1. Introduction

An increasing demand for aesthetics and advancements in technology contributes to the rise in popularity of all-ceramic restorations. In the last two decades, the fabrication of high-strength materials results from the continuous progress in ceramic material science for dental applications. The improvement of zirconia-based ceramics provides acceptable fracture resistance and long-term viability compared with silica-based materials [

1]. These properties induce the utilization of zirconia in a variety of dental applications, such as in fixed partial dentures (FPDs) [

2,

3].

Recently, zirconia was introduced to the family of dental ceramics. Its superior mechanical properties render it suitable for substructure, and it can be widely used for single- and multi-unit FPDs [

4]. Zirconia, specifically yttria-stabilized tetragonal zirconia polycrystal (Y-TZP), became favored as a core material for all-ceramic restorations because of its high mechanical strength and toughness [

5]. On the contrary, zirconia copings for crowns or multi-unit frameworks still require the application of porcelain ceramics, typically specialized porcelain, to achieve appropriate aesthetics [

6].

Zirconia-based core structures are veneered with zirconia veneering ceramics (VC), which generally consist of an amorphous and glassy silica matrix embedded in varying amounts of feldspar and leucite crystals [

7]. Although the Y-TZP substrate displays excellent mechanical properties, veneer chipping (debonding) [

8] is described in clinical service with a failure rate of 15% after 2–5 years [

6], and 21–23% after 5–10 years of service due to poor bond strength to veneering [

9]. This property is mainly due to the chemical stability of Y-TZP, whereby no inherent glass content is detected in the matrix, and a nonpolar covalent bond exists [

10]. The bond strength between the Y-TZP core and VC is determined by the cumulative effects of various factors, such as chemical bond strength, mechanical interlocking, firing shrinkage of VC, type and concentration of defects at the interface, and wetting properties of the core by VC. The adhesion between the zirconia core and VC is affected by the degree of compressive stress in the veneering layer due to a difference in the coefficients of thermal expansion (CTE) between zirconia and VC [

10,

11,

12,

13,

14]. Zirconia surface treatment techniques were developed to enhance bond strength and increase the

Ra and energy, thus directly improving the wetting and the bonding properties between the zirconia and VC [

15]. Various surface-conditioning methods of the zirconia substructure were researched to achieve enhanced zirconia/VC bonding. Among these methods, airborne-particle abrasion with Al

2O

3 particle sizes in the range of 30–125 µm [

16], with or without silica coating [

17], liner application [

14], laser etching [

18], and argon plasma treatment [

19] are all used alone or in association. Airborne-particle abrasion is recommended for zirconia surface modification because of its significant effect on bond strength. However, this method may promote phase transitions at the surface, thereby altering the crystal structure of zirconia from tetragonal to monoclinic [

6], which is accompanied by stress generation on the veneering layer and reverses the bonding strength to the zirconia substrate [

20]. The liner application was found to be affected by thermal cycling, which inversely compromises the bond strength between zirconia and VCs [

9]. The application of a CO

2 laser induces zirconia surface remodeling and promotes

Ra. However, high

Ra does not result in high shear bond strength (SBS) [

18]. Argon plasma cleaning improves the bond between ceramic and zirconia surfaces. However, when plasma cleaning was followed by a glassy liner application, the zirconia/VC bond was significantly reduced [

19]. Previous studies applied glaze as the coating material, using a glaze-on technique on the fitting surface (inner side) of the zirconia restoration [

21], or mixed with partially crystallized zirconia particles and applied on the core surface [

20] to improve the bonding strength. Results showed that the glazing technique remarkably improved the SBS of the resin-based cement [

21] and VC in the composite form [

20].

Alumina or Al

2O

3 is used in dentistry for anterior and posterior crowns, veneers, onlays, inlays, and short-span bridge restorations in all locations of the oral cavity [

22]. Previous investigations were performed using nano-alumina coating (Al) for resin cementation of zirconia by immersing the zirconia specimen in 3 wt % dilute aluminum nitride solution and heating it, resulting in remarkably increased

Ra and flexural bond strength between the Y-TZP ceramic and various dual-cured resin cements of zirconia [

23,

24,

25,

26]. Surface treatment with pre-sintered zirconia of different particle sizes was performed by airbrush spraying [

20] and the commonly used fine-brush paint coating [

27].

