Preparation and Performance of a Cr/CrN/TiAlCN Composite Coating on a GCr15 Bearing Steel Surface

Abstract

:1. Introduction

2. Materials and Methods

2.1. Coating Preparation

2.2. Characterization of the Coating Structure

2.3. Characterization of the Coatings’ Mechanical Properties

2.4. Friction and Wear Experiments

3. Results and Discussion

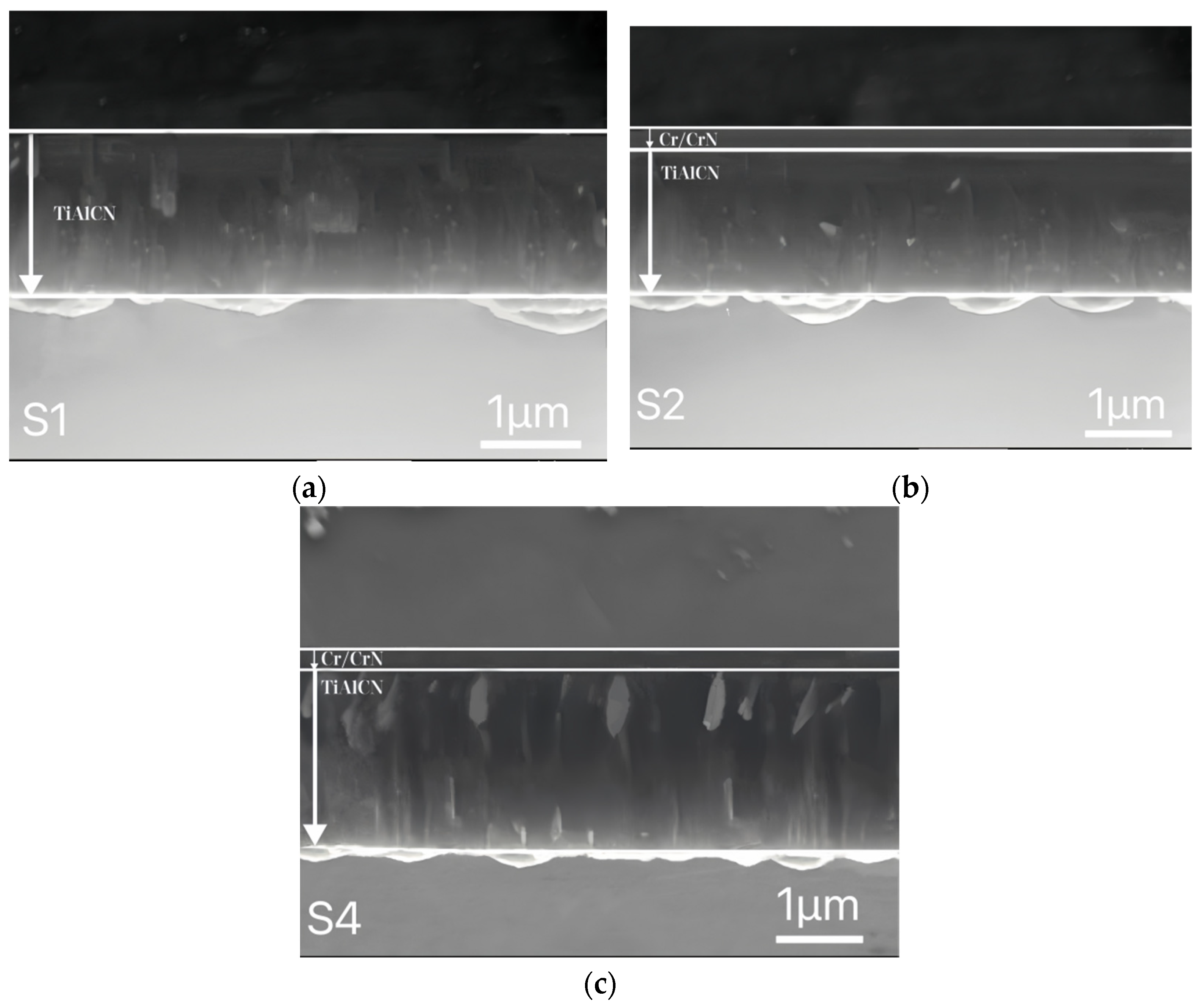

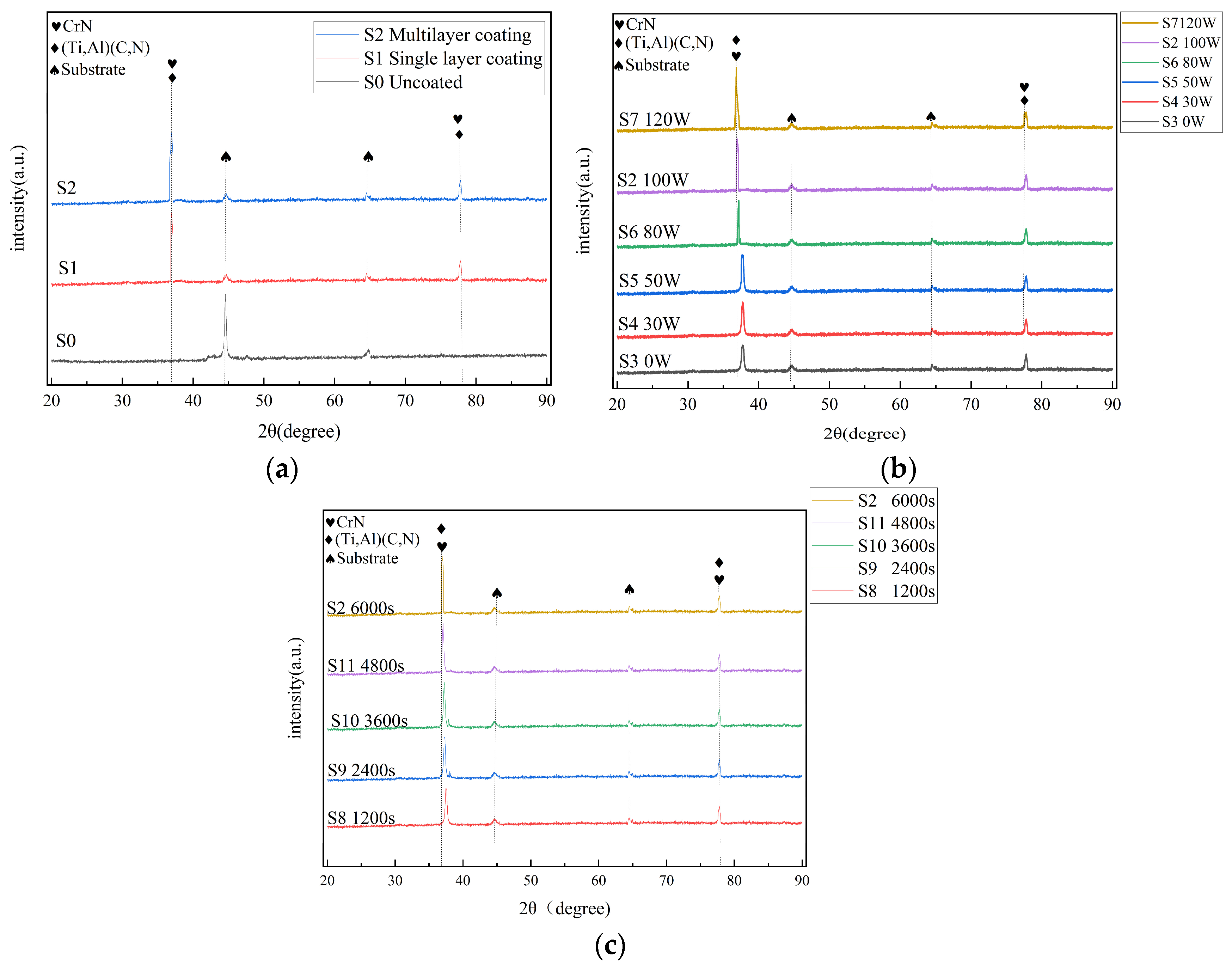

3.1. Morphology and Structure of the Coatings

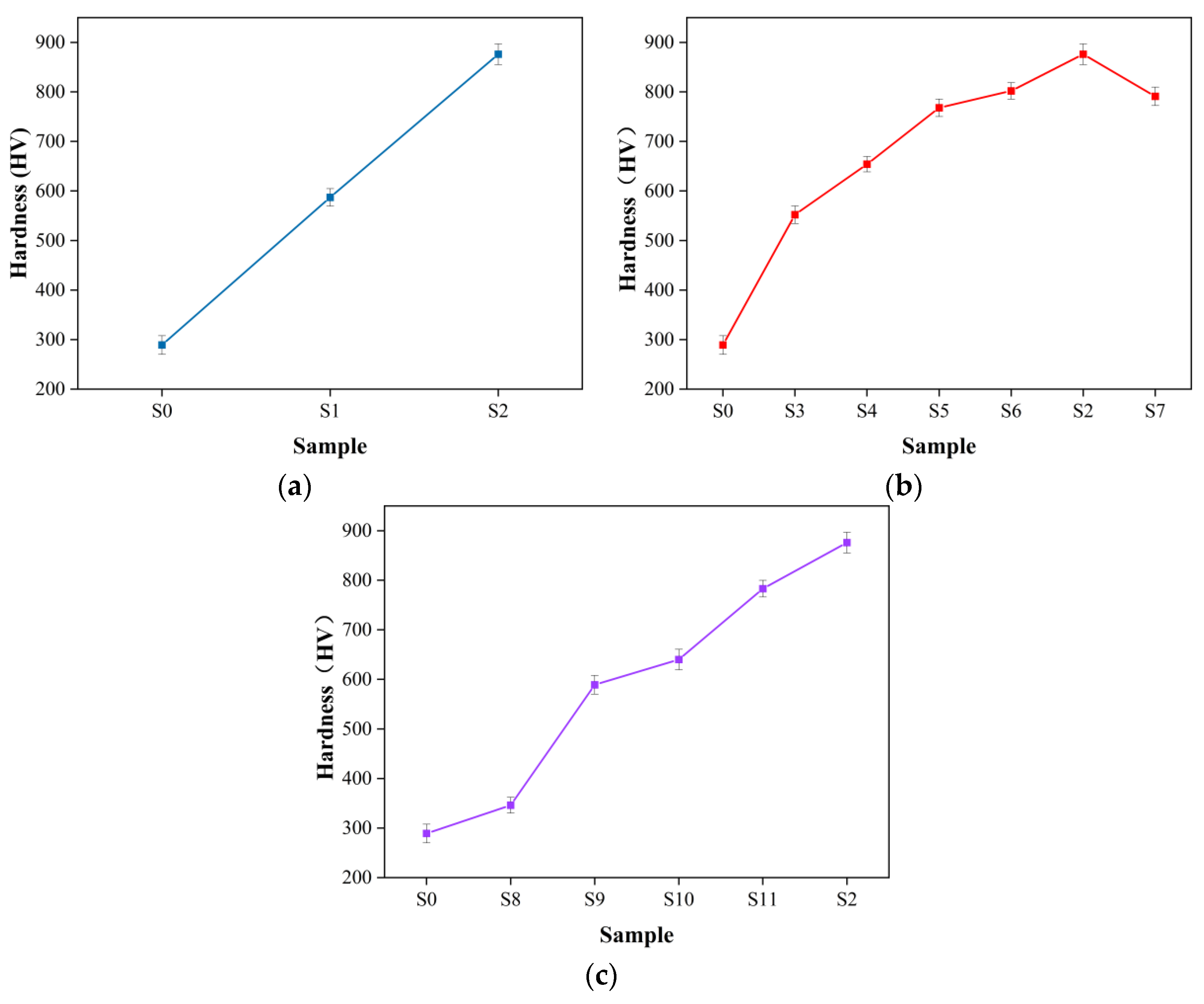

3.2. Mechanical Properties of the Coatings

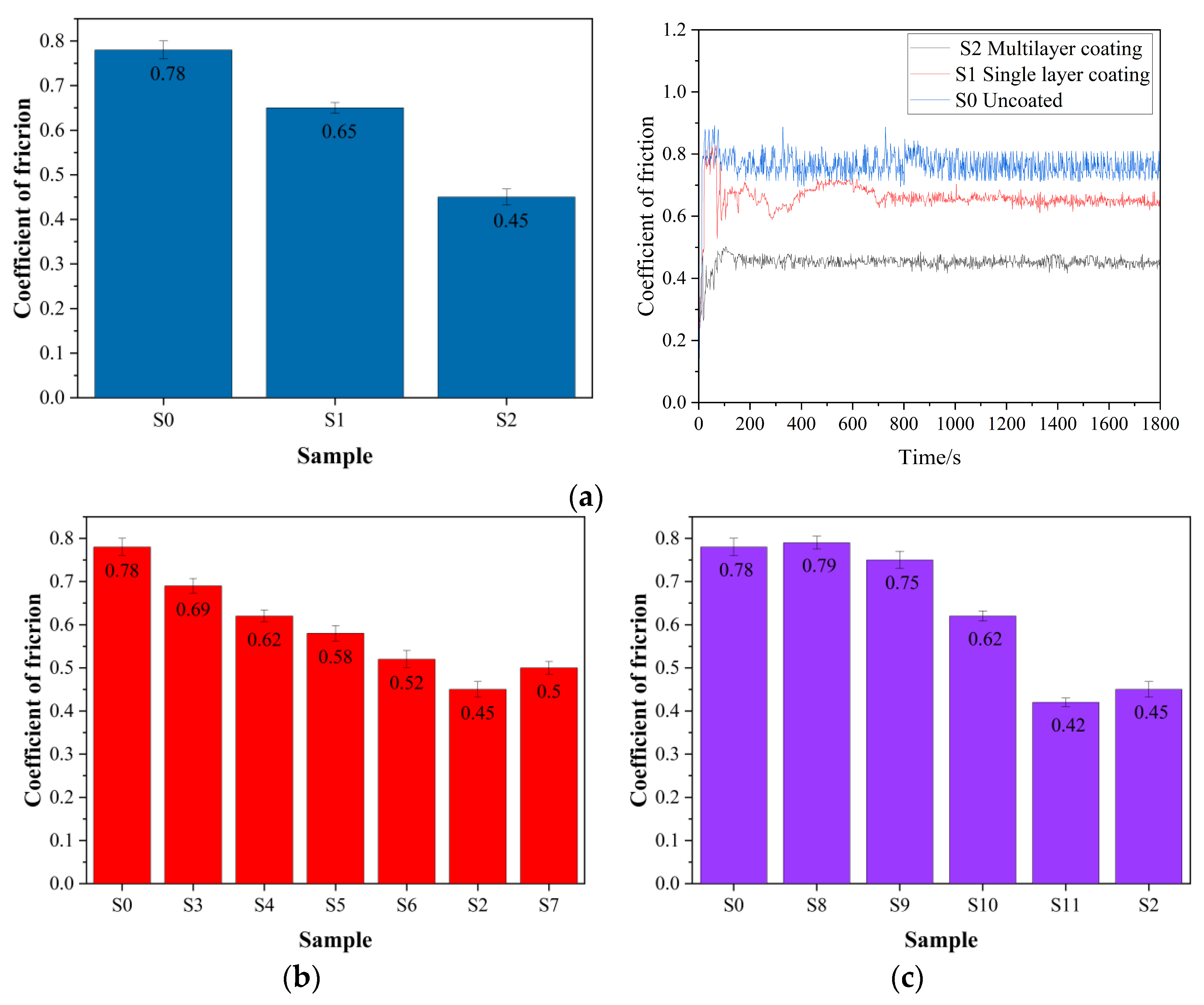

