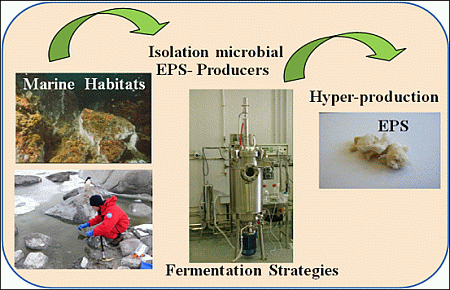

Fermentation Technologies for the Optimization of Marine Microbial Exopolysaccharide Production

Abstract

:1. Introduction

2. General Information of Microbial Exopolysaccharides: Chemical Structure, Ecological Role and Biosynthesis

3. Marine EPS Producers: Conventional and Non-Conventional (Extremophile) Microorganisms

4. EPS Production and Recovery

5. Fermentation Strategies

5.1. Effect of the Chemical Composition of the Medium and the Physical Parameters of Growth Conditions

| Microorganisms | Source | Max EPS-production | EPS Fermentation-increasing strategies | Production increment (fold) | References |

|---|---|---|---|---|---|

| Aeribacillus pallidus 418 | Hot springs Bulgaria | 0.13 g/L | Carbon and nitrogen sources: maltose, NH4Cl; temperature | 2 | Radchenkova et al., 2013 [53] |

| Alteromonas sp. 1644 | Hydrothermal vents East Pacific Rise | 7.5 g/L | Nitrogen source: ammonium chloride | 1.5 | Samain et al., 1997 [76] |

| Hahella chejuensis | Cheju Island | 9.23 g/L | Carbon/nitrogen ratio: sucrose, tryptone; temperature, pH | n.r. | Sung-Hwan Ko et al., 2000 [73] |

| Halomonas alkaliantarctica strain CRSS | Cape Russell lake, Antarctica | 2.9 g/g dry cells | Carbon source: maltose | 6 | Poli et al., 2004 [64] |

| Pantoea strain BM39 | Sediments in Tyrrhenian Sea | 21.30 g/L | Carbon source: glucose | 2 | Silvi et al., 2013 [66] |

| Pseudoalteromonas sp. AM | Sponge sample in Red Sea | 10.51 g/L | Carbon and nitrogen sources: meat extract, glucose; NaCl; pH; agitation speed | 5 | Al-Nahas et al., 2011 [74] |

| Pseudoalteromonas strain CAM025 | Antarctic sea ice | 99.9 mg/g dry cells | Temperature | 30 | Mancuso et al., 2005 [72] |

| Salipiger mucosus A3T | Spanish Mediterranean seaboard | 1.2 g/L | Stirring rate; incubation temperature; pH | n.r. | Llamas et al., (2010) [31] |

| Thermophilic bacterium strain 4009 | Ischia (Sorceto) Island | 60 mg/L | Carbon sources: trehalose | 1000 | Nicolaus et al., 2002 [80] |

| Zunongwangia profunda SM-A87 | Deep-sea sediment southern Okinawa Trough | 8.90 g/L | Carbon and nitrogen sources: lactose, peptone; temperature; statistical approach | 10 | Liu et al., 2011 [75] |

5.2. Alternative Cheap Sources for EPS Production

5.3. Statistical Tools

5.4. Genetic Approach

6. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Sponga, F.; Cavaletti, L.; Lazzarini, A.; Borghi, A.; Ciciliato, I.; Losi, D.; Marinelli, F. Biodiversity and potentials of marine-derived microorganisms. J. Biotechnol. 1999, 70, 65–69. [Google Scholar] [CrossRef]

- Mancuso Nichols, C.A.; Guezennec, J.; Bowman, J.P. Bacterial Exopolysaccharides from Extreme Marine Environments with Special Consideration of the Southern Ocean, Sea Ice, and Deep-Sea Hydrothermal Vents: A Review. Mar. Biotechnol. 2005, 7, 253–271. [Google Scholar] [CrossRef]

