and SPH theory continue to advance, the method’s applicability in tunnel and underground engineering is expected to expand. Future research should focus on addressing current technological limitations and exploring synergistic approaches with other numerical simulation techniques to enhance SPH’s utility in complex engineering environments. In summary, SPH, as an emerging numerical simulation tool, holds significant promise for tunnel and underground engineering and warrants further investigation and practical application.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Monaghan, J. An introduction to SPH. Comput. Phys. Commun. 1988, 48, 89–96. [Google Scholar] [CrossRef]

- Sun, X.; Wang, J. The theory and application of SPH method. Water Resour. Hydropower Technique 2007, 38, 44–46. [Google Scholar] [CrossRef]

- Tang, Y.; Shi, F.; Liao, X.; Zhou, S. Discussion on the influence of flow rule based on smooth particle hydrodynamics on large deformation of soil landslide. Rock. Soil. Mechan. 2018, 39, 1509–1516. [Google Scholar] [CrossRef]

- Yan, J.; Cheng, Y. Deep Learning-Meshless Method for Inverse Potential Problems. Int. J. Appl. Mech. 2024, 16, 2450069. [Google Scholar] [CrossRef]

- Liu, M.B.; Liu, G.R.; Zong, Z. An overview on smoothed particle hydrodynamics. Int. J. Comput. Methods 2008, 5, 135–188. [Google Scholar] [CrossRef]

- Yang, X.-F.; Liu, M.-B. An improved scheme for stress instability of smoothed particle dynamics SPH method. Acta Phys. Sin. 2012, 61, 224701. [Google Scholar] [CrossRef]

- Antoci, C.; Gallati, M.; Sibilla, S. Numerical simulation of fluid–structure interaction by SPH. Comput. Struct. 2007, 85, 879–890. [Google Scholar] [CrossRef]

- Yu, H.; Liang, H.; Hideto, N. The state of the art of SPH method applied in geotechnical engineering. Chin. J. Geotech. Eng. 2008, 30, 256–262. [Google Scholar] [CrossRef]

- Wijesooriya, K.; Mohotti, D.; Lee, C.-K.; Mendis, P. A technical review of computational fluid dynamics (CFD) applications on wind design of tall buildings and structures: Past, present and future. J. Build. Eng. 2023, 74, 106828. [Google Scholar] [CrossRef]

- Tu, X.L.; Gambaruto, A.M.; Newell, R.; Pregnolato, M.; Tu, X.L.; Gambaruto, A.M.; Newell, R.; Pregnolato, M. Computational fluid dynamics analysis of bridge scour with a comparison of pier shapes and a debris fin. Structures 2024, 67, 106966. [Google Scholar] [CrossRef]

