Snake Robots for Surgical Applications: A Review

Abstract

:1. Introduction

1.1. Medical Background and Rationale

- Neurosurgery;

- Ophthalmic surgery;

- Otolaryngology;

- Cardiothoracic surgery;

- Urological surgery;

- Gynaecology;

- Pancreatectomy;

- Prostate surgery.

- Tonsils and adenoids: Transoral robotic surgery is performed via the oral cavity, using a Crowe–Davis mouth gag for increased surgical exposure. The swelling of the tonsils at the rear end of the throat, which protect the body from infection, requires intervention to expedite swallowing movements. Sometimes, such inflammation in the throat can cause obstructive sleep apnoea and, in worst cases, high blood pressure and depression [12].

- Thyroids: Robotic thyroidectomy omits any dissection through the neck which may be highly risky, and instead utilizes a transaxillary approach with an incision of 5–7 cm via the underarm. There is scope for a flexible snake robot to be steered around the bony protrusions under the neck, around the collar bone and at the axilla, despite the restricted working area [13].

- Neck: Cancerous lesions can be extracted inside or on the neck using robotic techniques such as electrocautery. When the metastatic neck epithelium becomes cancerous, the affected cells spread to the lymph nodes in the neck. Robots are highly involved in biopsies, the microscope inspection and removal of neck tissue using endoscopic procedures through the nose, throat, rear of the tongue, stomach area, trachea and windpipe. Other treatments available for premature stages of throat cancer include cordectomy, laryngoscopy, vocal cord surgery, uvulectomy and free autologous tissue transfer [14,15].

- Trachea: The widening of a narrowed windpipe below the larynx requires urgent treatment due to breathlessness and fatigue experienced by the patient, usually reflected in children. Robotic laryngotracheal reconstruction is carried out by flexible endoscopic robots, widening the lumen through the use of a cartilage graft for anastomosis and enabling the cross-field respiration of the airways [16].

- Hiatic hernia: The excrescence of the upper abdomen, into the mediastinum through the hiatus of the diaphragm. Incompetency of the lower sphincter is caused by the loosening of the pharyngoesophageal membrane and expansion of the diaphragmatic hiatus. A peroral endoscopic myotomy and Nissen fundoplication can be performed using a flexible snake robot and are used to treat gastroesophageal reflux disease (GERD), increasing digestive mobility [17].

- Gastrointestinal tumours: The interstitial cells of the smooth muscle in the digestive tract may develop cancerous attributes. A laparoscopic pancreaticoduodenectomy, which is the removal of duodenal intestinal stromal tumours, involves excisions, suturing and anastomosing the inner walls of the stomach using a multifunctional robotic tip due to its malleability in restricted areas. The emerging treatment options for such robots include targeted drug delivery and the use of surgical patches for ulcers and tumours [18].

