Monitoring of Hip Joint Forces and Physical Activity after Total Hip Replacement by an Integrated Piezoelectric Element

Abstract

:1. Introduction

2. Materials and Methods

2.1. Calculation of the Maximum Hip Joint Reaction Force

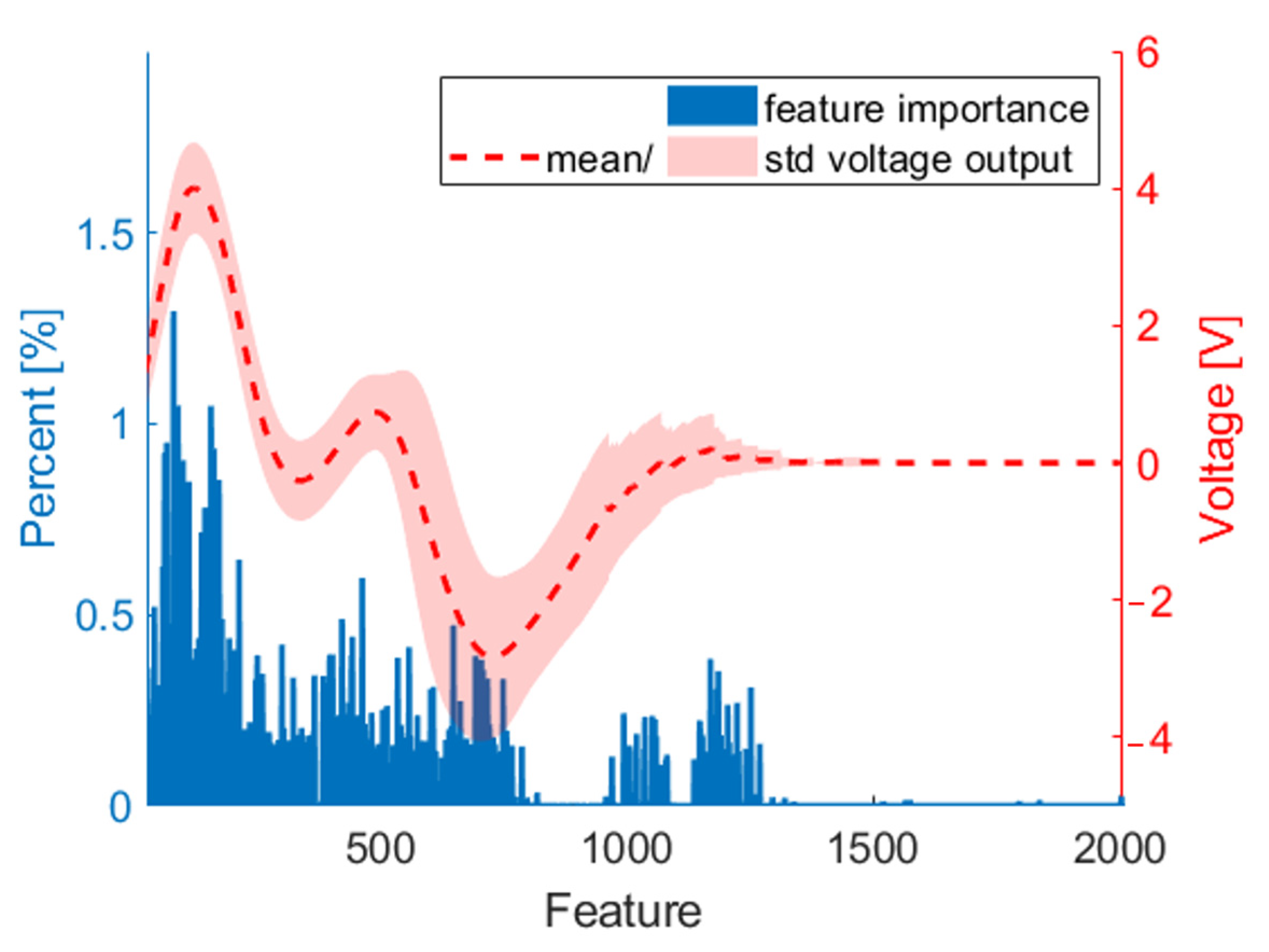

2.2. Detection of Physical Activity

3. Results

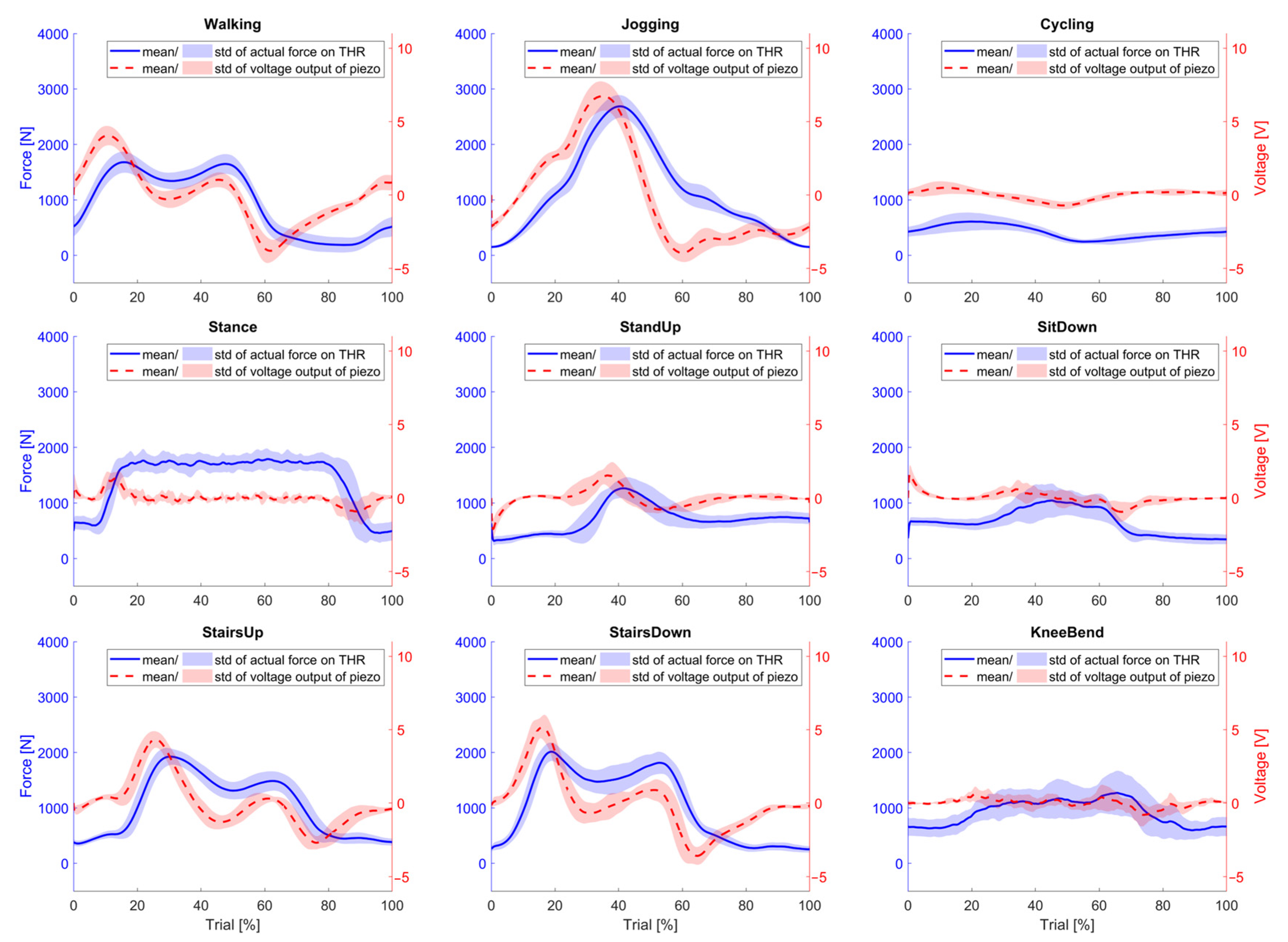

