Research Progress on Moisture-Sorption Actuators Materials

Abstract

:1. Introduction

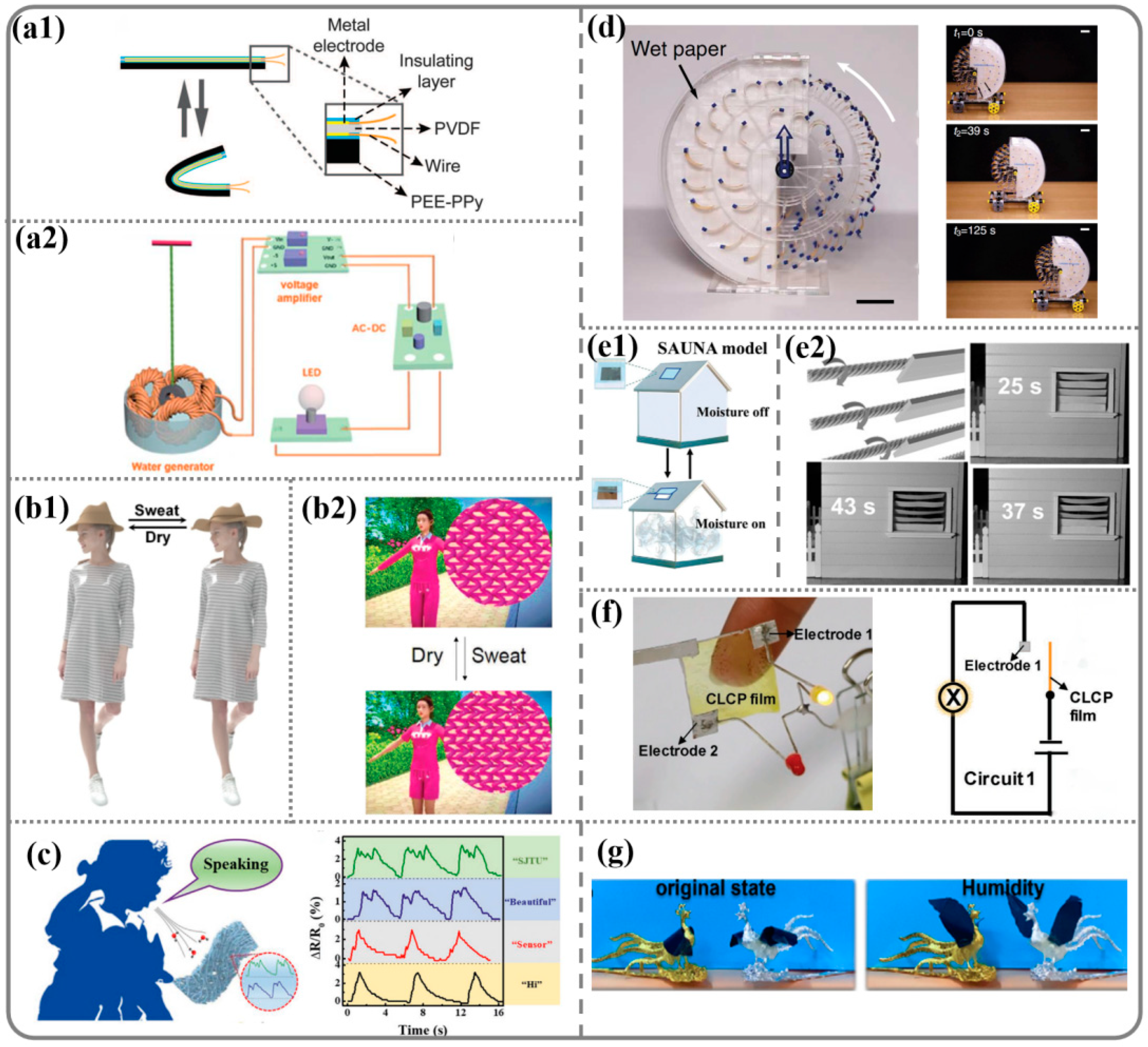

2. Mechanism of Moisture-Sorption Materials Responsiveness

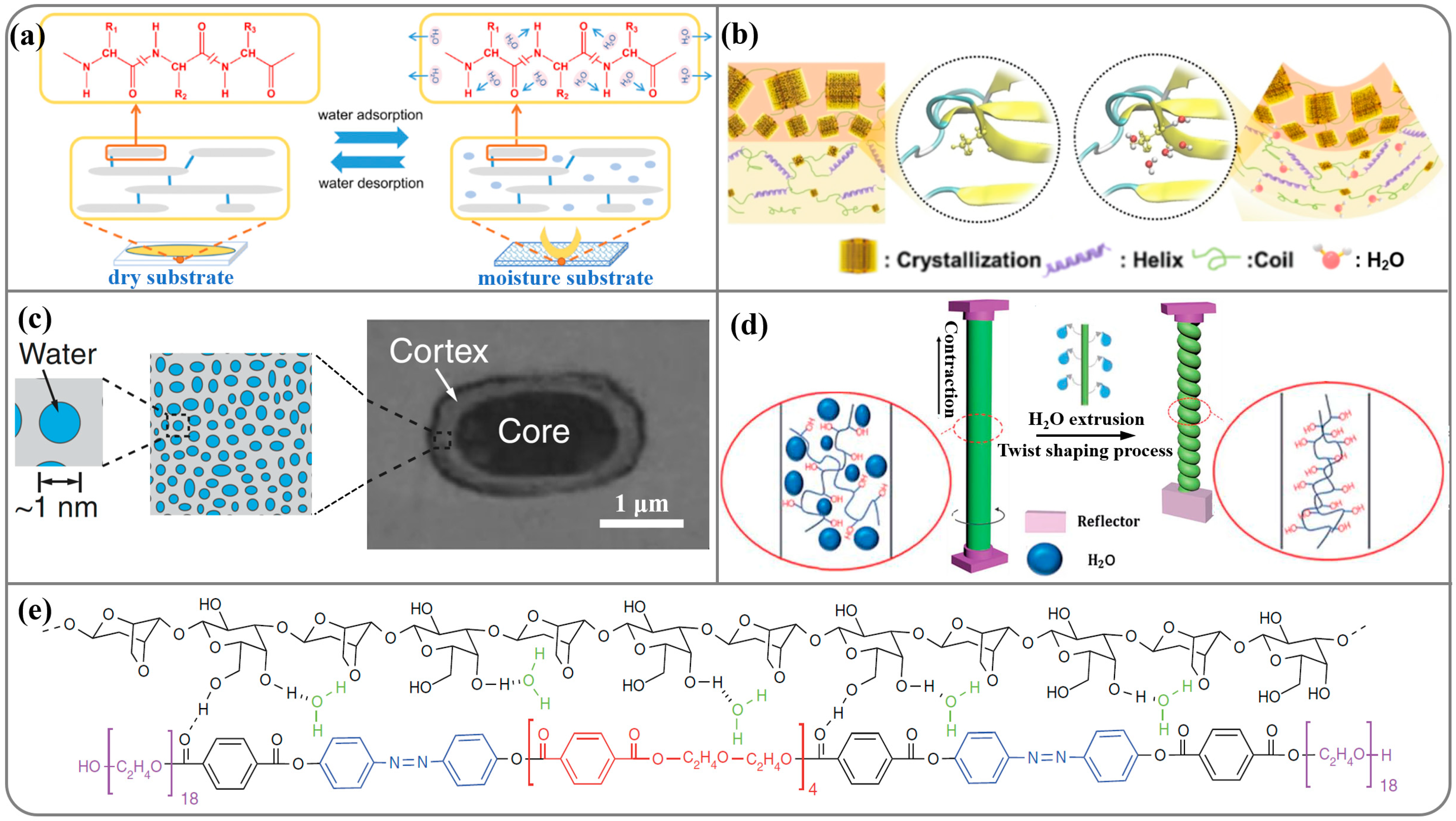

2.1. Biomaterials

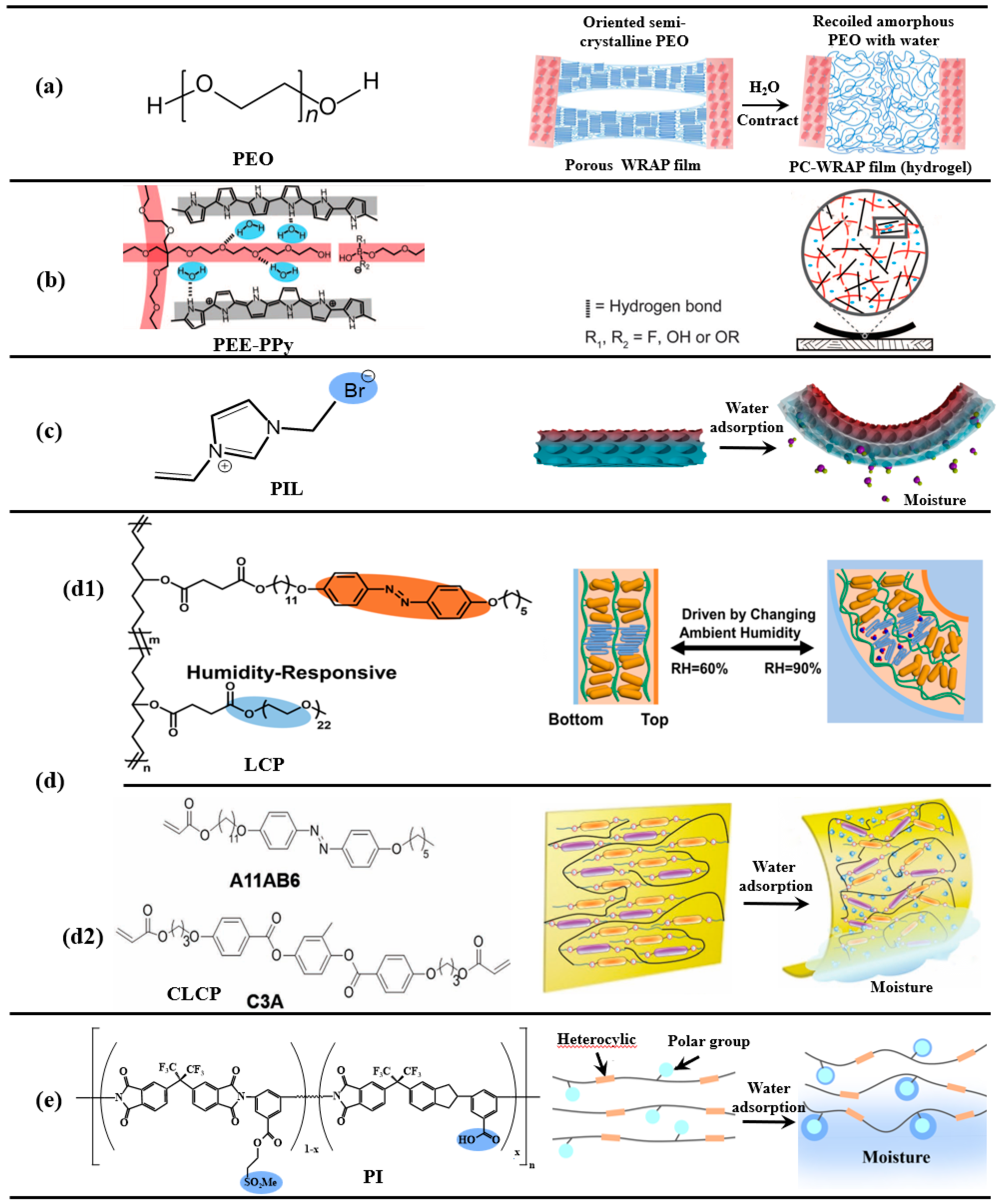

2.2. Polymers

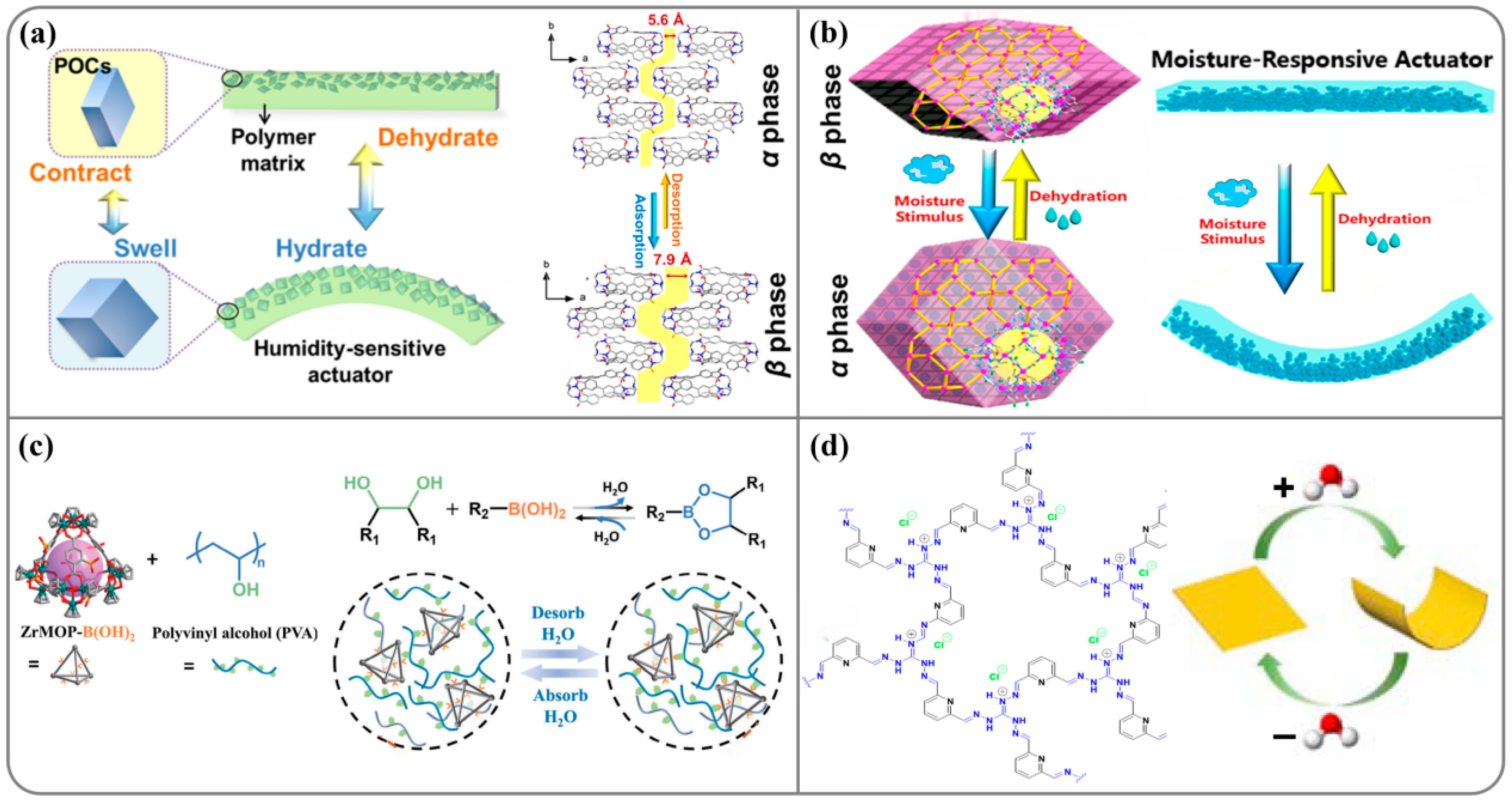

2.3. Nanomaterials

2.4. Crystalline Materials

3. Practicality and Application

4. Outlooks and Challenges

- (1)

- Biomaterials: In nature, an abundance of biomass raw materials with renewable, biocompatible, biodegradable, and excellent moisture absorption properties exists. However, the complex secondary processing required for biomass raw materials often limits their large-scale production. Therefore, there is a need to improve the mechanical properties and long-term stability and reliability of the prepared actuators.

- (2)

- Synthetic polymers: For synthetic polymers, the number, type, and positioning of hydrophilic groups can be tailored to achieve controllable water absorption and water adsorption/desorption capabilities. The modifiable flexibility and rigidity of molecular chains, as well as crystallinity and orientation, confer excellent mechanical properties and versatility for diverse applications. Furthermore, through compositing with other materials (CNT, COF, MOF, MXene, GO, and so on), the polymer can acquire unique properties and will be ideal for humidity-responsive