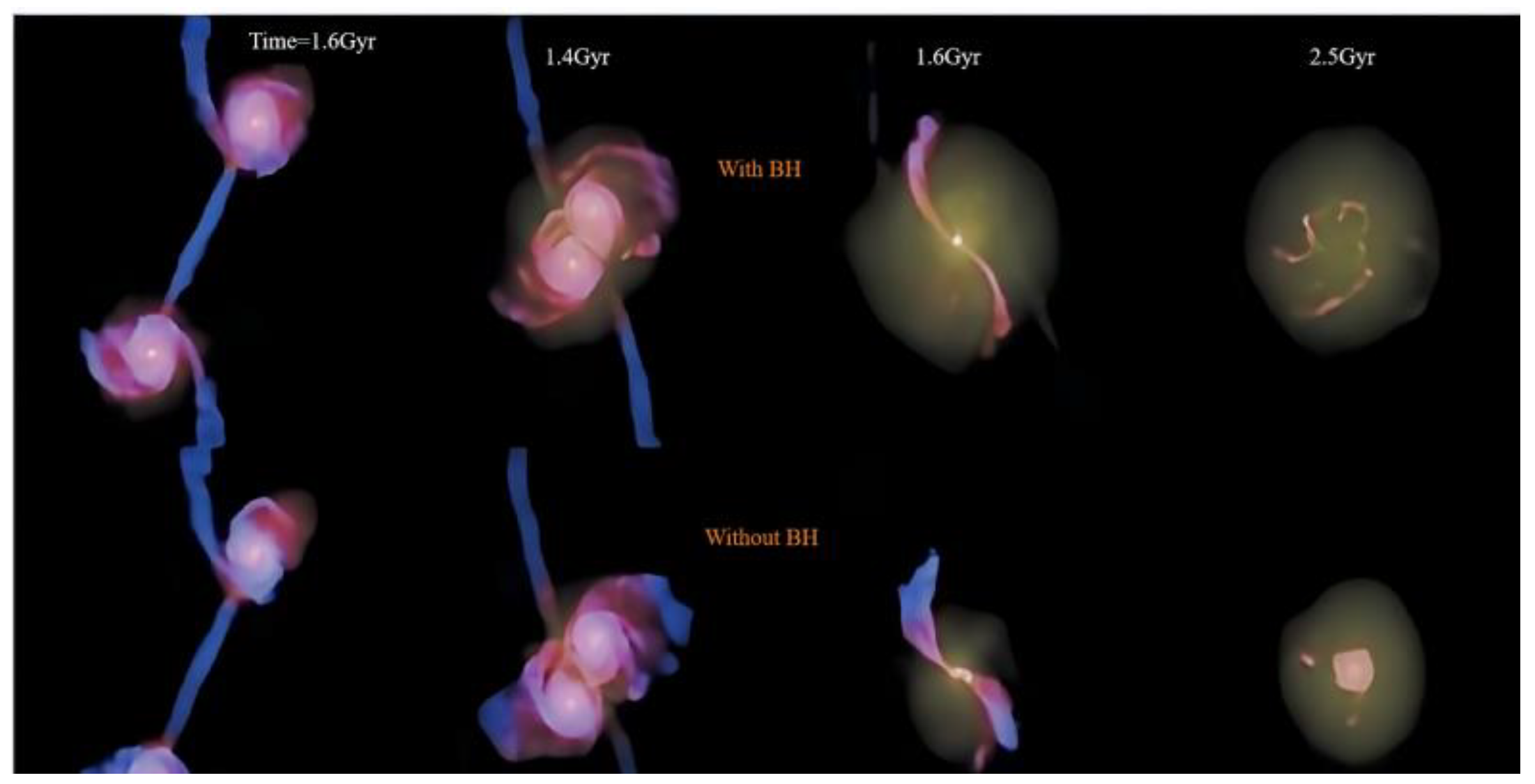

- Mirza, M.A.; Tahir, A.; Khan, F.M.; Holley-Bockelmann, H.; Baig, A.M.; Berczik, P.; Chishtie, F. Galaxy rotation and supermassive black hole binary evolution. Mon. Not. R. Astron. Soc. 2017, 470, 940–947. [Google Scholar] [CrossRef]

- Kazemi, E.; Koll, K.; Tait, S.; Shao, S. SPH modelling of turbulent open channel flow over and within natural gravel beds with rough interfacial boundaries. Adv. Water Resour. 2020, 140, 103557. [Google Scholar] [CrossRef]

- Meringolo, D.D.; Marrone, S.; Colagrossi, A.; Liu, Y. A dynamic δ-SPH model: How to get rid of diffusive parameter tuning. Comput. Fluids 2019, 179, 334–355. [Google Scholar] [CrossRef]

- Wu, J.-H.; Chen, C.-H. Application of DDA to simulate characteristics of the Tsaoling landslide. Comput. Geotech. 2011, 38, 741–750. [Google Scholar] [CrossRef]

- Xiang, Z.; Yu, S.; Wang, X. Modeling the Hydraulic Fracturing Processes in Shale Formations Using a Meshless Method. Water 2024, 16, 1855. [Google Scholar] [CrossRef]