The airbrush spraying method is an advanced coating process, which is used for the surface modification of all ceramic [

20,

28,

29] and bioceramic materials [

30]. The airbrush spraying of powder suspensions is a versatile method that allows the coating of differently shaped substrates, such as flat [

20] or curved [

30], substrates with adequate control of the thickness [

29]. Easily evaporable alcoholic-based carriers are often used to obtain high-flowing solutions [

29]. This technique is an effective method that improves the control of coating applications, thereby achieving continuous planes and a rough surface [

20]. Previous studies used composite zirconia/glaze materials as the coating material with the airbrush spraying approach, which consists of applying a composite zirconia slurry to the core surface of the zirconia-based crown to create

Ra, thereby improving the bond strength between VC and zirconia. This study concluded that the coatings remarkably improved the SBS of the VC [

20]. Fine-brush painting is a commonly-applied technique in dental laboratories. A previous investigation applied this method with un-sintered zirconia powder to modify the zirconia surface, and significant bond strength was achieved [

27]. In the present study, airbrush spraying and fine-brush painting are introduced as efficient deposition approaches for coating zirconia substrates in an effort to evaluate the effectiveness of each approach. Until now, there is no agreement regarding the most efficient surface-treatment method for achieving optimal bond strength between the zirconia core and VC. Enhancing the quality and bond strength between VC and the core ceramic is necessary because they are the key factors for successful bilayer restorations [

6,

7]. The development of an adequate surface treatment for the zirconia core will increase the adhesion and success rate of FPDs [

6].

The application of partially sintered alumina/glaze composites for coating zirconia has not been reported to date. In the present study, two coating techniques, namely airbrush spraying and fine-brush coating, are proposed for an alumina composite coating on a zirconia substrate. Herein, the composite coating (<60 µm) and glaze were utilized to enhance the overall bonding strength of VC.

The aim of the present study, therefore, was to assess the influence of different surface treatments using different techniques on the Ra of zirconia cores and the adhesion of the zirconia–VC systems through an SBS test.

The tested hypotheses were as follows: (1) the Ra of all surface-treated specimens will be unaffected by the application process (i.e., airbrush spraying and fine-brush painting); (2) the tested surface-coating methods will produce the same effects on the bonding of VC to zirconia.

2. Materials and Methods

2.1. Sample Fabrication

Computer aided design-computer aided manufacturing (CAD–CAM) pre-sintered Zenostar® translucent Y-TZP discs (Wieland Dental, Technik GmbH & Co. KG, Pforzheim, Germany) were shaped into cubes using the dry touch imes-icore system (imes-icore® in CNC and Dental Solutions, Ebner GmbH, Eiterfeld, Germany). The pre-sintered size of the cubes were cut 20 vol % larger than the desired dimensions to take into with consideration shrinkage after complete sintering. The firing shrinkage of the resultant zirconia cubes was calculated from the values of the specimen diameters before and after sintering. One square face of the white state of each pre-sintered cube for coating was dry ground using silicon carbide papers to a #600, #800, and #1000 grade finish (Ecomet, Buehler Ltd., Evanston, IL, USA). The cubes were cleaned with pure ethanol (≥99.7%) (Sinopharm Chemical Reagent Co., Ltd., Shanghai, China) by wiping their surfaces with cotton before coating to obtain a standardized surface.

2.2. Sample Preparation

The un-sintered nano-sized Al

2O

3 powder (α-Al

2O

3, >99.99%; average particle size, 100 nm; Taimei Chemicals Co., Ltd., Tokyo, Japan) was dry pressed under cold isostatic pressure by means of an Microelectronics Technology Inc. (MTI) laboratory cold press (MTI KJ group, YLJ-24T, Shenyang, China), in stainless steel dies to produce compact tablets (2 mm height and 8 mm diameter) under 200 MPa. To confirm partial sintering, thermal analysis of the alumina pellet was performed for one tablet using a thermal mechanical analyzer (Model SETSYS Evolution-24, Setaram, Lyons, France) in a flowing argon atmosphere (50 mL/min). The shrinkage percentage was shown to be 1.79% when the pellet was heat-treated to 1100 °C at a heating rate of 5 °C/min and cooled to the furnace rate (

Figure 1).

The rest of the pressed alumina specimens were partially sintered in an alumina crucible at 1100 °C for 2 h in a muffle furnace (Xinyu-1400, Nanyang Xinyu New Material Technology Co., Ltd., Nangyang, Henan, China) at a heating rate of 5 °C/min and subsequently cooled to room temperature. A heat treatment schedule was obtained from a previous study [

