High-Performance and Broad-Viewing-Angle Structural Colored Films with Carbon Black and Carbon Quantum Dot Doping

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of High-Performance Photonic Crystals

2.3. Preparation of the High-Brightness Photonic Crystal Hydrogel Sensor

2.4. Characterization

3. Results

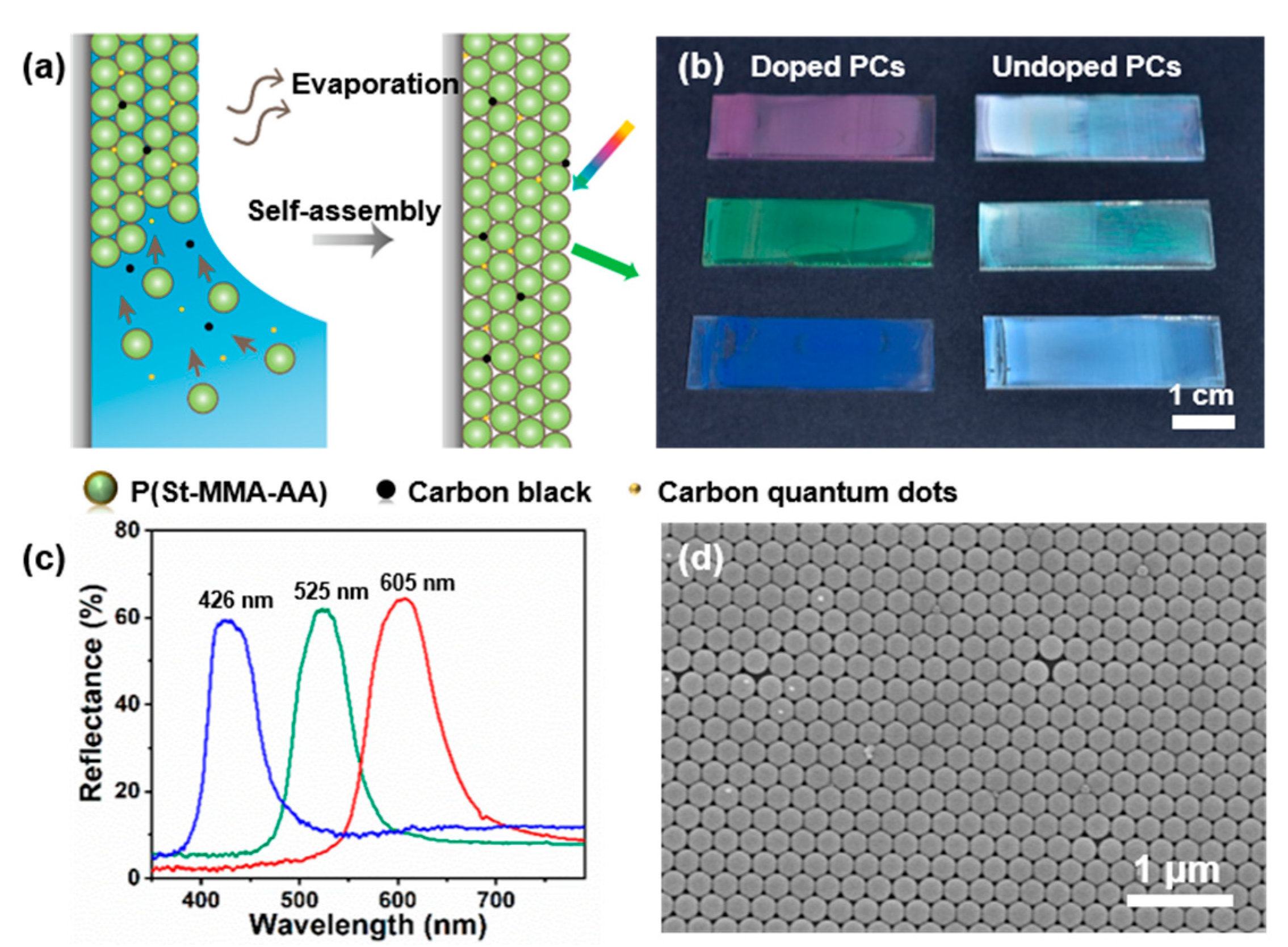

3.1. The High Optical Performance of Photonic Crystal Film Doped with CB and CQDs

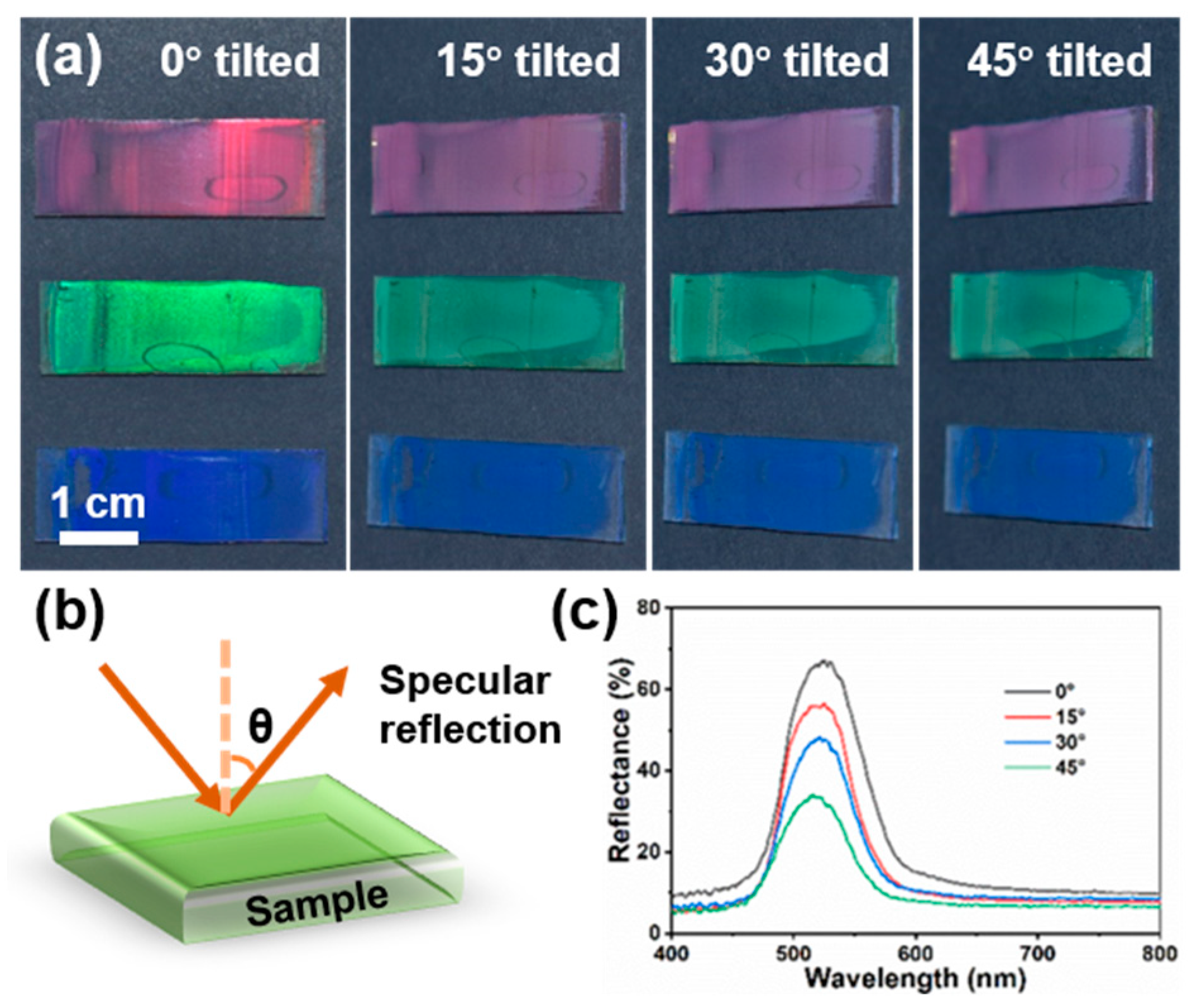

3.2. Non-Iridescent Structural Colors of Doped Photonic Crystal Films

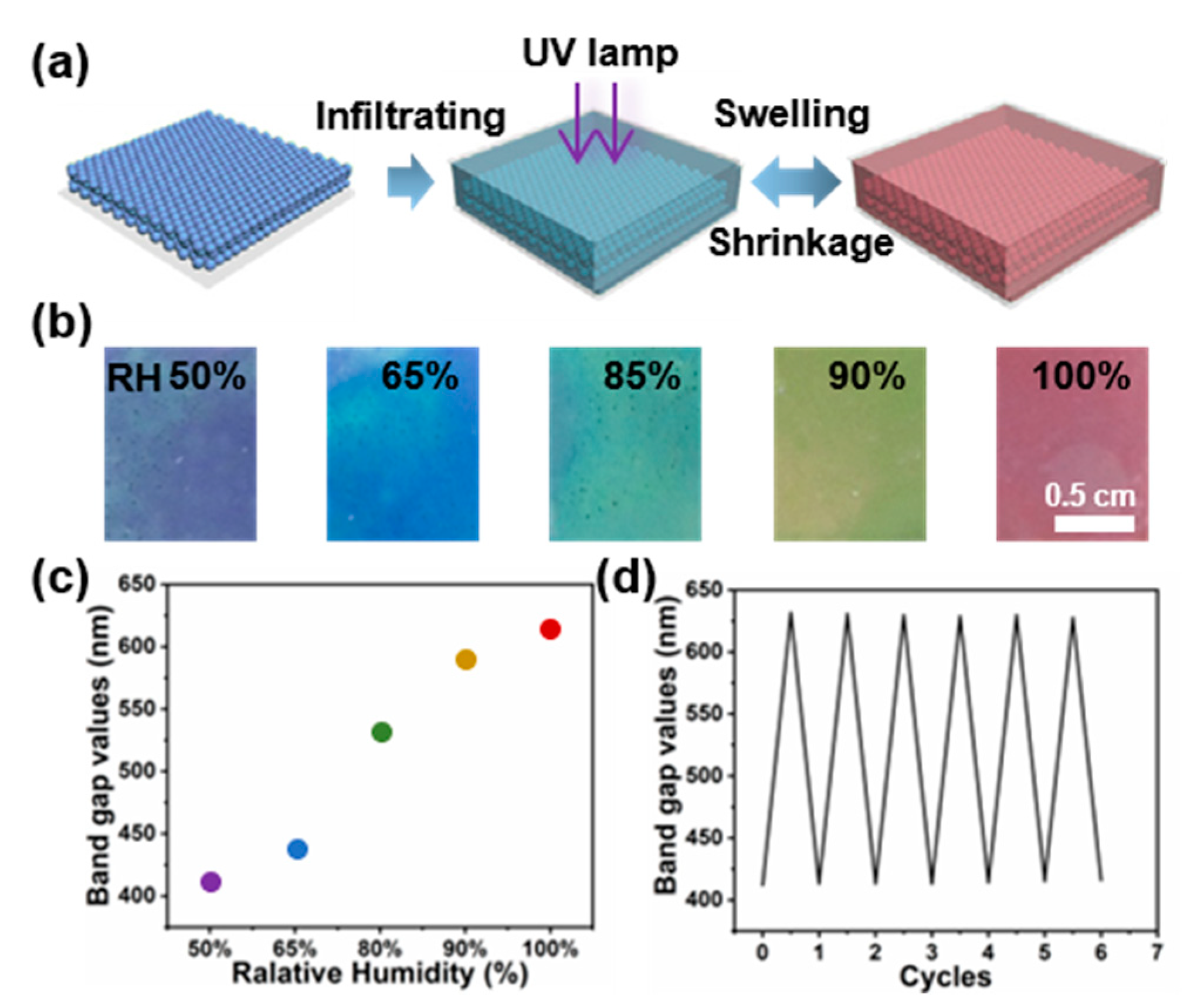

3.3. High Optical Performance of Doped Photonic Crystal Hydrogel Humidity Sensors