1.2. Outline

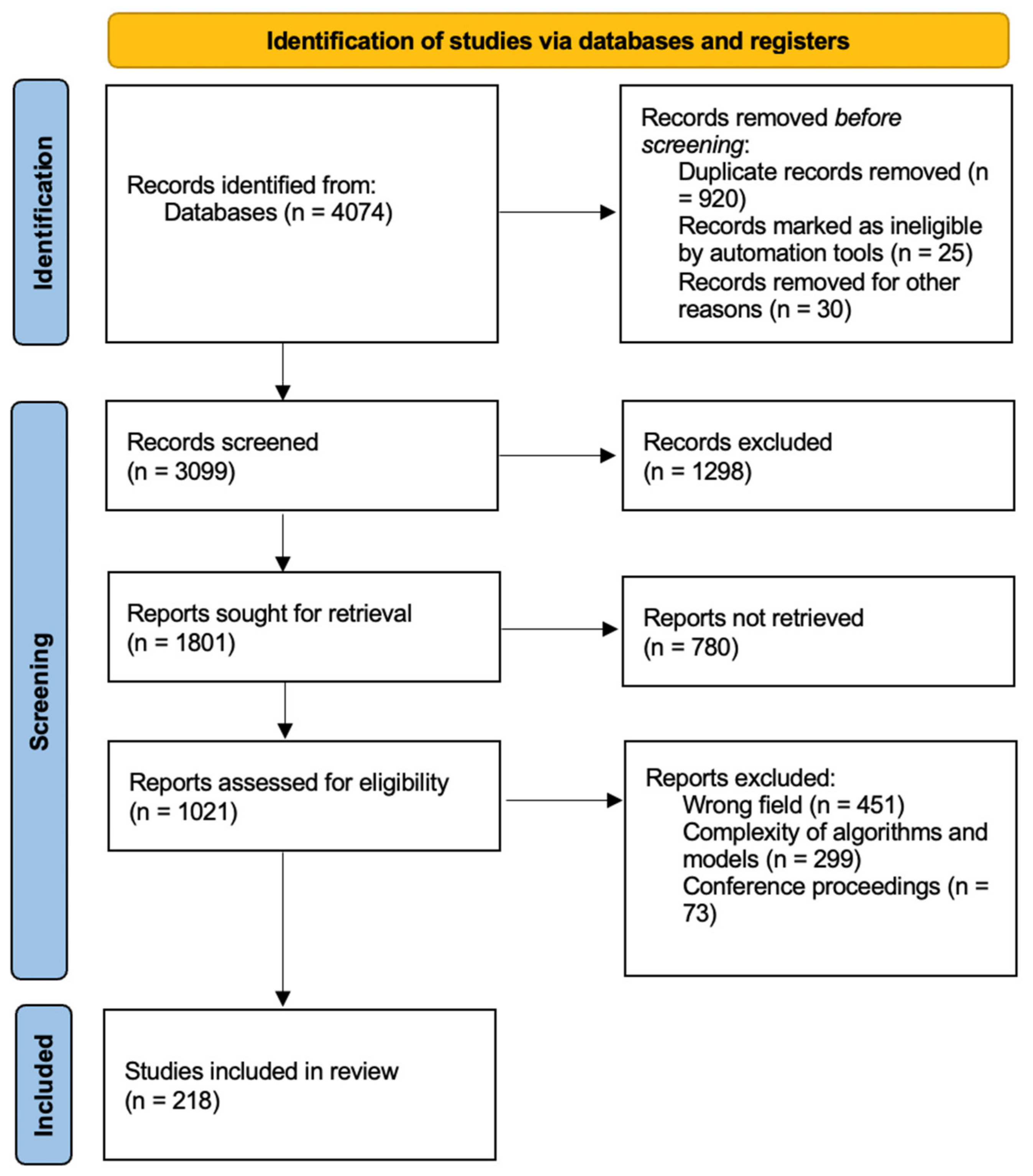

2. Literature Review

2.1. Commercial Snake Robot Systems

2.2. Academic Literature

3. Snake Robots: Structural Design Configuration

3.1. Types of Continuum Robots

3.1.1. Concentric Tube Continuum Robots

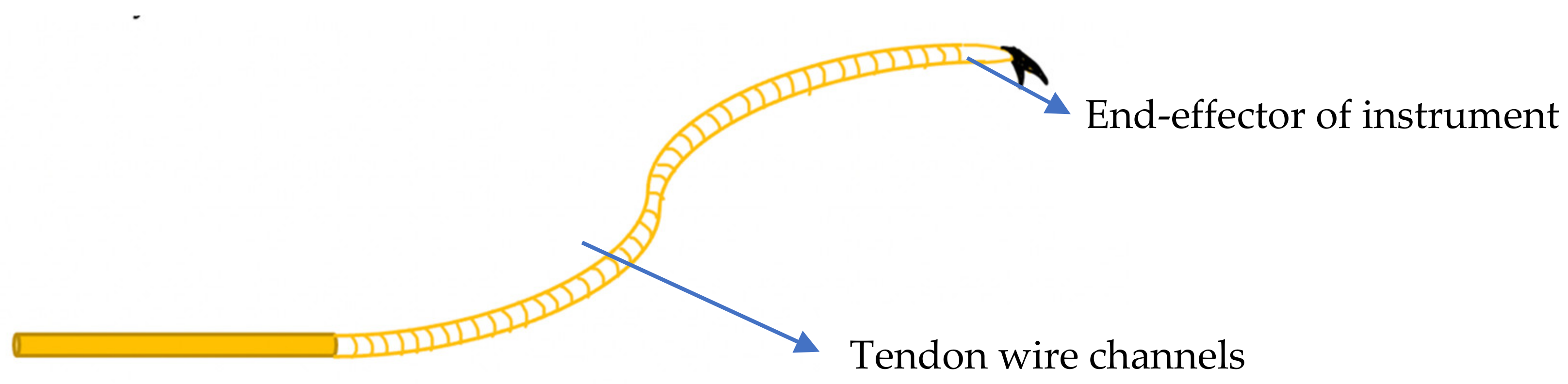

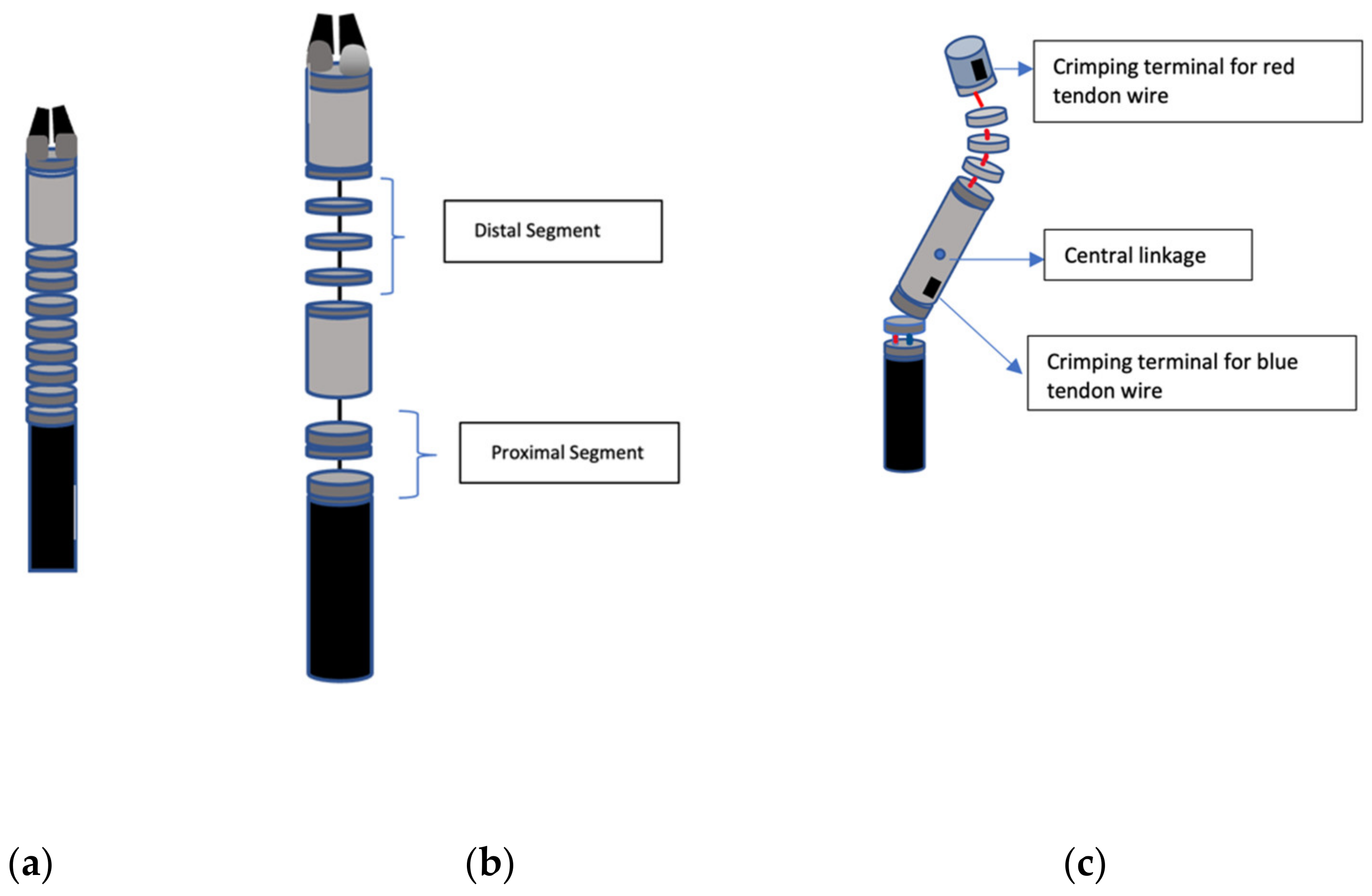

3.1.2. Tendon/Cable Continuum Robots

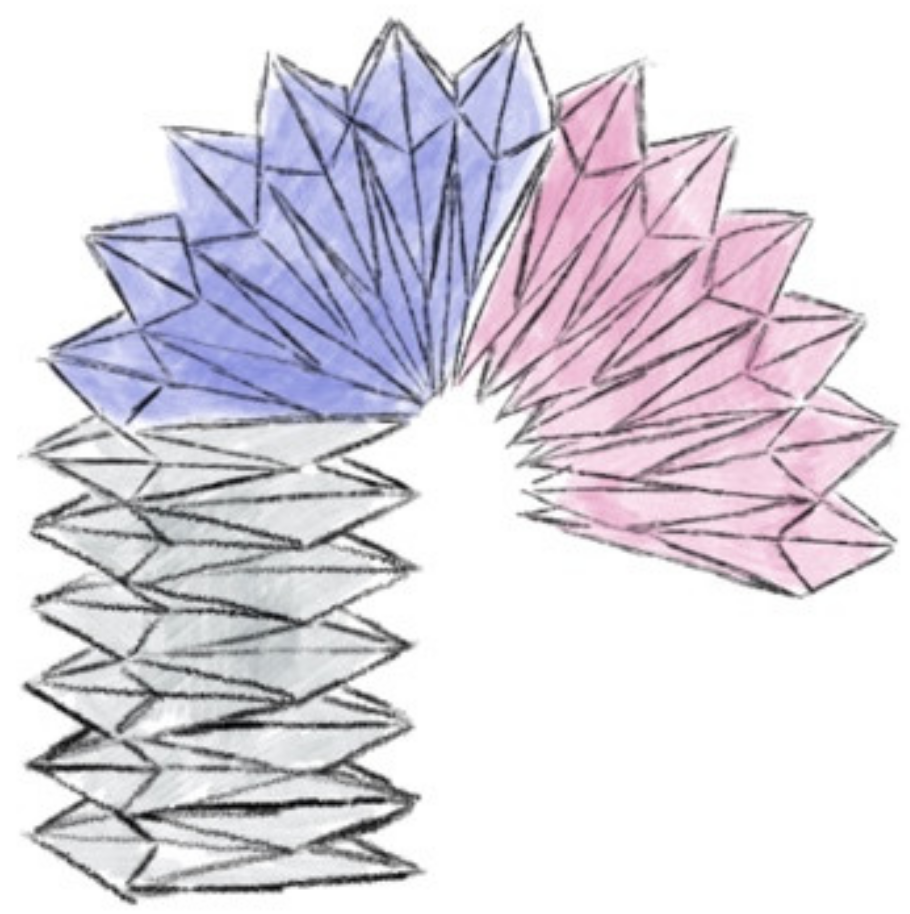

3.1.3. Origami Continuum Robots

3.1.4. Magnetic Continuum Robots

3.1.5. Dual Continuum Mechanism

4. Materials and Manufacturing

4.1. Materials Used in Snake Robot Manufacture and the Features Affecting Actuation

4.1.1. Mechanism-Based Variable Stiffness Actuators

4.1.2. Material-Based Variable Stiffness Actuators

Pneumatic and Granular Jamming Mechanisms

4.2. Manufacturing

4.2.1. Conceptual Design and CAD Models

4.2.2. Prototyping

3D Printing Techniques

Manufacture of the Final Structure

5. Dynamics and Control

5.1. Types of Gait Techniques in Snake Robots

5.2. Biological Principles of Snake Motion

5.3. Movement in Different Types of Snake Robots

5.3.1. Standard Snake Robots

5.3.2. Concentric Tube Continuum Robots

5.3.3. Tendon/Cable Continuum Robots

5.3.4. Pneumatic/Hydraulic Robots

5.4. Design Optimisation of Rolling Joints

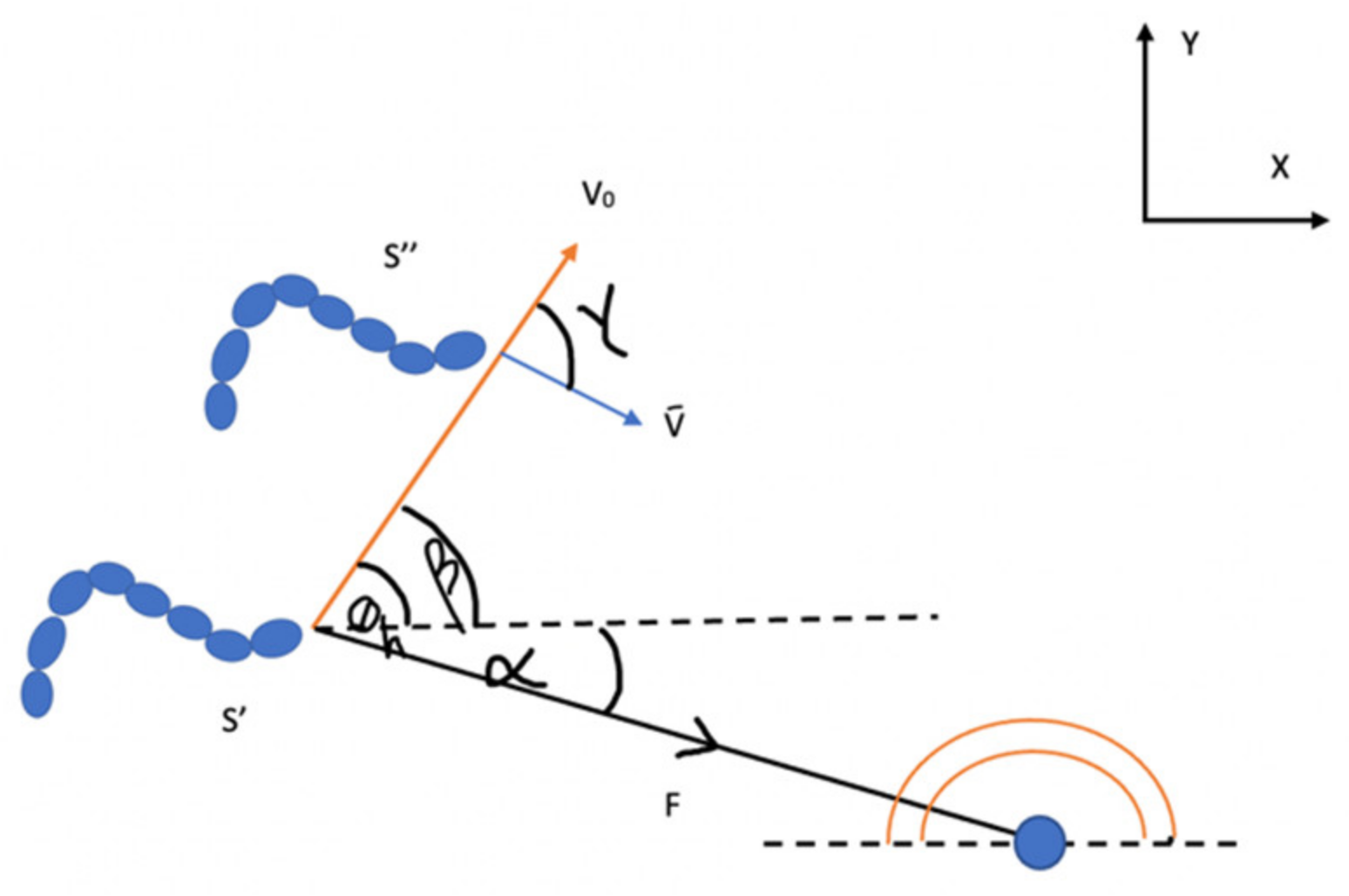

5.5. Kinematic Model of the Planar Snake Robot

6. Navigation and Planning

6.1. Path Planning of Snake Robot

6.2. Motion Planning of Snake Robot

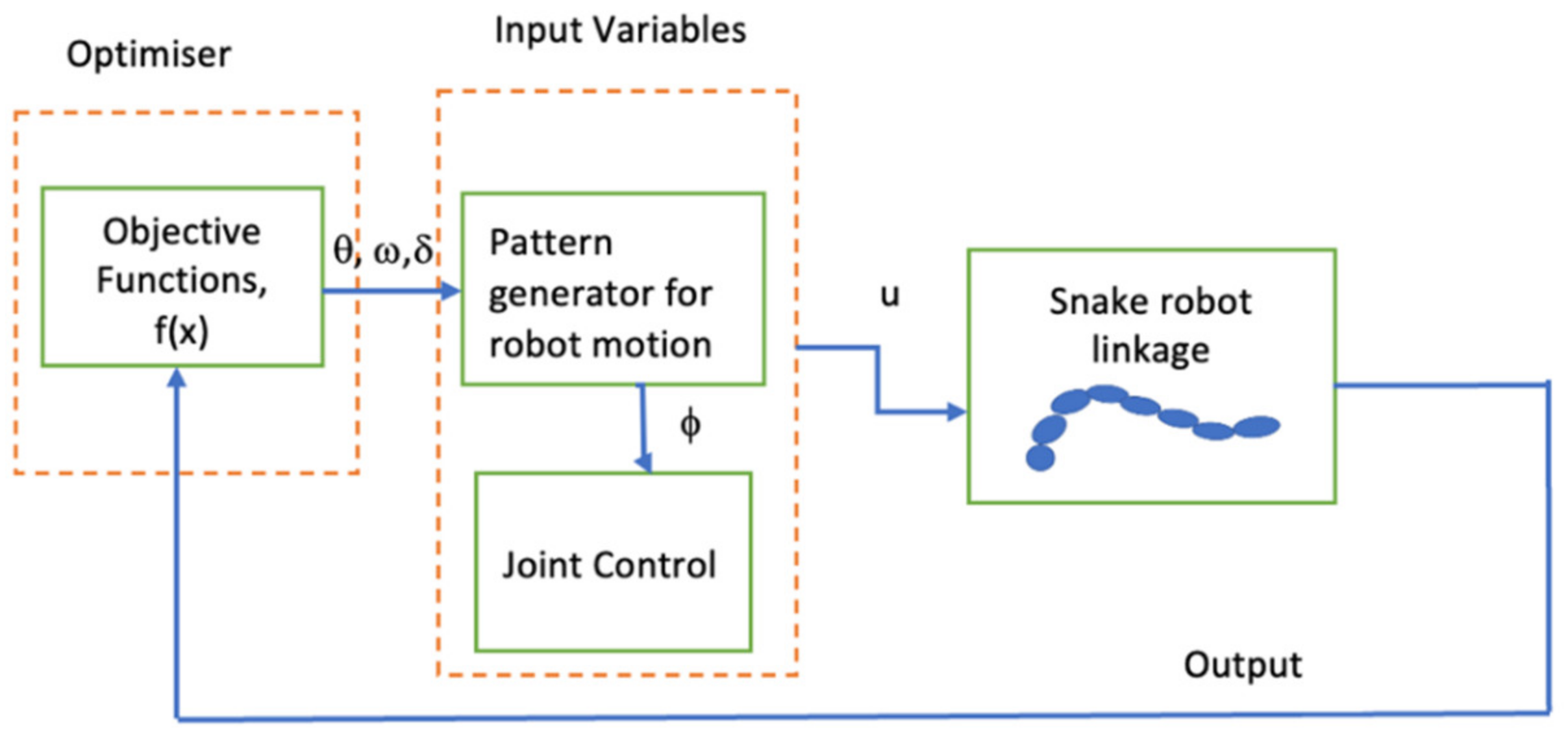

6.3. Optimisation Framework for Snake Robots

7. Sensing and Instrumentation

7.1. Fibre Bragg Grating (FBG) Sensors

7.2. Direction Bending Sensors

7.3. Electromagnetic Sensors

7.4. Optical Reflectance Sensors

8. Robot Verification and Validation

8.1. Kinematic Verification

8.2. Performance Verification

8.2.1. Deformation and Hysteresis Tests

8.2.2. Master–Slave Platform Tests

8.2.3. Testbed Workspace Analysis

8.3. Repeatability and Feasibility Criteria for Validation

8.4. Face and Construct Validity of Robot

9. Open Challenges and Future Applications

9.1. Increased Feedback for Surgical Snake Robots

9.2. Obstacle Collision Avoidance System

9.3. Nanoscale Smart Snake Robots

9.4. Biocompatibility of Materials

9.5. AI-Enabled Medical Snake Robots

9.5.1. Motion Learning and Optimization Using AR

9.5.2. Virtual Reality Systems in Surgery

10. Discussion

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Cambridge Firm Targets Medical Robots’ Boom—But Will It Stay British? Available online: https://www.theguardian.com/business/2021/oct/18/cambridge-firm-targets-medical-robots-boom-but-will-it-stay-british (accessed on 8 November 2021).

- Intuitive: ISRG for Investors. Investor Presentation Download. 2017. Available online: http://phx.corporate-ir.net/phoenix.zhtml?c=122359&p=irol-irhome (accessed on 8 November 2021).

- Khamis, A.; Meng, J.; Wang, J.; Azar, A.T.; Prestes, E.; Li, H.; Hameed, I.A.; Takács, Á.; Rudas, I.J.; Haidegger, T. Robotics and intelligent systems against a pandemic. Acta Polytech. Hung. 2021, 18, 13–35. [Google Scholar] [CrossRef]

- Baura, G.D. Medical Device Technologies; Academic Press: Oxford, UK, 2012. [Google Scholar]

- Wittbold, K.A.; Carroll, C.; Iansiti, M.; Zhang, H.M.; Landman, A.B. How hospitals are using AI to battle COVID-19. Harvard Bus. Rev. 2020, 3, 4. Available online: https://hbr.org/2020/04/how-hospitals-are-using-ai-to-battle-covid-19 (accessed on 10 January 2022).