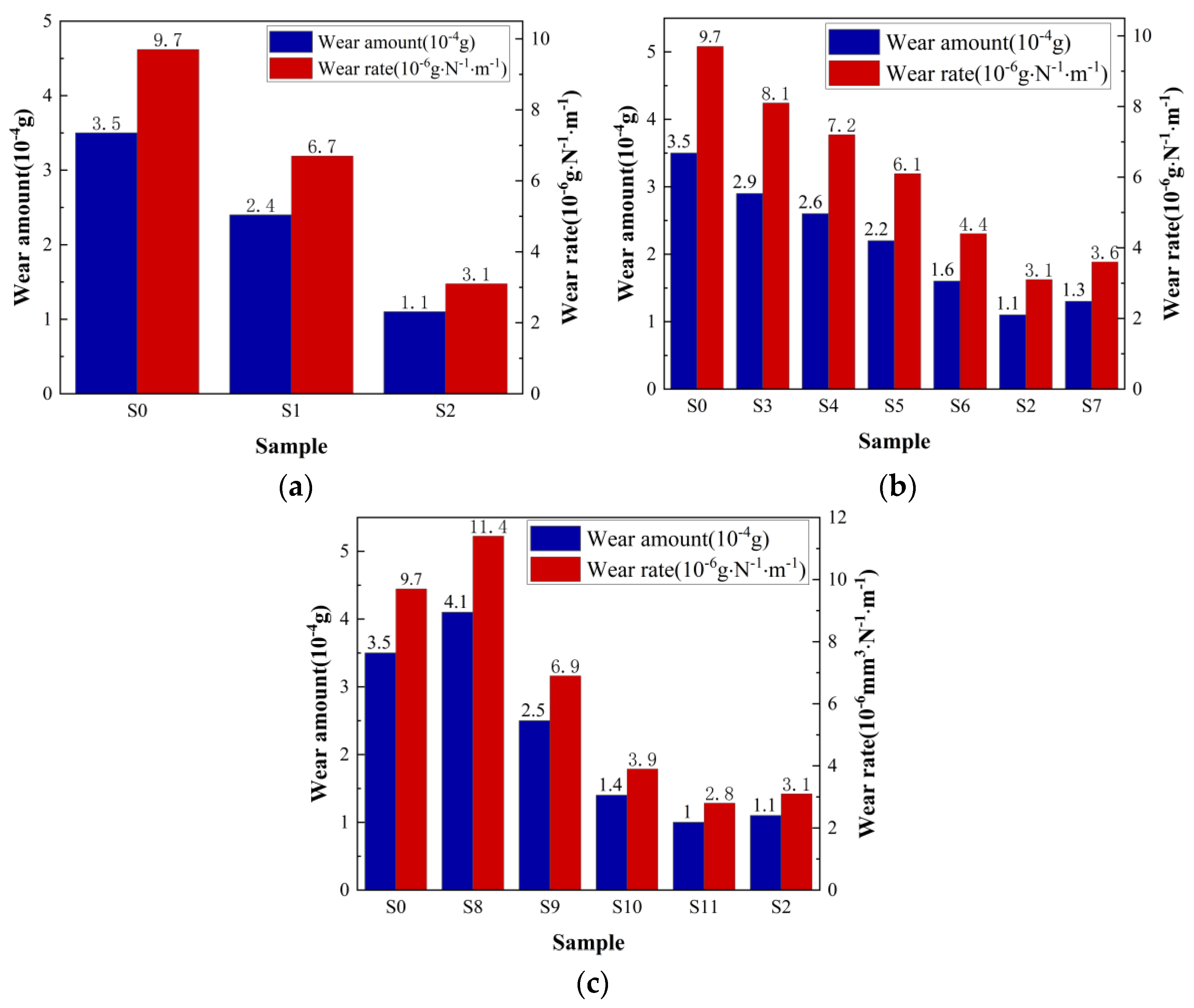

3.3. Friction and Wear Performance of the Coatings

4. Conclusions

- (1)

- This study innovatively added Cr/CrN as a transition layer in GCr15 bearing steel and TiAlCN to provide a buffering effect between the substrate and the coating, significantly improving the coating performance.

- (2)

- When the graphite target power was 0, the TiAlN coating showed a clear columnar crystal structure. After adding carbon atoms, the columnar crystal structure was weakened, and carbon atoms replaced nitrogen atoms, enhancing the mechanical and friction wear properties of the coating.

- (3)

- As the coating time increased, the roughness of the coating continuously changed, and the bonding performance and hardness continued to improve. The friction coefficient and wear parameters showed a trend of first decreasing and then increasing.