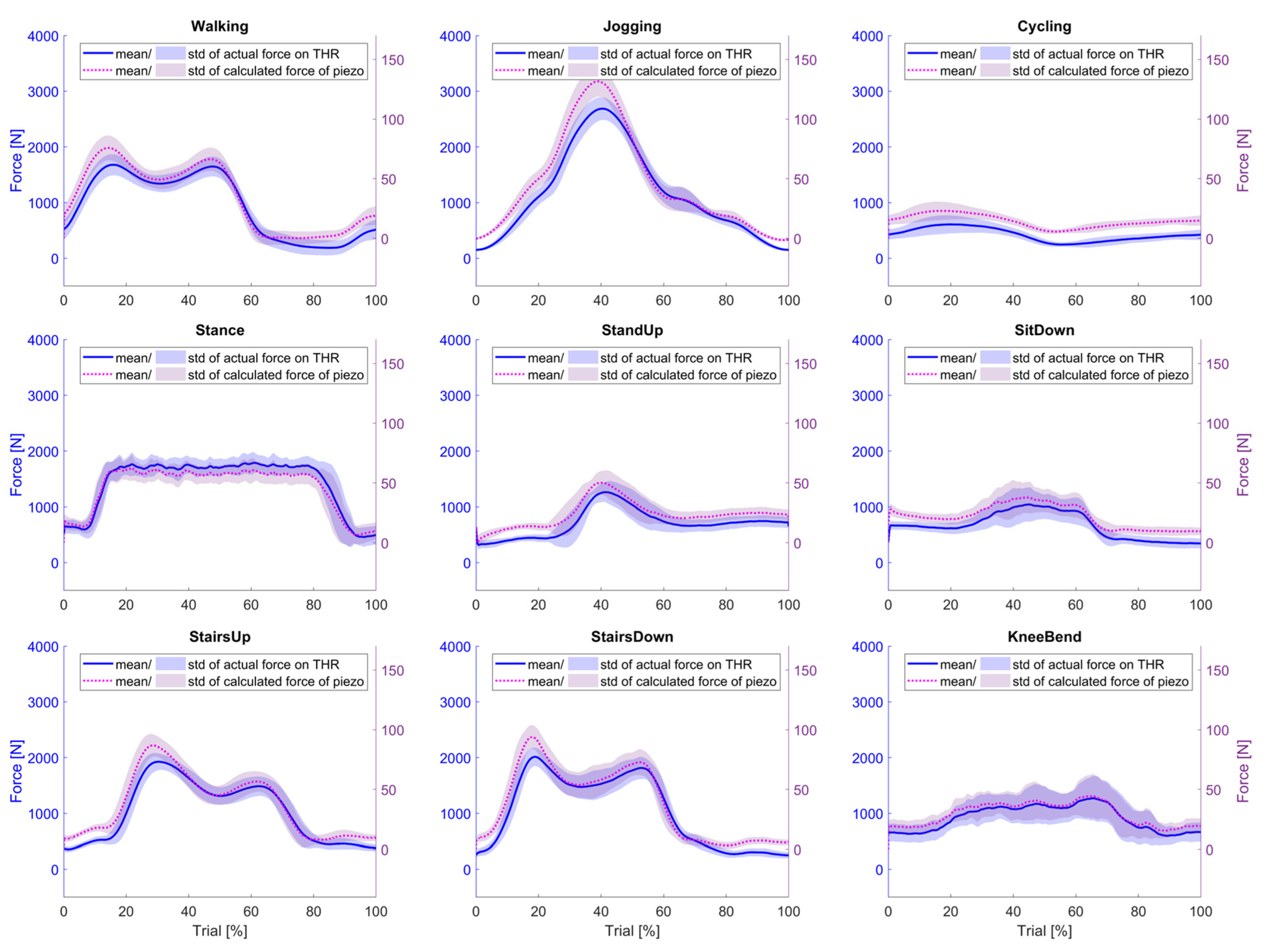

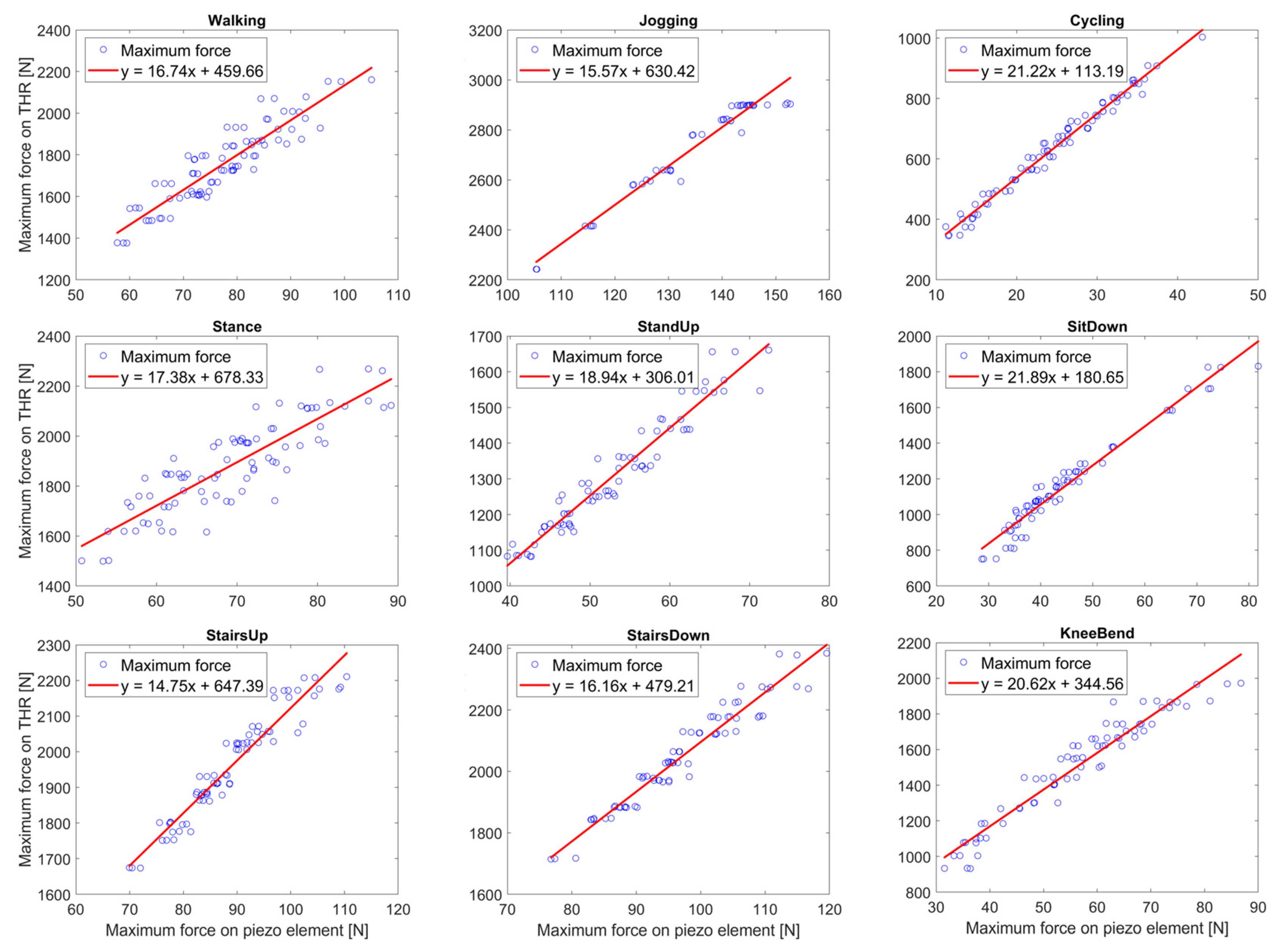

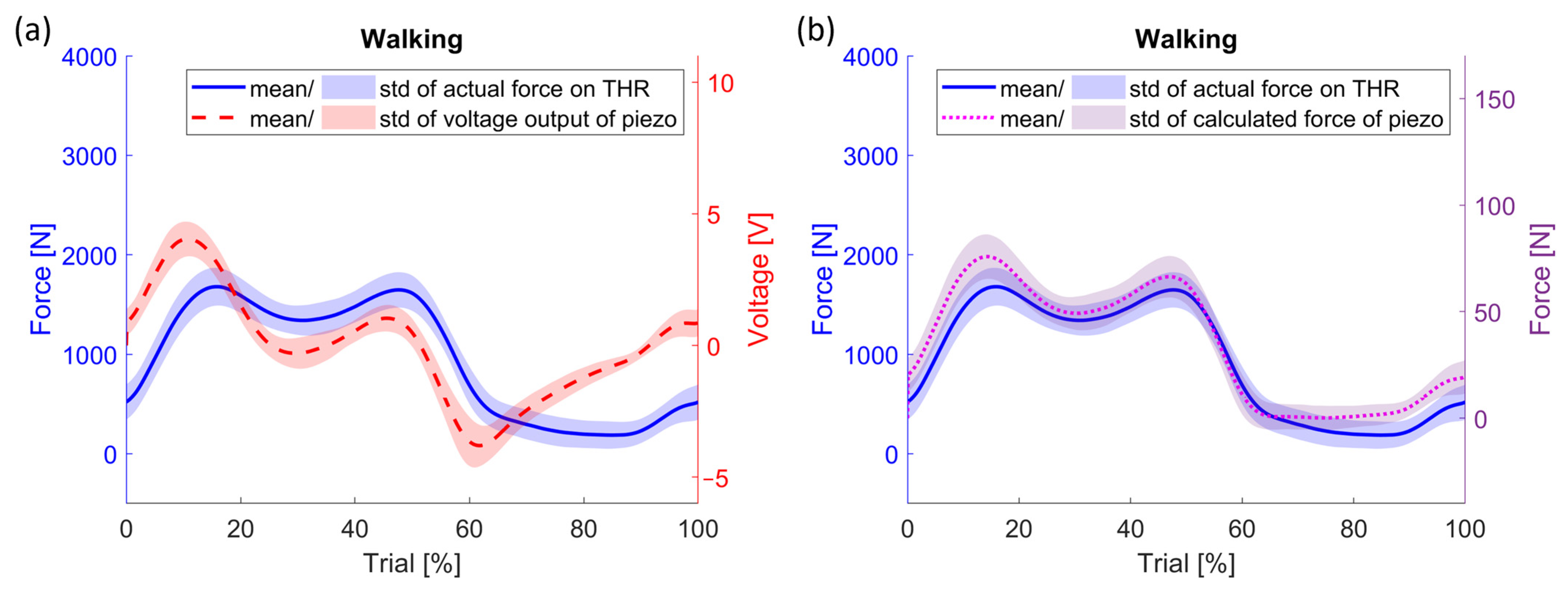

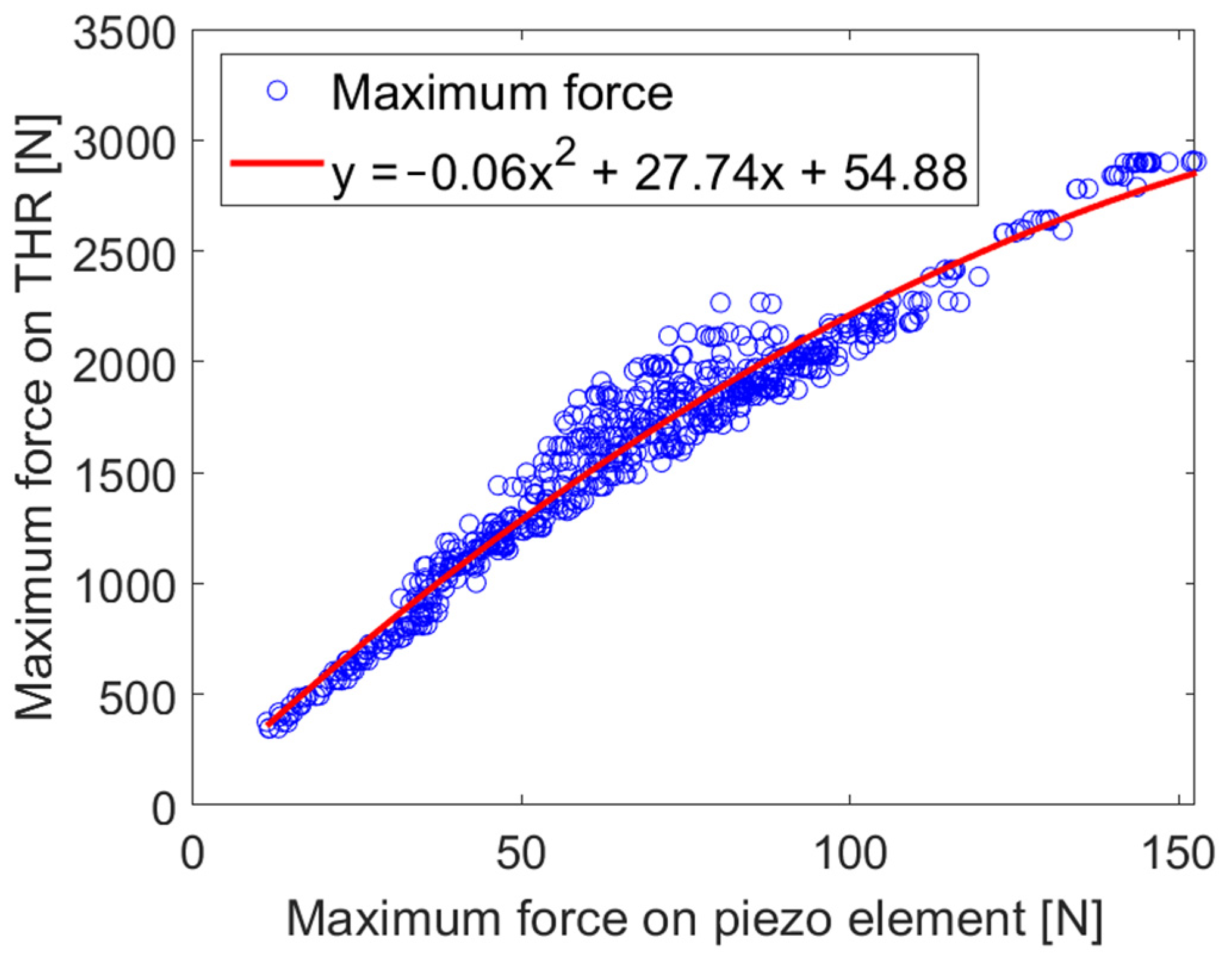

