A Decade Review of Research Trends Using Waste Materials in the Building and Construction Industry: A Pathway towards a Circular Economy

Abstract

:1. Introduction

2. Research Significance and Methodologies

3. Bibliometric Assessment Findings

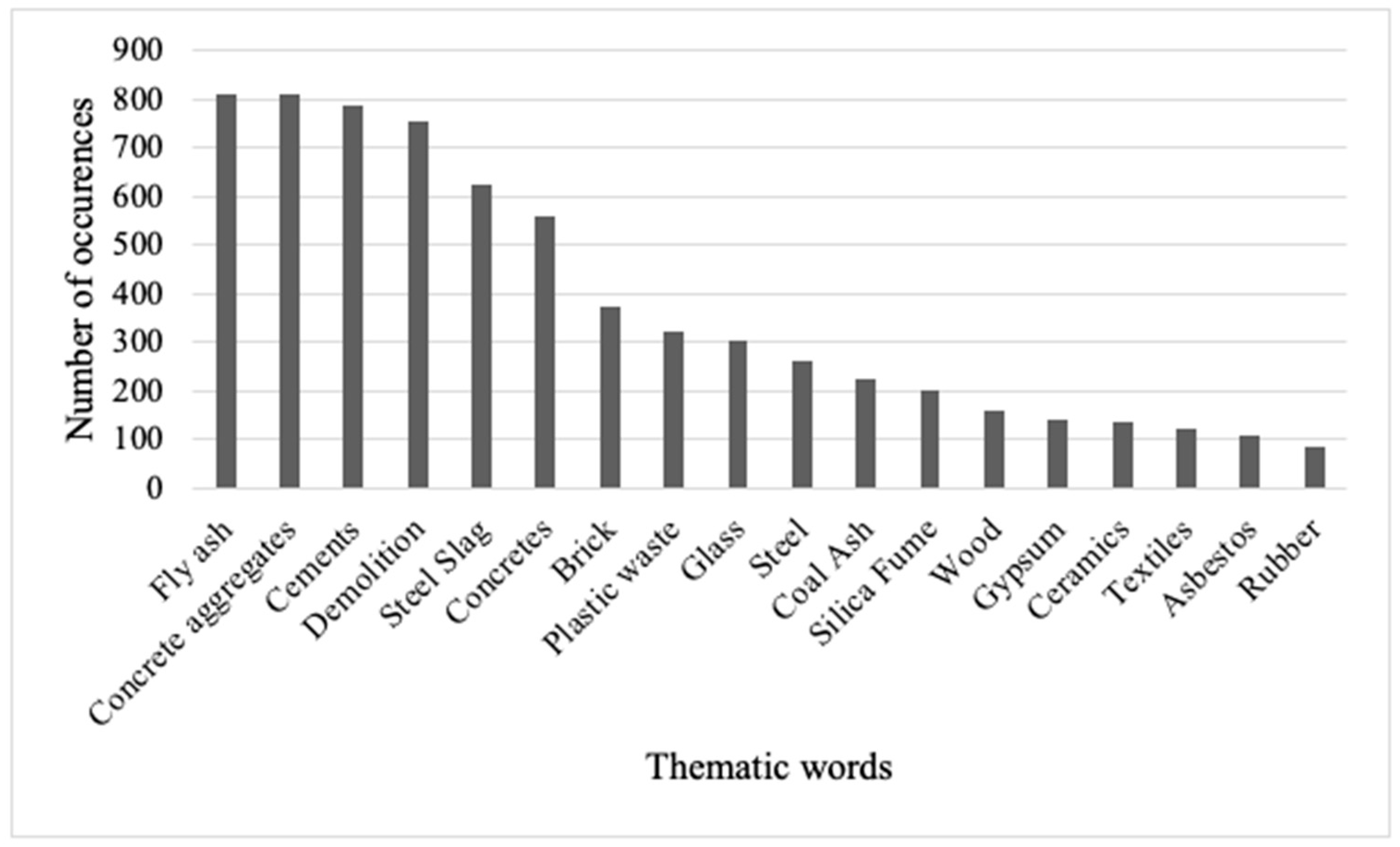

Summary of Bibliometric Assessment

- Rubber was the least researched waste material.

- Mechanical testing of compressive, tensile, and flexural is a key research focus.

- Fly Ash and slags are the dominant additives in concrete materials.

- Sustainability is a key driver of waste material research.

- Glass, steel, and plastics are heavy research focused.

- Gypsum, ceramics, and wood had similar trends of research focus.

4. Waste Materials

4.1. Rubber Waste

4.1.1. Sustainability Aspects of Using Rubber Waste

4.1.2. Applications and Viability of Using Waste Rubber

4.2. Textile Waste

4.2.1. Sustainability Aspects of Using Textile Waste

4.2.2. Applications and Viability of Using Textile Waste

4.3. Ceramic Waste

4.3.1. Sustainability Aspects of Using Ceramic Waste

4.3.2. Applications and Viability of Using Ceramic Waste

5. Conclusions, Limitations, and Future Research

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Oluleye, B.I.; Chan, D.W.; Olawumi, T.O.; Saka, A.B. Assessment of symmetries and asymmetries on barriers to circular economy adoption in the construction industry towards zero waste: A survey of international experts. Build. Environ. 2023, 228, 109885. [Google Scholar] [CrossRef]

- Upadhyay, A.; Laing, T.; Kumar, V.; Dora, M. Exploring barriers and drivers to the implementation of circular economy practices in the mining industry. Resour. Policy 2021, 72, 102037. [Google Scholar] [CrossRef]

- Kirchherr, J.; Piscicelli, L.; Bour, R.; Kostense-Smit, E.; Muller, J.; Huibrechtse-Truijens, A.; Hekkert, M. Barriers to the Circular Economy: Evidence from the European Union (EU). Ecol. Econ. 2018, 150, 264–272. [Google Scholar] [CrossRef]

- Oluleye, B.I.; Chan, D.W.; Olawumi, T.O. Barriers to circular economy adoption and concomitant implementation strategies in building construction and demolition waste management: A PRISMA and interpretive structural modeling approach. Habitat Int. 2022, 126, 102615. [Google Scholar] [CrossRef]

- Rios, F.C.; Grau, D.; Bilec, M. Barriers and Enablers to Circular Building Design in the US: An Empirical Study. J. Constr. Eng. Manag. 2021, 147, 04021117. [Google Scholar] [CrossRef]

- Schandl, H.; Miatto, A. On the importance of linking inputs and outputs in material flow accounts. The Weight of Nations report revisited. J. Clean. Prod. 2018, 204, 334–343. [Google Scholar] [CrossRef]

- European Commission. Circular Economy Action Plan. 2023. Available online: https://environment.ec.europa.eu/strategy/circular-economy-action-plan_en (accessed on 1 September 2023).

- Haigh, R.; Sandanayake, M.; Bouras, Y.; Vrcelj, Z. The durability performance of waste cardboard kraft fibre reinforced concrete. J. Build. Eng. 2023, 67, 106010. [Google Scholar] [CrossRef]

- Khan, M.I.; Siddique, R. Utilization of silica fume in concrete: Review of durability properties. Resour. Conserv. Recycl. 2011, 57, 30–35. [Google Scholar] [CrossRef]

- Sandanayake, M.; Gunasekara, C.; Law, D.; Zhang, G.; Setunge, S.; Wanijuru, D. Sustainable criterion selection framework for green building materials—An optimisation based study of fly-ash Geopolymer concrete. Sustain. Mater. Technol. 2020, 25, e00178. [Google Scholar] [CrossRef]

- Shobeiri, V.; Bennett, B.; Xie, T.; Visintin, P. Mix design optimization of concrete containing fly ash and slag for global warming potential and cost reduction. Case Stud. Constr. Mater. 2023, 18, e01832. [Google Scholar] [CrossRef]

- Haigh, R.; Sandanayake, M.; Bouras, Y.; Vrcelj, Z. A review of the mechanical and durability performance of kraft-fibre reinforced mortar and concrete. Constr. Build. Mater. 2021, 297, 123759. [Google Scholar] [CrossRef]

- Sandanayake, M.; Bouras, Y.; Haigh, R.; Vrcelj, Z. Current Sustainable Trends of Using Waste Materials in Concrete—A decade Review. Sustainability 2020, 12, 9622. [Google Scholar] [CrossRef]

- Haigh, R.; Joseph, P.; Sandanayake, M.; Bouras, Y.; Vrcelj, Z. Thermal Characterizations of Waste Cardboard Kraft Fibres in the Context of Their Use as a Partial Cement Substitute within Concrete Composites. Materials 2022, 15, 8964. [Google Scholar] [CrossRef] [PubMed]

- Haigh, R. A comparitive analysis of the mechanical properties with high volume waste cardboard fibres within concrete composite materials. In Proceedings of the Australasian Structural Engineering Conference: ASEC 2022, Melbourne, Australia, 9–10 November 2022; pp. 397–406. [Google Scholar]

- United Nations. Sustainable Development Goals. 2022. Available online: https://www.un.org/sustainabledevelopment/sustainable-development-goals/ (accessed on 1 August 2023).

