A Review of Recent Improvements, Developments, Effects, and Challenges on Using Phase-Change Materials in Concrete for Thermal Energy Storage and Release

Abstract

:1. Introduction

2. Conceptual Challenges of Utilising PCMs in the Concrete Industry

- It is essential to guarantee PCM compatibility with various concrete mix types. Some PCMs may interact with certain admixtures or additives used in the manufacture of concrete, changing its mechanical properties or posing compatibility problems.

- Over time, some PCMs may experience phase change cycling, which could result in performance loss, leakage, or deterioration. For construction to be sustainable and long-lasting, PCM stability inside the concrete matrix must be guaranteed.

- During phase transitions, some PCMs can experience volume changes, which could cause micro-cracking in the concrete matrix. To prevent damaging impacts on the concrete’s structural integrity, these volume variations must be controlled.

- Due to the super-cooling phenomenon, PCMs can experience a lack of solidification, which reduces their ability to store latent heat and causes an insufficient phase change cycle. As a result, ineffective phase change features of PCMs are anticipated.

- The inside environment of concrete is quite alkaline by nature, and in some circumstances, this high alkali causes the PCMs to degrade. For application in concrete, high-alkali PCMs such as polyethylene glycol ought to be excluded.

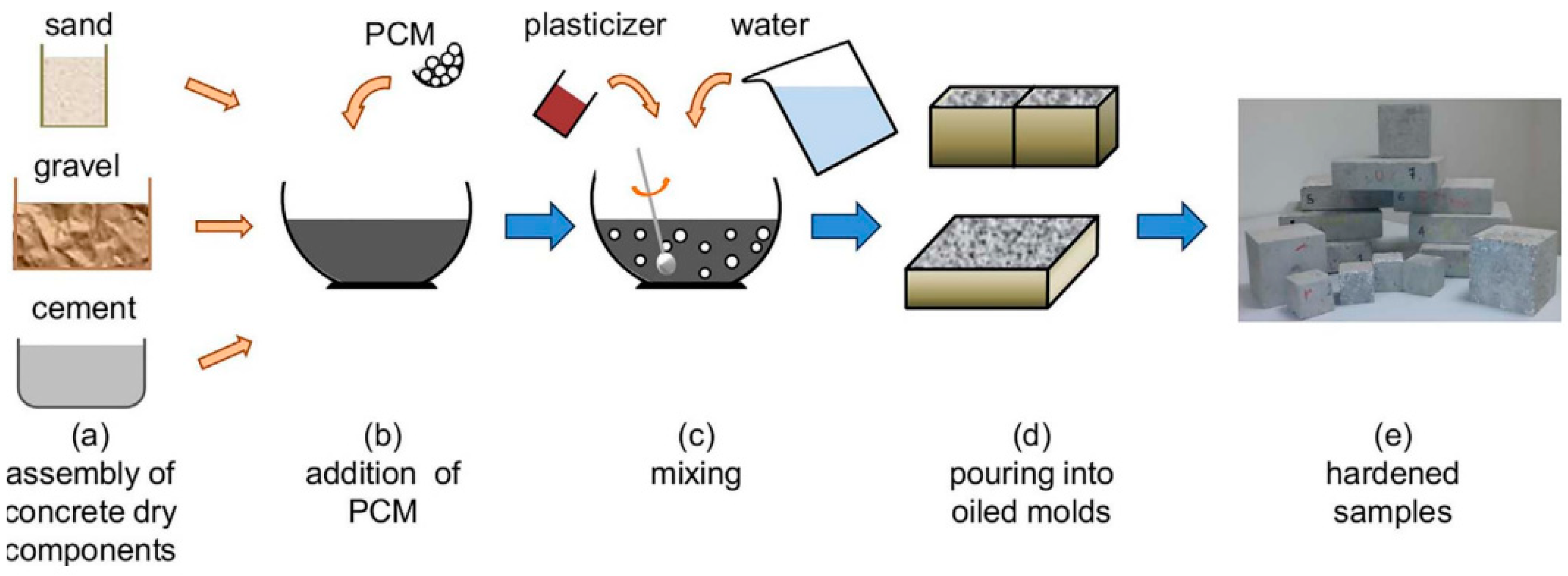

- When PCM is incorporated into concrete via the immersion method or the direct mixing method, PCM leakage from the concrete may result. During the mechanical mixing of these techniques with other concrete ingredients, some of the PCM that has been encapsulated may be broken. In order to achieve an efficient phase change of the PCMs while keeping the maximum strength of the concrete, extensive analysis must be performed to choose the appropriate way of PCM inclusion into the concrete.

- The rate of heat absorption and release during the phase transition operation is reduced considering PCM’s poor thermal conductivity. Particularly when the temperature varies quickly, low thermal conductivity PCM is useless for energy storage. Thus, it is crucial to ensure efficient heat transmission during phase change transitions to increase the capacity for energy storage and release.

- In contrast to conventional concrete materials, PCMs that are acceptable for concrete are not always inexpensive or easily obtainable on the market.

- Buildings that use PCM-enhanced concrete might need to comply with specific regulations and requirements. It is crucial to create standards and guidelines concerning PCM applications because they can promote business acceptance and regulatory acceptability. However, the absence of long-term data on how PCMs affect the longevity of concrete has deterred stakeholders from approving their use.

3. Studies on Using Organic PCM in Concrete for Thermal Energy Storage

4. Studies on Using Inorganic PCM in Concrete for Thermal Energy Storage

5. Studies on Using other Types of PMC in Concrete for Thermal Energy Storage

6. Critical Evaluation of the Utilisation of PCMs in the Concrete Industry and Their Improvements

- Microencapsulation and macroencapsulation technology advancements have improved PCM leakage and degradation protection. The consistency and endurance of PCMs within the concrete are ensured via encapsulation, making them more appropriate for long-term uses.

- PCM decreases concrete’s mass density by almost twice its weight. The higher quantities of Microencapsulated PCM added to denser concrete walls were also shown to improve the energy efficiency of buildings. As the paraffin concentration rises, so does the heat conductivity, reducing the insulating properties of otherwise perfect autoclave-aerated concrete.

- The mechanical strengths of the thermal energy storage cement-based composites have been reduced by raising the content of the form-stable hydrate salt PCMs. Nevertheless, they can still be used as covering subtractions for construction elements. The quantity of thermal energy saved and released also increased with PCM integration, doubling at the highest PCM integration percentage simulated (40%).

- Integrated PCM and a bio-based hygroscopic material (hemp concrete) have strong thermoregulation abilities, with an ultimate period shift of 30 min and a discrepancy in temperature of about 4.6 °C between the reference and PCM hemp concrete. Energy piles may be used if the suggested fibre-reinforced PCM-HSB can greatly increase concrete’s heat capacity and bearing capacity. Density, compressive strength, and flexural strength all showed upward increases with PCM aggregate content. As PCM aggregates increase, so does their thermal conductivity.

- To store and release more thermal energy during phase transitions, scientists have been creating novel PCMs such as Microencapsulated PCMs and Macroencapsulated PCMs with an 18 °C phase transition temperature and greater latent heat capacities. In concrete structures, high-performance PCMs can result in improved temperature control and increased energy savings.

- Research into creating PCMs with phase change temperatures that are best suited for particular regions and structural needs is expanding. PCM-enhanced concrete can be tailored to the appropriate indoor temperature range by adjusting the melting and solidification points.

- Efforts have been undertaken to improve PCM compatibility with different concrete mixtures, making sure that their incorporation does not compromise the concrete’s structural integrity or lifespan.

7. Conclusions

- The PCM layer made from bricks had greater thermal qualities than the PCM capsules, while the latter had better mechanical properties.

- The results of thermal analysis studies showed that PSC-5% has a higher heat storage capacity, leading to higher indoor thermal comfort.

- With the maximum PCM integration percentage simulated, corresponding to 40%, the quantity of stored and released thermal energy doubled from its initial value.

- The postponement of temperature peaks highlighted the improved energy efficiency of PCM wallboards as compared to conventional concrete, particularly in the case of the bilayer wallboard.

- When compared to a setup without PCM, the peak temperature was delayed by 70.4%, energy usage was cut by 50%/60%, and T/RH amplitude was lowered by 15.3%.

- Energy piles may be a viable option because of the suggested fibre-reinforced PCM-HSB, which increases concrete’s heat capacity and bearing capacity.

- Adding 15% as well as 30% PCM composite has decreased the maximum indoor temperature by 1.85 °C and 3.76 °C in the test room, respectively, while increasing the thermal storage capacity by 105% and 181%, respectively.

- Increasing the amount of microencapsulated phase change material aggregation in a unique coreshell or choosing a PCM with a more appropriate phase transition temperature might improve performance by facilitating a more effective heat storage and release procedure.

- In the model of the room with the ceramsite-based encapsulated thermal storage aggregate, the highest temperature drop at the centre point was 4.7 °C, while in the model of the room with the pumice-based encapsulated thermal storage aggregate, it was 8.7 °C.

- When PCMs are added to concrete, freeze-thaw damage is significantly mitigated.

8. Recommendations for Future Works and Challenges

- Further research is needed to investigate novel PCM materials with increased latent heat and acceptable phase change temperatures for particular environments, climates, and applications.

- The distribution of PCM inside the concrete mixture has an essential effect on the rate of heat transfer. Thus, a specific line of research to optimise the distribution and content of PCM is required to increase thermal conductivity and boost heat transfer effectiveness.

- Examining the durability and suitability of PCMs for use with various concrete mixes is interesting research to consider any potential volume changes and micro-cracking that may occur during phase transitions.

- Future research is needed to assess the real freeze-thaw performance of Microencapsulated mortar since this property depends not only on the heat cycles but also on the material’s strength.

- More research into the effects of specimen size, material composition, and environment on PCM’s thermal efficiency, as well as cost-effectiveness analysis and durability evaluation, is needed.

- To get an accurate prediction of the wall of an encapsulated ceramsite-based encapsulated thermal storage aggregate, it will be necessary to conduct a long-term examination of thermal storage stability and to design an adequate matching temperature programme control system.

- The same methodology may be used in the study of encapsulated PCMs with increased heat storage capacity. The suggested mix design allows for the construction and examination of models of large-scale buildings.