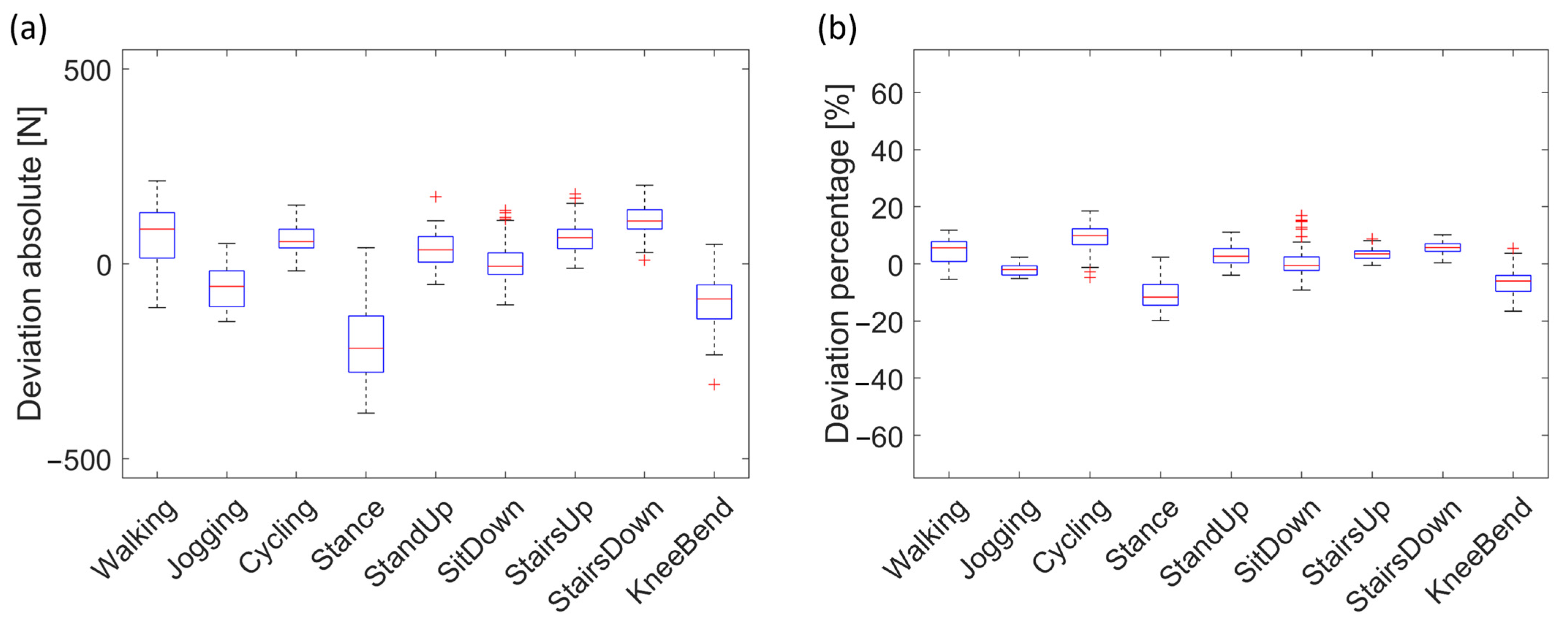

3.1. Maximum Hip Joint Reaction Forces

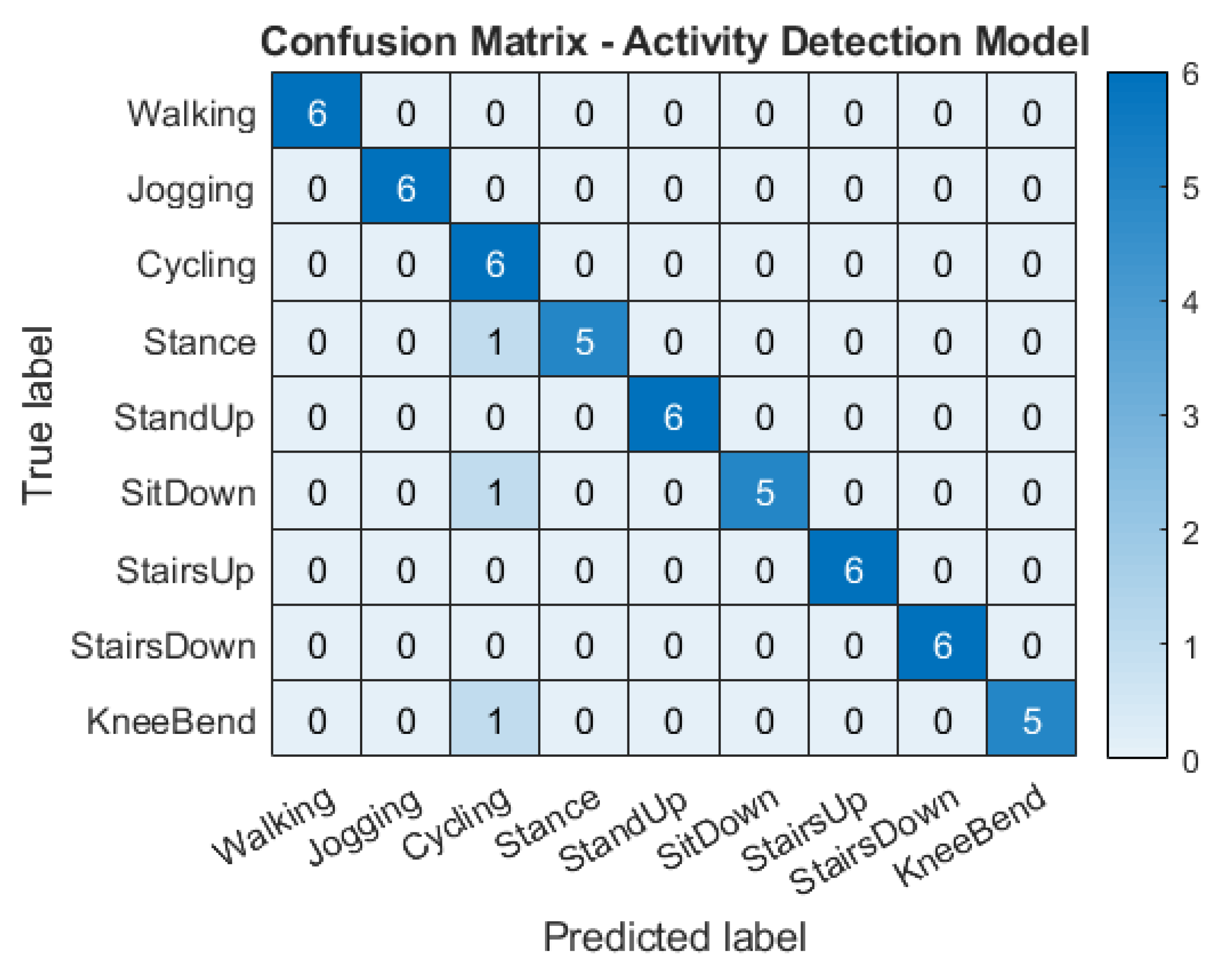

3.2. Physical Activity Recognition

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

References

- Knight, S.R.; Aujla, R.; Biswas, S.P. Total Hip Arthroplasty—Over 100 years of operative history. Orthop. Rev. 2011, 3, e16. [Google Scholar] [CrossRef]