- Kurniati, E.O.; Pederson, F.; Kim, H.-J. Application of steel slags, ferronickel slags, and copper mining waste as construction materials: A review. Resour. Conserv. Recycl. 2023, 198, 107175. [Google Scholar] [CrossRef]

- Maurya, N.; Srivastav, Y.; Rawat, S.; Ranjan, Y.; Srivastava, R.; Shukla, B.K.; Varadharajan, S. Reinforcing civil infrastructure with waste glass-enhanced concrete: A comprehensive review of properties, performance and applications. Mater. Today Proc. 2023; in press. [Google Scholar] [CrossRef]

- Elgarahy, A.M.; Priya, A.; Mostafa, H.Y.; Zaki, E.; Elsaeed, S.; Muruganandam, M.; Elwakeel, K.Z. Toward a circular economy: Investigating the effectiveness of different plastic waste management strategies: A comprehensive review. J. Environ. Chem. Eng. 2023, 11, 110993. [Google Scholar] [CrossRef]

- Mohajerani, A.; Vajna, J.; Cheung, T.H.H.; Kurmus, H.; Arulrajah, A.; Horpibulsuk, S. Practical recycling applications of crushed waste glass in construction materials: A review. Constr. Build. Mater. 2017, 156, 443–467. [Google Scholar] [CrossRef]

- Haigh, R.; Bouras, Y.; Sandanayake, M.; Vrcelj, Z. The mechanical performance of recycled cardboard kraft fibres within cement and concrete composites. Constr. Build. Mater. 2022, 317, 125920. [Google Scholar] [CrossRef]

- Munaro, M.R.; Tavares, S.F. A review on barriers, drivers, and stakeholders towards the circular economy: The construction sector perspective. Clean. Responsible Consum. 2023, 8, 100107. [Google Scholar] [CrossRef]

- Munaro, M.R.; Tavares, S.F.; Bragança, L. Towards circular and more sustainable buildings: A systematic literature review on the circular economy in the built environment. J. Clean. Prod. 2020, 260, 121134. [Google Scholar] [CrossRef]

- Ossio, F.; Salinas, C.; Hernández, H. Circular economy in the built environment: A systematic literature review and definition of the circular construction concept. J. Clean. Prod. 2023, 414, 137738. [Google Scholar] [CrossRef]

- Yan, L.; Kasal, B.; Huang, L. A review of recent research on the use of cellulosic fibres, their fibre fabric reinforced cementitious, geo-polymer and polymer composites in civil engineering. Compos. Part B Eng. 2016, 92, 94–132. [Google Scholar] [CrossRef]

- Aria, M.; Cuccurullo, C. bibliometrix: An R-tool for comprehensive science mapping analysis. J. Informetr. 2017, 11, 959–975. [Google Scholar] [CrossRef]

- United Nations. The 2030 Agenda for Sustainable Development. 2015. Available online: https://sdgs.un.org/goals (accessed on 2 August 2022).

- US Tire Manufacturers Association. Whats in a Tire. Available online: https://www.ustires.org/whats-tire-0 (accessed on 5 September 2023).

- TyreStewardship Australia. Australia Tyre Consumption and Recovery. Available online: https://www.tyrestewardship.org.au/wp-content/uploads/2022/03/TSA-Tyre-Consumption-Recovery.pdf (accessed on 4 September 2023).

- Popular Mechanics. Our Waste Tire Problem Is Getting Worse. 2018. Available online: https://www.popularmechanics.com/cars/car-technology/a22553570/waste-tires/ (accessed on 4 September 2023).

- EPA (United States Environmental Protection Agency). Guide to the Facts and Figures Report about Materials, Waste and Recycling. Available online: https://www.epa.gov/facts-and-figures-about-materials-waste-and-recycling/guide-facts-and-figures-report-about#Materials (accessed on 4 September 2023).

- Shukla, B.K.; Gupta, A.; Gowda, S.; Srivastav, Y. Constructing a greener future: A comprehensive review on the sustainable use of fly ash in the construction industry and beyond. Mater. Today Proc. 2023. [Google Scholar] [CrossRef]

- Michelin. Car Tyre Recycling. Available online: https://www.michelin.com.au/auto/advice/change-tyres/car-tyre-recycling (accessed on 4 September 2023).

- Haigh, R.; Bouras, Y.; Sandanayake, M.; Vrcelj, Z. Economic and environmental optimisation of waste cardboard kraft fibres in concrete using nondominated sorting genetic algorithm. J. Clean. Prod. 2023, 426, 138989. [Google Scholar] [CrossRef]

- Phuang, Z.X.; Mulya, K.S.; Hoy, Z.X.; Woon, K.S. Moving towards plastic waste circularity: Redefining extended producer responsibility with externality consideration via P-graph-life cycle optimization framework. Resour. Conserv. Recycl. 2023, 198, 107187. [Google Scholar] [CrossRef]

- Zhang, J.; Zhang, G.; Bhuiyan, M.A.; Agostino, J. Comparative life cycle assessment of kerbside collection methods for waste glass cullet for asphalt production. J. Clean. Prod. 2022, 374, 134055. [Google Scholar] [CrossRef]

- The Observers. The Toxic Impacts of Fires at the Worlds Largest Tyre Graveyard in Kuwait. Available online: https://observers.france24.com/en/tv-shows/the-observers/20211015-the-toxic-impacts-of-fires-at-the-world-s-largest-tyre-graveyard-in-kuwait (accessed on 5 September 2023).

- Stormwater Shepherds. The Impact of Stormwater- Tyre Rubber. 2023. Available online: https://www.stormwatershepherds.org.au/blog/the-impact-of-stormwater-tyre-rubber/ (accessed on 5 September 2023).

- Mohajerani, A.; Burnett, L.; Smith, J.V.; Markovski, S.; Rodwell, G.; Rahman, M.T.; Kurmus, H.; Mirzababaei, M.; Arulrajah, A.; Horpibulsuk, S.; et al. Recycling waste rubber tyres in construction materials and associated environmental considerations: A review. Resour. Conserv. Recycl. 2020, 155, 104679. [Google Scholar] [CrossRef]

- Hua, X.; Wang, D. Tire-rubber related pollutant 6-PPD quinone: A review of its transformation, environmental distribution, bioavailability, and toxicity. J. Hazard. Mater. 2023, 459, 132265. [Google Scholar] [CrossRef]

- Tushar, Q.; Santos, J.; Zhang, G.; Bhuiyan, M.A.; Giustozzi, F. Recycling waste vehicle tyres into crumb rubber and the transition to renewable energy sources: A comprehensive life cycle assessment. J. Environ. Manag. 2022, 323, 116289. [Google Scholar] [CrossRef]

- Kishan, G.S.; Kumar, Y.H.; Sakthivel, M.; Vijayakumar, R.; Lingeshwaran, N. Life cycle assesment on tire derived fuel as alternative fuel in cement industry. Mater. Today Proc. 2021, 47, 5483–5488. [Google Scholar] [CrossRef]

- Ma, Y.; Ma, X.; Luan, Y.; Jiang, S.; Zhang, J. Research on key influencing factors of scrap tire-soil retaining wall. Case Stud. Constr. Mater. 2023, 19, e02277. [Google Scholar] [CrossRef]

- Bodus, B.; O’Malley, K.; Dieter, G.; Gunawardana, C.; McDonald, W. Review of emerging contaminants in green stormwater infrastructure: Antibiotic resistance genes, microplastics, tire wear particles, PFAS, and temperature. Sci. Total. Environ. 2023, 906, 167195. [Google Scholar] [CrossRef]

- Schneider, K.; de Hoogd, M.; Madsen, M.P.; Haxaire, P.; Bierwisch, A.; Kaiser, E. ERASSTRI—European Risk Assessment Study on Synthetic Turf Rubber Infill—Part 1: Analysis of infill samples. Sci. Total. Environ. 2020, 718, 137174. [Google Scholar] [CrossRef] [PubMed]

- Wang, S.; Guo, X.; Yang, Y.; Liu, H. Compression and consolidation characteristics analysis of waste tire powder bed during gas pressurization. Chem. Eng. Res. Des. 2023, 197, 1–8. [Google Scholar] [CrossRef]

- Zhao, Z.; Wu, S.; Xie, J.; Yang, C.; Yang, X.; Chen, S.; Liu, Q. Recycle of waste tire rubber powder in a novel asphalt rubber pellets for asphalt performance enhancement. Constr. Build. Mater. 2023, 399, 132572. [Google Scholar] [CrossRef]

- Makitan, V. Waste Tyre Recycling: Current Status, Economic Analysis and Process Development. Ph.D. Thesis, Curtin University, Perth, Australia, 2010. [Google Scholar]

- Kerekes, Z.; Lublóy, É.; Kopecskó, K. Behaviour of tyres in fire. J. Therm. Anal. Calorim. 2018, 133, 279–287. [Google Scholar] [CrossRef]

- Islam, M.M.U.; Li, J.; Roychand, R.; Saberian, M.; Chen, F. A comprehensive review on the application of renewable waste tire rubbers and fibers in sustainable concrete. J. Clean. Prod. 2022, 374, 133998. [Google Scholar] [CrossRef]

- Chen, G.; Zheng, D.-P.; Chen, Y.-W.; Lin, J.-X.; Lao, W.-J.; Guo, Y.-C.; Chen, Z.-B.; Lan, X.-W. Development of high performance geopolymer concrete with waste rubber and recycle steel fiber: A study on compressive behavior, carbon emissions and economical performance. Constr. Build. Mater. 2023, 393, 131988. [Google Scholar] [CrossRef]

