Comparative Assessment of the Nutritional and Sanogenic Features of Certain Cheese Sorts Originating in Conventional Dairy Farms and in “Mountainous” Quality System Farms

Abstract

:1. Introduction

2. Materials and Methods

- -

- Raw milk for “mountain product”: density = 1.298 g/cm3, pH = 6.53; fat = 4.1%, protein = 3.42%, out of which casein = 33.7%; lactose = 5.82%; TGC = 87,000 CFU/cm3 (vs. max. admitted limit of 100,000 CFU/cm3), SCC = 112,300 cells/cm3 (vs. max. admitted limit of 400,000 cells/cm3);

- -

- Raw milk for conventional cheese: density = 1.282 g/cm3, pH = 6.61; fat = 3.9%, protein = 3.27%, out of which casein = 28.3%; lactose = 4.92%; TGC = 67,000 CFU/cm3 (vs. max. admitted limit of 100,000 CFU/cm3), SCC = 83,700 cells/cm3 (vs. max. admitted limit of 400,000 cells/cm3).

- -

- Raw milk for “Mountain product” produced in the study area, collected from 7 dairy farms in Calimani National Park, with cows grazing on the mountain meadows and fed mostly haystack harvested from the same area. Cows were not provided herbs or maize silage throughout the cold season;

- -

- Raw milk for conventional products, collected from many small-size producers in the whole of Suceava County, both from mountain areas and hilly-plain regions, whose feeding was not traced, but, usually, the smallest farm holders use local pastures, complete with corn silage and alfalfa hay, bought from all Northeast Romania, upon availability.

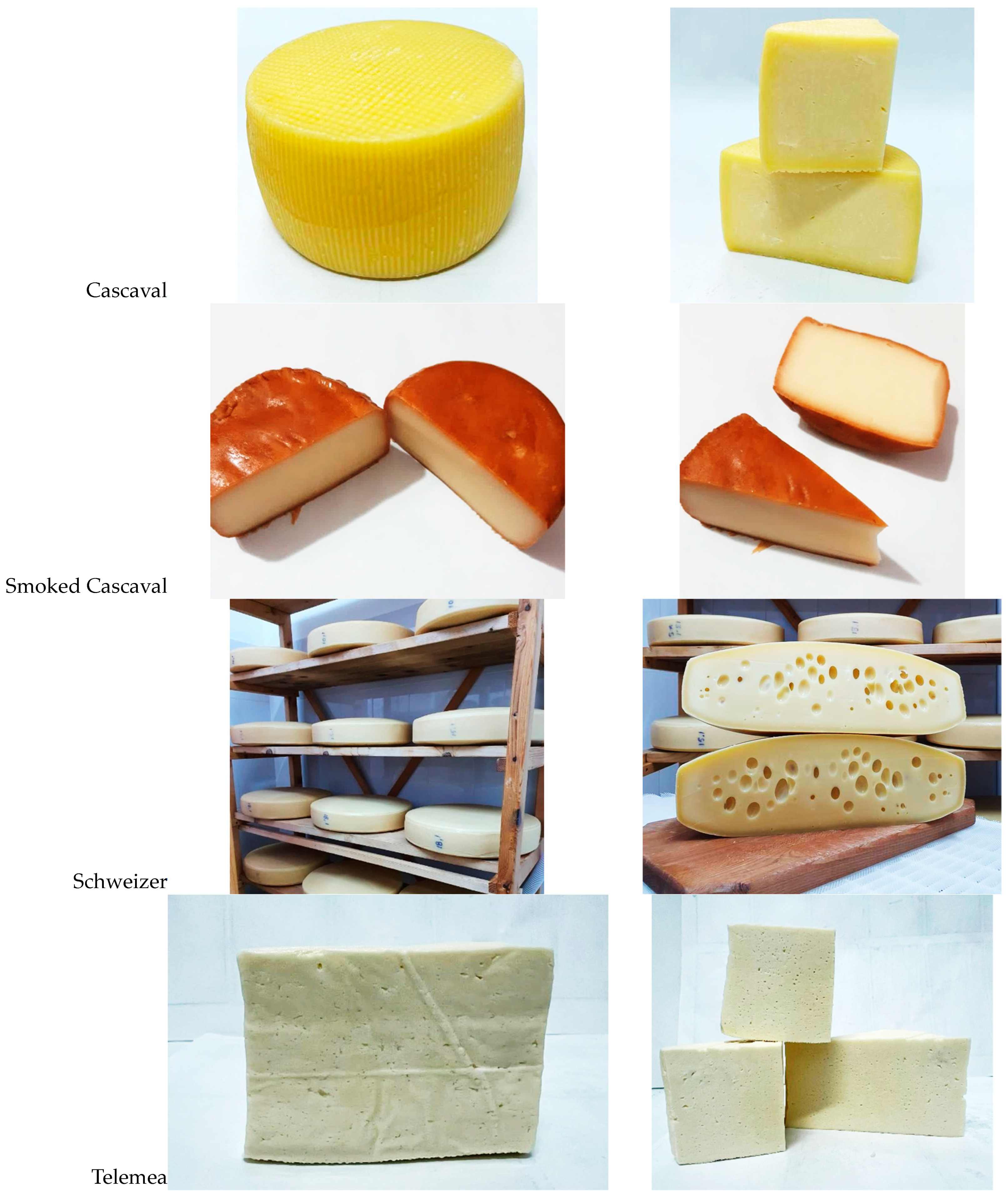

2.1. Cheese Sampling

- -

- They use, on a daily basis, the same raw matter procured from the farmers raising dairy cows in the specific study area;

- -

- Only one set of samples for analysis, from only one producer (local dairy workshop) would have been very subjective and narrow as data collected, considering there could be differences due to workshop influence;

- -

- The workshops use the same recipe to prepare each type of cheese and the same raw matter.