- The Swedish Arthroplasty Register. Annual Report 2022; The Swedish Arthroplasty Register: Gothenburg, Sweden, 2022. [Google Scholar]

- OECD Publishing. Health at a Glance 2021; OECD Publishing: Paris, France, 2021; ISBN 978-92-64-89762-5. [Google Scholar]

- Pabinger, C.; Lothaller, H.; Portner, N.; Geissler, A. Projections of hip arthroplasty in OECD countries up to 2050. Hip Int. 2018, 28, 498–506. [Google Scholar] [CrossRef]

- Ledet, E.H.; Liddle, B.; Kradinova, K.; Harper, S. Smart implants in orthopedic surgery, improving patient outcomes: A review. Innov. Entrep. Health 2018, 5, 41–51. [Google Scholar] [CrossRef] [PubMed]

- Soares Dos Santos, M.P.; Bernardo, R.M.C. Bioelectronic multifunctional bone implants: Recent trends. Bioelectron. Med. 2022, 8, 15. [Google Scholar] [CrossRef] [PubMed]

- Iyengar, K.P.; Kariya, A.D.; Botchu, R.; Jain, V.K.; Vaishya, R. Significant capabilities of SMART sensor technology and their applications for Industry 4.0 in trauma and orthopaedics. Sens. Int. 2022, 3, 100163. [Google Scholar] [CrossRef]

- Kelmers, E.; Szuba, A.; King, S.W.; Palan, J.; Freear, S.; Pandit, H.G.; van Duren, B.H. Smart Knee Implants: An Overview of Current Technologies and Future Possibilities. Indian J. Orthop. 2023, 57, 635–642. [Google Scholar] [CrossRef]

- Peres, I.; Rolo, P.; Soares Dos Santos, M.P. Multifunctional Smart Bone Implants: Fiction or Future?-A New Perspective. Front. Bioeng. Biotechnol. 2022, 10, 912081. [Google Scholar] [CrossRef] [PubMed]

- Qiblawey, Y.; Chowdhury, M.E.H.; Musharavati, F.; Zalnezhad, E.; Khandakar, A.; Islam, M.T. Instrumented Hip Implant: A Review. IEEE Sens. J. 2021, 21, 7179–7194. [Google Scholar] [CrossRef]

- Cachão, J.H.; Soares Dos Santos, M.P.; Bernardo, R.; Ramos, A.; Bader, R.; Ferreira, J.A.F.; Torres Marques, A.; Simões, J.A.O. Altering the Course of Technologies to Monitor Loosening States of Endoprosthetic Implants. Sensors 2019, 20, 104. [Google Scholar] [CrossRef]

- Schmidt, C.; Zimmermann, U.; van Rienen, U. Modeling of an optimized electrostimulative hip revision system under consideration of uncertainty in the conductivity of bone tissue. IEEE J. Biomed. Health Inform. 2015, 19, 1321–1330. [Google Scholar] [CrossRef]

- Bansod, Y.D.; Kebbach, M.; Kluess, D.; Bader, R.; van Rienen, U. Finite element analysis of bone remodelling with piezoelectric effects using an open-source framework. Biomech. Model. Mechanobiol. 2021, 20, 1147–1166. [Google Scholar] [CrossRef] [PubMed]

- Raben, H.; Kämmerer, P.W.; Bader, R.; van Rienen, U. Establishment of a Numerical Model to Design an Electro-Stimulating System for a Porcine Mandibular Critical Size Defect. Appl. Sci. 2019, 9, 2160. [Google Scholar] [CrossRef]

- Khare, D.; Basu, B.; Dubey, A.K. Electrical stimulation and piezoelectric biomaterials for bone tissue engineering applications. Biomaterials 2020, 258, 120280. [Google Scholar] [CrossRef]

- van Drongelen, S.; Holder, J.; Stief, F. Lower limb joint loading in patients with unilateral hip osteoarthritis during bipedal stance and the effect of total hip replacement. Front. Bioeng. Biotechnol. 2023, 11, 1190712. [Google Scholar] [CrossRef]

- Alves, S.A.; Polzehl, J.; Brisson, N.M.; Bender, A.; Agres, A.N.; Damm, P.; Duda, G.N. Ground reaction forces and external hip joint moments predict in vivo hip contact forces during gait. J. Biomech. 2022, 135, 111037. [Google Scholar] [CrossRef]

- Damm, P.; Brackertz, S.; Streitparth, F.; Perka, C.; Bergmann, G.; Duda, G.N.; Winkler, T. ESB Clinical Biomechanics Award 2018: Muscle atrophy-related increased joint loading after total hip arthroplasty and their postoperative change from 3 to 50 months. Clin. Biomech. 2019, 65, 105–109. [Google Scholar] [CrossRef] [PubMed]

- Haffer, H.; Popovic, S.; Martin, F.; Hardt, S.; Winkler, T.; Damm, P. In vivo loading on the hip joint in patients with total hip replacement performing gymnastics and aerobics exercises. Sci. Rep. 2021, 11, 13395. [Google Scholar] [CrossRef] [PubMed]