- Dong, W.; Li, W.; Wang, K.; Luo, Z.; Sheng, D. Self-sensing capabilities of cement-based sensor with layer-distributed conductive rubber fibres. Sens. Actuators A Phys. 2020, 301, 111763. [Google Scholar] [CrossRef]

- Gill, P.; Jangra, P.; Roychand, R.; Saberian, M.; Li, J. Effects of various additives on the crumb rubber integrated geopolymer concrete. Clean. Mater. 2023, 8, 100181. [Google Scholar] [CrossRef]

- Golafshani, E.M.; Arashpour, M.; Kashani, A. Green mix design of rubbercrete using machine learning-based ensemble model and constrained multi-objective optimization. J. Clean. Prod. 2021, 327, 129518. [Google Scholar] [CrossRef]

- Mohammed, B.S.; Adamu, M.; Liew, M.S. Evaluating the effect of crumb rubber and nano silica on the properties of high volume fly ash roller compacted concrete pavement using non-destructive techniques. Case Stud. Constr. Mater. 2018, 8, 380–391. [Google Scholar] [CrossRef]

- Onuaguluchi, O.; Panesar, D.K. Hardened properties of concrete mixtures containing pre-coated crumb rubber and silica fume. J. Clean. Prod. 2014, 82, 125–131. [Google Scholar] [CrossRef]

- Sidhu, A.S.; Siddique, R. Durability assessment of sustainable metakaolin based high strength concrete incorporating crumb tire rubber. J. Build. Eng. 2023, 72, 106660. [Google Scholar] [CrossRef]

- Valizadeh, A.; Hamidi, F.; Aslani, F.; Shaikh, F.U.A. The effect of specimen geometry on the compressive and tensile strengths of self-compacting rubberised concrete containing waste rubber granules. Structures 2020, 27, 1646–1659. [Google Scholar] [CrossRef]

- Wang, Q.-Z.; Wang, N.-N.; Tseng, M.-L.; Huang, Y.-M.; Li, N.-L. Waste tire recycling assessment: Road application potential and carbon emissions reduction analysis of crumb rubber modified asphalt in China. J. Clean. Prod. 2020, 249, 119411. [Google Scholar] [CrossRef]

- Zafar, I.; Rashid, K.; Tariq, S.; Ali, A.; Ju, M. Integrating technical-environmental-economical perspectives for optimizing rubber content in concrete by multi-criteria analysis. Constr. Build. Mater. 2022, 319, 125820. [Google Scholar] [CrossRef]

- Oleksik, M.; Dobrotă, D.; Dimulescu, C.S.; Dumitrașcu, O.; Petrașcu, R. Advanced use of waste rubber and fly ash to ensure an efficient circular economy. Ain Shams Eng. J. 2023; 102264, in press. [Google Scholar] [CrossRef]

- Ma, Q.; Mao, Z.; Zhang, J.; Du, G.; Li, Y. Behavior evaluation of concrete made with waste rubber and waste glass after elevated temperatures. J. Build. Eng. 2023, 78, 107639. [Google Scholar] [CrossRef]

- Valente, M.; Sambucci, M.; Chougan, M.; Ghaffar, S.H. Composite alkali-activated materials with waste tire rubber designed for additive manufacturing: An eco-sustainable and energy saving approach. J. Mater. Res. Technol. 2023, 24, 3098–3117. [Google Scholar] [CrossRef]

- Buddhacosa, N.; Khatibi, A.; Das, R.; Giustozzi, F.; Galos, J.; Kandare, E. Crush behaviour and vibration damping properties of syntactic foam incorporating waste tyre-derived crumb rubber. J. Mater. Res. Technol. 2023, 26, 3214–3233. [Google Scholar] [CrossRef]

- Xu, J.; Houndehou, J.D.; Wang, Z.; Ma, Q. Experimental investigation on the mechanical properties and damage evolution of steel-fiber-reinforced crumb rubber concrete with porcelain tile waste. Constr. Build. Mater. 2023, 370, 130643. [Google Scholar] [CrossRef]

- HimaBindu, K.; Naidu, L.N.; Hari, S.S.; Ashok, N.; Redd, O.R.M.; Kumar, T.S.; Sandeep, E. Experimental study on mechanical properties of M−25 grade concrete with cow dung ash and waste rubber tube pieces. Mater. Today Proc. 2023. [Google Scholar] [CrossRef]

- Eslami, A.; Akbarimehr, D. Failure analysis of clay soil-rubber waste mixture as a sustainable construction material. Constr. Build. Mater. 2021, 310, 125274. [Google Scholar] [CrossRef]

- Juveria, F.; Rajeev, P.; Jegatheesan, P.; Sanjayan, J. Impact of stabilisation on mechanical properties of recycled concrete aggregate mixed with waste tyre rubber as a pavement material. Case Stud. Constr. Mater. 2023, 18, e02001. [Google Scholar] [CrossRef]

- Pal, A.; Ahmed, K.S.; Hossain, F.Z.; Alam, M.S. Machine learning models for predicting compressive strength of fiber-reinforced concrete containing waste rubber and recycled aggregate. J. Clean. Prod. 2023, 423, 138673. [Google Scholar] [CrossRef]

- Valente, M.; Sambucci, M.; Sibai, A.; Iannone, A. Novel cement-based sandwich composites engineered with ground waste tire rubber: Design, production, and preliminary results. Mater. Today Sustain. 2022, 20, 100247. [Google Scholar] [CrossRef]

- Singh, B.K.; Kumar, R. Novel lightweight Portland Pozzolana cement (PPC) stabilized mud composites using crumb rubber & agricultural waste: Physico-mechanical and thermal performance. Mater. Today Proc. 2023. [Google Scholar] [CrossRef]

- Zhang, J.; Niu, W.; Yang, Y.; Hou, D.; Dong, B. Research on the mechanical properties of polyvinyl alcohol-modified waste rubber-filled cement paste using digital image correlation technology. Compos. Struct. 2023, 320, 117164. [Google Scholar] [CrossRef]

- Peng, L.; Ge, D.; Lv, S.; Xue, Y.; Chen, J.; Sun, H.; Wang, J. Use of waste rubber particles in cement-stabilized aggregate for the eco-friendly pavement base layer construction: Laboratory performance and field application. Constr. Build. Mater. 2023, 402, 133023. [Google Scholar] [CrossRef]

- Bai, R.; Zhang, J.; Yan, C.; Liu, S.; Wang, X.; Jiang, Z. Waste rubber-modified sulfur-fly ash-sand composites as low CO2-emission cements. Mater. Chem. Phys. 2023, 306, 128060. [Google Scholar] [CrossRef]

- Zhu, Z.; Lu, Y.; Zhou, M. A functionalized waste tire rubber powders for mitigating leaching of heavy metal ions and enhancing photocatalytic properties of rubberized cement mortar. J. Build. Eng. 2023, 78, 107749. [Google Scholar] [CrossRef]

- Werdine, D.; Oliver, G.A.; de Almeida, F.A.; Noronha, M.d.L.; Gomes, G.F. Analysis of the properties of the self-compacting concrete mixed with tire rubber waste based on design of experiments. Structures 2021, 33, 3461–3474. [Google Scholar] [CrossRef]

- Aleem, M.A.U.; Siddique, M.S.; Farooq, S.H.; Usman, M.; Ahsan, M.H.; Hussain, M.; Hanif, A. Axial compressive behavior of concrete incorporating crumb rubber pretreated with waste quarry dust. J. Build. Eng. 2022, 59, 105086. [Google Scholar] [CrossRef]

- Al-Tarbi, S.M.; Al-Amoudi, O.S.B.; Al-Osta, M.A.; Al-Awsh, W.A.; Ali, M.R.; Maslehuddin, M. Development of eco-friendly hollow concrete blocks in the field using wasted high-density polyethylene, low-density polyethylene, and crumb tire rubber. J. Mater. Res. Technol. 2022, 21, 1915–1932. [Google Scholar] [CrossRef]

- Letelier, V.; Bustamante, M.; Muñoz, P.; Rivas, S.; Ortega, J.M. Evaluation of mortars with combined use of fine recycled aggregates and waste crumb rubber. J. Build. Eng. 2021, 43, 103226. [Google Scholar] [CrossRef]

- Zhu, X.; Chen, X.; Tian, H.; Ning, Y. Experimental and numerical investigation on fracture characteristics of self-compacting concrete mixed with waste rubber particles. J. Clean. Prod. 2023, 412, 137386. [Google Scholar] [CrossRef]

- Xu, J.; Chen, X.; Yu, B. Experimental and simulation study of rubber/cement paste interface modified by waste paint and silica in two stages. Constr. Build. Mater. 2023, 382, 131323. [Google Scholar] [CrossRef]

- Xu, G.; Yao, Y.; Ma, T.; Hao, S.; Ni, B. Experimental study and molecular simulation on regeneration feasibility of high-content waste tire crumb rubber modified asphalt. Constr. Build. Mater. 2023, 369, 130570. [Google Scholar] [CrossRef]

- Tang, Y.; Feng, W.; Chen, Z.; Nong, Y.; Guan, S.; Sun, J. Fracture behavior of a sustainable material: Recycled concrete with waste crumb rubber subjected to elevated temperatures. J. Clean. Prod. 2021, 318, 128553. [Google Scholar] [CrossRef]

