Rapid Prototyping in Pakistan: A Technical Feasibility Study with Analytical Hierarchy Process Analysis, Bridging Civil and Industrial Engineering Perspectives †

Abstract

:1. Introduction

2. Methodology

2.1. Hierarchy Structure

2.2. Criterion

2.3. Alternatives

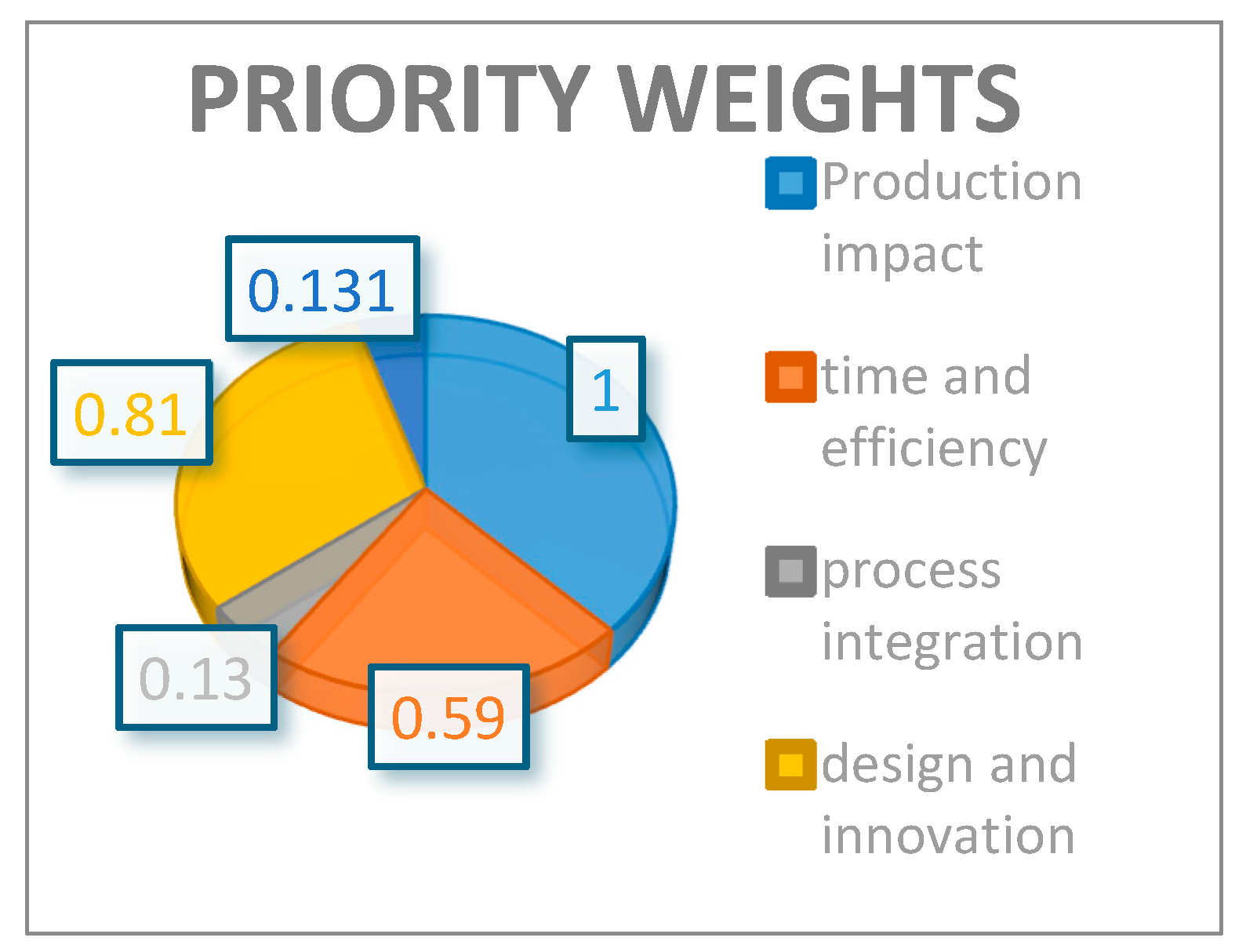

3. Priority Weights Assigned

4. Results

4.1. Inconsistency Ratio

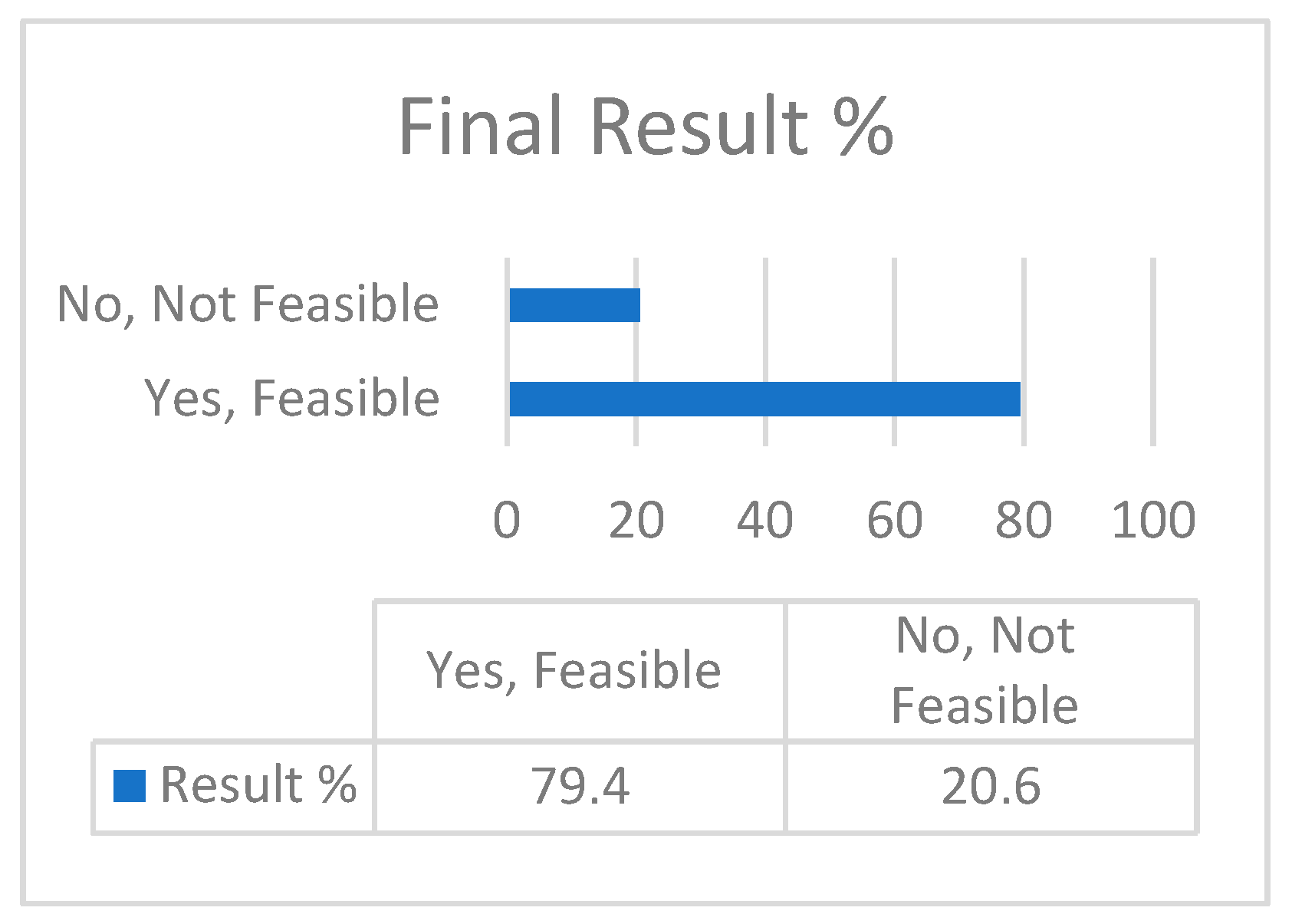

4.2. Alternative Selection

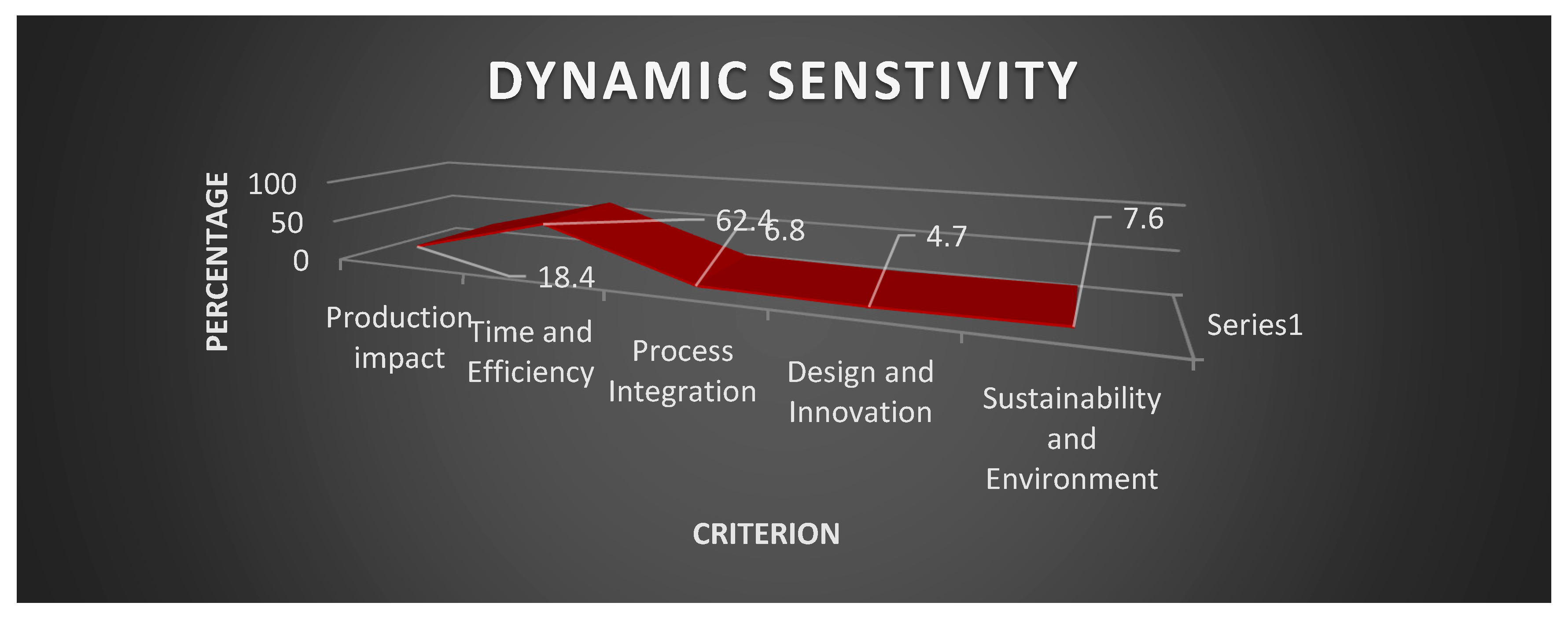

5. Sensitivity Analysis