actuators. Nevertheless, the current range of humidity-absorbing polymers is limited, with the narrow scope of humidity absorption being a primary constraint on its advancement. Therefore, the development of innovative humidity-absorbing polymers holds great significance for harnessing green energy.

- (3)

- Nanomaterials: The materials are primarily categorized as 1D and 2D nanomaterials, exhibiting either hydrophilic or hydrophobic properties. In the case of hydrophobic nanomaterials, surface modification with hydrophilic properties is necessary prior to layer-by-layer stacking for the formation of a moisture-responsive actuator. Nevertheless, these membrane actuators often exhibit low durability and are susceptible to delamination. Hence, enhancing the longevity of these materials remains an imminent challenge.

- (4)

- Crystalline materials: Crystalline materials have superior tunable water affinities. And the hydrophilic groups can be uniformly installed in the skeleton of the crystal materials to form ordered molecular arrays, making energy transfer between moisture-stimulus signals and responsive sites much faster and more efficient. However, most of the current crystalline materials are in the form of particles or powders, which must be blended with other polymers to form a humidity-responsive actuator. Although physically blending is conveniently used, it suffers from deficiencies from aggregation and precipitation, resulting in poor performance. As a result, improving the dispersion of crystal materials in polymers is a key factor in the future development of moisture-absorbing materials.