- Zhou, W.; Mo, J.; Xiang, S.; Zeng, L. Impact of elevated temperatures on the mechanical properties and microstructure of waste rubber powder modified polypropylene fiber reinforced concrete. Constr. Build. Mater. 2023, 392, 131982. [Google Scholar] [CrossRef]

- Aureliano, F.; Ariellen, A.; Júnior, I.; Pedroso, R. Pedroso Manufacture of structural blocks of concrete with waste tire rubbers. Procedia Manuf. 2019, 38, 464–470. [Google Scholar] [CrossRef]

- Zhu, Y.; Xu, G.; Ma, T.; Fan, J.; Li, S. Performances of rubber asphalt with middle/high content of waste tire crumb rubber. Constr. Build. Mater. 2022, 335, 127488. [Google Scholar] [CrossRef]

- Zhao, C.; Li, R.; Kuang, D.; Li, X.; Pei, J. Preparation of direct injection waste PE/rubber powder composite modified granules and performance for recycling asphalt. Constr. Build. Mater. 2023, 367, 130124. [Google Scholar] [CrossRef]

- Chen, Z.; Liang, Y.; Lin, Y.; Cai, J. Recycling of waste tire rubber as aggregate in impact-resistant engineered cementitious composites. Constr. Build. Mater. 2022, 359, 129477. [Google Scholar] [CrossRef]

- Zhu, X.; Jiang, Z. Reuse of waste rubber in pervious concrete: Experiment and DEM simulation. J. Build. Eng. 2023, 71, 106452. [Google Scholar] [CrossRef]

- Turkben, M.; Kocaman, S.; Özmeral, N.; Soydal, U.; Cerit, A.; Ahmetli, G. Sustainable production of recycled rubber waste composites with various epoxy systems: A comparative study on mechanical and thermal properties. Ind. Crop. Prod. 2023, 195, 116490. [Google Scholar] [CrossRef]

- Ince, C.; Shehata, B.M.H.; Derogar, S.; Ball, R.J. Towards the development of sustainable concrete incorporating waste tyre rubbers: A long-term study of physical, mechanical & durability properties and environmental impact. J. Clean. Prod. 2022, 334, 130223. [Google Scholar] [CrossRef]

- Hole, G.; Hole, A.S. Recycling as the way to greener production: A mini review. J. Clean. Prod. 2018, 212, 910–915. [Google Scholar] [CrossRef]

- TheRoundup. 17 Most Worrying Textile Waste Statistics and Facts. 2023. Available online: https://theroundup.org/textile-waste-statistics/ (accessed on 5 September 2023).

- Khan, M.I.; Wang, L.; Padhye, R. Textile waste management in Australia: A review. Resour. Conserv. Recycl. Adv. 2023, 18, 200154. [Google Scholar] [CrossRef]

- Earth.ORG. 10 Concerning Fast Fashion Waste Statistics. 2023. Available online: https://earth.org/statistics-about-fast-fashion-waste/ (accessed on 5 September 2023).

- News European Parliament. The Impact of Textile Production and Waste on the Environment (Infographics). 2023. Available online: https://www.europarl.europa.eu/news/en/headlines/society/20201208STO93327/the-impact-of-textile-production-and-waste-on-the-environment-infographics (accessed on 5 September 2023).

- EPA (United States Environmental Protection Agency). Fashion Forward: Fabric Recycling and Reuse This Spring. 2023. Available online: https://www.epa.gov/perspectives/fashion-forward-fabric-recycling-and-reuse-spring (accessed on 5 September 2023).

- Smith, C. Australia’s Textile Waste Problem and How the Key Players Are Responding. 2021. Available online: https://www.claytonutz.com/knowledge/2021/december/australias-textile-waste-problem-and-how-the-key-players-are-responding (accessed on 5 September 2023).

- Zhou, C.; Shi, S.Q.; Chen, Z.; Cai, L.; Smith, L. Comparative environmental life cycle assessment of fiber reinforced cement panel between kenaf and glass fibers. J. Clean. Prod. 2018, 200, 196–204. [Google Scholar] [CrossRef]

- Muthu, S.S. Assessing the environmental impact of textiles. In Assessing the Environmental Impact of Textiles and the Clothing Supply Chain; Woodhead Publishing: Hong Kong, China, 2020; pp. 181–186. [Google Scholar] [CrossRef]

- Fashion, S. The Water Consumption Attributable to Cotton Production. 2021. Available online: https://sustainfashion.info/the-water-consumption-attributable-to-cotton-production/ (accessed on 5 September 2023).

- Liu, Y.; Huang, H.; Zhu, L.; Zhang, C.; Ren, F.; Liu, Z. Could the recycled yarns substitute for the virgin cotton yarns: A comparative LCA. Int. J. Life Cycle Assess. 2020, 25, 2050–2062. [Google Scholar] [CrossRef]

- Loo, S.-L.; Yu, E.; Hu, X. Tackling critical challenges in textile circularity: A review on strategies for recycling cellulose and polyester from blended fabrics. J. Environ. Chem. Eng. 2023, 11, 110482. [Google Scholar] [CrossRef]

- Damayanti, D.; Wulandari, L.A.; Bagaskoro, A.; Rianjanu, A.; Wu, H.-S. Possibility Routes for Textile Recycling Technology. Polymers 2021, 13, 3834. [Google Scholar] [CrossRef]

- Duhoux, T.; Maes, E.; Hirschnitz-Garbers, M.; Peeters, K.; Asscherickx, L.; Christis, M.; Colignon, P.; Hinzmann, M.; Sachdeva, A. Study on the technical, regulatory, economic and environmental effectiveness of textile fibres recycling. Eur. Comm. Dir.-Gen. Intern. Mark. Ind. Entrep. SMEs 2021, 10, 828412. [Google Scholar]

- Ragaert, K.; Delva, L.; Van Geem, K. Mechanical and chemical recycling of solid plastic waste. Waste Manag. 2017, 69, 24–58. [Google Scholar] [CrossRef]

- Abdalla, J.A.; Hawileh, R.A.; Bahurudeen, A.; Jyothsna, G.; Sofi, A.; Shanmugam, V.; Thomas, B. A comprehensive review on the use of natural fibers in cement/geopolymer concrete: A step towards sustainability. Case Stud. Constr. Mater. 2023, 19, e02244. [Google Scholar] [CrossRef]

- Rostami, R.; Zarrebini, M.; Mandegari, M.; Sanginabadi, K.; Mostofinejad, D.; Abtahi, S.M. The effect of concrete alkalinity on behavior of reinforcing polyester and polypropylene fibers with similar properties. Cem. Concr. Compos. 2019, 97, 118–124. [Google Scholar] [CrossRef]

- Peña-Pichardo, P.; Martínez-Barrera, G.; Martínez-López, M.; Ureña-Núñez, F.; dos Reis, J.M.L. Recovery of cotton fibers from waste Blue-Jeans and its use in polyester concrete. Constr. Build. Mater. 2018, 177, 409–416. [Google Scholar] [CrossRef]

- Spadea, S.; Farina, I.; Carrafiello, A.; Fraternali, F. Recycled nylon fibers as cement mortar reinforcement. Constr. Build. Mater. 2015, 80, 200–209. [Google Scholar] [CrossRef]

- Rahman, S.S.; Siddiqua, S.; Cherian, C. Sustainable applications of textile waste fiber in the construction and geotechnical industries: A retrospect. Clean. Eng. Technol. 2022, 6, 100420. [Google Scholar] [CrossRef]

- Echeverria, C.A.; Handoko, W.; Pahlevani, F.; Sahajwalla, V. Cascading use of textile waste for the advancement of fibre reinforced composites for building applications. J. Clean. Prod. 2019, 208, 1524–1536. [Google Scholar] [CrossRef]

- Broda, J.; Grzybowska-Pietras, J.; Nguyen, G.; Gawlowski, A.; Laszczak, R.; Przybylo, S. Application of recycled fibres and geotextiles for the stabilisation of steep slopes. Mater. Sci. Eng. 2017, 254, 192005. [Google Scholar] [CrossRef]

- Stanković, S.B.; Popović, D.; Poparić, G.B. Thermal properties of textile fabrics made of natural and regenerated cellulose fibers. Polym. Test. 2008, 27, 41–48. [Google Scholar] [CrossRef]

- Sharkawi, A.M.; Mehriz, A.M.; Showaib, E.A.; Hassanin, A. Performance of sustainable natural yarn reinforced polymer bars for construction applications. Constr. Build. Mater. 2018, 158, 359–368. [Google Scholar] [CrossRef]

- Lior, N.; Erez, G.; Alva, P. Tensile behavior of fabric-cement-based composites reinforced with non-continuous load bearing yarns. Constr. Build. Mater. 2020, 236, 117432. [Google Scholar] [CrossRef]

- Silva, R.M.d.C.; Zhao, J.; Liebscher, M.; Curosu, I.; Silva, F.d.A.; Mechtcherine, V. Bond behavior of polymer- and mineral-impregnated carbon fiber yarns towards concrete matrices at elevated temperature levels. Cem. Concr. Compos. 2022, 133, 104685. [Google Scholar] [CrossRef]