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Hamidi, F.; Aslani, F. Additive manufacturing of cementitious composites: Materials, methods, potentials, and challenges. Constr. Build. Mater. 2019, 218, 582–609. [Google Scholar] [CrossRef]

- Huang, Y.; Leu, M.C.; Mazumder, J.; Donmez, A. Additive manufacturing: Current state, future potential, gaps and needs, and recommendations. J. Manuf. Sci. Eng. Trans. ASME 2015, 137, 014001. [Google Scholar] [CrossRef]

- Zhai, Y.; Lados, D.A.; Lagoy, J.L. Additive Manufacturing: Making Imagination the Major Limitation. JOM 2014, 66, 808–816. [Google Scholar] [CrossRef]

- Paolini, A.; Kollmannsberger, S.; Rank, E. Additive manufacturing in construction: A review on processes, applications, and digital planning methods. Addit. Manuf. 2019, 30, 100894. [Google Scholar] [CrossRef]

- Craveiro, F.; Duarte, J.P.; Bartolo, H.; Bartolo, P.J. Additive manufacturing as an enabling technology for digital construction: A perspective on Construction 4.0. Autom. Constr. 2019, 103, 251–267. [Google Scholar] [CrossRef]

- Ghaffar, S.H.; Corker, J.; Fan, M. Additive manufacturing technology and its implementation in construction as an eco-innovative solution. Autom. Constr. 2018, 93, 1–11. [Google Scholar] [CrossRef]

