1. Introduction

Manufacturing is a production business and its primary objective is to convert raw material into quality goods that have a value in the market place and as a result, generated profit. Factors such as system efficiency, product quality and reliability, productivity and lower cost, and efficient and effective management techniques contributing to increasing that profit [

1].

The manufacturing industry is key to the country’s development and economy. Since many years ago, this industry has been experiencing many changes to improve efficiency in order to produce products with higher quality and become more competitive in the market [

1].

In the past few years, new emerging technologies such as cloud computing, cyber-physical systems [

2], wireless sensor networks [

3], big data [

4], or mobile Internet have been introduced into the manufacturing environment [

5]. The fusion of manufacturing with these new technologies is enabling a game-changing transformation in terms of manufacturing models and approaches [

6], leading to a new concept called Industry 4.0.

The term “Industry 4.0” was first used in 2011 as part of the German government initiative establishing it as a critical strategy for industrial production [

7].

Industry 4.0 fuses production system technologies with smart production processes to prepare enterprises for the next technological era that is transforming business models and production value chains [

8].

The number of academic investigations focuses on the application of Industry 4.0 on large enterprises is higher [

9,

10] in comparison with micro, small, and medium enterprises (MSMEs). It is important to know how MSMEs will implement Industry 4.0 and how it will impact them because in many cases MSMEs play the role of suppliers to large size enterprises and vice versa [

11]. The performance of MSMEs affects the response of their bigger supply chain partners and their requirements influence the positioning of MSMEs in the technological developments derived from Industry 4.0 [

11]. Different methods that improve the performance already exist, for example, just-in-time, whose aim is to synchronize flows via production lines [

12]. Although the effectiveness has been proven in different cases [

13], this approach seems challenging to apply in small and medium enterprises (SMEs) because of their lack of leadership and proficiency [

14,

15]. Another case is the adoption of Material Requirement Planning (MRP) [

16] and Material Requirement Planning II (MRPII) [

17], driven by the development of computer tools such as Enteprise Resource Planning (ERP) [

18], was boarded differently in SMEs than in large companies [

19] because SMEs level of digitalization is lower than their large counterparts [

11].

Understanding the perspective of SMEs on how achievable it is for them to adopt Industry 4.0 helps to create a more comprehensive picture [

11] of how they can affront this new industrial revolution.

Research studies conducted in Germany show that SMEs waver to make use of Industry 4.0 applications because of the different challenges these technologies involve for the enterprises [

20].

In India, the most critical challenge for the Industry is to raise the manufacturing value chain in a way to cover the gap in critical technologies [

21].

In the case of New Zealand, the lack of enough experience and a shortage of available resources is one of the major challenges for SMEs to implement Industry 4.0 applications [

22].

To understand the Peruvian scenario, 49 manufacturing MSMEs business managers were surveyed. The goal of the present study was to identify the factors that are challenging the implementation of industry 4.0 technologies in Peruvian MSMEs. In order to achieve that, the analytic hierarchy process method was applied. The results obtained show that the there is a factor that affects the most in the implementation of Industry 4.0 technologies and is the lack financial of investment, followed by lack of advanced technology, lack of management vision, and lack of skilled workers. This method will guide public and private institutions that support small and medium enterprises to overcome the barriers that now are affecting the implementation of Industry 4.0 technologies in Peru. Finally, this study gives a new insight into the challenges and necessity of support for manufacturing enterprises in this new manufacturing era.

The paper is organized with the following structure.

Section 2 provides a review of the literature related to the concept of MSMEs in Peru and criterions that involve the implementations of new technologies in small enterprises.

Section 3 presents the research method and its applications used in this study, followed by

Section 4 which describes the results. The paper ends with our discussion and conclusions.

4. Results

Large-sized enterprises produce in high volumes; constant optimization is a standing factor of process management. In the case of medium, small, or micro enterprises the production is in low volume and as a consequence, the number of manual activities is in higher proportion. In comparison with SMEs, large companies will realize much higher efficiency gains from the use of Industry 4.0 technologies because of their level of production [

40]. The integration of communication and information technology into production, create concepts like the smart product and smart machine and enterprises that include these concepts in the business performance have begun to activate their power in today’s competitive environment [

55]. In this study, we examined the difficulties that MSMEs are facing in the application of Industry 4.0 technologies and with the support of the AHP method the most relevant factor will be determined. The application of AHP for this research is described the following steps:

Step 1. Identification of the decision problem. This research planned to identify the specific obstacle that is affecting Peruvian MSMEs in the implementation of Industry 4.0 technologies.

