Effect of Flammulina velutipes Soluble Dietary Fiber on Dough Processing Characteristics and Micro-Fermented Dried Noodles Quality Properties

Abstract

:1. Introduction

2. Materials and Methods

2.1. Preparation of Mixed Flour Dough and Fv-SDF Micro-Fermented Dried Noodles

2.2. Differential Scanning Calorimeter Analysis

2.3. Rapid Analysis of Viscosity

2.4. Determination of Farinograph Properties

2.5. Determination of the Dynamic Rheology Properties

2.6. Apparent Color Detection of Dried Noodles

2.7. Determination of the Best Cooking Time for Dried Noodles

2.8. Determination of the Cooking Characteristics of Dried Noodles

2.9. Determination of Sensory Evaluation of Dried Noodles

2.10. Determination of Flavor Compounds of Dried Noodles

2.11. Data Analysis

3. Results and Discussion

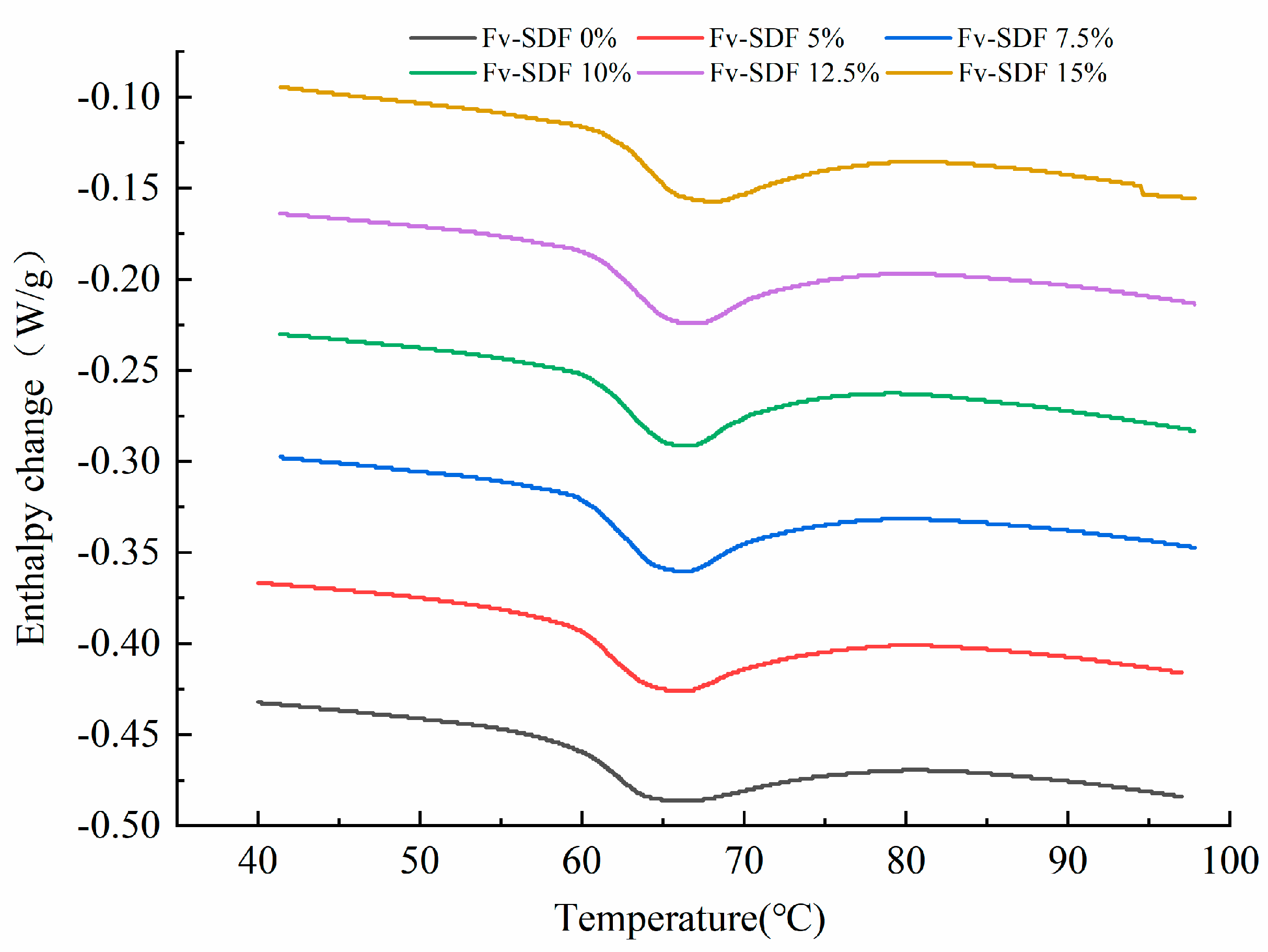

3.1. Effect of Fv-SDF Addition on Thermodynamic Properties of Wheat Starch

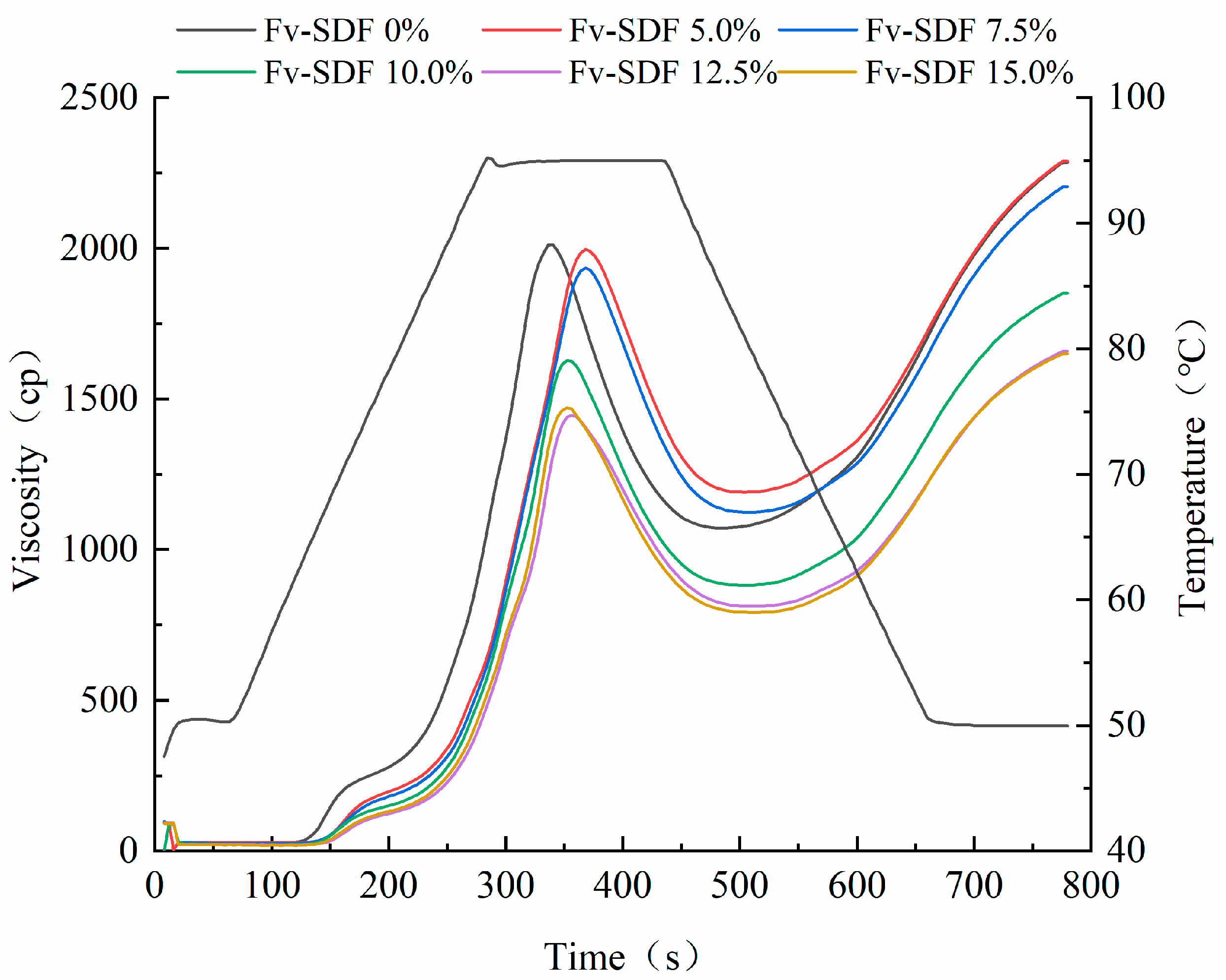

3.2. Effect of Fv-SDF Addition on Pasting Properties of Wheat Starch

3.3. Effect of Fv-SDF Addition on Farinograph Properties of Mix Powder

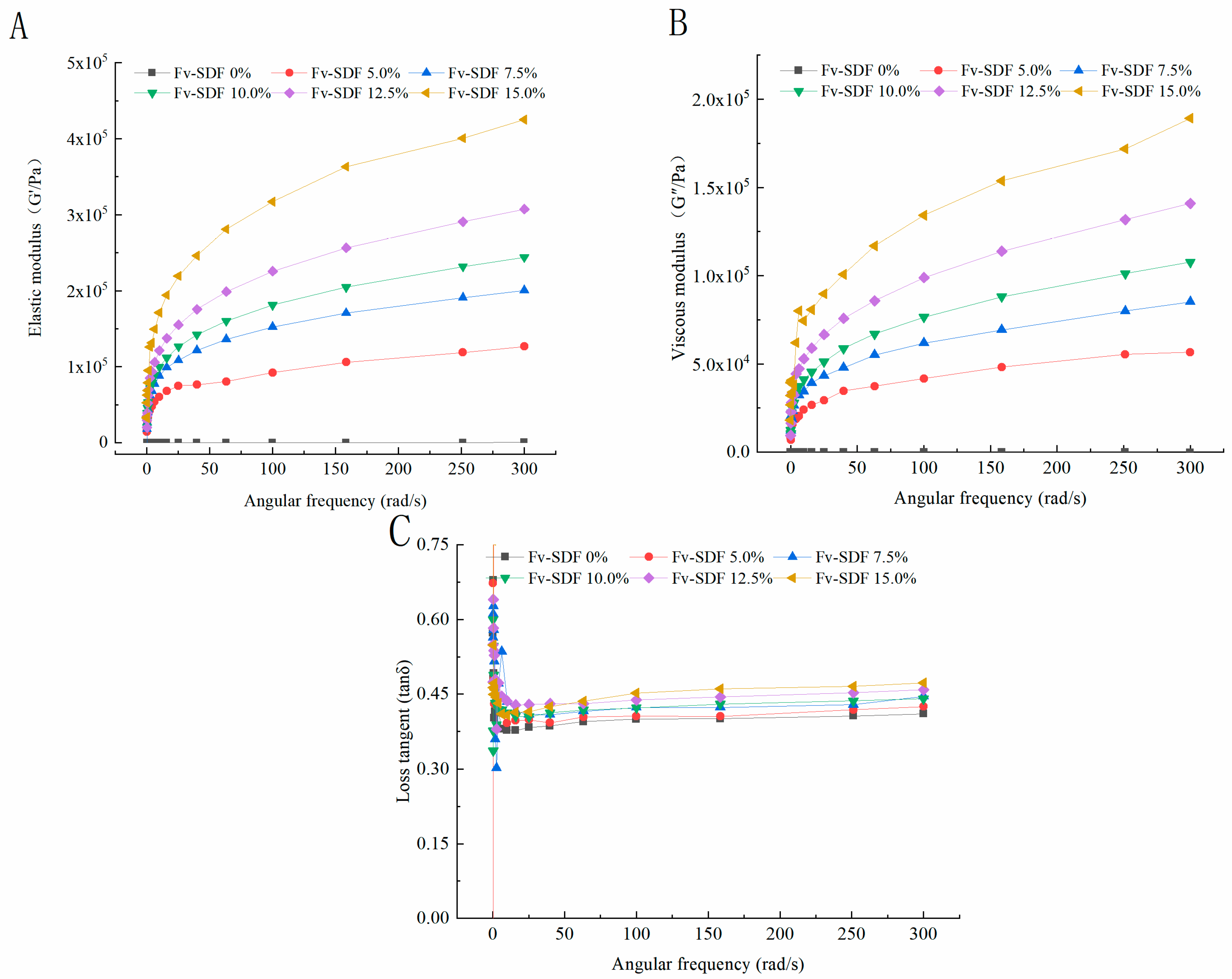

3.4. Effect of Fv-SDF Addition on Dynamic Rheological Properties of Dough

3.5. Effect of Fv-SDF Addition on Apparent Color of Dried Noodles

3.6. Effect of Fv-SDF Addition on the Cooking Quality of Dried Noodles

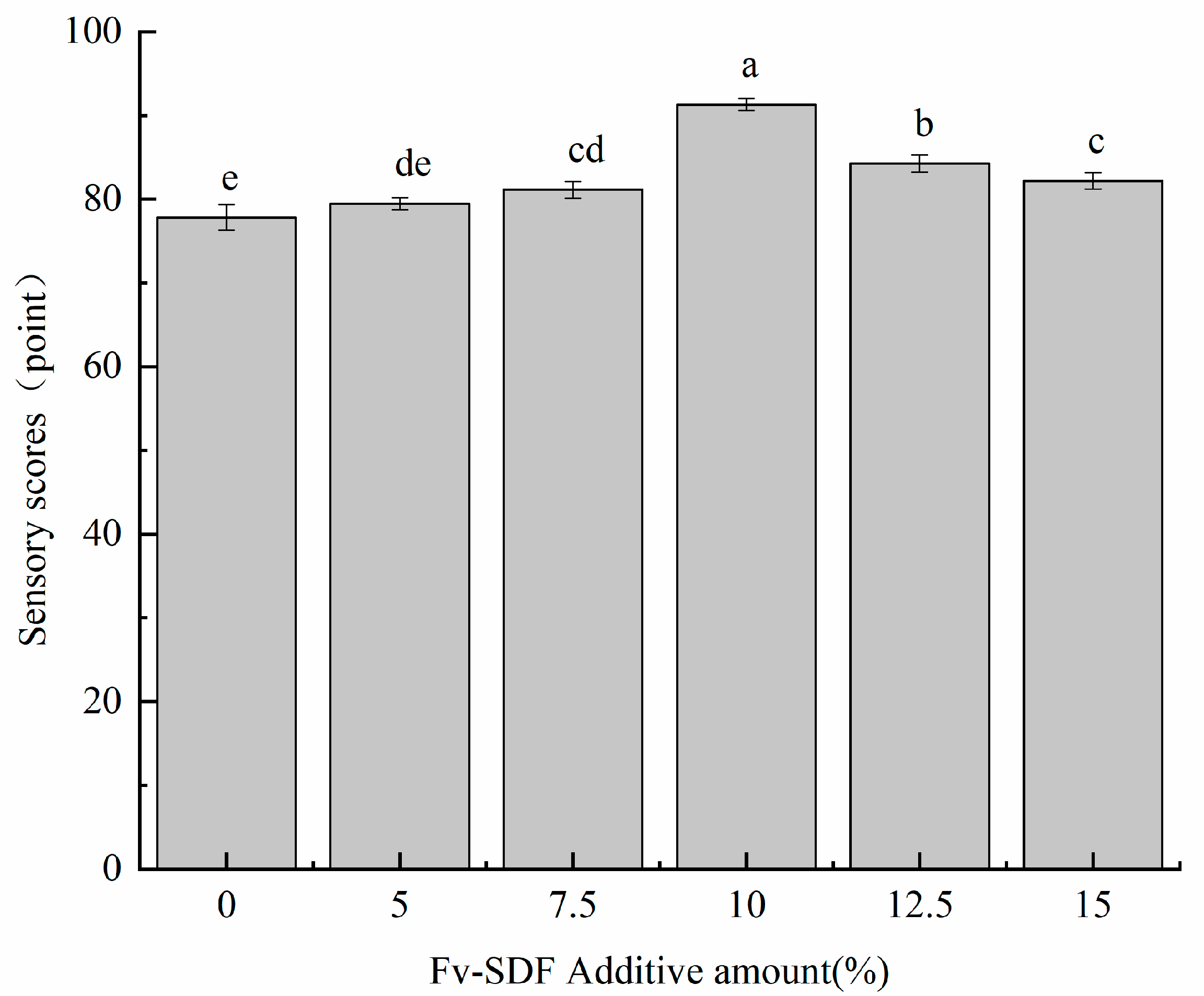