- Damm, P.; Graichen, F.; Rohlmann, A.; Bender, A.; Bergmann, G. Total hip joint prosthesis for in vivo measurement of forces and moments. Med. Eng. Phys. 2010, 32, 95–100. [Google Scholar] [CrossRef]

- Bergmann, G.; Bender, A.; Dymke, J.; Duda, G.; Damm, P. Standardized Loads Acting in Hip Implants. PLoS ONE 2016, 11, e0155612. [Google Scholar] [CrossRef]

- Babaei, N.; Hannani, N.; Dabanloo, N.J.; Bahadori, S. A Systematic Review of the Use of Commercial Wearable Activity Trackers for Monitoring Recovery in Individuals Undergoing Total Hip Replacement Surgery. Cyborg Bionic Syst. 2022, 2022, 9794641. [Google Scholar] [CrossRef]

- Bocchetta, G.; Fiori, G.; Sciuto, S.A.; Scorza, A. Performance of Smart Materials-Based Instrumentation for Force Measurements in Biomedical Applications: A Methodological Review. Actuators 2023, 12, 261. [Google Scholar] [CrossRef]

- Zaszczyńska, A.; Gradys, A.; Sajkiewicz, P. Progress in the Applications of Smart Piezoelectric Materials for Medical Devices. Polymers 2020, 12, 2754. [Google Scholar] [CrossRef] [PubMed]

- 176-1987; IEEE Standard on Piezoelectricity. IEEE/Institute of Electrical and Electronics Engineers Incorporated: Piscataway, NJ, USA, 1988; ISBN 0-7381-2411-7.

- Shaikh, F.K.; Zeadally, S. Energy harvesting in wireless sensor networks: A comprehensive review. Renew. Sustain. Energy Rev. 2016, 55, 1041–1054. [Google Scholar] [CrossRef]

- Safaei, M.; Sodano, H.A.; Anton, S.R. A review of energy harvesting using piezoelectric materials: State-of-the-art a decade later (2008–2018). Smart Mater. Struct. 2019, 28, 113001. [Google Scholar] [CrossRef]

- Sezer, N.; Koç, M. A comprehensive review on the state-of-the-art of piezoelectric energy harvesting. Nano Energy 2021, 80, 105567. [Google Scholar] [CrossRef]

- Rupitsch, S.J. Piezoelectric Sensors and Actuators; Springer: Berlin/Heidelberg, Germany, 2019; ISBN 978-3-662-57532-1. [Google Scholar]

- Almouahed, S.; Gouriou, M.; Hamitouche, C.; Stindel, E.; Roux, C. Design and evaluation of instrumented smart knee implant. IEEE Trans. Biomed. Eng. 2011, 58, 971–982. [Google Scholar] [CrossRef] [PubMed]

- Safaei, M.; Meneghini, R.M.; Anton, S.R. Compartmental force and contact location sensing in instrumented total knee replacements. Med. Eng. Phys. 2020, 83, 64–72. [Google Scholar] [CrossRef] [PubMed]

- Safaei, M.; Meneghini, R.M.; Anton, S.R. Force detection, center of pressure tracking, and energy harvesting from a piezoelectric knee implant. Smart Mater. Struct. 2018, 27, 114007. [Google Scholar] [CrossRef] [PubMed]

- Lange, H.-E.; Arbeiter, N.; Bader, R.; Kluess, D. Performance of a Piezoelectric Energy Harvesting System for an Energy-Autonomous Instrumented Total Hip Replacement: Experimental and Numerical Evaluation. Materials 2021, 14, 5151. [Google Scholar] [CrossRef]

- Lange, H.-E.; Hohlfeld, D.; Bader, R.; Kluess, D. A piezoelectric energy harvesting concept for an energy-autonomous instrumented total hip replacement. Smart Mater. Struct. 2020, 29, 115051. [Google Scholar] [CrossRef]

- Hoummadi, E.; Safaei, M.; Anton, S.R. Design, analysis, and fabrication of a piezoelectric force plate. In Health Monitoring of Structural and Biological Systems 2017; Kundu, T., Ed.; SPIE Smart Structures and Materials + Nondestructive Evaluation and Health Monitoring; SPIE: Portland, OR, USA, 2017; p. 101700W. [Google Scholar]

- PI Ceramic GmbH. Material Coefficients PIC255: v4.3; PI Ceramic GmbH: Lederhose, Germany, 2017. [Google Scholar]

- Luwe, Y.J.; Lee, C.P.; Lim, K.M. Wearable sensor-based human activity recognition with ensemble learning: A comparison study. IJECE 2023, 13, 4029. [Google Scholar] [CrossRef]

- Belgiu, M.; Drăguţ, L. Random forest in remote sensing: A review of applications and future directions. ISPRS J. Photogramm. Remote Sens. 2016, 114, 24–31. [Google Scholar] [CrossRef]

- PI Ceramic GmbH. Data Sheet Round PICMA® Chip Actuators: Miniature Multilayer Piezo Actuators with and without Inner Hole; PI Ceramic GmbH: Lederhose, Germany, 2019. [Google Scholar]

- Bowden, A.E.; Oneida, E.; Bergström, J. Computer Modeling and Simulation of UHMWPE. In UHMWPE Biomaterials Handbook; Elsevier: Amsterdam, The Netherlands, 2009; pp. 519–532. ISBN 9780123747211. [Google Scholar]

- Bergström, J.S.; Kurtz, S.M.; Rimnac, C.M.; Edidin, A.A. Constitutive modeling of ultra-high molecular weight polyethylene under large-deformation and cyclic loading conditions. Biomaterials 2002, 23, 2329–2343. [Google Scholar] [CrossRef] [PubMed]

- Bergström, J.S.; Rimnac, C.M.; Kurtz, S.M. Prediction of multiaxial mechanical behavior for conventional and highly crosslinked UHMWPE using a hybrid constitutive model. Biomaterials 2003, 24, 1365–1380. [Google Scholar] [CrossRef] [PubMed]