- Zhu, D.; Bai, X.; Yao, Q.; Rahman, Z.; Li, X.; Yang, T.; Guo, S. Effects of volume fraction and surface coating of textile yarns on the tensile performance of AR-glass textile reinforced concrete. J. Build. Eng. 2023, 71, 106420. [Google Scholar] [CrossRef]

- Li, H.; Liebscher, M.; Ranjbarian, M.; Hempel, S.; Tzounis, L.; Schröfl, C.; Mechtcherine, V. Electrochemical modification of carbon fiber yarns in cementitious pore solution for an enhanced interaction towards concrete matrices. Appl. Surf. Sci. 2019, 487, 52–58. [Google Scholar] [CrossRef]

- Sciegaj, A.; Larsson, F.; Lundgren, K. Experiments and calibration of a bond-slip relation and efficiency factors for textile reinforcement in concrete. Cem. Concr. Compos. 2022, 134, 104756. [Google Scholar] [CrossRef]

- Zhang, X.; Aljewifi, H.; Li, J. Failure behaviour investigation of continuous yarn reinforced cementitious composites. Constr. Build. Mater. 2013, 47, 456–464. [Google Scholar] [CrossRef]

- Donnini, J.; Lancioni, G.; Corinaldesi, V. Failure modes in FRCM systems with dry and pre-impregnated carbon yarns: Experiments and modeling. Compos. Part B Eng. 2018, 140, 57–67. [Google Scholar] [CrossRef]

- Franco, A.; Pisano, G.; Schiavi, L.; De Luca, G.; Bonati, A. Influence of displacement rate in the tensile testing of dry yarns for composite materials used in masonry strengthening. Procedia Struct. Integr. 2023, 44, 2246–2253. [Google Scholar] [CrossRef]

- Kurban, M.; Babaarslan, O.; Çağatay, H. Investigation of the flexural behavior of textile reinforced concrete with braiding yarn structure. Constr. Build. Mater. 2022, 334, 127434. [Google Scholar] [CrossRef]

- Abd, S.M.; Mhaimeed, I.S.; Tayeh, B.A.; Najm, H.M.; Qaidi, S. Investigation of the use of textile carbon yarns as sustainable shear reinforcement in concrete beams. Case Stud. Constr. Mater. 2023, 18, e01765. [Google Scholar] [CrossRef]

- Nadiv, R.; Peled, A.; Mechtcherine, V.; Hempel, S.; Schroefl, C. Micro- and nanoparticle mineral coating for enhanced properties of carbon multifilament yarn cement-based composites. Compos. Part B Eng. 2017, 111, 179–189. [Google Scholar] [CrossRef]

- Weber, W.E.; Mechtcherine, V. Modeling the dynamic properties of fibre-reinforced concrete with different coating technologies of multifilament yarns. Cem. Concr. Compos. 2016, 73, 257–266. [Google Scholar] [CrossRef]

- Butler, M.; Hempel, S.; Mechtcherine, V. Modelling of ageing effects on crack-bridging behaviour of AR-glass multifilament yarns embedded in cement-based matrix. Cem. Concr. Res. 2011, 41, 403–411. [Google Scholar] [CrossRef]

- Liu, S.; Rawat, P.; Chen, Z.; Guo, S.; Shi, C.; Zhu, D. Pullout behaviors of single yarn and textile in cement matrix at elevated temperatures with varying loading speeds. Compos. Part B Eng. 2020, 199, 108251. [Google Scholar] [CrossRef]

- Griffths, A.B.R. An assessment of the properties and degradation behaviour of glass-®bre-reinforced polyester polymer concrete. Compos. Sci. Technol. 2000, 60, 2747–2753. [Google Scholar] [CrossRef]

- Siddique, R.; Kapoor, K.; Kadri, E.-H.; Bennacer, R. Effect of polyester fibres on the compressive strength and abrasion resistance of HVFA concrete. Constr. Build. Mater. 2012, 29, 270–278. [Google Scholar] [CrossRef]

- Zarei, M.; Kordani, A.A.; Ghamarimajd, Z.; Khajehzadeh, M.; Khanjari, M.; Zahedi, M. Evaluation of fracture resistance of asphalt concrete involving Calcium Lignosulfonate and Polyester fiber under freeze–thaw damage. Theor. Appl. Fract. Mech. 2022, 117, 103168. [Google Scholar] [CrossRef]

- Nadupuru, S.R.; Jain, R.; Joshi, D.A.; Menon, R. Experimental analysis using polypropylene, polyester and waste denim fiber in road construction. Mater. Today Proc. 2022, 66, 2363–2369. [Google Scholar] [CrossRef]

- Zakki, A.F.; Windyandari, A. Simplified FE model and experimental study on the tensile properties of the glass fiber reinforced polyester polymer. Heliyon 2022, 8, e10999. [Google Scholar] [CrossRef] [PubMed]

- Suda, V.R.; Sutradhar, R. Strength characteristics of micronized silica concrete with polyester fibres. Mater. Today Proc. 2020, 38, 3392–3396. [Google Scholar] [CrossRef]

- Haripriya, D.; Naidu, G.G. Study of strength related resources of hybrid fiber reinforced concrete (HFRC) and energy absorption capacity (EAC). Mater. Today Proc. 2023, 72, 2933–2938. [Google Scholar] [CrossRef]

- Niu, S.; Wang, Z.; Wang, J.; Wang, D.; Sun, X. Experimental investigation on flexural performance of polyester polyurethane concrete steel bridge deck composite structure. Case Stud. Constr. Mater. 2023, 18, e01915. [Google Scholar] [CrossRef]

- Anurag, K.; Xiao, F.; Amirkhanian, S.N. Laboratory investigation of indirect tensile strength using roofing polyester waste fibers in hot mix asphalt. Constr. Build. Mater. 2009, 23, 2035–2040. [Google Scholar] [CrossRef]

- Shamsuddin, S.-R.; Lee, K.-Y.; Bismarck, A. Ductile unidirectional continuous rayon fibre-reinforced hierarchical composites. Compos. Part A Appl. Sci. Manuf. 2016, 90, 633–641. [Google Scholar] [CrossRef]

- Chokshi, S.; Gohil, P.; Patel, D. Experimental investigations of bamboo, cotton and viscose rayon fiber reinforced Unidirectional composites. Mater. Today Proc. 2020, 28, 498–503. [Google Scholar] [CrossRef]

- Escanio, C.A.; Antunes, E.F.; Trava-Airoldi, V.J.; Corat, E.J. Influence of sodium and calcium contaminant in the growth of carbon nanotube on rayon-based carbon fibers. Mater. Sci. Eng. B 2023, 287, 116089. [Google Scholar] [CrossRef]

- Franciszczak, P.; Merijs-Meri, R.; Kalniņš, K.; Błędzki, A.; Zicans, J. Short-fibre hybrid polypropylene composites reinforced with PET and Rayon fibres—Effects of SSP and interphase tailoring. Compos. Struct. 2017, 181, 121–137. [Google Scholar] [CrossRef]

- Prabhakar, C.S.; Babu, P.R. Characterization of mechanical and thermal properties of high strength glass epoxy and rayon carbon phenolic composites. Mater. Today Proc. 2018, 5, 26898–26903. [Google Scholar] [CrossRef]

- Bosia, D.; Savio, L.; Thiebat, F.; Patrucco, A.; Fantucci, S.; Piccablotto, G.; Marino, D. Sheep Wool for Sustainable Architecture. Energy Procedia 2015, 78, 315–320. [Google Scholar] [CrossRef]

- Alyousef, R. Enhanced acoustic properties of concrete composites comprising modified waste sheep wool fibers. J. Build. Eng. 2022, 56, 104815. [Google Scholar] [CrossRef]

- Ghaffar, S.H.; Al-Kheetan, M.; Ewens, P.; Wang, T.; Zhuang, J. Investigation of the interfacial bonding between flax/wool twine and various cementitious matrices in mortar composites. Constr. Build. Mater. 2019, 239, 117833. [Google Scholar] [CrossRef]

- Alyousef, R.; Alabduljabbar, H.; Mohammadhosseini, H.; Mohamed, A.M.; Siddika, A.; Alrshoudi, F.; Alaskar, A. Utilization of sheep wool as potential fibrous materials in the production of concrete composites. J. Build. Eng. 2020, 30, 101216. [Google Scholar] [CrossRef]

- Wani, I.A.; Kumar, R.U.R. Experimental investigation on using sheep wool as fiber reinforcement in concrete giving increment in overall strength. Mater. Today Proc. 2021, 45, 4405–4409. [Google Scholar] [CrossRef]

- Sudalai, P.; Manoharan, M. Experimental study on affordable thermal insulation of exhaust manifolds using modified sheep wool waste. Mater. Today Proc. 2023. [Google Scholar] [CrossRef]

- Ilangovan, M.; Navada, A.P.; Guna, V.; Touchaleaume, F.; Saulnier, B.; Grohens, Y.; Reddy, N. Hybrid biocomposites with high thermal and noise insulation from discarded wool, poultry feathers, and their blends. Constr. Build. Mater. 2022, 345, 128324. [Google Scholar] [CrossRef]

- Altin, M.; Yildirim, G. Investigation of usability of boron doped sheep wool as insulation material and comparison with existing insulation materials. Constr. Build. Mater. 2022, 331, 127303. [Google Scholar] [CrossRef]

- Erkmen, J.; Sari, M. Hydrophobic thermal insulation material designed from hazelnut shells, pinecone, paper and sheep wool. Constr. Build. Mater. 2023, 365, 130131. [Google Scholar] [CrossRef]

- Atbir, A.; Cherkaoui, M.; El Wardi, F.Z.; Khabbaz, A. Improvement of thermomechanical characteristics of multilayer biomaterial of sheep wool and clay. Mater. Today Proc. 2022, 58, 1331–1336. [Google Scholar] [CrossRef]

- Dénes, O.; Florea, I.; Manea, D.L. Utilization of Sheep Wool as a Building Material. Procedia Manuf. 2019, 32, 236–241. [Google Scholar] [CrossRef]

- Fantilli, A.P.; Sicardi, S.; Dotti, F. The use of wool as fiber-reinforcement in cement-based mortar. Constr. Build. Mater. 2017, 139, 562–569. [Google Scholar] [CrossRef]

- Dlimi, M.; Iken, O.; Agounoun, R.; Kadiri, I.; Sbai, K. Dynamic assessment of the thermal performance of hemp wool insulated external building walls according to the Moroccan climatic zoning. J. Energy Storage 2019, 26, 101007. [Google Scholar] [CrossRef]

- Gocha, A. Clay Culture: Zero Waste. 2017. Available online: https://ceramicartsnetwork.org/ceramics-monthly/ceramics-monthly-article/Clay-Culture-Zero-Waste# (accessed on 5 September 2023).

