Utilisation Potential of Mechanical Material Loads during Grinding by Means of a Novel Tool Concept

Abstract

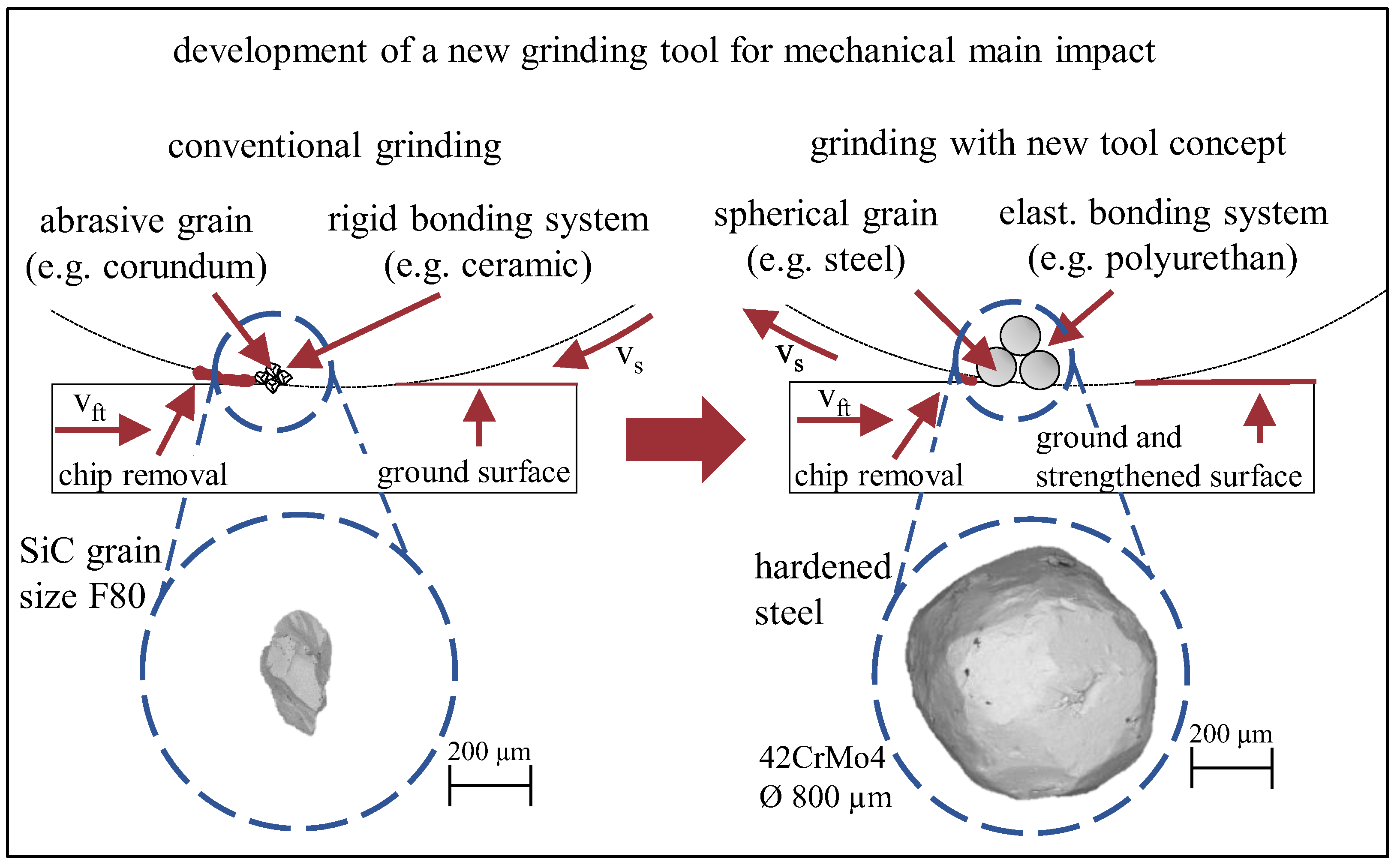

:1. Introduction

1.1. Size Effect

1.2. Elastic Bonding System

1.3. Further Tool Concept

1.4. Coarse Grains

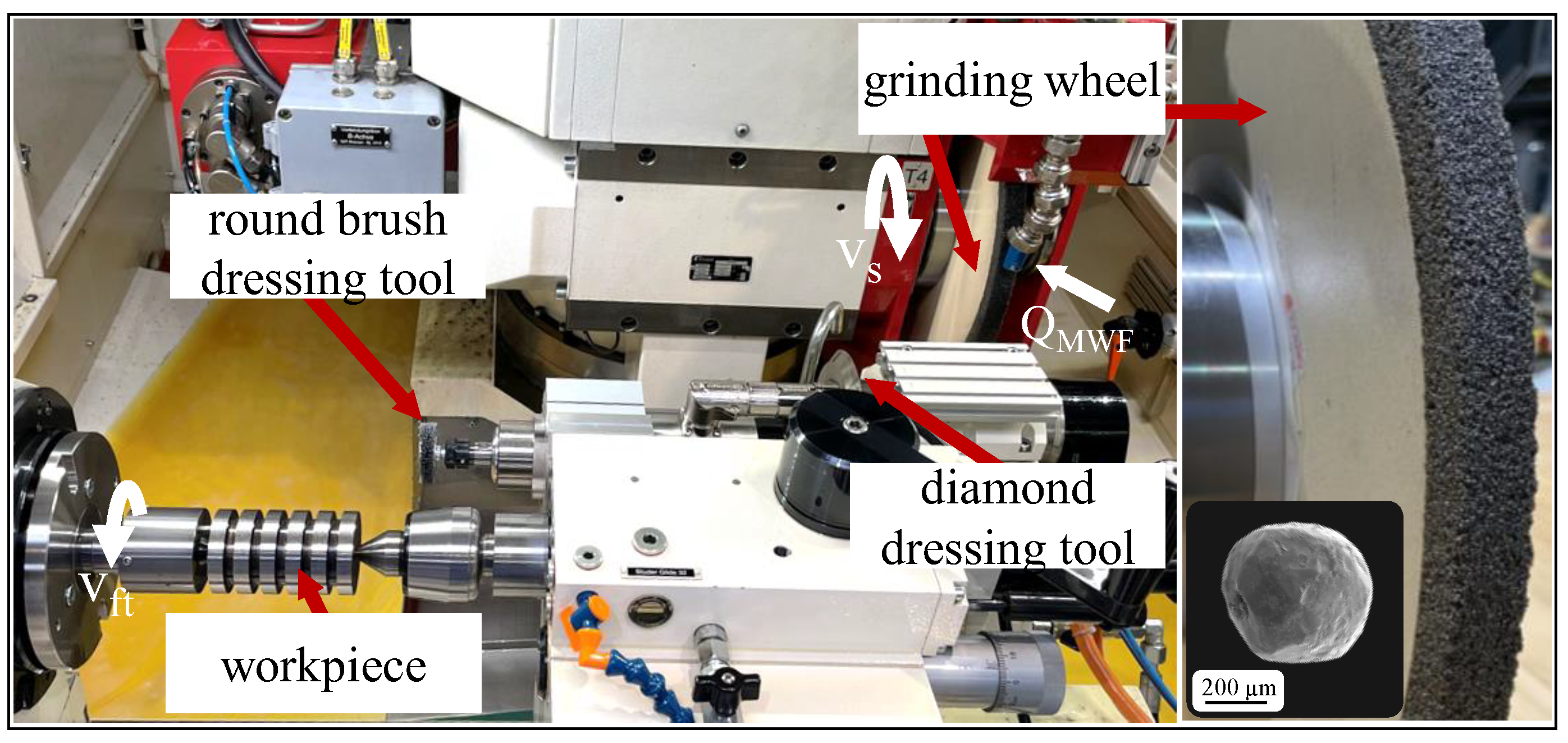

2. Materials and Methods

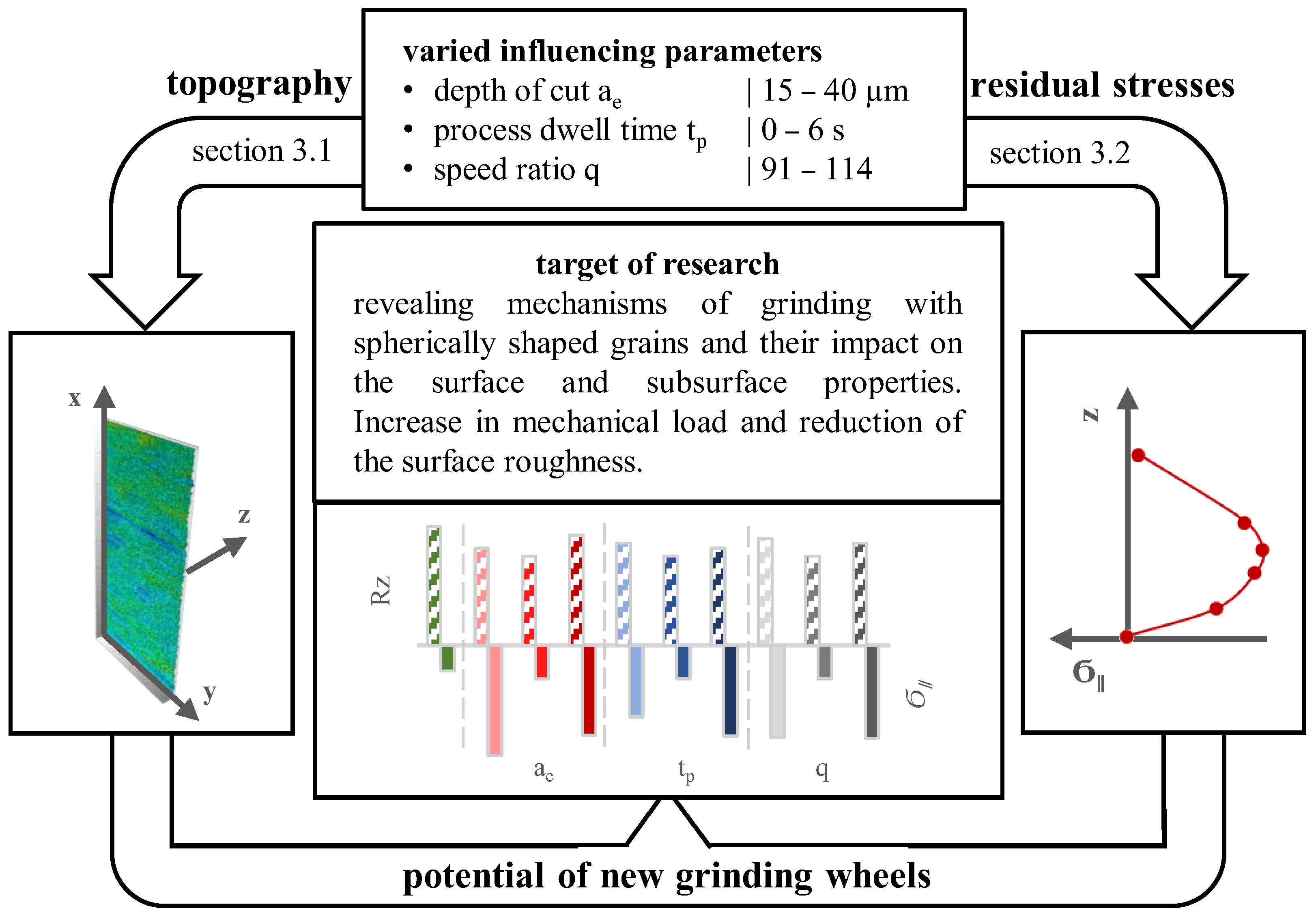

3. Experimental Results

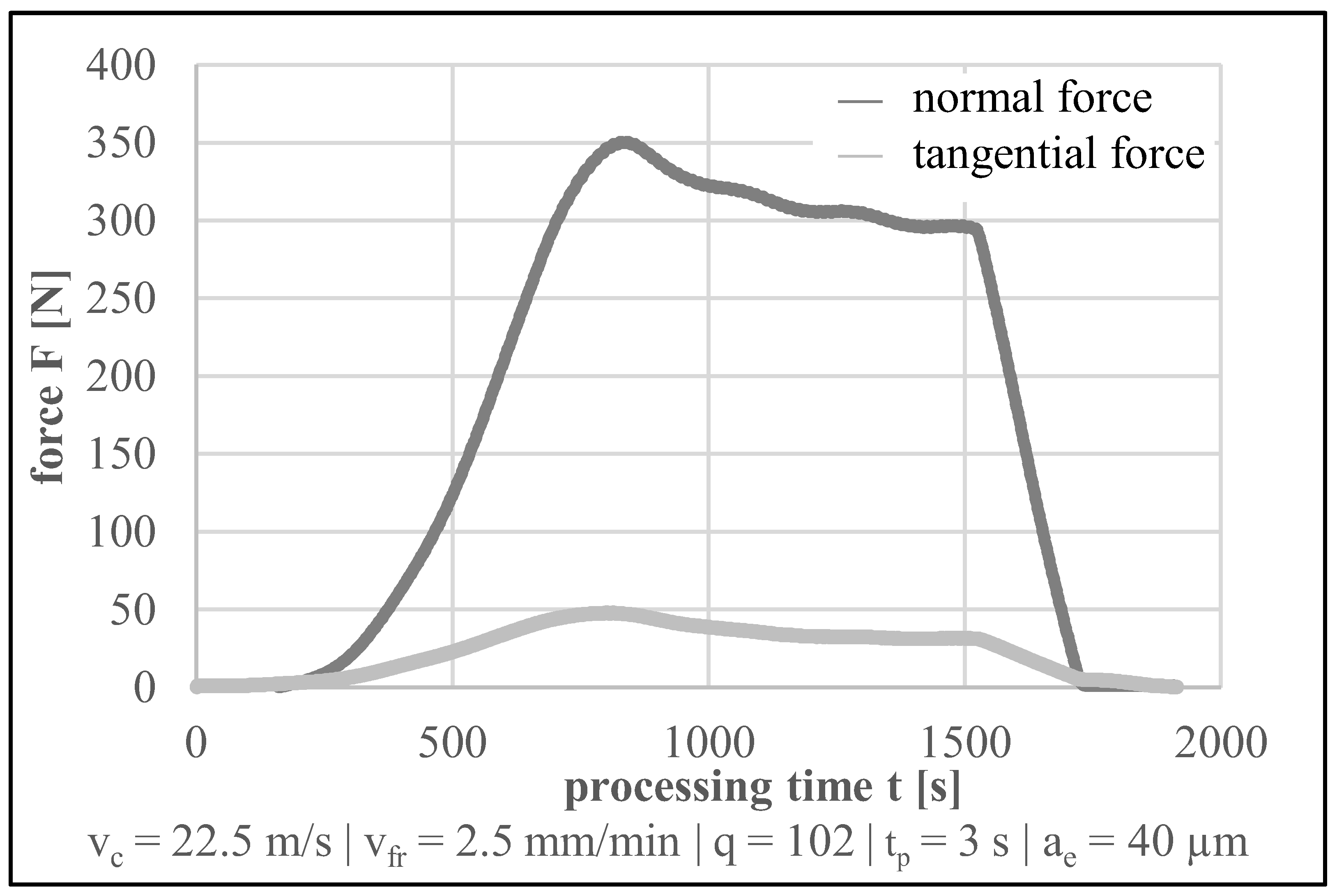

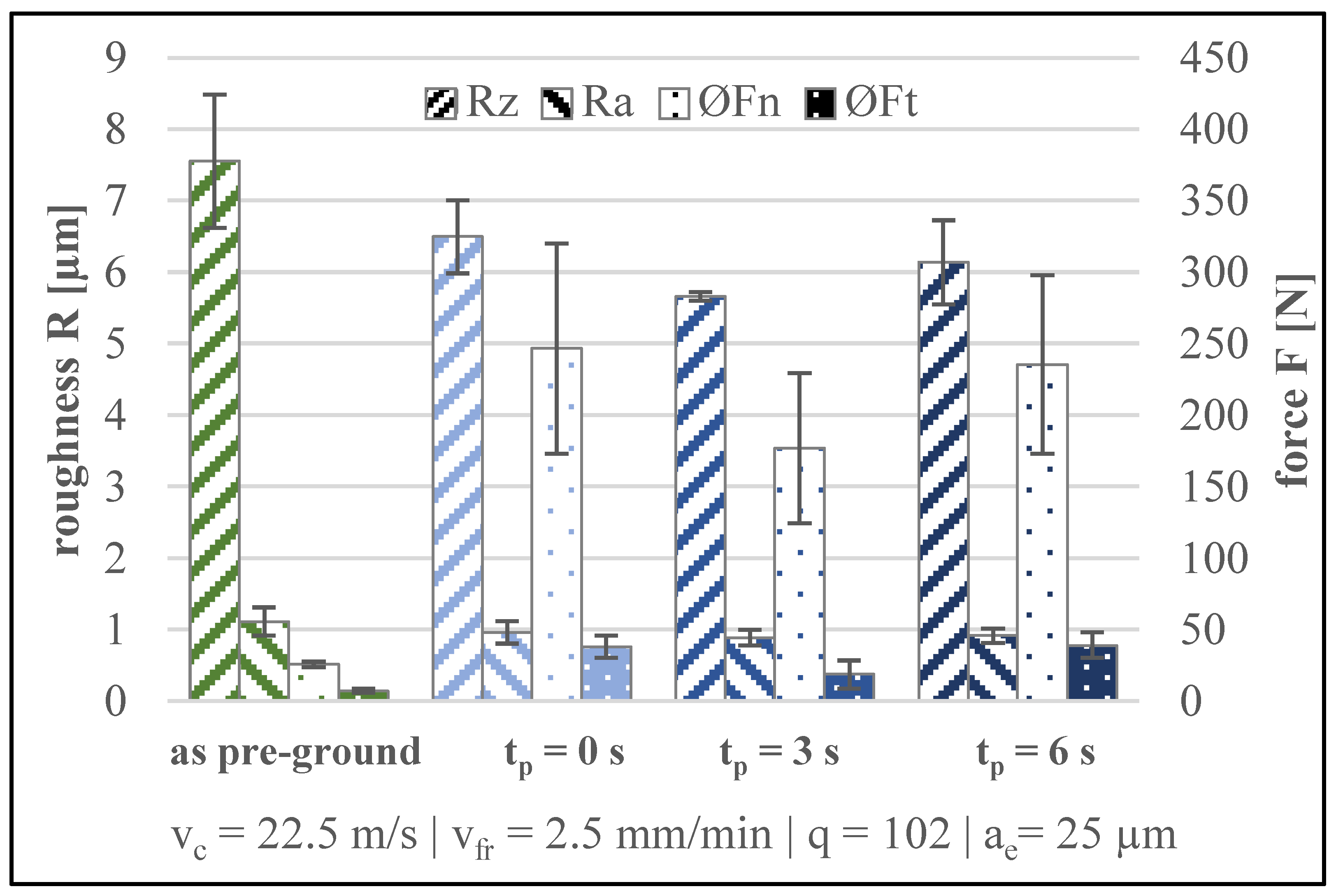

