Development of Electromagnetic-Wave-Shielding Polyvinylidene Fluoride–Ti3C2Tx MXene–Carbon Nanotube Composites by Improving Impedance Matching and Conductivity

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation

2.3. Characterization

3. Results and Discussion

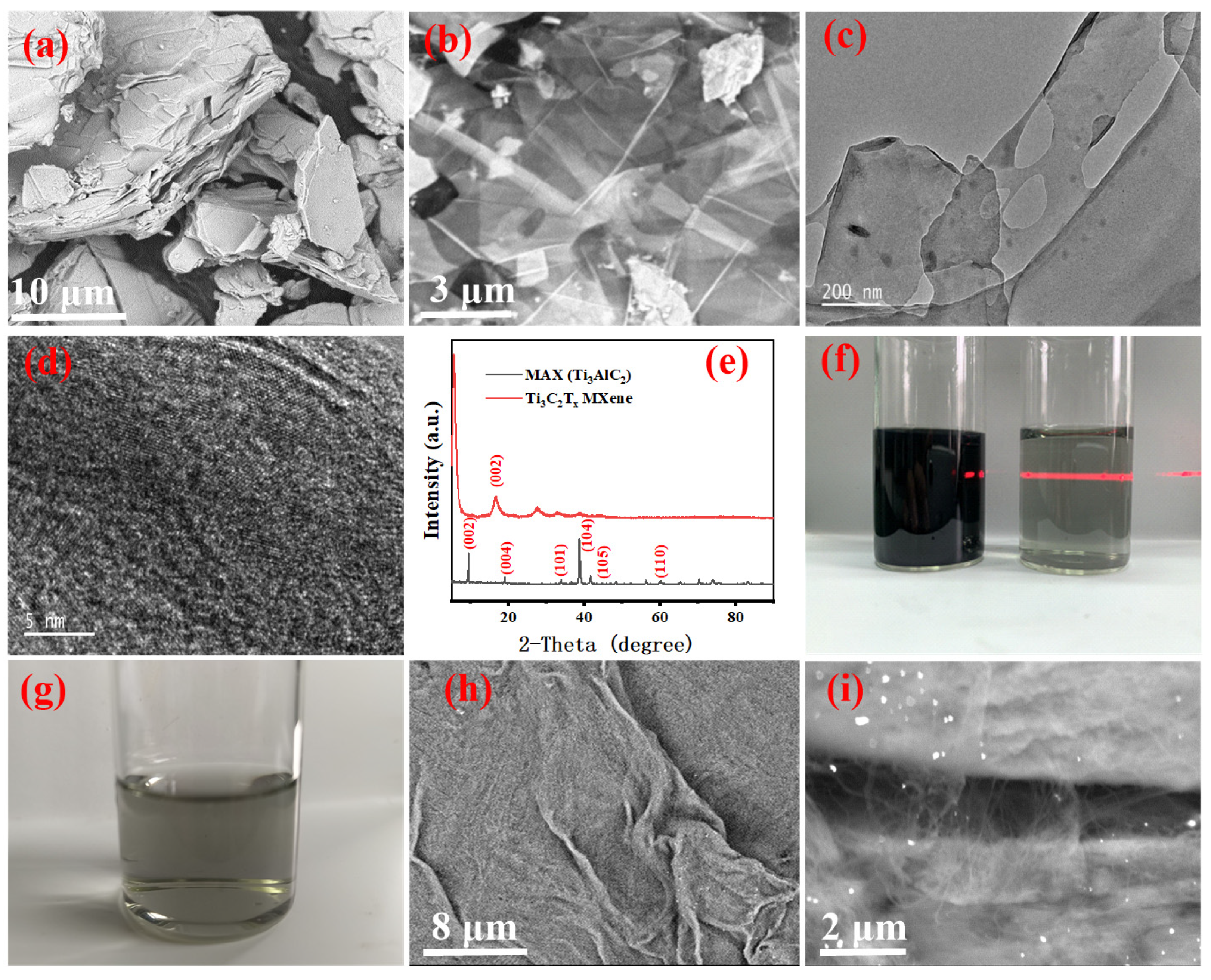

3.1. Characterization of MXene

3.2. Morphology of the SWCNTs

3.3. Potential Analysis of Electrostatic Self-Assembly

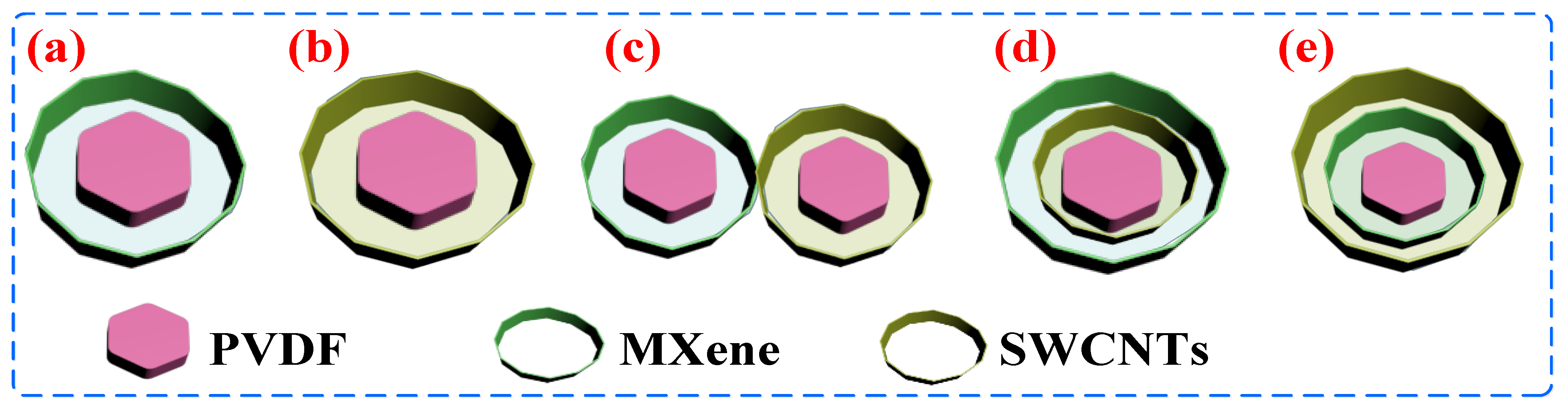

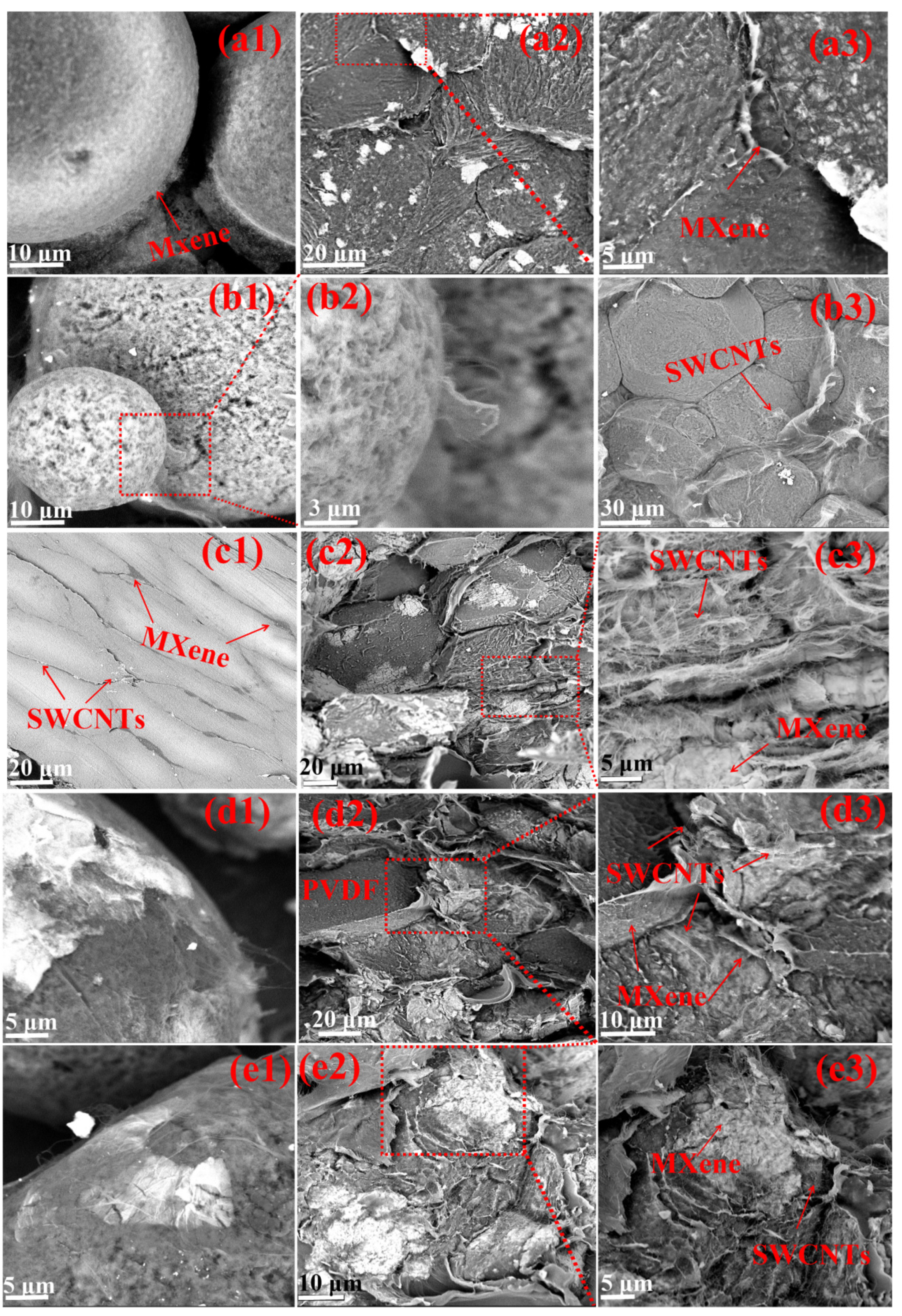

3.4. SEM Analysis of Composite Materials

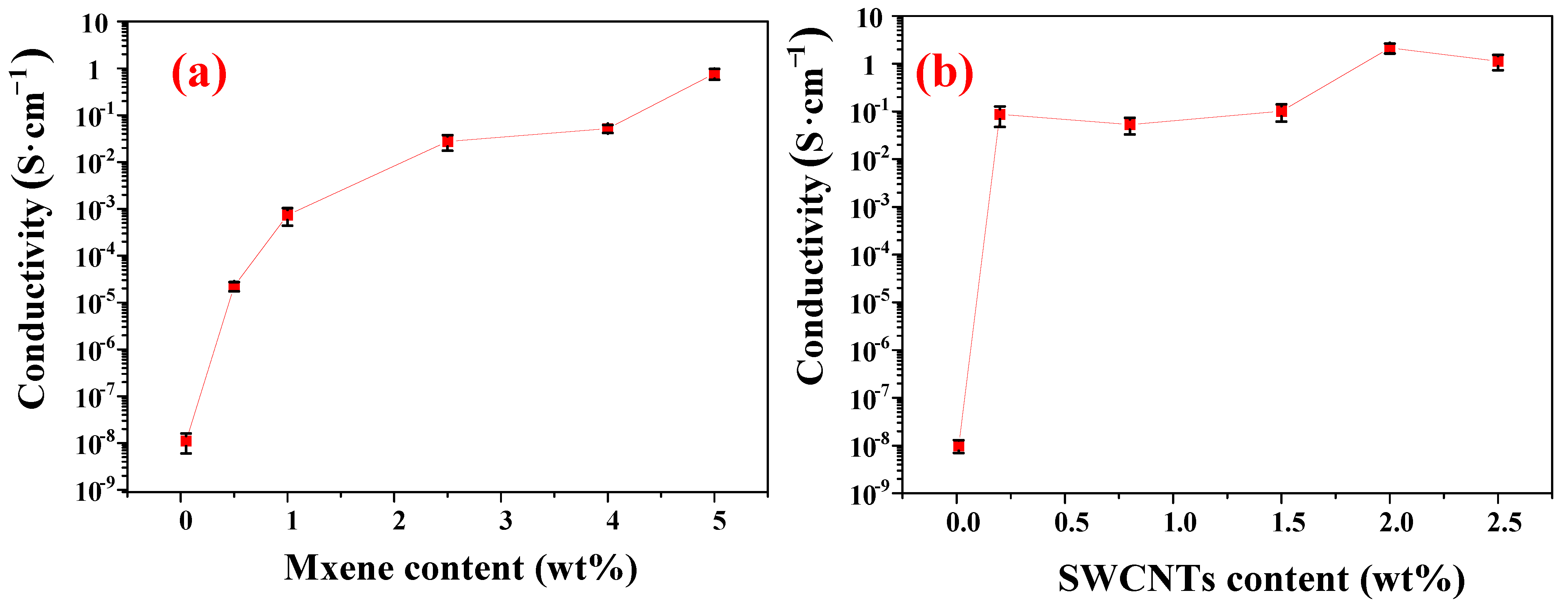

3.5. Optimization of the Filling Content in Composites

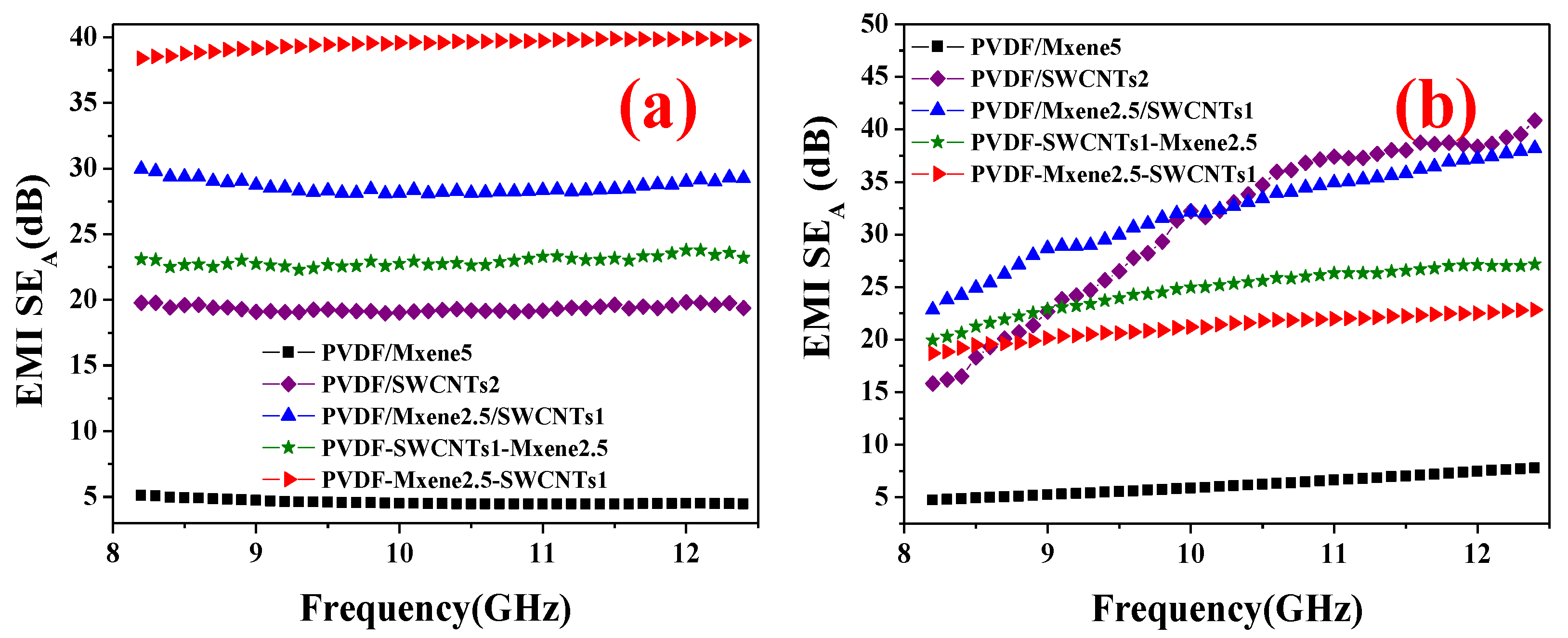

3.6. Conductivity, EMI Shielding, Impedance Matching, and Absorption Coefficient

3.7. Comparison of Theoretical and Experimental Absorption Performance

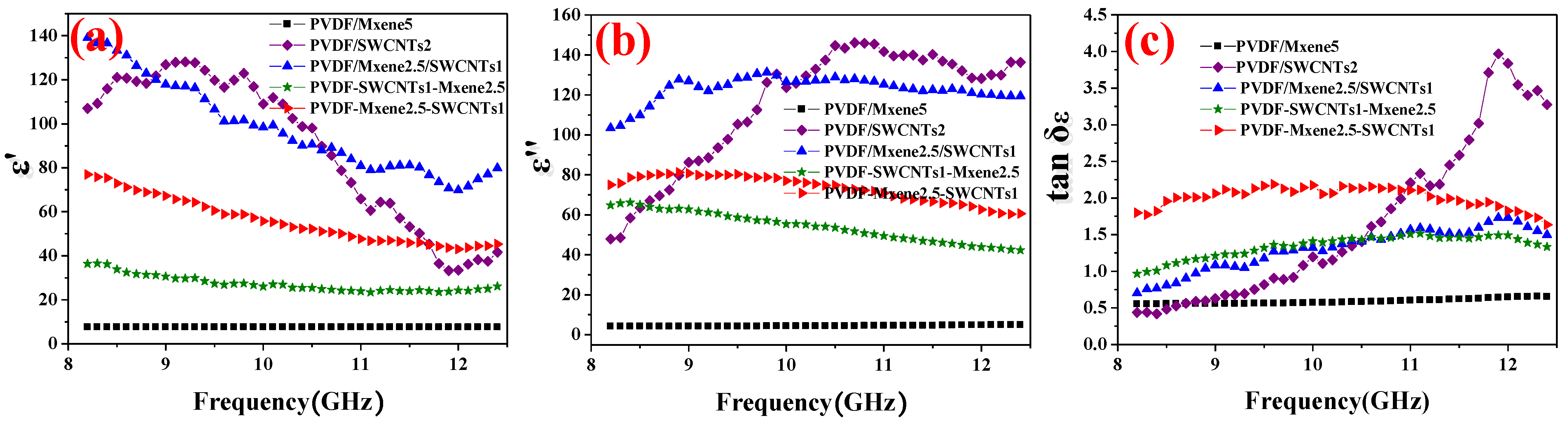