20]. Samples were ground using a silica pestle and mortar. Based on the pilot study, the resulting powder was sieved through a 60 µm mesh (Zhejiang Luda Machinery Instrument Co., Ltd., Shaoxing, Zhejiang, China) to separate powder with a particle size <60 µm. Two sets of composite powder for the coating were prepared and weighed using a precision balance (Sartorius Entris Analytical Balance, Brooklyn, NY, USA). The first powder mixture (composite) consisted of 50 wt % of partially-sintered alumina (<60 µm) and 50 wt % of Ivoclarvivadent Porcelain System (IPS) e.max Ceram glaze. The second powder mixture consisted of 50 wt % of partially-sintered alumina (<60 µm) and 50 wt % Noritake Cerabien ZR glaze porcelain (

Figure 2). The selection of the 50 wt % ratio was based on previous studies to avoid the risk of blocking the nozzle of the airbrush spraying system [

20,

30]. The composite powders were separately dry ball milled at 250 rpm for 15 min in a closed polyethene container with alumina balls of 10 mm diameter, and then subsequently sieved to separate the alumina balls.

2.3. Specimen Grouping according to Surface Modification

A total of 80 pre-sintered zirconia cubes were randomly assigned into four experimental groups (each group

n = 20) and subdivided according to the surface treatments applied (airbrush spraying or fine-brush painting by manual deposition) as shown in

Table 1.

The chemical components and manufacturers of the selected materials are summarized in

Table 2 according to the manufacturer’s data.

In the airbrush spraying surface treatment, including G1 (E60S) and G3 (N60S), the slurry comprised of mixed alumina powder diluted with 1.5 ml of pure ethanol (≥99.7%) for each of the 40 specimens (20 specimens in each group). The slurry was mixed using a magnetic stirrer (Biobase Meihua Trading Co., Ltd., Jinan, China) at 500 rpm for 15 min to ensure homogeneity of the mixture. The coating spray was applied to one surface of each zirconia specimen, using a mini airbrush spray gun (Model 130-dual action airbrush kit, Bartsharp Airbrush, Taiwan) fixed vertically to the prepared un-sintered zirconia cube by a clamp holder, yielding a spray-dried powder (

Figure 3a–c).

The samples were placed on a flat surface during the spraying process to achieve a unique layer of the coating on the core material. The standard quantity and quality of the spraying slurry were preserved by maintaining 2.5 bars of air pressure and 10 s spray time with 10 cm distance between the zirconia cube and airbrush nozzle with a lumen diameter of 0.3 mm. These parameters were applied on the basis of previous studies [

20,

30]. The coating parameters are summarized in

Table 3.

In the fine-brush coating surface treatment, including G2 (E60P) and G4 (N60P), 40 pre-sintered zirconia cubes (20 specimens in each group) were coated with the mixture which was prepared by mixing 55 wt % of alumina composite powders with the corresponding glaze liquid of IPS e.max Ceram and Noritake Cerabine ZR, respectively. The slurry was applied twice [

27] to the prepared pre-sintered zirconia cube specimens using a thin brush (Glaze brush (0) KYC series 2700, Shenzhen, China). After the first layer of coating, the specimens were rotated 90° clockwise to apply the second layer and fill the uncoated areas. The time interval between the two layers was 2 s (

Figure 3d,e). All eighty surface coated specimens were then fully sintered at 1530 °C for 6 h in the firing furnace of the supplier (Austromat

® baSicDekema, Dental Keramiköfen GmbH, Freilassing, Germany) according to a cycle recommended by the furnace manufacturer. The size of each cube following sintering was 10 mm × 10 mm × 10 mm. Then, all specimens were ultrasonically cleaned using a digital ultrasonic cleaner (Jeken, PS-20A, Shenzhen, China) in pure ethanol (≥99.7%) for 10 min, steam cleaned (Dental Steam Cleaner, Nurodent Model S-501, Guangzhou, China) for 10 s, and air dried with compressed air at room temperature.

2.4. Scanning Electron Microscopy (SEM) and Energy Dispersive Spectroscopy (EDS)

SEM (Ultra Plus, ZEISS, Oberkochen, Germany) operating at accelerating voltages of 15 kV was carried out to evaluate the surface morphology of the coated zirconia specimens with different methods. For the observation of the coating quality, morphology, and profile of all specimens, the surface-treated zirconia cubes were cut using a diamond blade under water cooling (MTI KJ group, SYJ-150 low-speed Diamond Saw, Shenyang, China). The specimens were subsequently cleaned with pure ethanol in an ultrasonic bath for 5 min and air dried at room temperature. In each group, two additional zirconia samples were prepared for the top and interface examination. The top surface of specimens, cross-sectional profile, and fractured surface of VC after SBS testing were attached to double-sided conductive carbon tape and sputtered with a thin layer of gold alloy using a sputter coater machine (JS-1600, Beijing HTCY Co., Ltd., Beijing, China) and imaged in a high-resolution SEM at different magnifications for microstructural analyses. The EDS analysis, which is equipped with SEM, was performed to reveal the elemental composition and the influence of the different chemical compositions of the materials used (glazes, VCs, and coated zirconia surfaces).