- Zheng, M.H.; Boni, L.; Fingerhut, A. Minimally invasive surgery, and the novel coronavirus outbreak: Lessons learned in China and Italy. Ann. Surg. 2020, 272, e5–e6. [Google Scholar] [CrossRef] [PubMed]

- Zemmar, A.; Lozano, A.M.; Nelson, B.J. The rise of robots in surgical environments during COVID-19. Nat. Mach. Intell. 2020, 2, 566–572. [Google Scholar] [CrossRef]

- Panesar, S.; Cagle, Y.; Chander, D.; Morey, J.; Fernandez-Miranda, J.; Kliot, M. Artificial Intelligence and the Future of Surgical Robotics. Ann. Surg. 2019, 270, 223–226. [Google Scholar] [CrossRef]

- Runciman, M.; Darzi, A.; Mylonas, G.P. Soft Robotics in Minimally Invasive Surgery. Soft Robot. 2019, 6, 423–443. [Google Scholar] [CrossRef] [Green Version]

- Endzinas, Z.; Jonciauskiene, J.; Mickevicius, A.; Kiudelis, M. Hiatal hernia recurrence after laparoscopic fundoplication. Medicina 2007, 43, 27. [Google Scholar] [CrossRef] [Green Version]

- Robotic Thread Is Designed to Slip Through the Brain’s Blood Vessels. Available online: https://news.mit.edu/2019/robot-brain-blood-vessels-0828 (accessed on 11 November 2021).

- Tsuda, S.; Kudsi, Y. Robotic Assisted Minimally Invasive Surgery: A Comprehensive Textbook; Springer: Cham, Switzerland, 2018. [Google Scholar] [CrossRef] [Green Version]

- Lee, J.; Chung, W.Y. Robotic thyroidectomy and neck dissection. Past, present and future. Cancer J. 2013, 19, 151–161. [Google Scholar] [CrossRef]

- Yee, S. Transoral Robotic Surgery. AORN J. 2017, 105, 73–84. [Google Scholar] [CrossRef]

- Lee, K.E.; Koo, D.; Kim, S.J.; Lee, J.; Park, K.S.; Oh, S.K.; Youn, Y.K. Outcomes of 109 patients with papillary thyroid carcinoma who underwent robotic total thyroidectomy with central node dissection via the bilateral axillo-breast approach. Surgery 2010, 148, 1207–1213. [Google Scholar] [CrossRef]

- Faust, R.A.; Rahbar, R. Robotic surgical technique for pediatric laryngotracheal reconstruction. Otolaryngol. Clin. N. Am. 2008, 41, 1045. [Google Scholar] [CrossRef] [PubMed]

- Galvani, C.A.; Loebl, H.; Osuchukwu, O.; Samame, J.; Apel, M.E.; Ghaderi, I. Robotic-assisted paraesophageal hernia repair: Initial experience at a single institution. J. Laparoendosc. Adv. Surg. Tech. A 2016, 26, 290–295. [Google Scholar] [CrossRef] [PubMed]

- Marano, A.; Allisiardi, F.; Perino, E.; Pellegrino, L.; Geretto, P.; Borghi, F. Robotic Treatment for Large Duodenal Gastrointestinal Stromal Tumor. Ann. Surg. Oncol. 2020, 27, 1101–1102. [Google Scholar] [CrossRef] [PubMed]

- Berthet-Rayne, P.; Gras, G.; Leibrandt, K.; Wisanuvej, P.; Schmitz, A.; Seneci, C.A.; Yang, G.-Z. The i2Snake Robotic Platform for Endoscopic Surgery. Ann. Biomed. Eng. 2018, 46, 1663–1675. [Google Scholar] [CrossRef] [Green Version]

- Dobbs, T.D.; Cundy, O.; Samarendra, H.; Khan, K.; Whitaker, I.S. A Systematic Review of the Role of Robotics in Plastic and Reconstructive Surgery—From Inception to the Future. Front. Surg. 2017, 4, 66. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Wutzler, A.; Wolber, T.; Haverkamp, W.; Boldt, L.H. Robotic ablation of atrial fibrillation. J. Vis. Exp. JoVE 2015, 99, e52560. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ruiter, J.; Rozeboom, E.; van der Voort, M.; Bonnema, M.; Broeders, I. Design, and evaluation of robotic steering of a flexible endoscope. In Proceedings of the 4th IEEE RAS & EMBS International Conference on Biomedical Robotics and Biomechatronics (BioRob), Rome, Italy, 24–27 June 2012; IEEE: New York, NY, USA, 2012; pp. 761–767. Available online: http://ieeexplore.ieee.org/document/6290272/ (accessed on 10 November 2021).