- Attaran, M. Additive Manufacturing: The Most Promising Technology to Alter the Supply Chain and Logistics. J. Serv. Sci. Manag. 2017, 10, 189–206. [Google Scholar] [CrossRef]

- Lakshmanan, R.; Nyamekye, P.; Virolainen, V.M.; Piili, H. The convergence of lean management and additive manufacturing: Case of manufacturing industries. Clean. Eng. Technol. 2023, 13, 100620. [Google Scholar] [CrossRef]

- Walia, K.; Khan, A.; Breedon, P. Polymer-based additive manufacturing: Process optimization for low-cost industrial robotics manufacture. Polymers 2021, 13, 2809. [Google Scholar] [CrossRef] [PubMed]

- Kalinke, C.; Crapnell, R.D.; De Oliveira, P.R.; Janegitz, B.C.; Bonacin, J.A.; Banks, C.E. How to improve sustainability in fused filament fabrication (3D printing) research? Glob. Chall. 2024, 8, 2300408. [Google Scholar] [CrossRef] [PubMed]

- Yadav, A.; Bhatnagar, A. Sustainable digital manufacturing processes in Industry 4.0. In Sustainability in Smart Manufacturing; CRC Press: Boca Raton, FL, USA, 2024; pp. 19–36. [Google Scholar] [CrossRef]

- Global 3D Printer Market Size, Forecast, Analysis & Share Surpass US$ 149.4 Billion by 2030, at 20.5% CAGR. J. Cyber Policy 2023. Available online: https://journalofcyberpolicy.com/latest-global-3d-printer-market-size-forecast-analysis-share-surpass-us-149-4-billion-by-2030-at-20-5-cagr/ (accessed on 12 September 2024).

- Dixit, N.K.; Srivastava, R.; Narain, R. Comparison of Two Different Rapid Prototyping System Based on Dimensional Performance Using Grey Relational Grade Method. Procedia Technol. 2016, 25, 908–915. [Google Scholar] [CrossRef]

- Kumar, N.; Kumar, H.; Khurmi, J.S. Experimental Investigation of Process Parameters for Rapid Prototyping Technique (Selective Laser Sintering) to Enhance the Part Quality of Prototype by Taguchi Method. Procedia Technol. 2016, 23, 352–360. [Google Scholar] [CrossRef]

- Li, C.; Yang, M.; Xie, Y.; Chen, Z.; Wang, C.; Bai, Y.; Zhu, X.; Li, M. Application of the polystyrene model made by 3-D printing rapid prototyping technology for operation planning in revision lumbar discectomy. J. Orthop. Sci. 2015, 20, 475–480. [Google Scholar] [CrossRef] [PubMed]

- Gil, R.S.; Roig, A.M.; Obispo, C.A.; Morla, A.; Pagès, C.M.; Perez, J.L. Surgical planning and microvascular reconstruction of the mandible with a fibular flap using computer-aided design, rapid prototype modeling, and pre-contoured titanium reconstruction plates: A prospective study. Br. J. Oral Maxillofac. Surg. 2015, 53, 49–53. [Google Scholar] [CrossRef] [PubMed]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mukhtar, G.A.; Shehzadi, S.; Ali, M.M.; Malik, A.A.; Arshad, M.M. Rapid Prototyping in Pakistan: A Technical Feasibility Study with Analytical Hierarchy Process Analysis, Bridging Civil and Industrial Engineering Perspectives. Eng. Proc. 2024, 75, 30. https://doi.org/10.3390/engproc2024075030

Mukhtar GA, Shehzadi S, Ali MM, Malik AA, Arshad MM. Rapid Prototyping in Pakistan: A Technical Feasibility Study with Analytical Hierarchy Process Analysis, Bridging Civil and Industrial Engineering Perspectives. Engineering Proceedings. 2024; 75(1):30. https://doi.org/10.3390/engproc2024075030

Chicago/Turabian StyleMukhtar, Ghulam Ameer, Sana Shehzadi, Muhammad Moazzam Ali, Abdul Ahad Malik, and Muhammad Mohsin Arshad. 2024. "Rapid Prototyping in Pakistan: A Technical Feasibility Study with Analytical Hierarchy Process Analysis, Bridging Civil and Industrial Engineering Perspectives" Engineering Proceedings 75, no. 1: 30. https://doi.org/10.3390/engproc2024075030