- (4)

- The optimal process parameters were a graphite target sputtering power of 100 W and a coating time of 4800 s. Compared with the uncoated GCr15 bearing steel, the coating hardness increased by two times after coating, the friction coefficient decreased by 0.36, the wear amount decreased by 2.5 × 10−4 g, and the wear rate decreased by 71%.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhang, F.; Yang, Z. Development of and Perspective on High-Performance Nanostructured Bainitic Bearing Steel. Engineering 2019, 5, 319–328. [Google Scholar] [CrossRef]

- Peng, B.; Bi, Y.; Xue, B.; Zhang, M.; Wan, S. A Survey on Fault Diagnosis of Rolling Bearings. Algorithms 2022, 15, 347. [Google Scholar] [CrossRef]

- You, S.; Yi, X.; Yang, Q. Surface Modification and Reproduction—A New On-line Micro-remanufacturing Technology. In Proceedings of the Remanufacturing International Forum 2012, Beijing, China, 2 September 2012. [Google Scholar]

- Liu, X.-L.; Lin, Z.; Zhao, H.-J.; Sun, F. Study on Microstructure, Mechanical Properties, Tribological Properties and Service Performance of CrAlN and CrAlBN Coatings Deposited on Powder Metallurgy High-Speed Steel (PM-HSS) and Shaper Cutter by Arc Ion Plating Technique. Coatings 2024, 14, 486. [Google Scholar] [CrossRef]

- Biava, G.; de Araujo Fernandes Siqueira, I.B.; Vaz, R.F.; de Souza, G.B.; Jambo, H.C.M.; Szogyenyi, A.; Pukasiewicz, A.G.M. Evaluation of high temperature corrosion resistance of CrN, AlCrN, and TiAlN arc evaporation PVD coatings deposited on Waspaloy. Surf. Coat. Technol. 2022, 438, 128398. [Google Scholar] [CrossRef]

- Bilgin, S.; Güler, O.; Alver, Ü.; Erdemir, F.; Aslan, M. Effect of TiN, TiAlCN, AlCrN, and AlTiN ceramic coatings on corrosion behavior of tungsten carbide tool. J. Aust. Ceram. Soc. 2021, 57, 263–273. [Google Scholar] [CrossRef]

- Gopi, R.; Saravanan, I.; Devaraju, A.; Sivasamy, P. A Review on Recent Progress in PVD-TiN Coatings. Diffus. Found. Mater. Appl. 2023, 34, 41–53. [Google Scholar] [CrossRef]

- Zhao, J.; Liu, Z.; Wang, B.; Song, Q.; Ren, X.; Wan, Y. Effects of Al content in TiAlN coatings on tool wear and cutting temperature during dry machining IN718. Tribol. Int. 2022, 171, 107540. [Google Scholar] [CrossRef]

- Zhou, B.; Wang, Y.; Liu, Z.; Zhi, J.; Sun, H.; Wang, Y.; Wu, Y.; Hei, H.; Yu, S. Effect of modulation ratio on microstructure and tribological properties of TiAlN/TiAlCN multilayer coatings prepared by multi-excitation source plasma. Vacuum 2023, 211, 111917. [Google Scholar] [CrossRef]

- Wang, L.; Jiang, W.; Yang, Z.; Wang, X.; Lu, Y.; Lv, W. Joining mechanism between Al2O3–Ag–Cu–Ti composite coating and GCr15 substrate. Surf. Coat. Technol. 2013, 223, 98–103. [Google Scholar] [CrossRef]

- Liu, K.; Ma, F.; Lou, M.; Dong, M.; Zhu, Y.; Wang, Y.; Wu, X.; Liu, X.; Li, J. Structure and tribocorrosion behavior of TiAlCN coatings with different Al contents in artificial seawater by multi-arc ion plating. Surf. Topogr. Metrol. Prop. 2021, 9, 045004. [Google Scholar] [CrossRef]

- Chen, S.N.; Zhao, Y.M.; Zhang, Y.F.; Chen, L.; Liao, B.; Zhang, X.; Ouyang, X.P. Influence of carbon content on the structure and tribocorrosion properties of TiAlCN/TiAlN/TiAl multilayer composite coatings. Surf. Coat. Technol. 2021, 411, 126886. [Google Scholar]

- Zhang, G.-P.; Wang, X.-Q.; Lü, G.-H.; Zhou, L.; Huang, J.; Chen, W.; Yang, S.-Z. Effect of pulsed bias on the properties of ZrN/TiZrN films deposited by a cathodic vacuum arc. Chin. Phys. B 2013, 22, 035204. [Google Scholar] [CrossRef]