- -

- 3–5 g/repetition in proximate composition investigations;

- -

- 5 g/repetition in fatty acids profiling;

- -

- 3 g/repetition in mineral micronutrients analysis;

- -

- 50 g/repetition in the microbiological investigations.

2.2. Chemical Proximate Composition and Gross Energy Content

2.3. Lipid Profile (Fatty Acids, Cholesterol)

2.4. Mineral Micronutrients Analysis

2.5. Microbiological Analysis

2.6. Statistical Analysis

3. Results

3.1. Proximate Chemical Composition and Gross Energy

3.2. Fatty Acids Profile

3.3. Content of Calcium, Phosphorus, Iron

3.4. Microbiological Assessment

4. Discussion

4.1. Chemical Composition and Gross Energy

4.2. Fatty Acids Profile and Sanogenic Indices

4.3. Content of Calcium, Phosphorus, Iron

4.4. Microbiological Assessment

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Derville, M.; Allaire, G.; Maigne, E.; Cahuzac, E. Internal and contextual drivers of dairy restructuring: Evidence from French mountainous areas and post-quota prospects. Agric. Econ. 2017, 48, 91–103. [Google Scholar] [CrossRef]

- Derville, M.; Allaire, G. What outlook for the mountain dairy supply chain after the end of the quota? An approach in terms of competitive system. INRA Prod. Anim. 2014, 27, 17–30. [Google Scholar]

- Maciuc, V.; Radu-Rusu, R.M. Assessment of Grey Steppe Cattle Genetic and Phenotypic Traits as Valuable Resources in Preserving Biodiversity. Environ. Eng. Manag. J. 2018, 17, 2741–2748. [Google Scholar]

- Maciuc, V.; Ujică, V.; Nistor, C.E.; Băcilă, V.; Nistor, I.; Olaru, S. Results concerning the indexes of milk production of RBP cow population taken into official control in 2012–2013. Lucr. Ştiinţifice Ser. Zooteh. 2014, 62, 49–51. [Google Scholar]

- Maciuc, V.; Creangă, Ș.; Maciuc, D.; Vidu, L. A New Software Programme for Data Management in Dairy Farms. “ST26733”. Agric. Agric. Sci. Procedia 2015, 6, 226–231. [Google Scholar]

- Farruggia, A.; Pomiès, D.; Coppa, M.; Ferlay, A.; Verdier-Metz, I.; Le Morvan, A.; Bethier, A.; Pompanon, F.; Troquier, O.; Martin, B. Animal performances, pasture biodiversity and dairy product quality: How it works in contrasted mountain grazing systems. Agric. Ecosyst. Environ. 2014, 185, 231–244. [Google Scholar] [CrossRef]

- Gâf-Deac, I. Strategic and Tactical Systematization of Local/Proximity Short Supply Chains. Noble Intl. J. Sci. Res. 2017, 1, 30–33. [Google Scholar]

- Lienard, G. Some lessons learned from long-term pastures maintained by extensive livestock suckler farming. Fourrages 2014, 218, 133–139. [Google Scholar]

- Loucougaray, G.; Dobremez, L.; Gos, P.; Pauthenet, Y.; Nettier, B.; Lavorel, S. Assessing the Effects of Grassland Management on Forage Production and Environmental Quality to Identify Paths to Ecological Intensification in Mountain Grasslands. Environ. Manag. 2015, 56, 1039–1052. [Google Scholar] [CrossRef]

- Nistor-Anton, M.; Maciuc, V. Study of milk production indices for cattle breeds exploited in private farms in Neamt county. Sci. Pap. Anim. Sci. 2020, 74, 39–42. [Google Scholar]

- Ciocan-Alupii, M.; Maciuc, V. The evolution of dairy products that benefited from the mention of optional quality “Mountain product” in the mountain area of Romania, during the period 2017–2020. Sci. Pap. Anim. Sci. 2020, 74, 109–115. [Google Scholar]

- Fotea, L.; Bocanici, M.; Vintila, A.L.; Tapaloaga, P.R.; Tapaloaga, D.; Panait, R.C. Obtaining acidophilus products through traditional methods of processing the milk obtained from cattle in the mountain area of Dorna Basin. Curr. Opin. Biotechnol. 2013, 24, S93. [Google Scholar] [CrossRef]

- Delagarde, R.; Faverdin, P.; Baratte, C.; Peyraud, J.L. Graze In: A model of herbage intake and milk production for grazing dairy cows. 2. Prediction of intake under rotational and continuously stocked grazing management. Grass Forage Sci. 2011, 66, 45–60. [Google Scholar] [CrossRef]

- Derville, M.; Allaire, G. Change of competition regime and regional innovative capacities: Evidence from dairy restructuring in France. Food Policy 2014, 49, 347–360. [Google Scholar] [CrossRef]

- Maciuc, V.; Radu-Rusu, C.G.; Popescu, C.E.; Radu-Rusu, R.M. Influence of season and cows farming system on milk physical, chemical and hygienic traits. Rom. Biotechnol. Lett. 2017, 22, 13096. [Google Scholar]