Funding

Conflicts of Interest

References

- Chen, X.; Mahadevan, L.; Driks, A.; Sahin, O. Bacillus Spores as Building Blocks for Stimuli-responsive Materials and Nanogenerators. Nat. Nanotechnol. 2014, 9, 137–141. [Google Scholar] [CrossRef]

- Cheng, H.H.; Hu, Y.; Zhao, F.; Dong, Z.L.; Wang, Y.H.; Chen, N.; Zhang, Z.P.; Qu, L.T. Moisture-Activated Torsional Graphene-Fiber Motor. Adv. Mater. 2014, 26, 2909–2913. [Google Scholar] [CrossRef]

- de Haan, L.T.; Verjans, J.M.N.; Broer, D.J.; Bastiaansen, C.W.M.; Schenning, A.P.H.J. Humidity-Responsive Liquid Crystalline Polymer Actuators with an Asymmetry in the Molecular Trigger That Bend, Fold, and Curl. J. Am. Chem. Soc. 2014, 136, 10585–10588. [Google Scholar] [CrossRef]

- Deng, J.; Li, J.F.; Chen, P.N.; Fang, X.; Sun, X.M.; Jiang, Y.S.; Weng, W.; Wang, B.J.; Peng, H.S. Tunable Photothermal Actuators Based on a Pre-programmed Aligned Nanostructure. J. Am. Chem. Soc. 2016, 138, 225–230. [Google Scholar] [CrossRef] [PubMed]

- Elbaum, R.; Zaltzman, L.; Burgert, I.; Fratzl, P. The role of wheat awns in the seed dispersal unit. Science 2007, 316, 884–886. [Google Scholar] [CrossRef]

- Islam, M.R.; Li, X.; Smyth, K.; Serpe, M.J. Polymer-based muscle expansion and contraction. Angew. Chem. Int. Ed. 2013, 52, 10330–10333. [Google Scholar] [CrossRef]