- Movassagh-Alanagh, F.; Mahdavi, M. Improving wear and corrosion resistance of AISI 304 stainless steel by a multilayered nanocomposite Ti/TiN/TiSiN coating. Surf. Interfaces 2020, 18, 100428. [Google Scholar] [CrossRef]

- Šnajdar, M.; Ćorić, D.; Sakoman, M. Comparative Study of Multilayer Hard Coatings Deposited on WC-Co Hardmetals. Coatings 2024, 14, 674. [Google Scholar] [CrossRef]

- Mori, T.; Noborisaka, M.; Watanabe, T.; Suzuki, T. Oxidation resistance and hardness of TiAlSiN/CrAlYN multilayer films deposited by the arc ion plating method. Surf. Coat. Technol. 2012, 213, 216–220. [Google Scholar] [CrossRef]

- Ghorbani, A.; Elmkhah, H.; Imantalab, O.; Meghdari, M.; Nouri, M.; Fattah-Alhosseini, A. The impact of mechanical post-treatment on the tribological and corrosion behavior of CrN/CrAlN coatings applied using the CAE-PVD technique. Appl. Surf. Sci. Adv. 2023, 18, 100477. [Google Scholar]

- Ali, L.A.; Dikici, B.; Aslan, N.; Yilmazer, Y.; Sen, A.; Yilmazer, H.; Niinomi, M. In-vitro corrosion and surface properties of PVD-coated β-type TNTZ alloys for potential usage as biomaterials: Investigating the hardness, adhesion, and antibacterial properties of TiN, ZrN, and CrN film. Surf. Coat. Technol. 2023, 466, 129624. [Google Scholar]

- Ramos, A.S.; Simões, S.; Maj, L.; Morgiel, J.; Vieira, M.T. Effect of Deposition Parameters on the Reactivity of Al/Ni Multilayer Thin Films. Coatings 2020, 10, 721. [Google Scholar] [CrossRef]

- Huang, Y.Z.; Stueber, M.; Hovsepian, P. The significance of carbon on the microstructure of TiAlN-C coatings deposited by reactive magnetron sputtering. Appl. Surf. Sci. 2006, 253, 2470–2473. [Google Scholar] [CrossRef]

- Harani, S.G.; Sumitra, S. Magnetron Sputtered Thin Films Based on Transition Metal Nitride: Structure and Properties. Phys. Status Solidi 2022, 220, 2200229. [Google Scholar]

- Sin, N.D.M.; Mamat, M.H.; Rusop, M. Effect of Deposition Time on Properties of Nanostructured ZnO Thin Films Deposited by RF Magnetron Sputtering. Adv. Mater. Res. 2013, 832, 460–465. [Google Scholar] [CrossRef]

- Ma, D.; Deng, Q.; Liu, H.; Leng, Y. Effect of Ion Energy on the Microstructure and Properties of Titanium Nitride Thin Films Deposited by High Power Pulsed Magnetron Sputtering. Coatings 2021, 11, 579. [Google Scholar] [CrossRef]

| Element | Cr | C | Mn | Si | P | S |

|---|---|---|---|---|---|---|

| Content (wt.%) | 1.30–1.65 | 0.95–1.05 | 0.20–0.40 | 0.15–0.35 | ≤0.027 | ≤0.020 |