- Poli, A.; Anzelmo, G.; Nicolaus, B. Bacterial Exopolysaccharides from Extreme Marine Habitats: Production, Characterization and Biological Activities. Mar. Drugs 2010, 8, 1779–1802. [Google Scholar] [CrossRef]

- Zanchetta, P.; Lagarde, N.; Guezennec, J. A new bone-healing material: A hyaluronic acid-like bacterial exopolysaccharide. Calcif. Tissue Int. 2003, 72, 74–79. [Google Scholar]

- Mansel, P.W.A. Polysaccharides in skin care. Cosmet. Toilet. 1994, 109, 67–72. [Google Scholar]

- Satpute, S.K.; Banat, I.M.; Dhakephalkar, P.K.; Banpurkar, A.G.; Chopade, B.A. Biosurfactants, bioemulsifiers and exopolysaccharides from marine microorganisms. Biotechnology 2010, 28, 436–450. [Google Scholar]

- Chu, K.H.; Kim, E.Y. Predictive modelling of competitive biosorption equilibrium data. Biotechnol. Bioprocess Eng. 2006, 11, 67–71. [Google Scholar]

- Santhiya, D.; Subramanian, S.; Natarajan, K.A. Surface chemical studies on sphalerite and galena using extracellular polysaccharides isolated from Bacillus polymyxa. J. Colloid Interface Sci. 2002, 256, 237–248. [Google Scholar] [CrossRef]

- Kumar, A.S.; Mody, K.; Jha, B. Bacterial exopolysaccharides: A perception. J. Basic Microbiol. 2007, 47, 103–117. [Google Scholar] [CrossRef]

- Donot, F.; Fontana, A.; Baccou, J.C.; Schorr-Galindo, S. Microbial exopolysaccharides: Main examples of synthesis, excretion, genetics and extraction. Carbohydr. Polym. 2012, 87, 951–962. [Google Scholar] [CrossRef]

- Decho, A.W. Microbial exopolymer secretions in ocean environments: Their role(s) in food webs and marine processes. In Oceanography and Marine Biology: An Annual Review; Barnes, H., Ed.; Aberdeen University Press: Aberdeen, UK, 1990; pp. 73–153. [Google Scholar]

- Kenne, L.; Lindberg, B. Bacterial polysaccharides. In The Polysaccharides; Aspinall, G.O., Ed.; Academic Press: New York, NY, USA, 1983; Volume 2, pp. 287–363. [Google Scholar]

- Sutherland, I.W. Microbial exopolysaccharide synthesis. In Extracellular Microbial Polysaccharides; Sanford, P.A., Laskin, A., Eds.; American Chemical Society: Washington, DC, USA, 1977; Volume 45, pp. 40–57. [Google Scholar]

- Sutherland, I.W. Structure-function relationship in microbial exopolysaccharides. Biotechnol. Adv. 1994, 12, 393–448. [Google Scholar] [CrossRef]

- Vandamme, E.; de Baets, S.; Steinbuchel, A. Biopolymers: Polysaccharides I—Polysaccharides from Prokaryotes; Wiley-VCH Verlag GmbH: Weinheim, Germany, 2002. [Google Scholar]

- Sutherland, I.W. Biosynthesis of microbial exopolysaccharides. Adv. Appl. Microbiol. 1982, 23, 79–150. [Google Scholar]

- Wolfaardt, G.M.; Lawrence, J.R.; Korbe, D.R. Function of EPS. In Microbial Extracellular Polymeric Substances: Characterization, Structure and Function; Wingender, J., Neu, T.R., Flemming, H.-C., Eds.; Springer-Verlag: New York, NY, USA, 1999; pp. 171–200. [Google Scholar]

- Remminghorst, U.; Rehm, B.H.A. Microbial production of alginate: Biosynthesis and applications. In Microbial Production of Biopolymers and Polymer Precursor: Applications and Perspectives; Caister Academic Press: Palmerston North, New Zealand, 2009. [Google Scholar]