- Pfeffer, J.; Grinshpon, R.; Rex, D.; Levin, B.; Rösch, T.; Arber, N.; Halpern, Z. The Aer-O-Scope: Proof of the concept of a pneumatic, skill-independent, self-propelling, self-navigating colonoscope in a pig model. Endoscopy 2006, 38, 144–148. [Google Scholar] [CrossRef] [PubMed]

- Uras, C.; Böler, D.E.; Ergüner, I.; Hamzaoğlu, I. Robotic single port cholecystectomy (R-LESS-C): Experience in 36 patients. Asian J. Surg. 2014, 37, 115–119. [Google Scholar] [CrossRef] [Green Version]

- Phee, S.J.; Low, S.C.; Huynh, V.A.; Kencena, A.P.; Sun, Z.L.; Yang, K. Master, and slave transluminal endoscopic robot (MASTER) for natural orifice transluminal endoscopic surgery (NOTES). In Proceedings of the 31st Annual International Conference of the IEEE Engineering in Medicine and Biology Society, Minneapolis, MN, USA, 3–6 September 2009; pp. 1192–1195. [Google Scholar]

- Xu, K.; Goldman, R.E.; Jienan, D.; Allen, P.K.; Fowler, D.L.; Simaan, N. System design of an insertable robotic effector platform for single port access (SPA) surgery. In Proceedings of the IEEE/RSJ International Conference on Intelligent Robots and Systems, St Louis, MO, USA, 10–15 October 2009; pp. 5546–5552. [Google Scholar]

- Degani, A.; Choset, H.; Wolf, A.; Zenati, M. Highly Articulated Robotic Probe for Minimally Invasive Surgery. In Proceedings of the IEEE International Conference on Robotics and Automation, Orlando, FL, USA, 15–19 May 2006; pp. 4167–4172. [Google Scholar]

- Kwok, K.W.; Tsoi, K.H.; Vitiello, V.; Clark, J.; Chow, G.C.; Luk, W.; Yang, G.Z. Dimensionality Reduction in Controlling Articulated Snake Robot for Endoscopy Under Dynamic Active Constraints. IEEE Trans. Robot. 2013, 29, 15–31. [Google Scholar] [CrossRef] [Green Version]

- Prasad, S.M.; Prasad, S.M.; Maniar, H.S.; Chu, C.; Schuessler, R.B.; Damiano, R.J., Jr. Surgical robotics: Impact of motion scaling on task performance. J. Am. Coll. Surg. 2004, 199, 863–868. [Google Scholar] [CrossRef] [PubMed]

- A New Era of Robotic-Assisted Surgery. Available online: https://www.nature.com/articles/d42473-021-00164-w (accessed on 11 November 2021).

- Berthet-Rayne, P. A Flexible Snake like Robot for Minimally Invasive Surgery: The i2Snake. Ph.D. Thesis, Hamlyn Centre for Robotic Surgery, Imperial College London, London, UK, 2016. [Google Scholar]

- Liljebäck, P.; Haugstuen, I.; Pettersen, K.Y. Path Following Control of Planar Snake Robots Using a Cascaded Approach. Control Syst. Technol. IEEE Trans. 2012, 20, 111–126. [Google Scholar] [CrossRef] [Green Version]

- Dupont, P.; Simaan, N.; Choset, H.; Rucker, C. Continuum Robots for Medical Interventions. Proc. IEEE 2022, 1–24. [Google Scholar] [CrossRef]

- Fujie, M.G.; Zhang, B. State-of-the-art of intelligent minimally invasive surgical robots. Front. Med. 2020, 14, 404–416. [Google Scholar] [CrossRef]

- Culmone, C.; Yikilmaz, S.F.; Trauzettel, F.; Breedveld, P. Follow-The-Leader Mechanisms in Medical Devices: A Review on Scientific and Patent Literature. IEEE Rev. Biomed. Eng. 2021, 20, 34543205. [Google Scholar] [CrossRef] [PubMed]

- Yu, S.; Xu, W.; Ren, H. Slender snake-like endoscopic robots in surgery. Flex. Robot. Med. 2020, 1, 1–17. [Google Scholar] [CrossRef]

- Simaan, N.; Xu, K.; Kapoor, A.; Wei, W.; Kazanzides, P.; Flint, P.; Taylor, R. Design and Integration of a Telerobotic System for Minimally Invasive Surgery of the Throat. Int. J. Robot. Res. 2009, 28, 1134–1153. [Google Scholar] [CrossRef] [PubMed]

- Shang, J.; Payne, C.J.; Clark, J.; Noonan, D.P.; Kwok, K.-W.; Darzi, A.; Yang, G.-Z. Design of a Multitasking Robotic Platform with Flexible Arms and Articulated Head for Minimally Invasive Surgery. Rep. US 2012, 2012, 1988–1993. [Google Scholar]

- Kuwada, A.; Tsujino, K.; Suzumori, K.; Kanda, K. Intelligent actuators realizing snake-like small robot for pipe inspection. In Proceedings of the 2006 IEEE International Symposium on MicroNanoMechanical and Human Science, Nagoya, Japan, 5–8 November 2006; pp. 1–6. [Google Scholar] [CrossRef]

- Hirose, S.; Mori, M. Biologically inspired snake-like robots. In Proceedings of the 2004 IEEE International Conference on Robotics and Biomimetics, Shenyang, China, 22–26 August 2004; pp. 1–7. [Google Scholar]

- Fjerdingen, S.A.; Liljeback, P.; Transeth, A.A. A snake-like robot for internal inspection of complex pipe structures (PIKo). In Proceedings of the 2009 IEEE/RSJ International Conference on Intelligent Robots and Systems, IROS 2009, St. Louis, MO, USA, 10–15 October 2009; pp. 5665–5671. [Google Scholar]

- Roh, K.S.; Yoon, S.; Kwon, Y.; Shim, Y.; Kim, Y. Single-Port Surgical Robot System with Flexible Surgical Instruments. Intell. Robot. Appl. 2015, 9245, 447–459. [Google Scholar] [CrossRef]

- Tappe, S.; Pohlmann, J.; Kotlarski, J.; Ortmaier, T. Towards a follow-the-leader control for a binary actuated hyper-redundant manipulator. In Proceedings of the IEEE/RSJ International Conference on Intelligent Robots and Systems, Hamburg, Germany, 28 September–2 October 2015; IEEE: New York, NY, USA, 2015; pp. 3195–3201. [Google Scholar]

- Ida, Y.; Sugita, N.; Ueta, T.; Tamaki, Y.; Tanimoto, K.; Mitsuishi, M. Microsurgical robotic system for vitreoretinal surgery. Int. J. Comput. Assist. Radiol. Surg. 2012, 7, 27–34. [Google Scholar] [CrossRef]

- Bhatti, O.S.; Mehmood-ul-Hassan, K.; Imtiaz, M.A. Attitude Control and Stabilization of a Two-Wheeled Self-Balancing Robot. Control Eng. Appl. Inform. 2015, 17, 98–104. [Google Scholar]

- Tanaka, M.; Tanaka, K.; Matsuno, F. Approximate path-tracking control of snake robot joints with switching constraints. IEEE/ASME Trans. Mechatron. 2015, 20, 1633–1641. [Google Scholar] [CrossRef]

- Ponte, H.; Queenan, M.; Gong, C.; Mertz, C.; Travers, M.; Enner, F.; Hebert, M.; Choset, H. Visual sensing for developing autonomous behavior in snake robots. In Proceedings of the 2014 IEEE International Conference on Robotics and Automation (ICRA), Seattle, WA, USA, 26–30 May 2014; pp. 2779–2784. [Google Scholar]

- Santoso, J.; Onal, C.D. An Origami Continuum Robot Capable of Precise Motion Through Torsionally Stiff Body and Smooth Inverse Kinematics. Soft Robot. 2021, 8, 371–386. [Google Scholar] [CrossRef] [PubMed]

- Transeth, A.A.; Leine, R.I.; Glocker, C.; Pettersen, K.Y. 3-d snake robot motion: Nonsmooth modeling, simulations, and experiments. IEEE Trans. Robot. 2008, 24, 361–376. [Google Scholar] [CrossRef] [Green Version]

- Osuka, K.; Kitajima, H. Development of mobile inspection robot for rescue activities: MOIRA. In Proceedings of the 2003 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS 2003) (Cat. No.03CH37453), Las Vegas, NV, USA, 27–31 October 2003; Volume 3, pp. 3373–3377. [Google Scholar]

- Singh, A.; Paigwar, A.; Manchukant, S.; Saroya, M.; Maurya, M.; Chiddarwar, S. Design and implementation of Omni-directional spherical modular snake robot (OSMOS). In Proceedings of the 2017 IEEE International Conference on Mechatronics (ICM), Churchill, VIC, Australia, 13–15 February 2017; pp. 79–84. [Google Scholar]

- Brown, H.B.; Vande Weghe, J.M.; Bererton, C.A.; Khosla, P.K. Millibot trains for enhanced mobility. IEEE/ASME Trans. Mechatron. 2002, 7, 452–461. [Google Scholar] [CrossRef]

- Armada, M.A.; Granosik, G.; Hansen, M.G.; Borenstein, J. The omnitread serpentine robot for industrial inspection and surveillance. Indus. Robot Int. J. 2005, 32, 139–148. [Google Scholar] [CrossRef] [Green Version]

- Robinson, G.; Davies, J.B.C. Continuum robots—A state of the art. In Proceedings of the 1999 IEEE International Conference on Robotics and Automation (Cat. No. 99CH36288C), Detroit, MI, USA, 10–15 May 1999; Volume 4, pp. 2849–2854. [Google Scholar] [CrossRef]