- Xiong, W.; Cai, C.; Kong, B.; Kong, X. CFD simulations and analyses for bridgescour development using a dynamic-mesh updating technique. J. Comput. Civ. Eng. 2016, 30, 04014121. [Google Scholar] [CrossRef]

- Zhang, J.; Wang, B.; Hou, G. Numerical simulation and experimental study of fluid–structure interactions in elastic structures based on the SPH method. Ocean. Eng. 2024, 301, 117523. [Google Scholar] [CrossRef]

- Bo, X.; Mowen, X.; Man, H. Research on SPH particle model of landslide based on GIS spatial data. Rock. Soil. Mech. 2016, 37, 2696–2705. [Google Scholar] [CrossRef]

- Pan, J.; Zeng, Q. Research review over the advances of the application of SPH method to the analysis of the serious geotechnical deformation. J. Saf. Environ. 2015, 15, 144–150. [Google Scholar] [CrossRef]

- Lian, Y.; Bui, H.H.; Nguyen, G.D.; Haque, A. An effective and stabilised (u−pl) SPH framework for large deformation and failure analysis of saturated porous media. Comput. Methods Appl. Mech. Eng. 2023, 408, 115967. [Google Scholar] [CrossRef]

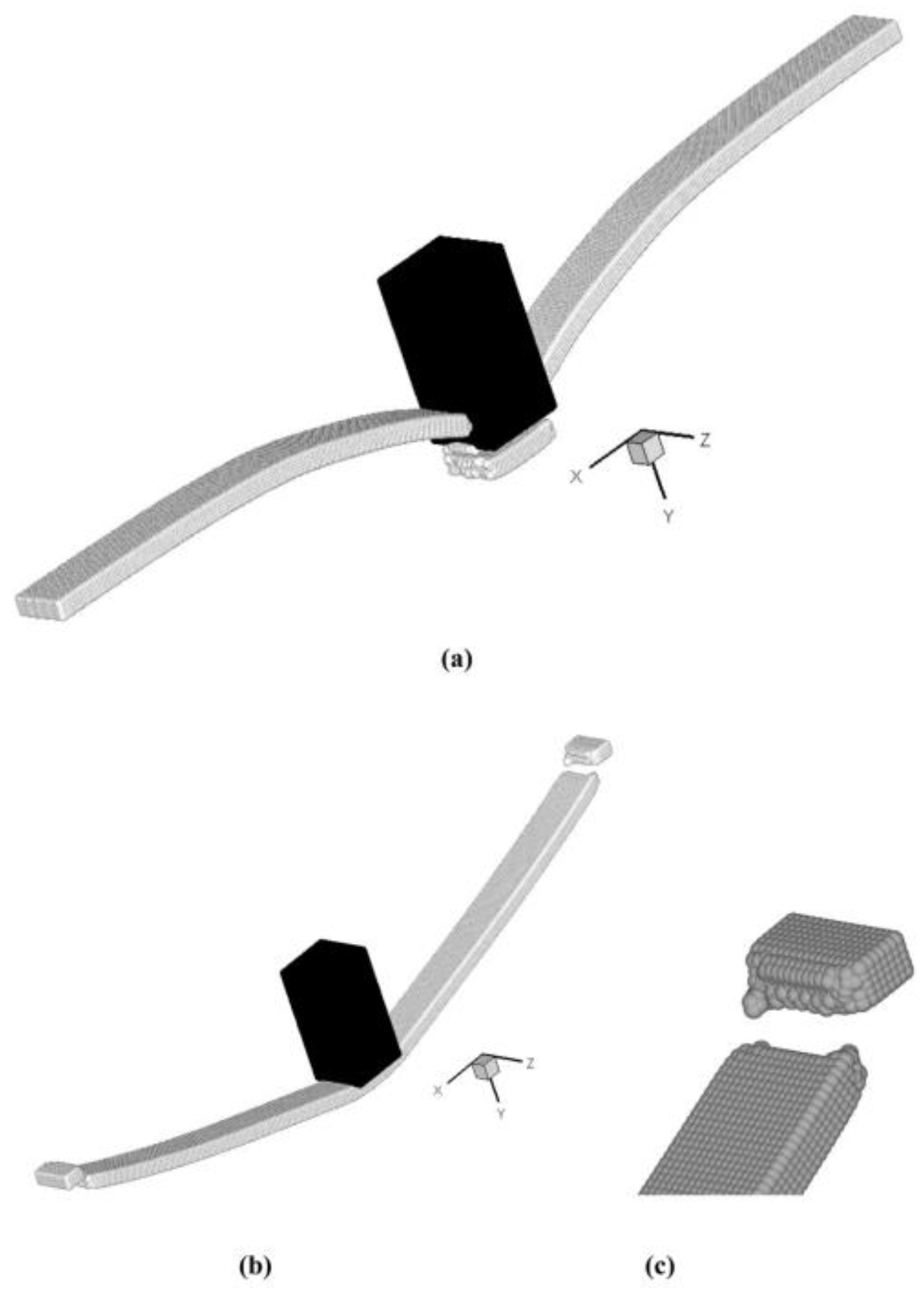

- Peng, X.; Chen, G.; Fu, H.; Yu, P.; Zhang, Y.; Tang, Z.; Zheng, L.; Wang, W. Development of coupled DDA-SPH method for dynamic modelling of interaction problems between rock structure and soil. Int. J. Rock. Mech. Min. Sci. Géoméch. Abstr. 2021, 146, 104890. [Google Scholar] [CrossRef]

- Hu, M.; Gao, T.; Dong, X.; Tan, Q.; Yi, C.; Wu, F.; Bao, A. Simulation of soil-tool interaction using smoothed particle hydrodynamics (SPH). Soil. Tillage Res. 2023, 229, 105671. [Google Scholar] [CrossRef]