- Ceramics of Italy. Recycling Waste, Reusing Water, Reducing Consumption. 2023. Available online: https://www.ceramica.info/en/articoli/recycling-waste-reusing-water-reducing-consumption/ (accessed on 6 September 2023).

- Intelligence, M. Italian Ceramic Tiles Market Size & Share Analysis—Growth Trends & Forecasts (2023–2028). 2022. Available online: https://www.mordorintelligence.com/industry-reports/italy-ceramic-tiles-market (accessed on 6 September 2023).

- Gautam, L.; Jain, J.K.; Jain, A.; Kalla, P. Recycling of bone china ceramic waste as cement replacement to produce sustainable self-compacting concrete. Structures 2022, 37, 364–378. [Google Scholar] [CrossRef]

- Hossain, S.S.; Roy, P. Sustainable ceramics derived from solid wastes: A review. J. Asian Ceram. Soc. 2020, 8, 984–1009. [Google Scholar] [CrossRef]

- European Commission. Internal Market, Industry, Entrepreneurship and SMEs- Ceramics. 2023. Available online: https://single-market-economy.ec.europa.eu/sectors/raw-materials/related-industries/non-metallic-products-and-industries/ceramics_en (accessed on 6 September 2023).

- Del Rio, D.D.F.; Sovacool, B.K.; Foley, A.M.; Griffiths, S.; Bazilian, M.; Kim, J.; Rooney, D. Decarbonizing the ceramics industry: A systematic and critical review of policy options, developments and sociotechnical systems. Renew. Sustain. Energy Rev. 2022, 157, 112081. [Google Scholar] [CrossRef]

- Ding, K.; Li, A.; Lv, J.; Gu, F. Decarbonizing ceramic industry: Technological routes and cost assessment. J. Clean. Prod. 2023, 419, 138278. [Google Scholar] [CrossRef]

- Chang, Y.; Yao, X.; Chen, Y.; Huang, L.; Zou, D. Review on ceramic-based composite phase change materials: Preparation, characterization and application. Compos. Part B Eng. 2023, 254, 110584. [Google Scholar] [CrossRef]

- United Nations. Take Urgent Action to Combat Climate Change and Its Impacts. 2023. Available online: https://unstats.un.org/sdgs/report/2021/goal-13/ (accessed on 5 August 2023).

- A Bernal, S.; Rodríguez, E.D.; Kirchheim, A.P.; Provis, J.L. Management and valorisation of wastes through use in producing alkali-activated cement materials. J. Chem. Technol. Biotechnol. 2016, 91, 2365–2388. [Google Scholar] [CrossRef]

- Cazacliu, B.; Sampaio, C.H.; Miltzarek, G.; Petter, C.; Le Guen, L.L.; Paranhos, R.S.; Huchet, F.; Kirchheim, A.P. The potential of using air jigging to sort recycled aggregates. J. Clean. Prod. 2014, 66, 46–53. [Google Scholar] [CrossRef]

- van Deventer, J.S.J.; Provis, J.L.; Duxson, P.; Brice, D.G. Chemical Research and Climate Change as Drivers in the Commercial Adoption of Alkali Activated Materials. Waste Biomass-Valorizat. 2010, 1, 145–155. [Google Scholar] [CrossRef]

- Chen, J.; Torres, J.F.; Hosseini, S.; Kumar, A.; Coventry, J.; Lipiński, W. High-temperature optical and radiative properties of alumina–silica-based ceramic materials for solar thermal applications. Sol. Energy Mater. Sol. Cells 2022, 242, 111710. [Google Scholar] [CrossRef]

- Joshi, P.; Parekh, D. Valorization of ceramic waste powder as cementitious blend in self-compacting concrete—A review. Mater. Today Proc. 2023, 77, 1007–1015. [Google Scholar] [CrossRef]

- Limami, H.; Manssouri, I.; Cherkaoui, K.; Khaldoun, A. Study of the suitability of unfired clay bricks with polymeric HDPE & PET wastes additives as a construction material. J. Build. Eng. 2019, 27, 100956. [Google Scholar] [CrossRef]

- Wong, C.L.; Mo, K.H.; Yap, S.P.; Alengaram, U.J.; Ling, T.-C. Potential use of brick waste as alternate concrete-making materials: A review. J. Clean. Prod. 2018, 195, 226–239. [Google Scholar] [CrossRef]

- Komnitsas, K.; Zaharaki, D.; Vlachou, A.; Bartzas, G.; Galetakis, M. Effect of synthesis parameters on the quality of construction and demolition wastes (CDW) geopolymers. Adv. Powder Technol. 2015, 26, 368–376. [Google Scholar] [CrossRef]

- Rovnaník, P.; Rovnaníková, P.; Vyšvařil, M.; Grzeszczyk, S.; Janowska-Renkas, E. Rheological properties and microstructure of binary waste red brick powder/metakaolin geopolymer. Constr. Build. Mater. 2018, 188, 924–933. [Google Scholar] [CrossRef]

- Younis, M.; Amin, M.; Tahwia, A.M. Durability and mechanical characteristics of sustainable self-curing concrete utilizing crushed ceramic and brick wastes. Case Stud. Constr. Mater. 2022, 17, e01251. [Google Scholar] [CrossRef]

- Iravanian, A.; Saber, S.A. Using Ceramic Wastes in Stabilization and Improving Soil Structures: A Review Study. In Proceedings of the IOP Conference Series: Earth and Environmental Science, Tashkent, Uzbekistan, 14–16 October 2020; Volume 614. [Google Scholar]

- Allaoui, D.; Nadi, M.; Hattani, F.; Majdoubi, H.; Haddaji, Y.; Mansouri, S.; Oumam, M.; Hannache, H.; Manoun, B. Eco-friendly geopolymer concrete based on metakaolin and ceramics sanitaryware wastes. Ceram. Int. 2022, 48, 34793–34802. [Google Scholar] [CrossRef]

- Amin, M.; Tayeh, B.A.; Agwa, I.S. Effect of using mineral admixtures and ceramic wastes as coarse aggregates on properties of ultrahigh-performance concrete. J. Clean. Prod. 2020, 273, 123073. [Google Scholar] [CrossRef]

- Chokkalingam, P.; El-Hassan, H.; El-Dieb, A.; El-Mir, A. Multi-response optimization of ceramic waste geopolymer concrete using BWM and TOPSIS-based taguchi methods. J. Mater. Res. Technol. 2022, 21, 4824–4845. [Google Scholar] [CrossRef]

- Ogawa, Y.; Bui, P.T.; Kawai, K.; Sato, R. Effects of porous ceramic roof tile waste aggregate on strength development and carbonation resistance of steam-cured fly ash concrete. Constr. Build. Mater. 2019, 236, 117462. [Google Scholar] [CrossRef]

- Ray, S.; Haque, M.; Rahman, M.; Sakib, N.; Al Rakib, K. Experimental investigation and SVM-based prediction of compressive and splitting tensile strength of ceramic waste aggregate concrete. J. King Saud Univ.—Eng. Sci. 2021. [Google Scholar] [CrossRef]

- Ray, S.; Rahman, M.; Haque, M.; Hasan, M.W.; Alam, M.M. Performance evaluation of SVM and GBM in predicting compressive and splitting tensile strength of concrete prepared with ceramic waste and nylon fiber. J. King Saud Univ.—Eng. Sci. 2023, 35, 92–100. [Google Scholar] [CrossRef]

- Liu, J.; Liu, T.; Wu, T.; Liu, J.; Lu, A. Analysis of pore morphology evolution of all-wastes ceramic foams based on the variation of composition and sintering process. Ceram. Int. 2023, 49, 29208–29217. [Google Scholar] [CrossRef]

- Aksoylu, C.; Özkılıç, Y.O.; Bahrami, A.; Yıldızel, S.A.; Hakeem, I.Y.; Özdöner, N.; Başaran, B.; Karalar, M. Application of waste ceramic powder as a cement replacement in reinforced concrete beams toward sustainable usage in construction. Case Stud. Constr. Mater. 2023, 19, e02444. [Google Scholar] [CrossRef]