- Burgner-Kahrs, J.; Rucker, D.C.; Choset, H. Continuum Robots for Medical Applications: A Survey. IEEE Trans. Robot. 2015, 31, 1261–1280. [Google Scholar] [CrossRef]

- Rolf, M.; Neumann, K.; Queißer, J.; Reinhart, F.; Nordmann, A.; Steil, J. A Multi-Level Control Architecture for the Bionic Handling Assistant. Adv. Robot. 2015, 29, 847–859. [Google Scholar] [CrossRef] [Green Version]

- Suh, J.W.; Kim, K.Y.; Jeong, J.W.; Lee, J.J. Design considerations for a hyper-redundant pulleyless rolling joint with elastic fixtures. IEEE/ASME Trans. Mechatron. 2015, 20, 2841–2852. [Google Scholar] [CrossRef]

- Wang, J.; Yang, X.; Li, P.; Song, S.; Liu, L.; Meng, M.Q. Design of a multi-arm concentric-tube robot system for transnasal surgery. Med. Biol. Eng. Comput. 2020, 58, 497–508. [Google Scholar] [CrossRef]

- Webster, R.J., III; Okamura, A.M.; Cowan, N.J. Toward active cannulas: Miniature snake-like surgical robots. In Proceedings of the 2006 IEEE/RSJ International Conference on Intelligent Robots and Systems, Beijing, China, 9–15 October 2006; pp. 2857–2863. [Google Scholar]

- Gao, A.; Li, J.; Zhou, Y.; Wang, Z.; Liu, H. Modeling and Task-Oriented Optimization of Contact-Aided Continuum Robots. IEEE/ASME Trans. Mechatron. 2020, 25, 1444–1455. [Google Scholar] [CrossRef]

- Ikuta, K.; Ichikawa, H.; Suzuki, K.; Yamamoto, T. Safety active catheter with multi-segments driven by innovative hydro-pressure micro actuators. In Proceedings of the Sixteenth Annual International Conference on Micro Electromechanical Systems, Kyoto, Tokyo, 19–21 January 2003; MEMS-03. Springer: Berlin/Heidelberg, Germany, 2003; pp. 130–135. [Google Scholar]

- Kato, T.; Okumura, I.; Kose, H.; Takagi, K.; Hata, N. Tendon-driven continuum robot for neuroendoscopy: Validation of extended kinematic mapping for hysteresis operation. Int. J. Comput. Assist. Radiol. Surg. 2016, 11, 589–602. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Salerno, M.; Zhang, K.; Menciassi, A.; Dai, J.S. A Novel 4-DOF Origami Grasper with an SMA-Actuation System for Minimally Invasive Surgery. IEEE Trans. Robot. 2016, 32, 484–498. [Google Scholar] [CrossRef]

- Vander Hoff, E.; Jeong, D.; Lee, K. Origami Bot-I: A thread-actuated origami robot for manipulation and locomotion. In Proceedings of the 2014 IEEE/RSJ International Conference on Intelligent Robots and Systems, Chicago, IL, USA, 14–18 September 2014; IEEE: New York, NY, USA, 2014; pp. 1421–1426. [Google Scholar]

- Zhang, K.; Qiu, C.; Dai, J.S. An extensible continuum robot with integrated origami parallel modules. J. Mech. Robot. 2016, 8, 031010. [Google Scholar] [CrossRef]

- Lee, K.; Wang, Y.; Zheng, C. TWISTER Hand: Underactuated Robotic Gripper Inspired by Origami Twisted Tower. IEEE Trans. Robot. 2020, 36, 488–500. [Google Scholar] [CrossRef]

- Kim, Y.; Parada, G.A.; Liu, S.; Zhao, X. Ferromagnetic soft continuum robots. Sci. Robot. 2019, 4, eaax7329. [Google Scholar] [CrossRef] [PubMed]

- Jeon, S.; Hoshiar, A.K.; Kim, K.; Lee, S.; Kim, E.; Lee, S.; Kim, J.-Y.; Nelson, B.J.; Cha, H.-J.; Yi, B.-J.; et al. A magnetically controlled soft microrobot steering a guidewire in a three-dimensional phantom vascular network. Soft Robot. 2018, 6, 54–68. [Google Scholar] [CrossRef] [Green Version]

- Kim, J.; Chung, S.E.; Choi, S.E.; Lee, H.; Kim, J.; Kwon, S. Programming magnetic anisotropy in polymeric microactuators. Nat. Mater. 2011, 10, 747–752. [Google Scholar] [CrossRef]

- Wu, Z.; Li, Q.; Zhao, J.; Gao, J.; Xu, K. Design of a Modular Continuum-Articulated Laparoscopic Robotic Tool with Decoupled Kinematics. IEEE Robot. Autom. Lett. 2019, 4, 3545–3552. [Google Scholar] [CrossRef]

- Jelínek, F.; Arkenbout, E.; Henselmans, P.; Pessers, R.; Breedveld, P. Classification of Joints Used in Steerable Instruments for Minimally Invasive Surgery—A Review of the State of the Art. J. Med. Devices 2015, 9, 010801. [Google Scholar] [CrossRef]

- Xu, Y.; Guo, K.; Sun, J.; Li, J. Design, modeling, and control of a reconfigurable variable stiffness actuator. Mech. Syst. Signal Process. 2021, 160, 107883. [Google Scholar] [CrossRef]

- Haycock, A.; Bassett, P.; Bladen, J.; Thomas-Gibson, S. Validation of the second-generation Olympus colonoscopy simulator for skills assessment. Endoscopy 2009, 41, 952–958. [Google Scholar] [CrossRef] [PubMed]

- Yagi, A.; Matsumiya, K.; Masamune, K.; Liao, H.; Dohi, T. Rigid-flexible outer sheath model using slider linkage locking mechanism and air pressure for endoscopic surgery. Med. Image Comput. Comput. 2006, 9, 503–510. [Google Scholar]

- Mylonas, G.; Vitiello, V.; Cundy, T.; Darzi, A.; Yang, G.Z. CYCLOPS: A versatile robotic tool for bimanual single-access and natural-orifice endoscopic surgery. In Proceedings of the IEEE International Conference on Robotics and Automation, Hong Kong, China, 31 May–7 June 2014. [Google Scholar]

- Maghooa, F.; Stilli, A.; Noh, Y.; Althoefer, K.; Wurdemann, H.A. Tendon and pressure actuation for a bio-inspired manipulator based on an antagonistic principle. In Proceedings of the IEEE International Conference on Robotics and Automation, Seattle, WA, USA, 26–30 May 2015; IEEE: New York, NY, USA, 2015; pp. 2556–2561. [Google Scholar]

- Sun, C.; Chen, L.; Liu, J.; Dai, J.S.; Kang, R. A hybrid continuum robot based on pneumatic muscles with embedded elastic rods. Proc. Inst. Mech. Eng. 2020, 234, 318–328. [Google Scholar] [CrossRef]

- Tadano, K.; Kawashima, K. Development of a master slave system with force-sensing abilities using pneumatic actuators for laparoscopic surgery. Adv. Robot. 2010, 24, 1763–1783. [Google Scholar] [CrossRef]

- Grissom, M.; Chitrakaran, V.; Dienno, D.; Csencits, M.; Pritts, M.; Jones, B.; Mcmahan, W.; Dawson, D.; Rahn, C.; Walker, I. Design and experimental testing of the OctArm soft robot manipulator. Proc. SPIE Int. Soc. Optic. Eng. 2006, 6230, 62301F. [Google Scholar]

- Sadati, S.M.H.; Noh, Y.; Naghibi, S.E.; Althoefer, K.; Nanayakkara, T. Stiffness Control of Soft Robotic Manipulator for Minimally Invasive Surgery (MIS) Using Scale Jamming. Intell. Robot. Appl. 2015, 9246, 141–151. [Google Scholar]

- Cianchetti, M.; Ranzani, T.; Gerboni, G.; Nanayakkara, T.; Althoefer, K.; Dasgupta, P.; Menciassi, A. Soft robotics technologies to address shortcomings in today’s minimally invasive surgery: The STIFF-FLOP approach. Soft Robot. 2014, 1, 122–131. [Google Scholar] [CrossRef]

- Ranzani, T.; Gerboni, G.; Cianchetti, M.; Menciassi, A. A bioinspired soft manipulator for minimally invasive surgery. Bioinsp. Biom. 2015, 10, 35008. [Google Scholar] [CrossRef]

- Fitzgerald, S.G.; Delaney, G.W.; Howard, D. A Review of Jamming Actuation in Soft Robotics. Actuators 2020, 9, 104. [Google Scholar] [CrossRef]

- Manti, M.; Hassan, T.; Passetti, G.; Cianchetti, M.; Laschi, C. An Under-Actuated and Adaptable Soft Robotic Gripper. Biomim. Biohydr. Syst. 2015, 9222, 64–74. [Google Scholar] [CrossRef]

- Henselmans, P.; Culmone, C.; Jager, D.; Starkenburg, R.; Breedveld, P. The MemoFlex II, a non-robotic approach to follow-the-leader motion of a snake-like instrument for surgery using four predetermine d physical tracks. Med. Eng. Phys. 2020, 86, 86–95. [Google Scholar] [CrossRef] [PubMed]

- Delda, R.N.M.; Basuel, R.B.; Hacla, R.P.; Martinez, D.W.C.; Cabibihan, J.-J.; Dizon, J.R.C. 3D Printing Polymeric Materials for Robots with Embedded Systems. Technologies 2021, 9, 82. [Google Scholar] [CrossRef]

- Preechayasomboon, P.; Rombokas, E. Negshell casting: 3D-printed structured and sacrificial cores for soft robot fabrication. PLoS ONE 2020, 15, e0234354. [Google Scholar] [CrossRef]

- Hu, Y.; Zhang, L.; Li, W.; Yang, G. Design and Fabrication of a 3-D Printed Metallic Flexible Joint for Snake-Like Surgical Robot. IEEE Robot. Autom. Lett. 2019, 4, 1557–1563. [Google Scholar] [CrossRef]