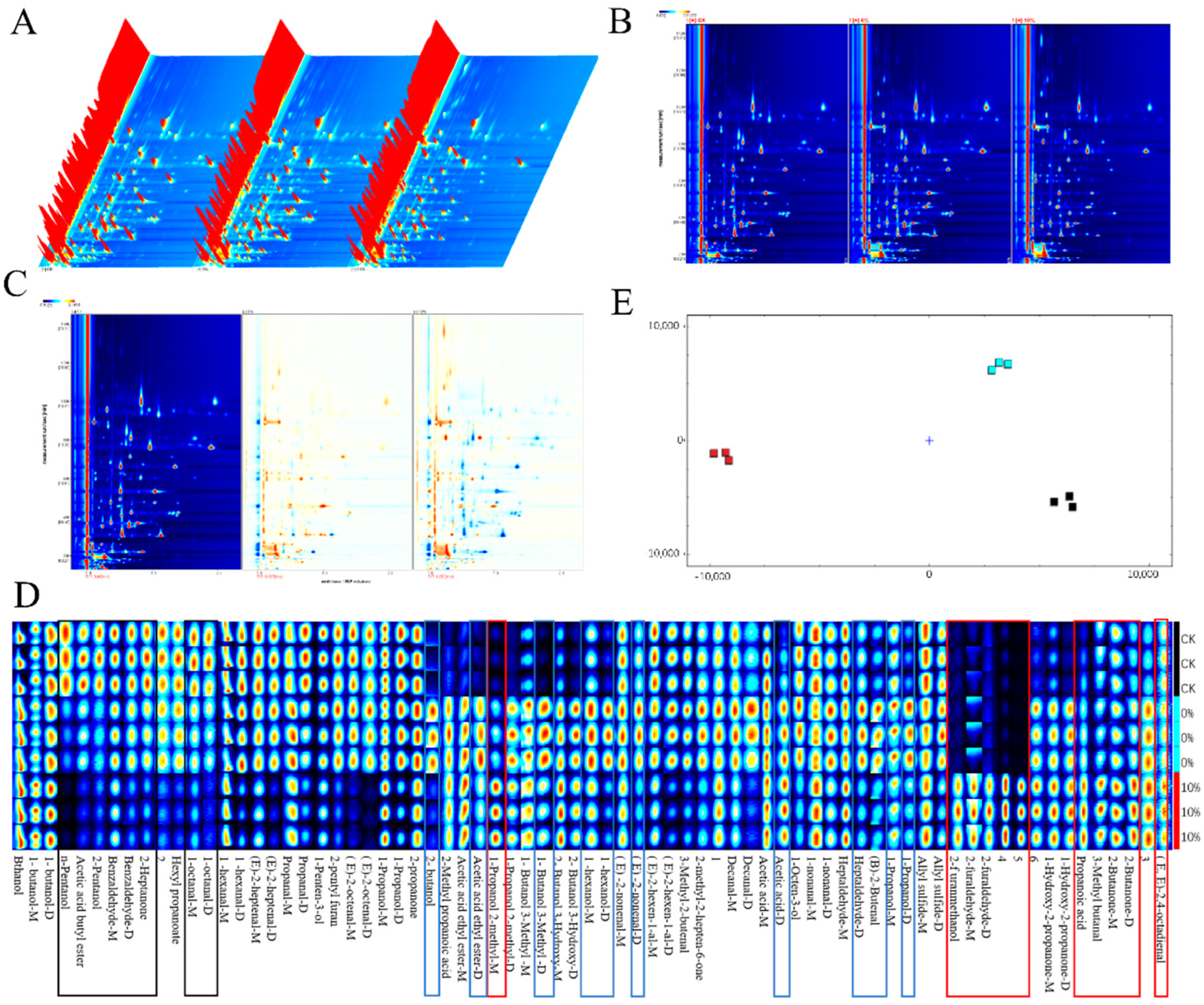

3.7. Comparative Analysis of Volatile Flavor Compounds in Dried Noodles

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Yeh, M.Y.; Ko, W.C.; Lin, L.Y. Hypolipidemic and antioxidant activity of enoki mushrooms (Flammulina velutipes). Biomed. Res. Int. 2014, 2014, 352385. [Google Scholar] [CrossRef] [PubMed]

- Liu, X.B.; Xia, E.H.; Li, M.; Cui, Y.Y.; Wang, P.M.; Zhang, J.X.; Xie, B.G.; Xu, J.P.; Yan, J.J.; Li, J.; et al. Transcriptome data reveal conserved patterns of fruiting body development and response to heat stress in the mushroom-forming fungus Flammulina filiformis. PLoS ONE 2020, 15, e0239890. [Google Scholar] [CrossRef]

- Wei, Q.; Pan, X.; Li, J.; Jia, Z.; Fang, T.; Jiang, Y. Isolation and Molecular Identification of the Native Microflora on Flammulina velutipes Fruiting Bodies and Modeling the Growth of Dominant Microbiota (Lactococcus lactis). Front. Microbiol. 2021, 12, 664874. [Google Scholar] [CrossRef]

- Wang, R.; Zhang, Y.; Lu, H.; Liu, J.; Song, C.; Xu, Z.; Yang, H.; Shang, X.; Feng, T. Comparative Aroma Profile Analysis and Development of a Sensory Aroma Lexicon of Seven Different Varieties of Flammulina velutipes. Front. Nutr. 2022, 9, 827825. [Google Scholar] [CrossRef]

