A Two-Echelon Routing Model for Sustainable Last-Mile Delivery with an Intermediate Facility: A Case Study of Pharmaceutical Distribution in Rome

Abstract

:1. Introduction

1.1. Context Description

- defining and formulating a two-echelon bi-objective routing problem with an intermediate facility to establish the delivery scheme within each urban zone with the aim of planning sustainable and cost-effective routes;

- solving the problem and conducting a what-if analysis based on the available data, assessing the benefits and drawbacks of this delivery scheme and the use of a mixed fleet.

2. Materials and Methods

2.1. Literature Review

2.2. Main Contribution

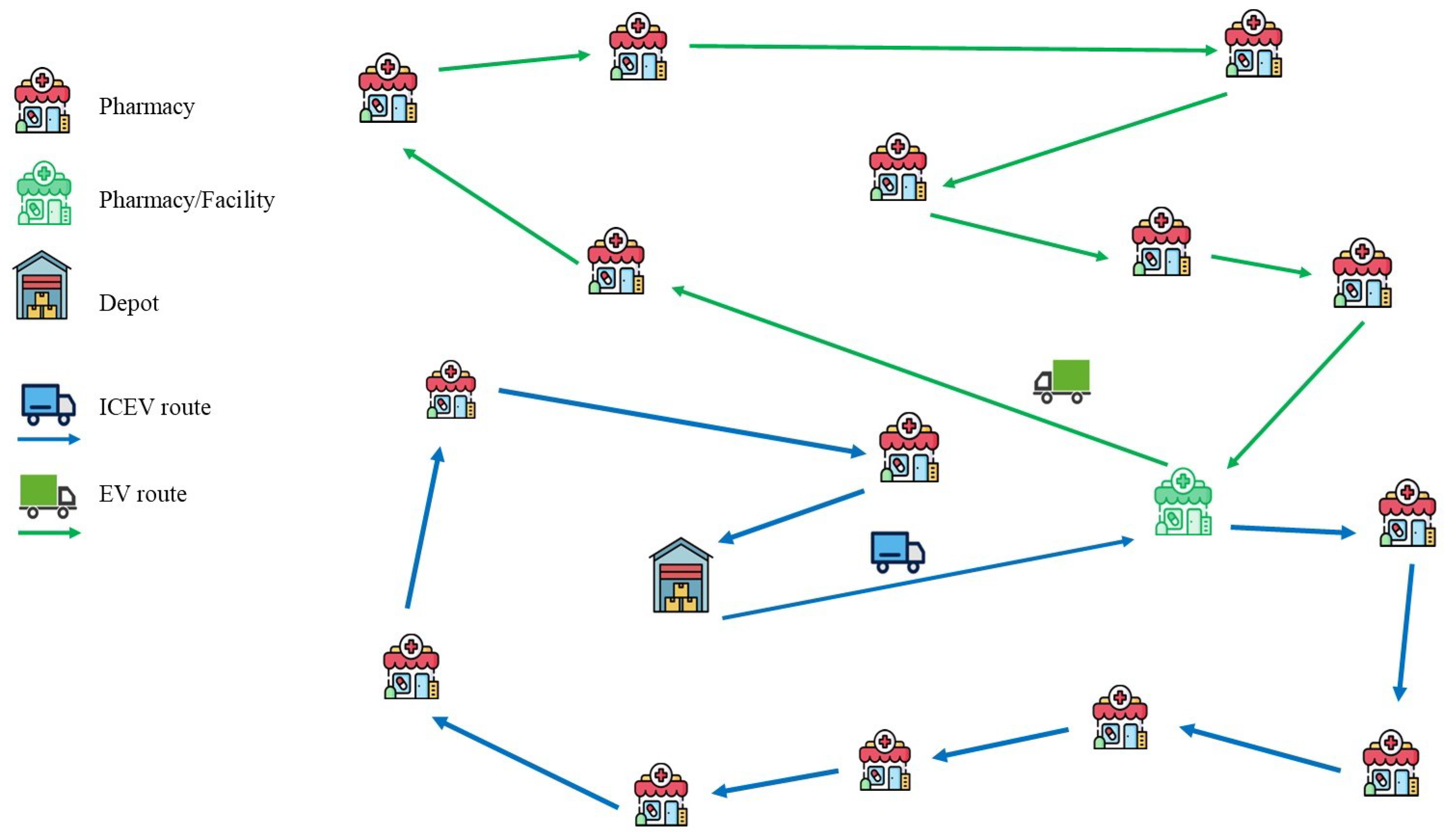

2.3. Problem Description

- n: number of nodes, consisting of customers to be visited and the depot, referred to as , from which the ICEV’s route originates and ends (hereafter also referred to as the first route);

- : a customer that also serves as a depot for the EV’s route, selected from the customers served by the ICEV. The EV’s route is hereafter referred to as the second route;

- , : length of the best route to move from node i to node j using the ICEV;

- , : length of the best route to move from node i to node j using the EV. Since the EV may be authorized to cross low-emission zones in urban areas, it generally happens that , ;

- and : CO2 emission (in kg/km) of the ICEV and EV, respectively;

- and : transportation cost (in EUR/km) of the ICEV and EV, respectively. Although the trend in future years favors a reduction in the cost per kilometer for electric vehicles, it is more realistically assumed that , which implies thatwhere ;

- k, : number of customers and depot served by the first route.

- the assignment of customers to the two vehicles, ensuring that each customer is served by only one vehicle. Specifically, the ICEV route starts and ends at depot , while the EV route starts and ends at depot ;

- the visiting order of the customers within each route.

- each vehicle can perform only one route that starts and ends at its designated depot;

- split deliveries are not allowed;

- the first node visited by the ICEV’s route must be node to ensure that the second tour can start as quickly as possible, thereby reducing the overall completion time for serving the customers.