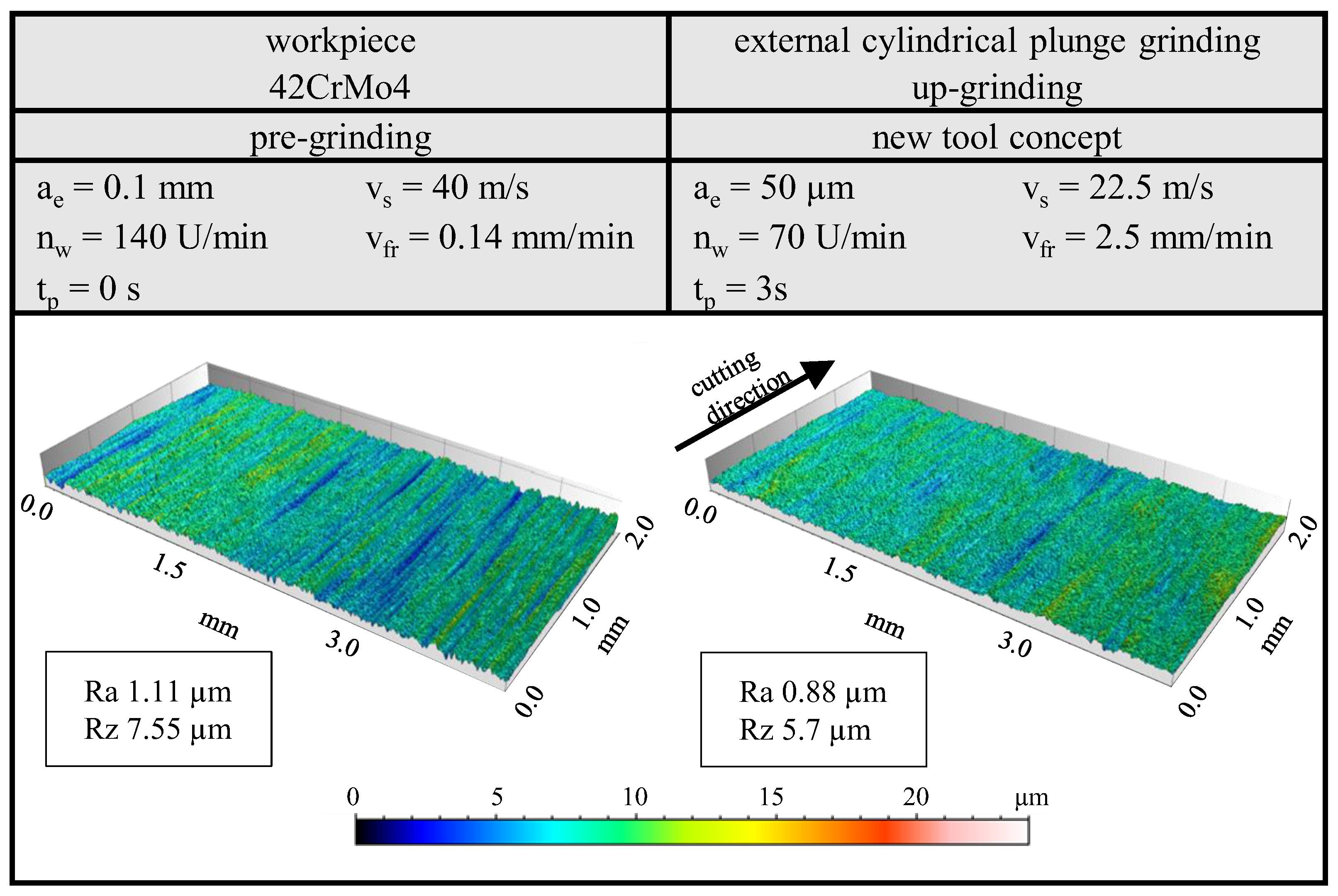

3.1. Mechanical Load and Surface Topography

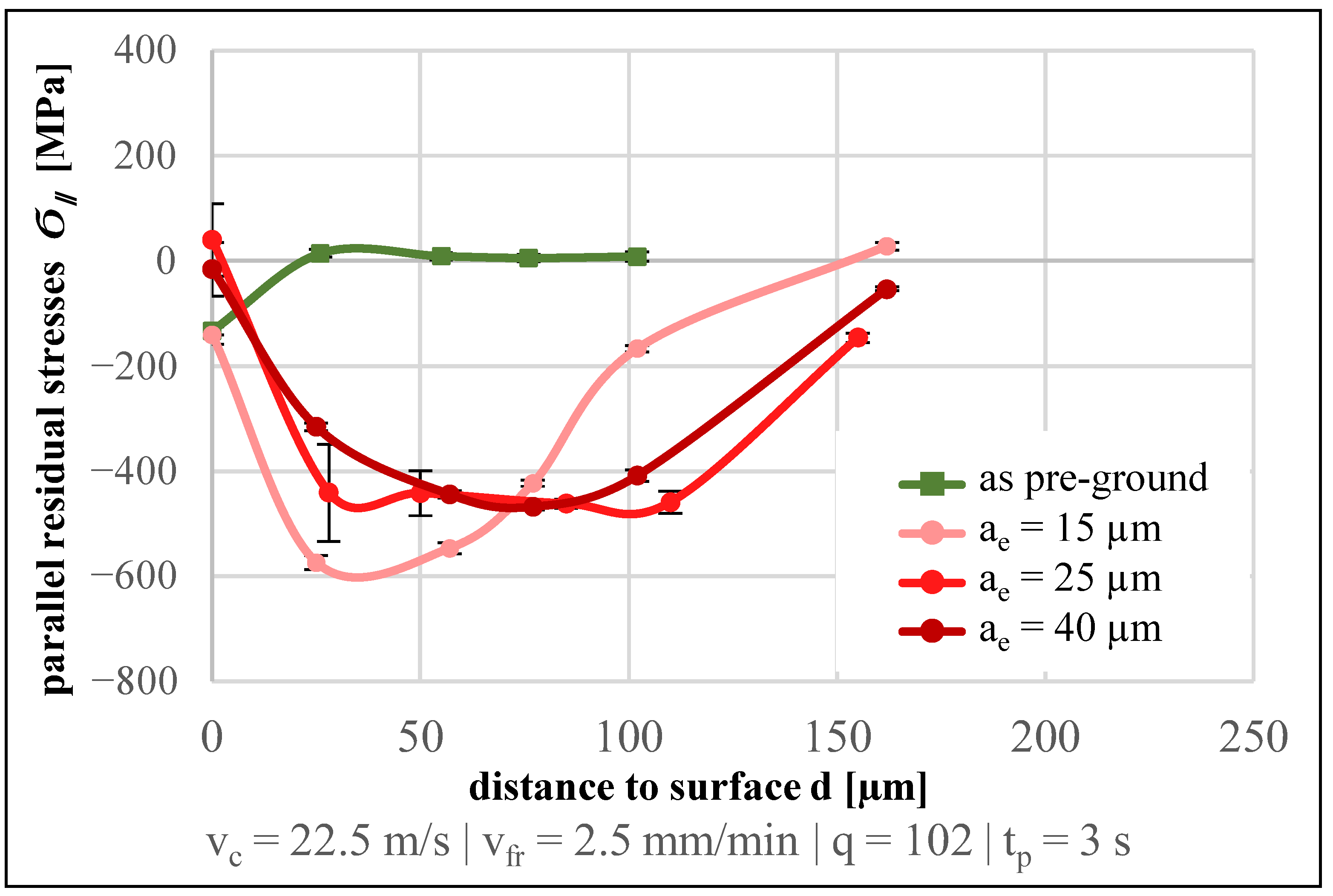

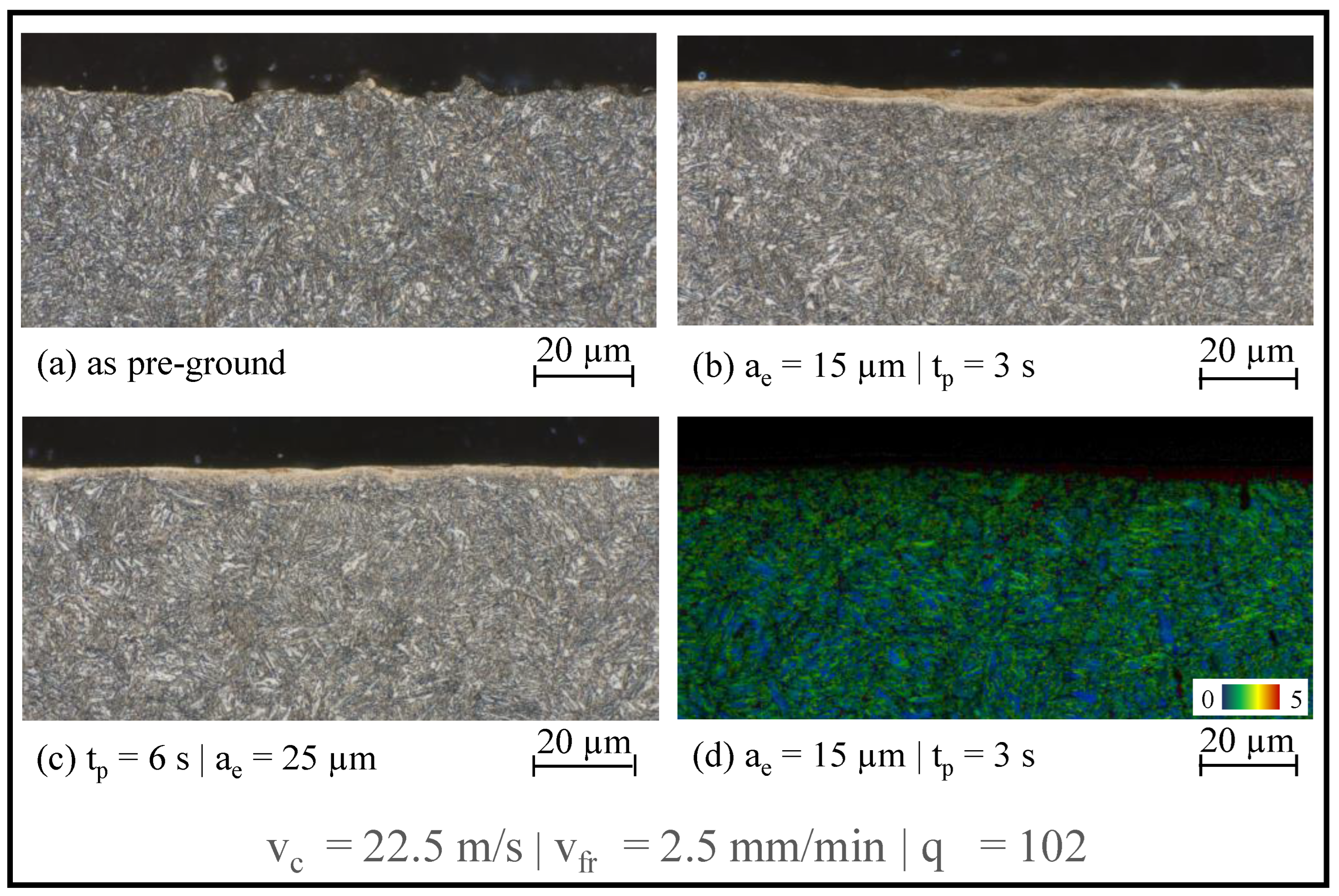

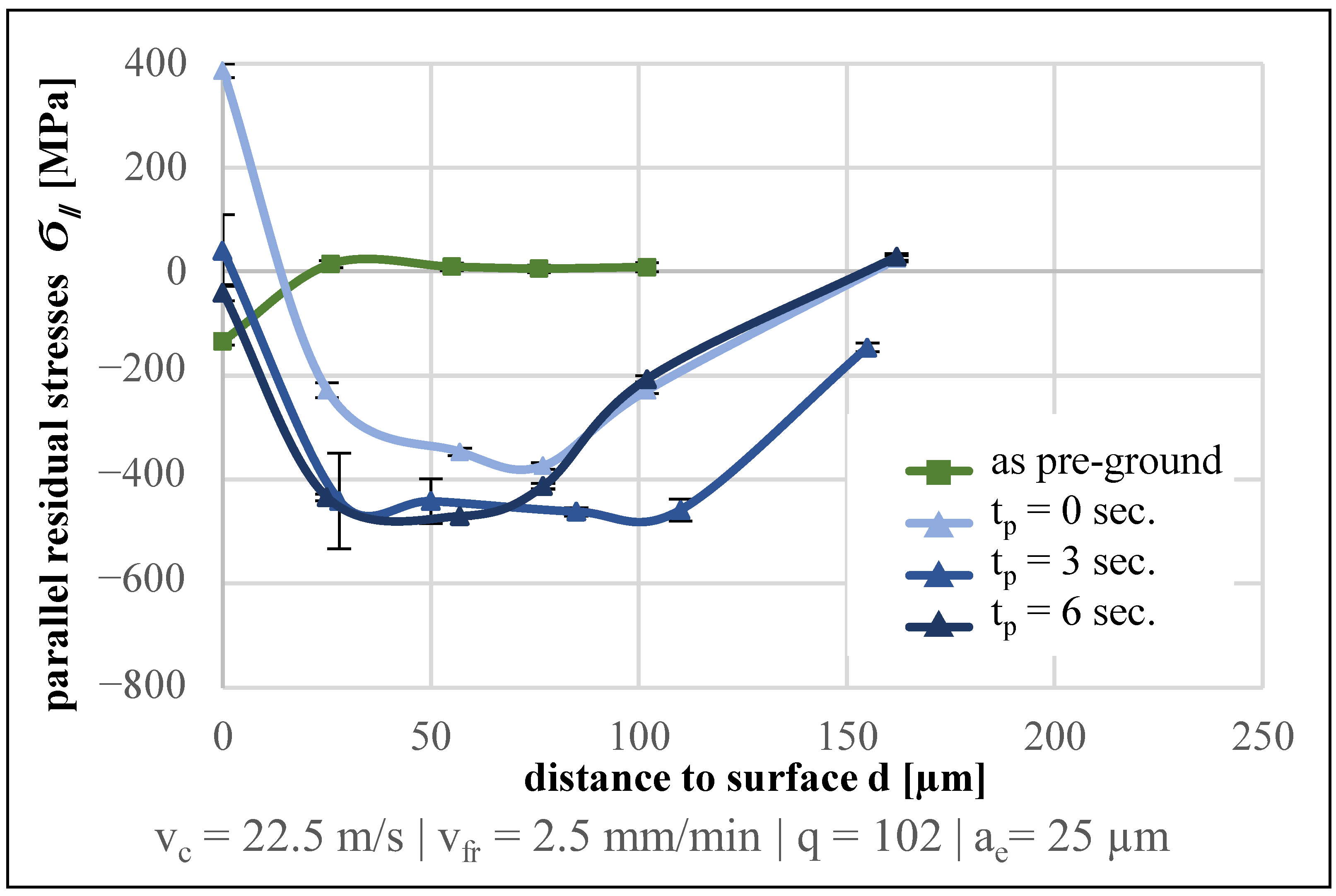

3.2. Impact on Subsurface Characteristics

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- DesRuisseaux, N.R. Thermal Aspects of Grinding Processes. Ph.D. Thesis, University of Cincinnati, Cincinnati, OH, USA, 1967. [Google Scholar]