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Chen, F.; Huang, Y.; Li, R.; Zhang, S.; Wang, B.; Zhang, W.; Wu, X.; Jiang, Q.; Wang, F.; Zhang, R. Bio-inspired structural colors and their applications. Chem. Commun. 2021, 57, 13448–13464. [Google Scholar] [CrossRef] [PubMed]

- Feng, L.; Wang, F.; Luo, H.; Qiu, B. Review of recent advancements in the biomimicry of structural colors. Dyes Pigment. 2023, 210, 111019. [Google Scholar] [CrossRef]

- Shang, L.; Zhang, W.; Xu, K.; Zhao, Y. Bio-inspired intelligent structural color materials. Mater. Horiz. 2019, 6, 945–958. [Google Scholar] [CrossRef]

- Shi, L.; Zhang, Y.; Dong, B.; Zhan, T.; Liu, X.; Zi, J. Amorphous photonic crystals with only short-range order. Adv. Mater. 2013, 25, 5314–5320. [Google Scholar] [CrossRef] [PubMed]

- Wei, B.; Zhang, D.; Ma, D.; Qi, C.; Yang, D.; Fu, Q.; Huang, S. Thermochromic structural color based on pressure storage-release toward emerging applications. Chem. Eng. J. 2024, 497, 154637. [Google Scholar] [CrossRef]

- Chen, H.; Wei, J.; Pan, F.; Yuan, T.; Fang, Y.; Wang, Q. Advances in photonic crystal research for structural color. Adv. Mater. Technol. 2024, 2400865. [Google Scholar] [CrossRef]

- Yoon, J.; Jung, C.; Kim, J.; Rho, J.; Lee, H. Chemically and geometrically programmable photoreactive polymers for transformational humidity-sensitive full-color devices. Nat. Commun. 2024, 15, 6470. [Google Scholar] [CrossRef] [PubMed]

- Geng, J.; Xu, L.; Yan, W.; Shi, L.; Qiu, M. High-speed laser writing of structural colors for full-color inkless printing. Nat. Commun. 2023, 14, 565. [Google Scholar] [CrossRef] [PubMed]