- Tsai, S.-Y.; Hwang, B.-F.; Wang, Y.-H.; Lin, C.-P. Moisture desorption and thermal properties of polysaccharide from pulsed light irradiated Flammulina velutipes. J. Therm. Anal. Calorim. 2017, 127, 469–481. [Google Scholar] [CrossRef]

- Liang, Q.; Zhao, Q.; Hao, X.; Wang, J.; Ma, C.; Xi, X.; Kang, W. The Effect of Flammulina velutipes Polysaccharide on Immunization Analyzed by Intestinal Flora and Proteomics. Front. Nutr. 2022, 9, 841230. [Google Scholar] [CrossRef] [PubMed]

- Banerjee, D.K.; Das, A.K.; Banerjee, R.; Pateiro, M.; Nanda, P.K.; Gadekar, Y.P.; Biswas, S.; McClements, D.J.; Lorenzo, J.M. Application of Enoki Mushroom (Flammulina velutipes) Stem Wastes as Functional Ingredients in Goat Meat Nuggets. Foods 2020, 9, 432. [Google Scholar] [CrossRef]

- Cao, Y.; Tian, B.; Zhang, Z.; Yang, K.; Cai, M.; Hu, W.; Guo, Y.; Xia, Q.; Wu, W. Positive effects of dietary fiber from sweet potato [Ipomoea batatas (L.) Lam.] peels by different extraction methods on human fecal microbiota in vitro fermentation. Front. Nutr. 2022, 9, 986667. [Google Scholar] [CrossRef]

- Bai, X.; He, Y.; Quan, B.; Xia, T.; Zhang, X.; Wang, Y.; Zheng, Y.; Wang, M. Physicochemical properties, structure, and ameliorative effects of insoluble dietary fiber from tea on slow transit constipation. Food Chem. X 2022, 14, 100340. [Google Scholar] [CrossRef]

- Li, S.; Hu, N.; Zhu, J.; Zheng, M.; Liu, H.; Liu, J. Influence of modification methods on physicochemical and structural properties of soluble dietary fiber from corn bran. Food Chem. X 2022, 14, 100298. [Google Scholar] [CrossRef]