- Hou, Z.B.; Komanduri, R. On the Mechanics of the Grinding Process, Part II—Thermal Analysis of Fine Grinding. Int. J. Mach. Tools Manuf. 2004, 44, 247–270. [Google Scholar] [CrossRef]

- Malkin, S.; Guo, C. Thermal Analysis of Grinding. Ann. CIRP 2007, 56, 760–782. [Google Scholar] [CrossRef]

- Heinzel, C.; Bleil, N. The Use of the Size Effect in Grinding for Work-Hardening. Ann. CIRP 2007, 56, 327–330. [Google Scholar] [CrossRef]

- Ehle, L.C.; Strunk, R.; Borchers, F.; Schwedt, A.; Clausen, C.; Mayer, J. Influence of process chains with thermal, mechanical and thermo-mechanical impact on the surface modifications of a grind-strengthened 42CrMo4 steel. Procedia CIRP 2022, 87, 426–431. [Google Scholar] [CrossRef]

- Borchers, F.; Clausen, B.; Eckert, S.; Ehle, L.; Epp, J.; Harst, S.; Hettig, M.; Klink, A.; Kohls, E.; Meyer, H.; et al. Comparison of Different Manufacturing Processes of AISI 4140 Steel with Regard to Surface Modification and Its Influencing Depth. Metals 2020, 10, 895. [Google Scholar] [CrossRef]

- Beaucamp, A.; Kirsch, B.; Zhu, W. Advances in grinding tools and abrasives. CIRP Ann.—Manuf. Technol. 2022, 71, 623–646. [Google Scholar] [CrossRef]

- Hahmann, W.C. Innovative Ansätze zur Finishbearbeitung von Funktionsoberflächen. Ph.D. Thesis, TU Braunschweig, Braunschweig, Germany, 2013. [Google Scholar]

- Hoffmeister, H.-W.; Hahmann, W.