- Examine the best building orientation and architectural layout for optimising the advantages of PCM-enhanced concrete in various temperature zones.

- Conducting an economic evaluation to determine whether PCM integration in the concrete industry is cost-effective is important. However, it should consider both immediate building costs and long-term energy savings.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviation

| PCMs | Phase-change materials |

| DSC | Differential scanning calorimeter |

| GPC | Geopolymer concrete |

| DSC | Differential scanning calorimeter |

| MPCM | Microencapsulated phase-change materials |

| AAC | Autoclave-aerated concrete |

| XLPE | Cross-linked polyethylene |

| PIA | Paraffin-impregnated burnt clay aggregate |

| LECA | Lightweight expanded clay aggregate |

| PEG | Polyethylene Glycol |

| OPKS | Oil palm kernel shell |

| RHA | Rice husk ash |

| LFCPCM | Leakage-free composite PCM |

| TESA | Thermal energy storage aggregates |

| EHS/ EGO | Eutectic hydrate salt/expanded graphite oxide |

| CTES | Concrete-based thermal energy storage |

| HTF | Heat transfer fluid |

| TRC | Textile-reinforced concrete |

| MbP | Microencapsulated bio-based phase change material |

| CSP | Concentrated solar power plant |

| ETSA | Encapsulated thermal storage aggregate |

| ACC | Autoclaved aerated concrete block |

| GGBS | Ground-granulated blast-furnace slag |

| SHSPCM | Synthetic heat storage form that incorporates phase change materials |

| ASF | Activated silica fume |

| HSB | Hollow steel ball |

| TES | Thermal energy storage |

References

- Rashid, F.L.; Rahbari, A.; Ibrahem, R.K.; Talebizadehsardari, P.; Basem, A.; Kaood, A.; Mohammed, H.I.; Abbas, M.H.; Al-Obaidi, M.A. Review of solidification and melting performance of phase change materials in the presence of magnetic field, rotation, tilt angle, and vibration. J. Energy Storage 2023, 67, 107501. [Google Scholar] [CrossRef]

- Nóbrega, C.R.; Ismail, K.A.; Lino, F.A. Solidification around axial finned tube submersed in PCM: Modeling and experiments. J. Energy Storage 2020, 29, 101438. [Google Scholar] [CrossRef]

- Khademi, A.; Shank, K.; Mehrjardi, S.A.A.; Tiari, S.; Sorrentino, G.; Said, Z.; Chamkha, A.J.; Ushak, S. A brief review on different hybrid methods of enhancement within latent heat storage systems. J. Energy Storage 2022, 54, 105362. [Google Scholar] [CrossRef]

- Baskin, D. Fixation and tissue processing in immunohistochemistry. In Pathobiology of Human Disease; Elsevier: San Diego, CA, USA, 2014; pp. 3797–3806. [Google Scholar]

- Nartowska, E.; Styś-Maniara, M.; Kozłowski, T. The Potential Environmental and Social Influence of the Inorganic Salt Hydrates Used as a Phase Change Material for Thermal Energy Storage in Solar Installations. Int. J. Environ. Res. Public Health 2023, 20, 1331. [Google Scholar] [CrossRef]

- Rai, U.; Pandey, P. Solidification and thermal behaviour of binary organic eutectic and monotectic; succinonitrile–pyrene system. J. Cryst. Growth 2003, 249, 301–308. [Google Scholar] [CrossRef]

- Li, Z.; Wu, Y.; Zhuang, B.; Zhao, X.; Tang, Y.; Ding, X.; Chen, K. Preparation of novel copper-powder-sintered frame/paraffin form-stable phase change materials with extremely high thermal conductivity. Appl. Energy 2017, 206, 1147–1157. [Google Scholar] [CrossRef]

- Joulin, A.; Zalewski, L.; Lassue, S.; Naji, H. Experimental investigation of thermal characteristics of a mortar with or without a micro-encapsulated phase change material. Appl. Therm. Eng. 2014, 66, 171–180. [Google Scholar] [CrossRef]

- Karaipekli, A.; Sarı, A.; Biçer, A. Thermal regulating performance of gypsum/(C18–C24) composite phase change material (CPCM) for building energy storage applications. Appl. Therm. Eng. 2016, 107, 55–62. [Google Scholar] [CrossRef]

- Zhang, Y.; Ding, J.; Wang, X.; Yang, R.; Lin, K. Influence of additives on thermal conductivity of shape-stabilized phase change material. Sol. Energy Mater. Sol. Cells 2006, 90, 1692–1702. [Google Scholar] [CrossRef]

- Cabeza, L.F.; Castell, A.; Barreneche, C.; De Gracia, A.; Fernández, A.I. Materials used as PCM in thermal energy storage in buildings: A review. Renew. Sustain. Energy Rev. 2011, 15, 1675–1695. [Google Scholar] [CrossRef]

- Ling, T.-C.; Poon, C.-S. Use of phase change materials for thermal energy storage in concrete: An overview. Constr. Build. Mater. 2013, 46, 55–62. [Google Scholar] [CrossRef]

- Kousksou, T.; Arid, A.; Jamil, A.; Zeraouli, Y. Thermal behavior of building material containing microencapsulated PCM. Thermochim. Acta 2012, 550, 42–47. [Google Scholar] [CrossRef]

- Dhaidan, N.S.; Kokz, S.A.; Rashid, F.L.; Hussein, A.K.; Younis, O.; Al-Mousawi, F.N. Review of solidification of phase change materials dispersed with nanoparticles in different containers. J. Energy Storage 2022, 51, 104271. [Google Scholar] [CrossRef]

- Rashid, F.L.; Hussein, A.K.; Malekshah, E.H.; Abderrahmane, A.; Guedri, K.; Younis, O. Review of Heat Transfer Analysis in Different Cavity Geometries with and without Nanofluids. Nanomaterials 2022, 12, 2481. [Google Scholar] [CrossRef]

- Tiji, M.E.; Al-Azzawi, W.K.; Mohammed, H.I.; Dulaimi, A.; Rashid, F.L.; Mahdi, J.M.; Majdi, H.S.; Talebizadehsardari, P.; Ali, H.M. Thermal Management of the Melting Process in a Latent Heat Triplex Tube Storage System Using Different Configurations of Frustum Tubes. J. Nanomater. 2022, 2022, 7398110. [Google Scholar] [CrossRef]

- Rashid, F.L.; Basem, A.; Khalaf, F.A.A.; Abbas, M.H.; Hashim, A. Recent Breakthroughs and Improvements in Phase Change Material Melting in a Triple-Tube Thermal Storage Unit. Rev. Compos. Matériaux Avancés-J. Compos. Adv. Mater. 2022, 32, 295–304. [Google Scholar] [CrossRef]

- Hashim, A.; Braihi, A.J.; Rashid, F.L.; Hashim, M.S. Synthesis and Characterization of Novel Cement/Polyvinyl Pyrrolidone-Carboxymethyl Cellulose-Y2O3 Nanocomposites for Piezoelectric Application. Adv. Sci., Eng. and Med. 2019, 11, 419–422. [Google Scholar] [CrossRef]

- Rashid, F.L.; Al-Obaidi, M.A.; Dulaimi, A.; Bahlol, H.Y.; Hasan, A. Recent Advances, Development, and Impact of Using Phase Change Materials as Thermal Energy Storage in Different Solar Energy Systems: A Review. Designs 2023, 7, 66. [Google Scholar] [CrossRef]

- Cellat, K.; Beyhan, B.; Güngör, C.; Konuklu, Y.; Karahan, O.; Dündar, C.; Paksoy, H. Thermal enhancement of concrete by adding bio-based fatty acids as phase change materials. Energy Build. 2015, 106, 156–163. [Google Scholar] [CrossRef]

- Agyenim, F.; Hewitt, N.; Eames, P.; Smyth, M. A review of materials, heat transfer and phase change problem formulation for latent heat thermal energy storage systems (LHTESS). Renew. Sustain. Energy Rev. 2010, 14, 615–628. [Google Scholar] [CrossRef]

- Hunger, M.; Entrop, A.G.; Mandilaras, I.; Brouwers, H.J.H.; Founti, M. The behavior of self-compacting concrete containing mi-cro-encapsulated phase change materials. Cem. Concr. Compos. 2009, 31, 731–743. [Google Scholar] [CrossRef]

- Akiyama, T.; Ashizawa, Y.; Yagi, J.-I. Storage and release of heat in a single spherical capsule containing phase change material with a high melting point. Heat Transf. Jpn. Res 1992, 21, 199–217. [Google Scholar] [CrossRef]

- Barreneche, C.; De Gracia, A.; Serrano, S.; Navarro, M.E.; Borreguero, A.M.; Fernandez, A.I.; Carmona, M.; Rodriguez, J.F.; Cabeza, L.F. Comparison of three different de-vices available in Spain to test thermal properties of building materials including phase change materials. Appl. Energy 2013, 109, 421–427. [Google Scholar] [CrossRef]

- Sharma, A.; Tyagi, V.V.; Chen, C.R.; Buddhi, D. Review on thermal energy storage with phase change materials and applications. Renew. Sustain. Energy Rev. 2009, 13, 318–345. [Google Scholar]

- Kalnæs, S.E.; Jelle, P.B. Review. Phase change materials and products for building applications: A state-of-the-art review and future research opportunities. Energy Build. 2015, 94, 150–176. [Google Scholar] [CrossRef]

- Alqallaf, H.J.; Alawadhi, E.M. Concrete roof with cylindrical holes containing PCM to reduce the heat gain. Energy Build. 2013, 61, 73–80. [Google Scholar] [CrossRef]

- Royon, L.; Karim, L.; Bontemps, A. Thermal energy storage and release of a new component with PCM for integration in floors for thermal management of buildings. Energy Build. 2013, 63, 29–35. [Google Scholar] [CrossRef]

- Navarro, L.; de Gracia, A.; Castell, A.; Álvarez, S.; Cabeza, L.F. PCM incorporation in a concrete core slab as a thermal storage and supply system: Proof of concept. Energy Build. 2015, 103, 70–82. [Google Scholar] [CrossRef]

- Giro-Paloma, J.; Al-Shannaq, R.; Fernández, A.I.; Farid, M.M. Preparation and characterization of microencapsulated phase change materials for use in building applications. Materials 2016, 9, 11. [Google Scholar] [CrossRef]

