Experimental Investigation on the Cutting of Additively Manufactured Ti6Al4V with Wire-EDM and the Analytical Modelling of Cutting Speed and Surface Roughness

Abstract

:1. Introduction

2. Materials and Methods

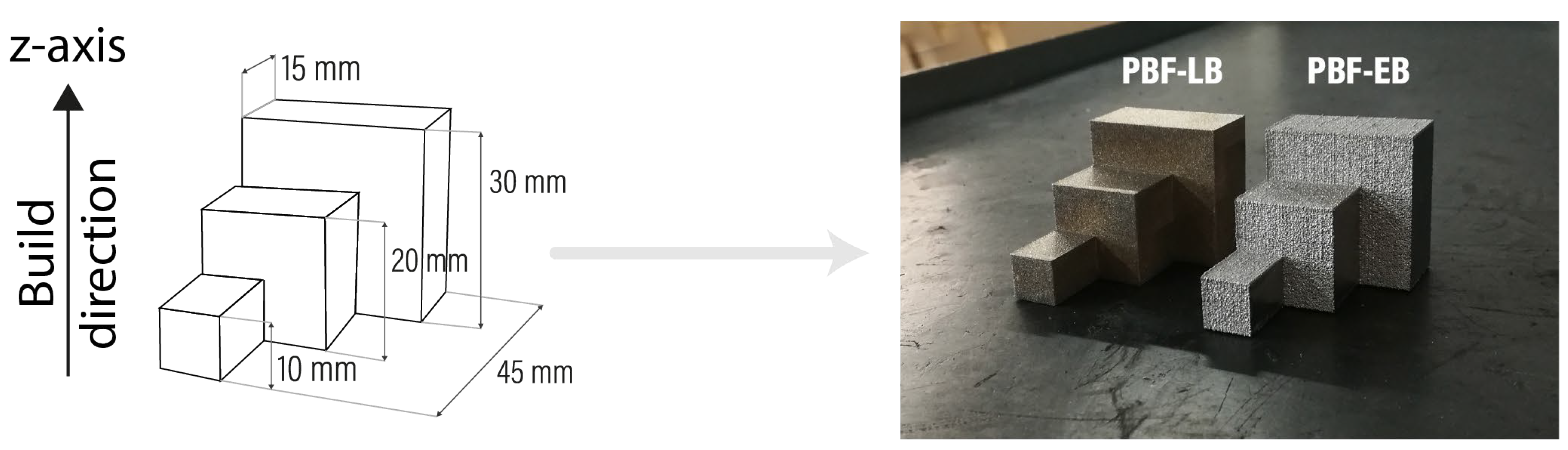

2.1. Design of the Artefacts and Production

2.2. Design of Experiment (DoE)

2.3. Performance Indexes Calculation

- Workpiece positioning and clamping on W-EDM machine guides;

- Wire electrode positioning and axis resetting;

- Setting process parameters and wire linear path;

- Machining the workpiece from the thinner to the thicker thickness;

- Measuring the time necessary to perform the cut for each thickness.