- Thomas, M.S.; Calle, M.; Fernandez, M.L. Healthy plant-based diets improve dyslipidemias, insulin resistance, and inflammation in metabolic syndrome. A narrative review. Adv. Nutr. 2023, 14, 44–54. [Google Scholar] [CrossRef] [PubMed]

- Coţovanu, I.; Mironeasa, C.; Mironeasa, S. Nutritionally Improved Wheat Bread Supplemented with Quinoa Flour of Large, Medium and Small Particle Sizes at Typical Doses. Plants 2023, 12, 1698. [Google Scholar] [CrossRef]

- Weng, J.; Chen, M.; Shi, B.; Liu, D.; Weng, S.; Guo, R. Konjac glucomannan defends against high-fat diet-induced atherosclerosis in rabbits by promoting the PI3K/Akt pathway. Heliyon 2023, 9, e13682. [Google Scholar] [CrossRef] [PubMed]

- Qi, J.; Gao, J.; Zhang, Y.; Hou, W.; Han, T.; Sun, C. The Association of Dietary Fiber Intake in Three Meals with All-Cause and Disease-Specific Mortality among Adults: The U.S. National Health and Nutrition Examination Survey, 2003–2014. Nutrients 2022, 14, 2521. [Google Scholar] [CrossRef] [PubMed]

- Elleuch, M.; Bedigian, D.; Roiseux, O.; Besbes, S.; Blecker, C.; Attia, H. Dietary fibre and fibre-rich by-products of food processing: Characterisation, technological functionality and commercial applications: A review. Food Chem. 2011, 124, 411–421. [Google Scholar] [CrossRef]