- Rost, A.; Schadle, S. The SLS-generated soft robotic hand—An integrated approach using additive manufacturing and reinforcement learning. In Proceedings of the 2013 12th International Conference on Machine Learning and Applications, Miami, FL, USA, 4–7 December 2013; IEEE: New York, NY, USA, 2013; pp. 215–220. [Google Scholar] [CrossRef]

- Roppenecker, D.B.; Pfaff, A.; Coy, J.A.; Lueth, T.C. Multi arm snake-like robot kinematics. In Proceedings of the 2013 IEEE/RSJ International Conference on Intelligent Robots and Systems, Tokyo, Japan, 3–7 November 2013; IEEE: New York, NY, USA; 2013, pp. 5040–5045. [Google Scholar]

- Dumitru, N.; Ciurezu-Gherghe, L.; Copiluși, C.; Geonea, I.; Dumitru, S. Theoretical and experimental study methods for a robotic system with deformable elements used in minimally invasive surgery. Mech. Mach. Theory 2022, 167, 104459. [Google Scholar] [CrossRef]

- Xu, K.; Simaan, N. Actuation compensation for flexible surgical snake-like robots with redundant remote actuation. In Proceedings of the IEEE International Conference on Robotics and Automation, Orlando, FL, USA, 15–19 May 2006; pp. 4148–4154. [Google Scholar]

- Vaida, C.; Plitea, N.; Pisla, D.; Gherman, B. Orientation module for surgical instruments—A systematical approach. Meccanica 2013, 48, 145–158. [Google Scholar] [CrossRef]

- Gray, J. The mechanism of locomotion in snakes. J. Exp. Biol. 1946, 23, 101–120. [Google Scholar] [CrossRef]

- Jayne, B.C. Muscular mechanisms of snake locomotion: An electromyographic study of the sidewinding and concertina modes of Crotalus cerastes, Nerodia fasciata and Elaphe obsoleta. J. Exp. Biol. 1988, 140, 1–33. [Google Scholar] [CrossRef] [PubMed]

- Marvi, H.; Gong, C.; Gravish, N.; Astley, H.; Travers, M.; Hatton, R.L.; Mendelson, J.R.; Choset, H.; Hu, D.L.; Goldman, D.I. Sidewinding with minimal slip: Snake and robot ascent of sandy slopes. Science 2014, 346, 224–229. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Gong, C.; Travers, M.J.; Astley, H.C.; Li, L.; Mendelson, J.R.; Goldman, D.I.; Choset, H. Kinematic gait synthesis for snake robots. Int. J. Robot. Res. 2016, 35, 100–113. [Google Scholar] [CrossRef]

- Dear, T.; Buchanan, B.; Abrajan-Guerrero, R.; Kelly, S.D.; Travers, M.; Choset, H. Locomotion of a multi-link non-holonomic snake robot with passive joints. Int. J. Robot. Res. 2020, 39, 027836491989850. [Google Scholar] [CrossRef]

- Yaqub, S.; Ali, A.; Usman, M.; Zuhaib, K.M.; Khan, A.M.; An, B.; Moon, H.; Lee, J.-Y.; Han, C. A spiral curve gait design for a modular snake robot moving on a pipe. Int. J. Control Autom. Syst. 2019, 17, 2565–2573. [Google Scholar] [CrossRef]

- Hu, D.L.; Nirody, J.; Scott, T.; Shelley, M.J. The mechanics of slithering locomotion. Proc. Natl. Acad. Sci. USA 2009, 106, 10081–10085. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Dowling, K. Limbless locomotion: Learning to crawl. In Proceedings of the IEEE International Conference on Robotics and Automation, Detroit, MI, USA, 10–15 May 1999; Volume 4, pp. 3001–3006. [Google Scholar]

- Chen, L.; Wang, Y.; Ma, S.; Li, B. Studies on lateral rolling locomotion of a snake robot. In Proceedings of the IEEE International Conference on Robotics and Automation, Barcelona, Spain, 26 April–1 May 2004; pp. 5070–5074. [Google Scholar]

- Yim, M. New locomotion gaits. In Proceedings of the IEEE International Conference on Robotics and Automation, San Diego, CA, USA, 8–13 May 1994; Volume 3, pp. 2508–2514. [Google Scholar]

- Wei, W.; Goldman, R.; Fine, H.; Chang, S.; Simaan, N. Performance evaluation for multi-arm manipulation of hollow suspended organs. IEEE Trans. Robot. 2009, 25, 147–157. [Google Scholar] [CrossRef] [Green Version]

- Rezaei, S.M.; Barazandeh, F.; Haidarzadeh, M.S.; Sadat, S.M. The effect of snake muscular system on actuators’ torque. J. Intell. Robot. Syst. 2010, 59, 299–318. [Google Scholar] [CrossRef]

- Wang, X.; Tian, F. The Design of a Tendon-Sheath-Driven Robot. In Proceedings of the 2008 15th International Conference on Mechatronics and Machine Vision in Practice, Auckland, New Zealand, 2–4 December 2008; pp. 280–284. [Google Scholar]

- Li, M.; Kang, R.; Geng, S.; Guglielmino, E. Design and control of a tendon-driven continuum robot. Trans. Inst. Meas. Control 2017, 40, 3263–3272. [Google Scholar] [CrossRef]

- Neumann, M.; Burgner-Kahrs, J. Considerations for follow-the-leader motion of extensible tendon-driven continuum robots. In Proceedings of the 2016 IEEE International Conference on Robotics and Automation (ICRA), Stockholm, Sweden, 16–20 May 2016; pp. 917–923. [Google Scholar]

- Tondu, B.; Lopez, P. Modeling and control of McKibben artificial muscle robot actuators. IEEE Control Syst. Mag. 2000, 20, 15–38. [Google Scholar] [CrossRef]

- Granosik, G.; Borenstein, J. Integrated joint actuator for serpentine robots. IEEE/ASME Trans. Mechatron. 2005, 10, 473–481. [Google Scholar] [CrossRef]

- Marchese, A.D.; Rus, D. Design, kinematics, and control of a soft spatial fluidic elastomer manipulator. Int. J. Robot. Res. 2016, 35, 840–869. [Google Scholar] [CrossRef]

- Kakogawa, A.; Jeon, S.; Ma, S. Stiffness design of a resonance-based planar snake robot with parallel elastic actuators. IEEE Robot. Autom. Lett. 2018, 3, 1284–1291. [Google Scholar] [CrossRef]

- Kim, Y.J.; Cheng, S.B.; Kim, S.; Iagnemma, K. A stiffness-adjustable hyperredundant manipulator using a variable neutral-line mechanism for minimally invasive surgery. IEEE Trans. Rob. 2014, 30, 382–395. [Google Scholar] [CrossRef] [Green Version]

- Shapere, A.; Wilczek, F. Geometry of self-propulsion at low reynolds number. J. Fluid Mech. 1989, 198, 557–585. [Google Scholar] [CrossRef] [Green Version]

- Murray, R.; Sastry, S. Nonholonomic motion planning: Steering using sinusoids. IEEE Trans. Autom. Control 1993, 38, 700–715. [Google Scholar] [CrossRef] [Green Version]

- Ostrowski, J. The mechanics and Control of Undulatory Robotic Locomotion. Ph.D. Thesis, California Institute of Technology, Pasadena, CA, USA, 1995. [Google Scholar]

- Lipták, T.; Virgala, I.; Frankovský, P.; Šarga, P.; Gmiterko, A.; Baločková, L. A geometric approach to modeling of four- and five-link planar snake-like robot. Int. J. Adv. Robot. Syst. 2016, 13, 1729881416663714. [Google Scholar] [CrossRef]

- Dong, X.; Raffles, M.; Guzman, S.; Axinte, D.; Kell, J. Design and analysis of a family of snake arm robots connected by compliant joints. Mech. Mach. Theory 2014, 77, 73–91. [Google Scholar] [CrossRef]

- Schmitz, A. Flexible Instruments for a Snake-Like Robot. Ph.D. Thesis, Imperial College London, London, UK, 2020. [Google Scholar]

- Sato, M.; Fukaya, M.; Iwasaki, T. Serpentine locomotion with robotic snakes. IEEE Control Syst. 2002, 22, 64–81. [Google Scholar]

- Zhao, X.; Dou, L.; Su, Z.; Liu, N. Study of the Navigation Method for a Snake Robot Based on the Kinematics Model with MEMS IMU. Sensors 2018, 18, 879. [Google Scholar] [CrossRef] [Green Version]

- Murray, R.M.; Li, Z.; Sastry, S.S. A Mathematical Introduction to Robotic Manipulation, 1st ed.; CRC Press: Boca Raton, FL, USA, 1994. [Google Scholar]

- Berthet-Rayne, P.; Leibrandt, K.; Kim, K.; Seneci, C.A.; Shang, J.; Yang, G.-Z. Rolling-joint design optimization for tendon driven snake-like surgical robots. In Proceedings of the 2018 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), Madrid, Spain, 1–5 October 2018. [Google Scholar]

- Kaelbling, L.P.; Littman, M.L.; Moore, A.W. Reinforcement learning: A survey. J. Artif. Intell. Res. 1996, 4, 237–285. [Google Scholar] [CrossRef] [Green Version]

- Luo, M.; Pan, Y.; Skorina, E.H.; Tao, W.; Chen, F.; Ozel, S.; Onal, C.D. Slithering towards autonomy: A self-contained soft robotic snake platform with integrated curvature sensing. Bioinspir. Biomimet. 2015, 10, 055001. [Google Scholar] [CrossRef]

- Moore, K.L.; Xu, J.-X. Iterative Learning Control; Taylor & Francis: Oxfordshire, UK, 2000. [Google Scholar]

- Choset, H.M.; Lynch, K.M.; Hutchinson, S.; Kantor, G.A.; Burgard, W. Principles of Robot Motion: Theory, Algorithms, and Implementation; MIT Press: Cambridge, UK, 2005. [Google Scholar]

- Spong, M.W.; Hutchinson, S.; Vidyasagar, M. Robot Modeling and Control; John Wiley & Sons: Hoboken, NJ, USA, 2006. [Google Scholar]