2.5. Phase Analysis by X-ray Diffraction (XRD)

One coated specimen from each experimental group was randomly selected, then cleaned with pure ethanol in an ultrasonic bath and air dried at room temperature. Phase analysis of the partially sintered powder of alumina and specimens were accomplished using a Smart Lab X-ray diffractometer (Smartlab, Rigaku, Tokyo, Japan) with Cu Kα radiation (λ) of 1.5406 Å, and an accelerating voltage of 40 kV in the 2θ range of 10–90° using a step-scanning technique with a fixed step size of 0.02° at a rate of 10°/min. Data were analyzed using the Origin Pro 8.5 program (OriginLab Corporation, v9.0, Northampton, MA, USA), together with the search and match software Materials Data Inc.(MDI) Jade 6 program (Materials Data Inc., Jada XRD pattern processing, Livermore, CA, USA), to identify the phase following surface treatment. The pattern was plotted by a set of line positions 2θ (°) against the intensity (arbitrary units).

2.6. Ra Evaluation

After surface modification, ten specimens from each group were randomly selected to measure

Ra values. The

Ra in the micrometer (µm) of the top surface of the study groups were analyzed with a profilometer (Surtronic 25, Taylor Hobson Ltd., Leicester, UK). The

Ra, which stands for arithmetical mean roughness, was then determined as the indication of surface roughness of the substructure. A higher

Ra value indicated optimum surface roughness [

31]. For each new specimen, a calibration was conducted for a standard sample (6.00 µm) which was provided by the manufacturer. Filtering of the measured data at the cut-off (λ

c) length (0.03 inch = 0.8 mm) was then determined according to recommended ISO 4288-1996 [

32]. The test was performed on a flat surface. For each sample, three readings of measured roughness were recorded, and the average

Ra was then calculated [

18].

2.7. Veneering Procedure

All eighty surface treated specimens were ultrasonically cleaned in ethanol for 10 min and air-dried at room temperature. A specially-designed separable dimensionally-stable custom-made silicon mold (Zhermack S.P.A, Badia Polesine (RO), Italy) was used as a key to layer the VC on the coated face of each cube, covering an area of 3 mm diameter and 5 mm height at the center of the cube face (

Figure 4).

The VC cylinders were fabricated using the same layering technique to create 3 mm diameter and 5 mm height specimens [

33]. The silicon mold was isolated with the separating medium (Ceramic Separating Stick, Ivoclar Vivadent, Schaan, Liechtenstein, Germany) to avoid the adhesion of VC around the pre-fabricated hole of the silicone mold during layering. Two VCs were utilized including IPS e.max Ceram Type I, Class II Dentine C2/TI3 powder (only dentin) for groups E60S and E60P, and Noritake Cerabien ZR for groups N60S and N60P in the veneering procedure. The IPS e.max Ceram was mixed with an appropriate amount of the respective liquid according to common practice in the dental laboratory and filled into the mold. With gentle vibration, excess liquid was removed with a tissue, and a uniform cylinder was ensured in the layers to prevent air bubble trapping. In each combination, 40 specimens were veneered to E60S (

n = 20) and E60P (

n = 20) groups. An identical procedure was performed for veneering N60S (

n = 20) and N60P (

n = 20) groups with Noritake Cerabien ZR VC. The coated zirconia specimens with VC were fired into full density in a programmable and calibrated ceramic oven (Programat P300, Ivoclar Vivadent, Liechtenstein, Germany) according to suggested firing schedule by the manufacturer for each VC (

Table 4). The percentage of shrinkage after sintering was 10% for IPS e.max Ceram and 20% Noritake Cerabine ZR, respectively according to manufacture information [

34].

To compensate for the shrinkage of sintering under the same conditions, a second firing was carried out to achieve a final veneering of 3 mm diameter and 5 mm height. After firing, the specimens were cooled to air atmosphere. Excess VC was removed with a dental laboratory engine (N3 Micromotor Polishing Unit, Beijing, China) with a low-speed carbide hand piece (HP) fissure bur (Busch and Co., Ltd., Engelskirchen, Germany), which was gently applied with minimal pressure to yield the correct final dimensions of VCs and clear the interface without a damaging effect on the interface. All the specimens were then kept at room temperature for 24 h before the further processing.

