Sensors Auto-calibration Method - Using Programmable Interface Circuit Front-end

Abstract

:Introduction

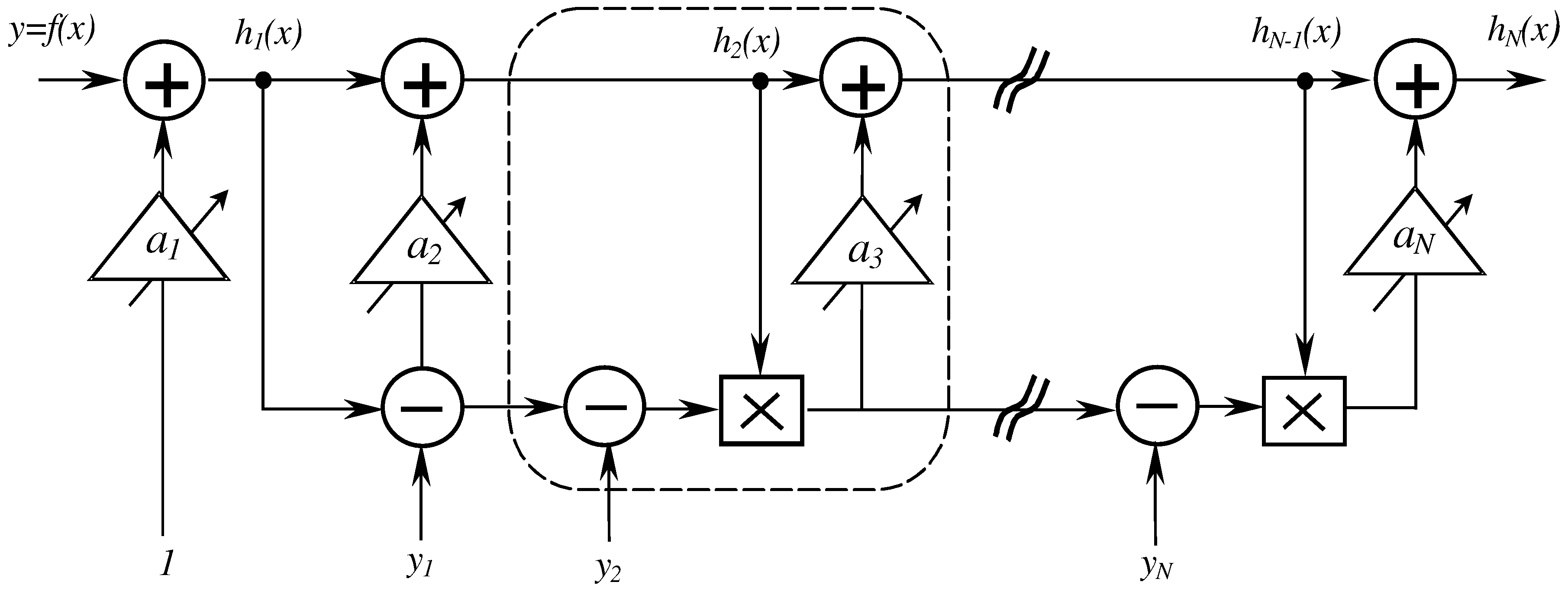

Reconfigurable measurement chain

Auto-test step

Auto-Adjustment step

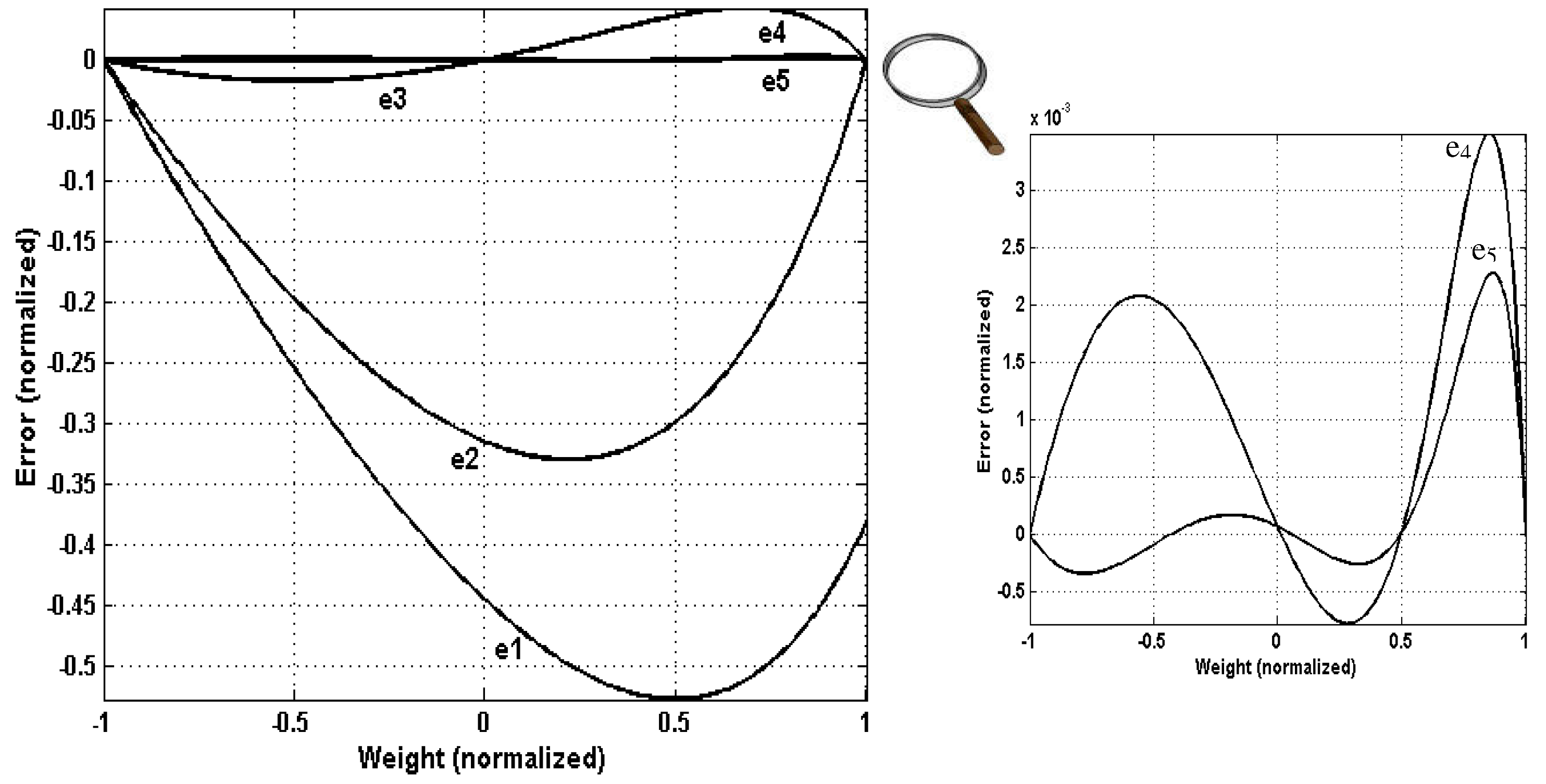

Progressive correction and linarization Method

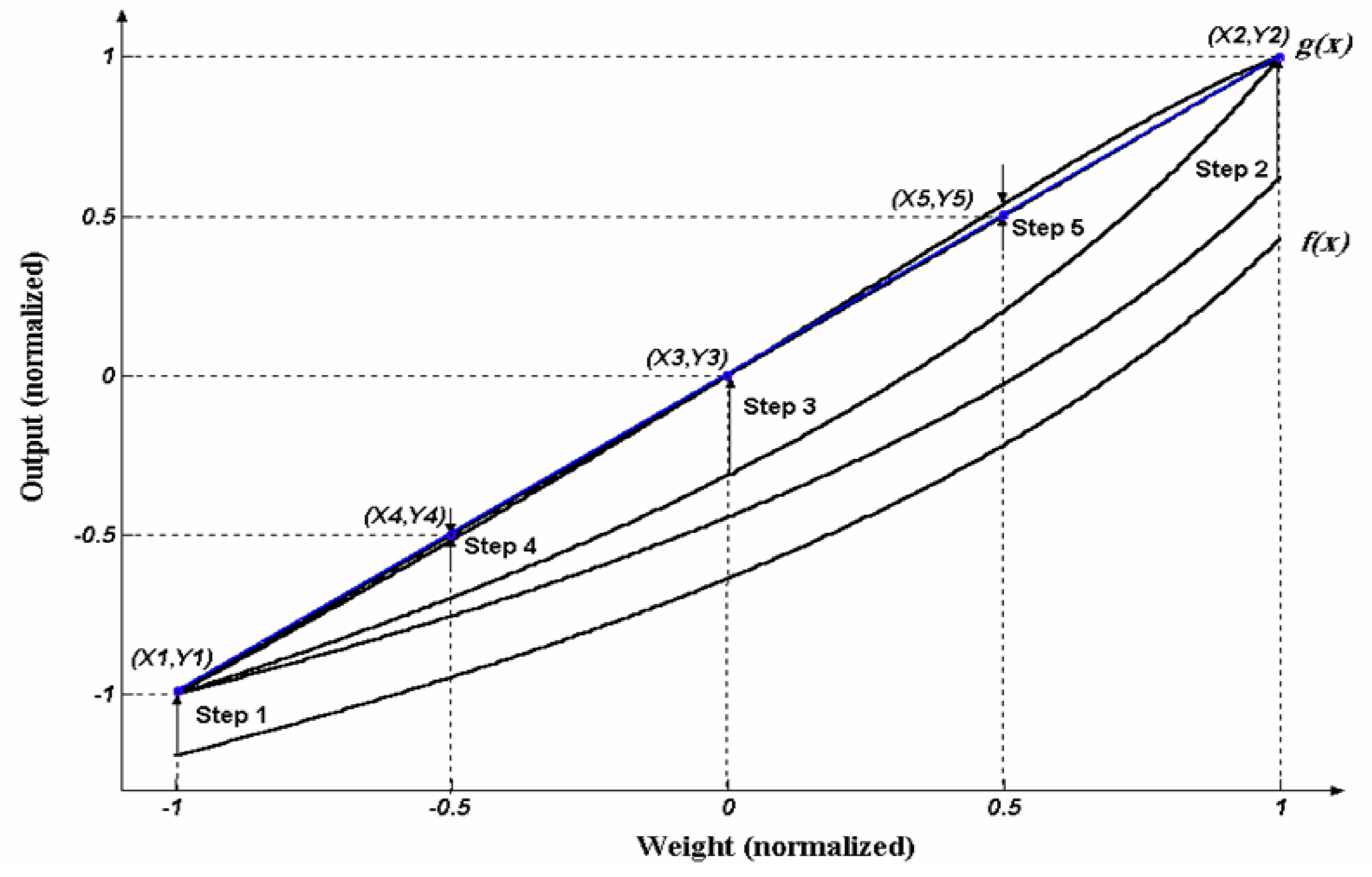

One-dimensional calibration function

| Correction Functions | Calibration Coefficients | |

| Step 1 (x1,y1) | h1( x )= f( x )+a1 | a1=y1−f( x1 ) |

| Step 2 (x2,y2) | h2(x)=h1( x )+a2.(h1( x )−y1 ) | |