Step 2. Construction of the hierarchical structure. Although there is a presence of Industry 4.0 in Peruvian enterprises, its level of the establishment have not yet a very representative position; furthermore, it is considered that, in terms of digital transformation, only 1% of the massive consumption enterprises could be considered to belong to category 4.0 [

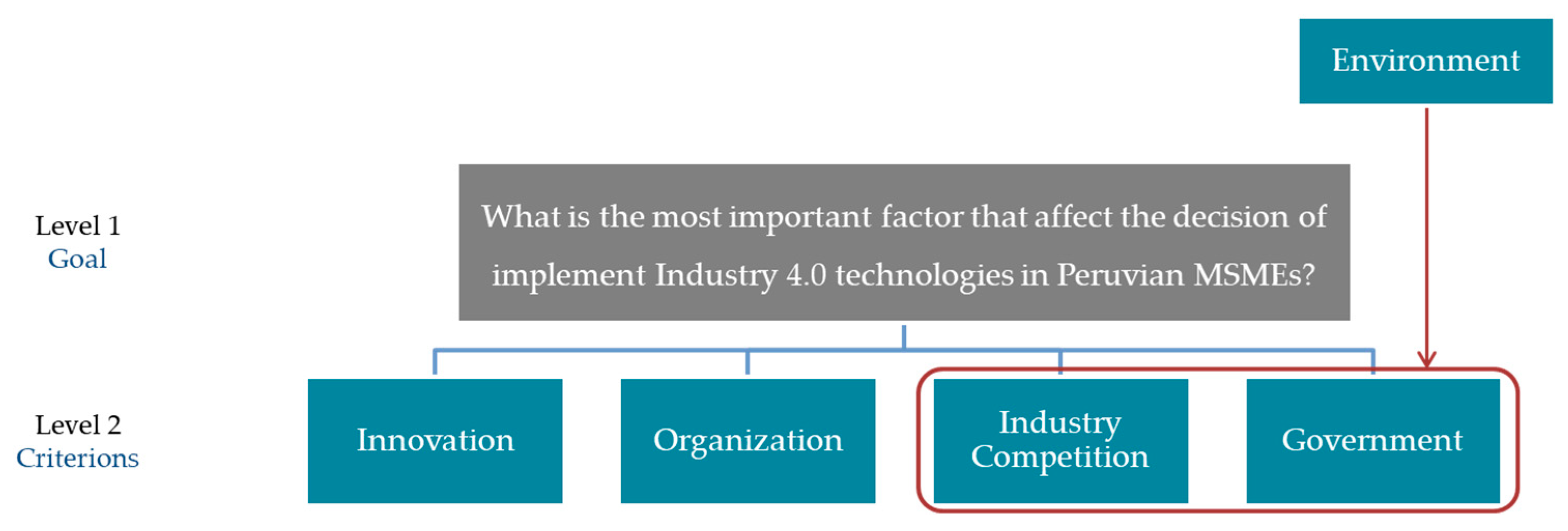

56]. The criterions influencing are based in two sources—literature and authors perspective. In the case of literature, the study presented by Premkumar and Roberts [

37] and Ali Sevinç et al. [

55] was used to support the criterions. From the author’s perspective, the criterion environment was divided into two—industry competition and government. As a consequence, in this study, industry innovation, organization, industry competition, and government were defined as the four criterions constituting the second level of the hierarchy by the criterions as is shown in

Figure 3.