Mathematical Model

3. Results

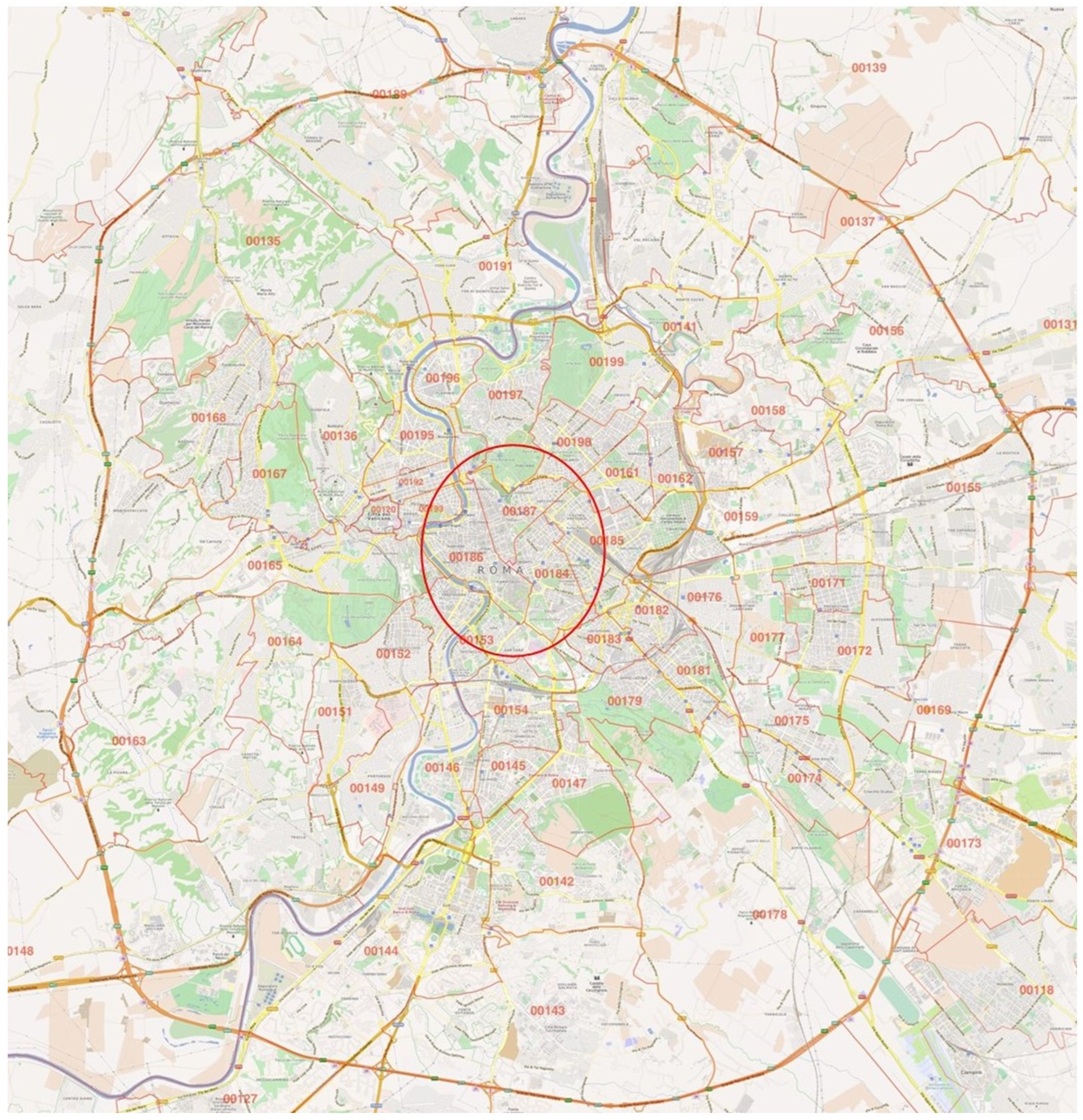

3.1. Data of the Case Study

- in Equation (1). In this scenario, there are no differences in the transportation cost per kilometer between the ICEV and the EV. This is evident from the data provided by the LSP and presented in Table A2 in Appendix A (the cost breakdown includes fuel consumption, maintenance, other operational expenses, and the purchase cost amortized over eight years). The 2-EATSP model can therefore be simplified by removing the budget constraint (18) and focusing solely on minimizing CO2 emissions (see Section 3.2);

- in Equation (1). In this more general scenario, several Pareto-optimal solutions can be generated for different values of budget B in Constraint (18). These solutions are evaluated and compared in a what-if analysis presented in Section 3.3.