| … | … | … |

| Step N (xn,yn) |

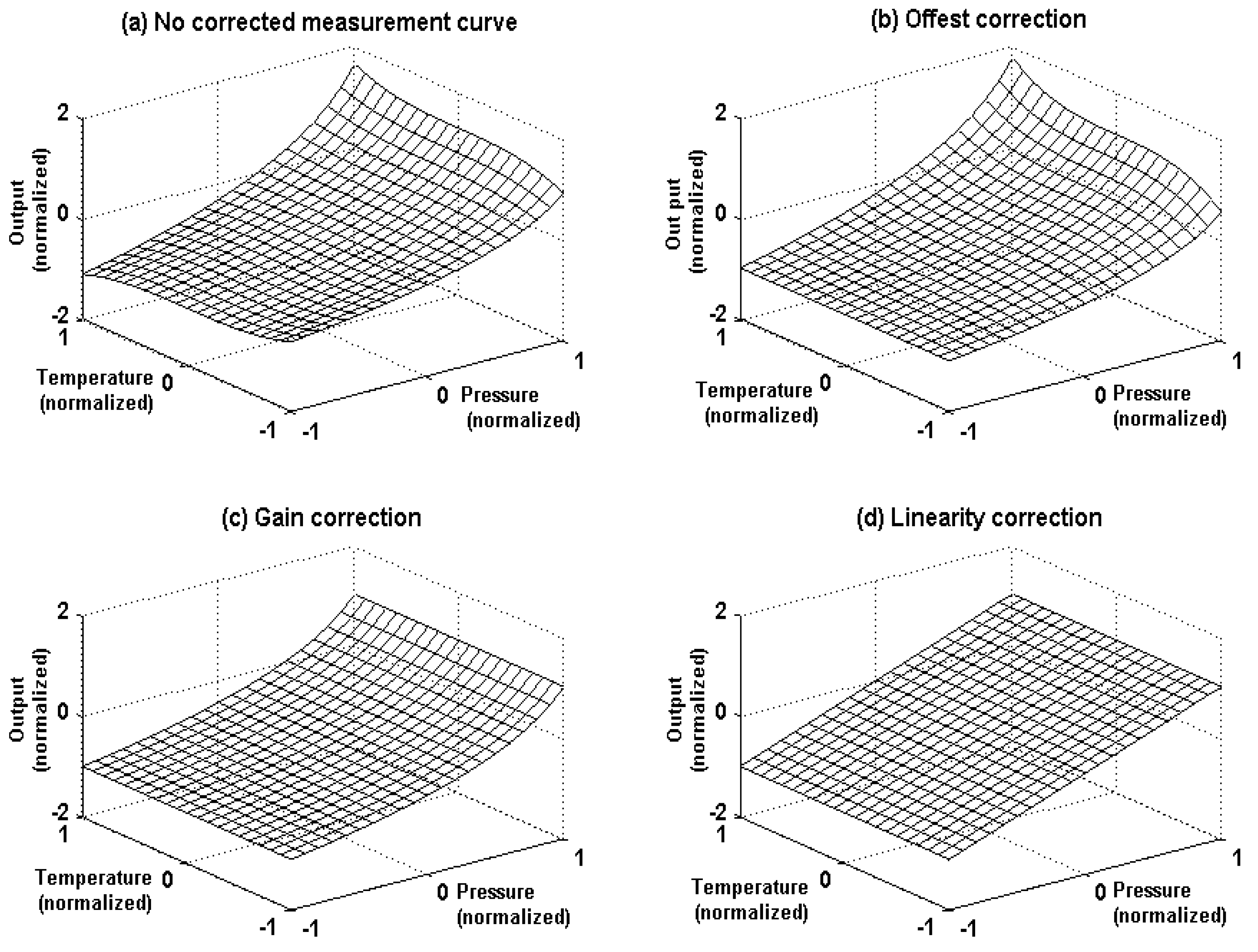

Two-dimensional calibration function

Conclusion

References

- Pallás-Areny, R.; Webster, J.G. Sensors and Signal Conditioning; John Wiley & Sons: New York, 1991; pp. 32–40. [Google Scholar]

- Brignell, J.E. Software techniques for sensor compensation. Sensors and Actuators A 1991, Vol.25-27, 29–35. [Google Scholar]

- Dunbar, M.L. Single chip ASICs for smart sensor signal conditioning. In Proceeding Wescon’98, Anaheim, CA, USA, 1998; pp. 44–50.