- Picht, G.; Bouvier, V.; Frank, S.; Koruza, J.; Felten, F.; Lindemann, G. Ferroelastic Properties of PZT: Characterization Under Compressive and Tensile Stress, Finite-Element Simulation, and Lifetime Calculation. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2018, 65, 1542–1551. [Google Scholar] [CrossRef] [PubMed]

- Safaei, M.; Dupre, S.; Hoummadi, E.; Anton, S.R. Design, Analysis, and Fabrication of a Piezoelectric Force Tray for Total Knee Replacements. J. Intell. Mater. Syst. Struct. 2019, 30, 3163–3175. [Google Scholar] [CrossRef] [PubMed]

- Cheng, L.; Liu, W.; Hou, Z.-G.; Yu, J.; Tan, M. Neural-Network-Based Nonlinear Model Predictive Control for Piezoelectric Actuators. IEEE Trans. Ind. Electron. 2015, 62, 7717–7727. [Google Scholar] [CrossRef]

- Taylor, W.; Shah, S.A.; Dashtipour, K.; Zahid, A.; Abbasi, Q.H.; Imran, M.A. An Intelligent Non-Invasive Real-Time Human Activity Recognition System for Next-Generation Healthcare. Sensors 2020, 20, 2653. [Google Scholar] [CrossRef] [PubMed]

- Qiu, S.; Zhao, H.; Jiang, N.; Wang, Z.; Liu, L.; An, Y.; Zhao, H.; Miao, X.; Liu, R.; Fortino, G. Multi-sensor information fusion based on machine learning for real applications in human activity recognition: State-of-the-art and research challenges. Inf. Fusion 2022, 80, 241–265. [Google Scholar] [CrossRef]

- Attal, F.; Mohammed, S.; Dedabrishvili, M.; Chamroukhi, F.; Oukhellou, L.; Amirat, Y. Physical Human Activity Recognition Using Wearable Sensors. Sensors 2015, 15, 31314–31338. [Google Scholar] [CrossRef]

- Narayanan, A.; Desai, F.; Stewart, T.; Duncan, S.; Mackay, L. Application of Raw Accelerometer Data and Machine-Learning Techniques to Characterize Human Movement Behavior: A Systematic Scoping Review. J. Phys. Act. Health 2020, 17, 360–383. [Google Scholar] [CrossRef] [PubMed]

- Yadav, S.K.; Tiwari, K.; Pandey, H.M.; Akbar, S.A. A review of multimodal human activity recognition with special emphasis on classification, applications, challenges and future directions. Knowl.-Based Syst. 2021, 223, 106970. [Google Scholar] [CrossRef]

- Nweke, H.F.; Teh, Y.W.; Mujtaba, G.; Al-Garadi, M.A. Data fusion and multiple classifier systems for human activity detection and health monitoring: Review and open research directions. Inf. Fusion 2019, 46, 147–170. [Google Scholar] [CrossRef]

- Yoo, S.; Lee, J.; Joo, H.; Sunwoo, S.-H.; Kim, S.; Kim, D.-H. Wireless Power Transfer and Telemetry for Implantable Bioelectronics. Adv. Healthc. Mater. 2021, 10, e2100614. [Google Scholar] [CrossRef]

- Plocksties, F.; Kober, M.; Niemann, C.; Heller, J.; Fauser, M.; Nüssel, M.; Uster, F.; Franz, D.; Zwar, M.; Lüttig, A.; et al. The software defined implantable modular platform (STELLA) for preclinical deep brain stimulation research in rodents. J. Neural Eng. 2021, 18, 056032. [Google Scholar] [CrossRef]

| Activity | Walking | Jogging | Cycling | Stance | Stand Up | Sit Down | Stairs Up | Stairs Down | Knee Bend |

|---|---|---|---|---|---|---|---|---|---|

| Maximum force on THR [N] | 1757 (±185) | 2708 (±200) | 634,48 (±159) | 1882 (±182) | 1314 (±160) | 1151 (±259) | 1960 (±145) | 2049 (±160) | 1503 (±288) |

| Parameter [Unit] | Value |

|---|---|

| [m] | 0.005 |

| [-] | 86 |

| [m2] | 1.473 × 10−5 |

| [m/Vm] | 3.996 × 10−10 |

| 8.854 × 10−12 | |

| [-] | 1751 |

| Activity | Walking | Jogging | Cycling | Stance | Stand Up | Sit Down | Stairs Up | Stairs Down | Knee Bend |

|---|---|---|---|---|---|---|---|---|---|

| Coefficient of determination R2 | 0.91 | 0.98 | 0.99 | 0.87 | 0.97 | 0.98 | 0.96 | 0.97 | 0.96 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Geiger, F.; Bathel, H.; Spors, S.; Bader, R.; Kluess, D. Monitoring of Hip Joint Forces and Physical Activity after Total Hip Replacement by an Integrated Piezoelectric Element. Technologies 2024, 12, 51. https://doi.org/10.3390/technologies12040051

Geiger F, Bathel H, Spors S, Bader R, Kluess D. Monitoring of Hip Joint Forces and Physical Activity after Total Hip Replacement by an Integrated Piezoelectric Element. Technologies. 2024; 12(4):51. https://doi.org/10.3390/technologies12040051

Chicago/Turabian StyleGeiger, Franziska, Henning Bathel, Sascha Spors, Rainer Bader, and Daniel Kluess. 2024. "Monitoring of Hip Joint Forces and Physical Activity after Total Hip Replacement by an Integrated Piezoelectric Element" Technologies 12, no. 4: 51. https://doi.org/10.3390/technologies12040051

APA StyleGeiger, F., Bathel, H., Spors, S., Bader, R., & Kluess, D. (2024). Monitoring of Hip Joint Forces and Physical Activity after Total Hip Replacement by an Integrated Piezoelectric Element. Technologies, 12(4), 51. https://doi.org/10.3390/technologies12040051