- Lu, X.; Zhang, Z.T.; Li, H.P.; Sun, X.M.; Peng, H.S. Conjugated polymer composite artificial muscle with solvent-induced anisotropic mechanical actuation. J. Mater. Chem. A 2014, 2, 17272–17280. [Google Scholar] [CrossRef]

- Zhang, L.D.; Naumov, P. Light- and Humidity-Induced Motion of an Acidochromic Film. Angew. Chem. Int. Ed. 2015, 54, 8642. [Google Scholar] [CrossRef] [PubMed]

- Zeng, S.; Ye, Y.; Zhou, P.; Yi, S.; Guo, Q.; Chen, H.; Shen, G.; Weng, M. Programmable and Reconfigurable Humidity-driven Actuators made with MXene (Ti3C2Tx)-cellulose Nanofiber Composites for Biomimetic Applications. Nano Res. 2024, 17, 6619–6629. [Google Scholar] [CrossRef]

- Xu, C.; Jiang, Z.; Wang, B.; Chen, J.; Sun, T.; Fu, F.; Wang, C.; Wang, H. Biospinning of Hierarchical Fibers for a Self-sensing Actuator. Chem. Eng. J. 2024, 485, 150014. [Google Scholar] [CrossRef]

- Xu, J.; Wang, P.; Bai, Z.; Cheng, H.; Wang, R.; Qu, L.; Li, T. Sustainable Moisture Energy. Nat. Rev. Mater. 2024, 1–16. [Google Scholar] [CrossRef]

- Yang, M.; Zhang, F.; Wang, S. Bioinspired Strategies for Biomimetic Actuators from Ultrafast to Ultraslow. Nano Research. 2023, 17, 570–586. [Google Scholar] [CrossRef]

- Lan, R.; Shen, W.; Yao, W.; Chen, J.; Chen, X.; Yang, H. Bioinspired humidity-responsive liquid crystalline materials: From adaptive soft actuators to visualized sensors and detectors. Mater. Horiz. 2023, 10, 2824–2844. [Google Scholar] [CrossRef] [PubMed]

- Chang, L.; Wang, D.; Jiang, A.; Hu, Y. Soft Actuators Based on Carbon Nanomaterials. Chem. Plus. Chem. 2022, 87, e202100437. [Google Scholar] [CrossRef]

- Yan, D.; Wang, Z.; Zhang, Z. Stimuli-Responsive Crystalline Smart Materials: From Rational Design and Fabrication to Applications. Acc. Chem. Res. 2022, 55, 1047–1058. [Google Scholar] [CrossRef] [PubMed]

- Mao, T.; Liu, Z.; Guo, X.; Wang, Z.; Liu, J.; Wang, T.; Geng, S.; Chen, Y.; Cheng, P.; Zhang, Z. Engineering Covalent Organic Frameworks with Polyethylene Glycol as Self-Sustained Humidity-Responsive Actuators. Angew. Chem. Int. Ed. 2022, 62, e202216318. [Google Scholar] [CrossRef]

- Li, J.; Liu, Z.; Liu, J.; Liu, X.; Luo, Y.; Liang, J.; Zhang, Z. Humidity-Induced Self-Oscillating and Self-Healing Hypercrosslinked Metal–Organic Polyhedra Membranes. Adv. Sci. 2024, 11, 2307376. [Google Scholar] [CrossRef]

- Yang, M.; Wang, S.-Q.; Liu, Z.; Chen, Y.; Zaworotko, M.J.; Cheng, P.; Ma, J.-G.; Zhang, Z. Fabrication of Moisture-Responsive Crystalline Smart Materials for Water Harvesting and Electricity Transduction. J. Am. Chem. Soc. 2021, 143, 7732–7739. [Google Scholar] [CrossRef]

- Ilmain, F.; Tanaka, T.; Kokufuta, E. Volume Transition in a Gel Driven by Hydrogen-Bonding. Nature 1991, 349, 400–401. [Google Scholar] [CrossRef]

- Ma, M.M.; Guo, L.; Anderson, D.G.; Langer, R. Bio-Inspired Polymer Composite Actuator and Generator Driven by Water Gradients. Science 2013, 339, 186–189. [Google Scholar] [CrossRef]

- Zhang, L.; Liang, H.; Jacob, J.; Naumov, P. Photogated humidity-driven motility. Nat. Commun. 2015, 6, 7429. [Google Scholar] [CrossRef] [PubMed]

- Yao, C.; Liu, Z.; Yang, C.; Wang, W.; Ju, X.J.; Xie, R.; Chu, L.Y. Smart Hydrogels with Inhomogeneous Structures Assembled Using Nanoclay-Cross-Linked Hydrogel Subunits as Building Blocks. ACS Appl. Mater. Interfaces 2016, 8, 21721–21730. [Google Scholar] [CrossRef] [PubMed]

- Wong, W.S.Y.; Li, M.F.; Nisbet, D.R.; Craig, V.S.J.; Wang, Z.K.; Tricoli, A. Mimosa Origami: A Nanostructure-enabled Directional Self-organization Regime of Materials. Sci. Adv. 2016, 2, e1600417. [Google Scholar] [CrossRef]

- Zhang, F.; Yang, M.; Xu, X.; Liu, X.; Liu, H.; Jiang, L.; Wang, S. Unperceivable Motion Mimicking Hygroscopic Geometric Reshaping of Pine Cones. Nat. Mater. 2022, 21, 1357–1365. [Google Scholar] [CrossRef]

- Zhang, L.D.; Chizhik, S.; Wen, Y.Z.; Naumov, P. Directed Motility of Hygroresponsive Biomimetic Actuators. Adv. Funct. Mater. 2016, 26, 1040–1053. [Google Scholar] [CrossRef]

- Fratzl, P.; Barth, F.G. Biomaterial Systems for Mechanosensing and Actuation. Nature 2009, 462, 442–448. [Google Scholar] [CrossRef]

- Armon, S.; Efrati, E.; Kupferman, R.; Sharon, E. Geometry and Mechanics in the Opening of Chiral Seed Pods. Science 2011, 333, 1726–1730. [Google Scholar] [CrossRef]

- Erb, R.M.; Sander, J.S.; Grisch, R.; Studart, A.R. Self-shaping Composites with Programmable Bioinspired Microstructures. Nat. Commun. 2013, 4, 1712. [Google Scholar] [CrossRef] [PubMed]

- Lu, L.; Jiang, C.; Hu, G.; Liu, J.; Yang, B. Flexible Noncontact Sensing for Human-Machine Interaction. Adv. Mater. 2021, 33, e2100218. [Google Scholar] [CrossRef]