3.8. Electromagnetic Parameter Analysis

3.9. Mechanism Analysis

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Sun, B.B.; Sun, S.J.; He, P.; Mi, H.Y.; Dong, B.B.; Liu, C.T.; Shen, C.Y. Asymmetric layered structural design with segregated conductive network for absorption-dominated high-performance electromagnetic interference shielding. Chem. Eng. J. 2021, 416, 129083. [Google Scholar] [CrossRef]

- Wang, C.; Murugadoss, V.; Kong, J.; He, Z.F.; Mai, X.M.; Shao, Q.; Chen, Y.J.; Guo, L.; Liu, C.T.; Angaiah, S.; et al. Overview of carbon nanostructures and nanocomposites for electromagnetic wave shielding. Carbon 2018, 140, 696–733. [Google Scholar] [CrossRef]

- Ma, W.-J.; Cai, W.-R.; Chen, W.-H.; Liu, P.-J.; Wang, J.-F.; Liu, Z.-X. A novel structural design of shielding capsule to prepare high-performance and self-healing MXene-based sponge for ultra-efficient electromagnetic interference shielding. Chem. Eng. J. 2021, 426, 130729. [Google Scholar] [CrossRef]

- Meng, X.-M.; Zhang, X.-J.; Lu, C.; Pan, Y.-F.; Wang, G.-S. Enhanced absorbing properties of three-phase composites based on a thermoplastic-ceramic matrix (BaTiO3 + PVDF) and carbon black nanoparticles. J. Mater. Chem. A 2014, 2, 18725–18730. [Google Scholar] [CrossRef]

- Shen, B.; Zhai, W.-T.; Tao, M.-M.; Ling, J.-Q.; Zheng, W.-G. Lightweight, multifunctional polyetherimide/graphene@ Fe3O4 composite foams for shielding of electromagnetic pollution. ACS Appl. Mater. Interfaces 2013, 5, 11383–11391. [Google Scholar] [CrossRef]

- Cao, M.-S.; Cai, Y.-Z.; He, P.; Shu, J.-C.; Cao, W.-Q.; Yuan, J. 2D MXenes: Electromagnetic property for microwave absorption and electromagnetic interference shielding. Chem. Eng. J. 2019, 359, 1265–1302. [Google Scholar] [CrossRef]