2.8. Shear Bond Strength (SBS) Test

For performing SBS testing, ten specimens in each group were evaluated for the initial SBS (not stored in deionized water (DW) without aging), and the other half of the specimens in each group were evaluated after being stored in DW at 37 °C for one month (aging). At pre-determined times, specimens were thoroughly rinsed and air-dried at room temperature. Specimens were individually mounted in a special sample holder before being loaded in a universal testing machine (Shimadzu, AG-X plus, Tokyo, Japan). A testing load was applied perpendicular to the long axis of the specimen and close to the interface using a semicircular shaped piston (

Figure 5) at a constant crosshead speed of 1 mm/min until specimen fracture as recommended by the International Standards Organization (ISO) [

35]. The SBS test in MPa was calculated by the corresponding software (Trapezium X, Version 1.4.0, Shimdazu Corporation, Tokyo, Japan) by dividing the ultimate load to failure in Newton (N) by the area of the bonded surface (mm

2). The recorded load was calculated using the formula

b =

f/

s, where

b,

f, and

s denote the bonding, force, and surface area, respectively.

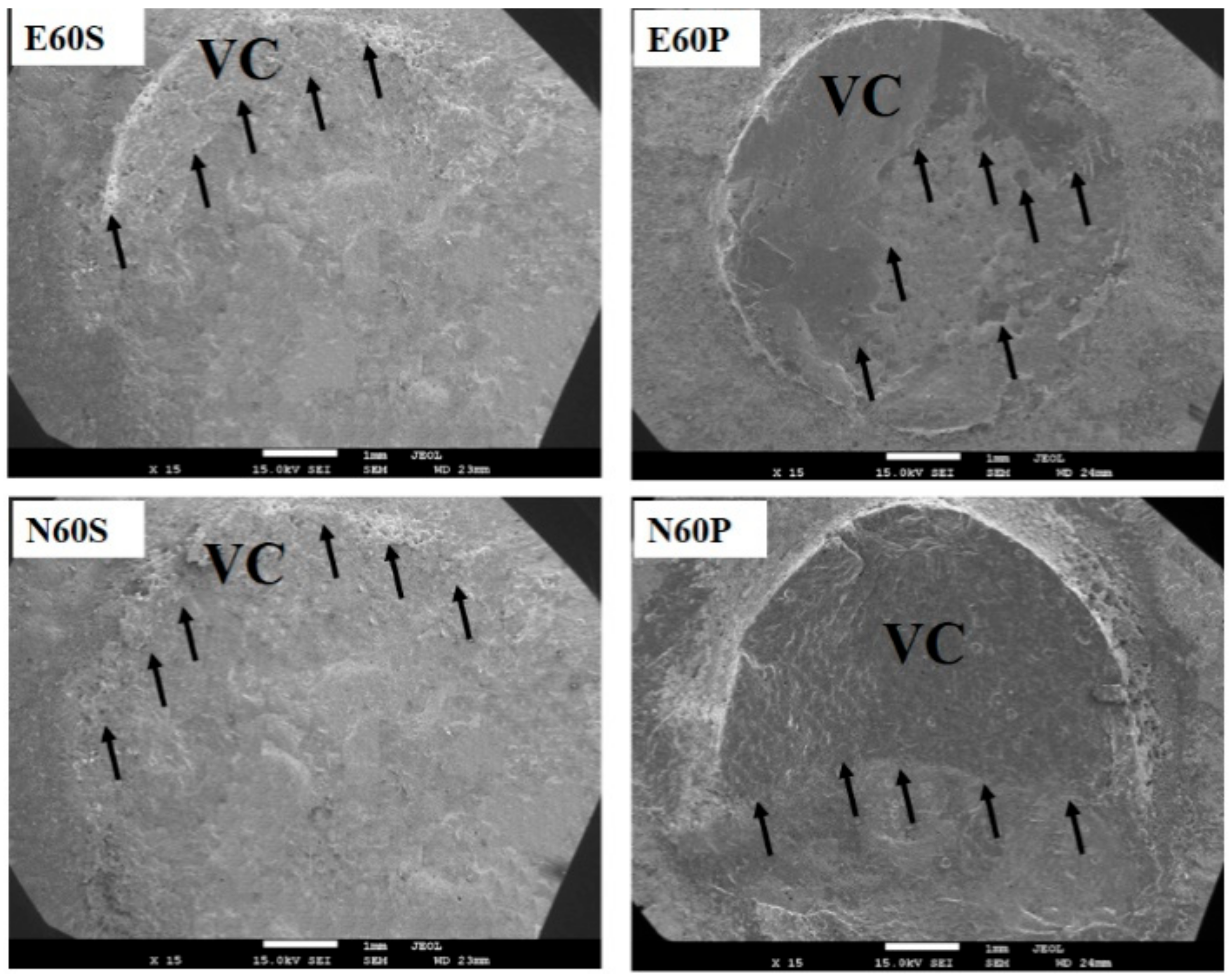

2.9. Fracture Pattern Examination

The coated surface of each experimental group before and after sintering (

Figure 3c,e) and the pattern of failure following SBS testing were visually examined under a stereomicroscope (Olympus SZ61, Shanghai, China) at 20× magnification and further investigated with SEM. The failure modes were classified as follows:

Adhesive failure modes at the core-VC interface;

Cohesive failure within the VC;

Mixed mode of failure combination of the adhesive and cohesive modes.