3.2. Case of

3.2.1. Discussion

3.2.2. Benchmark Comparison

3.3. Case of

4. Conclusions

Funding

Data Availability Statement

Conflicts of Interest

Appendix A

| ID | Point of Interest | Latitude | Longitude |

|---|---|---|---|

| 1 | Pharmacy 1 | 41.8797075 | 12.5017273 |

| 2 | Pharmacy 2 | 41.8815379 | 12.5131229 |

| 3 | Pharmacy 3 | 41.8960212 | 12.4904504 |

| 4 | Pharmacy 4 | 41.8889683 | 12.4964994 |

| 5 | Pharmacy 5 | 41.8941843 | 12.4906858 |

| 6 | Pharmacy 6 | 41.9025231 | 12.5016612 |

| 7 | Pharmacy 7 | 41.9009856 | 12.4932650 |

| 8 | Pharmacy 8 | 41.8984073 | 12.4905973 |

| 9 | Pharmacy 9 | 41.8974436 | 12.4952554 |

| 10 | Pharmacy 10 | 41.8951780 | 12.4997721 |

| 11 | Pharmacy 11 | 41.8996024 | 12.4947634 |

| 12 | Pharmacy 12 | 41.8950950 | 12.5009679 |

| 13 | Pharmacy 13 | 41.8982191 | 12.5155031 |

| 14 | Pharmacy 14 | 41.9022693 | 12.5049111 |

| 15 | Pharmacy 15 | 41.8919719 | 12.5017881 |

| 16 | Pharmacy 16 | 41.8941144 | 12.5033891 |

| 17 | Pharmacy 17 | 41.8980393 | 12.4996115 |

| 18 | Pharmacy 18 | 41.9015448 | 12.5031056 |

| 19 | Pharmacy 19 | 41.8925406 | 12.5054307 |

| 20 | Pharmacy 20 | 41.9053853 | 12.5038711 |

| 21 | Pharmacy 21 | 41.8974293 | 12.5126908 |

| 22 | Pharmacy 22 | 41.8950682 | 12.5053476 |

| 23 | Pharmacy 23 | 41.8910022 | 12.5022499 |

| 24 | Pharmacy 24 | 41.9012792 | 12.5022033 |

| 25 | Pharmacy 25 | 41.8965883 | 12.5148512 |

| 26 | Pharmacy 26 | 41.9029806 | 12.4957247 |

| 27 | Pharmacy 27 | 41.8977001 | 12.5020334 |

| 28 | Pharmacy 28 | 41.8937245 | 12.5077524 |

| 29 | Pharmacy 29 | 41.8895619 | 12.5137454 |

| 30 | Pharmacy 30 | 41.8906894 | 12.5063857 |

| 31 | Regional depot | 41.8864490 | 12.5159620 |

| Cost Component | ICEV [EUR/km] | EV [EUR/km] |

|---|---|---|

| Fuel/Electricity | 0.16 | 0.12 |

| Maintenance | 0.05 | 0.06 |

| Other Operational Costs | 0.03 | 0.04 |

| Amortized Purchase Cost | 0.10 | 0.12 |

| Total Cost | 0.34 | 0.34 |

| k | CO2 [kg/km] | STC [h] |

|---|---|---|

| 2 | 2.435 | 4.928 |

| 9 | 2.855 | 4.131 |

| 15 | 3.862 | 3.143 |

| 19 | 4.440 | 2.959 |

| 31 | 6.845 | 5.067 |

| From/To | ID 1 | ID 2 | ID 3 | ID 4 | ID 5 | ID 6 | ID 7 | ID 8 |

|---|---|---|---|---|---|---|---|---|

| ID 1 | - | 1.274 | 3.849 | 2.738 | 3.093 | 3.619 | 4.112 | 3.723 |

| ID 2 | 1.681 | - | 3.604 | 2.780 | 3.113 | 3.567 | 3.795 | 3.478 |

| ID 3 | 3.237 | 3.404 | - | 1.695 | 0.264 | 1.814 | 1.104 | 0.715 |

| ID 4 | 2.183 | 2.485 | 3.909 | - | 3.153 | 3.680 | 4.173 | 3.783 |

| ID 5 | 3.018 | 3.330 | 1.246 | 1.475 | - | 1.595 | 1.509 | 1.120 |

| ID 6 | 3.960 | 3.653 | 2.579 | 3.947 | 2.517 | - | 1.919 | 2.453 |

| ID 7 | 3.931 | 3.478 | 1.136 | 2.388 | 0.957 | 0.895 | - | 0.937 |

| ID 8 | 3.643 | 3.810 | 0.848 | 2.100 | 0.669 | 1.285 | 0.389 | - |

| ID 9 | 3.697 | 3.194 | 0.603 | 2.154 | 0.723 | 1.133 | 0.866 | 0.477 |

| ID 10 | 2.915 | 2.566 | 1.521 | 2.196 | 0.765 | 1.365 | 1.784 | 1.395 |

| ID 11 | 3.613 | 3.264 | 1.032 | 2.401 | 0.970 | 1.411 | 1.112 | 0.723 |

| ID 12 | 2.939 | 2.590 | 1.619 | 2.294 | 0.863 | 1.389 | 1.882 | 1.493 |

| ID 13 | 3.393 | 2.714 | 3.411 | 3.380 | 3.152 | 3.197 | 2.994 | 3.285 |

| ID 14 | 3.890 | 3.583 | 2.674 | 3.877 | 2.448 | 1.879 | 1.538 | 2.383 |

| ID 15 | 2.513 | 2.164 | 1.923 | 1.993 | 1.167 | 1.693 | 2.186 | 1.797 |

| ID 16 | 2.517 | 2.210 | 1.638 | 2.504 | 1.097 | 1.600 | 1.828 | 1.511 |

| ID 17 | 3.170 | 2.862 | 1.446 | 2.815 | 1.384 | 0.935 | 1.162 | 1.320 |

| ID 18 | 3.792 | 3.485 | 2.412 | 3.779 | 2.350 | 2.093 | 1.752 | 2.285 |

| ID 19 | 2.257 | 1.950 | 1.897 | 2.244 | 1.357 | 1.860 | 2.087 | 1.771 |

| ID 20 | 4.332 | 4.025 | 2.296 | 3.547 | 2.116 | 1.501 | 1.159 | 2.096 |

| ID 21 | 3.467 | 2.787 | 2.630 | 3.453 | 2.568 | 2.416 | 2.671 | 2.504 |

| ID 22 | 3.218 | 2.911 | 1.710 | 3.079 | 1.648 | 1.496 | 1.724 | 1.584 |

| ID 23 | 2.399 | 2.050 | 2.037 | 1.878 | 1.281 | 1.807 | 2.300 | 1.911 |

| ID 24 | 3.952 | 3.644 | 2.733 | 3.939 | 2.509 | 1.939 | 1.597 | 2.445 |

| ID 25 | 3.617 | 2.938 | 3.027 | 3.604 | 3.376 | 2.813 | 3.068 | 2.900 |

| ID 26 | 4.262 | 3.769 | 1.467 | 2.719 | 1.288 | 0.673 | 0.331 | 1.267 |

| ID 27 | 3.289 | 2.982 | 1.793 | 3.163 | 1.732 | 1.580 | 1.807 | 1.667 |

| ID 28 | 2.584 | 2.379 | 2.515 | 2.570 | 1.975 | 2.314 | 2.541 | 2.389 |

| ID 29 | 2.189 | 1.561 | 2.705 | 2.392 | 2.164 | 2.503 | 2.731 | 2.579 |

| ID 30 | 2.037 | 1.730 | 2.117 | 2.024 | 1.577 | 2.080 | 2.308 | 1.991 |

| ID 31 | 1.924 | 1.183 | 3.202 | 2.457 | 2.661 | 3.000 | 3.228 | 3.076 |

| From/To | ID 9 | ID 10 | ID 11 | ID 12 | ID 13 | ID 14 | ID 15 | ID 16 |

|---|---|---|---|---|---|---|---|---|

| ID 1 | 3.108 | 2.328 | 3.087 | 2.352 | 3.286 | 3.841 | 1.926 | 2.586 |

| ID 2 | 3.056 | 2.348 | 3.034 | 2.201 | 2.844 | 3.399 | 1.946 | 1.967 |

| ID 3 | 1.740 | 0.985 | 1.091 | 1.082 | 3.006 | 2.335 | 1.386 | 1.317 |

| ID 4 | 3.168 | 2.388 | 3.147 | 2.412 | 2.971 | 3.525 | 1.986 | 2.481 |

| ID 5 | 1.520 | 0.765 | 1.496 | 0.863 | 2.786 | 2.115 | 1.167 | 1.097 |

| ID 6 | 2.031 | 1.653 | 2.009 | 1.555 | 1.698 | 0.521 | 1.980 | 1.558 |

| ID 7 | 0.546 | 0.943 | 0.214 | 1.038 | 3.197 | 1.416 | 1.314 | 1.298 |

| ID 8 | 0.880 | 1.390 | 0.548 | 1.488 | 3.587 | 1.805 | 1.792 | 1.722 |

| ID 9 | - | 0.659 | 0.853 | 0.754 | 2.704 | 1.654 | 1.030 | 1.014 |

| ID 10 | 0.854 | - | 0.833 | 0.098 | 2.022 | 1.886 | 0.402 | 0.332 |

| ID 11 | 1.344 | 1.932 | - | 0.824 | 2.773 | 1.932 | 1.100 | 1.084 |

| ID 12 | 0.878 | 0.098 | 0.857 | - | 1.924 | 2.478 | 0.426 | 0.235 |

| ID 13 | 2.862 | 2.388 | 2.841 | 2.290 | - | 1.529 | 2.547 | 2.055 |

| ID 14 | 1.961 | 1.583 | 1.752 | 1.485 | 1.628 | - | 1.911 | 1.489 |