- Zhou, D.; Zhao, C.Y.; Tian, Y. Review on thermal energy storage with phase change materials (PCMs) in building applications. Appl. Energy 2012, 92, 593–605. [Google Scholar] [CrossRef]

- Baetens, R.; Jelle, B.P.; Gustavsen, A. Phase change materials for building applications: A state-of-the-art review. Energy Build. 2010, 42, 1361–1368. [Google Scholar] [CrossRef]

- Sukontasukkul, P.; Nontiyutsirikul, N.; Songpiriyakij, S.; Sakai, K.; Chindaprasirt, P. Use of phase change material to improve thermal properties of lightweight geopolymer panel. Mater. Struct. 2016, 49, 4637–4645. [Google Scholar] [CrossRef]

- Bentz, D.P.; Turpin, R. Potential applications of phase change materials in concrete technology. Cem. Concr. Compos. 2007, 29, 527–532. [Google Scholar] [CrossRef]

- Stoll, F.; Drake, M.L.; Salyer, I.O. Use of phase change materials to prevent overnight freezing of bridge decks. In IDEA Program; Transportation Research Board: Washington, DC, USA, 1996; pp. 1–23. [Google Scholar]

- Drissi, S.; Eddhahak, A.; Caré, S.; Neji, J. Thermal analysis by DSC of phase change materials, study of the damage effect. J. Build. Eng. 2015, 1, 13–19. [Google Scholar] [CrossRef]

- Zhu, Q.; Xie, M.; Yang, J.; Li, Y. A fractal model for the coupled heat and mass transfer in porous fibrous media. Int. J. Heat Mass Transf. 2011, 54, 1400–1409. [Google Scholar] [CrossRef]

- Fan, L.-W.; Hu, Y.-C.; Tian, T.; Yu, Z.-T. The prediction of effective thermal conductivities perpendicular to the fibers of wood using a fractal and an improved transient measurement technique. Int. J. Heat Mass Transf. 2006, 49, 4116–4123. [Google Scholar] [CrossRef]

- Al-Garah, N.H.; Rashid, F.L.; Hadi, A.; Hashim, A. Synthesis and Characterization of Novel (Organic–Inorganic) Nanofluids for Antibacterial, Antifungal and Heat Transfer Applications. J. Bionanosci. 2018, 12, 336–340. [Google Scholar] [CrossRef]

- Sakulich, A.R.; Bentz, D.P. Increasing the service life of bridge decks by incorporating phase-change materials to reduce freeze-thaw cycles. J. Mater. Civ. Eng. 2011, 24, 1034–1042. [Google Scholar] [CrossRef]

- Farnam, Y.; Krafcik, M.; Liston, L.; Washington, T.; Erk, K.; Tao, B.; Weiss, J. Evaluating the use of phase change materials in concrete pavement to melt ice and snow. J. Mater. Civ. Eng. 2016, 28, 04015161. [Google Scholar] [CrossRef]

- Sharshir, S.W.; Joseph, A.; Elsharkawy, M.; Hamada, M.A.; Kandeal, A.; Elkadeem, M.R.; Thakur, A.K.; Ma, Y.; Moustapha, M.E.; Rashad, M.; et al. Thermal energy storage using phase change materials in building applications: A review of the recent development. Energy Build. 2023, 285, 112908. [Google Scholar] [CrossRef]

- Wang, X.; Li, W.; Luo, Z.; Wang, K.; Shah, S.P. A critical review on phase change materials (PCM) for sustainable and energy efficient building: Design, characteristic, performance and application. Energy Build. 2022, 260, 111923. [Google Scholar] [CrossRef]

- Braihi, A.J.; Hashim, A.; Rashid, F.L.; Hashim, M.S. Novel of Piezoelectric Application for Cement Mortar/CMC-PVP-ZrO2 Nanocomposites. Adv. Sci., Eng. and Med. 2019, 11, 415–418. [Google Scholar] [CrossRef]

- Adesina, A. Use of phase change materials in concrete: Current challenges. Renew. Energy Environ. Sustain. 2019, 4, 9. [Google Scholar] [CrossRef]

- Sharma, R.; Jang, J.-G.; Hu, J.-W. Phase-Change Materials in Concrete: Opportunities and Challenges for Sustainable Construction and Building Materials. Materials 2022, 15, 335. [Google Scholar] [CrossRef] [PubMed]

- Rashid, F.L.; Hashim, A. Recent Review on Nanofluid/ Nanocomposites for Solar Energy Storage. Int. J. Sci. Res. Eng. Dev. 2020, 3, 780–789. [Google Scholar]

- Tyagi, V.; Kaushik, S.; Tyagi, S.; Akiyama, T. Development of phase change materials based microencapsulated technology for buildings: A review. Renew. Sustain. Energy Rev. 2011, 15, 1373–1391. [Google Scholar] [CrossRef]

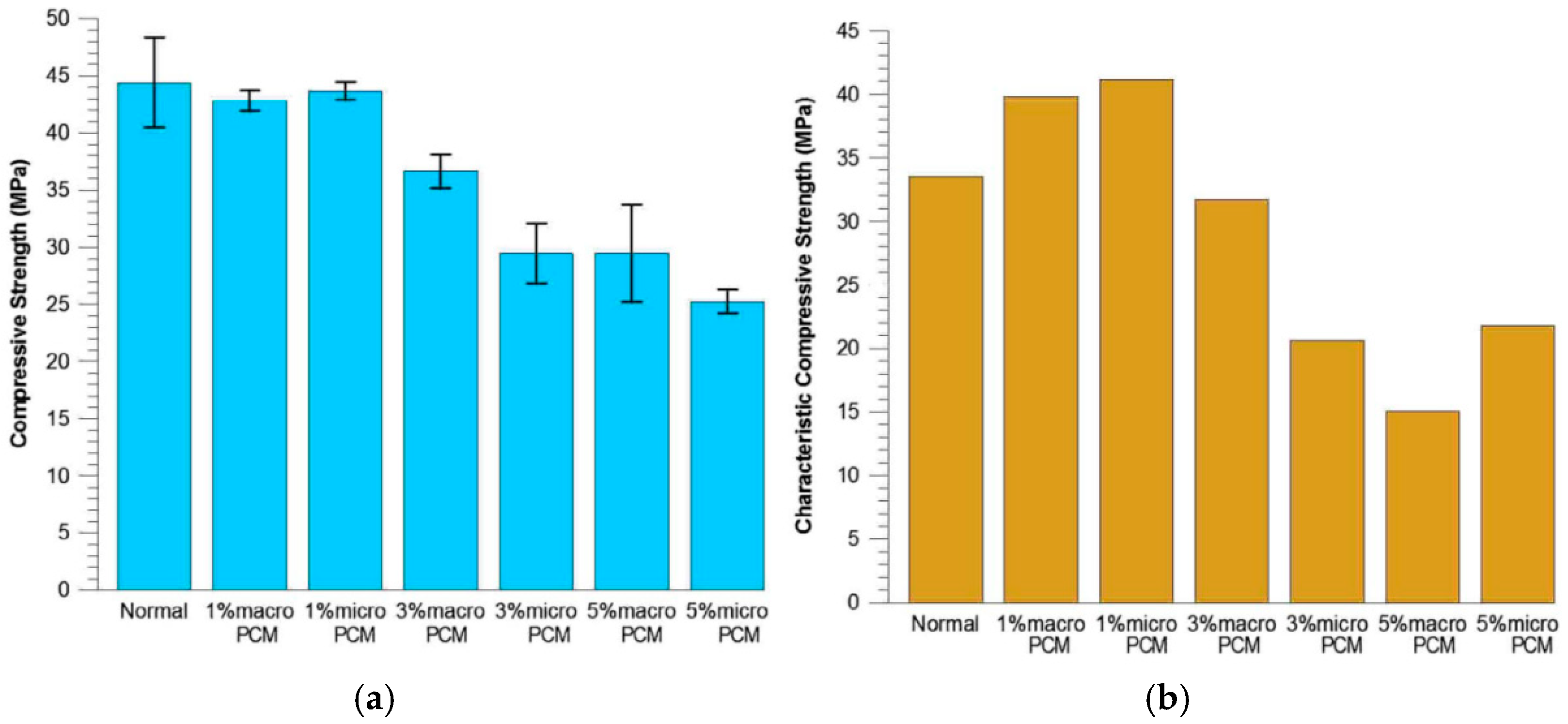

- D’Alessandro, A.; Pisello, A.L.; Fabiani, C.; Ubertini, F.; Cabeza, L.F.; Cotana, F. Multifunctional smart concretes with novel phase change materials: Mechanical and thermo-energy investigation. Appl. Energy 2018, 212, 1448–1461. [Google Scholar] [CrossRef]

- Cao, V.D.; Pilehvar, S.; Salas-Bringas, C.; Szczotok, A.M.; Bui, T.Q.; Carmona, M.; Rodriguez, J.F.; Kjøniksen, A.-L. Thermal performance and numerical simulation of geopolymer concrete containing different types of thermoregulating materials for passive building applications. Energy Build. 2018, 173, 678–688. [Google Scholar] [CrossRef]

- Cao, V.D.; Pilehvar, S.; Salas-Bringas, C.; Szczotok, A.M.; Valentini, L.; Carmona, M.; Rodriguez, J.F.; Kjøniksen, A.-L. Influence of microcapsule size and shell polarity on thermal and mechanical properties of thermoregulating geopolymer concrete for passive building applications. Energy Convers. Manag. 2018, 164, 198–209. [Google Scholar] [CrossRef]

- Qian, T.; Li, J. Octadecane/C-decorated diatomite composite phase change material with enhanced thermal conductivity as aggregate for developing structural–functional integrated cement for thermal energy storage. Energy 2018, 142, 234–249. [Google Scholar] [CrossRef]

- Moldgy, A.; Parameshwaran, R. Study on thermal energy storage properties of organic phase change material for waste heat recovery applications. Mater. Today Proc. 2018, 5, 16840–16848. [Google Scholar] [CrossRef]