The fracture mode patterns for each tested group were recorded regarding percentages.

2.10. Statistical Analysis

The final results were statistically analyzed using the IBM Statistical Package for Social Sciences software (SPSS 20.0, IBM®SPSS®Inc., Chicago, IL, USA).

The Kolmogorov–Smirnov normality test was applied for checking the distribution of Ra and for SBS values, and the Levene statistic test was used to test the homogeneity (equality) of variances.

The results of normal and non-normal distributed variables were tested with a one-way ANOVA test with the multiple comparisons post hoc test and Kruskal–Wallis H test in conjunction with unpaired Mann-Whitney U test, respectively. A parametric paired t-test was performed to compare the means of SBS values of specimens before and after storage in water in normally distributed groups and non-parametric paired Wilcoxon test for non-normally distributed groups.

The general linear model (univariate) was used to test the effect of treatment methods (airbrush spraying and fine-brush painting), and coating materials to find the outcomes between-subjects effects for two factors, with Ra as the dependent variable. The general linear model was also used to test the effect of treatment methods, coating materials and aging to find the outcomes between-subjects effects for two and three factors, with SBS as the dependent variable.

The Spearman correlation coefficient test was used to find a correlation between Ra and SBS. The thickness of the coating at the interface level in µm was measured in four different areas with the SMile View™ software (SMile View™ version 2.1, JEOL Ltd., Tokyo, Japan). The significance level was calculated at α = 0.05.

4. Discussion

Previous studies have reported that the application of a glaze or low fusion porcelain on the zirconia core prior to VC promoted zirconia–porcelain bond strength [

8,

36]. However, the zirconia/glazed interface layer has been shown to provide a relatively weak bond, and delamination related to a mismatch in their CTE can occur [

36]. The rationale for using alumina (<60 µm) was based on optimizing a rough surface to enhance micromechanical retention, and combining with a glaze as a mediator increases the wetting property [

13] and improves the chemical adhesion on the zirconia surface between coating and zirconia specimens and VC [

20]. On such bases, alumina composite coatings on surface modification of the inert surfaces of high strength zirconia ceramics has been proposed in this study. Alumina is a suitable candidate for zirconia surface modification due to its high strength, toughness and excellent biocompatibility [

22]. XRD, SEM and EDS evaluations demonstrated that the deposition of composite crystal alumina (<60 µm) and glaze porcelain successfully modified the zirconia surface using different strategies at a high sintering temperature (1530 °C). Non-invasive alumina composite treatment on zirconia surfaces can survive thermal cycling [

25]. Alumina is one of the most important ceramic materials, as it has relatively high melting (2054 °C) and boiling temperatures (2980 °C), ultra-high thermal stability and mechanical strength [

37]. The XRD trace revealed that partially-sintered alumina (<60 µm) resulted in the formation of a purely alpha alumina crystalline phase. When subjected to a higher temperature with different glazes as a coating on the zirconia surface, a composite alpha alumina crystalline phase and glass were formed, and alumina peaks were dominant as the major crystalline phase instead of zirconia. The sharp peak intensities indicate high crystallinity and small peaks referred to the glass content.

The high-strength and fracture toughness of zirconia support its extensive application in aesthetic dentistry [

27]. However, VC delamination from the core structure is frequently observed in the clinical situation [

20], and its fracture remains a primary cause of failure [

14,

27]. Therefore, in achieving acceptable VC bonding in a wide range of clinical applications, alternative treatment methods that ideally utilize chemical adhesion in addition to mechanical retention [

38] are required for zirconia ceramics.

The choice of non-destructive methods, such as airbrush spraying [

20] and fine-brush deposition [

27] are desirable for surface modification of inert zirconia ceramics to produce functionalized surfaces. A continuous composite coating with some degree of porosity for E60S and N60S with a constant thickness and minor irregularities was formed with zirconia substrate using airbrush spraying. Many variables, such as spraying air pressure, nozzle diameter, mixture dilution, the distance of the airbrush nozzle to the substrate, and the total spray time can affect the production of a homogenous and uniform thickness of deposited layers [

20,

30]. In this study, these parameters were selected and kept constant on the basis of the previous study to achieve the desirable coating thickness [

20].