| ID 15 | 1.182 | 0.402 | 1.161 | 0.426 | 2.000 | 2.555 | - | 0.660 |

| ID 16 | 1.089 | 0.332 | 1.068 | 0.235 | 1.689 | 2.244 | 0.660 | - |

| ID 17 | 0.897 | 0.747 | 0.876 | 0.649 | 2.342 | 1.455 | 1.075 | 0.653 |

| ID 18 | 1.863 | 1.485 | 1.842 | 1.387 | 1.530 | 0.353 | 1.813 | 1.391 |

| ID 19 | 1.349 | 0.592 | 1.327 | 0.494 | 1.587 | 2.142 | 0.920 | 0.260 |

| ID 20 | 1.705 | 2.024 | 1.373 | 1.927 | 1.520 | 0.638 | 2.352 | 1.930 |

| ID 21 | 2.081 | 1.703 | 2.060 | 1.605 | 0.306 | 1.205 | 2.031 | 1.609 |

| ID 22 | 1.161 | 0.795 | 1.140 | 0.697 | 1.659 | 2.214 | 1.123 | 0.701 |

| ID 23 | 1.296 | 0.516 | 1.275 | 0.540 | 1.886 | 2.441 | 0.114 | 0.774 |

| ID 24 | 2.022 | 1.644 | 1.811 | 1.547 | 1.690 | 0.513 | 1.972 | 1.550 |

| ID 25 | 2.478 | 2.612 | 2.457 | 2.514 | 0.388 | 1.602 | 2.771 | 2.279 |

| ID 26 | 0.877 | 1.234 | 0.545 | 1.329 | 2.370 | 1.193 | 1.605 | 1.450 |

| ID 27 | 1.245 | 0.867 | 1.223 | 0.769 | 1.973 | 2.528 | 1.195 | 0.772 |

| ID 28 | 1.967 | 1.210 | 1.945 | 1.112 | 1.215 | 1.770 | 1.538 | 0.878 |

| ID 29 | 2.156 | 1.400 | 2.135 | 1.302 | 1.633 | 2.187 | 1.728 | 1.067 |

| ID 30 | 1.569 | 0.812 | 1.547 | 0.714 | 1.650 | 2.204 | 1.140 | 0.480 |

| ID 31 | 2.653 | 1.897 | 2.632 | 1.799 | 2.146 | 2.701 | 1.624 | 1.564 |

| From/To | ID 17 | ID 18 | ID 19 | ID 20 | ID 21 | ID 22 | ID 23 | ID 24 |

|---|---|---|---|---|---|---|---|---|

| ID 1 | 3.067 | 3.777 | 2.425 | 4.139 | 2.981 | 2.772 | 1.812 | 3.723 |

| ID 2 | 3.015 | 3.866 | 1.707 | 4.149 | 2.538 | 2.055 | 1.832 | 3.812 |

| ID 3 | 1.262 | 1.972 | 1.577 | 2.334 | 2.701 | 1.767 | 1.501 | 1.918 |

| ID 4 | 3.127 | 3.837 | 2.221 | 4.275 | 2.665 | 2.569 | 1.872 | 3.783 |

| ID 5 | 1.042 | 1.752 | 1.357 | 2.114 | 2.481 | 1.547 | 1.281 | 1.698 |

| ID 6 | 1.989 | 0.158 | 1.818 | 1.204 | 1.262 | 1.463 | 2.095 | 0.103 |

| ID 7 | 0.898 | 1.053 | 1.558 | 1.422 | 2.157 | 1.748 | 1.428 | 0.999 |

| ID 8 | 1.232 | 1.442 | 1.982 | 1.811 | 2.547 | 2.172 | 1.906 | 1.388 |

| ID 9 | 0.581 | 1.291 | 1.274 | 1.653 | 2.398 | 1.464 | 1.144 | 1.237 |

| ID 10 | 0.813 | 1.523 | 0.592 | 1.885 | 1.716 | 0.782 | 0.516 | 1.469 |

| ID 11 | 0.684 | 1.569 | 1.344 | 1.931 | 2.468 | 1.534 | 1.214 | 1.515 |

| ID 12 | 0.837 | 1.547 | 0.494 | 1.909 | 1.618 | 0.684 | 0.540 | 1.493 |

| ID 13 | 2.821 | 1.996 | 2.005 | 2.279 | 0.306 | 1.701 | 2.433 | 1.942 |

| ID 14 | 1.920 | 0.465 | 1.748 | 0.822 | 1.193 | 1.394 | 2.025 | 0.411 |

| ID 15 | 1.141 | 1.851 | 0.848 | 2.213 | 1.695 | 1.110 | 0.114 | 1.797 |

| ID 16 | 1.048 | 1.758 | 0.260 | 2.120 | 1.384 | 0.450 | 0.774 | 1.704 |

| ID 17 | - | 1.092 | 0.912 | 1.454 | 2.036 | 1.103 | 1.189 | 1.038 |

| ID 18 | 1.822 | - | 1.650 | 1.036 | 1.094 | 1.296 | 1.927 | 0.766 |

| ID 19 | 1.307 | 2.018 | - | 2.380 | 1.281 | 0.348 | 1.034 | 1.964 |

| ID 20 | 1.623 | 0.581 | 2.190 | - | 1.351 | 1.835 | 2.466 | 0.527 |

| ID 21 | 2.040 | 1.673 | 1.869 | 1.955 | - | 1.514 | 2.145 | 1.618 |

| ID 22 | 1.120 | 1.654 | 0.961 | 2.016 | 1.354 | - | 1.237 | 1.600 |

| ID 23 | 1.255 | 1.965 | 0.734 | 2.327 | 1.581 | 1.082 | - | 1.911 |

| ID 24 | 1.981 | 0.149 | 1.810 | 0.881 | 1.254 | 1.455 | 2.086 | - |

| ID 25 | 2.437 | 2.069 | 2.230 | 2.352 | 0.397 | 1.925 | 2.657 | 2.015 |

| ID 26 | 0.795 | 0.830 | 1.710 | 1.199 | 1.935 | 1.569 | 1.719 | 0.776 |

| ID 27 | 1.203 | 1.737 | 1.032 | 2.099 | 1.668 | 0.911 | 1.309 | 1.683 |

| ID 28 | 1.925 | 2.237 | 0.822 | 2.520 | 0.909 | 0.817 | 1.652 | 2.183 |

| ID 29 | 2.115 | 2.655 | 1.012 | 2.937 | 1.327 | 1.007 | 1.445 | 2.600 |

| ID 30 | 1.527 | 2.238 | 0.220 | 2.954 | 1.344 | 0.568 | 1.254 | 2.184 |

| ID 31 | 2.612 | 3.168 | 1.509 | 3.451 | 1.840 | 1.504 | 1.509 | 3.114 |

| From/To | ID 25 | ID 26 | ID 27 | ID 28 | ID 29 | ID 30 | ID 31 |

|---|---|---|---|---|---|---|---|

| ID 1 | 3.250 | 5.143 | 3.249 | 2.787 | 2.392 | 2.205 | 2.401 |

| ID 2 | 2.441 | 4.214 | 2.532 | 2.069 | 1.195 | 1.487 | 0.807 |

| ID 3 | 2.970 | 2.234 | 1.856 | 1.781 | 2.384 | 1.797 | 3.098 |

| ID 4 | 2.935 | 4.987 | 3.045 | 2.583 | 2.420 | 2.001 | 2.883 |

| ID 5 | 2.750 | 2.748 | 1.636 | 1.562 | 2.164 | 1.577 | 3.024 |

| ID 6 | 1.532 | 2.112 | 1.177 | 1.496 | 2.241 | 1.978 | 3.354 |

| ID 7 | 2.427 | 1.132 | 1.272 | 1.763 | 2.365 | 1.778 | 3.172 |

| ID 8 | 2.816 | 1.628 | 1.662 | 2.187 | 2.789 | 2.202 | 3.503 |

| ID 9 | 2.667 | 2.105 | 1.175 | 1.479 | 2.082 | 1.494 | 2.888 |

| ID 10 | 1.986 | 3.023 | 1.259 | 0.797 | 1.400 | 0.812 | 2.259 |

| ID 11 | 2.737 | 2.351 | 1.106 | 1.549 | 2.151 | 1.564 | 2.957 |

| ID 12 | 1.888 | 2.036 | 1.161 | 0.699 | 1.302 | 0.714 | 2.786 |

| ID 13 | 0.508 | 3.309 | 1.552 | 2.010 | 1.362 | 1.785 | 2.313 |

| ID 14 | 1.462 | 1.731 | 1.108 | 1.427 | 2.172 | 1.909 | 3.285 |

| ID 15 | 1.964 | 2.340 | 1.587 | 1.125 | 1.251 | 0.628 | 1.858 |

| ID 16 | 1.653 | 2.247 | 0.927 | 0.465 | 1.067 | 0.480 | 2.551 |

| ID 17 | 2.306 | 1.581 | 0.604 | 1.117 | 1.720 | 1.132 | 3.204 |

| ID 18 | 1.364 | 1.945 | 1.010 | 1.329 | 2.074 | 1.811 | 3.187 |

| ID 19 | 1.551 | 2.507 | 0.824 | 0.362 | 0.965 | 0.220 | 2.449 |

| ID 20 | 1.620 | 1.352 | 1.549 | 1.868 | 2.613 | 2.350 | 3.726 |

| ID 21 | 0.347 | 2.985 | 1.228 | 1.547 | 1.436 | 1.859 | 2.386 |

| ID 22 | 1.623 | 2.143 | 0.477 | 0.602 | 1.347 | 1.181 | 2.580 |

| ID 23 | 1.850 | 2.454 | 1.558 | 1.096 | 1.137 | 0.514 | 1.743 |

| ID 24 | 1.523 | 1.790 | 1.169 | 1.488 | 2.233 | 1.970 | 3.346 |

| ID 25 | - | 3.382 | 1.625 | 2.234 | 1.587 | 2.010 | 2.537 |

| ID 26 | 2.204 | - | 1.049 | 1.602 | 2.517 | 1.930 | 3.580 |

| ID 27 | 1.937 | 2.226 | - | 0.944 | 1.689 | 1.252 | 2.922 |

| ID 28 | 1.179 | 2.960 | 1.294 | - | 1.027 | 0.602 | 1.978 |

| ID 29 | 1.399 | 3.150 | 1.484 | 1.022 | 100 - | 0.792 | 1.484 |