- Pankiewicz, U.; Zielińska, E.; Sobota, A.; Wirkijowska, A. The Use of Saccharomyces cerevisiae Supplemented with Intracellular Magnesium Ions by Means of Pulsed Electric Field (PEF) in the Process of Bread Production. Foods 2022, 11, 3496. [Google Scholar] [CrossRef]

- Huber, E.; Francio, D.L.; Biasi, V.; Mezzomo, N.; Ferreira, S.R. Characterization of vegetable fiber and its use in chicken burger formulation. J. Food Sci. Technol. 2016, 53, 3043–3052. [Google Scholar] [CrossRef]

- Iversen, K.N.; Jonsson, K.; Landberg, R. The Effect of Rye-Based Foods on Postprandial Plasma Insulin Concentration: The Rye Factor. Front. Nutr. 2022, 9, 868938. [Google Scholar] [CrossRef]

- Lin, Q.; Ren, A.; Liu, R.; Xing, Y.; Yu, X.; Jiang, H. Flavor properties of Chinese noodles processed by dielectric drying. Front. Nutr. 2022, 9, 1007997. [Google Scholar] [CrossRef]

- Adamczyk, G.; Posadzka, Z.; Witczak, T.; Witczak, M. Comparison of the Rheological Behavior of Fortified Rye-Wheat Dough with Buckwheat, Beetroot and Flax Fiber Powders and Their Effect on the Final Product. Foods 2023, 12, 559. [Google Scholar] [CrossRef]

- Hu, Z.; Guo, W.; Liu, C.; Wang, X.; Hong, J.; Liu, M.; Sun, B.; Zheng, X. Effect of polysaccharide on rheology of dough, microstructure, physicochemical properties and quality of fermented hollow dried noodles. LWT 2024, 200, 116214. [Google Scholar] [CrossRef]

- Yan, J.K.; Wu, L.X.; Cai, W.D.; Xiao, G.S.; Duan, Y.; Zhang, H. Subcritical water extraction-based methods affect the physicochemical and functional properties of soluble dietary fibers from wheat bran. Food Chem. 2019, 298, 124987. [Google Scholar] [CrossRef] [PubMed]

- Ginindza, A.; Solomon, W.K.; Shelembe, J.S.; Nkambule, T.P. Valorisation of brewer’s spent grain flour (BSGF) through wheat-maize-BSGF composite flour bread: Optimization using D-optimal mixture design. Heliyon 2022, 8, e09514. [Google Scholar] [CrossRef] [PubMed]

- Guo, S.; Wu, H.; Liu, X.; Zhao, W.; Zheng, J.; Li, W. Structural, Physicochemical and Digestive Property Changes of Potato Starch after Continuous and Repeated Dry Heat Modification and Its Comparative Study. Foods 2023, 12, 335. [Google Scholar] [CrossRef]

- Ghalambor, P.; Asadi, G.; Mohammadi Nafchi, A.; Seyedin Ardebili, S.M. Investigation of dual modification on physicochemical, morphological, thermal, pasting, and retrogradation characteristics of sago starch. Food Sci. Nutr. 2022, 10, 2285–2299. [Google Scholar] [CrossRef] [PubMed]

- Zhang, B.; Chen, M.; Xia, B.; Lu, Z.; Khoo, K.S.; Show, P.L.; Lu, F. Characterization and Preliminary Application of a Novel Lipoxygenase from Enterovibrio norvegicus. Foods 2022, 11, 2864. [Google Scholar] [CrossRef]

- Huang, C.; Huang, J.; Zhang, B.; Omedi, J.O.; Chen, C.; Zhou, L.; Liang, L.; Zou, Q.; Zheng, J.; Zeng, Y.; et al. Rheo-Fermentation Dough Properties, Bread-Making Quality and Aroma Characteristics of Red Bean (Vigna angularis) Sourdough Induced by LAB Weissella confusa QS813 Strain Fermentation. Foods 2023, 12, 605. [Google Scholar] [CrossRef]

- Kayama, K.; Wei, R.; Zhang, Y.; Wu, F.; Su, Z.; Dong, J.; Liu, X. Effects of Tea Powder on the Cooking Properties, Antioxidative Potential and Volatile Profiles of Dried Noodles. Foods 2022, 11, 858. [Google Scholar] [CrossRef]

- Noonim, P.; Rajasekaran, B.; Venkatachalam, K. Effect of Palm Oil-Carnauba Wax Oleogel That Processed with Ultrasonication on the Physicochemical Properties of Salted Duck Egg White Fortified Instant Noodles. Gels 2022, 8, 487. [Google Scholar] [CrossRef]

- Wang, R.; Li, M.; Wei, Y.; Guo, B.; Brennan, M.; Brennan, C.S. Quality Differences between Fresh and Dried Buckwheat Noodles Associated with Water Status and Inner Structure. Foods 2021, 10, 187. [Google Scholar] [CrossRef]

- Yeoh, S.Y.; Tan, H.L.; Muhammad, L.; Tan, T.C.; Murad, M.; Mat Easa, A. Sensory, structural breakdown, microstructure, salt release properties, and shelf life of salt-coated air-dried yellow alkaline noodles. NPJ Sci. Food 2023, 7, 8. [Google Scholar] [CrossRef]

- Hou, F.; Song, S.; Cui, W.; Yu, Z.; Gong, Z.; Wang, Y.; Wang, W. Flavor Improvement of Maillard Reaction Intermediates Derived from Enzymatic Hydrolysates of Oudemansiella raphanipes Mushroom. Foods 2024, 13, 1688. [Google Scholar] [CrossRef]

- Zhou, S.; Feng, D.; Zhou, Y.; Duan, H.; He, Y.; Jiang, Y.; Yan, W. Characteristic Volatile Organic Compound Analysis of Different Cistanches Based on HS-GC-IMS. Molecules 2022, 27, 6789. [Google Scholar] [CrossRef] [PubMed]

- Guardianelli, L.M.; Salinas, M.V.; Brites, C.; Puppo, M.C. Germination of White and Red Quinoa Seeds: Improvement of Nutritional and Functional Quality of Flours. Foods 2022, 11, 3272. [Google Scholar] [CrossRef] [PubMed]

- Chipón, J.; Ramírez, K.; Morales, J.; Díaz-Calderón, P. Rheological and Thermal Study about the Gelatinization of Different Starches (Potato, Wheat and Waxy) in Blend with Cellulose Nanocrystals. Polymers 2022, 14, 1560. [Google Scholar] [CrossRef] [PubMed]