-C. Superfinishing of Bearing Rings Using Elastic Bonded Grinding Wheels. In Proceedings of the 26th ASPE Annual Meeting, Denver, CO, USA, 13–18 November 2011. [Google Scholar]

- Wagner, A. Feinschleifen von Verzahnung mit elastischen Schleifscheiben. Ph.D. Thesis, University of Bremen, Bremen, Germany, 2016. [Google Scholar]

- Heinzel, C.; Wagner, A. Fine finishing of gears with high shape accuracy. CIRP Ann.—Manuf. Technol. 2013, 62, 359–362. [Google Scholar] [CrossRef]

- Aurich, J.C.; Effgen, C.; Kirsch, B. Cutting edge preparation with elastic bonded superabrasive grinding wheels. CIRP Ann.—Manuf. Technol. 2016, 65, 329–332. [Google Scholar] [CrossRef]

- Heymann, T. Schleifen und Polierschleifen von wendelförmigen Spannuten an Vollhartmetallbohrwerkzeugen. Ph.D. Thesis, TU Dortmund, Dortmund, Germany, 2015. [Google Scholar]

- Uhlmann, E.; Hoyer, A. Surface Finishing of Zirconium Dioxide with abrasive brushing tools. Machines 2020, 8, 89. [Google Scholar] [CrossRef]