- Chakraborty, S.; Shaw, A. A pseudo-spring based fracture model for SPH simulation of impact dynamics. Int. J. Impact Eng. 2013, 58, 84–95. [Google Scholar] [CrossRef]

- Lu, G.; Tao, C.; Xia, C.; Cao, B.; Zhu, X. Stability analysis of layered circular rock tunnels considering anchor reinforcement based on an enhanced mesh-free method. Eng. Anal. Bound. Elem. 2024, 166, 105850. [Google Scholar] [CrossRef]

- Beyabanaki, S.A.R.; Bagtzoglou, A.C.; Liu, L. Applying disk-based discontinuous deformation analysis (DDA) to simulate Donghekou landslide triggered by the Wenchuan earthquake. Géoméch. Geoengin. 2016, 11, 177–188. [Google Scholar] [CrossRef]

- Lee, E.M. Landslide risk assessment: The challenge of communicating uncertainty to decision-makers. Q. J. Eng. Geol. Hydrogeol. 2016, 49, 21–35. [Google Scholar] [CrossRef]

- Sekine, H.; Ito, R.; Shintate, K. A single energy-based parameter to assess protection capability of debris shields. Int. J. Impact Eng. 2007, 34, 958–972. [Google Scholar] [CrossRef]

- Tang, Y.; Shi, F.; Liu, X. Failure criteria based on SPH slope stability analysis. Chin. J. Geotech. Eng. 2016, 38, 904–908. [Google Scholar] [CrossRef]

- He, F.; Chen, Y.; Wang, L.; Li, S.; Huang, C. A multi-layer SPH method to simulate water-soil coupling interaction-based on a new wall boundary model. Eng. Anal. Bound. Elem. 2024, 164, 105755. [Google Scholar] [CrossRef]

- Hu, M.; Liu, M.B.; Xie, M.W.; Liu, G.R. Three-dimensional run-out analysis and prediction of flow-like landslides using smoothed particle hydrodynamics. Environ. Earth Sci. 2015, 73, 1629–1640. [Google Scholar] [CrossRef]

