RETRACTED: The Effect of Intrinsic Mechanical Properties on Reducing the Friction-Induced Ripples of Hard-Filler-Modified HDPE

Abstract

:1. Introduction

2. Methods and Experiments

2.1. Experimental Materials and Sample Preparation

2.2. Experimental Apparatus

2.3. Measurement Techniques and Procedures

3. Results and Discussions

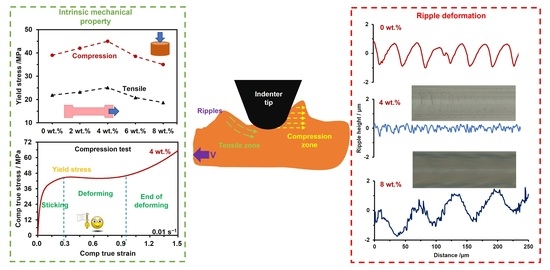

3.1. Intrinsic Mechanical Properties of the HDPE Composites

3.2. Internal Structures of the HDPE Composites

3.3. Frictional Responses of the HDPE Composites

3.4. Ripple Deformation Response on the HDPE Frictional Surfaces

3.5. Influence of the Micro Ripple Responses from the Scratch Test to the Universal Friction Test

3.6. Influence of the Intrinsic Mechanical Properties on Ripple Deformation

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Huang, Y.X.; Meng, X.C.; Xie, Y.M.; Wan, L.; Lv, Z.L.; Cao, J.; Feng, J.C. Friction stir welding/processing of polymers and polymer matrix composites. Compos. Part A Appl. Sci. Manuf. 2018, 105, 235–257. [Google Scholar] [CrossRef]

- Gong, J.P.; Osada, Y. Surface friction of polymer gels. Prog. Polym. Sci. 2002, 27, 3–38. [Google Scholar] [CrossRef]

- Wang, C.B.; Bai, X.Q.; Dong, C.L.; Guo, Z.W.; Yuan, C.Q. Friction properties of polyacrylamide hydrogel particle/HDPE composite under water lubrication. Polymer 2019, 180, 121703. [Google Scholar] [CrossRef]

- Biswas, S.K.; Vijayan, K. Friction and wear of PTFE—A review. Wear 1992, 158, 193–211. [Google Scholar] [CrossRef]

- Myshkin, N.; Kovalev, A. Adhesion and surface forces in polymer tribology—A review. Friction 2018, 6, 143–155. [Google Scholar] [CrossRef]

- Ren, Y.L.; Zhang, L.; Xie, G.X.; Li, Z.B.; Chen, H.; Gong, H.J.; Xu, W.H.; Guo, D.; Luo, J.B. A review on tribology of polymer composite coatings. Friction 2021, 9, 429–470. [Google Scholar] [CrossRef]

- Wu, Y.H.; Bai, X.Q.; Yuan, C.Q.; Dong, C.L.; Zhang, L.Y.; Liu, S.T. Effects of typical physical properties on tribological behaviors of three kinds of polymer materials for water-lubricated bearings. Tribol. Trans. 2019, 62, 1019–1028. [Google Scholar] [CrossRef]

- Litwin, W.; Dymarski, C. Experimental research on water-lubricated marine stern tube bearings in conditions of improper lubrication and cooling causing rapid bush wear. Tribol. Int. 2016, 95, 449–455. [Google Scholar] [CrossRef]

- Liu, S.T.; Dong, C.L.; Yuan, C.Q.; Bai, X.Q. Study of the synergistic effects of fiber orientation, fiber phase and resin phase in a fiber-reinforced composite material on its tribological properties. Wear 2019, 426–427 Pt B, 1047–1055. [Google Scholar] [CrossRef]

- Dong, C.L.; Shi, L.C.; Li, L.Z.; Bai, X.Q.; Yuan, C.Q.; Tian, Y. Stick-slip behaviours of water lubrication polymer materials under low speed conditions. Tribol. Int. 2017, 106, 5–61. [Google Scholar] [CrossRef]