- Romanian Parliament. Decision No. 506/2016 on the Establishing of Institutional Framework and of Implementing Measured of the Commission Delegated Regulation (EU) No 665/2014 of 11 March 2014 Supplementing Regulation (EU) No 1151/2012 of the European Parliament and of the Council with Regard to Conditions of Use of the Optional Quality Term ‘Mountain Product’; Romanian Parliament: Bucharest, Romania, 2016. [Google Scholar]

- Romanian Parliament. Mountain Law No. 197/20 July 2018; Romanian Parliament: Bucharest, Romania, 2018. [Google Scholar]

- Romanian Ministry of Agriculture. Order No. 174/20 July 2021 on the Approval of the Procedure of Conformity Verification of Data Comprised within the Documentation Required to Achieve the Right of Using Facultative Quality Indication “Mountain Product” and of Inspection of Compliance with the European and National Regulation by the Economic Economics That Achieved the Right of the Above-Mentioned Indication; Romanian Parliament: Bucharest, Romania, 2021. [Google Scholar]

- Dopieralska, P.; Barłowska, J.; Teter, A.; Król, J.; Brodziak, A.; Domaradzki, P. Changes in Fatty Acid and Volatile Compound Profiles during Storage of Smoked Cheese Made from the Milk of Native Polish Cow Breeds Raised in the Low Beskids. Animals 2020, 10, 2103. [Google Scholar] [CrossRef]

- Esposito, G.; Masucci, F.; Napolitano, F.; Braghieri, A.; Romano, R.; Manzo, N.; Di Francia, A. Fatty acid and sensory profiles of Caciocavallo cheese as affected by management system. J. Dairy Sci. 2014, 97, 1918–1928. [Google Scholar] [CrossRef]

- Agradi, S.; Curone, G.; Negroni, D.; Vigo, D.; Brecchia, G.; Bronzo, V.; Panseri, S.; Chiesa, L.M.; Peric, T.; Danes, D.; et al. Determination of Fatty Acids Profile in Original Brown Cows Dairy Products and Relationship with Alpine Pasture Farming System. Animals 2020, 10, 1231. [Google Scholar] [CrossRef]

- Povolo, M.; Pelizzola, V.; Lombardi, G.; Tava, A.; Contarini, G. Hydrocarbon and fatty acid composition of cheese as affected by the pasture vegetation type. J. Agric. Food Chem. 2012, 60, 299–308. [Google Scholar] [CrossRef]

- Corazzin, M.; Romanzin, A.; Sepulcri, A.; Pinosa, M.; Piasentier, E.; Bovolenta, S. Fatty Acid Profiles of Cow’s Milk and Cheese as Affected by Mountain Pasture Type and Concentrate Supplementation. Animals 2019, 9, 68. [Google Scholar] [CrossRef]

- European Commission. Delegated Regulation (EU) No 665/2014 of 11 March 2014 Supplementing Regulation (EU) No 1151/2012 of the European Parliament and of the Council with Regard to Conditions of Use of the Optional Quality Term ‘Mountain Product’; European Commission: Brussels, Belgium, 2014. [Google Scholar]

- European Commission. Regulation (EU) No 1151/2012 of the European Parliament and of the Council of 21 November 2012 on Quality Schemes for Agricultural Products and Foodstuffs; European Commission: Brussels, Belgium, 2012. [Google Scholar]

- Zuliani, A.; Esbjerg, L.; Grunert, K.G.; Bovolenta, S. Animal Welfare and Mountain Products from Traditional Dairy Farms: How Do Consumers Perceive Complexity? Animals 2018, 8, 207. [Google Scholar] [CrossRef] [PubMed]

- Morgan-Davies, C.; Wilson, R.; Waterhouse, T. Impacts of farmers’ management styles on income and labour under alternative extensive land use scenarios. Agric. Syst. 2017, 155, 168–178. [Google Scholar] [CrossRef]

- Necula, D.; Ilea, A.; Coman, I.; Krumpe-Tamas, O.; FenesanDaria Ognean, L. Characteristics of the Compostion and Bioactive Properties of Mountain Milk used for Emmental Cheese Making. Sci. Pap. Ser. D Anim. Sci. 2021, 64, 191–198. [Google Scholar]

- Onaciu, G.; Jurco, E.; Jurco, S.; Maciuc, V.; Ognean, L. Influence of varying milk urea nitrogen on chemical, hygienic and physical traits of cow milk. Rom. Biotechnol. Lett. 2019, 24, 866–873. [Google Scholar] [CrossRef]

- Vidu, L.; Chelmu, S.S.; Băcilă, V.; Maciuc, V. The content of minerals and fatty acids in buffalo milk, depending on the reank of lactation. Rom. Biotechnol. Lett. 2015, 20, 10076–10084. [Google Scholar]

- Cucu, G.I.; Maciuc, V.; Maciuc, D. Scientific Research and Elements of Experimental Technique in Animal Sciences; Alfa Publishing House: Iaşi, Romania, 2004. [Google Scholar]

- AOAC 920.122-1920; Cheese—Collection of Samples Procedure. AOAC International: Rockville, MD, USA, 2015. Available online: http://www.aoacofficialmethod.org/index.php?main_page=product_info&cPath=1&products_id=1563 (accessed on 5 April 2022).

- AOAC 926.08-1927; Cheese—Loss on Drying (Moisture) in Cheese. Method I. AOAC International: Rockville, MD, USA, 2015. Available online: http://www.aoacofficialmethod.org/index.php?main_page=advanced_search_result&search_in_description=1&keyword=drying+%28moisture%29+in+cheese&x=0&y=0 (accessed on 5 April 2022).