- In-System Programmable Analog Circuit, Lattice analog product. http:\\www.latticesemi.com.

- de-Silva, C. Sensors/transducer technology, Part 5A, Instrument error analysis. Measurements-andcontrol October. 1999, 197, 53–62. [Google Scholar]

- Horn, G.v.d.; Huijsing, J.H. Programmable analog signal processor for polynomial calibration. In Proceeding ESSCIRC’96, Neuchatel, Switzerland, 1996; pp. 400–403.

- Sample Availability: Available from the authors.

© 2003 by MDPI (http://www.mdpi.org). Reproduction is permitted for noncommercial purposes.

Share and Cite

Kouider, M.; Nadi, M.; Kourtiche, D. Sensors Auto-calibration Method - Using Programmable Interface Circuit Front-end. Sensors 2003, 3, 491-497. https://doi.org/10.3390/s31000491

Kouider M, Nadi M, Kourtiche D. Sensors Auto-calibration Method - Using Programmable Interface Circuit Front-end. Sensors. 2003; 3(10):491-497. https://doi.org/10.3390/s31000491

Chicago/Turabian StyleKouider, M., M. Nadi, and D. Kourtiche. 2003. "Sensors Auto-calibration Method - Using Programmable Interface Circuit Front-end" Sensors 3, no. 10: 491-497. https://doi.org/10.3390/s31000491