- Tian, S.-Q.; Yu, S.-F.; Wang, X.; Fan, L.-W.; Yu, Z.-T.; Xu, X.; Ge, J. Experimental determination and fractal modeling of the effective thermal conductivity of autoclave aerated concrete (AAC) impregnated with paraffin for improved thermal storage performance. Appl. Therm. Eng. 2019, 163, 114387. [Google Scholar] [CrossRef]

- Zéhil, G.-P.; Assaad, J.J. Feasibility of concrete mixtures containing cross-linked polyethylene waste materials. Constr. Build. Mater. 2019, 226, 1–10. [Google Scholar] [CrossRef]

- Afgan, S.; Khushnood, R.A.; Memon, S.A.; Iqbal, N. Development of structural thermal energy storage concrete using paraffin intruded lightweight aggregate with nano-refined modified encapsulation paste layer. Constr. Build. Mater. 2019, 228, 116768. [Google Scholar] [CrossRef]

- Pongsopha, P.; Sukontasukkul, P.; Phoo-Ngernkham, T.; Imjai, T.; Jamsawang, P.; Chindaprasirt, P. Use of burnt clay aggregate as phase change material carrier to improve thermal properties of concrete panel. Case Stud. Constr. Mater. 2019, 11, e00242. [Google Scholar] [CrossRef]

- Hassan, A.; Mourad, A.-H.I.; Rashid, Y.; Ismail, N.; Laghari, M.S. Thermal and structural performance of geopolymer concrete containing phase change material encapsulated in expanded clay. Energy Build. 2019, 191, 72–81. [Google Scholar] [CrossRef]

- Cao, V.D.; Pilehvar, S.; Salas-Bringas, C.; Szczotok, A.M.; Bui, T.Q.; Carmona, M.; Rodriguez, J.F.; Kjøniksen, A.-L. Thermal analysis of geopolymer concrete walls containing microencapsulated phase change materials for building applications. Sol. Energy 2019, 178, 295–307. [Google Scholar] [CrossRef]

- Chen, J.; Zhang, W.; Shi, X.; Yao, C.; Kuai, C. Use of PEG/SiO2 phase change composite to control porous asphalt concrete temperature. Constr. Build. Mater. 2020, 245, 118459. [Google Scholar] [CrossRef]

- Kim, H.G.; Qudoos, A.; Jeon, I.K.; Woo, B.H.; Ryou, J.-S. Assessment of PCM/SiC-based composite aggregate in concrete: Energy storage performance. Constr. Build. Mater. 2020, 258, 119637. [Google Scholar] [CrossRef]

- Chin, C.O.; Yang, X.; Paul, S.C.; Susilawati; Wong, L.S.; Kong, S.Y. Development of thermal energy storage lightweight concrete using paraffin-oil palm kernel shell-activated carbon composite. J. Clean. Prod. 2020, 261, 121227. [Google Scholar] [CrossRef]

- Benkaddour, A.; Faraji, M.; Faraji, H. Numerical study of the thermal energy storage behaviour of a novel composite PCM/Concrete wall integrated solar collector. Mater. Today Proc. 2020, 30 Pt 4, 905–908. [Google Scholar] [CrossRef]

- Ramakrishnan, S.; Pasupathy, K.; Sanjayan, J. Synthesis and properties of thermally enhanced aerated geopolymer concrete using form-stable phase change composite. J. Build. Eng. 2021, 40, 102756. [Google Scholar] [CrossRef]

- Gencel, O.; Sarı, A.; Kaplan, G.; Ustaoglu, A.; Hekimoğlu, G.; Bayraktar, O.Y.; Ozbakkaloglu, T. Properties of eco-friendly foam concrete containing PCM impregnated rice husk ash for thermal management of buildings. J. Build. Eng. 2022, 58, 104961. [Google Scholar] [CrossRef]

- Kalombe, R.M.; Sobhansarbandi, S.; Kevern, J. Low-cost phase change materials based concrete for reducing deicing needs. Constr. Build. Mater. 2023, 363, 129129. [Google Scholar] [CrossRef]

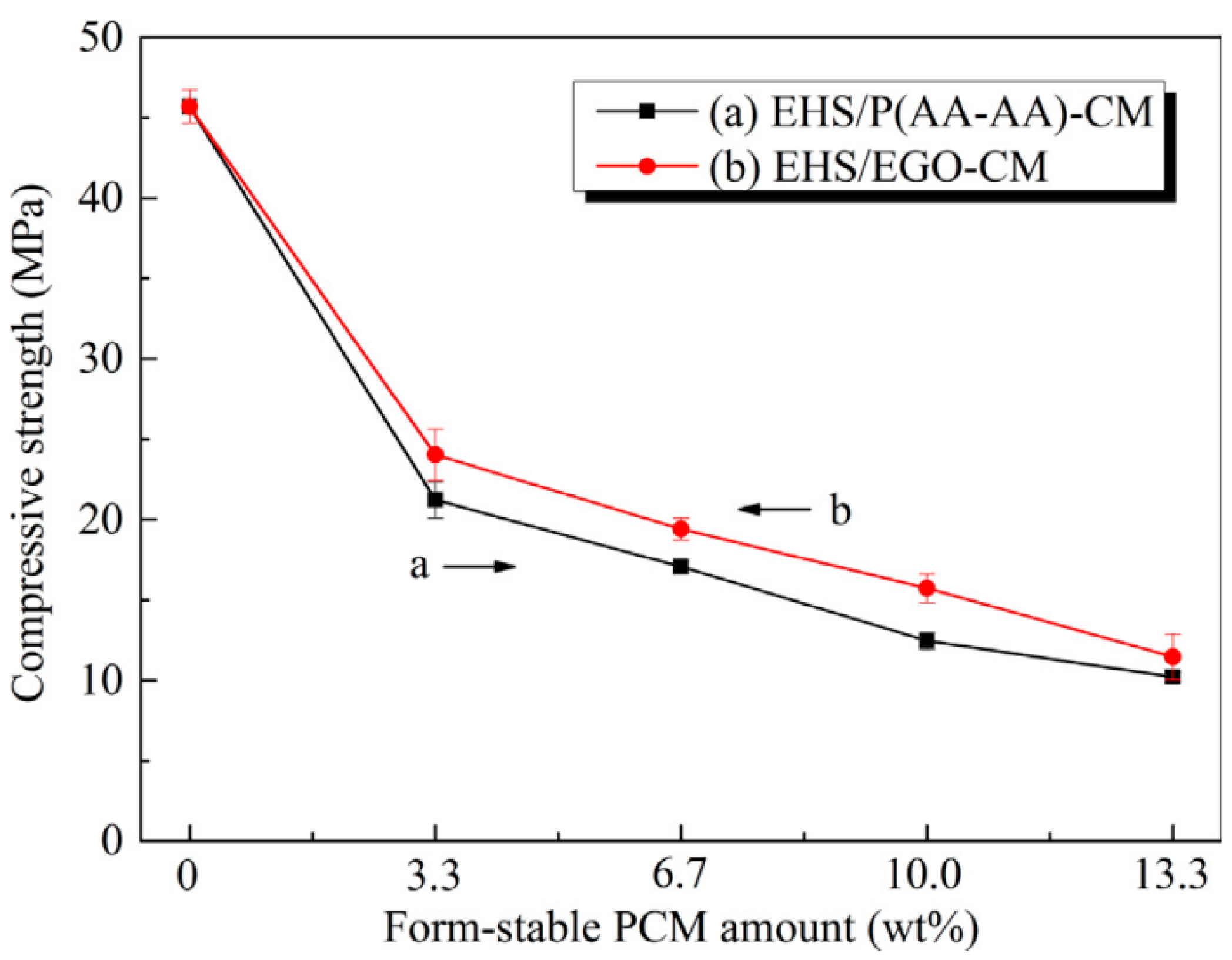

- Liu, Y.; Xie, M.; Gao, X.; Yang, Y.; Sang, Y. Experimental exploration of incorporating form-stable hydrate salt phase change materials into cement mortar for thermal energy storage. Appl. Therm. Eng. 2018, 140, 112–119. [Google Scholar] [CrossRef]

- Erlbeck, L.; Schreiner, P.; Schlachter, K.; Dörnhofer, P.; Fasel, F.; Methner, F.-J.; Rädle, M. Adjustment of thermal behavior by changing the shape of PCM inclusions in concrete blocks. Energy Convers. Manag. 2018, 158, 256–265. [Google Scholar] [CrossRef]

- Bahrar, M.; Djamai, Z.I.; EL Mankibi, M.; Larbi, A.S.; Salvia, M. Numerical and experimental study on the use of microencapsulated phase change materials (PCMs) in textile reinforced concrete panels for energy storage. Sustain. Cities Soc. 2018, 41, 455–468. [Google Scholar] [CrossRef]

- Sukontasukkul, P.; Uthaichotirat, P.; Sangpet, T.; Sisomphon, K.; Newlands, M.; Siripanichgorn, A.; Chindaprasirt, P. Thermal properties of lightweight concrete incorporating high contents of phase change materials. Constr. Build. Mater. 2019, 207, 431–439. [Google Scholar] [CrossRef]

- Vigneshwaran, K.; Sodhi, G.S.; Muthukumar, P.; Subbiah, S. Concrete based high temperature thermal energy storage system: Experimental and numerical studies. Energy Convers. Manag. 2019, 198, 111905. [Google Scholar] [CrossRef]