A successful surface adhesion was also obtained using fine-brush painting between zirconia and coating layers in E60P and N60P without evidence of cracking, spacing, or delamination at the interface when the composite was blended with the glaze liquid. The previous investigation applied this method with un-sintered zirconia powder mixed with glue (GF-8023) to modify the zirconia surface [

27]. The thickness of the airbrush spraying groups represented a slightly higher value than the fine-brush painting groups. This phenomenon can be explained by the presence of irregularities in the latter group, and the thickness is dependent on the number of spraying cycles when airbrush spraying is used [

30].

The surface coating is the additive approach for increasing the

Ra of zirconia. In this study, it was also observed that the

Ra promotion, which was caused by both procedures, resulted in the remodeling of zirconia surfaces. The values of the zirconia

Ra were claimed to be significantly promoted after being airbrush sprayed with two different particle sizes—26.0 ± 0.3 µm and 47.0 ± 0.5 µm of pre-sintered zirconia [

20]—and recorded higher

Ra values than the current investigation. In this study, the particle size of alumina (<60 µm) was kept constant. Discrepancies in the results between the previous investigation [

20] and the current study may be due to the use of various particle sizes and coating materials. Varying the glass percentage by weight may influence the melting temperature and its effectiveness in infiltrating the zirconia surface [

39]. However, in the present study, results revealed a significant improvement in the average

Ra of the fine-brush treated groups when compared to the alcoholic vapor deposition groups, particularly in N60P (

Table 5). This finding is consistent with the previously reported literature [

27]. This phenomenon can be explained by the different application mode (treatment) and coating materials (

Table 6). The

Ra in the airbrush spraying groups were the lower than their counterpart groups, and they also showed the lowest resistance to aging conditions. The current findings highlighted a potential influence of the application process (treatment technique) on

Ra behavior of the treated zirconia ceramic, which denied the first hypothesis.

The enhancement of bonding between zirconia and VC is a prerequisite for improving clinical success and longevity of prosthetic restorations [

6]. Clinical failures of zirconia FPDs often occur due to fractures or chipping of the VC, and this problem must be solved to obtain greater adhesion [

6].

In the present study, the adhesion of two different VCs to surface-modified zirconia cores with different surface treatment processes was determined using the SBS test. SBS tests or microtensile tests are generally used to evaluate the bond strength of bi-layered zirconia-based ceramic systems [

13]. The SBS test was used in this study because of its simplicity compared with other test methods, the ease of specimen preparation, applied forces perpendicular to the bonding zone, and the test reading was unaffected by inner structural flaws, which may be formed by the small cross-sectional area of the bonded surface to test the material [

20,

40]. The rationale for one-month water storage was based on observation of the longevity of the bond stability between the zirconia core and coating and the coating and VC. It was found in our study that after being subjected to the aging treatment, the bond strength is still higher in fine-brush painting than airbrush spraying. It has been observed that all aged specimens could survive the wet condition without evidence of chipping and delamination in either coating or spontaneous detachment of VC materials in one-month aging by storage in DW. Increased

Ra in turn resulted in increased surface energy and better wetting for bonding [

41]. The positive effect of stability in zirconia/coating and coating/VC integration needs to be invested further in long-term water storage.

The previous study reported that the mean (SD) SBS value was 47.02 ± 6.4 MPa for fine-brush painted 3 µm un-sintered zirconia on a zirconia core surface in dry conditions [

27]. In this study, the initial SBS values of fine-brush painting of E60P and N60P were 34.51 ± 5.152 MPa and 37.22 ± 4.954 MPa, respectively. The discrepancy in the values of SBS with the current study can be attributed to factors such as coating materials, the use of different VC (Cercon Ceram), heating schedules for VC, and the specimen design. The results indicated a variation in the coating process, and materials involved in the VC adhesion—a rough surface resulted in high SBS. The irregularities in the core surface and the increased contact area with the VC improved the mechanical retention and the SBS values, thereby reducing the possibility of delamination [

9]. The fine-brush painting groups showed the highest mean value of SBS of VC in initial and aged conditions (

Table 7), which implied that these irregularities created a rougher surface and increased the contact area with the veneering material compared to those in the other coated groups, which is supported by the SEM and

Ra values. These irregularities may act as the mechanical retentive means, which strengthened the integration between VC and the zirconia substructure [

20]. The results are in accordance with the previous study that such treatment significantly enhanced

Ra and SBS between zirconia and the VC [

27].