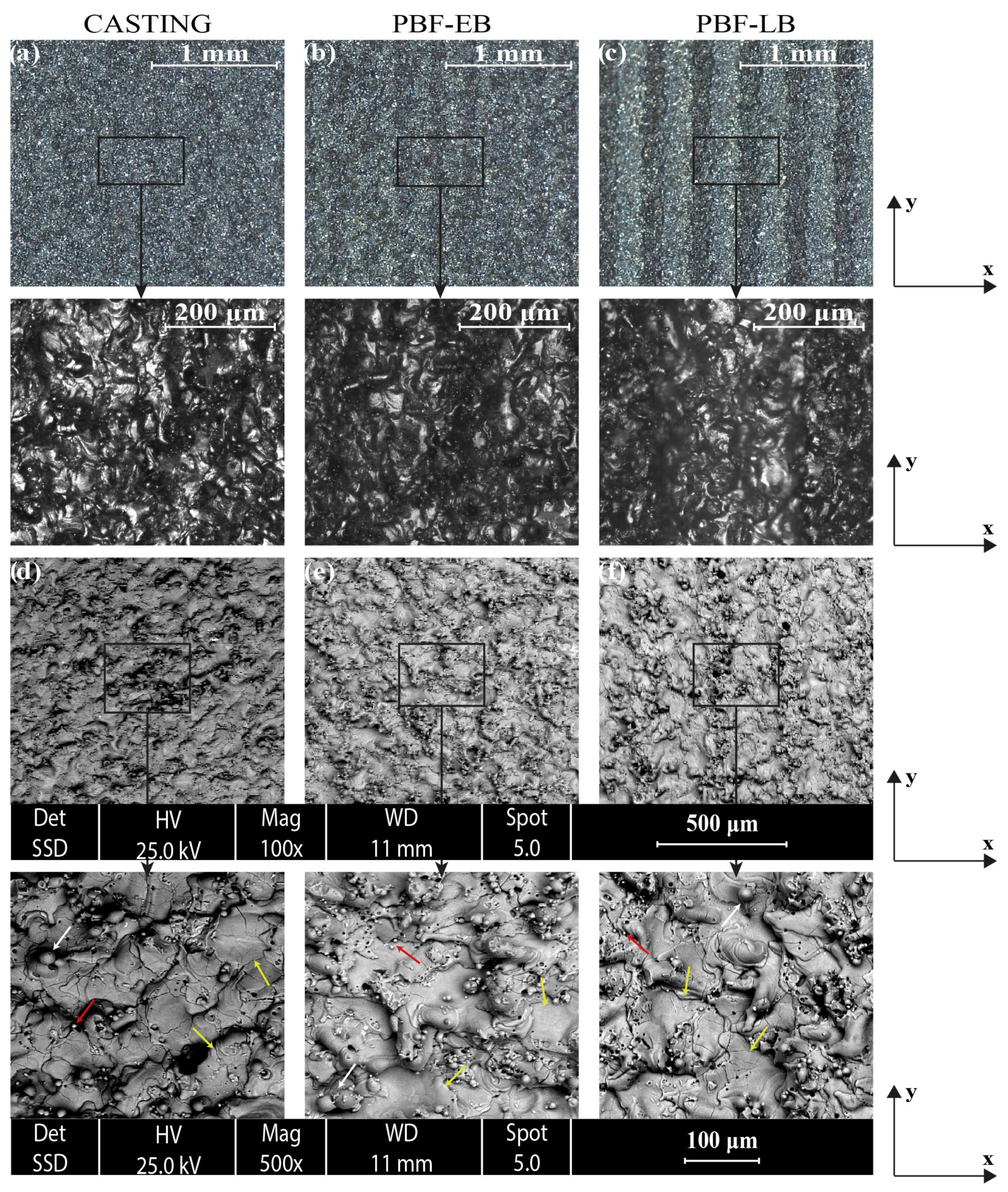

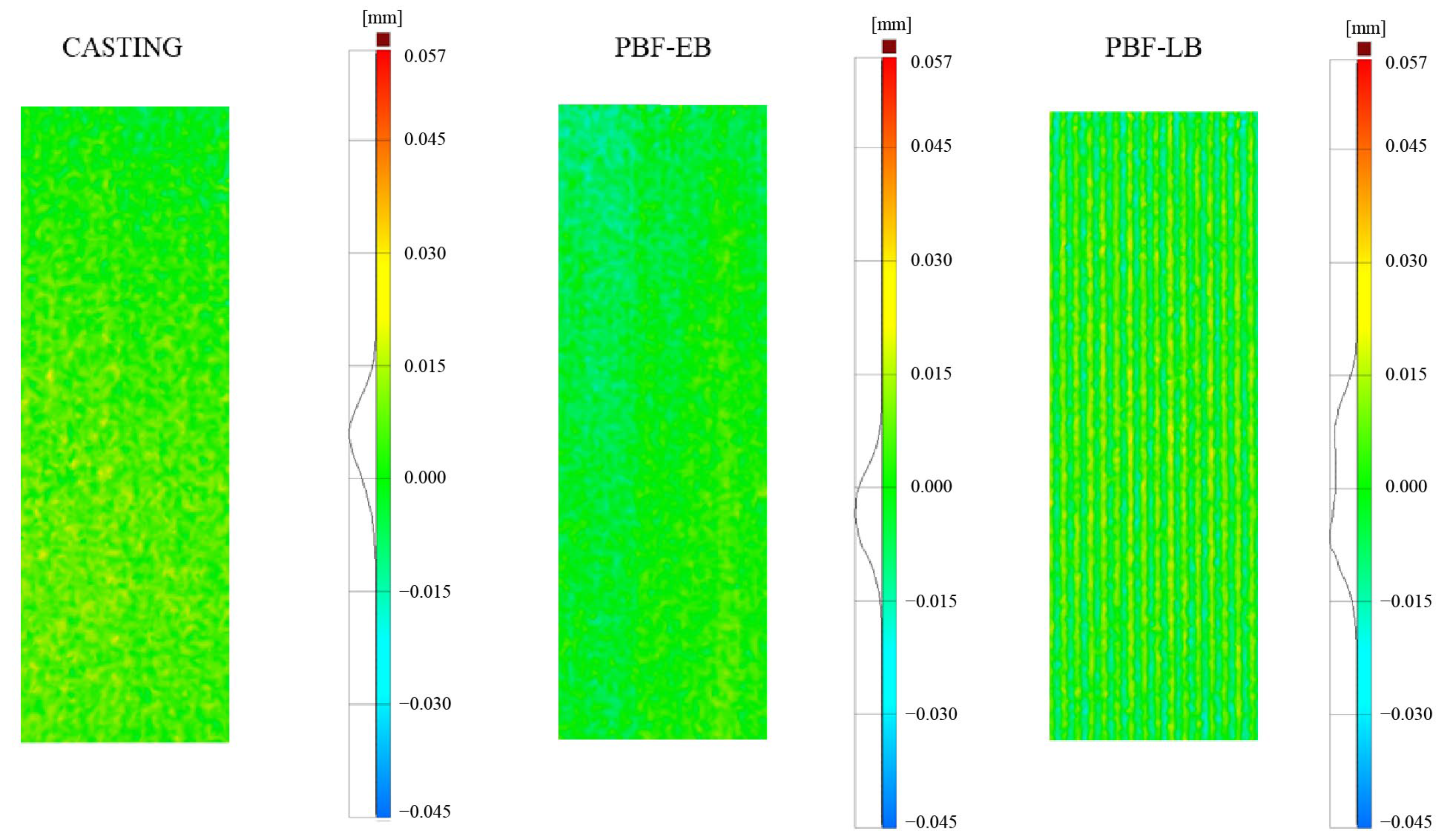

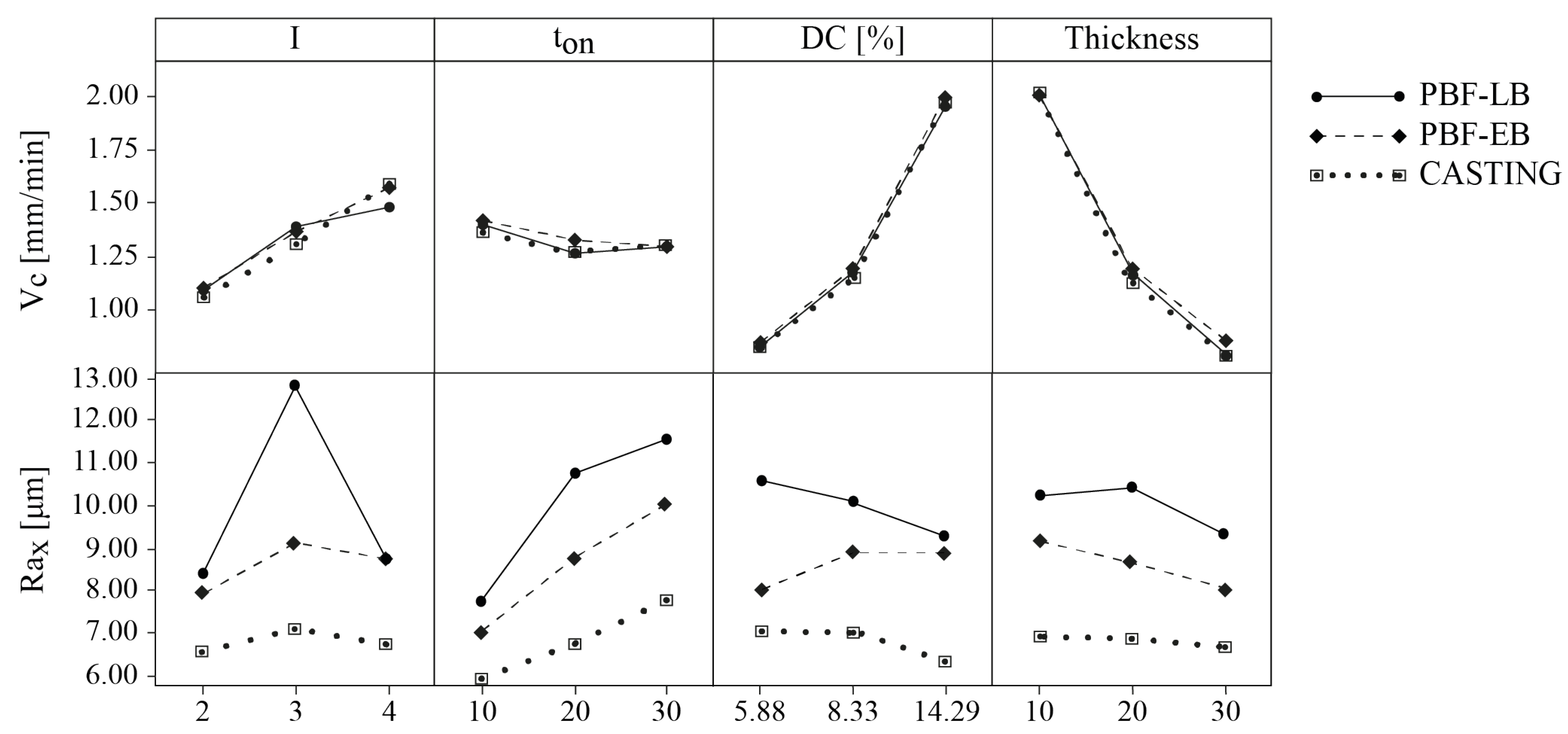

3. Results and Discussion

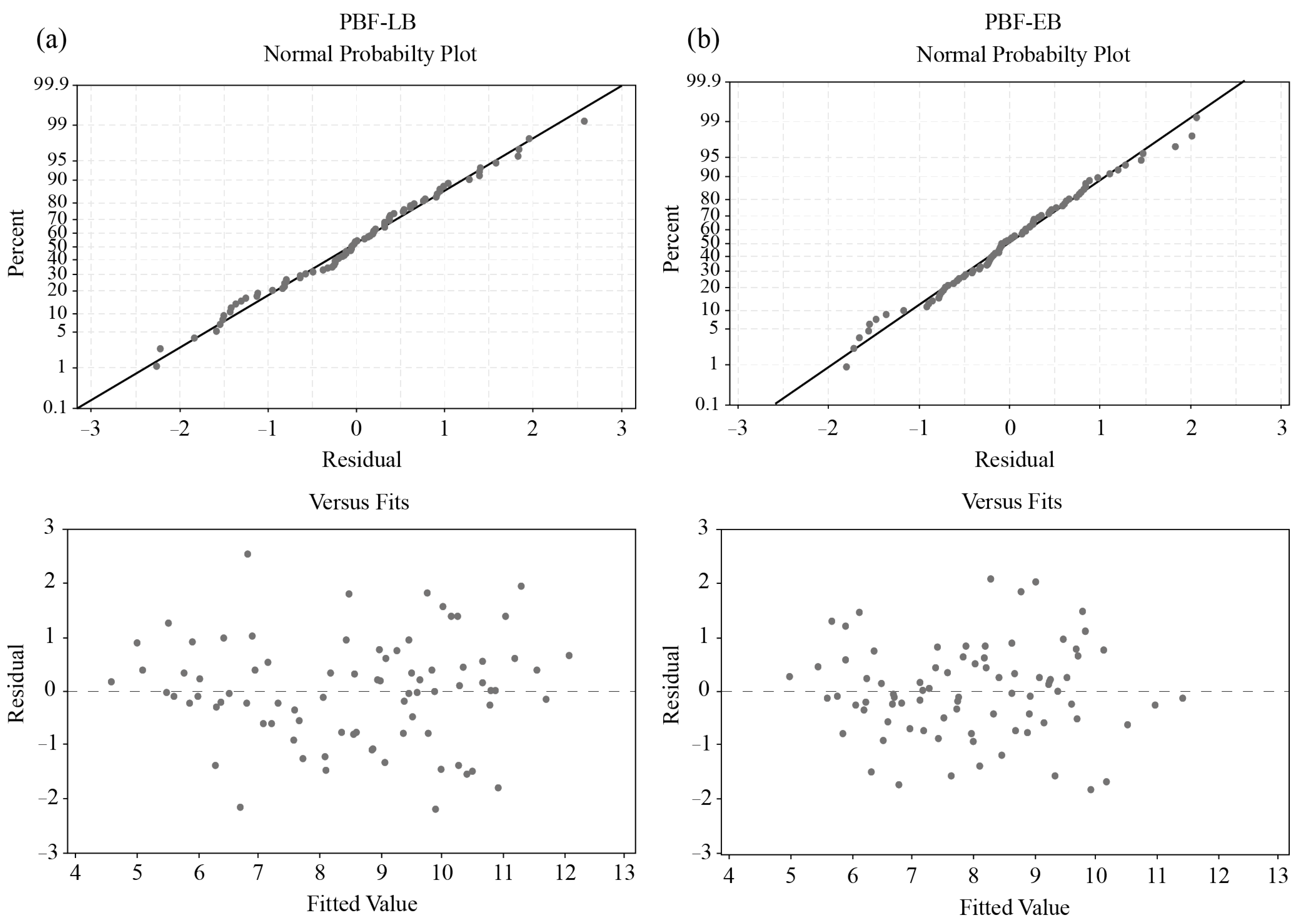

Regression Models

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

| Variation Cause | DoF | Variance | F-Ratio | F-Max |

|---|---|---|---|---|

| Examined Factor | 2 | 79.06 | 25.97 | 3.03 |

| Random Errors | 240 | 3.04 | ||

| Total | 242 |