- Kipp, M.; Biermann, D. Polierschleifen—Herausforderungen beim Abrichten elastisch gebundener Diamantschleifwerkzeuge für die Feinbearbeitung von Hartmetall. Forum Sonderausg. 2018, 31, 136–140. [Google Scholar]

- Müller, A. Polieren Keramischer Knieimplantate Mit Nachgiebigen Diamantwerkzeugen. Ph.D. Thesis, Universität Hannover, Hannover, Germany, 2014. [Google Scholar]

- Koshy, P.; Iwsaki, A.; Elbestawi, M. Surface Generation with Engineered Diamond Grinding Wheels: Insights from Simulation. Ann. CIRP 2003, 52, 271–274. [Google Scholar] [CrossRef]

- Denkena, B.; Bouabid, A.; Kroedel, A. Single grain grinding: A novel approach to model the interactions at the grain/bond interface during grinding. Int. J. Adv. Manuf. Technol. 2020, 107, 4811–4822. [Google Scholar] [CrossRef]

- García Lunaa, G.; Axinte, D.; Novovic, D. Engineered grinding tools reimplemented by precise sharpening: A case study on an ultrahard ceramic matrix composite (CMC). Ann. CIRP 2022, 71, 289–292. [Google Scholar] [CrossRef]

- Heinzel, C.; Borchers, F.; Berger, D.; Ehle, L. Surface and material modifications of tempered steel after precision grinding with electroplated coarse grained diamond wheels. Procedia CIRP 2016, 45, 191–194. [Google Scholar] [CrossRef]

- Aurich, J.C.; Herzenstiel, P.; Sudermann, H.; Magg, T. High-performance dry grinding using a grinding wheel with a defined grain pattern. CIRP Ann. 2008, 57, 357–362. [Google Scholar] [CrossRef]

- Borchers, F.; Meyer, H.; Heinzel, C.; Meyer, D.; Epp, J. Development of surface residual stress and surface state of 42CrMo4 in multistage grinding. Procedia CIRP 2020, 87, 198–203. [Google Scholar] [CrossRef]

- Borchers, F.; Wagner, A.; Heinzel, C.; Meyer, D. Schleifen mit elastischen Werkzeugen: Prozessauslegung und Oberflächenbeeinflussung beim Außenrundschleifen. Wt Werkstattstech. Online 2016, 106, 380–386. [Google Scholar] [CrossRef]

- Rausch, S.; Odendahl, S.; Kersting, P.; Biermann, D.; Zabel, A. Simulation-Based Prediction of Process Forces for Grinding Free-Formed Surfaces on Machining Centers. Procedia CIRP 2012, 4, 161–165. [Google Scholar] [CrossRef]

- Habrat, W. Effect of Bond Type and Process Parameters on Grinding Force Components in Grinding of Cemented Carbide. Procedia Eng. 2016, 149, 122–129. [Google Scholar] [CrossRef]

- Schulze, V.; Bleicher, F.; Groche, P.; Guo, Y.B.; Pyun, Y.S. Surface modification by machine hammer peening and burnishing. CIRP Ann.—Manuf. Technol. 2016, 65, 809–832. [Google Scholar] [CrossRef]

- Ehle, L. Randschichtmodifikationen Erzeugt Durch Mechanische, Thermische und Chemische Wirkung Verschiedener Herstellungsprozesse am 42CrMo4 Stahl. Ph.D. Thesis, RWTH Aachen University, Aachen, Germany, 2021. [Google Scholar]

- González, J.; Peral, L.B.; Colombo, C.; Fernández Pariente, I. A study on the microstructural evolution of a low alloy steel by different shot peening treatments. Metals 2018, 8, 187. [Google Scholar] [CrossRef]

- Czenkusch, C. Technologische Untersuchungen und Prozessmodelle zum Rundschleifen. Ph.D. Thesis, Leibniz University Hannover, Hanover, Germany, 2000. [Google Scholar]

- Lerra, F.; Ascari, A.; Fortunato, A. Hardness Penetration Depth Prediction in the Grind-Hardening Process through a Combined FEM model. Procedia CIRP 2022, 108, 194–198. [Google Scholar] [CrossRef]

| Notation Unit | C % | Cr % | Mn % | P % | S % | Si % | Mo % | Ni % | Al % | Cu % |

|---|---|---|---|---|---|---|---|---|---|---|

| AISI 4140 | 0.448 | 1.09 | 0.735 | 0.012 | 0.002 | 0.264 | 0.244 | 0.200 | 0.018 | 0.065 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Eich, M.; Meyer, D.; Heinzel, C. Utilisation Potential of Mechanical Material Loads during Grinding by Means of a Novel Tool Concept. J. Manuf. Mater. Process. 2023, 7, 167. https://doi.org/10.3390/jmmp7050167

Eich M, Meyer D, Heinzel C. Utilisation Potential of Mechanical Material Loads during Grinding by Means of a Novel Tool Concept. Journal of Manufacturing and Materials Processing. 2023; 7(5):167. https://doi.org/10.3390/jmmp7050167

Chicago/Turabian StyleEich, Marco, Daniel Meyer, and Carsten Heinzel. 2023. "Utilisation Potential of Mechanical Material Loads during Grinding by Means of a Novel Tool Concept" Journal of Manufacturing and Materials Processing 7, no. 5: 167. https://doi.org/10.3390/jmmp7050167

APA StyleEich, M., Meyer, D., & Heinzel, C. (2023). Utilisation Potential of Mechanical Material Loads during Grinding by Means of a Novel Tool Concept. Journal of Manufacturing and Materials Processing, 7(5), 167. https://doi.org/10.3390/jmmp7050167