The relatively low SBS measured after airbrush spraying compared with those generated by the manual deposition approach in dry and wet conditions could also support this claim. The SBS values in a dry condition in the present study in the airbrush spraying groups of E60S and N60S were 27.93 ± 3.096 MPa and 29.80 ± 3.799 MPa, respectively. In contrast to our findings, the previous study showed that the zirconia specimens treated with airbrush spraying significantly improved the SBS to the VC (Cercon Ceram Kiss) with cylindrical shape (3 mm height × 3 mm diameter). The coated group revealed the highest value of SBS 37.54 ±4.38 MPa in dry conditions, which had a modified zirconia core surface with 47 µm un-sintered zirconia powder with Cercon Ceram Kiss glaze [

20]. The discrepancy in results may be attributed to the same reasons explained earlier. Given that our findings depicted that the fine-brush painting groups presented high SBS, the second tested hypothesis was also rejected.

Both mechanical interlocking and primary chemical bonding have been documented to play a pivotal role in the interfacial adhesion mechanism [

42]. The EDS analysis of elements found in the present study confirmed the general components provided by the manufacture (

Figure 11) and no major elemental changes in the coating mixture after the sintering process had occurred (

Figure 12). During EDS analysis, the carbon element and other automatic selection of elements by the system were removed to eliminate the bias of the procedural section [

43]. The differences in interfacial adhesion mechanisms between the interface of the coating/zirconia and coating/VC were that the former adhered to the flat surface and the latter to the rough surface. It has been shown that if the ceramic surface is smooth, the bond is dependent only on the silicon and oxygen and this then becomes a function of the surface composition and chemistry of the ceramic and not its surface topography [

43]. In addition, a possible glass infiltration may occur during sintering. Nonetheless, according to the results of airbrush spraying in the current study, it may still be difficult to get a stable coated zirconia/VC adhesion. The EDS analysis showed lower silicon on the airbrush sprayed groups; this compromised the proper chemical bonding (

Figure 13). The addition of Si-containing porcelain provides the necessary foundation for the establishment of chemical integration [

36].

The presence of some microporosity in the interface level within the airbrush sprayed group might account for these results, in addition to the application process. This treatment did not appear to enhance the micromechanical retention needed for efficient mechanical and chemical bonding between zirconia and VC and the reduced Ra reflected in the reduced SBS values compared to the counterpart treatment.

Failure mode classification was consistent with the previous study using the SBS test [

21]. In this study, the fractographic analysis of SBS tested specimens using SEM exhibited different fracture modes for the tested groups. The results of the E60P and N60P groups revealed a higher percentage of the mixed and cohesive mode of failure in both initial and wet storage than the other tested groups. It has been reported that when the surface becomes rougher, the bond strength will increase [

13]. The Spearman test confirmed this claim that there is a significant correlation between

Ra and the SBS test. A high percentage of the adhesive mode of fracture obtained for both the E60S and N60S groups in dry and wet conditions were due to the lower roughness values.

Interestingly, none of the specimens of the airbrush spraying groups failed cohesively. The results are not consistent with the previously reported literature [

20]. The results have been explained by the effect of mechanical and chemical bonding, as has been proven by EDS analysis (

Figure 14). Accurate selection of treatment technique and appropriate use of materials will assist in the approach to obtain reliable and durable zirconia/VC bonding.

The fine-brush painting technique can be considered an alternative treatment modality to other surface treatments to zirconia cores to avoid VC delamination and microcrack formation at the intergrain level, which will be detrimental to the longevity of ceramic restoration. This procedure is a highly versatile yet practical approach, which allows for the fabrication of rough bearing thin film coatings that are simple, strong, technique insensitive, and cost-effective material processing techniques. Furthermore, such coatings present the potential for a wide range of applications for the zirconia core with conventional and complex shapes (single crown and bridge) of fixed zirconia ceramic restorations.

The generalizability of these results is subject to certain limitations. For instance, the study did not include a control group because different materials and processes were used. The current study was unable to evaluate the possible negative effects of the CTE mismatch since glass and alumina have distinct CTE to that of zirconia. With the glass infiltrated zirconia, however, possible new crystalline phases formed during sintering could potentially minimize or compromise this aspect. The current in vitro study has only examined 30 days DW storage of the samples, and longer durations or an in vivo study is required to evaluate this approach regarding performance during clinical service. Although in vitro experiments are valid in determining the effects of such variables, randomized clinical studies should be incentivized to provide information about alumina composite coating behavior during service to improve the long-term success of restorations.