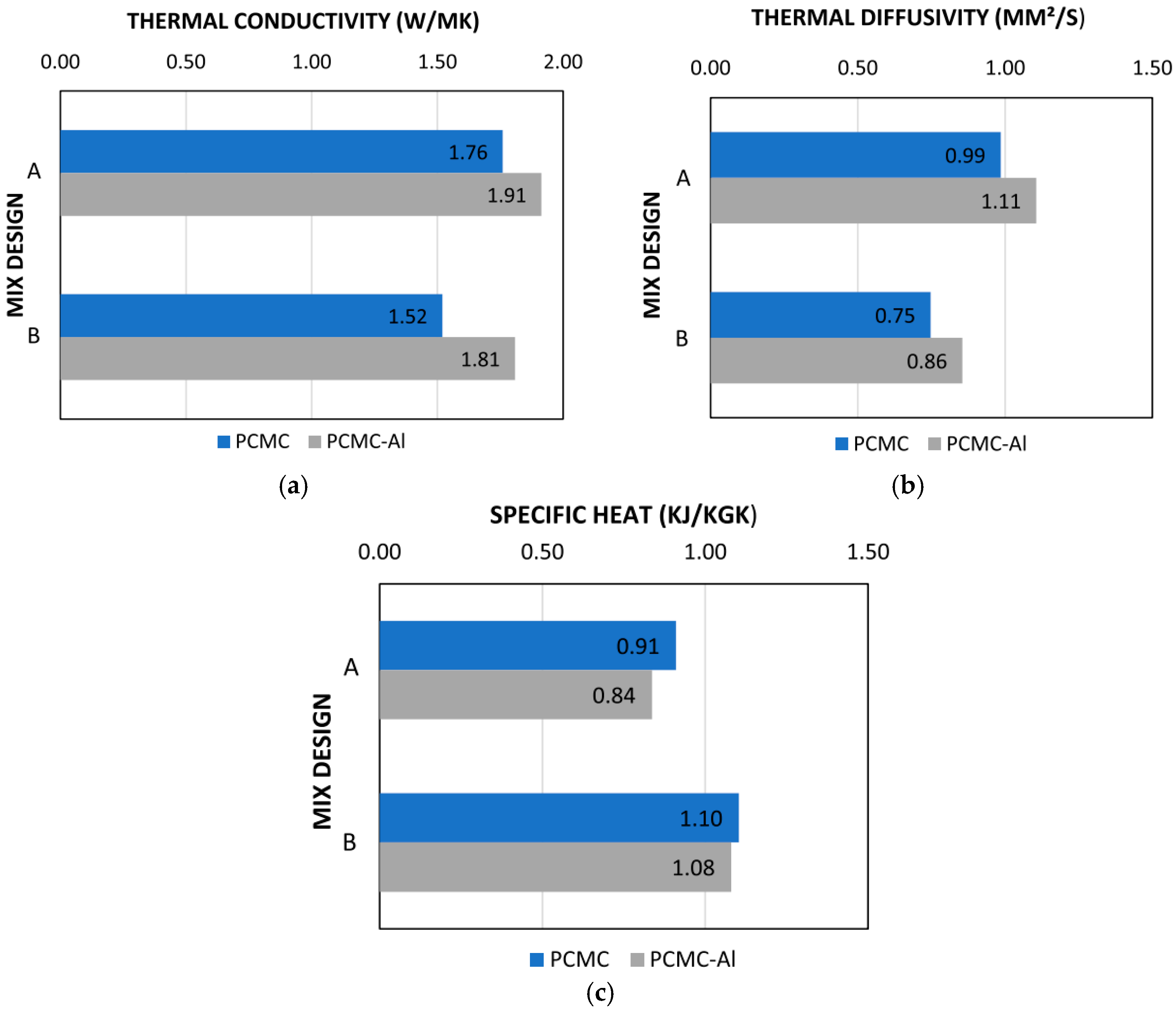

- Mohseni, E.; Tang, W.; Khayat, K.H.; Cui, H. Thermal performance and corrosion resistance of structural-functional concrete made with inorganic PCM. Constr. Build. Mater. 2020, 249, 118768. [Google Scholar] [CrossRef]

- Qu, Y.; Chen, J.; Liu, L.; Xu, T.; Wu, H.; Zhou, X. Study on properties of phase change foam concrete block mixed with paraffin/fumed silica composite phase change material. Renew. Energy 2020, 150, 1127–1135. [Google Scholar] [CrossRef]

- Drissi, S.; Ling, T.-C.; Mo, K.H. Thermal performance of a solar energy storage concrete panel incorporating phase change material aggregates developed for thermal regulation in buildings. Renew. Energy 2020, 160, 817–829. [Google Scholar] [CrossRef]

- Djamai, Z.I.; Le Nguyen, K.; Larbi, A.S.; Salvatore, F.; Cai, G. PCM-modified textile-reinforced concrete slab: A multiscale and multiphysics investigation. Constr. Build. Mater. 2021, 293, 123483. [Google Scholar] [CrossRef]

- Parameshwaran, R.; Naresh, R.; Ram, V.V.; Srinivas, P. Microencapsulated bio-based phase change material-micro concrete composite for thermal energy storage. J. Build. Eng. 2021, 39, 102247. [Google Scholar] [CrossRef]

- Essid, N.; Eddhahak, A.; Neji, J. Experimental and numerical analysis of the energy efficiency of PCM concrete wallboards under different thermal scenarios. J. Build. Eng. 2022, 45, 103547. [Google Scholar] [CrossRef]

- Martelletto, F.; Doretti, L.; Mancin, S. Numerical simulation through experimental validation of latent and sensible concrete thermal energy storage system. J. Energy Storage 2022, 51, 104567. [Google Scholar] [CrossRef]

- Tetuko, A.P.; Sebayang, A.M.S.; Fachredzy, A.; Setiadi, E.A.; Asri, N.S.; Sari, A.Y.; Purnomo, F.; Muslih, C.; Fajrin, M.A.; Sebayang, P. Encapsulation of paraffin-magnetite, paraffin, and polyethylene glycol in concretes as thermal energy storage. J. Energy Storage 2023, 68, 107684. [Google Scholar] [CrossRef]

- Frahat, N.B.; Amin, M.; Heniegal, A.M.; Ibrahim, O.M.O. Optimizing microencapsulated PCM ratios of sustainable cement mortar for energy savings in buildings. Constr. Build. Mater. 2023, 391, 107684. [Google Scholar] [CrossRef]

- Wang, R.; Ren, M.; Gao, X.; Qin, L. Preparation and properties of fatty acids based thermal energy storage aggregate concrete. Constr. Build. Mater. 2018, 165, 1–10. [Google Scholar] [CrossRef]

- Yeon, J.H.; Kim, K.-K. Potential applications of phase change materials to mitigate freeze-thaw deteriorations in concrete pavement. Constr. Build. Mater. 2018, 177, 202–209. [Google Scholar] [CrossRef]

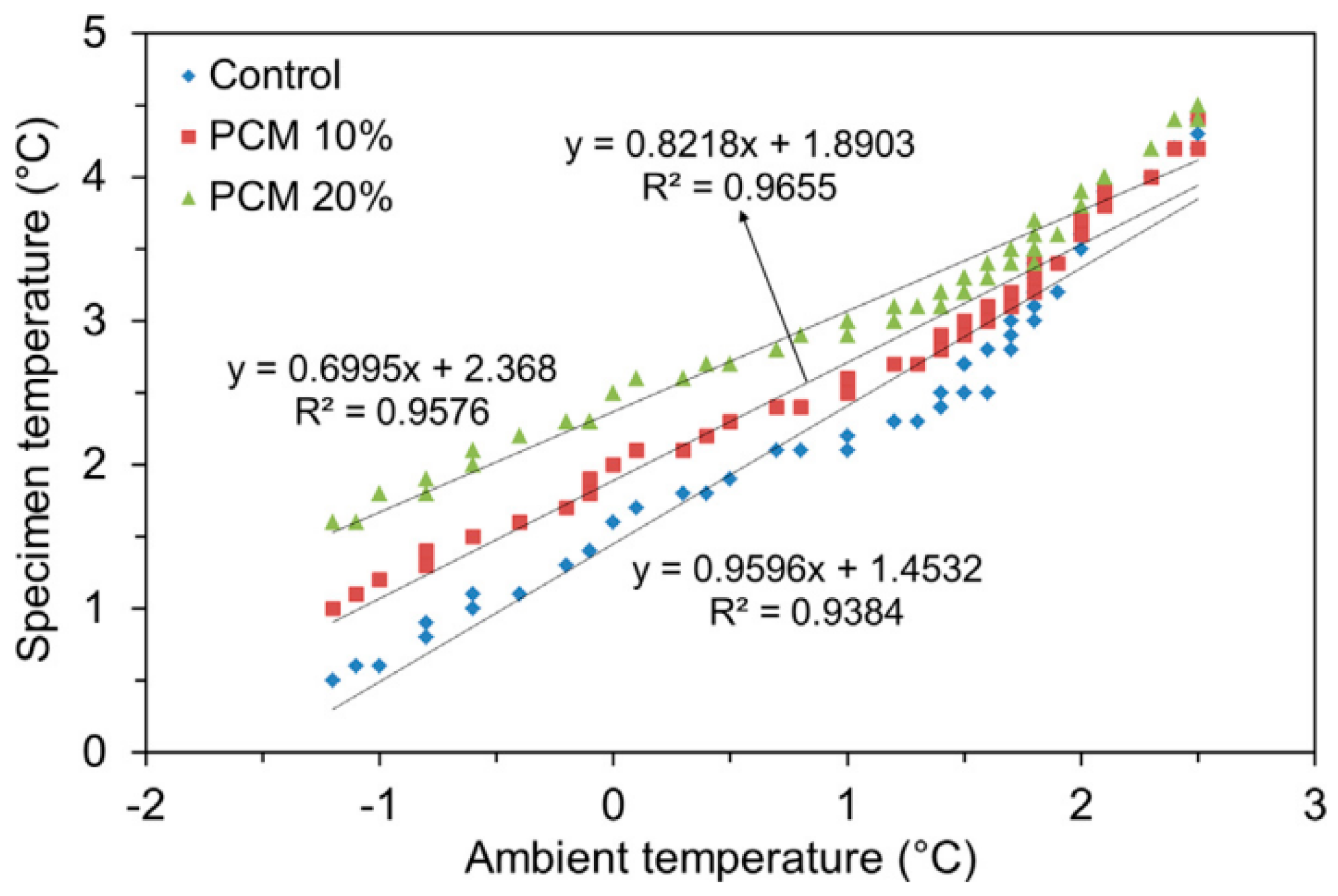

- Urgessa, G.; Yun, K.-K.; Yeon, J.; Yeon, J.H. Thermal responses of concrete slabs containing microencapsulated low-transition temperature phase change materials exposed to realistic climate conditions. Cem. Concr. Compos. 2019, 104, 103391. [Google Scholar] [CrossRef]

- Nayak, S.; Krishnan, N.A.; Das, S. Microstructure-guided numerical simulation to evaluate the influence of phase change materials (PCMs) on the freeze-thaw response of concrete pavements. Constr. Build. Mater. 2019, 201, 246–256. [Google Scholar] [CrossRef]