- Mourou, C.; Zamorano, M.; Ruiz, D.P.; Martín-Morales, M. Characterization of ceramic tiles coated with recycled waste glass particles to be used for cool roof applications. Constr. Build. Mater. 2023, 398, 132489. [Google Scholar] [CrossRef]

- Chang, Q.; Liu, L.; Farooqi, M.U.; Thomas, B.; Özkılıç, Y.O. Data-driven based estimation of waste-derived ceramic concrete from experimental results with its environmental assessment. J. Mater. Res. Technol. 2023, 24, 6348–6368. [Google Scholar] [CrossRef]

- Yang, J.; Jiang, P.; Nassar, R.-U.; Suhail, S.A.; Sufian, M.; Deifalla, A.F. Experimental investigation and AI prediction modelling of ceramic waste powder concrete—An approach towards sustainable construction. J. Mater. Res. Technol. 2023, 23, 3676–3696. [Google Scholar] [CrossRef]

- Gharibi, H.; Mostofinejad, D.; Bahmani, H.; Hadadzadeh, H. Improving thermal and mechanical properties of concrete by using ceramic electrical insulator waste as aggregates. Constr. Build. Mater. 2022, 338, 127647. [Google Scholar] [CrossRef]

- Arias-Trujillo, J.; Matías-Sanchez, A.; Cantero, B.; López-Querol, S. Mechanical stabilization of aeolian sand with ceramic brick waste aggregates. Constr. Build. Mater. 2023, 363, 129846. [Google Scholar] [CrossRef]

- Cunha, S.; Costa, D.; Aguiar, J.B.; Castro, F. Mortars with the incorporation of treated ceramic molds shells wastes. Constr. Build. Mater. 2023, 365, 130074. [Google Scholar] [CrossRef]

- Goyal, R.K.; Agarwal, V.; Gupta, R.; Rathore, K.; Somani, P. Optimum utilization of ceramic tile waste for enhancing concrete properties. Mater. Today Proc. 2021, 49, 1769–1775. [Google Scholar] [CrossRef]

- Manikandan, K.; Nanthakumar, P.; Balachandar, M.; Shankar, D.G.; Vijayakumari, G. Partial replacement of aggregate with ceramic tile in concrete. Mater. Today Proc. 2023. [Google Scholar] [CrossRef]

- Balaji, Y.B.; Goud, E.S.K.; Yesuratnam, G. Study of concrete behavior by partial replacement of cement with Ceramic Waste Powder in the presence of Sisal fiber. Mater. Today Proc. 2023. [Google Scholar] [CrossRef]

- Gaibor, N.; Mateus, R.; Leitão, D.; Cristelo, N.; Miranda, T.; Pereira, E.N.; Cunha, V.M. Sustainability assessment of half-sandwich panels based on alkali-activated ceramic/slag wastes cement versus conventional building solutions. J. Clean. Prod. 2023, 389, 136108. [Google Scholar] [CrossRef]

- Cherene, M.G.P.; Xavier, G.d.C.; Barroso, L.d.S.; Oliveira, J.d.S.M.; de Azevedo, A.R.G.; Vieira, C.M.; Alexandre, J.; Monteiro, S.N. Technological and microstructural perspective of the use of ceramic waste in cement-based mortars. Constr. Build. Mater. 2023, 367, 130256. [Google Scholar] [CrossRef]

- Taher, M.J.; Abed, E.; Hashim, M.S. Using ceramic waste tile powder as a sustainable and eco-friendly partial cement replacement in concrete production. Mater. Today Proc. 2023. [Google Scholar] [CrossRef]

- Faldessai, K.; Lawande, S.; Kelekar, A.; Gurav, R.; Kakodkar, S. Utilization of ceramic waste as a partial replacement for cement in concrete manufacturing. Mater. Today Proc. 2023. [Google Scholar] [CrossRef]

- Meena, R.V.; Beniwal, A.S.; Gupta, G. Fresh characteristics and compressive strength evaluation of self-compacting concrete prepared with ceramic waste tile and fly ash. Mater. Today Proc. 2023. [Google Scholar] [CrossRef]

- Meena, R.V.; Jain, J.K.; Beniwal, A.S.; Chouhan, H.S. Sustainable self-compacting concrete containing waste ceramic tile aggregates: Fresh, mechanical, durability, and microstructural properties. J. Build. Eng. 2022, 57, 104941. [Google Scholar] [CrossRef]

- Yarramsetty, B.B.; Palakamsetti, S. Effect of partial replacement of cement with alkali activated Ceramic Waste Powder. Mater. Today Proc. 2023. [Google Scholar] [CrossRef]

- Achak, H.; Sohrabi, M.R.; Hoseini, S.O. Effects of microsilica and polypropylene fibers on the rheological properties, mechanical parameters and durability characteristics of green self-compacting concrete containing ceramic wastes. Constr. Build. Mater. 2023, 392, 131890. [Google Scholar] [CrossRef]

- Altheeb, A. Engineering attributes of alkali-activated mortars containing ceramic tiles waste as aggregates replacement: Effect of high-volume fly ash inclusion. Mater. Today Proc. 2023. [Google Scholar] [CrossRef]

- Meena, R.V.; Beniwal, A.S.; Jain, A.; Choudhary, R.; Mandolia, R. Evaluating resistance of ceramic waste tile self-compacting concrete to sulphuric acid attack. Constr. Build. Mater. 2023, 393, 132042. [Google Scholar] [CrossRef]

- Kavipriya, S.; Dhavashankaran, D.; Ramkumar, S.; Lingeshwaran, N.; Deepanraj, C. Flexural strength characteristics of high performance geopolymer concrete using ceramic waste aggregates and silica fume. Mater. Today Proc. 2022, 62, 6879–6883. [Google Scholar] [CrossRef]

- Paithankar, D.; Sharma, A.; Thenmozhi, S.; Ramteke, P.; Dhanalakshmi, A.; Sivakumar, S. Influence of glass powder silica fume and scrapped ceramic waste on the mechanical properties of concrete. Mater. Today Proc. 2023. [Google Scholar] [CrossRef]

- Uysal, M.; Aygörmez, Y.; Canpolat, O.; Cosgun, T.; Kuranlı, F. Investigation of using waste marble powder, brick powder, ceramic powder, glass powder, and rice husk ash as eco-friendly aggregate in sustainable red mud-metakaolin based geopolymer composites. Constr. Build. Mater. 2022, 361, 129718. [Google Scholar] [CrossRef]

- Ellatief, M.A.; Abadel, A.A.; Federowicz, K.; Elrahman, M.A. Mechanical properties, high temperature resistance and microstructure of eco-friendly ultra-high performance geopolymer concrete: Role of ceramic waste addition. Constr. Build. Mater. 2023, 401, 132677. [Google Scholar] [CrossRef]

- Jia, Z.; Aguiar, J.; de Jesus, C.; Castro, F.; Cunha, S. Physical and mechanical properties of lightweight concrete with incorporation of ceramic mold casting waste. Materialia 2023, 28, 101765. [Google Scholar] [CrossRef]

| Description | Results |

|---|---|

| Timespan | 2013:2024 |

| Sources (Journals, Books, etc.) | 1482 |

| Documents | 6238 |

| Document Average Age | 3.75 |

| Average citations per doc | 14.68 |

| References | 1 |

| Authors | 17,022 |

| Authors of single-authored docs | 384 |

| Single-authored docs | 561 |

| Co-Authors per Doc | 3.93 |

| Document types | |

| Article | 3775 |

| Book | 20 |

| Book chapter | 273 |

| Conference paper | 1738 |

| Review | 432 |

| Material Type | Material Application | Main Study Focus | Ref. |

|---|---|---|---|

| Tire rubber and steel fibres | Geopolymer concrete | Mechanical, microstructure, environmental and economical | [51] |

| Rubber fibres | Cement | Mechanical and microstructure | [52] |

| Crumb rubber | Geopolymer concrete | Mechanical and microstructure | [53] |

| Rubber | Concrete | Optimisation, economic, environmental, and mechanical | [54] |

| Crumb rubber | Geopolymer concrete | Mechanical | [55] |

| Crumb rubber | Concrete | Mechanical | [56] |

| Tire rubber | High strength concrete | Mechanical and microstructure | [57] |

| Rubber granules | Concrete | Mechanical | [58] |

| Tire rubber | Asphalt | Economic and environmental | [59] |

| Tire rubber | Concrete | Mechanical, environmental, and economical | [60] |

| Tire rubber and Fly Ash | Composite | Mechanical and microstructure | [61] |

| Tire rubber and waste glass | Concrete | Mechanical and microstructure | [62] |

| Tire rubber | Composite | Mechanical and microstructure | [63] |

| Tire rubber | Syntactic foam | Mechanical and microstructure | [64] |

| Tire rubber, steel fibre and porcelain | Concrete | Mechanical and microstructure | [65] |

| Rubber tube and cow dung ash | Concrete | Mechanical and microstructure | [66] |

| Tire rubber | Clay soil-rubber | Mechanical and microstructure | [67] |

| Tire rubber and recycled aggregate | Pavement | Mechanical and microstructure | [68] |

| Rubber fibre and recycled aggregate | Concrete | Machine learning modelling | [69] |