| PBF-LB | PBF-EB | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Source | DF | Adj. SS | Adj. MS | p-Value | Source | DF | Adj. SS | Adj. MS | p-Value |

| Regression | 6 | 277.20 | 46.20 | 0.000 | Regression | 5 | 168.36 | 33.67 | 0.000 |

| I | 1 | 18.87 | 18.87 | 0.000 | I | 1 | 7.13 | 7.13 | 0.003 |

| ton | 1 | 20.36 | 20.36 | 0.000 | ton | 1 | 123.28 | 123.28 | 0.000 |

| DC | 1 | 23.45 | 23.45 | 0.000 | DC | 1 | 12.71 | 12.71 | 0.000 |

| Thickness | 1 | 14.41 | 14.42 | 0.000 | Thickness | 1 | 11.32 | 11.32 | 0.000 |

| I × I | 1 | 17.76 | 17.75 | 0.000 | I × DC | 1 | 17.52 | 17.52 | 0.000 |

| ton × ton | 1 | 6.01 | 6.01 | 0.017 | |||||

| Error | 74 | 74.79 | 1.01 | Error | 75 | 56.29 | 0.75 | ||

| Total | 80 | Total | 80 | ||||||

References

- Ho, K.H.; Newman, S.T.; Rahimifard, S.; Allen, R.D. State of the art in wire electrical discharge machining (WEDM). Int. J. Mach. Tools Manuf. 2004, 44, 1247–1259. [Google Scholar] [CrossRef]