| ID 30 | 1.614 | 2.727 | 1.044 | 0.582 | 0.682 | - | 1.423 |

| ID 31 | 1.743 | 3.647 | 1.981 | 1.519 | 0.497 | 1.289 | - |

| From/To | ID 1 | ID 2 | ID 3 | ID 4 | ID 5 | ID 6 | ID 7 | ID 8 |

|---|---|---|---|---|---|---|---|---|

| ID 1 | - | 1.274 | 2.848 | 1.774 | 2.112 | 2.548 | 3.187 | 2.885 |

| ID 2 | 1.681 | - | 2.586 | 1.960 | 2.467 | 2.507 | 2.932 | 2.746 |

| ID 3 | 2.494 | 2.195 | - | 1.695 | 0.264 | 1.814 | 1.104 | 0.715 |

| ID 4 | 1.632 | 1.833 | 2.957 | - | 2.104 | 2.734 | 3.150 | 2.698 |

| ID 5 | 2.106 | 2.191 | 1.246 | 1.475 | - | 1.595 | 1.509 | 1.120 |

| ID 6 | 2.897 | 2.907 | 2.018 | 3.138 | 1.758 | - | 1.919 | 1.839 |

| ID 7 | 3.097 | 2.621 | 1.136 | 1.848 | 0.957 | 0.895 | - | 0.937 |

| ID 8 | 2.805 | 2.504 | 0.848 | 1.499 | 0.669 | 1.285 | 0.389 | - |

| ID 9 | 2.954 | 2.294 | 0.603 | 1.579 | 0.723 | 1.133 | 0.866 | 0.477 |

| ID 10 | 2.004 | 1.904 | 1.521 | 1.416 | 0.765 | 1.365 | 1.784 | 1.395 |

| ID 11 | 2.716 | 2.462 | 1.032 | 1.907 | 0.970 | 1.411 | 1.112 | 0.723 |

| ID 12 | 2.283 | 1.869 | 1.619 | 1.473 | 0.863 | 1.389 | 1.882 | 1.493 |

| ID 13 | 2.585 | 1.855 | 2.528 | 2.362 | 2.202 | 2.284 | 2.352 | 2.189 |

| ID 14 | 3.026 | 2.671 | 2.090 | 2.528 | 1.614 | 1.879 | 1.538 | 1.808 |

| ID 15 | 1.797 | 1.647 | 1.923 | 1.993 | 1.167 | 1.693 | 1.716 | 1.797 |

| ID 16 | 1.877 | 1.645 | 1.638 | 1.712 | 1.097 | 1.600 | 1.828 | 1.511 |

| ID 17 | 2.493 | 2.216 | 1.446 | 1.847 | 1.384 | 0.935 | 1.162 | 1.320 |

| ID 18 | 3.031 | 2.698 | 1.718 | 2.605 | 1.635 | 1.599 | 1.752 | 1.568 |

| ID 19 | 1.536 | 1.950 | 1.897 | 1.562 | 1.357 | 1.860 | 1.386 | 1.771 |

| ID 20 | 3.297 | 2.593 | 1.693 | 2.332 | 1.479 | 1.501 | 1.159 | 1.410 |

| ID 21 | 2.416 | 2.151 | 1.708 | 2.235 | 1.678 | 1.790 | 2.130 | 1.631 |

| ID 22 | 2.411 | 2.250 | 1.710 | 2.189 | 1.648 | 1.496 | 1.724 | 1.584 |

| ID 23 | 1.683 | 1.315 | 1.584 | 1.878 | 1.281 | 1.807 | 1.649 | 1.911 |

| ID 24 | 2.718 | 2.705 | 2.058 | 2.641 | 1.682 | 1.939 | 1.597 | 1.617 |

| ID 25 | 2.518 | 2.020 | 2.037 | 2.370 | 2.518 | 2.081 | 2.408 | 2.052 |

| ID 26 | 3.048 | 2.689 | 1.467 | 1.898 | 1.288 | 0.673 | 0.331 | 1.267 |

| ID 27 | 2.213 | 2.257 | 1.793 | 2.308 | 1.732 | 1.580 | 1.807 | 1.667 |

| ID 28 | 1.779 | 1.747 | 1.942 | 1.992 | 1.975 | 1.758 | 1.810 | 1.638 |

| ID 29 | 1.557 | 1.561 | 1.899 | 1.753 | 1.645 | 1.859 | 1.854 | 2.057 |

| ID 30 | 1.476 | 1.730 | 1.635 | 1.479 | 1.577 | 1.531 | 1.619 | 1.991 |

| ID 31 | 1.924 | 1.183 | 2.123 | 1.707 | 2.060 | 2.366 | 2.250 | 2.448 |

| From/To | ID 9 | ID 10 | ID 11 | ID 12 | ID 13 | ID 14 | ID 15 | ID 16 |

|---|---|---|---|---|---|---|---|---|

| ID 1 | 2.457 | 1.539 | 2.173 | 1.615 | 2.618 | 2.477 | 1.926 | 1.725 |

| ID 2 | 1.981 | 1.515 | 2.035 | 1.654 | 2.231 | 2.347 | 1.946 | 1.967 |

| ID 3 | 1.740 | 0.985 | 1.091 | 1.082 | 2.032 | 1.517 | 1.386 | 1.317 |

| ID 4 | 2.463 | 1.604 | 2.480 | 1.549 | 2.010 | 2.708 | 1.986 | 1.983 |

| ID 5 | 1.520 | 0.765 | 1.496 | 0.863 | 2.018 | 1.652 | 1.167 | 1.097 |

| ID 6 | 1.460 | 1.653 | 1.315 | 1.555 | 1.698 | 0.521 | 1.980 | 1.558 |

| ID 7 | 0.546 | 0.943 | 0.214 | 1.038 | 2.082 | 1.416 | 1.314 | 1.298 |

| ID 8 | 0.880 | 1.390 | 0.548 | 1.488 | 2.407 | 1.805 | 1.792 | 1.722 |

| ID 9 | - | 0.659 | 0.853 | 0.754 | 2.067 | 1.654 | 1.030 | 1.014 |

| ID 10 | 0.854 | - | 0.833 | 0.098 | 1.307 | 1.886 | 0.402 | 0.332 |

| ID 11 | 0.332 | 0.729 | - | 0.824 | 1.948 | 1.932 | 1.100 | 1.084 |

| ID 12 | 0.878 | 0.098 | 0.857 | - | 1.924 | 1.886 | 0.426 | 0.235 |

| ID 13 | 2.143 | 1.839 | 2.254 | 1.615 | - | 1.529 | 1.762 | 1.639 |

| ID 14 | 1.961 | 1.583 | 1.752 | 1.485 | 1.628 | - | 1.911 | 1.489 |

| ID 15 | 1.182 | 0.402 | 1.161 | 0.426 | 2.000 | 1.677 | - | 0.660 |

| ID 16 | 1.089 | 0.332 | 1.068 | 0.235 | 1.689 | 1.473 | 0.660 | - |

| ID 17 | 0.897 | 0.747 | 0.876 | 0.649 | 1.647 | 1.455 | 1.075 | 0.653 |

| ID 18 | 1.863 | 1.485 | 1.842 | 1.387 | 1.530 | 0.353 | 1.813 | 1.391 |

| ID 19 | 1.349 | 0.592 | 1.327 | 0.494 | 1.587 | 1.489 | 0.920 | 0.260 |

| ID 20 | 1.705 | 1.456 | 1.373 | 1.927 | 1.520 | 0.638 | 1.665 | 1.930 |

| ID 21 | 1.522 | 1.703 | 1.329 | 1.605 | 0.306 | 1.205 | 1.312 | 1.609 |

| ID 22 | 1.161 | 0.795 | 1.140 | 0.697 | 1.659 | 1.439 | 1.123 | 0.701 |

| ID 23 | 1.296 | 0.516 | 1.275 | 0.540 | 1.886 | 1.610 | 0.114 | 0.774 |

| ID 24 | 1.322 | 1.644 | 1.811 | 1.547 | 1.690 | 0.513 | 1.972 | 1.550 |

| ID 25 | 1.968 | 1.895 | 1.753 | 1.896 | 0.388 | 1.602 | 1.955 | 1.812 |

| ID 26 | 0.877 | 1.234 | 0.545 | 1.329 | 1.621 | 1.193 | 1.605 | 1.450 |

| ID 27 | 1.245 | 0.867 | 1.223 | 0.769 | 1.973 | 1.990 | 1.195 | 0.772 |

| ID 28 | 1.967 | 1.210 | 1.945 | 1.112 | 1.215 | 1.770 | 1.538 | 0.878 |

| ID 29 | 1.685 | 1.400 | 1.692 | 1.302 | 1.633 | 1.736 | 1.728 | 1.067 |

| ID 30 | 1.569 | 0.812 | 1.547 | 0.714 | 1.650 | 1.539 | 1.140 | 0.480 |

| ID 31 | 1.873 | 1.897 | 1.710 | 1.799 | 1.519 | 1.993 | 1.624 | 1.564 |

| From/To | ID 17 | ID 18 | ID 19 | ID 20 | ID 21 | ID 22 | ID 23 | ID 24 |

|---|---|---|---|---|---|---|---|---|

| ID 1 | 2.350 | 2.912 | 1.869 | 3.110 | 2.135 | 2.026 | 1.812 | 2.805 |

| ID 2 | 2.200 | 3.018 | 1.707 | 2.990 | 2.016 | 1.345 | 1.832 | 2.892 |

| ID 3 | 1.262 | 1.972 | 1.577 | 1.533 | 1.903 | 1.767 | 1.501 | 1.918 |

| ID 4 | 2.094 | 2.636 | 1.518 | 2.892 | 2.100 | 1.908 | 1.872 | 2.956 |

| ID 5 | 1.042 | 1.752 | 1.357 | 1.450 | 1.683 | 1.547 | 1.281 | 1.698 |

| ID 6 | 1.989 | 0.158 | 1.818 | 1.204 | 1.262 | 1.463 | 1.592 | 0.103 |

| ID 7 | 0.898 | 1.053 | 1.558 | 1.422 | 1.447 | 1.748 | 1.428 | 0.999 |

| ID 8 | 1.232 | 1.442 | 1.982 | 1.811 | 1.673 | 1.627 | 1.906 | 1.388 |

| ID 9 | 0.581 | 1.291 | 1.274 | 1.653 | 1.872 | 1.464 | 1.144 | 1.237 |