- Li, W.; Ling, C.; Jiang, Z.; Yu, Q.-Q. Evaluation of the potential use of form-stable phase change materials to improve the freeze-thaw resistance of concrete. Constr. Build. Mater. 2019, 203, 621–632. [Google Scholar] [CrossRef]

- Cao, V.D.; Bui, T.Q.; Kjøniksen, A.-L. Thermal analysis of multi-layer walls containing geopolymer concrete and phase change materials for building applications. Energy 2019, 186, 115792. [Google Scholar] [CrossRef]

- Doretti, L.; Martelletto, F.; Mancin, S. A simplified analytical approach for concrete sensible thermal energy storages simulation. J. Energy Storage 2019, 22, 68–79. [Google Scholar] [CrossRef]

- Ren, M.; Liu, Y.; Gao, X. Incorporation of phase change material and carbon nanofibers into lightweight aggregate concrete for thermal energy regulation in buildings. Energy 2020, 197, 117262. [Google Scholar] [CrossRef]

- Uthaichotirat, P.; Sukontasukkul, P.; Jitsangiam, P.; Suksiripattanapong, C.; Sata, V.; Chindaprasirt, P. Thermal and sound properties of concrete mixed with high porous aggregates from manufacturing waste impregnated with phase change material. J. Build. Eng. 2020, 29, 101111. [Google Scholar] [CrossRef]

- Arivazhagan, R.; Prakash, S.A.; Kumaran, P.; Sankar, S.; Loganathan, G.B.; Arivarasan, A. Performance analysis of concrete block integrated with PCM for thermal management. Mater. Today Proc. 2020, 22 Pt 3, 370–374. [Google Scholar] [CrossRef]

- Ram, V.V.; Singhal, R.; Parameshwaran, R. Energy efficient pumpable cement concrete with nanomaterials embedded PCM for passive cooling application in buildings. Mater. Today Proc. 2020, 28 Pt 2, 1054–1063. [Google Scholar] [CrossRef]

- Liu, Y.; Sun, F.; Yu, K.; Yang, Y. Experimental and numerical research on development of synthetic heat storage form incorporating phase change materials to protect concrete in cold weather. Renew. Energy 2020, 149, 1424–1433. [Google Scholar] [CrossRef]

- Shen, Y.; Liu, S.; Zeng, C.; Zhang, Y.; Li, Y.; Han, X.; Yang, L.; Yang, X. Experimental thermal study of a new PCM-concrete thermal storage block (PCM-CTSB). Constr. Build. Mater. 2021, 293, 123540. [Google Scholar] [CrossRef]

- Pongsopha, P.; Sukontasukkul, P.; Maho, B.; Intarabut, D.; Phoo-Ngernkham, T.; Hanjitsuwan, S.; Choi, D.; Limkatanyu, S. Sustainable rubberized concrete mixed with surface treated PCM lightweight aggregates subjected to high temperature cycle. Constr. Build. Mater. 2021, 303, 124535. [Google Scholar] [CrossRef]

- Al-Yasiri, Q.; Szabó, M. Effect of encapsulation area on the thermal performance of PCM incorporated concrete bricks: A case study under Iraq summer conditions. Case Stud. Constr. Mater. 2021, 15, e00686. [Google Scholar] [CrossRef]

- Cui, H.; Zou, J.; Gong, Z.; Zheng, D.; Bao, X.; Chen, X. Study on the thermal and mechanical properties of steel fibre reinforced PCM-HSB concrete for high performance in energy piles. Constr. Build. Mater. 2022, 350, 128822. [Google Scholar] [CrossRef]

- Wu, D.; Rahim, M.; El Ganaoui, M.; Bennacer, R.; Djedjig, R.; Liu, B. Dynamic hygrothermal behavior and energy performance analysis of a novel multilayer building envelope based on PCM and hemp concrete. Constr. Build. Mater. 2022, 341, 127739. [Google Scholar] [CrossRef]

- Sawadogo, M.; Benmahiddine, F.; Hamami, A.E.A.; Belarbi, R.; Godin, A.; Duquesne, M. Investigation of a novel bio-based phase change material hemp concrete for passive energy storage in buildings. Appl. Therm. Eng. 2022, 212, 118620. [Google Scholar] [CrossRef]

- Dora, S.; Barta, R.B.; Mini, K. Study on foam concrete incorporated with expanded vermiculite/capric acid PCM—A novel thermal storage high-performance building material. Constr. Build. Mater. 2023, 392, 131903. [Google Scholar] [CrossRef]

- Li, D.; Tang, Y.; Zuo, X.; Zhao, X.; Zhang, X.; Yang, H. Preparation of hierarchical porous microspheres composite phase change material for thermal energy storage concrete in buildings. Appl. Clay Sci. 2023, 232, 106771. [Google Scholar] [CrossRef]

- Al-Yasiri, Q.; Szabó, M. Thermal analysis of concrete bricks-embedded phase change material: A case study under hot weather conditions. Case Stud. Constr. Mater. 2023, 18, e02193. [Google Scholar] [CrossRef]

- Muntasell, J.; Barrio, M.; Font, J.; López, D.O.; Tamarit, J.L.; Diarte, M.A.C.; Guion, J.; Teisseire, M.; Chanh, N.B.; Haget, Y. Plastic crystals and their potential use in new technologies. J. Therm. Anal. Calorim. 1991, 37, 2395–2398. [Google Scholar] [CrossRef]

- Fallahi, A.; Guldentops, G.; Tao, M.; Granados-Focil, S.; Van Dessel, S. Review on solid-solid phase change materials for thermal energy storage: Molecular structure and thermal properties. Appl. Therm. Eng. 2017, 127, 1427–1441. [Google Scholar] [CrossRef]

| Authors (Year) [Reference] | Configuration/Composition | Type of Study | Studied Parameters | Results/Findings |

|---|---|---|---|---|

| D’Alessandro et al. (2018) [49] | Concrete innovations using paraffin-based polymer cementitious materials. | Experimental | Impact of adding PCM on density and compressive strength. | When PCM is added to concrete, the material’s density drops by about double the weight of the PCM itself. While adding PCM reduces average compressive strength, it has less of an effect on the coefficient of variation, which bodes well for the structural dependability of the material. |

| Cao et al. (2018) [50] | Microencapsulated phase change materials (MPCM) are embedded inside a geopolymer concrete (GPC) matrix. | Numerical and experimental | Effect of MPCM quantity and concrete thickness. | With more MPCM and thicker concrete walls, it takes less energy to keep a room at a comfortable 23 °C. Using a concrete wall with 5.2 wt.% MPCM at 75 mm thickness led to a decrease in electricity consumption of about 35%. |

| Cao et al. (2018) [51] | From multi-phase phase transition materials to geopolymer concrete. | Experimental | Effect of MPCM size on the bonds between the microcapsules and the GPC matrix. | It was discovered that decreasing the size of the MPCM strengthened the bonds between the matrix of GPC and microcapsules, thereby increasing the capability of GPC for storing energy. |

| Qian and Li (2018) [52] | Shape-stabilised composite PCM made of n-octadecane (OC) as well as diatomite is introduced into the cement composite. | Experimental | Impact of PCM on thermal conductivity, thermal energy storage capacity, and the cement’s chemical, mechanical, and thermal dependability. | Incorporating more OC/DC into cement mixes reduced its thermal conductivity and increased its thermal energy storage capacity, and the cement’s chemical, mechanical, and thermal dependability remained mostly unaffected by the 400 melt-freeze cycles. |

| Moldgy and Parameshwaran (2018) [53] | Applications of organic PCM in waste heat recovery systems. | Experimental | Effect of organic PCM on thermal conductivity, thermal stability, and phase transition. | The organic PCM used has shown strong thermal conductivity, thermal stability, and a phase transition temperature of 60.8 °C, in addition to a high latent heat capacity of 164.28 kJ/kg. |

| Tian et al. (2019) [54] | Paraffin oil may be used to autoclave aerated concrete (AAC). | Numerical and experimental | Effect of paraffin on the thermal insulating properties. | Adding more paraffin lowers the thermal insulating properties of pure AAC because its thermal conductivity rises as its paraffin concentration rises. |

| Zéhil and Assaad (2019) [55] | Using XLPE scraps as an additive in cement. | Experimental | Effect of XLPE scraps on residual compressive strengths. | The residual compressive strengths of XLPE-modified concrete mixes decrease due to the thermal breakdown of XLPE after exposure to heat. |

| Afgan et al. (2019) [56] | To successfully encapsulate the aggregate holding phase transition materials, a nano-refined epoxy paste was created employing the optimal proportions of nano-silica fume and graphite powder. | Experimental | Impact of incorporating macro-encapsulated aggregates. | A compressive strength of over 15 MPa was shown by the thermocrete created by incorporating macro-encapsulated aggregates at a rate of 100%. This material has the potential to reduce energy consumption. |

| Pongsopha et al. (2019) [57] | Paraffin is blended with charred clay particles. | Experimental | Effect of paraffin blended with the charred clay particles. | Using PIA, regular burned clay aggregate concrete gained strength and thermal insulation. |

| Hassan et al. (2019) [58] | The volume ratios of 25%, 50%, and 75% were used to include innovative GP-L-PCM macrocapsules into GPC. | Experimental | Impact of innovative geopolymer-coated expanded clay-phase change material macrocapsules into geopolymer concrete (GPC). | Maximum surface temperatures on LECA and GP-L-PCM slabs are lower than those of GPC slabs by 5.6 °C and 8.0 °C, respectively, indicating decreased heat transfer. |

| Cao et al. (2019) [59] | The walls were made of GPC and MPCM. | Numerical | Effect of MPCM addition and concrete wall thickness on the energy efficiency of buildings. | The higher quantities of MPCM added to denser walls of concrete were found to enhance the construction’s energy efficacy. |

| Chen et al. (2020) [60] | Mixed with porous asphalt concrete, this composite material comprises a shell of SiO2 as well as a phase transition material of PEG. | Experimental | Impact of using a shell of SiO2 and material of PEG. | The optimal replacement amount was found to be 1.4% of the total weight of aggregate, while the suitable particle size range for phase change composites was found to be 0.6–1.18 mm. |