- Kunieda, M.; Lauwers, B.; Rajurkar, K.P.; Schumacher, B.M. Advancing EDM through Fundamental Insight into the Process. CIRP Ann. 2005, 54, 64–87. [Google Scholar] [CrossRef]

- Garg, R.K.; Singh, K.K.; Sachdeva, A.; Sharma, V.S.; Ojha, K.; Singh, S. Review of research work in sinking EDM and WEDM on metal matrix composite materials. Int. J. Adv. Manuf. Technol. 2010, 50, 611–624. [Google Scholar] [CrossRef]

- Defanti, S.; Denti, L.; Vincenzi, N.; Gatto, A. Preliminary assessment of electro-chemical machining for aluminum parts produced by laser-based powder bed fusion. Smart Sustain. Manuf. Syst. 2020, 4, 121–134. [Google Scholar] [CrossRef]

- Abhilash, P.M.; Chakradhar, D. Sustainability improvement of WEDM process by analysing and classifying wire rupture using kernel-based naive Bayes classifier. J. Braz. Soc. Mech. Sci. Eng. 2021, 43, 1–9. [Google Scholar] [CrossRef]

- Rao, P.S.; Ramji, K.; Satyanarayana, B. Experimental Investigation and Optimization of Wire EDM Parameters for Surface Roughness, MRR and White Layer in Machining of Aluminium Alloy. Procedia Mater. Sci. 2014, 5, 2197–2206. [Google Scholar] [CrossRef]

- Kumar, A.; Kumar, V.; Kumar, J. Multi-response optimization of process parameters based on response surface methodology for pure titanium using WEDM process. Int. J. Adv. Manuf. Technol. 2013, 68, 2645–2668. [Google Scholar] [CrossRef]

- Ghodsiyeh, D.; Lahiji, M.A.; Ghanbari, M.; Shirdar, M.R.; Golshan, A. Optimizing material removal rate (MRR) in WEDMing titanium alloy (Ti6Al4V) using the taguchi method. Res. J. Appl. Sci. Eng. Technol. 2012, 4, 3154–3161. [Google Scholar]

- Tosun, N.; Cogun, C.; Inan, A. The effect of cutting parameters on workpiece surface roughness in wire EDM. Mach. Sci. Technol. 2003, 7, 209–219. [Google Scholar] [CrossRef]

- Dabade, U.A.; Karidkar, S.S. Analysis of Response Variables in WEDM of Inconel 718 Using Taguchi Technique. Procedia Cirp 2016, 41, 886–891. [Google Scholar] [CrossRef] [Green Version]

- Venkatarao, K.; Anup Kumar, T. An experimental parametric analysis on performance characteristics in wire electric discharge machining of Inconel 718. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2019, 14, 4836–4849. [Google Scholar] [CrossRef]

- Rao, K.V.; Raju, L.R.; Kumar, C.K. Modeling of kerf width and surface roughness in wire cut electric discharge machining of Ti-6Al-4V. Proc. Inst. Mech. Eng. Part E J. Process. Mech. Eng. 2020, 234, 533–542. [Google Scholar] [CrossRef]

- Nain, S.S.; Garg, D.; Kumar, S. Evaluation and analysis of cutting speed, wire wear ratio, and dimensional deviation of wire electric discharge machining of super alloy Udimet-L605 using support vector machine and grey relational analysis. Adv. Manuf. 2018, 6, 225–246. [Google Scholar] [CrossRef]

- Devarajaiah, D.; Muthumari, C. Evaluation of power consumption and MRR in WEDM of Ti–6Al–4V alloy and its simultaneous optimization for sustainable production. J. Braz. Soc. Mech. Sci. Eng. 2018, 40, 1–18. [Google Scholar] [CrossRef]

- Singh, T.; Misra, J.P.; Singh, B. Experimental Investigation of Influence of Process Parameters on MRR during WEDM of Al6063 alloy. Mater. Today Proc. 2017, 4, 2242–2247. [Google Scholar] [CrossRef]

- Singh, H.; Garg, R. Effects of process parameters on material removal rate in WEDM. J. Achiev. Mater. Manuf. Eng. 2009, 32, 70–74. [Google Scholar]

- Sharma, N.; Khanna, R.; Gupta, R. Multi Quality Characteristics of WEDM Process Parameters with RSM. Procedia Eng. 2013, 64, 710–719. [Google Scholar] [CrossRef] [Green Version]

- Chalisgaonkar, R.; Kumar, J. Optimization of WEDM process of pure titanium with multiple performance characteristics using Taguchi’s DOE approach and utility concept. Front. Mech. Eng. 2013, 8, 201–214. [Google Scholar] [CrossRef]

- Poros, D.; Wisniewska, M.; Zaborski, S. Comparative analysis of wedm with different wire electrodes applied to cut titanium ti6al4v. J. Mach. Eng. 2020, 20, 116–125. [Google Scholar] [CrossRef]