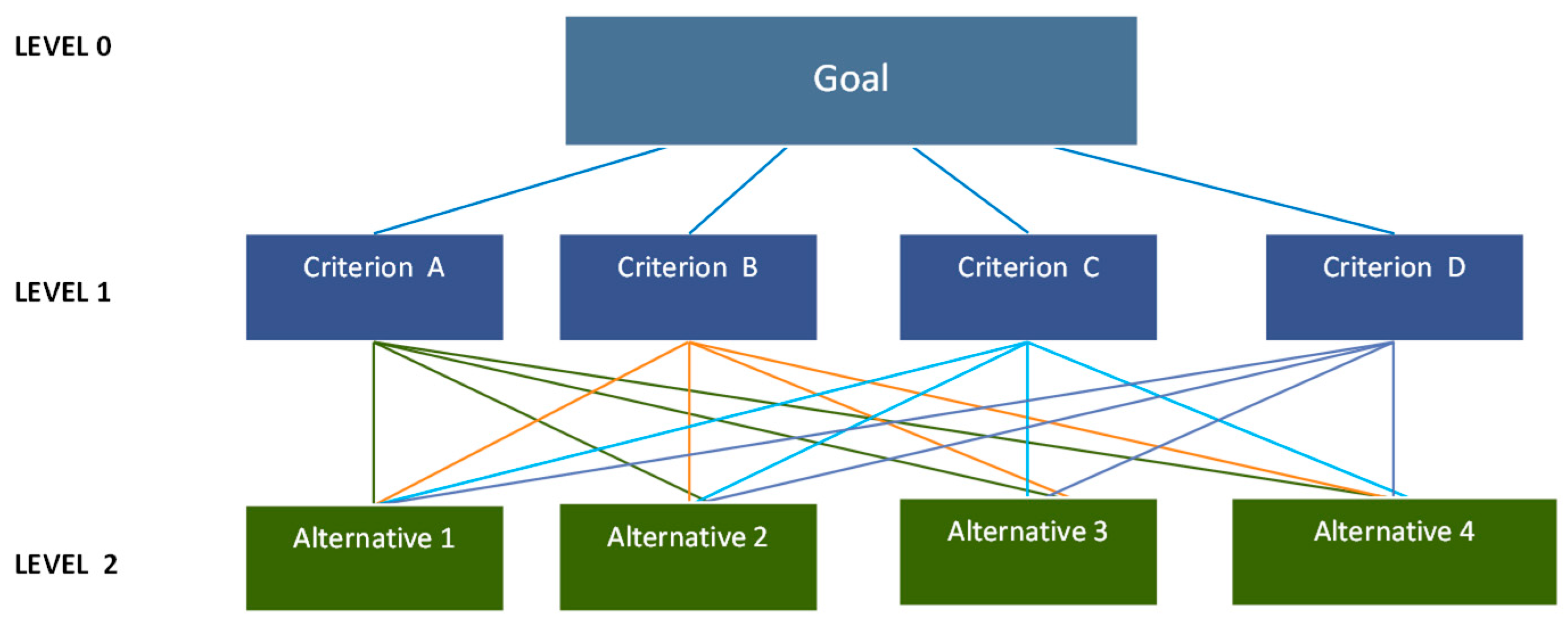

The AHP method structures the problem as a hierarchy. After defining the goal to be achieved and the criterion to be used, the next step is to define the factors to be evaluated. The factors were based on Schröder’s [

40] study, related to the challenges of industry 4.0 for SMEs and the findings from the 26 semi-structured interviews conducted with MSMEs experts.

Figure 4 present the hierarchy proposed for this study. The first level is the goal; in this case, what is the most important factor that affects the decision to implement Industry 4.0 technologies in Peruvian SMEs? The second level is constituted by the criterions, and in this case, are represented by organization, industry competition, and government support. The third level presents the available alternatives, which means the factors that will help to answer the initial goal. According to the findings from the semi-structured interviews conducted with relevant stakeholders, four factors, including lack of advanced technology, lack of financial investment, poor management vision, and skilled workers, were selected as key factors for the assessment.

In

Figure 5, the criterions and the factors involved are presented in a diagram by taking into account the answers obtained in the survey presented in

Appendix A. The lack of advanced technology factor is the tough access to the use of technologies, which implies a low technological intensity production, according to the new technological trends. The experts have opined that the lack of technological device markets still create barriers for the Peruvian manufacturing business managers to think regarding industry 4.0.

In terms of the lack of financial investment, finance is a major restriction facing SMEs and it can have a remarkable impact on their performance [

38]. Different costs are involved in the implementation of new technologies or systems that need to be integrated with the company for these processes cost such as the cost of maintenance and technical support to ensure the continuity of new technologies integrated into enterprises or the cost of training when the new technologies are integrated into the enterprises. The installation of new technologies to gain the benefits of Industry 4.0 are consider very expensive; therefore, the companies do not like to apply them in the factory sector, which is another challenge for the application of Industry 4.0 [

43].

The poor management vision involves the support for new technologies and the adoption of innovations. With the support of top management, various studies can be done, and sufficient resources can be allocated for the adoption of new technologies.