| ID 10 | 0.813 | 1.523 | 0.592 | 1.885 | 1.716 | 0.782 | 0.516 | 1.469 |

| ID 11 | 0.684 | 1.569 | 1.344 | 1.931 | 1.776 | 1.534 | 1.214 | 1.515 |

| ID 12 | 0.837 | 1.547 | 0.494 | 1.909 | 1.618 | 0.684 | 0.540 | 1.493 |

| ID 13 | 2.026 | 1.996 | 1.531 | 1.588 | 0.324 | 1.701 | 1.878 | 1.942 |

| ID 14 | 1.920 | 0.465 | 1.748 | 0.822 | 1.193 | 1.394 | 1.406 | 0.411 |

| ID 15 | 1.141 | 1.851 | 0.848 | 1.451 | 1.695 | 1.110 | 0.114 | 1.797 |

| ID 16 | 1.048 | 1.758 | 0.260 | 1.395 | 1.384 | 0.450 | 0.774 | 1.704 |

| ID 17 | - | 1.092 | 0.912 | 1.454 | 1.626 | 1.103 | 1.189 | 1.038 |

| ID 18 | 1.822 | - | 1.650 | 1.036 | 1.094 | 1.296 | 1.927 | 0.766 |

| ID 19 | 1.307 | 1.431 | - | 1.868 | 1.281 | 0.348 | 1.034 | 1.964 |

| ID 20 | 1.623 | 0.581 | 1.579 | - | 1.351 | 1.835 | 1.896 | 0.527 |

| ID 21 | 1.354 | 1.673 | 1.869 | 1.955 | - | 1.514 | 1.615 | 1.618 |

| ID 22 | 1.120 | 1.654 | 0.961 | 1.388 | 1.354 | - | 1.237 | 1.600 |

| ID 23 | 1.255 | 1.965 | 0.734 | 1.586 | 1.581 | 1.082 | - | 1.911 |

| ID 24 | 1.981 | 0.149 | 1.810 | 0.881 | 1.254 | 1.455 | 1.498 | - |

| ID 25 | 1.935 | 1.383 | 1.655 | 1.834 | 0.397 | 1.925 | 1.904 | 1.364 |

| ID 26 | 0.795 | 0.830 | 1.710 | 1.199 | 1.935 | 1.569 | 1.719 | 0.776 |

| ID 27 | 1.203 | 1.737 | 1.032 | 1.670 | 1.668 | 0.911 | 1.309 | 1.683 |

| ID 28 | 1.925 | 1.554 | 0.822 | 1.903 | 0.909 | 0.817 | 1.652 | 1.413 |

| ID 29 | 1.403 | 1.825 | 1.012 | 2.127 | 1.327 | 1.007 | 1.445 | 2.039 |

| ID 30 | 1.527 | 1.774 | 0.220 | 2.186 | 1.344 | 0.568 | 1.254 | 1.528 |

| ID 31 | 1.821 | 2.302 | 1.509 | 2.460 | 1.840 | 1.504 | 1.509 | 2.022 |

| From/To | ID 25 | ID 26 | ID 27 | ID 28 | ID 29 | ID 30 | ID 31 |

|---|---|---|---|---|---|---|---|

| ID 1 | 2.282 | 3.999 | 2.447 | 2.067 | 1.739 | 1.487 | 1.844 |

| ID 2 | 1.694 | 3.161 | 1.815 | 1.474 | 1.195 | 1.487 | 0.807 |

| ID 3 | 1.938 | 1.755 | 1.856 | 1.781 | 1.832 | 1.797 | 2.456 |

| ID 4 | 1.943 | 3.493 | 2.275 | 2.04 | 1.816 | 1.497 | 1.97 |

| ID 5 | 1.953 | 1.859 | 1.636 | 1.562 | 1.56 | 1.577 | 2.166 |

| ID 6 | 1.532 | 1.551 | 1.177 | 1.496 | 1.522 | 1.978 | 2.56 |

| ID 7 | 1.696 | 1.132 | 1.272 | 1.763 | 1.562 | 1.778 | 2.13 |

| ID 8 | 2.203 | 1.628 | 1.662 | 1.67 | 2.04 | 1.474 | 2.32 |

| ID 9 | 1.99 | 1.366 | 1.175 | 1.479 | 1.558 | 1.494 | 2.07 |

| ID 10 | 1.986 | 2.296 | 1.259 | 0.797 | 1.4 | 0.812 | 1.627 |

| ID 11 | 2.167 | 1.776 | 1.106 | 1.549 | 1.408 | 1.564 | 2.253 |

| ID 12 | 1.888 | 1.41 | 1.161 | 0.699 | 1.302 | 0.714 | 1.889 |

| ID 13 | 0.508 | 2.281 | 1.552 | 1.484 | 1.362 | 1.785 | 1.503 |

| ID 14 | 1.462 | 1.731 | 1.108 | 1.427 | 1.454 | 1.909 | 2.336 |

| ID 15 | 1.964 | 1.635 | 1.587 | 1.125 | 1.251 | 0.628 | 1.858 |

| ID 16 | 1.653 | 1.518 | 0.927 | 0.465 | 1.067 | 0.48 | 1.779 |

| ID 17 | 1.808 | 1.581 | 0.604 | 1.117 | 1.72 | 1.132 | 2.223 |

| ID 18 | 1.364 | 1.945 | 1.01 | 1.329 | 1.58 | 1.811 | 2.384 |

| ID 19 | 1.551 | 1.858 | 0.824 | 0.362 | 0.965 | 0.22 | 1.855 |

| ID 20 | 1.62 | 1.352 | 1.549 | 1.868 | 1.788 | 1.774 | 2.967 |

| ID 21 | 0.347 | 2.204 | 1.228 | 1.547 | 1.436 | 1.859 | 1.584 |

| ID 22 | 1.623 | 1.519 | 0.477 | 0.602 | 1.347 | 1.181 | 2.024 |

| ID 23 | 1.85 | 1.689 | 1.558 | 1.096 | 1.137 | 0.514 | 1.743 |

| ID 24 | 1.523 | 1.79 | 1.169 | 1.488 | 1.607 | 1.97 | 2.25 |

| ID 25 | - | 2.589 | 1.625 | 1.564 | 1.587 | 1.581 | 2.009 |

| ID 26 | 1.419 | - | 1.049 | 1.602 | 1.806 | 1.93 | 2.679 |

| ID 27 | 1.937 | 1.438 | - | 0.944 | 1.689 | 1.252 | 1.947 |

| ID 28 | 1.179 | 2.019 | 1.294 | - | 1.027 | 0.602 | 1.978 |

| ID 29 | 1.399 | 2.272 | 1.484 | 1.022 | - | 0.792 | 1.484 |

| ID 30 | 1.614 | 1.962 | 1.044 | 0.582 | 0.682 | - | 1.423 |

| ID 31 | 1.743 | 2.693 | 1.981 | 1.519 | 0.497 | 1.289 | - |

References

- World Economic Forum. The Future of the Last-Mile Ecosystem; Technical Report; World Economic Forum: Geneva, Switzerland, 2020. [Google Scholar]

- United Nations. The 17 Goals. 2022. Available online: https://sdgs.un.org/goals (accessed on 17 July 2024).

- Winkelhaus, S.; Grosse, E.H. Logistics 4.0: A systematic review towards a new logistics system. Int. J. Prod. Res. 2019, 58, 18–43. [Google Scholar] [CrossRef]

- Ciancio, C.; De Maio, A.; Laganà, D.; Santoro, F.; Violi, A. A Genetic Algorithm Framework for the Orienteering Problem with Time Windows. In New Trends in Emerging Complex Real Life Problems; Daniele, P., Scrimali, L., Eds.; AIRO Springer Series; Springer: Cham, Switzerland, 2018; Volume 1. [Google Scholar] [CrossRef]

- Ding, N.; Li, M.; Hao, J. A Two-Phase Approach to Routing a Mixed Fleet with Intermediate Depots. Mathematics 2023, 11, 1924. [Google Scholar] [CrossRef]

- Pingale, S.; Kaur, A.; Agarwal, R. Collaborative last mile delivery: A two-echelon vehicle routing model with collaboration points. Expert Syst. Appl. 2024, 252 Pt B, 124164. [Google Scholar] [CrossRef]

- Kucukoglu, I.; Dewil, R.; Cattrysse, D. The electric vehicle routing problem and its variations: A literature review. Comput. Ind. Eng. 2021, 161, 107650. [Google Scholar] [CrossRef]

- Herrera, E.; Panadero, J.; Juan, A.A.; Neroni, M.; Bertolini, M. Last-Mile Delivery of Pharmaceutical Items to Heterogeneous Healthcare Centers with Random Travel Times and Unpunctuality Fees. In Proceedings of the Winter Simulation Conference (WSC), Phoenix, AZ, USA, 12–15 December 2021; pp. 1–12. [Google Scholar] [CrossRef]

- Schneikart, G.; Mayrhofer, W.; Löffler, C.; Frysak, J. A roadmap towards circular economies in pharma logistics based on returnable transport items enhanced with Industry 4.0 technologies. Resour. Conserv. Recycl. 2024, 206, 107615. [Google Scholar] [CrossRef]