- Charles, K.C.; Ahmed, E.E.; Langer, J.S.; Carlson, J.M. Stick-slip instabilities in sheared granular flow: The role of friction and acoustic vibrations. Phys. Rev. E 2015, 92, 022209. [Google Scholar]

- Briscoe, B.J. Isolated contact stress deformations of polymers: The basis for interpreting polymer tribology. Tribol. Int. 1998, 31, 121–126. [Google Scholar] [CrossRef]

- Wang, D.W.; Mo, J.L.; Zhu, Z.Y.; Ouyang, H.; Zhu, M.H.; Zhou, Z.R. How do grooves on friction interface affect tribological and vibration and squeal noise performance. Tribol. Int. 2017, 109, 192–205. [Google Scholar] [CrossRef]

- Liu, S.T.; Dong, C.L.; Yuan, C.Q.; Bai, X.Q.; Tian, Y.; Zhang, G.L. A new polyimide matrix composite to improve friction-induced chatter performance through reducing fluctuation in friction force. Compos. Part B-Eng. 2021, 217, 108887. [Google Scholar] [CrossRef]

- Marian, M.; Berman, D.; Rota, A.; Jackson, R.L.; Rosenkranz, A. Layered 2D nanomaterials to tailor friction and wear in machine elements—A review. Adv. Mater. Interfaces 2022, 9, 2101622. [Google Scholar] [CrossRef]

- Wang, W.; Xie, G.X.; Luo, J.B. Black phosphorus as a new lubricant. Friction 2018, 6, 116–142. [Google Scholar] [CrossRef]

- Lv, Y.; Wang, W.; Xie, G.X.; Luo, J.B. Self-lubricating PTFE-based composites with black phosphorus nanosheets. Tribol. Lett. 2018, 66, 61. [Google Scholar] [CrossRef]

- Zhang, L.Y.; Dong, C.L.; Yuan, C.Q.; Bai, X.Q.; Tian, Y. The role of graphene nanoplatelets in the friction reducing process of polymer. Polym. Compos. 2022, 43, 8213–8227. [Google Scholar] [CrossRef]

- Dong, C.L.; Yuan, C.Q.; Bai, X.Q.; Tian, Y. A novel approach to reduce deformation behaviours of HDPE polymer during friction. Appl. Surf. Sci. 2020, 503, 144311. [Google Scholar] [CrossRef]

- Zeng, A.R.; Zheng, Y.Y.; Guo, Y.; Qiu, S.C.; Cheng, L. Effect of tetra-needle-shaped zinc oxide whisker (T-ZnOw) on mechanical properties and crystallization behaviour of isotactic polypropylene. Mater. Des. 2012, 34, 691–698. [Google Scholar] [CrossRef]

- Xu, Z.Y.; Xu, Y.; Hu, K.H.; Xu, Y.F.; Hu, X.G. Formation and tribological properties of hollow sphere-like nano-MoS2 precipitated in TiO2 particles. Tribol. Int. 2015, 81, 139–148. [Google Scholar] [CrossRef]

- Dong, C.L.; Yuan, C.Q.; Xu, A.J.; Bai, X.Q.; Tian, Y. Rippled polymer surface generated by stick-slip friction. Langmuir 2019, 35, 2878–2884. [Google Scholar] [CrossRef] [PubMed]

- Pawlak, A.; Galeski, A.; Rozanski, A. Cavitation during deformation of semicrystalline polymers. Prog. Polym. Sci. 2014, 39, 921–958. [Google Scholar] [CrossRef]

- Young, R.J.; Eichhom, S.J. Deformation mechanisms in polymer fibers and nanocomposites. Polymer 2007, 48, 2–18. [Google Scholar] [CrossRef]

- Dong, C.L.; Mo, J.L.; Yuan, C.Q.; Bai, X.Q.; Tian, Y. Vibration and noise behaviours during stick–slip friction. Tribol. Lett. 2019, 67, 103. [Google Scholar] [CrossRef]

- Meijer, H.E.H.; Govaert, L.E. Mechanical performance of polymer systems: The relation between structure and properties. Prog. Polym. Sci. 2005, 30, 915–938. [Google Scholar] [CrossRef]