- AOAC 935.42-1935; Ash of Cheese. Gravimetric Method. AOAC International: Rockville, MD, USA, 2015. Available online: http://www.aoacofficialmethod.org/index.php?main_page=product_info&cPath=1&products_id=551 (accessed on 5 April 2022).

- AOAC 920.123-1920; Nitrogen in Cheese. AOAC International: Rockville, MD, USA, 2015. Available online: http://www.aoacofficialmethod.org/index.php?main_page=product_info&cPath=1&products_id=852 (accessed on 5 April 2022).

- AOAC 920.125-1920; Examination of Fat in Cheese. AOAC International: Rockville, MD, USA, 2015. Available online: http://www.aoacofficialmethod.org/index.php?main_page=product_info&cPath=1&products_id=1195 (accessed on 5 April 2022).

- FAO. Methods of food analysis (chapter 2). In FAO Food Nutrition Paper, Food Energy—Methods of Analysis and Conversion Factors; FAO: Rome, Italy, 2003; Volume 77, pp. 12–17. [Google Scholar]

- FAO. Calculation of the energy content of foods—energy conversion factors (chapter 3). In FAO Food Nutrition Paper, Food Energy—Methods of Analysis and Conversion Factors; FAO: Rome, Italy, 2003; Volume 77, pp. 18–56. [Google Scholar]

- ISO/TS 17764-1:2002; Animal Feeding Stuffs—Determination of the Content of Fatty Acids—Part 1: Preparation of Methyl Esters. ISO: Geneva, Switzerland, 2002. Available online: https://www.iso.org/standard/34610.html (accessed on 5 April 2022).

- ISO/TS 17764-2:2002; Animal Feeding Stuffs—Determination of the Content of Fatty Acids—Part 2: Gas Chromatographic Method. ISO: Geneva, Switzerland, 2002. Available online: https://www.iso.org/standard/34611.html (accessed on 5 April 2022).

- Simeanu, C.; Măgdici, E.; Păsărin, B.; Avarvarei, B.-V.; Simeanu, D. Quantitative and Qualitative Assessment of European Catfish (Silurus glanis) Flesh. Agriculture 2022, 12, 2144. [Google Scholar] [CrossRef]

- AOAC 994.10-1994(2010); Cholesterol in Foods. Direct Saponification-Gas Chromatographic Method. AOAC International: Rockville, MD, USA, 2014. Available online: http://www.aoacofficialmethod.org/index.php?main_page=product_info&products_id=186 (accessed on 5 April 2022).

- AOAC 968.31-1969; Calcium in Canned Vegetables—Titrimetric Method. AOAC International: Rockville, MD, USA, 2014. Available online: http://www.aoacofficialmethod.org/index.php?main_page=product_info&cPath=1&products_id=79 (accessed on 5 April 2022).

- Singh, M.; Yadav, P.; Garg, V.K.; Sharma, A.; Singh, B.; Sharma, H. Quantification of minerals and trace elements in raw caprine milk using flame atomic absorption spectrophotometry and flame photometry. J. Food Sci. Technol. 2015, 52, 5299–5304. [Google Scholar] [CrossRef] [PubMed]

- European Commission (EC). Regulation No 152/2009 of 27 January 2009 Laying Down the Methods of Sampling and Analysis for the Official Control of Feed (Text with EEA Relevance); OJ L 54; European Commission: Brussels, Belgium, 2009; pp. 1–130. [Google Scholar]

- ISO 21528-1:2017; Microbiology of the Food Chain—Horizontal Method for the Detection and Enumeration of Enterobacteriaceae—Part 1: Detection of Enterobacteriaceae. ISO: Geneva, Switzerland, 2017. Available online: https://www.iso.org/standard/55228.html (accessed on 5 April 2022).

- DIN EN ISO 6888-1:2021; Microbiology of the Food Chain—Horizontal Method for the Enumeration of Coagulase-Positive Staphylococci (Staphylococcus aureus and Other Species)—Part 1: Method Using Baird-Parker Agar Medium. European Standards: Brussels, Belgium, 2021. Available online: https://www.en-standard.eu/din-en-iso-6888-1-microbiology-of-the-food-chain-horizontal-method-for-the-enumeration-of-coagulase-positive-staphylococci-staphylococcus-aureus-and-other-species-part-1-method-using-baird-parker-agar-medium-iso-6888-1-2021 (accessed on 5 April 2022).

- ISO 16649-2:2001; Microbiology of Food and Animal Feeding Stuffs—Horizontal Method for the Enumeration of Beta-Glucuronidase-Positive Escherichia coli—Part 2: Colony-Count Technique at 44 Degrees C Using 5-Bromo-4-chloro-3-indolyl beta-D-glucuronide. ISO: Geneva, Switzerland, 2019. Available online: https://www.iso.org/standard/29824.html (accessed on 5 April 2022).

- ISO 11290-1:2017; Microbiology of the Food Chain—Horizontal Method for the Detection and Enumeration of Listeria monocytogenes and of Listeria s—Part 1: Detection Method. ISO: Geneva, Switzerland, 2017. Available online: https://www.iso.org/standard/60313.html (accessed on 5 April 2022).