- Yin, J.; Zhang, J.-X.; Zhang, S.-D.; Liu, C.; Yu, X.-L.; Chen, L.-Q.; Song, Y.-P.; Han, S.; Xi, M.; Zhang, C.-L.; et al. Flexible 3D porous graphene film decorated with nickel nanoparticles for absorption-dominated electromagnetic interference shielding. Chem. Eng. J. 2021, 421, 129763. [Google Scholar] [CrossRef]

- Li, S.S.; Tang, X.W.; Zhang, Y.W.; Lan, Q.Q.; Hu, Z.W.; Li, L.; Zhang, N.; Ma, P.M.; Dong, W.F.; Tjiu, W.; et al. Corrosion-resistant graphene-based magnetic composite foams for efficient electromagnetic absorption. ACS Appl. Mater. Interfaces 2022, 14, 8297–8310. [Google Scholar] [CrossRef]

- Sun, R.H.; Zhang, H.B.; Liu, J.; Xie, X.; Yang, R.; Li, Y.; Hong, S.; Yu, Z.Z. Highly conductive transition metal carbide/carbonitride (MXene)@polystyrene nanocomposites fabricated by electrostatic assembly for highly efficient electromagnetic interference shielding. Adv. Funct. Mater. 2017, 27, 1702807. [Google Scholar] [CrossRef]