- Liljebäck, P.; Pettersen, K.Y.; Stavdahl, O.; Gravdahl, J.T. Snake Robots: Modelling, Mechatronics, and Control; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2012. [Google Scholar]

- Wang, Y.; Chirikjian, G. Workspace generation of hyper- redundant manipulators as a diffusion process on se(n). IEEE Trans. Rob. Automat. 2004, 20, 399–408. [Google Scholar] [CrossRef]

- Sheng, L.; Yiqing, W.; Qingwei, C.; Weili, H. A new geometrical method for the inverse kinematics of the hyper-redundant manipulators. In Proceedings of the IEEE International Conference On Robotics And Biomimetics, Kunming, China, 1–20 December 2006. [Google Scholar]

- Yahya, S.; Moghavvemi, M.; Mohamed, H. Geometrical approach of planar hyper-redundant manipulators: Inverse kinematics. Path. Plan. Workspace Simul. Model. Pract. Theory 2011, 19, 406–422. [Google Scholar] [CrossRef]

- Omisore, O.M.; Han, S.; Ren, L.; Zhang, N.; Ivanov, K.; Elazab, A.; Wang, L. Non-iterative geometric approach for inverse kinematics of redundant lead-module in a radiosurgical snake-like robot. Biomed. Eng. Online 2017, 16, 93. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Poi, G.; Scarabeo, C.; Allotta, B. Traveling wave locomotion hyper-redundant mobile robot. In Proceedings of the IEEE International Conference on Robotics and Automation, Lueven, Belgium, 24–28 April 1998; Volume 1, pp. 418–423. [Google Scholar]

- Liljeback, P.; Stavdahl, O.; Pettersen, K.Y. Modular pneumatic snake robot: 3D modelling, implementation and control. In Proceedings of the 16th IFAC World Congress, Prague, Czech Republic, 3–8 July 2005. [Google Scholar]

- Kelasidi, E.; Jesmani, M.; Pettersen, K.Y.; Gravdahl, J.T. Locomotion Efficiency Optimization of Biologically Inspired Snake Robots. Appl. Sci. 2018, 8, 80. [Google Scholar] [CrossRef] [Green Version]

- Kuo, P.D.; Grierson, D. Genetic algorithm optimization of escape and normal swimming gaits for a hydrodynamical model of carangiform locomotion. In Proceedings of the Genetic and Evolutionary Computation Conference (GECCO), Chicago, IL, USA, 12–16 July 2003; pp. 170–177. [Google Scholar]

- Kennedy, J.; Eberhart, R. Particle swarm optimization. In Proceedings of the IEEE International Conference on Neural Networks, Perth, WA, Australia, 27 November–1 December 1995; pp. 1942–1948. [Google Scholar]

- Hůlka, T.; Matoušek, R.; Dobrovský, L.; Dosoudilová, M.; Nolle, L. Optimization of Snake-like Robot Locomotion Using GA: Serpenoid Design. Mendel 2020, 26, 1–6. [Google Scholar] [CrossRef]

- Frede, T.; Stock, C.; Renner, C.; Budair, Z.; Abdel-Salam, Y.; Rassweiler, J. Geometry of laparoscopic suturing and knotting techniques. J. Endourol. 1999, 13, 191–198. [Google Scholar] [CrossRef] [PubMed]

- Monet, F.; Sefati, S.; Lorre, P.; Poiffaut, A.; Kadoury, S.; Armand, M.; Iordachita, I.; Kashyap, R. High-Resolution Optical Fiber Shape Sensing of Continuum Robots: A Comparative Study. IEEE Int. Conf. Robot. Autom. 2020, 2020, 9197454. [Google Scholar] [CrossRef]

- Polito, D.; Arturo Caponero, M.; Polimadei, A.; Saccomandi, P.; Massaroni, C.; Silvestri, S.; Schena, E. A Needlelike Probe for Temperature Monitoring During Laser Ablation Based on Fiber Bragg Grating: Manufacturing and Characterization. ASME J. Med. Dev. 2015, 9, 041006. [Google Scholar] [CrossRef]

- Bogue, R. Robots in healthcare. Ind. Robot Int. J. 2011, 38, 218–223. [Google Scholar] [CrossRef]

- Ramesh, D.; Fu, Q.; Li, C. SenSnake: A snake robot with contact force sensing for studying locomotion in complex 3-D terrain. In Proceedings of the IEEE International Conference on Robotics and Automation (ICRA) 2022, Philadelphia, PA, USA, 23–27 May 2022. [Google Scholar]

- Miqdad, A.; Suhairi, R.; Ali, A.M.M.; Roslan, N.F.; Aziz, P.D.A. Development of artificial hand gripper by using flex force sensor. In Proceedings of the 2014 4th International Conference on Engineering Technology and Technopreneurship (ICE2T), Kuala Lumpur, Malaysia, 18–20 September 2014; pp. 305–308. [Google Scholar] [CrossRef]

- Dario, P.; Carrozza, M.; Marcacci, M.; D’Attanasio, S.; Magnami, B.; Tonet, O.; Megali, G. A novel mechatronic tool for computer-assisted arthroscopy. In IEEE Transactions on Information Technology in Biomedicine: A Publication of the IEEE Engineering in Medicine and Biology Society; IEEE: New York, NY, USA, 2000; Volume 4, pp. 15–29. [Google Scholar] [CrossRef]

- Zhang, Z.; Shang, J.; Seneci, C.; Yang, G.Z. Snake robot shape sensing using micro-inertial sensors. In Proceedings of the IEEE/RSJ International Conference on Intelligent Robots and Systems, Tokyo, Japan, 3–7 November 2013; pp. 831–836. [Google Scholar]

- Franz, A.M.; Haidegger, T.; Birkfellner, W.; Cleary, K.; Peters, T.M.; Maier-Hein, L. Electromagnetic tracking in medicine—A review of technology, validation, and applications. IEEE Trans. Med. Imaging 2014, 33, 1702–1725. [Google Scholar] [CrossRef] [Green Version]

- Hummel, J.; Figl, M.; Bax, M.; Shahidi, R.; Bergmann, H.; Birkfellner, W. Evaluation of dynamic electromagnetic tracking deviation. Proc. SPIE Med. Imag. Visualizat. 2009, 7261, 1–7. [Google Scholar]

- Chirikjian, G.S. Design and analysis of some nonanthropomorphic, biologically inspired robots: An overview. J. Rob. Syst. 2001, 18, 701–713. [Google Scholar] [CrossRef]

- Locke, R.C.O.; Patel, R.V. Optimal remote center-of-motion location for robotics-assisted minimally invasive surgery. In Proceedings of the IEEE International Conference on Robotics and Automation, Rome, Italy, 11–16 April 2007; pp. 1900–1905. [Google Scholar]

- Azimian, H.; Patel, R.V.; Naish, M.D. On constrained manipulation in robotics-assisted minimally invasive surgery. In Proceedings of the IEEE RAS EMBS International Conference on Biomedical Robotics and Biomechatronics, Tokyo, Japan, 26–29 September 2010; pp. 650–655. [Google Scholar]

- Mower, T.M.; Long, M.J. Mechanical behavior of additive manufactured powder-bed laser-fused materials. Mater. Sci. Eng. A 2016, 651, 198–213. [Google Scholar] [CrossRef]

- Spierings, A.B.; Starr, T.L.; Wegener, K. Fatigue performance of additive manufactured metallic parts. Rapid Prototyp. J. 2013, 19, 88–94. [Google Scholar] [CrossRef]

- Okamura, A.M. Methods for haptic feedback in teleoperated robot-assisted surgery. Ind. Rob. 2004, 31, 499–508. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Schreuder, H.W.R.; Persson, J.E.U.; Wolswijk, R.G.H.; Ihse, I.; Schijven, M.P.; Verheijen, R.H.M. Validation of a Novel Virtual Reality Simulator for Robotic Surgery. Sci. World J. 2014, 2014, 507076. [Google Scholar] [CrossRef]

- Berthet-Rayne, P.; Leibrandt, K.; Gras, G.; Fraisse, P.; Crosnier, A.; Yang, G.Z. Inverse kinematics control methods for redundant snakelike robot teleoperation during minimally invasive surgery. IEEE Robot. Autom. Lett. 2018, 3, 2501–2508. [Google Scholar] [CrossRef]

- Abboudi, H.; Khan, M.S.; Aboumarzouk, O.; Guru, K.A.; Challacombe, B.; Dasgupta, P.; Ahmed, K. Status of validation for robotic surgery simulators—A systematic review. BJU Int. 2013, 111, 194–205. [Google Scholar] [CrossRef]

- Seixas-Mikelus, S.A.; Stegemann, A.P.; Kesavadas, T.; Srimathveeravalli, G.; Sathyaseelan, G.; Chandrasekhar, R.; Guru, K. Content validation of a novel robotic surgical simulator. BJU Int. 2011, 107, 1130–1135. [Google Scholar] [CrossRef] [PubMed]

- Hung, A.J.; Zehnder, P.; Patil, M.B.; Cai, J.; Ng, C.K.; Aron, M.; Gill, I.S.; Desai, M.M. Face, content and construct validity of a novel robotic surgery simulator. J. Urol. 2011, 186, 1019–1024. [Google Scholar] [CrossRef]

- Lendvay, T.S.; Casale, P.; Sweet, R.; Peters, C. VR robotic surgery: Randomized blinded study of the dV-Trainer robotic simulator. Stud. Health Technol. Inform. 2008, 132, 242–244. [Google Scholar]

- Haidegger, T. Autonomy for Surgical Robots: Concepts and Paradigms. IEEE Trans. Med. Robot. Bionics 2019, 1, 65–76. [Google Scholar] [CrossRef]

- Müller, C.; Laengle, J.; Riss, S.; Bergmann, M.; Bachleitner-Hofmann, T. Surgical Complexity and Outcome During the Implementation Phase of a Robotic Colorectal Surgery Program-A Retrospective Cohort Study. Front. Oncol. 2021, 10, 603216. [Google Scholar] [CrossRef] [PubMed]