- James, M.C.; Terry, S. A First Course in Statistics; Global Edition; Pearson: London, UK, 2018. [Google Scholar]

- Sendra, E. Dairy Fat and Cardiovascular Health. Foods 2020, 9, 838. [Google Scholar] [CrossRef]

- Hu, M.-J.; Tan, J.-S.; Gao, X.-J.; Yang, J.-G.; Yang, Y.-J. Effect of Cheese Intake on Cardiovascular Diseases and Cardiovascular Biomarkers. Nutrients 2022, 14, 2936. [Google Scholar] [CrossRef]

- Manuelian, C.L.; Currò, S.; Penasa, M.; Cassandro, M.; De Marchi, M. Characterization of major and trace minerals, fatty acid composition, and cholesterol content of Protected Designation of Origin cheeses. J. Dairy Sci. 2017, 100, 3384–3395. [Google Scholar] [CrossRef]

- Pillonel, L.; Badertscher, R.; Bütikofer, U.; Casey, M.; Dalla Torre, M.; Lavanchy, P.; Meyer, J.; Tabacchi, R.; Bosset, J.O. Analytical methods for the determination of the geographic origin of Emmentaler cheese. Main framework of the project; chemical, biochemical, microbiological, colour and sensory analyses. Eur. Food Res. Technol. 2002, 215, 260–267. [Google Scholar]

- Sulejmani, E.; Hayaloglu, A.A.; Rafajlovska, V. Study of the chemical composition, proteolysis, volatile compounds, and textural properties of industrial and traditional Beaten (Bieno sirenje) ewe milk cheese. J. Dairy Sci. 2014, 97, 1210–1224. [Google Scholar] [CrossRef] [PubMed]

- Lourenco, A.; Handschuh, S.; Fenelon, M.; Gómez-Mascaraque, G.L. X-ray computerized microtomography and confocal Raman microscopy as complementary techniques to conventional imaging tools for the microstructural characterization of Cheddar cheese. J. Dairy Sci. 2022, 105, 9387–9403. [Google Scholar] [CrossRef] [PubMed]

- Regan, J.T.; Marton, S.; Barrantes, O.; Ruane, E.; Hanegraaf, M.; Berland, J.; Korevaar, H.; Pellerin, S.; Nesme, T. Does the recoupling of dairy and crop production via cooperation between farms generate environmental benefits? A case-study approach in Europe. Eur. J. Agron. 2017, 82, 342–356. [Google Scholar] [CrossRef]

- Wiesner, S.; Duff, A.J.; Desai, A.R.; Panke-Buisse, K. Increasing Dairy Sustainability with Integrated Crop–Livestock Farming. Sustainability 2020, 12, 765. [Google Scholar] [CrossRef]

- Renhe, I.R.T.; Corredig, M. Effect of partial whey protein depletion during membrane filtration on thermal stability of milk concentrates. J. Dairy Sci. 2018, 101, 8757–8766. [Google Scholar] [CrossRef]

- Steinwidder, A.; Starz, W.; Rohrer, H.; Hausler, J.; Pfister, R. Milk performance per area of pasture- or silage-fed organic dairy cows in mountainous regions of Austria. Zuchtungskunde 2018, 90, 218–239. [Google Scholar]

- Steinwidder, A.; Starz, W.; Podstatzky, L.; Gasteiner, J.; Pfister, R.; Rohrer, H.; Gallnbock, M. Effects of time of calving on pasture-based dairy systems in mountainous regions. Zuchtungskunde 2011, 83, 203–215. [Google Scholar]

- Sturaro, E.; Marchiori, E.; Cocca, G.; Penasa, M.; Ramanzin, M.; Bittante, G. Dairy systems in mountainous areas: Farm animal biodiversity, milk production and destination, and land use. Livest. Sci. 2013, 158, 157–168. [Google Scholar] [CrossRef]

- Vilela, T.P.; Gomes, A.M.; Ferreira, J.P. Probing the structure-holding interactions in cheeses by dissociating agents—A review and an experimental evaluation with Emmental cheese. Curr. Res. Food Sci. 2020, 3, 201–206. [Google Scholar] [CrossRef]

- Xia, X.; Tobin, T.J.; Subhir, S.; Fenelon, A.M.; Corrigan, M.B.; McSweeney, P.L.; Sheehan, J.J. Effect of b-casein reduction and high heat treatment of micellar casein concentrate on the rennet coagulation properties, composition and yield of Emmental cheese made therefrom. Int. Dairy J. 2022, 126, 105240. [Google Scholar] [CrossRef]

- González, M.; Budelli, E.; Lema, P.N. Acoustic techniques to detect eye formation during ripening of Emmental type cheese. Innov. Food Sci. Emerg. Technol. 2020, 59, 102270. [Google Scholar] [CrossRef]

- Romdhane, K.; Abdul, M.M.; Dufour, E.; Pillonel, L.; Schaller, E.; Baerdemaeker De, J.; Bosset, J.O. Chemical characterisation of European Emmental cheeses by near infrared spectroscopy using chemometric tools. Int. Dairy J. 2006, 16, 1211–1217. [Google Scholar]

- Chen, J.; Liu, H. Nutritional Indices for Assessing Fatty Acids: A Mini-Review. Int. J. Mol. Sci. 2020, 21, 5695. [Google Scholar] [CrossRef] [PubMed]

- Ohlsson, L. Dairy products and plasma cholesterol levels. Food Nutr. Res. 2010, 54, 5124. [Google Scholar] [CrossRef] [PubMed]