- Zhang, S.; Ying, H.; Yuan, B.; Hu, R.; Han, W.Q. Partial Atomic Tin Nanocomplex Pillared Few-Layered Ti3C2Tx MXenes for Superior Lithium-Ion Storage. Nano-Micro Lett. 2020, 12, 78. [Google Scholar] [CrossRef]

- Fu, H.L.; Yang, Z.P.; Zhang, Y.Y.; Zhu, M.; Jia, Y.H.; Chao, Z.; Hu, D.M.; Li, Q.W. SWCNT-modulated folding-resistant sandwich-structured graphene film for high-performance electromagnetic interference shielding. Carbon 2020, 162, 490–496. [Google Scholar] [CrossRef]

- Zhou, E.Z.; Xi, J.B.; Guo, Y.; Liu, Y.J.; Xu, Z.; Peng, L.; Gao, W.W.; Ying, J.; Chen, Z.Z.; Gao, C.; et al. Synergistic effect of graphene and carbon nanotube for high-performance electromagnetic interference shielding films. Carbon 2018, 133, 316–322. [Google Scholar] [CrossRef]

- Cao, W.-T.; Ma, C.; Tan, S.; Ma, M.-G.; Wan, P.-B.; Chen, F. Ultrathin and flexible CNTs/MXene/cellulose nanofibrils composite paper for electromagnetic interference shielding. Nano-Micro Lett. 2019, 11, 72–88. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Weng, G.M.; Li, J.Y.; Alhabeb, M.; Karpovich, C.; Wang, H.; Lipton, J.; Maleski, K.; Kong, J.; Shaulsky, E.; Elimelech, M.; et al. Layer-by-layer assembly of cross-functional semi-transparent MXene-carbon nanotubes composite films for next-generation electromagnetic interference shielding. Adv. Funct. Mater. 2018, 28, 1803360. [Google Scholar] [CrossRef]

- Li, Y.; Chen, C.; Li, J.T.; Zhang, S.; Ni, Y.; Cai, S.; Huang, J. Enhanced dielectric constant for efficient electromagnetic shielding based on carbon-nanotube-added styrene acrylic emulsion based composite. Nanoscale Res. Lett. 2010, 5, 1170–1176. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Thomassin, J.-M.; Pagnoulle, C.; Bednarz, L.; Huynen, I.; Jerome, R.; Detrembleur, C. Foams of polycaprolactone/MWNT nanocomposites for efficient EMI reduction. J. Mater. Chem. 2008, 18, 792–796. [Google Scholar] [CrossRef]

- Su, X.G.; Wang, J.; Zhang, X.X.; Zhang, B.; Wu, Q.L.; Dai, W.; Zou, Y.; Shao, C.R. Synthesis of core-shell Fe3O4@ppy/graphite nanosheets composites with enhanced microwave absorption performance. Mater. Lett. 2019, 239, 136–139. [Google Scholar] [CrossRef]

- Jia, L.C.; Yan, D.X.; Cui, C.H.; Jiang, X.; Ji, X.; Li, Z.M. Electrically conductive and electromagnetic interference shielding of polyethylene composites with devisable carbon nanotube networks. J. Mater. Chem. C 2015, 3, 9369–9378. [Google Scholar] [CrossRef]

- He, P.; Cao, M.S.; Cao, W.Q.; Yuan, J. Developing MXenes from wireless communication to electromagnetic attenuation. Nano-Micro. Lett. 2021, 13, 115–148. [Google Scholar] [CrossRef]

- Nouchokgwe, Y.; Lheritier, P.; Hong, C.H.; Torelló, A.; Faye, R.; Jo, W.; Bahl, C.R.H.; Defay, E. Giant electrocaloric materials energy efficiency in highly ordered lead scandium tantalate. Nat. Commun. 2021, 12, 3298–3304. [Google Scholar] [CrossRef]

- Zhang, W.D.; Zhang, X.; Qiao, Y.L.; Yan, H.X.; Qi, S.H. Covalently bonded GNPs-NH-PANI nanorod arrays modified by Fe3O4 nanoparticles as high-performance electromagnetic wave absorption materials. Mater. Lett. 2018, 216, 101–105. [Google Scholar] [CrossRef]

- Bao, S.P.; Liang, G.D.; Tjong, S.C. Positive temperature coefficient effect of polypropylene/carbon nanotube/montmorillonite hybrid nanocomposites. IEEE Trans. Nanotechnol. 2009, 8, 729–736. [Google Scholar] [CrossRef]

- Palza, H.; Reznik, B.; Wilhelm, M.; Arias, O.; Vargas, A. Electrical, thermal, and mechanical characterization of poly (propylene)/carbon nanotube/clay hybrid composite materials. Macromol. Mater. Eng. 2012, 297, 474–480. [Google Scholar] [CrossRef]

- Park, S.-H.; Hwang, J.; Park, G.-S.; Ha, J.-H.; Zhang, M.; Kim, D.; Yun, D.-J.; Lee, S.; Lee, S.-H. Modeling the electrical resistivity of polymer composites with segregated structures. Nat. Commun. 2019, 10, 1–11. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Yan, D.X.; Pang, H.; Li, B.; Vajtai, R.; Xu, L.; Ren, P.G.; Wang, J.H.; Li, Z.M. Structured reduced graphene oxide/polymer composites for ultra-efficient electromagnetic interference shielding. Adv. Funct. Mater. 2015, 25, 559–566. [Google Scholar] [CrossRef]