Skilled workers are the key to make every global scenario different and to achieve that is necessary to demand a better education and development new skills [

21]. A qualified workforce is very important for the development and implementation of Industry 4.0. The high demand for skilled workers and a lack of know-how is one of the biggest impediments to achieve the implementation of Industry 4.0 [

40]. Enterprises will need qualified managers for complex global supply chains and very qualified employees. Also, to support ongoing efforts to upgrade pedagogy and course content, policy makers (which involves that compromise from the government) must work with educational institutions and industry and to ensure that youth workforce develops new skill sets [

21]. The insertion of new educational trends, such as: customizing learning based on each student’s capabilities; learning at diverse times and places (virtual classes); using new learning devices, tools, and resources; execution of project-based and problem-based learning approaches; remote laboratories for teaching engineering; using collaborative and experimental learning; involving students in the curriculum design; and promoting mentorship programs is important for the development of skilled workers [

57].

Step 3. Calculation of the priority (weight) of the criterion. After the hierarchical structure was established, the paired comparison matrices were developed with the results obtained from the 49 MSMEs managers opinion.

Table 7 shows the first comparison matrix established between the main criteria.

After the pairwise comparison matrix was obtained, the next step was the calculation of the normalized matrix, as is presented in

Table 8. Then, the priority of each criterion (column Weight vector in

Table 8) is obtained by merely calculating the average value per each row.

Once the priority of each criterion was calculated, it was necessary to review if they are consistent in order to continue with the method.

Step 4. Calculation and analysis of the consistency ratio of criterion. The CR was calculated by multiplying the pair-wise matrix by the weights vector (Equation (1)); as a result of that two vectors were obtained—weight sum (Equation (2)) and

λ vector (Equation (3)), as is shown in

Table 9.

Then λ

max, which is the average of the λ vector, is calculated as follows:

After obtaining λ

max, the consistency index (CI) is calculated, as follows:

Finally, the consistency ratio (CR) is calculated, as Equation (5) indicates:

Since this value of 0.062 and is less than 0.10, it is assumed that the comparison matrix between criterion is consistent so is possible to continue with the decision-making process.

From

Table 8, it could be seen that organization and government support are the two major reasons that influence MSMEs to consider the implementation of Industry 4.0. These are represented by relative weights of 0.632 and 0.219, respectively. These two criterions were strongly expressed by manufacturing managers surveyed. This can be assigned to the fact that they know the real condition of the manufacturing sector in the country. It is important to mention that the results are consistent with the findings presented by Gutarra et al. [

58], who indicated that “An articulated and systemic regulatory framework that promotes technological development and innovation” is a variable that will support the future development of the Peruvian technological MSMEs.

Step 5. Calculation of the weight (priority) of each ʺalternativeʺ with respect to the criterion, and creation of comparison matrices of alternatives with respect of each criterion and the respective consistency ratio. This step consists of identifying and deriving the relative weight of the alternatives with respect to each criterion. In other words, what are the priorities of the alternatives with respect to innovation, organization, industry competition, and government support, respectively? For this purpose, a pairwise comparison of all the alternatives with respect to each criterion was developed and followed based on the response of the 49 MSMEs business managers surveyed.

Comparison Question I: With respect to the innovation criterion, which alternative is preferable: Lack of advanced technology, lack of financial investment, lack of management vision, or lack of skilled workers? The results of this first question are presented in

Table 10, followed by its normalized matrix presented in

Table 11.

Comparison Question II: With respect to the organization criterion, which alternative is preferable: Lack of advanced technology, lack of financial investment, lack of management vision, or lack of skilled workers? The results of this second question are presented in

Table 12, followed by its normalized matrix presented in

Table 13.

Comparison Question III: With respect to industry competition criterion, which alternative is preferable: Lack of Technology, lack of financial investment, lack of management vision, or lack of government Support? The results of this third question are presented in

Table 14, followed by its normalized matrix presented in

Table 15.

Comparison Question IV: With respect to government support criterion, which alternative is preferable: Lack of Technology, lack of financial investment, lack of management vision, or lack of government support? The results of this fourth question are presented in

Table 16, followed by its normalized matrix presented in

Table 17.

Step 6. This step consisted of calculating the final priority for each alternative; in other words, priorities that take into account only the weight of alternatives for each criterion but also consider the point that each criterion has a different weight.

Table 18 shows the synthesis of

Table 8,

Table 11,

Table 13,

Table 15 and

Table 17.

Step 7. Finally, after obtaining the weight of the alternatives respect to the criterion we can rank them in order of importance as is shown in

Table 19.