- Noakes, M.; Nestel, P.J.; Clifton, P.M. Modifying the fatty acid profile of dairy products through feedlot technology lowers plasma cholesterol of humans consuming the products. Am. J. Clin. Nutr. 1996, 63, 42–46. [Google Scholar] [CrossRef] [PubMed]

- Grummer, R.R. Effect of feed on the composition of milk fat. J. Dairy Sci. 1991, 74, 3244–3257. [Google Scholar] [CrossRef]

- Ciocan-Alupii, M.; Maciuc, V.; Nistor-Anton, M. The evolution of meat products which have benefited from the optional quality mention “Mountain Product” in the Mountain Area of Romania, during the period 2017-2020. Sci. Pap. Anim. Sci. 2021, 76, 79–84. [Google Scholar]

- Lotric, M.Z.; Salehar, A.; Kompan, D.M. Alpine dairy farming in connection with the Slovenian autochthonous Cika cattle. In Animal Farming and Environmental Interactions in the Mediterranean Region; Casasus, I., Rogosic, J., Rosati, A., Eds.; Wageningen Academic: Wageningen, The Netherlands, 2012. [Google Scholar]

- Zucali, M.; Tamburini, A.; Sandrucci, A.; Bava, L. Global warming and mitigation potential of milk and meat production in Lombardy (Italy). J. Clean. Prod. 2017, 153, 474–482. [Google Scholar] [CrossRef]

- Avondo, M.; Secchiari, P.; Battaglini, L.M.; Bonanno, A.; Pulina, G. Soil, pasture and animal product quality. Ital. J. Agron. 2013, 8, e19. [Google Scholar] [CrossRef]

- Montel, M.C.; Buchin, S.; Mallet, A.; Delbes-Paus, C.; Vuitton, D.A.; Desmasures, N.; Berthier, F. Traditional cheeses: Rich and diverse microbiota with associated benefits. Int. J. Food Microbiol. 2014, 177, 136–154. [Google Scholar] [CrossRef] [PubMed]

- Bărzoi, D. Microbiology of Animal Originated Food Products; Ceres Publishing House: Bucharest, Romania, 1985. [Google Scholar]

| Cascaval Type | Statistics | Water (g/100 g) | Dry Matter (g/100 g) | Total Minerals (g/100 g) | NaCl (g/100 g) | Total Proteins (g/100 g) | Total Lipids (g/100 g) | Nitrogen Free Extract (g/100 g) | Energy (Kcal/100 g) |

|---|---|---|---|---|---|---|---|---|---|

| “Mountain” | Mean ± StDev | 56.54 a ± 0.40 | 43.46 a ± 0.40 | 1.62 a ± 0.60 | 0.77 a ± 0.11 | 22.55 a ± 0.32 | 19.04 a ± 0.73 | 0.25 a ± 0.16 | 264.58 a ± 5.96 |

| Conventional | Mean ± StDev | 45.26 d ± 0.62 | 54.74 d ± 0.62 | 4.38 d ± 0.91 | 2.88 d ± 0.18 | 22.95 d ± 0.37 | 25.84 d ± 0.85 | 1.57 d ± 0.18 | 331.22 d ± 6.37 |

| Smoked Cascaval Type | Statistics | Water (g/100 g) | Dry Matter (g/100 g) | Total Minerals (g/100 g) | NaCl (g/100 g) | Total Proteins (g/100 g) | Total Lipids (g/100 g) | Nitrogen Free Extract (g/100 g) | Energy (Kcal/100 g) |

|---|---|---|---|---|---|---|---|---|---|

| “Mountain” | Mean ± StDev | 56.39 a ± 0.50 | 43.61 a ± 0.50 | 1.52 a ± 0.65 | 0.78 a ± 0.13 | 22.50 a ± 0.30 | 19.16 a ± 0.80 | 0.43 a ± 0.23 | 266.11 a ± 6.33 |

| Conventional | Mean ± StDev | 47.19 d ± 0.61 | 52.81 d ± 0.61 | 2.80 d ± 1.18 | 1.60 d ± 0.27 | 23.86 d ± 0.36 | 25.62 d ± 1.65 | 0.54 b ± 0.08 | 329.18 d ± 14.31 |

| Schweizer Type | Statistics | Water (g/100 g) | Dry Matter (g/100 g) | Total Minerals (g/100 g) | NaCl (g/100 g) | Total Proteins (g/100 g) | Total Lipids (g/100 g) | Nitrogen Free Extract (g/100 g) | Energy (Kcal/100 g) |

|---|---|---|---|---|---|---|---|---|---|

| “Mountain” | Mean ± StDev | 36.38 a ± 0.50 | 63.62 a ± 0.50 | 4.03 a ± 0.45 | 1.95 a ± 0.11 | 26.52 a ± 0.27 | 27.46 a ± 0.27 | 5.61 a ± 0.51 | 376.33 a ± 2.99 |

| Conventional | Mean ± StDev | 43.69 d ± 0.68 | 56.31 d ± 0.68 | 2.29 d ± 0.26 | 3.76 d ± 1.65 | 22.86 d ± 0.49 | 26.09 d ± 0.32 | 5.00 d ± 0.44 | 346.28 d ± 3.03 |

| Telemea Type | Statistics | Water (g/100 g) | Dry Matter (g/100 g) | Total Minerals (g/100 g) | NaCl (g/100 g) | Total Proteins (g/100 g) | Total Lipids (g/100 g) | Nitrogen Free Extract (g/100 g) | Energy (Kcal/100 g) |