- Cleary, P.; Ha, J.; Prakash, M.; Nguyen, T. 3D SPH flow predictions and validation for high pressure die casting of automotive components. Appl. Math. Model. 2006, 30, 1406–1427. [Google Scholar] [CrossRef]

- Morris, J.P.; Fox, P.J.; Zhu, Y. Modeling Low Reynolds Number Incompressible Flows Using SPH. J. Comput. Phys. 1997, 136, 214–226. [Google Scholar] [CrossRef]

- Bui, H.H.; Fukagawa, R.; Sako, K.; Ohno, S. Lagrangian meshfree particles method (SPH) for large deformation and failure flows of geomaterial using elastic–plastic soil constitutive model. Int. J. Numer. Anal. Methods Géoméch. 2008, 32, 1537–1570. [Google Scholar] [CrossRef]

- Nonoyama, H.; Moriguchi, S.; Sawada, K.; Yashima, A. Slope stability analysis using smoothed particle hydrodynamics (SPH) method. Soils Found. 2015, 55, 458–470. [Google Scholar] [CrossRef]

- Chen, J.K.; Beraun, J.E.; Carney, T.C. A corrective smoothed particle method for boundary value problems in heat conduction. Int. J. Numer. Methods Eng. 1999, 46, 231–252. [Google Scholar] [CrossRef]

- Xia, C.; Shi, Z.; Li, B. a modified SPH framework of for simulating progressive rock damage and water inrush disasters in tunnel constructions. Comput. Geotech. 2024, 167, 106042. [Google Scholar] [CrossRef]

- Bao, Y.; Ye, G.; Ye, B.; Zhang, F. Seismic evaluation of soil–foundation–superstructure system considering geometry and material nonlinearities of both soils and structures. Soils Found. 2012, 52, 257–278. [Google Scholar] [CrossRef]

- Nonoyama, H. Application of SPH method in geotechnical engineering. J. Sand Control. Soc. 2015, 68, 68–71. [Google Scholar] [CrossRef]

- Man, H.; Fei, W.; Shiji, W.; Fuyu, Z. Modeling of influenced area after slope failure based on smoothed particle hydrodynamics (SPH). J. Chongqing Univ. 2019, 42, 56–65. [Google Scholar] [CrossRef]