- Tashiro, K. Molecular theory of mechanical properties of crystalline polymers. Prog. Polym. Sci. 1993, 18, 377–435. [Google Scholar] [CrossRef]

- Li, S.F.; Dong, C.L.; Yuan, C.Q.; Liu, S.T.; Bai, X.Q. Effects of CeO2 nano-particles on anti-aging performance of HDPE polymer during friction. Wear 2021, 477, 203832. [Google Scholar] [CrossRef]

- Mehdikhani, H.; Mostafapour, A.; Laieghi, H.; Najjar, R.; Lionetto, F. Mechanical and microstructural properties of HDPE pipes manufactured via orbital friction stir welding. Materials 2022, 15, 3810. [Google Scholar] [CrossRef]

- Liu, C.B.; Liu, S.T.; Dong, C.L.; Yuan, C.Q.; Bai, X.Q. The Reduction in the deformation of HDPE composites using self-Lubricating fillers in an aqueous environment. Polymers 2022, 14, 433. [Google Scholar] [CrossRef]

- Guo, P.F.; Geng, Z.R.; Lu, Z.B.; Zhang, G.G.; Wu, Z.G. Probing the lubrication mechanism of rough diamond-like carbon films against silicon nitride under water. Tribol. Int. 2018, 128, 248–259. [Google Scholar] [CrossRef]

- Guo, F.; Wang, Z.X.; Liu, Y.; Wang, Y.M.; Tian, Y. Investigation of ultra–low friction between self–mated Si3N4 in water after running–in. Tribol. Int. 2017, 115, 365–369. [Google Scholar] [CrossRef]

- Zhou, F.; Chen, K.; Wang, M.; Xu, X.; Meng, H.; Yu, M. Friction and wear properties of CrN coatings sliding against Si3N4 balls in water and air. Wear 2018, 265, 1029–1037. [Google Scholar] [CrossRef]

- Badzian, A. Stability of Silicon Carbonitride Phases. J. Am. Ceram. Soc. 2002, 85, 16–20. [Google Scholar] [CrossRef]

- Morozov, A.N.; Saarloos, W.V. An introductory essay on subcritical instabilities and the transition to turbulence in visco-elastic parallel shear flows. Phys. Rep. 2007, 447, 112–143. [Google Scholar] [CrossRef]

- Varghese, A.J.; Ronald, B.A. Low velocity impact, fatigue and visco-elastic behaviour of Carbon/E-glass intra-ply fiber-reinforced nano-silica toughened epoxy composite. Silicon 2021, 13, 1655–1661. [Google Scholar] [CrossRef]

- Salari, S.; Beheshti, A. Asperity-based contact and static friction with provision for creep: A review. Surf. Interfaces 2021, 24, 101144. [Google Scholar] [CrossRef]

- Bhushan, B. Contact Mechanics of Rough Surfaces in Tribology: Single Asperity Contact. Appl. Mech. Rev. 1996, 49, 275–298. [Google Scholar] [CrossRef]

- Looijmans, S.F.S.P.; Anderson, P.D.; van Breemen, L.C. Contact mechanics of high-density polyethylene: Effect of pre-stretch on the frictional response and the onset of wear. Wear 2018, 410–411, 142–148. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, C.; Yuan, C.; Liu, S. RETRACTED: The Effect of Intrinsic Mechanical Properties on Reducing the Friction-Induced Ripples of Hard-Filler-Modified HDPE. Polymers 2023, 15, 268. https://doi.org/10.3390/polym15020268

Liu C, Yuan C, Liu S. RETRACTED: The Effect of Intrinsic Mechanical Properties on Reducing the Friction-Induced Ripples of Hard-Filler-Modified HDPE. Polymers. 2023; 15(2):268. https://doi.org/10.3390/polym15020268

Chicago/Turabian StyleLiu, Chuanbo, Chengqing Yuan, and Shutian Liu. 2023. "RETRACTED: The Effect of Intrinsic Mechanical Properties on Reducing the Friction-Induced Ripples of Hard-Filler-Modified HDPE" Polymers 15, no. 2: 268. https://doi.org/10.3390/polym15020268