|---|---|---|---|---|---|---|---|---|---|

| “Mountain” | Mean ± StDev | 61.80 a ± 0.51 | 38.20 a ± 0.51 | 5.39 a ± 0.17 | 3.57 a ± 0.25 | 16.09 a ± 0.36 | 15.45 a ± 0.36 | 1.27 a ± 0.70 | 209.34 a ± 2.53 |

| Conventional | Mean ± StDev | 63.66 d ± 0.50 | 36.34 d ± 0.50 | 4.91 d ± 0.17 | 4.22 d ± 0.28 | 17.09 d ± 0.39 | 12.96 d ± 0.52 | 1.39 d ± 0.67 | 192.25 d ± 3.23 |

| Fatty Acid | Cheese Type (Fatty Acids Methyl Esters Content, Expressed as g FAME/100 g Total FAME) | |||||||

|---|---|---|---|---|---|---|---|---|

| Cascaval | Smoked Cascaval | Schweizer | Telemea | |||||

| M * | C ** | M | C | M | C | M | C | |

| Butyric acid | 0.12 | 0.14 | 0.18 | 0.22 | 0.14 | 0.19 | 0.25 | 0.28 |

| Caproic acid | 1.43 | 1.49 | 1.61 | 1.69 | 1.45 | 1.47 | 0.18 | 0.19 |

| Caprylic acid | 1.36 | 1.38 | 1.36 | 1.42 | 1.32 | 1.41 | 1.32 | 1.38 |

| Nonanoic acid | 0.07 | 0.10 | 0.21 | 0.12 | 0.02 | 0.04 | 0.02 | 0.03 |

| Capric acid | 2.92 | 2.95 | 2.83 | 2.89 | 2.90 | 2.95 | 2.78 | 2.85 |

| Undecanoic acid | 0.35 | 0.34 | 0.34 | 0.42 | 0.35 | 0.42 | 0.33 | 0.39 |

| Tridecanoic acid | 3.43 | 3.48 | 3.28 | 3.31 | 3.48 | 3.54 | 3.31 | 3.41 |

| Lauric acid | 0.10 | 0.12 | 0.10 | 0.11 | 0.10 | 0.11 | 0.11 | 0.12 |

| Myristic acid | 12.78 | 12.81 | 12.68 | 12.74 | 13.18 | 13.25 | 12.75 | 13.01 |

| Myristoleic acid | 1.49 | 1.51 | 1.52 | 1.48 | 1.61 | 1.58 | 1.55 | 1.42 |

| Pentadecanoic acid | 0.73 | 0.76 | 0.80 | 0.85 | 0.82 | 0.84 | 0.91 | 0.95 |

| Pentadecenoic acid | 1.90 | 2.10 | 1.88 | 1.74 | 2.02 | 1.98 | 2.15 | 2.08 |

| Palmitic acid | 33.93 | 34.22 | 33.73 | 33.92 | 33.81 | 33.85 | 33.93 | 34.03 |

| Palmitoleic acid | 1.95 | 1.97 | 2.13 | 2.08 | 1.96 | 1.92 | 2.25 | 2.14 |

| Heptadecanoic acid | 0.55 | 0.62 | 0.57 | 0.62 | 0.56 | 0.62 | 0.62 | 0.69 |

| Heptadecenoic acid | 0.98 | 0.97 | 0.99 | 0.87 | 1.00 | 0.97 | 0.99 | 0.95 |

| Stearic acid | 8.71 | 8.82 | 8.34 | 8.41 | 8.12 | 8.24 | 8.05 | 8.06 |

| Oleic cis acid | 21.19 | 21.08 | 21.83 | 21.79 | 20.89 | 20.74 | 22.50 | 22.30 |

| Linoleic trans Ω-6 acid | 0.32 | 0.26 | 0.29 | 0.25 | 0.35 | 0.31 | 0.25 | 0.21 |

| Linoleic cis Ω-6 acid | 1.79 | 1.68 | 1.71 | 1.68 | 1.73 | 1.68 | 1.79 | 1.73 |

| Arachidic acid | 0.05 | 0.06 | 0.05 | 0.04 | 0.10 | 0.14 | 0.09 | 0.12 |

| Gamma linolenic Ω-3 acid | 0.15 | 0.11 | 0.15 | 0.13 | 0.17 | 0.15 | 0.16 | 0.12 |

| Alpha linolenic Ω-3 acid | 1.51 | 1.41 | 1.32 | 1.28 | 1.46 | 1.38 | 1.35 | 1.29 |

| Conjugated linolenic acid | 0.60 | 0.51 | 0.65 | 0.61 | 0.67 | 0.61 | 0.63 | 0.58 |

| Eicosadienoic Ω-6 acid | 0.10 | 0.08 | 0.13 | 0.11 | 0.11 | 0.09 | 0.12 | 0.09 |

| Eicosatrienoic Ω-3 acid | 0.11 | 0.05 | 0.13 | 0.12 | 0.15 | 0.11 | 0.11 | 0.08 |

| Eicosatetraenoic Ω-3acid | 0.26 | 0.17 | 0.19 | 0.15 | 0.14 | 0.10 | 0.21 | 0.19 |