- Li, Z.; Wang, L.; Sun, D.; Zhang, Y.; Liu, B.; Hu, Q.; Zhou, A. Synthesis and thermal stability of two-dimensional carbide MXene Ti3C2. Mater. Sci. Eng. 2015, 191, 33–40. [Google Scholar] [CrossRef]

- Wang, G.-S.; Wu, Y.-Y.; Zhang, X.-J.; Li, Y.; Guo, L.; Cao, M.-S. Controllable synthesis of uniform ZnO nanorods and their enhanced dielectric and absorption properties. J. Mater. Chem. 2014, 2, 8644–8651. [Google Scholar] [CrossRef]

- Shao, W.; Li, J.; Zhang, Y.; Sun, N.; Wu, T.; Yan, M.; Liu, F.; Jiang, H.; Chen, X.; He, J.; et al. Polyvinylidene fluoride multi-scale nanofibrous membrane modified using N-halamine with high filtration efficiency and durable antibacterial properties for air filtration. J. Colloid Interf. Sci. 2022, 628, 627–636. [Google Scholar] [CrossRef]

- Bregman, A.; Michielssen, E.; Taub, A. Comparison of experimental and modeled EMI shielding properties of periodic porous xGNP/PLA composites. Polymers 2019, 11, 1233. [Google Scholar] [CrossRef] [Green Version]

- Alhabeb, M.; Maleski, K.; Anasori, B.; Lelyukh, P.; Clark, L.; Sin, S.; Gogotsi, Y. Guidelines for synthesis and processing of two-dimensional titanium carbide (Ti3C2Tx MXene). Chem. Mater. 2017, 29, 7633–7644. [Google Scholar] [CrossRef]

- Yun, T.; Kim, H.; Iqbal, A.; Cho, Y.S.; Lee, G.S.; Kim, M.K.; Kim, S.J.; Kim, D.; Gogotsi, Y.; Kim, S.O.; et al. Electromagnetic shielding of monolayer MXene assemblies. Adv. Mater. 2020, 32, 1906769. [Google Scholar] [CrossRef] [PubMed]

- Shahzad, F.; Alhabeb, M.; Hatter, C.B.; Anasori, B.; Man Hong, S.; Koo, C.M.; Gogotsi, Y. Electromagnetic interference shielding with 2D transition metal carbides (MXenes). Science 2016, 353, 1137–1140. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ding, L.; Wei, Y.; Li, L.; Zhang, T.; Wang, H.; Xue, J.; Ding, L.X.; Wang, S.; Caro, J.; Gogotsi, Y.; et al. MXene molecular sieving membranes for highly efficient gas separation. Nat. Commun. 2018, 9, 155–161. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Anasori, B.; Lukatskaya, M.R.; Gogotsi, Y. 2D metal carbides and nitrides (MXenes) for energy storage. Nat. Mater. 2017, 2, 34–50. [Google Scholar] [CrossRef]

- Wang, L.; Qiu, H.; Song, P.; Zhang, Y.; Lu, Y.; Liang, C.; Kong, J.; Chen, L.; Gu, J. Manufacturing. 3D Ti3C2Tx MXene/C hybrid foam/epoxy nanocomposites with superior electromagnetic interference shielding performances and robust mechanical properties. Compos. Part A Appl. Sci. Manuf. 2019, 123, 293–300. [Google Scholar] [CrossRef]

- Ghidiu, M.; Lukatskaya, M.R.; Zhao, M.Q.; Gogotsi, Y.; Barsoum, M.W. Conductive two-dimensional titanium carbide ‘clay’ with high volumetric capacitance. Nature 2014, 516, 78–81. [Google Scholar] [CrossRef]

- Yang, L.; Kan, D.; Dall’Agnese, C.; Dall’Agnese, Y.; Wang, B.; Jena, A.K.; Wei, Y.; Chen, G.; Wang, X.F.; Gogotsi, Y.; et al. Performance improvement of MXene-based perovskite solar cells upon property transition from metallic to semiconductive by oxidation of Ti3 C2 Tx in air. J. Mater. Chem. A 2021, 9, 5016–5025. [Google Scholar] [CrossRef]

- Li, D.; Müller, M.B.; Gilje, S.; Kaner, R.B.; Wallace, G.G. Processable aqueous dispersions of graphene nanosheets. Nat. Nano Technol. 2008, 3, 101–105. [Google Scholar] [CrossRef]

- Kumar, R.; Kumari, S.; Dhakate, S.R. Nickel nanoparticles embedded in carbonfoam for improving electromagnetic shielding effectiveness. Appl. Nanosci. 2015, 5, 553–561. [Google Scholar] [CrossRef] [Green Version]

- Sun, X.; Liu, X.; Shen, X.; Wu, Y.; Wang, Z.; Kim, J.K. Graphene foam/carbon nanotube/poly (dimethyl siloxane) composites for exceptional microwave shielding. Compos. Part A Appl. Sci. Manuf. 2016, 85, 199–206. [Google Scholar] [CrossRef]

- Wang, X.; Jiang, Q.; Xu, W.; Cai, W.; Inoue, Y.; Zhu, Y. Effect of carbon nanotube length on thermal, electrical and mechanical properties of CNT/bismaleimide composites. Carbon 2013, 53, 145–152. [Google Scholar] [CrossRef]

- Sakurai, S.; Kamada, F.; Futaba, D.N.; Yumura, M.; Hata, K. Influence of lengths of millimeter-scale single-walled carbon nanotube on electrical and mechanical properties of buckypaper. Nanoscale Res. Lett. 2013, 8, 546–552. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zhao, S.; Yan, Y.; Gao, A.; Zhao, S.; Cui, J.; Zhang, G. Flexible polydimethylsilane nanocomposites enhanced with a three-dimensional graphene/carbon nanotube bicontinuous framework for high-performance electromagnetic interference shielding. ACS Appl. Mater. Interfaces 2018, 10, 26723–26732. [Google Scholar] [CrossRef] [PubMed]