- Jiang, X.; Chen, K.; Long, Y.; Liu, S.; Chi, Z.; Xu, J.; Zhang, Y. Design and Synthesis of Vertical Gradient of Expansion Structure based on Polyimide Humidity Sensing Layer with Ultra-fast Response, High Sensitivity, and Large Deformation Driven by Humidity. Chem. Eng. J. 2023, 468, 143805. [Google Scholar] [CrossRef]

- Zhou, P.; Chen, L.; Yao, L.; Weng, M.; Zhang, W. Humidity- and Light-driven Actuators based on Carbon Nanotube-coated Paper and Polymer Composite. Nanoscale 2018, 10, 8422–8427. [Google Scholar] [CrossRef] [PubMed]

- Han, D.D.; Zhang, Y.L.; Jiang, H.B.; Xia, H.; Feng, J.; Chen, Q.D.; Xu, H.L.; Sun, H.B. Moisture-Responsive Graphene Paper Prepared by Self-Controlled Photoreduction. Adv. Mater. 2015, 27, 332–338. [Google Scholar] [CrossRef]

- Das, G.; Shinde, D.B.; Melepurakkal, A.; Shelke, M.V.; Garai, B.; Bazin, P.; Ait Blal, A.; Benyettou, F.; Prakasam, T.; Halim, R.A.; et al. Synergistic Humidity-responsive Mechanical Motion and Proton Conductivity in a Cationic Covalent Organic Framework. Chem. 2024, 10, 2500–2517. [Google Scholar] [CrossRef]

- Zhang, Y.; Ionov, L. Actuating Porous Polyimide Films. ACS Appl. Mater. Interfaces 2014, 6, 10072–10077. [Google Scholar] [CrossRef] [PubMed]

- Zhang, X.; Wang, M.; Wu, Y.; Chen, X.; Wu, K.; Fu, Q.; Deng, H. Biomimetic Aerogel for Moisture-Induced Energy Harvesting and Self-Powered Electronic Skin. Adv. Funct. Mater. 2022, 33, 2210027. [Google Scholar] [CrossRef]

- Xu, L.; Xue, F.; Zheng, H.; Ji, Q.; Qiu, C.; Chen, Z.; Zhao, X.; Li, P.; Hu, Y.; Peng, Q.; et al. An Insect Larvae Inspired MXene-based Jumping Actuator with Controllable Motion Powered by Light. Nano Energy 2022, 103, 107848. [Google Scholar] [CrossRef]

- Wan, B.; Yang, X.; Dong, X.; Zheng, M.S.; Zhao, Q.; Zhang, H.; Chen, G.; Zha, J.W. Dynamic Sustainable Polyimide Film Combining Hardness with Softness via a “Mimosa-Like” Bionic Strategy. Adv. Mater. 2022, 35, 2207451. [Google Scholar] [CrossRef]

- Liu, H.; Liu, R.; Chen, K.; Liu, Y.; Zhao, Y.; Cui, X.; Tian, Y. Bioinspired Gradient Structured Soft Actuators: From Fabrication to Application. Chem. Eng. J. 2023, 461, 141966. [Google Scholar] [CrossRef]

- Agnarsson, I.; Dhinojwala, A.; Sahni, V.; Blackledge, T.A. Spider silk as a Novel High Performance Biomimetic Muscle Driven by Humidity. J. Exp. Biol. 2009, 212, 1990–1994. [Google Scholar] [CrossRef]

- Wani, O.M.; Zeng, H.; Priimagi, A. A light-driven Artificial Flytrap. Nat. Commun. 2017, 8, 15546. [Google Scholar] [CrossRef]

- Xiao, J.; Liu, H.; Wang, S.; Ma, S.; Zhang, L.; Qi, Y. Reprogrammable Multi-Responsiveness of Regenerated Silk for Versatile Soft Actuators. Adv. Funct. Mater. 2024, 34, 2316301. [Google Scholar] [CrossRef]

- Xi, J.; Yang, H.; Li, X.; Wei, R.; Zhang, T.; Dong, L.; Yang, Z.; Yuan, Z.; Sun, J.; Hua, Q. Recent Advances in Tactile Sensory Systems: Mechanisms, Fabrication, and Applications. Nanomaterials 2024, 14, 465. [Google Scholar] [CrossRef]

- Weng, X.; Weng, Z.; Qin, M.; Zhang, J.; Wu, Y.; Jiang, H. Bioinspired Moisture-Driven Soft Actuators Based on MXene/Aramid Nanofiber Nanocomposite Films. ACS Appl. Nano. Mater. 2024, 7, 5587–5597. [Google Scholar] [CrossRef]

- Wei, S.; Ghosh, T.K. Moisture-Driven Cellulose Actuators with Directional Motion and Programmable Shapes. Adv. Intellt. Syst. 2024, 6, 2300638. [Google Scholar] [CrossRef]

- Nan, M.; Go, G.; Song, H.W.; Darmawan, B.A.; Zheng, S.; Kim, S.; Nguyen, K.T.; Lee, K.; Kim, H.; Park, J.O.; et al. Multistimulus-responsive Miniature Soft Actuator with Programmable Shape-morphing Design for Biomimetic and Biomedical Applications. Adv. Funct. Mater. 2024, 34, 2401776. [Google Scholar] [CrossRef]

- Yang, Z.; Wang, Y.; Lan, L.; Wang, Y.; Zhang, X. Bioinspired H-Bonding Connected Gradient Nanostructure Actuators Based on Cellulose Nanofibrils and Graphene. Small 2024, 20, 2401580. [Google Scholar] [CrossRef] [PubMed]

- Lin, S.; Ma, S.; Chen, K.; Zhang, Y.; Lin, Z.; Liang, Y.; Ren, L. A Humidity-driven Film with Fast Response and Continuous Rolling Locomotion. Chem. Eng. J. 2024, 495, 153294. [Google Scholar] [CrossRef]

- Li, B.; Zhu, X.; Xu, C.; Yu, J.; Fan, Y. A Tough, Reversible and Highly Sensitive Humidity Actuator based on Cellulose Nanofiber Films by Intercalation Modulated Plasticization. Carbohyd. Polym. 2024, 335, 122108. [Google Scholar] [CrossRef]

- Chen, Z.; Zhao, X.; Gao, B.; Xu, L.; Chen, H.; Liu, Z.; Li, P.; Yan, Q.; Zheng, H.; Xue, F.; et al. Biobased Inks Based on Cuttlefish Ink and Cellulose Nanofibers for Biodegradable Patterned Soft Actuators. ACS Appl. Mater Interfaces 2024, 16, 22547–22557. [Google Scholar] [CrossRef]