- Wang, H.; Qiu, J.; Wu, Y.; Ouyang, J. Impact of soluble soybean polysaccharide on the gelatinization and retrogradation of corn starches with different amylose content. Food Res. Int. 2024, 184, 114254. [Google Scholar] [CrossRef] [PubMed]

- Zhang, L.; Chen, J.; Xu, F.; Han, R.; Quan, M. Effect of Tremella fuciformis and Different Hydrocolloids on the Quality Characteristics of Wheat Noodles. Foods 2022, 11, 2617. [Google Scholar] [CrossRef]

- Liu, Y.; Wei, Z.; Wang, J.; Wu, Y.; Xu, X.; Wang, B.; Abd El-Aty, A.M. Effects of different proportions of erythritol and mannitol on the physicochemical properties of corn starch films prepared via the flow elongation method. Food Chem. 2024, 437, 137899. [Google Scholar] [CrossRef]

- Boonkor, P.; Sagis, L.M.C.; Lumdubwong, N. Pasting and Rheological Properties of Starch Paste/Gels in a Sugar-Acid System. Foods 2022, 11, 4060. [Google Scholar] [CrossRef]

- Li, L.; Zhou, W.; Wu, A.; Qian, X.; Xie, L.; Zhou, X.; Zhang, L. Effect of Ginkgo Biloba Powder on the Physicochemical Properties and Quality Characteristics of Wheat Dough and Fresh Wet Noodles. Foods 2022, 11, 698. [Google Scholar] [CrossRef]

- Li, S.; Chen, W.; Zongo, A.W.S.; Chen, Y.; Liang, H.; Li, J.; Li, B. Effects of non-starch polysaccharide on starch gelatinization and digestibility: A review. Food Innov. Adv. 2023, 2, 302–312. [Google Scholar] [CrossRef]

- Wang, J.; He, Y.; Li, X.; Xie, Y.; Wang, X.; Zhu, D.; Liu, H. Effect of soluble soybean polysaccharides on the short- and long-term retrogradation properties of instant rice. J. Sci. Food Agric. 2023, 103, 4850–4857. [Google Scholar] [CrossRef] [PubMed]

- Cui, C.; Caporaso, N.; Chen, J.; Fearn, T. Farinograph characteristics of wheat flour predicted by near infrared spectroscopy with an ensemble modelling method. J. Food Eng. 2023, 359, 111689. [Google Scholar] [CrossRef]

- Dufour, M.; Chaunier, L.; Lourdin, D.; Réguerre, A.L.; Hugon, F.; Dugué, A.; Kansou, K.; Saulnier, L.; Della Valle, G. Unravelling the relationships between wheat dough extensional properties, gluten network and water distribution. Food Hydrocoll. 2024, 146, 109214. [Google Scholar] [CrossRef]

- Liu, M.; Chen, G.; Zhang, H.; Yu, Q.; Mei, X.; Kan, J. Heat-induced inulin-gluten gel: Insights into the influences of inulin molecular weight on the rheological and structural properties of gluten gel to molecular and physicochemical characteristics. Food Hydrocoll. 2021, 111, 106397. [Google Scholar] [CrossRef]

- Liu, S.; Liu, Q.; Li, X.; Obadi, M.; Jiang, S.; Li, S.; Xu, B. Effects of dough resting time on the development of gluten network in different sheeting directions and the textural properties of noodle dough. LWT 2021, 141, 110920. [Google Scholar] [CrossRef]

- Okami, Y.; Tsunoda, H.; Watanabe, J.; Kataoka, Y. Efficacy of a meal sequence in patients with type 2 diabetes: A systematic review and meta-analysis. BMJ Open Diabetes Res. Care 2022, 10, 002534. [Google Scholar] [CrossRef]

- Li, Q.M.; Li, Y.; Zou, J.H.; Guo, S.Y.; Wang, F.; Yu, P.; Su, X.J. Influence of Adding Chinese Yam (Dioscorea opposita Thunb.) Flour on Dough Rheology, Gluten Structure, Baking Performance, and Antioxidant Properties of Bread. Foods 2020, 9, 256. [Google Scholar] [CrossRef]

- Shang, J.; Zhao, B.; Liu, C.; Li, L.; Hong, J.; Liu, M.; Zhang, X.; Lei, Y.; Zheng, X. Impact of wheat starch granule size on viscoelastic behaviors of noodle dough sheet and the underlying mechanism. Food Hydrocoll. 2023, 134, 108111. [Google Scholar] [CrossRef]

- Sun, H.; Zhang, Y.; Sun, J. Dietary inulin supplementation improves the physicochemical and gel properties of duck myofibrillar protein: Insights into the effect of muscle fiber types. Food Hydrocoll. 2024, 150, 109722. [Google Scholar] [CrossRef]

- Zhang, M.; Suo, W.; Deng, Y.; Jiang, L.; Qi, M.; Liu, Y.; Li, L.; Wang, C.; Zheng, H.; Li, H. Effect of ultrasound-assisted dough fermentation on the quality of dough and steamed bread with 50% sweet potato pulp. Ultrason. Sonochem. 2022, 82, 105912. [Google Scholar] [CrossRef] [PubMed]

- Fan, H.; Fu, F.; Chen, Y.; Liu, M.; Ai, Z.; Bian, K. Effect of NaCl on rheological properties of dough and noodle quality. J. Cereal Sci. 2020, 93, 102936. [Google Scholar] [CrossRef]

- Tang, P.; Zhang, S.; Meng, L.; Wang, Z.; Yang, Y.; Shen, X.; Tang, X. Effects of different content of EGCG or caffeic acid addition on the structure, cooking, antioxidant characteristics and in vitro starch digestibility of extruded buckwheat noodles. Int. J. Biol. Macromol. 2023, 252, 126426. [Google Scholar] [CrossRef] [PubMed]