- Priyankara, K.P.M.; Perera, G.I.P. Experimental Investigation to Achieve Minimum Surface Roughness in Wire EDM Process. In ICSBE 2018: Proceedings of the 9th International Conference on Sustainable Built Environment; Springer: Singapore, 2020; pp. 239–251. [Google Scholar]

- Sharma, P.; Chakradhar, D.; Narendranath, S. Evaluation of WEDM performance characteristics of Inconel 706 for turbine disk application. Mater. Des. 2015, 88, 558–566. [Google Scholar] [CrossRef]

- Kumar, A.; Kumar, V.; Kumar, J. Experimental investigation on material transfer mechanism in wedm of pure titanium (Grade-2). Adv. Mater. Sci. Eng. 2013, 2013, 847876. [Google Scholar] [CrossRef] [Green Version]

- kumar, S.; Khan, M.A.; Muralidharan, B. Processing of titanium-based human implant material using wire EDM. Mater. Manuf. Process. 2019, 34, 695–700. [Google Scholar] [CrossRef]

- Sen, R.; Choudhuri, B.; Barma, J.D.; Chakraborti, P. Study the impact of process parameters and electrode material on wire electric discharge machining performances. Mater. Today Proc. 2018, 5, 7552–7560. [Google Scholar] [CrossRef]

- Calvo, R.; Daniel, M. Wire electrical discharge machining (EDM) setup parameters influence in functional surface roughness. Procedia Manuf. 2019, 41, 602–609. [Google Scholar] [CrossRef]

- Durairaj, M.; Sudharsun, D.; Swamynathan, N. Analysis of process parameters in wire EDM with stainless steel using single objective Taguchi method and multi objective grey relational grade. Procedia Eng. 2013, 64, 868–877. [Google Scholar] [CrossRef] [Green Version]

- Tosun, N.; Cogun, C.; Tosun, G. A study on kerf and material removal rate in wire electrical discharge machining based on Taguchi method. J. Mater. Process. Technol. 2004, 152, 316–322. [Google Scholar] [CrossRef]

- Mahapatra, S.S.; Patnaik, A. Optimization of wire electrical discharge machining (WEDM) process parameters using Taguchi method. Int. J. Adv. Manuf. Technol. 2007, 34, 911–925. [Google Scholar] [CrossRef]

- Tosun, N. The effect of the cutting parameters on performance of WEDM. KSME Int. J. 2003, 17, 816–824. [Google Scholar] [CrossRef]

- Kumar, A.; Kumar, U.A.; Laxminarayana, P. Optimization of surface roughness and kerf width by wire cut-electrical discharge machining on inconel 625. Mater. Today Proc. 2020, 27, 1460–1465. [Google Scholar] [CrossRef]

- Gamage, J.R.; DeSilva, A.K.M.; Chantzis, D.; Antar, M. Sustainable machining: Process energy optimisation of wire electrodischarge machining of Inconel and titanium superalloys. J. Clean Prod. 2017, 164, 642–651. [Google Scholar] [CrossRef] [Green Version]

- Kumar, A.; Kumar, V.; Kumar, J. Parametric Effect on Wire Breakage Frequency and Surface Topography in WEDM of Pure Titanium. J. Mech. Eng. Technol. 2013, 1, 51–56. [Google Scholar] [CrossRef]

- Ikram, A.; Mufti, N.A.; Saleem, M.Q.; Khan, A.R. Parametric optimization for surface roughness, kerf and MRR in wire electrical discharge machining (WEDM) using Taguchi design of experiment. J. Mech. Sci. Technol. 2013, 27, 2133–2141. [Google Scholar] [CrossRef]

- Vaidyaa, P.; John, J.J.; Puviyarasan, M.; Prabhu, T.R.; Prasad, N.E. Wire EDM Parameter Optimization of AlSi10Mg Alloy. Trans. Indian Inst. Met. 2021, 74, 2869–2885. [Google Scholar] [CrossRef]

- Franczyk, E.; Machno, M.; Zębala, W. Investigation and optimization of the slm and wedm processes’ parameters for the AlSi10Mg-sintered part. Materials 2021, 14, 410. [Google Scholar] [CrossRef] [PubMed]

- Calignano, F.; Manfredi, D.; Ambrosio, E.P.; Biamino, S.; Pavese, M.; Fino, P. Direct fabrication of joints based on direct metal laser sintering in aluminum and titanium alloys. Procedia CIRP 2014, 21, 129–132. [Google Scholar] [CrossRef] [Green Version]

- Galati, M.; Rizza, G.; Defanti, S.; Denti, L. Surface roughness prediction model for Electron Beam Melting (EBM) processing Ti6Al4V. Precis. Eng. 2021, 69, 19–28. [Google Scholar] [CrossRef]

- Kumar, S.; Singh, R.; Singh, T.P.; Sethi, B.L. Surface modification by electrical discharge machining: A review. J. Mater. Process. Technol. 2009, 209, 3675–3687. [Google Scholar] [CrossRef]

- ISO 4288; 1996-Geometrical Product Specifications (GPS)—Surface Texture: Profile Method—Rules and Procedures for the Assessment of Surface Texture. International Organization for Standardization: Geneva, Switzerland, 1996.