| Kim et al. (2020) [61] | Paraffin wax, silicon carbide, and slag aggregate form a phase change material (PCM)/SiC-based composite aggregate used in concrete. | Experimental | Incorporation of PCM/SiC-based composite aggregate into the concrete construction. | The incorporation of PCM/SiC-based composite aggregate into the concrete construction led to a 3 °C reduction in both ambient and latent heat. |

| Chin et al. (2020) [62] | Up to 31% of the paraffin mass was retained by the activated carbon. | Experimental | Impact of adding paraffin-OPKS-activated carbon. | The thermal lag and peak temperature of the composite PCM phase transition are both increased in concrete panels that comprise paraffin-OPKS-activated carbon. |

| Benkaddour et al. (2020) [63] | Paraffin wax PCM is the intermediate layer of a three-layer composite PCM/concrete wall. | Numerical | Paraffin wax PCM has a latent heat storage capacity. | With further paraffin removal from the wall-mounted solar absorber, the PCM’s latent heat storage capacity decreases. |

| Ramakrishnan et al. (2021) [64] | Composite integrated aerated/foamed geopolymer concrete (GFC) made from phase change materials (PCMs). | Experimental | Effect of composite integrated aerated/foamed geopolymer concrete. | The peak indoor temperature of the test room was lowered by 1.85 °C and 3.76 °C, respectively, when 15% and 30% PCM composite were included, while the thermal storage capability increased by 105% and 181%. |

| Gencel et al. (2022) [65] | Composite PCM made from rice husk ash (RHA) and lauryl alcohol (LA) is the basis for a novel kind of environmentally friendly foam concrete (FC). | Experimental | Impact of PCM made from rice husk ash (RHA) and lauryl alcohol (LA) on daily energy. | FC-LFCPCM50 wallboard may reduce daily energy use by 14.28 kWh. |

| Kalombe et al. (2023) [66] | Personalised concoctions of coconut oil, soy oil, and paraffin wax. | Experimental | Impact of coconut oil, soy oil, and paraffin wax on heat storage capacity and the rate at which water freezes. | A PCM consisting of both paraffin wax and soybean oil significantly increases heat storage capacity and reduces the rate at which water freezes. |

| Authors (Year) [Reference] | Configuration/Composition | Type of Study | Studied Parameters | Results/Findings |

|---|---|---|---|---|

| Liua et al. (2018) [67] | Form-stable hydrate salt cement mortar. | Experimental | Impact of incorporation of form-stable hydrate salt PCMs on mechanical strength and energy storage. | Despite a drop in mechanical strength due to the incorporation of form-stable hydrate salt PCMs, thermal energy storage cement-based composites are nevertheless suitable for use in the construction of building envelopes. |

| Erlbeck et al. (2018) [68] | A wooden box with infrared radiators and a chiller for testing several shapes of phase-change packaging, including cubes, cylinders, plates, and spheres. | Numerical and experimental | Effects of thermal shading and uniform PCM dispersion inside concrete blocks. | Reduced heat transfer into interior spaces is achieved by the use of thermal shading and uniform PCM dispersion inside concrete blocks. |

| Bahrar et al. (2018) [69] | Microencapsulated phase change materials (PCMs) are being incorporated into new textile-reinforced concrete panels, which come in a wide range of mix patterns. | Numerical and experimental | Microencapsulated phase change materials (PCMs) are being incorporated into new textile reinforced concrete panels. | The thermal conductivity of concrete is decreased when PCM particles are mixed into the concrete’s bulk, and this effect is amplified when more and more PCMs are used. |

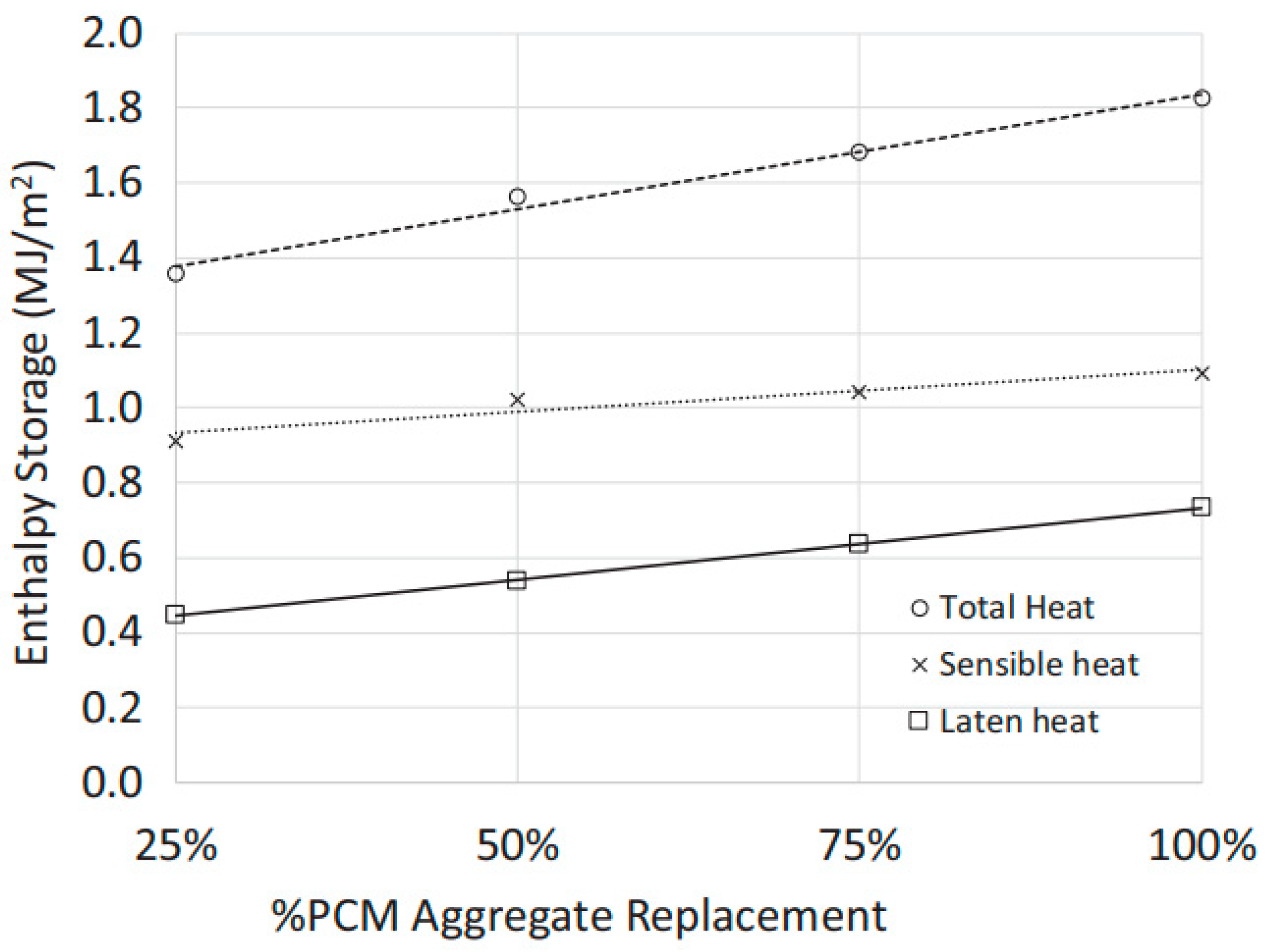

| Sukontasukkul et al. (2019) [70] | Phase change material (PCM)-heavy lightweight concrete (up to roughly 7.8% by weight of concrete). | Experimental | Effect of incorporating phase change material (PCM)-heavy, lightweight concrete on the concrete’s characteristics. | As the percentage of PCM aggregate rises, the mechanical characteristics seem to improve. It was discovered that when the PCM aggregate replacement rate increased, so did the latent heat. |

| Vigneshwaran et al. (2019) [71] | An efficient concrete thermal energy storage (CTES) technology. | Numerical and experimental | Effect of HTF temperature on the heat transfer rate. | As the temperature of the Heat Transfer Fluid (HTF) decreases throughout the length of the CTES module, the heat transfer rate decreases correspondingly. |

| Mohseni et al. (2020) [72] | Macroporous ceramic microsphere-lightweight aggregate (PCM-LWA) concrete. | Experimental | Impact of incorporating macroporous ceramic microsphere-lightweight aggregate (PCM-LWA) concrete. | Compared to the control combination, TESA concrete had a cooler surface temperature. |

| Qu et al. (2020) [73] | Low-thermal-conductivity phase-change foam concrete with an appropriate phase-change temperature. | Experimental | Impact of composite PCM inside the concrete. | The phase variation temperature (around 41 °C) as well as the phase variation latent heat of the suggested composite PCM inside the concrete are both acceptable. |

| Drissi et al. (2020) [74] | A new kind of phase change material aggregate (AGGsPCM) with a coreshell structure. | Experimental | Effect of phase change material aggregates (AGGsPCM) with a coreshell structure on phase transition temperature. | Increasing the amount of MPCMs in AGGsPCM or choosing a PCM with a more appropriate phase transition temperature might improve performance by making heat storage and release more efficient. |

| Djamai et al. (2021) [75] | Phase change material (PCM)-enhanced textile-reinforced concrete (TRC) composite. | Experimental | Effect of phase change material (PCM) on enhanced textile-reinforced concrete (TRC) composite. | The (10 wt%) PCM-TRC slab (with a thickness of 4.5 cm) reduces peak temperatures by 4 °C and reduces energy consumption by 37% compared to the standard TRC slab. |

| Parameshwaran et al. (2021) [76] | Micro-concrete composite (MbPMC) with encapsulated bio-based phase transition material (MbP). | Experimental | Impact of MbPMC on storing thermal energy in buildings. | The effectiveness and durability of micro-concrete composites (MbPMC) for storing thermal energy as well as providing passive cooling in constructions. |

| Essid et al. (2022) [77] | Variations in PCM content in concrete compositions. | Numerical and experimental | Effect of PCM content in concrete compositions. | The delayed peak temperatures highlighted the improved energy efficiency of PCM wallboards over conventional concrete, particularly in the case of the bilayer wallboard. |