| Arachidonic Ω-6 acid | 0.11 | 0.10 | 0.13 | 0.12 | 0.10 | 0.08 | 0.09 | 0.06 |

| Other fatty acids | 1.01 | 0.71 | 0.87 | 0.83 | 1.29 | 1.33 | 1.20 | 1.25 |

| Total SFAs | 66.53 | 67.29 | 66.08 | 66.76 | 66.35 | 67.07 | 64.65 | 65.51 |

| Total UFAs | 32.46 | 32 | 33.05 | 32.41 | 32.36 | 31.7 | 34.15 | 33.24 |

| Total MUFAs | 27.51 | 27.63 | 28.35 | 27.96 | 27.48 | 27.19 | 29.44 | 28.89 |

| Total PUFAs | 4.95 | 4.37 | 4.70 | 4.45 | 4.88 | 4.51 | 4.71 | 4.35 |

| SFAs/UFAs | 2.05 | 2.10 | 2.00 | 2.06 | 2.05 | 2.12 | 1.89 | 1.97 |

| PUFAs/MUFAs | 0.18 | 0.16 | 0.17 | 0.16 | 0.18 | 0.17 | 0.16 | 0.15 |

| Omega 3 FAs | 2.03 | 1.74 | 1.79 | 1.68 | 1.92 | 1.74 | 1.83 | 1.68 |

| Omega 6 FAs | 2.92 | 2.63 | 2.91 | 2.77 | 2.96 | 2.77 | 2.88 | 2.67 |

| Omega 6/Omega 3 | 1.44 | 1.51 | 1.63 | 1.65 | 1.54 | 1.59 | 1.57 | 1.59 |

| Polyunsaturation index | 5.13 | 4.76 | 4.64 | 4.49 | 5.00 | 4.75 | 4.74 | 4.52 |

| Atherogenic index | 2.62 | 2.67 | 2.56 | 2.62 | 2.68 | 2.74 | 2.49 | 2.59 |

| Thrombohenic index | 0.55 | 0.59 | 0.55 | 0.57 | 0.54 | 0.56 | 0.53 | 0.54 |

| Hypocholesterolemic/hypercholesterolemic ratio | 0.56 | 0.54 | 0.57 | 0.56 | 0.55 | 0.53 | 0.58 | 0.57 |

| Cholesterol content (mg/100 g sample) | 28.99 | 31.24 | 35.76 | 38.25 | 43.54 | 45.19 | 16.37 | 17.84 |

| Cheese Type | Statistics | Ca (g/100 g) | P (g/100 g) | Fe (mg/100 g) | |

|---|---|---|---|---|---|

| Cascaval | “Mountain” | Mean ± StDev | 0.65 | 0.63 | 2.46 a |

| 0.04 | 0.04 | 0.16 | |||

| Conventional | Mean ± StDev | 0.62 | 0.64 | 2.19 c | |

| 0.04 | 0.03 | 0.18 | |||

| Smoked Cascaval | “Mountain” | Mean ± StDev | 0.74 | 0.72 | 2.49 |

| 0.09 | 0.06 | 0.16 | |||

| Conventional | Mean ± StDev | 0.72 | 0.71 | 2.31 | |

| 0.07 | 0.07 | 0.20 | |||

| Schweizer | “Mountain” | Mean ± StDev | 0.73 | 0.74 | 5.87 a |

| 0.05 | 0.05 | 0.25 | |||

| Conventional | Mean ± StDev | 0.74 | 0.72 | 2.27 d | |

| 0.06 | 0.05 | 0.20 | |||

| Telemea | “Mountain” | Mean ± StDev | 0.72 a | 0.69 a | 2.19 a |

| 0.07 | 0.05 | 0.18 | |||

| Conventional | Mean ± StDev | 0.65 b | 0.63 b | 2.46 c | |

| 0.04 | 0.04 | 0.16 | |||

| Cheese Type | Enterobacteriaceae MPN/g | Staphylococci CFU/g | Escherichia coli CFU/g | Listeria monocytogenes CFU/25 g | |

|---|---|---|---|---|---|

| Cascaval | “Mountain” | 1.6 | <10 | - | - |

| Conventional | 0 | <10 | - | - | |

| Smoked Cascaval | “Mountain” | 4.3 | <10 | - | - |

| Conventional | 0 | <10 | - | - | |

| Schweizer | “Mountain” | 4.3 | <10 | - | - |

| Conventional | 0 | <10 | - | - | |

| Telemea | “Mountain” | 9.3 | <10 | - | - |

| Conventional | 0 | <10 | - | - | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Maciuc, V.; Pânzaru, C.; Ciocan-Alupii, M.; Radu-Rusu, C.-G.; Radu-Rusu, R.-M. Comparative Assessment of the Nutritional and Sanogenic Features of Certain Cheese Sorts Originating in Conventional Dairy Farms and in “Mountainous” Quality System Farms. Agriculture 2024, 14, 172. https://doi.org/10.3390/agriculture14020172

Maciuc V, Pânzaru C, Ciocan-Alupii M, Radu-Rusu C-G, Radu-Rusu R-M. Comparative Assessment of the Nutritional and Sanogenic Features of Certain Cheese Sorts Originating in Conventional Dairy Farms and in “Mountainous” Quality System Farms. Agriculture. 2024; 14(2):172. https://doi.org/10.3390/agriculture14020172

Chicago/Turabian StyleMaciuc, Vasile, Claudia Pânzaru, Maria Ciocan-Alupii, Cristina-Gabriela Radu-Rusu, and Răzvan-Mihail Radu-Rusu. 2024. "Comparative Assessment of the Nutritional and Sanogenic Features of Certain Cheese Sorts Originating in Conventional Dairy Farms and in “Mountainous” Quality System Farms" Agriculture 14, no. 2: 172. https://doi.org/10.3390/agriculture14020172