- Wu, F.; Lin, X.; Xu, Y.; Chen, Y.; He, Y.; Wang, J.; Liu, M. Bilayer PVA Composite Film with Structural Color for High-Performance and Multifunctional Sensing. Compos. Sci. Technol. 2023, 241, 110106. [Google Scholar] [CrossRef]

- Chen, J.; Xu, H.; Zhang, C.; Wu, R.; Fan, S.; Zhang, Y. Gradient structure enabled robust silk origami with moisture responsiveness. Chem. Eng. J. 2023, 45, 140021. [Google Scholar] [CrossRef]

- Wang, Y.; Duan, R.; Tong, Z.; Wang, B.; Zhang, Z.; Li, Y. Sensitively Humidity-driven Actuator and Sensor Derived from Natural Skin System. Sensor. Actuat. B—Chem. 2022, 370, 132388. [Google Scholar] [CrossRef]

- Wang, Q.; Wu, Z.; Li, J.; Wei, J.; Guo, J.; Yin, M. Spontaneous and Continuous Actuators Driven by Fluctuations in Ambient Humidity for Energy-Harvesting Applications. ACS Appl. Mater. Interfaces 2022, 14, 38972–38980. [Google Scholar] [CrossRef] [PubMed]

- Fu, L.; Zhao, W.; Ma, J.; Yang, M.; Liu, X.; Zhang, L.; Chen, Y. A Humidity-Powered Soft Robot with Fast Rolling Locomotion. Research 2022, 2022, 9832901. [Google Scholar] [CrossRef]

- Wang, Y.; Feng, P.; Liu, R.; Song, B. Rational design of a porous nanofibrous actuator with highly sensitive, ultrafast, and large deformation driven by humidity. Sensor. Actuat. B-Chem. 2021, 330, 129236. [Google Scholar] [CrossRef]

- Chen, X.; Goodnight, D.; Gao, Z.H.; Cavusoglu, A.H.; Sabharwal, N.; DeLay, M.; Driks, A.; Sahin, O. Scaling up Nanoscale Water-driven Energy Conversion into Evaporation-Driven Engines and Generators. Nat. Commun. 2015, 6, 7346. [Google Scholar] [CrossRef]

- Wang, W.; Xiang, C.; Liu, Q.; Li, M.; Zhong, W.; Yan, K.; Wang, D. Natural alginate fiber-based actuator driven by water or moisture for energy harvesting and smart controller applications. J. Mater. Chem. A 2018, 6, 22599–22608. [Google Scholar] [CrossRef]

- Lee, W.E.; Jin, Y.J.; Park, L.S.; Kwak, G. Fluorescent Actuator Based on Microporous Conjugated Polymer with Intramolecular Stack Structure. Adv. Mater. 2012, 24, 5604–5609. [Google Scholar] [CrossRef]

- Khan, M.K.; Hamad, W.Y.; MacLachlan, M.J. Tunable Mesoporous Bilayer Photonic Resins with Chiral Nematic Structures and Actuator Properties. Adv. Mater. 2014, 26, 2323–2328. [Google Scholar] [CrossRef]

- Liu, W.; Kong, D.; Zhao, W.; Leng, J. Multi-stimulus responsive shape memory polyurea incorporating stress-mismatching structure for soft actuators and reversible deployable structures. Compos. Struct. 2024, 334, 117966. [Google Scholar] [CrossRef]

- Ye, Y.; Zhu, Y.; Zhou, P.; Weng, M. Multi-functional and Integrated Actuator based on Carbon Nanotube–Cellulose Nanofiber Composites. Cellulose 2023, 30, 7221–7234. [Google Scholar] [CrossRef]

- Yi, J.; Zou, G.; Huang, J.; Ren, X.; Tian, Q.; Yu, Q.; Wang, P.; Yuan, Y.; Tang, W.; Wang, C.; et al. Water-responsive Supercontractile Polymer Films for Bioelectronic Interfaces. Nature 2023, 624, 295–302. [Google Scholar] [CrossRef] [PubMed]

- Tang, G.; Zhao, C.; Zhao, X.; Mei, D.; Pan, Y.; Li, B.; Li, L.; Wang, Y. Nafion/polyimide based Programmable Moisture-driven Actuators for Functional Structures and Robots. Sensor. Actuat. B—Chem. 2023, 393, 134152. [Google Scholar] [CrossRef]

- Liu, T.; Qu, D.; Guo, L.; Zhou, G.; Zhang, G.; Du, T.; Wu, W. MXene/TPU Composite Film for Humidity Sensing and Human Respiration Monitoring. Adv. Sens. Res. 2023, 3, 2300014. [Google Scholar] [CrossRef]

- Druvari, D.; Kyriakopoulou, F.; Lainioti, G.C.; Vlamis-Gardikas, A.; Kallitsis, J.K. Humidity-Responsive Antimicrobial Membranes Based on Cross-Linked Copolymers Functionalized with Ionic Liquid Moieties. ACS Appl. Mater. Interfaces 2023, 15, 11193–11207. [Google Scholar] [CrossRef]

- Qin, H.; Yan, Y.; Feng, Q.; Liu, H.; Cong, H.P.; Yu, S.H. Rapid Printing and Patterning of Tough, Self-Healable, and Recyclable Hydrogel Thin-Films toward Flexible Sensing Devices. Nano. Lett. 2022, 22, 8101–8108. [Google Scholar] [CrossRef]

- Li, X.; Liu, J.; Li, D.; Huang, S.; Huang, K.; Zhang, X. Bioinspired Multi-Stimuli Responsive Actuators with Synergistic Color- and Morphing-Change Abilities. Adv. Sci. 2021, 8, e2101295. [Google Scholar] [CrossRef]

- He, Y.; Kong, K.; Guo, Z.; Fang, W.; Ma, Z.; Pan, H.; Tang, R.; Liu, Z. A Highly Sensitive, Reversible, and Bidirectional Humidity Actuator by Calcium Carbonate Ionic Oligomers Incorporated Poly(Vinylidene Fluoride). Adv. Funct. Mater. 2021, 31, 2101291. [Google Scholar] [CrossRef]

- Zhang, Y.-L.; Ma, J.-N.; Liu, S.; Han, D.-D.; Liu, Y.-Q.; Chen, Z.-D.; Mao, J.-W.; Sun, H.-B. A “Yin”-“Yang” Complementarity Strategy for Design and Fabrication of Dual-Responsive Bimorph Actuators. Nano Energy 2020, 68, 104302. [Google Scholar] [CrossRef]