- Zhang, X.; Wang, A.; Yao, H.; Zhou, W.; Wang, M.; Liang, B.; Wang, F.; Tong, L.-T. Research advancements on the flavor compounds formation mechanism of pickled bamboo shoots in river snails rice noodles. LWT 2023, 186, 115226. [Google Scholar] [CrossRef]

| Fv-SDF Addition/% | Initial Gelatinization Temperature T0/°C | Peak Temperature Tp/°C | Terminating Gelatinization Temperature Tc/°C | Gelatinization Enthalpy/(ΔH, W/g) |

|---|---|---|---|---|

| 0 | 56.32 ± 0.23 d | 63.65 ± 0.16 e | 69.40 ± 0.35 d | 1.80 ± 0.45 b |

| 5.0 | 59.58 ± 0.16 c | 65.38 ± 0.23 d | 71.60 ± 0.95 c | 2.14 ± 0.43 a |

| 7.5 | 59.89 ± 0.08 c | 65.89 ± 0.20 c | 72.02 ± 1.10 c | 2.29 ± 0.21 a |

| 10.0 | 60.81 ± 0.33 b | 66.56 ± 0.47 b | 73.47 ± 1.85 a | 2.30 ± 0.29 a |

| 12.5 | 61.06 ± 0.42 b | 66.66 ± 0.16 b | 72.17 ± 0.33 bc | 2.29 ± 0.14 a |

| 15.0 | 61.55 ± 0.79 a | 67.12 ± 0.23 a | 73.26 ± 0.72 ab | 2.22 ± 0.16 a |

| Fv-SDF Addition/% | Peak Viscosity/cp | Trough Viscosity/cp | Breakdown Value/cp | Final Viscosity/cp | Setback Value/cp | Peak Time/min | Pasting Temperature/°C |

|---|---|---|---|---|---|---|---|

| 0 | 2015.0 ± 14.24 a | 1069.5 ± 23.54 a | 945.5 ± 7.78 a | 2250.0 ± 50.91 a | 1180.5 ± 47.38 a | 5.8 ± 0.14 a | 64.8 ± 1.87 e |

| 5.0 | 1962.5 ± 47.38 ab | 1168.5 ± 30.41 a | 809.0 ± 4.24 b | 2237.0 ± 74.95 a | 1106.0 ± 8.49 b | 6.1 ± 0.86 a | 69.3 ± 1.00 d |

| 7.5 | 1876.0 ± 82.02 b | 1031.5 ± 30.81 a | 844.5 ± 48.79 b | 1972.0 ± 38.10 ab | 940.5 ± 87.28 c | 5.9 ± 0.37 a | 76.9 ± 0.47 c |

| 10.0 | 1595.0 ± 46.67 c | 845.0 ± 52.33 b | 750.0 ± 5.66 c | 1706.0 ± 25.06 b | 861.0 ± 52.74 cd | 5.8 ± 0.10 a | 86.2 ± 1.34 b |

| 12.5 | 1481.0 ± 24.04 c | 850.0 ± 53.74 b | 631.0 ± 5.66 d | 1689.5 ± 42.43 b | 839.0 ± 11.31 d | 6.0 ± 0.10 a | 88.0 ± 1.23 a |

| 15.0 | 1488.0 ± 48.08 c | 799.5 ± 12.02 b | 688.5 ± 12.02 d | 1669.5 ± 27.58 b | 870.0 ± 15.56 cd | 5.9 ± 0.04 a | 87.6 ± 0.53 ab |

| Fv-SDF Addition/% | Consistency/ FU | Water Absorption (Adjust 500 FU/%) | Dough Development Time/min | Stability Time/min | Weakening Degree (Firs 10 min/FU) | Weakening Degree (ICC/after Reaching the Maximum 12 min) | Flour Quality Index/mm |

|---|---|---|---|---|---|---|---|

| 0 | 491.3 ± 3.18 a | 62.2 ± 1.52 a | 3.2 ± 0.14 c | 2.8 ± 0.39 d | 93.5 ± 6.36 ab | 126.5 ± 7.78 a | 48.0 ± 1.41 e |

| 5.0 | 505.0 ± 5.66 a | 55.1 ± 1.38 b | 3.5 ± 0.25 bc | 3.3 ± 0.25 d | 109.3 ± 16.62 a | 137.5 ± 14.85 a | 52.3 ± 1.77 de |

| 7.5 | 507.8 ± 15.20 a | 51.8 ± 0.74 c | 3.7 ± 0.04 bc | 3.8 ± 0.42 cd | 92.0 ± 12.73 ab | 120.3 ± 16.62 ab | 57.0 ± 1.41 d |

| 10.0 | 497.5 ± 0.71 a | 49.2 ± 0.07 d | 4.5 ± 0.39 ab | 4.7 ± 0.53 bc | 78.8 ± 6.01 bc | 111.8 ± 7.42 abc | 66.5 ± 0.71 c |

| 12.5 | 490.0 ± 12.73 a | 46.6 ± 0.12 e | 4.9 ± 0.21 a | 5.5 ± 0.71 ab | 59.5 ± 7.78 cd | 97.3 ± 10.96 bc | 75.75 ± 5.30 b |

| 15.0 | 500.0 ± 7.07 a | 44.5 ± 0.85 e | 5.6 ± 0.88 a | 6.7 ± 0.57 a | 43.5 ± 4.95 d | 88.0 ± 2.83 c | 88.0 ± 4.24 a |

| Fv-SDF Addition/% | L* | a* | b* |

|---|---|---|---|

| 100.0 (Fv-SDFpowder) | 38.21 ± 7.75 f | 12.75 ± 0.40 a | 27.88 ± 3.92 a |

| 0 | 88.25 ± 1.47 a | 0.19 ± 0.05 e | 9.89 ± 0.34 d |

| 5.0 | 64.32 ± 0.86 b | 5.51 ± 0.41 d | 13.61 ± 0.78 c |

| 7.5 | 58.34 ± 1.51 c | 6.56 ± 0.78 c | 13.74 ± 0.39 c |

| 10.0 | 52.25 ± 0.65 d | 8.92 ± 0.56 b | 17.18 ± 0.98 b |

| 12.5 | 47.80 ± 1.04 e | 9.53 ± 0.38 b | 17.23 ± 0.48 b |

| 15.0 | 46.84 ± 0.67 e | 9.56 ± 0.22 b | 17.52 ± 0.79 b |

| Name | CAS | Rt [s] | Molecular | Odor Description | |

|---|---|---|---|---|---|

| Alcohols | 1-octene-3-ol | C3391864 | 867.68 | C8H16O | Mushroom aroma |

| 1-hexanol-M | C111273 | 713.00 | C6H14O | Fresh, fruity, alcohol, | |

| 1-hexanol-D | C111273 | 712.41 | C6H14O | Fresh, fruity, alcohol, | |

| 1-Pentanol-M | C71410 | 533.20 | C5H12O | balm | |

| 1-Pentanol-D | C71410 | 532.28 | C5H12O | balm | |

| 1-butanol, 3-methyl-M | C123513 | 457.43 | C5H12O | Whisky, banana fruit | |

| 1-butanol, 3-methyl-D | C123513 | 456.99 | C5H12O | Whisky, banana fruit | |

| 1-pentene-3-ol | C616251 | 388.08 | C5H10O | Ethereal, green, tropical fruit | |