- Lu, F.; Chen, W.; Feng, W.; Bi, H. 4PL routing problem using hybrid beetle swarm optimization. Soft Comput. 2023, 27, 17011–17024. [Google Scholar] [CrossRef]

- Ghiani, G.; Laporte, G.; Musmanno, R. Introduction to Logistics Systems Management: With Microsoft Excel and Python Examples; Wiley: Hoboken, NJ, USA, 2022. [Google Scholar]

- Bertazzi, L.; De Maio, A.; Laganà, D. The Impact of a Clustering Approach on Solving the Multi-depot IRP. In Optimization and Decision Science: Methodologies and Applications; Sforza, A., Sterle, C., Eds.; ODS 2017, Springer Proceedings in Mathematics & Statistics; Springer: Cham, Switzerland, 2017; Volume 217. [Google Scholar] [CrossRef]

- Beraldi, P.; De Maio, A.; Laganà, D.; Violi, A. A pick-up and delivery problem for logistics e-marketplace services. Optim. Lett. 2021, 15, 1565–1577. [Google Scholar] [CrossRef]

- Pokorska, A.; Wiśniewski, T. Electromobility as a Challenge of Modern City Logistics—Indicator Analysis. Energies 2024, 17, 3167. [Google Scholar] [CrossRef]

- İmre, Ş.; Çelebi, D.; Asan, U. Estimating potential adoption rate of electric vehicles in urban logistics. Transp. Plan. Technol. 2023, 47, 370–399. [Google Scholar] [CrossRef]

- Tomislav, E.; Tonči, C. A Survey on the Electric Vehicle Routing Problem: Variants and Solution Approaches. J. Adv. Transp. 2019, 2019, 5075671. [Google Scholar] [CrossRef]

- Nielsen, P.; Dahanayaka, M.; Perera, H.N.; Thibbotuwawa, A.; Kenan Kilic, D. A systematic review of vehicle routing problems and models in multi-echelon distribution networks. Supply Chain. Anal. 2024, 7, 100072. [Google Scholar] [CrossRef]

- Yuan, Z.; Gao, J. Dynamic Uncertainty Study of Multi-Center Location and Route Optimization for Medicine Logistics Company. Mathematics 2022, 10, 953. [Google Scholar] [CrossRef]

- Li, X.; Zhou, K. Multi-objective cold chain logistic distribution center location based on carbon emission. Environ. Sci. Pollut. Res. 2021, 28, 32396–32404. [Google Scholar] [CrossRef]

- Hamdan, B.; Diabat, A. Robust design of blood supply chains under risk of disruptions using Lagrangian relaxation. Transp. Res. Part E Logist. Transp. Rev. 2020, 134, 101764. [Google Scholar] [CrossRef]

- Wu, X.; Li, R.; Chu, C.H.; Amoasi, R.; Shan Liu, S. Managing pharmaceuticals delivery service using a hybrid particle swarm intelligence approach. Ann. Oper. Res. 2022, 308, 653–684. [Google Scholar] [CrossRef]

- Bouziyanea, B.; Dkhissia, B.; Cherkaouia, M. Multiobjective optimization in delivering pharmaceutical products with disrupted vehicle routing problem. Int. J. Ind. Eng. Comput. 2020, 11, 299–316. [Google Scholar] [CrossRef]

- Kramer, R.; Cordeau, J.-F.; Iori, M. Rich vehicle routing with auxiliary depots and anticipated deliveries: An application to pharmaceutical distribution. Transp. Res. Part E Logist. Transp. Rev. 2019, 129, 162–174. [Google Scholar] [CrossRef]

- Lee, S.J.; Kim, B.S. Vehicle routing and scheduling problem with order acceptance for pharmaceutical refrigerated logistics. Appl. Soft Comput. 2024, 164, 111983. [Google Scholar] [CrossRef]

- Campelo, P.; Neves-Moreira, F.; Amorim, P.; Almada-Lobo, B. Consistent vehicle routing problem with service level agreements: A case study in the pharmaceutical distribution sector. Eur. J. Oper. Res. 2019, 273, 131–145. [Google Scholar] [CrossRef]

- Repolho, H.M.; Marchesi, J.F.; Júnior, O.S.S.; Bezerra, R.R.R. Cargo theft weighted vehicle routing problem: Modeling and application to the pharmaceutical distribution sector. Soft Comput. 2019, 23, 5865–5882. [Google Scholar] [CrossRef]

- Ahlaqqach, M.; Benhra, J.; Mouatassim, S.; Lamrani, S. Closed loop location routing supply chain network design in the end of life pharmaceutical products. Supply Chain. Forum: Int. J. 2020, 21, 79–92. [Google Scholar] [CrossRef]

- Li, J.; Peng, K.; Deng, X.; Wang, J.; Liu, A. Model and algorithm for pharmaceutical distribution routing problem considering customer priority and carbon emissions. Data-Centric Eng. 2024, 5, e16. [Google Scholar] [CrossRef]

- Shahparvari, S.; Hassanizadeh, B.; Mohammadi, A.; Kiani, B.; Lau, K.H.; Chhetri, P.; Abbasi, B. A decision support system for prioritised COVID-19 two-dosage vaccination allocation and distribution. Transp. Res. Part E Logist. Transp. Rev. 2022, 159, 102598. [Google Scholar] [CrossRef] [PubMed]

- Habibi, F.; Abbasi, A.; Chakrabortty, R.K. Designing an efficient vaccine supply chain network using a two-phase optimization approach: A case study of COVID-19 vaccine. Int. J. Syst. Sci. Oper. Logist. 2022, 10, 2121623. [Google Scholar] [CrossRef]

- Ramos, T.R.P.; Vigo, D. A new hybrid distribution paradigm: Integrating drones in medicines delivery. Expert Syst. Appl. 2023, 234, 120992. [Google Scholar] [CrossRef]

- De Maio, A.; Ghiani, G.; Laganà, D.; Manni, E. Sustainable last-mile distribution with autonomous delivery robots and public transportation. Transp. Res. Part C Emerg. Technol. 2024, 163, 104615. [Google Scholar] [CrossRef]

- Hwang, C.-L.; Masud, A.S.M. Multiple Objective Decision Making, Methods and Applications: A State-of-the-Art Survey; Springer: Berlin/Heidelberg, Germany, 1979; ISBN 978-0-387-09111-2. [Google Scholar]

- De Maio, A.; Musmanno, R.; Skrame, A. The Green Tourist Trip Design Problem with Time Windows: A Model Application on a Urban Scale. In Proceedings of the 12th International Conference on Operations Research and Enterprise Systems—Volume 1: ICORES, Lisbon, Portugal, 19–21 February 2023; pp. 62–70, ISBN 978-989-758-627-9. [Google Scholar] [CrossRef]

- Hessami, S.; Davari-Ardakani, H.; Javid, Y.; Ameli, M. Bi-objective optimization of a multi-mode, multi-site resource-constrained project scheduling problem. J. Model. Manag. 2024, 19, 1136–1154. [Google Scholar] [CrossRef]

| Reference | Problem | Application/Area of Application | Features | Objective |

|---|---|---|---|---|

| Yuan and Gao, 2017 [18] | Location routing | Medical logistic company | Long-haul distribution, uncertainty | Minimization of operational costs |

| Kramer et al., 2019 [23] | Rich vehicle routing | Tuscany (Italy) | Regional distribution | Minimization of operational costs |

| Campelo et al., 2019 [25] | Consistent Vehicle Routing | Pharmaceutical distribution company | Pharmaceutical cold chain | Minimization of total distance traveled |

| Hamdan and Diabat, 2020 [20] | Bi-objective robust design | Jordan | Blood supply chain under disasters | Minimization of time and delivery cost |

| Bouziyane et al., 2020 [22] | Multi-objective Disrupted Vehicle Routing with Soft Time Windows | - | Disruption | Minimization of transportation time and delay |

| Ahlaqqach et al., 2020 [27] | Multi-objective location | Casablanca (Morocco) | Closed-loop routing supply chain | Maximization of profit and job creation, minimization of risk |

| Li and Zhou, 2021 [19] | Multi-objective location | Lianyungang (China) | Regional distribution | Minimization of operational costs, emissions and customer unsatisfaction |

| Wu et al., 2021 [21] | Vehicle assingment and routing | Tianjin (China) | Urban distribution (mega-city) | Minimization of total vehicle cost |