- Calignano, F. Investigation of the accuracy and roughness in the laser powder bed fusion process. Virtual Phys. Prototyp. 2018, 13, 97–104. [Google Scholar] [CrossRef]

- Altug, M.; Erdem, M.; Ozay, C. Experimental investigation of kerf of Ti6Al4V exposed to different heat treatment processes in WEDM and optimization of parameters using genetic algorithm. Int. J. Adv. Manuf. Technol. 2015, 78, 1573–1583. [Google Scholar] [CrossRef]

- Eshkabilov, S.; Ara, I.; Sevostianov, I.; Azarmi, F.; Tangpong, X. Mechanical and thermal properties of stainless steel parts, manufactured by various technologies, in relation to their microstructure. Int. J. Eng. Sci. 2021, 159, 103398. [Google Scholar] [CrossRef]

- Strumza, E.; Yeheskel, O.; Hayun, S. The effect of texture on the anisotropy of thermophysical properties of additively manufactured AlSi10Mg. Addit. Manuf. 2019, 29, 100762. [Google Scholar] [CrossRef]

- Han, F.; Jiang, J.; Yu, D. Influence of machining parameters on surface roughness in finish cut of WEDM. Int. J. Adv. Manuf. Technol. 2007, 34, 538–546. [Google Scholar] [CrossRef]

- Choudhuri, B.; Sen, R.; Ghosh, S.K.; Saha, S.C. Comparative machinability characterization of wire electrical discharge machining on different specialized AISI steels. Bull. Mater. Sci. 2020, 43, 1–12. [Google Scholar] [CrossRef]

- Mouralova, K.; Kovar, J.; Klakurkova, L.; Blazik, P.; Kalivoda, M.; Kousal, P. Analysis of surface and subsurface layers after WEDM for Ti-6Al-4V with heat treatment. Measurement 2018, 116, 556–564. [Google Scholar] [CrossRef]

- Mouralova, K.; Kovar, J.; Klakurkova, L.; Prokes, T.; Horynova, M. Comparison of morphology and topography of surfaces of WEDM machined structural materials. Measurement 2017, 104, 12–20. [Google Scholar] [CrossRef]

| Laser Power [W] | Scan Speed [mm/s] | Hatching Distance [mm] | Layer Thickness [µm] | Laser Spot Size [mm] | |

|---|---|---|---|---|---|

| Hatch (Core) | 170 | 1250 | 0.10 | 30 | 0.10 |

| Hatch (Skin) | 150 | 1000 | 0.10 | 30 | 0.10 |

| Contour | 120 | 1250 | - | - | 0.10 |

| Scan Speed [mm/s] | Focus Offset [mA] | Beam Current [mA] | Number of Contours | Hatch Contours [mm] | Line Offset [mm] | |

|---|---|---|---|---|---|---|

| Hatch | 45 | 25 | 20 | - | - | 0.2 |

| Contour | 850 | 6 | 5 | 3 | 0.290 | 0.200 |

| Level | Low | Medium | High |

|---|---|---|---|

| I [A] | 2 | 3 | 4 |

| ton [µs] | 10 | 20 | 30 |

| DC [%] | 5.88 | 8.33 | 14.29 |

| Thickness [mm] | 10 | 20 | 30 |

| Process | Rax (Std. Deviation) [μm] | Ray (Std. Deviation) [μm] | Vc (Std. Deviation) [μm] |