- Han, P.; He, X.; Zhang, Y.; Zhou, H.; Liu, M.; Wu, N.; Jiang, J.; Wei, Y.; Yao, X.; Zhou, J.; et al. Cascade-microphase-separation-induced hierarchical photonic structures in supramolecular organogel for deformation-insensitive structural colors. Adv. Opt. Mater. 2019, 7, 1801749. [Google Scholar] [CrossRef]

- Ren, J.; Wu, Y.; Han, Y.; Zhang, S.; Wu, S. Noniridescent and robust structural-colored coating for automotives based on the Mie scattering of ZnO spheres. Ind. Eng. Chem. Res. 2022, 61, 18772–18779. [Google Scholar] [CrossRef]

- Potyrailo, R.; Ghiradella, H.; Vertiatchikh, A.; Dovidenko, K.; Cournoyer, J.; Olson, E. Morpho butterfly wing scales demonstrate highly selective vapour response. Nat. Photonics 2007, 1, 123–128. [Google Scholar] [CrossRef]

- Li, Q.; Zhang, Y.; Shi, L.; Qiu, H.; Zhang, S.; Qi, N.; Hu, J.; Yuan, W.; Zhang, X.; Zhang, K. Additive mixing and conformal coating of noniridescent structural colors with robust mechanical properties fabricated by atomization deposition. ACS Nano 2018, 12, 3095–3102. [Google Scholar] [CrossRef] [PubMed]

- Takeoka, Y.; Yoshioka, S.; Takano, A.; Arai, S.; Nueangnoraj, K.; Nishihara, H.; Teshima, M.; Ohtsuka, Y.; Seki, T. Production of colored pigments with amorphous arrays of black and white colloidal particles. Angew. Chem. Int. Ed. 2013, 52, 7261–7265. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.; Dong, B.; Chen, A.; Liu, X.; Shi, L.; Zi, J. Using cuttlefish ink as an additive to produce non-iridescent structural colors of high color visibility. Adv. Mater. 2015, 27, 4719–4724. [Google Scholar] [CrossRef] [PubMed]

- Tran, V.; Kim, J.; Oh, S.; Jeong, K.-J.; Lee, J. Rapid assembly of magnetoplasmonic photonic arrays for brilliant, noniridescent, and stimuli-responsive structural colors. Small 2022, 18, 2200317. [Google Scholar] [CrossRef] [PubMed]

- Pursiainen, O.L.J.; Baumberg, J.; Winkler, H.; Viel, B.; Spahn, P.; Ruhl, T. Nanoparticle-tuned structural color from polymer opals. Opt. Express 2007, 15, 9553–9561. [Google Scholar] [CrossRef] [PubMed]

- Han, P.; Li, X.; Zhao, B.; Li, Y.; Li, H.; Wang, Z.; Meng, W. Brilliant non-iridescent structural colors of hierarchical photonic films by hydrophobic substrates assembly design. Dyes Pigment. 2023, 219, 111587. [Google Scholar] [CrossRef]

- Li, F.; Tang, B.; Wu, S.; Zhang, S. Facile synthesis of monodispersed polysulfide spheres for building structural colors with high color visibility and broad viewing angle. Small 2017, 13, 1602565. [Google Scholar] [CrossRef] [PubMed]

- Wang, J.; Wen, Y.; Ge, H.; Sun, Z.; Zheng, Y.; Song, Y.; Jiang, L. Simple fabrication of full color colloidal crystal films with tough mechanical strength. Macromol. Chem. Phys. 2006, 207, 596–604. [Google Scholar] [CrossRef]

- Sun, Y.; Zhou, B.; Lin, Y.; Wang, W.; Fernando, K.; Pathak, P.; Meziani, M.; Harruff, B.; Wang, X.; Wang, H.; et al. Quantum-sized carbon dots for bright and colorful photoluminescence. J. Am. Chem. Soc. 2006, 128, 7756–7757. [Google Scholar] [CrossRef] [PubMed]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Han, P.; Li, Y.; Liu, J.; Meng, W.; Zhao, B. High-Performance and Broad-Viewing-Angle Structural Colored Films with Carbon Black and Carbon Quantum Dot Doping. Coatings 2024, 14, 1177. https://doi.org/10.3390/coatings14091177

Han P, Li Y, Liu J, Meng W, Zhao B. High-Performance and Broad-Viewing-Angle Structural Colored Films with Carbon Black and Carbon Quantum Dot Doping. Coatings. 2024; 14(9):1177. https://doi.org/10.3390/coatings14091177

Chicago/Turabian StyleHan, Peng, Yuan Li, Jiarou Liu, Weihua Meng, and Bin Zhao. 2024. "High-Performance and Broad-Viewing-Angle Structural Colored Films with Carbon Black and Carbon Quantum Dot Doping" Coatings 14, no. 9: 1177. https://doi.org/10.3390/coatings14091177