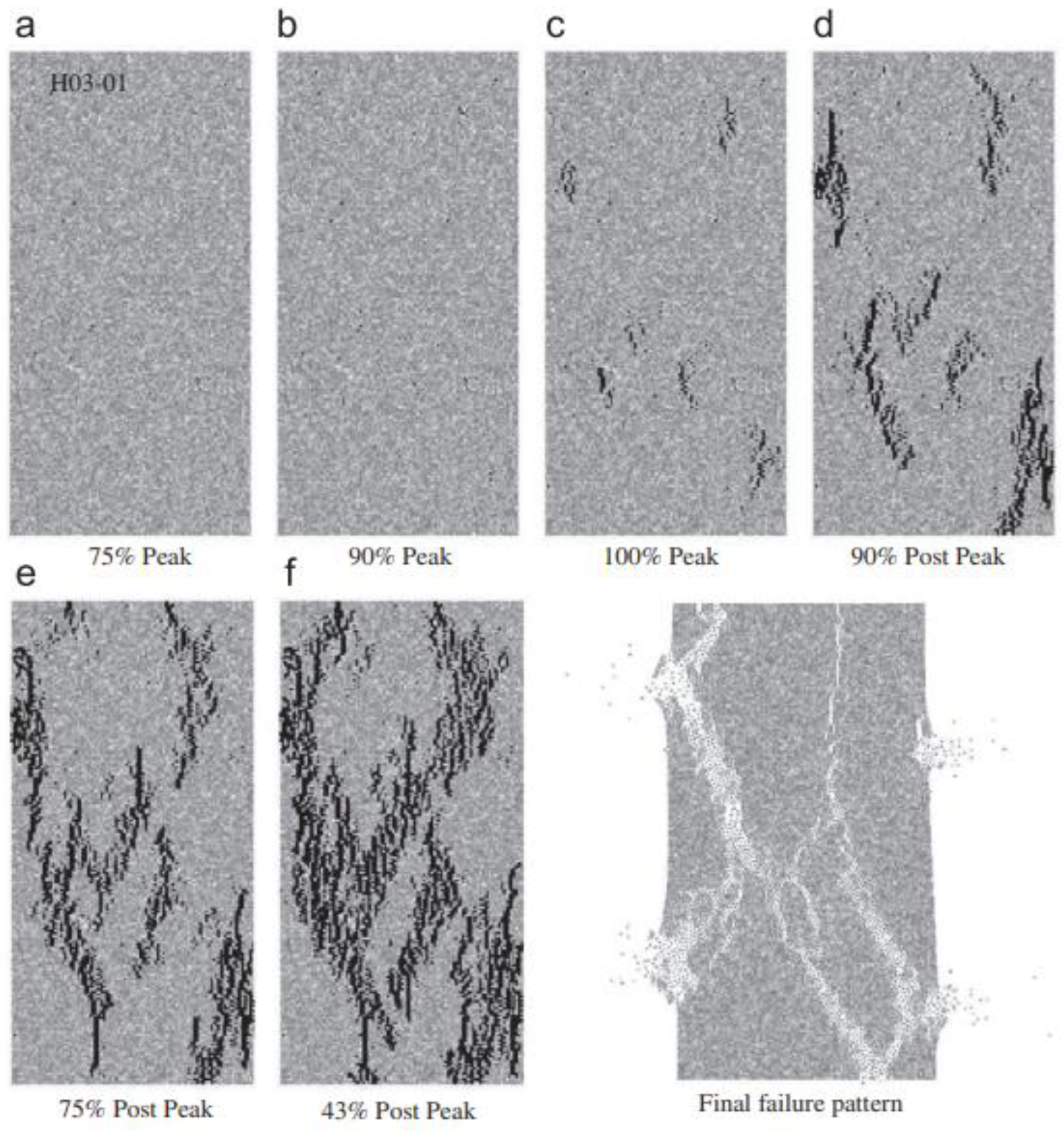

- Ma, G.; Wang, X.; Ren, F. Numerical simulation of compressive failure of heterogeneous rock-like materials using SPH method. Int. J. Rock. Mech. Min. Sci. Géoméch. Abstr. 2011, 48, 353–363. [Google Scholar] [CrossRef]

| Surrounding Rock Classification | Volumetric Weight/(kN/m3) | E/(GPa) | Poisson Ratio | Angle of Internal Friction/(°) | Cohesion/(MPa) |

|---|---|---|---|---|---|

| Va | 19 | 1.65 | 0.37 | 24 | 0.16 |

| Density/(g·cm−3) | Detonation Velocity/(m·s−1) | C-J Pressure/(GPa) |

|---|---|---|

| 0.95 | 3150 | 4.0 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fan, R.; Chen, T.; Li, M.; Wang, S. Applications and Prospects of Smooth Particle Hydrodynamics in Tunnel and Underground Engineering. Appl. Sci. 2024, 14, 8552. https://doi.org/10.3390/app14188552

Fan R, Chen T, Li M, Wang S. Applications and Prospects of Smooth Particle Hydrodynamics in Tunnel and Underground Engineering. Applied Sciences. 2024; 14(18):8552. https://doi.org/10.3390/app14188552

Chicago/Turabian StyleFan, Rong, Tielin Chen, Man Li, and Shunyu Wang. 2024. "Applications and Prospects of Smooth Particle Hydrodynamics in Tunnel and Underground Engineering" Applied Sciences 14, no. 18: 8552. https://doi.org/10.3390/app14188552