| Process Parameters | |||

|---|---|---|---|

| Coating | Cr | CrN | TiAlCN |

| Background vacuum degree (GPa) | 8 × 10−4 | 8 × 10−4 | 8 × 10−4 |

| Working air pressure (Pa) | 1 | 1 | 1 |

| Coating power (W) | Cr:100 | Cr:100 | TiAl: 110 Graphite: 0–120 |

| Coating time (s) | 300 | 600 | 1200, 2400, 3600, 4800, 6000 |

| Ar2 flow (sccm) | 90 | 60 | 60 |

| N2 flow (sccm) | 0 | 50 | 50 |

| Sample | Graphite Target Power (W) | Coating Time (s) | Number of Layers |

|---|---|---|---|

| S0 | 0 | 0 | 0 |

| S1 | 100 | 6000 | 1 |

| S2 | 100 | 6000 | 3 |

| S3 | 0 | 6000 | 3 |

| S4 | 30 | 6000 | 3 |

| S5 | 50 | 6000 | 3 |

| S6 | 80 | 6000 | 3 |

| S7 | 120 | 6000 | 3 |

| S8 | 100 | 1200 | 3 |

| S9 | 100 | 2400 | 3 |

| S10 | 100 | 3600 | 3 |

| S11 | 100 | 4800 | 3 |

| Sample | Cr/at.% | Ti/at.% | Al/at.% | C/at.% | N/at.% |

|---|---|---|---|---|---|

| S1 | 0 | 18.04 | 21.73 | 12.03 | 48.20 |

| S2 | 14.86 | 15.30 | 19.38 | 11.37 | 39.09 |

| S3 | 17.32 | 17.61 | 21.74 | 0 | 45.33 |

| S4 | 16.95 | 18.37 | 19.09 | 4.85 | 42.74 |

| S5 | 15.59 | 15.01 | 20.52 | 6.97 | 41.91 |

| S6 | 14.53 | 16.31 | 19.94 | 9.76 | 39.46 |

| S7 | 15.20 | 13.86 | 17.09 | 13.03 | 38.82 |

| S8 | 32.83 | 5.27 | 7.28 | 8.25 | 46.37 |

| S9 | 25.46 | 7.09 | 9.93 | 9.93 | 47.59 |

| S10 | 21.09 | 9.91 | 12.17 | 9.02 | 47.89 |

| S11 | 17.26 | 12.93 | 13.88 | 10.16 | 45.77 |

| Sample | m1 (g) | m2 (g) | M (10−4 g) | L (m) | S (N) | W (10−6 g/N.m) | Average Coefficient of Friction |

|---|---|---|---|---|---|---|---|

| S0 | 36.08332 | 36.08297 | 3.5 | 36 | 1 | 9.7 | 0.78 |

| S1 | 36.18471 | 36.18447 | 2.4 | 36 | 1 | 6.7 | 0.65 |

| S2 | 36.17425 | 36.17414 | 1.1 | 36 | 1 | 3.1 | 0.45 |

| S3 | 36.16532 | 36.16503 | 2.9 | 36 | 1 | 8.1 | 0.69 |

| S4 | 36.17406 | 36.17380 | 2.6 | 36 | 1 | 7.2 | 0.62 |

| S5 | 36.17517 | 36.17495 | 2.2 | 36 | 1 | 6.1 | 0.58 |

| S6 | 36.05428 | 36.17495 | 1.6 | 36 | 1 | 4.4 | 0.52 |

| S7 | 36.15085 | 36.15072 | 1.3 | 36 | 1 | 3.6 | 0.5 |

| S8 | 36.23594 | 36.23543 | 4.1 | 36 | 1 | 11.4 | 0.79 |

| S9 | 36.20076 | 36.20051 | 2.5 | 36 | 1 | 6.9 | 0.75 |

| S10 | 36.17523 | 36.17509 | 1.4 | 36 | 1 | 3.9 | 0.62 |

| S11 | 36.15367 | 36.15357 | 1.0 | 36 | 1 | 2.8 | 0.42 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yan, N.; Zhu, Z.; Cheng, Y.; Liu, F.; Shen, M.; Li, H. Preparation and Performance of a Cr/CrN/TiAlCN Composite Coating on a GCr15 Bearing Steel Surface. Coatings 2024, 14, 782. https://doi.org/10.3390/coatings14070782

Yan N, Zhu Z, Cheng Y, Liu F, Shen M, Li H. Preparation and Performance of a Cr/CrN/TiAlCN Composite Coating on a GCr15 Bearing Steel Surface. Coatings. 2024; 14(7):782. https://doi.org/10.3390/coatings14070782

Chicago/Turabian StyleYan, Nu, Ziyun Zhu, Yuchuan Cheng, Fang Liu, Min Shen, and Hongjun Li. 2024. "Preparation and Performance of a Cr/CrN/TiAlCN Composite Coating on a GCr15 Bearing Steel Surface" Coatings 14, no. 7: 782. https://doi.org/10.3390/coatings14070782