| Tire rubber | Composite | Mechanical and microstructure | [70] |

| Tire rubber and agricultural waste | Composite | Mechanical | [71] |

| Tire rubber powder | Asphalt | Mechanical and microstructure | [47] |

| Polyvinyl alcohol and rubber | Cement paste | Mechanical | [72] |

| Tire rubber | Pavement | Mechanical and microstructure | [73] |

| Tire rubber and fly ash | Composite | Mechanical and microstructure | [74] |

| Tire rubber | Cement mortar | Mechanical and microstructure | [75] |

| Tire rubber | Self-compacting concrete | Mechanical and microstructure | [76] |

| Crumb rubber and quarry dust | Concrete | Mechanical | [77] |

| Tire rubber and plastic waste | Concrete blocks | Mechanical, economical, and environmental | [78] |

| Crumb rubber and recycled aggregates | Mortar | Mechanical and microstructure | [79] |

| Rubber particles | Self-compacting concrete | Mechanical and microstructure | [80] |

| Rubber tire, waste paint and silica | Cement paste | Microstructure | [81] |

| Tire rubber | Asphalt | Mechanical and microstructure | [82] |

| Tire rubber and recycled concrete | Concrete | Mechanical and microstructure | [83] |

| Rubber powder and polypropylene fibre | Concrete | Mechanical and microstructure | [84] |

| Tire rubber | Concrete blocks | Mechanical | [85] |

| Tire rubber | Asphalt | Mechanical | [86] |

| Rubber powder granules | Asphalt | Thermal | [87] |

| Tire rubber | Composite | Mechanical and microstructure | [88] |

| Tire rubber | Pervious concrete | Mechanical and simulation | [89] |

| Tire rubber | Composite | Mechanical and microstructure | [90] |

| Tire rubber | Concrete | Mechanical and environmental | [91] |

| Material Type | Material Application | Main Study Focus | Ref. |

|---|---|---|---|

| Jute yarn, flax yarn | Reinforced polyester bars | Mechanical, | [115] |

| Multifilament carbon yarns | Fabric cement-based composite | Mechanical, microstructure | [116] |

| Carbon fibre yarn | Geopolymer concrete composites | Mechanical, thermal | [117] |

| Textile yarn | Alkali resistant glass textile reinforced concrete | Mechanical, physical | [118] |

| Poly-acrylonitrile based carbon fibre yarn | Concrete | Mechanical, microstructure, thermal | [119] |

| Textile carbon mesh yarn | Textile reinforced concrete | Mechanical, physical | [120] |

| Glass fibre yarn | Reinforced cementitious composite | Mechanical | [121] |

| Textile carbon fibre yarn | Fibre reinforced cementitious matrices | Mechanical, microstructure, | [122] |

| Glass fibre yarn | Composite reinforced mortar | Mechanical | [123] |

| Basalt, AR-glass, carbon fibre and PP filament yarn | Textile reinforced concrete | Mechanical | [124] |

| Textile carbon yarns | Reinforced concrete beams | Mechanical | [125] |

| Carbon multifilament yarn | Cement based composites | Mechanical, microstructure | [126] |

| Textile carbon multifilament yarn | Fibre reinforced concrete | Mechanical, microstructure | [127] |

| AR-glass multifilament yarn | Cement based composites | Mechanical, microstructure | [128] |

| AR-glass and basalt yarn | Cement based composites | Mechanical, | [129] |

| Glass and polyester fibre | Polymer concrete | Mechanical, durability | [130] |

| Polyester fibres | Concrete | Mechanical, physical | [131] |

| Polyester fibres | Asphalt concrete | Mechanical, durability | [132] |

| Polypropylene and polyester fibre | Asphalt | Physical | [133] |

| Waste denim jeans | Concrete | Mechanical, thermal, microstructure | [109] |

| Glass fibre reinforced polyester | Concrete | Mechanical | [134] |

| Polyester fibres | Concrete | Mechanical | [135] |

| Steel and polyester fibres | Concrete | Mechanical | [136] |

| Polypropylene and polyester fibres | Concrete | Mechanical, microstructure, thermal | [108] |

| Polyester and polyurethane | Concrete | Mechanical | [137] |

| Polyester waste fibres | Asphalt | Mechanical | [138] |

| Rayon textile fibre | Polyhydroxy butyrate nanocomposites | Mechanical and microstructure | [139] |

| Bamboo, cotton, and rayon fibre | Composites | Mechanical | [140] |

| Rayon based carbon fibres | Fibre investigations | Microstructure | [141] |

| Polypropylene, PET, and rayon fibres | Hybrid composites | Mechanical | [142] |

| Rayon fabric and glass epoxy | Polymeric composites | Mechanical | [143] |

| Sheep wool | Insulation | Thermal, acoustic | [144] |

| Sheep wool | Concrete composites | Mechanical, acoustic | [145] |

| Flax wool twine | Mortar composites | Mechanical, microstructure, durability | [146] |

| Sheep wool | Concrete composites | Mechanical, microstructure, | [147] |

| Sheep wool | Fibre reinforced concrete | Mechanical | [148] |

| Sheep wool | Mechanical insulation | Thermal | [149] |

| Sheep wool | Hybrid bio-composites | Thermal, acoustic | [150] |

| Sheep wool | Insulation | Thermal, acoustic, microstructure | [151] |

| Sheep wool, shell pinecone and paper | Thermal insulation | Mechanical, thermal, microstructure, absorptivity | [152] |

| Sheep wool | Thermal insulation | Mechanical, thermal, microstructure | [153] |

| Sheep wool | Reinforced concrete | Mechanical, thermal, | [154] |

| Wool | Mortar | Mechanical, microstructure | [155] |

| Hemp wool | External wall panels | Thermal, economic | [156] |

| Material Type | Material Application | Main Study Focus | Ref. |

|---|---|---|---|

| Ceramic sanitary waste | Geopolymer concrete | Mechanical and microstructure | [178] |

| Fired clay ceramics | High performance concrete | Mechanical and microstructure | [179] |

| Ceramic tiles | Geopolymer concrete | Optimisation, mechanical and microstructure | [180] |

| Ceramic roof tiles | Geopolymer concrete | Mechanical | [181] |

| Ceramic waste | Concrete | Machine learning and mechanical | [182] |

| Ceramic waste and nylon fibre | Concrete | Machine learning and mechanical | [183] |

| Ceramic foams | Electrical insulating material | Microstructure | [184] |

| Ceramic powder | Concrete beams | Mechanical | [185] |

| Tiles with waste glass particles | Roof applications | Mechanical and microstructure | [186] |

| Ceramic powder | Concrete | Optimisation, mechanical and environmental | [187] |

| Ceramic powder | Concrete | Optimisation and mechanical | [188] |

| Ceramic electrical insulator | Concrete | Mechanical | [189] |

| Ceramic bricks | Soil stabilization | Mechanical and microstructure | [190] |

| Ceramic mould shells | Mortar | Mechanical and microstructure | [191] |

| Tile waste | Concrete | Mechanical | [192] |

| Tile waste | Concrete aggregates | Mechanical | [193] |

| Ceramic waste powder and sisal fibre | Concrete | Mechanical | [194] |

| Ceramic and slag wastes | Sandwich panels | Environmental | [195] |

| Ceramic waste | Mortar | Microstructure | [196] |

| Tile powder | Concrete | Mechanical | [197] |

| Ceramic waste powder | Concrete | Mechanical | [198] |

| Tiles | Self-compacting concrete | Mechanical and microstructure | [199] |

| Tiles | Self-compacting concrete | Mechanical, durability and microstructure | [200] |

| Ceramic waste powder | Cement | Mechanical | [201] |

| Ceramic waste and polypropylene fibres | Self-compacting concrete | Mechanical, durability and microstructure | [202] |

| Tiles | Mortar | Mechanical and microstructure | [203] |

| Tiles | Self-compacting concrete | Mechanical, durability and microstructure | [204] |

| Ceramic waste | Geopolymer concrete | Mechanical | [205] |

| Ceramic waste and glass powder silica fume | Concrete | Mechanical | [206] |

| Ceramic waste, brick powder, marble powder, glass powder and rice husk ash | Composite | Mechanical and microstructure | [207] |

| Ceramic waste | Geopolymer concrete | Mechanical and microstructure | [208] |

| Ceramic mould casting waste | Lightweight concrete | Mechanical and microstructure | [209] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Haigh, R. A Decade Review of Research Trends Using Waste Materials in the Building and Construction Industry: A Pathway towards a Circular Economy. Waste 2023, 1, 935-959. https://doi.org/10.3390/waste1040054

Haigh R. A Decade Review of Research Trends Using Waste Materials in the Building and Construction Industry: A Pathway towards a Circular Economy. Waste. 2023; 1(4):935-959. https://doi.org/10.3390/waste1040054

Chicago/Turabian StyleHaigh, Robert. 2023. "A Decade Review of Research Trends Using Waste Materials in the Building and Construction Industry: A Pathway towards a Circular Economy" Waste 1, no. 4: 935-959. https://doi.org/10.3390/waste1040054

APA StyleHaigh, R. (2023). A Decade Review of Research Trends Using Waste Materials in the Building and Construction Industry: A Pathway towards a Circular Economy. Waste, 1(4), 935-959. https://doi.org/10.3390/waste1040054