| Martelletto et al. (2022) [78] | PCMs were a binary salt combination of 40% KNO3 and 60% NaNO3, which was absorbed by the porous fossil flour diatomite. | Numerical and experimental | Impact of integrating PCM on the quantity of thermal energy stored and released. | The greatest PCM integration percentage simulated was 40%, and this resulted in a doubling of the quantity of thermal energy stored and released. |

| Tetuko et al. (2023) [79] | Lightweight aggregate, cement, sand, and water made up the components of the concrete that was made. | Experimental | Effect of the addition of magnetite particles to paraffin on the thermal conductivity. | When compared to pure paraffin (0.32 W/m °C) and PEG (0.28 W/m °C), the addition of magnetite particles in paraffin may increase the thermal conductivity to 0.53 W/m °C. |

| Frahat et al. (2023) [80] | PCMs in mortar are eco-friendly. | Experimental | Impact of PCMs on thermal performance. | The use of ceramic in lieu of sand was shown to improve thermal performance. |

| Authors (Year) [Reference] | Configuration/Composition | Type of Study | Studied Parameters | Results/Findings |

|---|---|---|---|---|

| Wang et al. (2018) [81] | The PCM was a ternary fatty acid eutectic comprising lauric, myristic, and palmitic acids, and the thermal energy storage aggregates were made from diatomite and ceramsite. | Experimental | Impact of PCM on the compressive strength of concrete and energy storage. | The concrete’s compressive strength with the aggregate’s thermal energy storage at a volume fraction of 80% is more than 18 MPa. Early age hydration temperature increases can be better suppressed by using a diatomite-based thermal energy storage aggregate as opposed to a ceramsite-based one. |

| Yeon et al. (2018) [82] | A melamine-formaldehyde resin was used to microencapsulate PCM. | Experimental | Effect of incorporating PCM on the mortar’s compressive and flexural strengths and volume stability. | Incorporating PCM that has been MPCM was shown to reduce the mortar’s compressive and flexural strengths but improve its volume stability at younger ages. |

| Urgessa et al. (2019) [83] | The concrete was microencapsulated with phase change material (PCM) that had a low transition temperature. | Experimental | Impact of incorporating PCM on transition temperature. | It was discovered that PCM worked best when temperatures fluctuated near the transition temperature (mild-cold seasons), but lost its significance when exposed to severe climatic extremes like freezing winters or scorching summers for an extended period of time. |

| Nayak et al. (2019) [84] | Concrete pavements using phase-change materials. | Numerical | Impact of incorporating PCMs into concrete on the damage caused by freeze-thaw cycles. | Incorporating PCMs into concrete significantly reduces the damage caused by freeze-thaw cycles. |

| Li et al. (2019) [85] | Preferred Phase-Change Materials and Low-Weight Aggregates. | Experimental | When PCM carriers made up as much as half the volume of the LWA, the amount of heat emitted by the PCM was significant enough to prevent ice formation. | |

| Cao et al. (2019) [86] | Phase-change material-equipped multilayer walls. | Numerical and experimental | Effect of phase-change material equipped with multilayer walls. | Although the high heat storage capacity of the MPCM/PCM may be mitigated by increasing the insulating layer’s thickness and decreasing its thermal conductivity, doing so greatly affects the efficiency of the heating and cooling systems. |

| Doretti et al. (2019) [87] | Using a single-phase working fluid flowing via a tube implanted in the concrete, a parallelepiped-shaped concrete module may be heated (during the charging phase) or cooled (during the discharging phase). | Numerical and experimental | Effect of oil mass flow on effectiveness. | The effectiveness maximises at an asymptotic value as the oil’s mass flow and time rise. |

| Ren et al. (2020) [88] | To inhibit the leaking of PCMs, ceramite or pumice may be infused with PCMs and then covered with a multi-layer shell. | Experimental | Impact of incorporating PCMs. | Maximum decreases in central room temperature while using ETESC made from ceramsite and ETESC made from pumice were 4.7 degrees Celsius and 8.7 degrees Celsius, respectively. |

| Uthaichotirat et al. (2020) [89] | Concrete has a low specific gravity because it is made by soaking porous particles in PCM. | Experimental | Effect of incorporating PCM on density, compressive strength, and flexural strength of concrete. | There are strong correlations between PCM aggregate composition and density, compressive strength, and flexural strength. Increasing PCM aggregates is also associated with better thermal behaviour. |

| Arivazhagan et al. (2020) [90] | Concrete blocks have layers of phase-change materials embedded in them. | Experimental | Impact of the addition of PCM to concrete blocks. | The addition of PCM to concrete blocks led to a 3 °C decrease in the maximum air temperature compared to blocks without PCM. |

| Ram et al. (2020) [91] | Cement may be replaced by a mixture of fly ash and ground-granulated blast furnace slag (GGBS). | Experimental | Impact of the PCN-PCM composites. | The PCN-PCM composite’s latent heat potential was high, meaning it was able to store thermal energy and maintain a constant 24 °C in the test room’s air. |

| Liu et al. (2020) [92] | This new SHSPCM synthetic heat storage format makes use of phase change materials. | Numerical and experimental | Effect of PCM on mechanical strength and hydration. | Using this innovative heat storage technology, concrete treated at a temperature of −15 °C obtained exceptional mechanical strength and rapid hydration. |

| Shen et al. (2021) [93] | To improve PCM-concrete’s heat-storage capabilities, we added clastic light shale ceramsite (CLSC). | Experimental | Impact of adding clastic light shale ceramsite (CLSC) on PCM-concrete’s heat-storage capabilities. | The average specific heat capacity of PCM-concrete thermal storage blocks rose via 12.54% (2 wt.% PCM), 31.60 (4 wt.% PCM), and 41.23% (6 wt.% PCM), whereas the thermal conductivity and compressive strength decreased with the increase in PCM weight percentage. |

| Pongsopha et al. (2021) [94] | Coated PCMA (ASF-PCMA) and polymethyl methacrylate. | Experimental | Impact of using coated PCMA (ASF-PCMA) and poly(methyl methacrylate). | After being put through 100 heat/cool cycles, the ASF coating reduced PCM leakage by around 5.4 times. |

| Al-Yasiri and Szabó (2021) [95] | Incorporating the PCM into the blocks of concrete. | Experimental | Impact of incorporating phase change material (PCM) into concrete blocks. | The highest PTR, HTRc, and TD are achieved by Brick-D, relative to the reference brick, at maximum outside temperatures of 156.5%, −61%, and −133%, respectively. |

| Cui et al. (2022) [96] | To produce PCM-HSB aggregates, a hollow steel ball (HSB) is used to macro-encapsulate the PCM. | Experimental | The effect of using fibre-reinforced PCM-HSB. | By increasing concrete’s heat capacity and bearing capacity, the suggested fibre-reinforced PCM-HSB may secure energy piles’ future uses. |

| Wu et al. (2022) [97] | PCM and a bio-based hygroscopic material (hemp concrete) are merged to create a unique multi-layer building shell. | Experimental | Impact of PCM and a bio-based hygroscopic material. | When compared to a setup without PCM, the peak T was delayed by 70.4%, the T/RH amplitude was decreased by 50%/60%, and energy usage was decreased by 15.3%. |

| Sawadogo et al. (2022) [98] | Hemp-PCM concrete is made with renewable materials. | Experimental | Impact of hemp PCM concrete. | With an ultimate period shift of 30 min as well as a discrepancy in temperature between the reference and the PCM hemp concrete of about 4.6 °C, the PCM hemp concrete has excellent thermo-regulating potential. |

| Dora et al. (2023) [99] | Different types of foam concrete using EV, PCM made from CA-EA and EV, as well as PCM with nano silica and coir fibres added (PSC). | Experimental | Impact of using different types of foam concrete on the thermal analysis. | Results of the thermal analysis tests showed that the PSC-5% has a higher heat storage capacity, leading to higher levels of thermal comfort in buildings. |

| Li et al. (2023) [100] | Spray-dried microspheres of hierarchical porous composite (PCN) material. | Experimental | Impact of spray-dried microspheres of hierarchical porous composite (PCN) material on the thermal management of buildings. | P-PCN’s elevated melting enthalpy of 130.2 J/g demonstrates considerable improvements in the thermal management of buildings. |

| Al-Yasiri and Szabó (2023) [101] | PCM layers and capsules are made from concrete bricks. | Experimental | Impact of PCM layer/capsules on the thermal and mechanical characteristics. | The PCM layer made from bricks performed better thermally, whereas the PCM capsules performed better mechanically. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rashid, F.L.; Al-Obaidi, M.A.; Dulaimi, A.; Bernardo, L.F.A.; Eleiwi, M.A.; Mahood, H.B.; Hashim, A. A Review of Recent Improvements, Developments, Effects, and Challenges on Using Phase-Change Materials in Concrete for Thermal Energy Storage and Release. J. Compos. Sci. 2023, 7, 352. https://doi.org/10.3390/jcs7090352

Rashid FL, Al-Obaidi MA, Dulaimi A, Bernardo LFA, Eleiwi MA, Mahood HB, Hashim A. A Review of Recent Improvements, Developments, Effects, and Challenges on Using Phase-Change Materials in Concrete for Thermal Energy Storage and Release. Journal of Composites Science. 2023; 7(9):352. https://doi.org/10.3390/jcs7090352

Chicago/Turabian StyleRashid, Farhan Lafta, Mudhar A. Al-Obaidi, Anmar Dulaimi, Luís Filipe Almeida Bernardo, Muhammad Asmail Eleiwi, Hameed B. Mahood, and Ahmed Hashim. 2023. "A Review of Recent Improvements, Developments, Effects, and Challenges on Using Phase-Change Materials in Concrete for Thermal Energy Storage and Release" Journal of Composites Science 7, no. 9: 352. https://doi.org/10.3390/jcs7090352

APA StyleRashid, F. L., Al-Obaidi, M. A., Dulaimi, A., Bernardo, L. F. A., Eleiwi, M. A., Mahood, H. B., & Hashim, A. (2023). A Review of Recent Improvements, Developments, Effects, and Challenges on Using Phase-Change Materials in Concrete for Thermal Energy Storage and Release. Journal of Composites Science, 7(9), 352. https://doi.org/10.3390/jcs7090352