- Ren, F.; Guo, H.; Guo, Z.Z.; Jin, Y.L.; Duan, H.J.; Ren, P.G.; Yan, D.X. Highly bendable and durable waterproof paper for ultra-high electromagnetic interference shielding. Polymers 2019, 11, 1486. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ramírez-Herrera, C.A.; Gonzalez, H.; Felipe de la, T.; Benitez, L.; Cabañas-Moreno, J.G.; Lozano, K. Electrical properties and electromagnetic interference shielding effectiveness of interlayered systems composed by carbon nanotube filled carbon nanofiber mats and polymer composites. Nanomaterials 2019, 9, 238. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Cheng, X.K.; Zhou, X.B.; Wang, S.P.; Liu, Z.L.; Liu, Q.Z.; Zhang, Y.X.; Liu, Q.C.; Li, B. Fabrication of NiO/NiCo2O4 Mixtures as Excellent Microwave Absorbers. Nanoscale Res. Lett. 2019, 14, 155. [Google Scholar] [CrossRef] [Green Version]

- Carbonell, J.; Díaz-Rubio, A.; Torrent, D.; Cervera, F.; Kirleis, M.A.; Piqué, A.; Sánchez-Dehesa, J. Radial Photonic Crystal for detection of frequency and position of radiation sources. Sci. Rep. 2012, 2, 558. [Google Scholar] [CrossRef] [Green Version]

- Magdi, S.; El-Diwany, F.; Swillam, A.M. Broadband MIR harvester using silicon nanostructures. Sci. Rep. 2019, 9, 5829. [Google Scholar] [CrossRef] [Green Version]

- Schelkunoff, S. Electromagnetic Waves; Van Nostrand: New York, NY, USA, 1943; pp. 429–430. [Google Scholar]

- Lee, J.H.; Kim, Y.S.; Ru, H.J.; Lee, S.Y.; Park, S.J. Highly Flexible Fabrics/Epoxy Composites with Hybrid Carbon Nanofillers for Absorption-Dominated Electromagnetic Interference Shielding. Nano-Micro. Lett. 2022, 14, 307–323. [Google Scholar] [CrossRef]

- Mamunya, Y.; Matzui, L.; Vovchenko, L.; Maruzhenko, O.; Oliynyk, V.; Pusz, S.; Kumanek, B.; Szelug, U. Influence of conductive nano- and microfiller distribution on electrical conductivity and EMI shielding properties of polymer/carbon composites. Compos. Sci. Technol. 2019, 170, 51–59. [Google Scholar] [CrossRef]

- Han, M.; Shuck, C.E.; Rakhmanov, R.; Parchment, D.; Anasori, B.; Koo, C.M.; Friedman, G.; Gogotsi, Y. Beyond Ti3C2T x: MXenes for electromagnetic interference shielding. ACS Nano 2020, 14, 5008–5016. [Google Scholar] [CrossRef] [PubMed]

- Shi, X.L.; Cao, M.S.; Fang, X.Y.; Yuan, J.; Kang, Y.Q.; Song, W.L. High-temperature dielectric properties and enhanced temperature-response attenuation of β-MnO2 nanorods. Appl. Phys. Lett. 2008, 93, 223112. [Google Scholar] [CrossRef]

- Cao, M.S.; Song, W.L.; Hou, Z.L.; Wen, B.; Yuan, J. The effects of temperature and frequency on the dielectric properties, electromagnetic interference shielding and microwave-absorption of short carbon fiber/silica composites. Carbon 2010, 48, 788–796. [Google Scholar] [CrossRef]

- Hwang, J.S.; Kim, Y.J.; Yoo, Y.J.; Kim, K.W.; Rhee, J.Y.; Chen, L.Y.; Lee, Y.P. Switching and extension of transmission response, based on bending metamaterials. Sci. Rep. 2017, 7, 1–8. [Google Scholar] [CrossRef] [PubMed]

- Yang, Y.D.; Wan, C.C.; Huang, Q.T.; Hua, J. Pore-Rich Cellulose-Derived Carbon Fiber@ Graphene Core-Shell Composites for Electromagnetic Interference Shielding. Nanomaterials 2023, 13, 174. [Google Scholar] [CrossRef] [PubMed]

- Li, X.; Dong, Z.Q.; Yu, P.; Wang, L.P.; Niu, X.D.; Hiroshi, Y.; Li, D.C. Effect of self-assembly on fluorescence in magnetic multiphase flows and its application on the novel detection for COVID-19. Phys. Fluids 2021, 33, 042004. [Google Scholar] [CrossRef]

- Iqbal, A.; Sambyal, P.; Koo, C.M. 2D MXenes for electromagnetic shielding: A review. Adv. Funct. Mater. 2020, 30, 2000883. [Google Scholar] [CrossRef]

- Robinson, M.P.; Benson, T.M.; Christopoulos, C.; Dawson, J.F.; Ganley, M.D.; Marvin, A.C.; Porter, S.J.; Thomas, D.W.P. Analytical formulation for the shielding effectiveness of enclosures with apertures. IEEE Trans. Electromagn. Compat. 1998, 40, 240–248. [Google Scholar] [CrossRef] [Green Version]

- Clérico, P.; Pichon, L.; Mininger, X.; Dubrunfaut, O.; Gannouni, C.; He, D.; Bai, J.; Prevond, L. Design of a lightweight multilayered composite for dc to 20 ghz electromagnetic shielding. Electronics 2021, 10, 3144. [Google Scholar] [CrossRef]