Considering the importance of the organization as the most relevant criterion (0.632), financial investment (0.491) is the factor that affects the most in the implementation of Industry 4.0 in manufacturing MSMEs in Peru.

5. Discussion and Conclusions

The present research aimed to identify the factors that are affecting the implementation of Industry 4.0 in Peruvian MSMEs. The analysis of the criterions and alternatives were done by the AHP method. The AHP method was chosen for two reasons: (1) the identified problem involved more than one criterion and finding the solution required a multi-criterion decision-making method and (2) the method helped to determine the level of importance of the involved factors.

Table 8 presents the resulted pairwise comparison of the criterion in perspective of the overall goal of the assessment. From this table, it could be seen that organization and government support are the two major reasons that influence enterprises’ decision to consider the option of Industry 4.0 technologies. These are represented by relative weights of 0.632 and 0.219, respectively. These two factors were strongly express by the business managers during the interviews. This can be attributed to the fact that they face the reality of the sector. Although important, the weight (0.092) of innovation implies that the factor does not have meaningful influence in affecting managers’ decision in the implementation of Industry 4.0 technologies. Meanwhile, from the result, it is likely that industry competition is not a major factor that managers consider because was with the least weight (0.057).

From

Table 19, the lack of financial investment (0.491) is the factor that most interfere with the implementation of Industry 4.0 in Peruvian MSMEs. This is followed by a lack of advanced technology (0.225), poor management vision (0.173), and, finally, lack of skilled workers (0.111), in that order. The fact that Industry 4.0 technologies are not implemented in Peruvian MSMEs is supported by the organization criterion and, specifically, for the lack of financial investment factor. The high cost of investment and the long time of the return of the investment are factors that stop firms from being convinced. The factor for the development of MSMEs is the capacity to access finance. There is a very notorious difference between a large enterprise (LE) and an MSMEs when applying for bank loans because while the LEs have the chance to explore the potential of capital markets, the MSMEs only have limited financing possibilities as compared to large companies [

59,

60]. Understanding the benefits of Industry 4.0 technologies will make it easier for business managers to make positive decisions [

55]. This study provides a transparent and consistent method of deciding the best factor that is likely to affect the decision of MSMEs in the implementation of Industry 4.0.

The literature review included in the present study explain the relationship between SMEs and Industry 4.0 [

11,

14,

29,

36], and most of the authors try to respond the answer: How can we help or make less challenging the adoption of Industry 4.0 solutions by SMEs? Even though each author point of view differs from each other, all conclude that part of the step is to let SMEs decide to consider the big step showing them the effectiveness of the technologies, that will be one the ways to attract the attention of traditional manufacturing.

The present study contributes to this literature by identifying four specific factors involved in the decision of MSMEs to give the big step from traditional manufacturing to Industry 4.0, and they are: Lack of advanced technology, lack of financial investment, lack of management vision, and lack of skilled workers. According to the findings, it has been identified that Peruvian manufacturing MSMEs need to work in strategies that will help to improve these four factors and give an opportunity to implement Industry 4.0 technologies. However, it would not be difficult for the country if it concentrated on technological integration and infrastructure development.

In this respect, it is highly recommended to the Peruvian government that they increase the support for the integration of Industry 4.0 technologies. Otherwise, the country will not be a part of the new industrial revolution, which could accelerate its present economic progress and would contribute to building a stronger economy in South America. A good example to cite is Thailand, where the government presented as the second point in their Agenda 3, a strategy called ʺthe transformation of traditional SMEs into “Smart SMEs” “Thailand 4.0” [

61], in which the objective is to increase the profit and contribution of SMEs. Basically, the government plans to expand SMEs through financial support for those enterprises that have business potential and management skills but lack financial liquidity.

This study is one of the first studies that analyzes the challenges of MSMEs in Peru; it presents the factors that are challenging the adoption processes and their reasons were approached analytically, but also has some limitations. First, we only include the data obtained from 49 enterprises, hence it cannot be generalized. Future research could increase the number of enterprises surveyed so a stronger generalization could be produced. Therefore, by systematically following all the scientific procedures, applying the AHP technique, it is further argued, could be one of the effective ways to find the best option that could help to solve a problem [

48], but it is important to consider that the results obtained are based on the evaluations received from the business managers. The AHP methodology just defines which alternative is the most consistent based in the criteria and level of importance that we give them [

62]. Considering the mentioned limits of the study, future researches may be made in order to improve the study.