| 1-butanol-M | C71363 | 369.98 | C4H10O | Red wine taste | |

| 1-butanol-D | C71363 | 369.04 | C4H10O | Red wine taste | |

| 1-propanol, 2-methyl-M | C78831 | 311.92 | C4H10O | Fresh, wine, leather | |

| 1-propanol, 2-methyl-D | C78831 | 310.98 | C4H10O | Fresh, wine, leather | |

| 1-propanol-M | C71238 | 260.59 | C3H8O | Alcohol, pungent odor | |

| 1-propanol-D | C71238 | 259.72 | C3H8O | Alcohol, pungent odor | |

| Ethyl alcohol | C64175 | 191.40 | C2H6O | toasty | |

| 2-fluoro-uranyl alcohol | C98000 | 1358.68 | C5H6O2 | toasty | |

| 1-octanol-M | C124130 | 609.80 | C8H16O | Aldehyde, waxy, fruity, fat | |

| 1-octanol-D | C124130 | 609.23 | C8H16O | Aldehyde, waxy, fruity, fat | |

| 2-Pentanol | C6032297 | 339.50 | C5H12O | Fusel oil, fragrant | |

| 2-butanol | C78922 | 228.99 | C4H10O | fruity | |

| Aldehyde | Benzaldehyde -M | C100527 | 957.31 | C7H6O | Bitter almond, cherry and nut notes |

| Benzaldehyde D | C100527 | 957.31 | C7H6O | Bitter almond, cherry and nut notes | |

| (E)-2-octenal -M | C2548870 | 809.46 | C8H14O | Fresh cucumber, fat, green fragrance | |

| (E)-2-octenal-D 1-nonaldehyde-D | C2548870 | 807.91 | C8H14O | Fresh cucumber, fat, green fragrance | |

| 1-nonanal-M | C124196 | 759.05 | C9H18O | Rose, citrus, etc | |

| 1-nonaldehyde-D | C124196 | 759.05 | C9H18O | Rose, citrus, etc | |

| (E)-2-heptenaldehyde-M | C18829555 | 660.72 | C7H12O | Green fragrant vegetables, fresh, fat | |

| (E)-2-heptenaldehyd-D | C18829555 | 662.94 | C7H12O | Green fragrant vegetables, fresh, fat | |

| (E)-2-hexene-1-aldehyde-M | C6728263 | 476.27 | C6H10O | Green fragrant vegetables, fresh, fat | |

| (E)-2-hexene-1-aldehyde-D | C6728263 | 476.27 | C6H10O | Green fragrant vegetables, fresh, fat | |

| 3-methyl-2-butenal | C107868 | 447.79 | C5H8O | fruity | |

| Heptaldehyde -M | C111717 | 424.13 | C7H14O | Fresh, fat, green and fruity | |

| Heptyl aldehyde D | C111717 | 425.00 | C7H14O | Fresh, aldehyde, fat, green, | |

| 1-hexaldehyde-M | C66251 | 302.95 | C6H12O | Fresh, green, fat, | |

| 1-hexaldehyde-D | C66251 | 302.16 | C6H12O | Fresh, green, fat, | |

| (E)-2-butenal | C123739 | 267.24 | C4H6O | null | |

| n-valeraldehyde | C110623 | 221.23 | C5H10O | Grass smell, taste exciting | |

| Propanal-M | C123386 | 134.93 | C3H6O | Pungent smell, grass smell | |

| Propional-D | C123386 | 135.47 | C3H6O | Pungent smell, grass smell | |

| 3-methylbutyraldehyde | C590863 | 182.31 | C5H10O | Chocolate, fat | |

| (E, E)-2, 4-octanedienal | C30361285 | 1256.70 | C8H12O | Fat, green, pear, melon | |

| 2-furfural-M | C98011 | 878.87 | C5H4O2 | Sweet, wood, toast | |

| 2-furfural-D | C98011 | 879.98 | C5H4O2 | Sweetness, wood, bread | |

| Ketone | 2-methyl-2-heptene-6-one | C110930 | 683.56 | C8H14O | Citrus, fruity, keto |

| 1-hydroxy-2-acetone-M | C116096 | 628.11 | C3H6O2 | Pungent smell, caramel taste | |

| 1-hydroxy-2-acetone-D | C116096 | 628.57 | C3H6O2 | Pungent smell, caramel taste | |

| 3-hydroxy-2-butanone-M | C513860 | 599.09 | C4H8O2 | Buttery, creamy | |

| 2-butanone, 3-hydroxy-D | C513860 | 599.09 | C4H8O2 | Buttery, creamy | |

| 2-heptanone | C110430 | 411.30 | C7H14O | Pear, banana like fruit | |

| 2-butanone-M | C78933 | 176.41 | C4H8O | Fruity, camphor aromas | |

| 2-butanone-D | C78933 | 177.48 | C4H8O | Fruity, camphor aromas | |

| 2-acetone | C67641 | 144.05 | C3H6O | Fresh, apple, pear | |

| Esters | Hexyl propionate | C2445763 | 671.85 | C9H18O2 | Sweet fruity smell, soil fragrance |

| Butyl acetate | C123864 | 287.17 | C6H12O2 | fruity | |

| Ethyl acetate -M | C141786 | 169.26 | C4H8O2 | Fresh, fruity, sweet | |

| Ethyl acetate -D | C141786 | 169.08 | C4H8O2 | Fresh, fruity, sweet |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, W.; Yang, S.; Wang, L.; Hou, F.; Song, S.; Wang, Y.; Gong, Z.; Jia, F. Effect of Flammulina velutipes Soluble Dietary Fiber on Dough Processing Characteristics and Micro-Fermented Dried Noodles Quality Properties. Foods 2024, 13, 2764. https://doi.org/10.3390/foods13172764

Wang W, Yang S, Wang L, Hou F, Song S, Wang Y, Gong Z, Jia F. Effect of Flammulina velutipes Soluble Dietary Fiber on Dough Processing Characteristics and Micro-Fermented Dried Noodles Quality Properties. Foods. 2024; 13(17):2764. https://doi.org/10.3390/foods13172764

Chicago/Turabian StyleWang, Wenliang, Shuang Yang, Lihong Wang, Furong Hou, Shasha Song, Yansheng Wang, Zhiqing Gong, and Fengjuan Jia. 2024. "Effect of Flammulina velutipes Soluble Dietary Fiber on Dough Processing Characteristics and Micro-Fermented Dried Noodles Quality Properties" Foods 13, no. 17: 2764. https://doi.org/10.3390/foods13172764