|---|---|---|---|

| CASTING | 6.88 (1.33) | 6.62 (1.39) | 1.30 (0.77) |

| PBF-EB | 8.63 (1.72) | 7.93 (1.68) | 1.32 (0.76) |

| PBF-LB | 9.99 (2.96) | 8.55 (2.10) | 1.35 (0.74) |

| Source of Variation | DoF | Variance | F-Ratio | F-Max | |

|---|---|---|---|---|---|

| CASTING | Examined factor | 1 | 2.809 | 1.52 | 3.90 |

| Error | 160 | 1.849 | |||

| Total | 161 | ||||

| PBF-EB | Examined factor | 1 | 19.806 | 6.86 | 3.90 |

| Error | 160 | 2.889 | |||

| Total | 161 | ||||

| PBF-LB | Examined factor | 1 | 84.216 | 12.77 | 3.90 |

| Error | 160 | 6.594 | |||

| Total | 161 |

| Source of Variation | DoF | Variance | F-Ratio | F-Max | |

|---|---|---|---|---|---|

| Vc | Examined factor | 2 | 3.80 × 10−2 | 0.07 | 3.03 |

| Random errors | 240 | 5.75 × 10−1 | |||

| Total | 242 | ||||

| Rax | Examined factor | 2 | 1.97 × 102 | 43.74 | 3.03 |

| Random errors | 240 | 4.51 | |||

| Total | 242 |

| PBF-LB | PBF-EB | ||||||

|---|---|---|---|---|---|---|---|

| Source | DF | Adj. SS | Adj. MS | p-Value | Adj. SS | Adj. MS | p-Value |

| Regression | 10 | 43.63 | 4.36 | 0.000 | 41.51 | 4.15 | 0.000 |

| I | 1 | 0.01 | 0.01 | 0.545 | 0.02 | 0.02 | 0.321 |

| ton | 1 | 0.01 | 0.01 | 0.543 | 0.05 | 0.05 | 0.109 |

| DC | 1 | 1.58 | 1.58 | 0.000 | 1.38 | 1.38 | 0.000 |

| Thickness | 1 | 5 × 10−4 | 5 × 10−4 | 0.911 | 4.3 ×10−3 | 4.3 × 10−3 | 0.647 |

| I × ton | 1 | 0.01 | 0.01 | 0.558 | 0.04 | 0.04 | 0.173 |

| I × DC | 1 | 0.40 | 0.40 | 0.003 | 0.37 | 0.37 | 0.000 |

| I × Thickness | 1 | 0.22 | 0.22 | 0.026 | 0.18 | 0.18 | 0.004 |

| ton × DC | 1 | 0.17 | 0.17 | 0.050 | 0.05 | 0.05 | 0.107 |

| ton × Thickness | 1 | 0.16 | 0.16 | 0.059 | 0.08 | 0.08 | 0.050 |

| DC × Thickness | 1 | 2.07 | 2.07 | 0.000 | 1.89 | 1.89 | 0.000 |

| Error | 70 | 2.97 | 0.04 | 2.41 | 0.03 | ||

| Total | 80 | ||||||

| PBF-LB | PBF-EB | ||||||

|---|---|---|---|---|---|---|---|

| Source | DF | Adj. SS | Adj. MS | p-Value | Adj. SS | Adj. MS | p-Value |

| Regression | 14 | 607.05 | 43.36 | 0.000 | 179.61 | 12.83 | 0.000 |

| I | 1 | 274.36 | 274.36 | 0.000 | 4.36 | 4.36 | 0.029 |

| ton | 1 | 39.57 | 39.57 | 0.000 | 3.34 | 3.34 | 0.056 |

| DC | 1 | 2.92 | 2.92 | 0.162 | 3.95 | 3.95 | 0.038 |

| Thickness | 1 | 0.80 | 0.80 | 0.461 | 0.80 | 0.80 | 0.342 |

| I × I | 1 | 324.76 | 324.76 | 0.000 | 9.96 | 9.96 | 0.001 |

| ton × ton | 1 | 20.75 | 20.75 | 0.000 | 1.13 | 1.13 | 0.261 |

| DC × DC | 1 | 0.23 | 0.23 | 0.692 | 7.99 | 7.99 | 0.003 |

| Thickness × Thickness | 1 | 7.08 | 7.08 | 0.031 | 0.32 | 0.32 | 0.850 |

| I × ton | 1 | 0.45 | 0.45 | 0.580 | 0.95 | 0.95 | 0.301 |

| I × DC | 1 | 0.95 | 0.95 | 0.421 | 6.64 | 6.64 | 0.008 |

| I × Thickness | 1 | 0.00 | 0.00 | 0.984 | 1.06 | 1.06 | 0.276 |

| ton × DC | 1 | 1.4 | 1.4 | 0.330 | 0.19 | 0.19 | 0.647 |

| ton × Thickness | 1 | 2.00 | 2.00 | 0.245 | 0.00 | 0.00 | 0.998 |

| DC × Thickness | 1 | 16.37 | 16.37 | 0.001 | 0.17 | 0.17 | 0.659 |

| Error | 66 | 95.97 | 1.45 | 58.00 | 0.87 | ||

| Total | 80 | ||||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Galati, M.; Antonioni, P.; Calignano, F.; Atzeni, E. Experimental Investigation on the Cutting of Additively Manufactured Ti6Al4V with Wire-EDM and the Analytical Modelling of Cutting Speed and Surface Roughness. J. Manuf. Mater. Process. 2023, 7, 69. https://doi.org/10.3390/jmmp7020069

Galati M, Antonioni P, Calignano F, Atzeni E. Experimental Investigation on the Cutting of Additively Manufactured Ti6Al4V with Wire-EDM and the Analytical Modelling of Cutting Speed and Surface Roughness. Journal of Manufacturing and Materials Processing. 2023; 7(2):69. https://doi.org/10.3390/jmmp7020069

Chicago/Turabian StyleGalati, Manuela, Paolo Antonioni, Flaviana Calignano, and Eleonora Atzeni. 2023. "Experimental Investigation on the Cutting of Additively Manufactured Ti6Al4V with Wire-EDM and the Analytical Modelling of Cutting Speed and Surface Roughness" Journal of Manufacturing and Materials Processing 7, no. 2: 69. https://doi.org/10.3390/jmmp7020069

APA StyleGalati, M., Antonioni, P., Calignano, F., & Atzeni, E. (2023). Experimental Investigation on the Cutting of Additively Manufactured Ti6Al4V with Wire-EDM and the Analytical Modelling of Cutting Speed and Surface Roughness. Journal of Manufacturing and Materials Processing, 7(2), 69. https://doi.org/10.3390/jmmp7020069