- Lv, C.; Xia, H.; Shi, Q.; Wang, G.; Wang, Y.-S.; Chen, Q.-D.; Zhang, Y.-L.; Liu, L.-Q.; Sun, H.-B. Sensitively Humidity-Driven Actuator Based on Photopolymerizable PEG-DA Films. Adv. Mater. Interfaces 2017, 4, 1601002. [Google Scholar] [CrossRef]

- Wang, Z.; Lan, R.; Bao, J.; Shen, C.; Huang, R.; Song, C.; Zhang, L.; Yang, H. Reprogrammable Humidity-Driven Liquid Crystalline Polymer Actuator Enabled by Dynamic Ionic Bonds. ACS Appl. Mater. Interfaces 2022, 14, 17869–17877. [Google Scholar] [CrossRef] [PubMed]

- Zhang, D.; Liu, J.; Chen, B.; Zhao, Y.; Wang, J.; Ikeda, T.; Jiang, L. A Hydrophilic/Hydrophobic Janus Inverse-Opal Actuator via Gradient Infiltration. ACS Nano. 2018, 12, 12149–12158. [Google Scholar] [CrossRef]

- Wu, H.; Kuang, M.; Cui, L.; Tian, D.; Wang, M.; Luan, G.; Wang, J.; Jiang, L. Single-material Solvent-sensitive Actuator from Poly(Ionic Liquid) Inverse Opals based on Gradient Dewetting. Chem. Commun. 2016, 52, 5924–5927. [Google Scholar] [CrossRef]

- Sun, H.; Chai, X.; Yang, H.; Wei, J.; Yu, Y. Photo- and Humidity-Responsive Liquid Crystal Copolymer Actuators Fabricated via Vapor-Assisted Alignment. ACS Appl. Mater. Interfaces 2024, 16, 15405–15415. [Google Scholar] [CrossRef] [PubMed]

- Liu, Y.Y.; Xu, B.; Sun, S.T.; Wei, J.; Wu, L.M.; Yu, Y.L. Humidity- and Photo-Induced Mechanical Actuation of Cross-Linked Liquid Crystal Polymers. Adv. Mater. 2017, 29, 1604792. [Google Scholar] [CrossRef]

- Wang, D.H.; McKenzie, R.N.; Buskohl, P.R.; Vaia, R.A.; Tan, L.S. Hygromorphic Polymers: Synthesis, Retro-Michael Reaction, and Humidity-Driven Actuation of Ester-Sulfonyl Polyimides and Thermally Derived Copolyimides. Macromolecules 2016, 49, 3286–3299. [Google Scholar] [CrossRef]

- Ma, B.; Ma, J.-N.; Song, P.; Wang, K.; Zhang, D.-M.; Li, Q.; Zhang, Q.; Sang, S.-B. Quantum-Confined-Superfluidics-Enabled Multiresponsive MXene-Based Actuators. ACS Appl. Mater. Interfaces 2024, 16, 15215–15226. [Google Scholar] [CrossRef]

- Pan, B.; Su, P.; Jin, M.; Huang, X.; Wang, Z.; Zhang, R.; Xu, H.; Liu, W.; Ye, Y. Ultrathin Hierarchical Hydrogel–carbon Nanocomposite for Highly Stretchable Fast-response Water-Proof Wearable Humidity Sensors. Mater. Horiz. 2023, 10, 5263–5276. [Google Scholar] [CrossRef]

- Ge, Y.; Zeng, J.; Hu, B.; Yang, D.-Y.; Shao, Y.; Lu, H. Bioinspired Flexible Film as Intelligent Moisture-Responsive Actuators and Noncontact Sensors. Giant 2022, 11, 100107. [Google Scholar] [CrossRef]

- Yang, L.; Cui, J.; Zhang, L.; Xu, X.; Chen, X.; Sun, D. A Moisture-Driven Actuator Based on Polydopamine-Modified MXene/Bacterial Cellulose Nanofiber Composite Film. Adv. Funct. Mater. 2021, 31, 2101378. [Google Scholar] [CrossRef]

- Wang, S.; Gao, Y.; Wei, A.; Xiao, P.; Liang, Y.; Lu, W.; Chen, C.; Zhang, C.; Yang, G.; Yao, H.; et al. Asymmetric Elastoplasticity of Stacked Graphene Assembly Actualizes Programmable Untethered Soft Robotics. Nat. Commun. 2020, 11, 4359. [Google Scholar] [CrossRef] [PubMed]

- Wang, M.; Li, Q.; Shi, J.; Cao, X.; Min, L.; Li, X.; Zhu, L.; Lv, Y.; Qin, Z.; Chen, X.; et al. Bio-Inspired High Sensitivity of Moisture-Mechanical GO Films with Period-Gradient Structures. ACS Appl. Mater. Interfaces 2020, 12, 33104–33112. [Google Scholar] [CrossRef]

- Zhang, L.; Zhang, Y.; Li, F.; Yan, S.; Wang, Z.; Fan, L.; Zhang, G.; Li, H. Water-Evaporation-Powered Fast Actuators with Multimodal Motion Based on Robust Nacre-Mimetic Composite Film. ACS Appl. Mater. Interfaces 2019, 11, 12890–12897. [Google Scholar] [CrossRef] [PubMed]

- Li, H.; Wang, J. Ultrafast yet Controllable Dual-Responsive All-Carbon Actuators for Implementing Unusual Mechanical Movements. ACS Appl. Mater. Interfaces 2019, 11, 10218–10225. [Google Scholar] [CrossRef] [PubMed]

- He, S.S.; Chen, P.N.; Qiu, L.B.; Wang, B.J.; Sun, X.M.; Xu, Y.F.; Peng, H.S. A Mechanically Actuating Carbon-Nanotube Fiber in Response to Water and Moisture. Angew. Chem. Int. Ed. 2015, 54, 14880–14884. [Google Scholar] [CrossRef]

- Cheng, H.H.; Liu, J.; Zhao, Y.; Hu, C.G.; Zhang, Z.P.; Chen, N.; Jiang, L.; Qu, L.T. Graphene Fibers with Predetermined Deformation as Moisture-Triggered Actuators and Robots. Angew. Chem. Int. Ed. 2013, 52, 10482–10486. [Google Scholar] [CrossRef]

- Arazoe, H.; Miyajima, D.; Akaike, K.; Araoka, F.; Sato, E.; Hikima, T.; Kawamoto, M.; Aida, T. An Autonomous Actuator Driven by Fluctuations in Ambient Humidity. Nat. Mater. 2016, 15, 1084. [Google Scholar] [CrossRef]

- Wang, J.; Liu, Y.; Cheng, Z.; Xie, Z.; Yin, L.; Wang, W.; Song, Y.; Zhang, H.; Wang, Y.; Fan, Z. Highly Conductive MXene Film Actuator Based on Moisture Gradients. Angew. Chem. Int. Ed. 2020, 59, 14029–14033. [Google Scholar] [CrossRef]