- Ju, M.H.; Huh, J.H.; Lee, C.H.; Kim, H.J.; Je, H.G.; Kim, J.B.; Jung, S.H.; Lee, J.W. Robotic-Assisted Surgical Ablation of Atrial Fibrillation Combined with Mitral Valve Surgery. Ann. Thorac. Surg. 2019, 107, 762–768. [Google Scholar] [CrossRef] [PubMed]

- Valderrábano, M.; Dave, A.S.; Báez-Escudero, J.L.; Rami, T. Robotic catheter ablation of left ventricular tachycardia: Initial experience. Heart Rhythm 2011, 8, 1837–1846. [Google Scholar] [CrossRef] [Green Version]

- Poffo, R.; Toschi, A.P.; Pope, R.B.; Celullare, A.L.; Benício, A.; Fischer, C.H.; Vieira, M.L.; Teruya, A.; Hatanaka, D.M.; Rusca, G.F.; et al. Robotic surgery in cardiology: A safe and effective procedure. Einstein 2013, 11, 296–302. [Google Scholar] [CrossRef] [Green Version]

- Do, T.N.; Tjahjowidodo, T.; Lau, M.; Phee, S. An investigation of friction-based tendon sheath model appropriate for control purposes. Mech. Syst. Signal Process. 2014, 42, 97–114. [Google Scholar] [CrossRef]

- Okamura, A.M. Haptic feedback in robot-assisted minimally invasive surgery. Curr. Opin. Urol. 2009, 19, 102–107. [Google Scholar] [CrossRef]

- Hwang, M.; Lee, D.H.; Ahn, J.; You, J.; Baek, D.; Kim, H.; Kirchmeier, R.R.; Kwon, D.S. Flexible Endoscopic Surgery Robot System, K-FLEX. In Proceedings of the 2018 18th International Conference on Control, Automation and Systems (ICCAS 2018), PyeongChang, Korea, 17–20 October 2018. [Google Scholar]

- Da Veiga, T.; Chandler, J.; Lloyd, P.; Pittiglio, G.; Wilkinson, N.J.; Hoshiar, A.K.; Harris, R.A.; Valdastri, P. Challenges of continuum robots in clinical context: A review. Prog. Biomed. Eng. 2020, 2, 032003. [Google Scholar] [CrossRef]

- Park, J.; Son, B.; Han, I.; Lee, W. Effect of Cutaneous Feedback on the Perception of Virtual Object Weight during Manipulation. Sci. Rep. 2020, 10, 1357. [Google Scholar] [CrossRef] [Green Version]

- Moe, S.; Pettersen, K.Y. Set-based line-of-sight (LOS) path following with collision avoidance for underactuated unmanned surface vessel. In Proceedings of the 24th Mediterranean Conference on Control and Automation, Athens, Greece, 21–24 June 2016; pp. 402–409. [Google Scholar]

- Arming Biological Nanobots to Deliver Drugs Inside Our Bodies. Available online: https://www.labiotech.eu/in-depth/nanobots-drug-delivery (accessed on 20 January 2022).

- Singh, G.; Singh, S.; Prakash, C.; Kumar, R.; Kumar, R.; Ramakrishna, S. Characterization of three-dimensional printed thermal-stimulus polylactic acid-hydroxyapatite-based shape memory scaffolds. Polym. Compos. 2020, 41, 3871–3891. [Google Scholar] [CrossRef]

- Yin, M.J.; Yao, M.; Gao, S.; Zhang, A.P.; Tam, H.Y.; Wai, P.K.A. Rapid 3D patterning of poly (acrylic acid) ionic hydrogel for miniature pH sensors. Adv. Mater. 2016, 28, 1394–1399. [Google Scholar] [CrossRef] [PubMed]

- Singh, S.; Singh, G.; Prakash, C.; Ramakrishna, S.; Lamberti, L.; Pruncu, C.I. 3D printed biodegradable composites: An insight into mechanical properties of PLA/chitosan scaffold. Polym. Test. 2020, 89, 106722. [Google Scholar] [CrossRef]

- Takács, A.; Nagy, D.Á.; Rudas, I.; Haidegger, T. Origins of surgical robotics: From space to the operating room. Acta Polytech. Hung. 2016, 13, 13–30. [Google Scholar]

- Hussain, R.; Lalande, A.; Marroquin, R.; Guigou, C.; Grayeli, A.B. Video-based augmented reality combining CT-scan and instrument position data to microscope view in middle ear surgery. Sci. Rep. 2020, 10, 6767. [Google Scholar] [CrossRef] [Green Version]

- Pfefferle, M.; Shahub, S.; Shahedi, M.; Gahan, J.; Johnson, B.; Le, P.; Vargas, J.; Judson, B.O.; Alshara, Y.; Li, O.; et al. Renal biopsy under augmented reality guidance. Med. Imag. 2020, 11315, 113152W. [Google Scholar] [CrossRef]

- El-Hariri, H.; Pandey, P.; Hodgson, A.J.; Garbi, R. Augmented reality visualisation for orthopaedic surgical guidance with pre- and intra-operative multimodal image data fusion. Healthc. Technol. Lett. 2018, 5, 189–193. [Google Scholar] [CrossRef]

- Buettner, R.; Renner, A.; Boos, A. A systematic literature review of research in the surgical field of medical robotics. In Proceedings of the 2020 IEEE 44th Annual Computers, Software, and Applications Conference (COMPSAC), Madrid, Spain, 13–17 July 2020; pp. 517–522. [Google Scholar] [CrossRef]

- Se-Joon, C. Hand Pose Estimation and Prediction for Virtual Reality Applications. Ph.D. Thesis, Carnegie Mellon University, Pittsburgh, PA, USA, 2021. [Google Scholar]

- Venkatesan, M.; Mohan, H.; Ryan, J.R.; Schürch, C.M.; Nolan, G.P.; Frakes, D.H.; Coskun, A.F. Virtual and augmented reality for biomedical applications. Cell Rep. Med. 2021, 2, 100348. [Google Scholar] [CrossRef] [PubMed]

| Project Name | Author/Institute | Functioning Principle | Degrees of Freedom | Analysis Method |

|---|---|---|---|---|

| Telerobotic System for Minimally Invasive Surgery of the Throat | Simaan et al. [37] | Shortening and lengthening of circumferentially located NiTi backbones | 2 | Force sensing and kinematic modelling |

| I-Snake Surgical Robotic system | Shang et al. [38] | Interventions with the peritoneal cavity through a single orifice of 12.5 mm | 4 | N/A |

| CardioARM (Carnegie Mellon University) | Degani and Choset [27] | Multiple links strung together by cables actuated by conventional motors | Five for distal apparatus, 2 DOF for joystick | Variable stiffness in central cable tensioning, pose estimation and internal shape |

| Small snake-like robot for pipe inspection | Kuwada et al. [39] | Sinusoidal wave drive formed by coupling DC motors in series by rotational joints | N/R | Diameter variation analysis and its effect on movement |

| ACM-III robot | Hirose et al. [40] | Temporal and spatial motion for triggering locomotive recoil forces. Use of passive wheels along the body, with radio-servos for propulsion | 1 | Demonstrating Hirose’s serpenoid curve, use of tactile sensors for obstacle-aided locomotion |

| PIKo robot | Fjerdingen et al. [41] | Identical modules linked by two rotational joints, with wheels for forward and backward propulsion | 8 | Horizontal motion through bend, vertical climbing |

| Snake-like robot | Roh et al. [42] | Quad-tendon sheath mechanism and rolling joint control, associated with stereovision through 3D cameras | Two 7-DOF surgical tools, and a 5-DOF slave arm (14 in total) | N/A |

| Magnetic controlled snake robot | Tappe et al. [43] | Magnets were bevelled so that the joint could curve with angle commutation | N/R | N/A |

| Handheld flexible surgical robot | Ida et al. [44] | three linear motions and one rotational plane | 4 | N/A |

| Three-dimensional slithering snake-like robot | Bhatti et al. [45] | Three-dimensional autonomous locomotion—smooth slithering gait transition of speed, changing direction and body shape | N/R | CPG models based on convergence behaviour of the gradient |

| Approximate path-tracking snake robot | Tanaka M et al. [46] | Path tracking, the robot can switch the wheels that touch the ground by lifting the required parts of its body | N/R | N/A |

| CMU modular snake robot | Ponte et al. [47] | Maps remote 3D environments, pole climbing and pipe navigation with structured light sensors | N/R | Three-dimensional point clouds used to provide external data when locating obstacles in planning and operation |

| A continuum robot based on the origami structure | Santoso et al. [48] | The driving force of the motor consists of four wires passing through the origami space | N/R | Inverse kinematics of the manipulator for path following and lower vibrations with grow-to-shape equations |

| Aiko robot | Transeth et al. [49] | Portable DC motor-operated platform | N/R | Rough surface dynamics and convex analysis with stick–slip transitions |

| MOIRA | Osuka and Kitajima [50] | Actuated by pneumatic cylinders, with two longitudinal tracks for each side | 2 | N/A |

| OSMOS snake | Singh et al. [51] | Use of sphere-shaped modules to locomote the snake structure without changes in shape | N/R | N/A |

| Millibot train (Carnegie Mellon University) | Brown et al. [52] | Couplers ensure active connection and disconnection of segments, lifts three proximal segments | 1 | N/A |

| OmniTread | Armada et al. [53] | Pneumatic actuation for surface terrain compliance and shock absorption | 2 | Position and stiffness variation by bellow-shaped actuators |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Seetohul, J.; Shafiee, M. Snake Robots for Surgical Applications: A Review. Robotics 2022, 11, 57. https://doi.org/10.3390/robotics11030057

Seetohul J, Shafiee M. Snake Robots for Surgical Applications: A Review. Robotics. 2022; 11(3):57. https://doi.org/10.3390/robotics11030057

Chicago/Turabian StyleSeetohul, Jenna, and Mahmood Shafiee. 2022. "Snake Robots for Surgical Applications: A Review" Robotics 11, no. 3: 57. https://doi.org/10.3390/robotics11030057

APA StyleSeetohul, J., & Shafiee, M. (2022). Snake Robots for Surgical Applications: A Review. Robotics, 11(3), 57. https://doi.org/10.3390/robotics11030057