- Zhang, X.F.; Guan, P.F.; Dong, X.L. Transform between the permeability and permittivity in the close-packed Ni nanoparticles. Appl. Phys. Lett. 2010, 97, 033107. [Google Scholar] [CrossRef]

- Dahan, Y.; Holdengreber, E.; Glassner, E.; Sorkin, O.; Schacham, S.-E.; Farber, E. Measurement of electrical properties of superconducting YBCO thin films in the VHF range. Materials 2021, 14, 3360. [Google Scholar] [CrossRef] [PubMed]

- Wen, B.; Cao, M.S.; Hou, Z.L.; Song, W.L.; Zhang, L.; Lu, M.M.; Jin, H.B.; Fang, X.Y.; Wang, W.Z.; Yuan, J. Temperature dependent microwave attenuation behavior for carbon-nanotube/silica composites. Carbon 2013, 65, 124–139. [Google Scholar] [CrossRef]

- Zhang, X.; Zhang, Z.; Zhou, Z. MXene-based materials for electrochemical energy storage. J. Energy Chem. 2018, 27, 73–85. [Google Scholar] [CrossRef] [Green Version]

- Lv, H.L.; Li, Y.; Jia, Z.R.; Wang, L.J.; Guo, X.Q.; Zhao, B.; Zhang, R. Exceptionally porous three-dimensional architectural nanostructure derived from CNTs/graphene aerogel towards the ultra-wideband EM absorption. Compos. Part B Eng. 2020, 196, 7. [Google Scholar] [CrossRef]

- He, X.; Feng, L.; Zhang, Z.; Hou, X.J.; Ye, X.H.; Song, Q.; Yang, Y.L.; Suo, G.Q.; Zhang, L.; Fu, Q.G.; et al. High-performance multifunctional carbon–silicon carbide composites with strengthened reduced graphene oxide. ACS Nano 2021, 15, 2880–2892. [Google Scholar] [CrossRef]

- Zhang, D.F.; Hao, Z.F.; Qian, Y.N.; Huang, Y.X.; Mao, B.Z.; Yang, Z.D.; Wu, Q.B. Simulation and measurement of optimized microwave reflectivity for carbon nanotube absorber by controlling electromagnetic factors. Sci. Rep. 2017, 7, 1–8. [Google Scholar] [CrossRef] [Green Version]

- Saxena, P.; Shukla, P. A comprehensive review on fundamental properties and applications of poly (vinylidene fluoride) (PVDF). Adv. Compos. Hybrid Mater. 2021, 4, 8–26. [Google Scholar] [CrossRef]

- He, P.; Cao, M.S.; Shu, J.C.; Cai, Y.Z.; Wang, X.X.; Zhao, Q.L.; Yuan, J. Atomic layer tailoring titanium carbide MXene to tune transport and polarization for utilization of electromagnetic energy beyond solar and chemical energy. ACS Appl. Mater. Interfaces 2019, 11, 12535–12543. [Google Scholar] [CrossRef]

| Samples | MXene Content (wt%) | SWCNTs Content (wt%) | Composition Structure Unit |

|---|---|---|---|

| PVDF/MXene5 | 5 | 0 | PVDF/MXene5 |

| PVDF/SWCNTs2 | 0 | 2 | PVDF/SWCNTs2 |

| PVDF/MXene2.5/SWCNTs1 | 2.5 | 1 | PVDF/MXene5 and PVDF/SWCNTs2 1 |

| PVDF-SWCNTs1-MXene2.5 | 2.5 | 1 | PVDF@SWCNTs1/MXene2.5 |

| PVDF-MXene2.5-SWCNTs1 | 2.5 | 1 | PVDF/MXene2.5@SWCNTs1 |

| Samples * | SWCNTs Contents (wt %) | Conductivity (S cm−1) | EMI SEA (dB) | EMI SET (dB) | SEA/SET (%) |

|---|---|---|---|---|---|

| PVDF/MXene2.5/SWCNTs0.2 | 0.2 | 2.89 × 10−3 | 12. 1 | 19.4 | 61.7 |

| PVDF/MXene2.5/SWCNTs0.5 | 0.5 | 4.71 × 10−1 | 18.33 | 30.6 | 59.8 |

| PVDF/MXene2.5/SWCNTs 1 | 1 | 1.05 | 30.2 | 41.2 | 73.3 |

| PVDF/MXene2.5/SWCNTs 1.5 | 1.5 | 3.77 | 32.4 | 45.9 | 70.6 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Q.; Cui, J.; Zhao, S.; Zhang, G.; Gao, A.; Yan, Y. Development of Electromagnetic-Wave-Shielding Polyvinylidene Fluoride–Ti3C2Tx MXene–Carbon Nanotube Composites by Improving Impedance Matching and Conductivity. Nanomaterials 2023, 13, 417. https://doi.org/10.3390/nano13030417

Zhang Q, Cui J, Zhao S, Zhang G, Gao A, Yan Y. Development of Electromagnetic-Wave-Shielding Polyvinylidene Fluoride–Ti3C2Tx MXene–Carbon Nanotube Composites by Improving Impedance Matching and Conductivity. Nanomaterials. 2023; 13(3):417. https://doi.org/10.3390/nano13030417

Chicago/Turabian StyleZhang, Qimei, Jian Cui, Shuai Zhao, Guangfa Zhang, Ailin Gao, and Yehai Yan. 2023. "Development of Electromagnetic-Wave-Shielding Polyvinylidene Fluoride–Ti3C2Tx MXene–Carbon Nanotube Composites by Improving Impedance Matching and Conductivity" Nanomaterials 13, no. 3: 417. https://doi.org/10.3390/nano13030417