- He, J.; Xiao, P.; Zhang, J.W.; Liu, Z.Z.; Wang, W.Q.; Qu, L.T.; Ouyang, Q.; Wang, X.F.; Chen, Y.S.; Chen, T. Highly Efficient Actuator of Graphene/Polydopamine Uniform Composite Thin Film Driven by Moisture Gradients. Adv. Mater. Interfaces 2016, 3, 1600169. [Google Scholar] [CrossRef]

- She, P.; Qin, Y.; Wang, X.; Zhang, Q. Recent Progress in External-Stimulus-Responsive 2D Covalent Organic Frameworks. Adv. Mater. 2021, 34, 2101175. [Google Scholar] [CrossRef]

- Jin, F.; Liu, J.; Chen, Y.; Zhang, Z. Tethering Flexible Polymers to Crystalline Porous Materials: A Win–Win Hybridization Approach. Angew. Chem. Int. Ed. 2021, 60, 14222–14235. [Google Scholar] [CrossRef] [PubMed]

- Liu, Z.; Wang, Z.; Wang, S.-Q.; Li, J.; Chen, Y.; Cheng, P.; Zaworotko, M.J.; Zhang, Z. Porous Organic Cage with Water Vapor-Triggered Structural Transition for Actuation Applications. ACS Mater. Lett 2023, 5, 2139–2147. [Google Scholar] [CrossRef]

- Kim, H.; Yang, S.; Rao, S.R.; Narayanan, S.; Kapustin, E.A.; Furukawa, H.; Umans, A.S.; Yaghi, O.M.; Wang, E.N. Water Harvesting from Air with Metal-Organic Frameworks Powered by Natural Sunlight. Science 2017, 356, 430–434. [Google Scholar] [CrossRef]

- Nguyen, H.L.; Gropp, C.; Hanikel, N.; Möckel, A.; Lund, A.; Yaghi, O.M. Hydrazine-Hydrazide-Linked Covalent Organic Frameworks for Water Harvesting. ACS Cent. Sci. 2022, 8, 926–932. [Google Scholar] [CrossRef]

- Hanikel, N.; Kurandina, D.; Chheda, S.; Zheng, Z.; Rong, Z.; Neumann, S.E.; Sauer, J.; Siepmann, J.I.; Gagliardi, L.; Yaghi, O.M. MOF Linker Extension Strategy for Enhanced Atmospheric Water Harvesting. ACS Cent. Sci. 2023, 9, 551–557. [Google Scholar] [CrossRef]

- Zhang, F.L.; Fan, J.B.; Zhang, P.C.; Liu, M.J.; Meng, J.X.; Jiang, L.; Wang, S. A Monolithic Hydro/organo Macro Copolymer Actuator Synthesized via Interfacial Copolymerization. Npg Asia Mater. 2017, 9, e380. [Google Scholar] [CrossRef]

- Liu, Y.Q.; Ma, J.N.; Liu, Y.; Han, D.D.; Jiang, H.B.; Mao, J.W.; Han, C.H.; Jiao, Z.Z.; Zhang, Y.L. Facile Fabrication of Moisture Responsive Graphene Actuators by Moderate Flash Reduction of Graphene Oxides Films. Opt. Mater. Express. 2017, 7, 2617–2625. [Google Scholar] [CrossRef]

- Chen, M.L.; Frueh, J.; Wang, D.L.; Lin, X.K.; Xie, H.; He, Q. Polybenzoxazole Nanofiber-Reinforced Moisture-Responsive Soft Actuators. Sci. Rep. 2017, 7, 769. [Google Scholar] [CrossRef]

- Zhao, F.; Liang, Y.; Cheng, H.H.; Jiang, L.; Qu, L.T. Highly Efficient Moisture-enabled Electricity Generation from Graphene Oxide Frameworks. Energ. Environ. Sci. 2016, 9, 912–916. [Google Scholar] [CrossRef]

- Zhang, D.; Liu, J.; Chen, B.; Wang, J.; Jiang, L. Research Progress of Solvent-based Smart Actuator Materials. Acta. Chimica. Sin. 2018, 76, 425–435. [Google Scholar] [CrossRef]

- Jia, T.; Wang, Y.; Dou, Y.; Li, Y.; Jung de Andrade, M.; Wang, R.; Fang, S.; Li, J.; Yu, Z.; Qiao, R.; et al. Moisture Sensitive Smart Yarns and Textiles from Self-Balanced Silk Fiber Muscles. Adv. Funct. Mater. 2019, 29, 1808241. [Google Scholar] [CrossRef]

- Liu, W.; Yang, X.; Yan, G.; Wang, L.; Lai, J.; Li, Z.; Zhao, C.; Xiang, D.; Li, H.; Wu, Y. Super-Flexible Water-Proof Actuators. Small 2024, 20, 2400482. [Google Scholar] [CrossRef] [PubMed]

- Li, X.; Li, J.; Zhao, Y.; Zhai, W.; Wang, S.; Zhang, Y.; Dai, K.; Liu, C.; Shen, C. Multi-stimuli-responsive Ti3C2TX MXene-based Actuators Actualizing Intelligent Interpretation of Traditional Shadow Play. Carbon 2024, 218, 118652. [Google Scholar] [CrossRef]

- Liu, L.; Jiang, S.H.; Sun, Y.; Agarwal, S. Giving Direction to Motion and Surface with Ultra-Fast Speed Using Oriented Hydrogel Fibers. Adv. Funct. Mater. 2016, 26, 1021–1027. [Google Scholar] [CrossRef]

- Ji, M.Y.; Jiang, N.; Chang, J.; Sun, J.Q. Near-Infrared Light-Driven, Highly Efficient Bilayer Actuators Based on Polydopamine-Modified Reduced Graphene Oxide. Adv. Funct. Mater. 2014, 24, 5412–5419. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, D.; Ding, J.; Zhou, Y.; Ju, J. Research Progress on Moisture-Sorption Actuators Materials. Nanomaterials 2024, 14, 1544. https://doi.org/10.3390/nano14191544

Zhang D, Ding J, Zhou Y, Ju J. Research Progress on Moisture-Sorption Actuators Materials. Nanomaterials. 2024; 14(19):1544. https://doi.org/10.3390/nano14191544

Chicago/Turabian StyleZhang, Dajie, Jia Ding, Yulin Zhou, and Jie Ju. 2024. "Research Progress on Moisture-Sorption Actuators Materials" Nanomaterials 14, no. 19: 1544. https://doi.org/10.3390/nano14191544