| Shahparvari et al., 2022 [29] | Allocation and distribution | Melbourne (Australia) | Covid-19 Vaccines distribution | Minimization of risk of infection, vaccine degradation and service time |

| Habibi et al., 2022 [30] | Location of distribution centers, inventory policies, and routing decisions | Iran | Covid-19 Vaccines distribution | Minimization of total procurement, inventory, and distribution costs |

| Ramos and Vigo, 2023 [31] | Dynamic Parallel Drone Scheduling Vehicle Routing with Lead Time | Portugal | Rural delivery with drones | Minimization of transportation cost |

| De Maio et al., 2024 [32] | Autonomous Delivery Robot Routing Problem with Public Transportation | Rome (Italy) | Urban distribution | Minimization of transportation cost |

| Lee and Kim, 2024 [24] | Vehicle routing and scheduling with order acceptance | - | Pharmaceutical cold chain | Maximization of profit |

| Li et al., 2024 [28] | Vehicle routing | - | Pharmaceutical distribution | Minimization of customer priority, costs, and carbon emissions |

| Repolho et al., 2019 [26] | Vehicle routing | Brazil | Pharmaceutical distribution in high-theft-risk areas | Minimization of total costs |

| First Tour | Second Tour | Total | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| k | Length | SCT | Emission | Length | SCT | Emission | Length | SCT | Emission | Time |

| [km] | [h] | [kg/km] | [km] | [h] | [kg/km] | [km] | [h] | [kg/km] | [s] | |

| 2 | 4.156 | 0.712 | 1.317 | 19.202 | 4.928 | 1.119 | 23.358 | 4.928 | 2.435 | 1.11 |

| 3 | 4.132 | 0.792 | 1.309 | 19.202 | 4.844 | 1.119 | 23.334 | 4.844 | 2.428 | 4.75 |

| 4 | 4.156 | 0.878 | 1.317 | 18.502 | 4.683 | 1.078 | 22.658 | 4.683 | 2.394 | 4.00 |

| 5 | 4.132 | 0.959 | 1.309 | 18.952 | 4.650 | 1.104 | 23.084 | 4.650 | 2.413 | 3.00 |

| 6 | 4.133 | 1.043 | 1.309 | 18.830 | 4.553 | 1.097 | 22.963 | 4.553 | 2.406 | 2.57 |

| 7 | 4.876 | 1.208 | 1.545 | 17.973 | 4.374 | 1.047 | 22.849 | 4.374 | 2.592 | 10.55 |

| 8 | 5.091 | 1.316 | 1.613 | 18.135 | 4.309 | 1.056 | 23.226 | 4.309 | 2.669 | 9.10 |

| 9 | 5.834 | 1.482 | 1.848 | 17.278 | 4.131 | 1.006 | 23.112 | 4.131 | 2.855 | 11.67 |

| 10 | 6.423 | 1.630 | 2.035 | 16.775 | 3.991 | 0.977 | 23.198 | 3.991 | 3.012 | 36.31 |

| 11 | 7.092 | 1.788 | 2.247 | 15.875 | 3.808 | 0.925 | 22.967 | 3.808 | 3.171 | 27.24 |

| 12 | 7.842 | 1.955 | 2.484 | 15.027 | 3.630 | 0.875 | 22.869 | 3.630 | 3.360 | 42.00 |

| 13 | 8.484 | 2.109 | 2.688 | 14.063 | 3.440 | 0.819 | 22.547 | 3.440 | 3.507 | 477.26 |

| 14 | 9.071 | 2.258 | 2.874 | 14.056 | 3.356 | 0.819 | 23.127 | 3.356 | 3.692 | 234.38 |

| 15 | 9.821 | 2.425 | 3.111 | 12.889 | 3.143 | 0.751 | 22.710 | 3.143 | 3.862 | 218.47 |

| 16 | 10.002 | 2.528 | 3.169 | 14.541 | 3.243 | 0.847 | 24.543 | 3.243 | 4.016 | 450.54 |

| 17 | 10.291 | 2.643 | 3.260 | 14.980 | 3.209 | 0.873 | 25.271 | 3.209 | 4.133 | 800.44 |

| 18 | 10.918 | 2.796 | 3.459 | 14.206 | 3.039 | 0.827 | 25.124 | 3.039 | 4.286 | 347.18 |

| 19 | 11.632 | 2.959 | 3.685 | 12.962 | 2.818 | 0.755 | 24.594 | 2.959 | 4.440 | 204.61 |

| 20 | 12.127 | 3.097 | 3.842 | 12.270 | 2.657 | 0.715 | 24.397 | 3.097 | 4.557 | 120.87 |

| 21 | 12.634 | 3.237 | 4.002 | 12.003 | 2.544 | 0.699 | 24.637 | 3.237 | 4.702 | 108.72 |

| 22 | 13.194 | 3.383 | 4.180 | 11.319 | 2.385 | 0.659 | 24.513 | 3.383 | 4.839 | 50.18 |

| 23 | 13.916 | 3.546 | 4.409 | 9.977 | 2.153 | 0.581 | 23.893 | 3.546 | 4.990 | 35.57 |

| 24 | 14.659 | 3.712 | 4.644 | 9.224 | 1.986 | 0.537 | 23.883 | 3.712 | 5.181 | 31.78 |

| 25 | 15.428 | 3.881 | 4.888 | 8.431 | 1.814 | 0.491 | 23.859 | 3.881 | 5.379 | 27.77 |

| 26 | 16.242 | 4.055 | 5.145 | 7.011 | 1.573 | 0.408 | 23.253 | 4.055 | 5.554 | 26.87 |

| 27 | 16.685 | 4.187 | 5.286 | 7.315 | 1.524 | 0.426 | 24.000 | 4.187 | 5.712 | 26.10 |

| 28 | 17.407 | 4.351 | 5.515 | 5.837 | 1.276 | 0.340 | 23.244 | 4.351 | 5.855 | 7.58 |

| 29 | 18.291 | 4.532 | 5.795 | 4.587 | 1.054 | 0.267 | 22.878 | 4.532 | 6.062 | 3.86 |

| 30 | 20.193 | 4.827 | 6.397 | 3.020 | 0.796 | 0.176 | 23.213 | 4.827 | 6.573 | 1.29 |

| 31 | 21.606 | 5.067 | 6.845 | 0.000 | 0.000 | 0.000 | 21.606 | 5.067 | 6.845 | 0.59 |

| k | α | β | B | SCT | GAPSCT | CO2 | GAPCO2 | cost | GAPcost |

|---|---|---|---|---|---|---|---|---|---|

| [EUR] | [h] | [%] | [kg/km] | [%] | [EUR] | [%] | |||

| 9 | 0.25 | 0.75 | 8.95 | 3.917 | −5.18 | 3.171 | 11.07 | 8.90 | 15.32 |

| 9 | 0.50 | 0.75 | 10.16 | 3.791 | −8.21 | 3.385 | 18.56 | 9.92 | 28.57 |

| 15 | 0.25 | 0.75 | 8.95 | 3.143 | 0.00 | 3.862 | 0.00 | 8.75 | 15.39 |

| 15 | 0.50 | 0.75 | 10.16 | 3.143 | 0.00 | 3.862 | 0.00 | 9.84 | 29.72 |

| 19 | 0.25 | 0.75 | 8.95 | 3.026 | 2.25 | 4.533 | 2.10 | 8.90 | 8.32 |

| 19 | 0.50 | 0.75 | 10.16 | 2.988 | 0.97 | 4.453 | 0.29 | 9.97 | 21.44 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

De Maio, A. A Two-Echelon Routing Model for Sustainable Last-Mile Delivery with an Intermediate Facility: A Case Study of Pharmaceutical Distribution in Rome. Mathematics 2024, 12, 2679. https://doi.org/10.3390/math12172679

De Maio A. A Two-Echelon Routing Model for Sustainable Last-Mile Delivery with an Intermediate Facility: A Case Study of Pharmaceutical Distribution in Rome. Mathematics. 2024; 12(17):2679. https://doi.org/10.3390/math12172679

Chicago/Turabian StyleDe Maio, Annarita. 2024. "A Two-Echelon Routing Model for Sustainable Last-Mile Delivery with an Intermediate Facility: A Case Study of Pharmaceutical Distribution in Rome" Mathematics 12, no. 17: 2679. https://doi.org/10.3390/math12172679