- Grobben, G.J.; Smith, M.R.; Sikkema, J.; de Bont, J.A. Influence of fructose and glucose on the production of exopolysaccharides and the activities of enzymes involved in the sugar metabolism and the synthesis of sugar nucleotides in Lactococcus delbrueckii subsp. bulgaricus NCFB 2772. Appl. Microbiol. Biotechnol. 1996, 46, 279–284. [Google Scholar] [CrossRef]

- Laws, A.; Gu, Y.; Marshall, V. Biosynthesis, characterisation, and design of bacterial exopolysaccharides from lactic acid bacteria. Biotechnol. Adv. 2001, 19, 597–625. [Google Scholar] [CrossRef]

- Ateş, Ö.; Toksoy, E.O.; Arga, K.Y. Genome-scale Reconstruction of Metabolic Network for a Halophilic Extremophile, Chromohalobacter salexigens DSM 3043. BMC Syst. Biol. 2011, 5. [Google Scholar] [CrossRef]

- Ateş, Ö.; Arga, K.Y.; Öner, E.O. The stimulatory effect of mannitol on levan biosynthesis: Lessons from metabolic systems analysis of Halomonas smyrnensis AAD6T. Biotechnol. Progress 2013, 29, 1386–1397. [Google Scholar] [CrossRef]

- Nicolaus, B.; Kambourova, M.; Toksoy, E.O. Exopolysaccharides from extremophiles: From fundamentals to biotechnology. Environ. Technol. 2010, 31, 1145–1158. [Google Scholar] [CrossRef]

- Fenical, W. Chemical studies of marine bacteria: Developing a new resource. Chem. Rev. 1993, 93, 1673–1683. [Google Scholar] [CrossRef]

- Iyer, A.; Mody, K.; Jha, B. Characterization of an exopolysaccharide produced by a marine Enterobacter cloacae. Indian J. Exp. Biol. 2005, 43, 467–471. [Google Scholar]

- Mancuso Nichols, C.A.; Garon, S.; Bowman, J.P.; Raguénès, G.; Guézennec, J. Production of exopolysaccharides by Antarctic marine bacterial isolates. J. Appl. Microbiol. 2004, 96, 1057–1066. [Google Scholar]

- Rougeaux, H.; Guezennec, J.; Carlson, R.W.; Kervarec, N.; Pichon, R.; Talaga, P. Structural determination of the exopolysaccharide of Pseudoalteromonas strain HYD 721 isolated from a deep-sea hydrothermal vent. Carbohydr. Res. 1999, 315, 273–285. [Google Scholar] [CrossRef]

- Qin, K.; Zhu, L.; Chen, L.; Wang, P.G.; Zhang, Y. Structural characterization and ecological roles of a novel exopolysaccharide from the deep-sea psychrotolerant bacterium Pseudoalteromonas sp. SM9913. Microbiology 2007, 153, 1566–1572. [Google Scholar] [CrossRef]

- Li, W.W.; Zhou, W.Z.; Zhang, Y.Z.; Wang, J.; Zhu, X.B. Flocculation behavior and mechanism of an exopolysaccharide from the deep-sea psychrophilic bacterium Pseudoalteromonas sp. SM9913. Bioresour. Technol. 2008, 99, 6893–6899. [Google Scholar]

- Liu, S.B.; Chen, X.L.; He, H.L; Zhang, X.Y.; Xie, B.B.; Yu, Y.; Chen, B.; Zhou, B.C.; Zhang, Y.Z. Structure and Ecological Roles of a Novel Exopolysaccharide from the Arctic Sea Ice Bacterium Pseudoalteromonas sp. Strain SM20310. Appl. Environ. Microbiol. 2013, 79, 224–230. [Google Scholar] [CrossRef]

- Llamas, I.; Mata, J.A.; Tallon, R.; Bressollier, P.; Urdaci, M.C.; Quesada, E.; Béjar, V. Characterization of the Exopolysaccharide Produced by Salipiger mucosus A3T, a Halophilic Species Belonging to the Alphaproteobacteria, Isolated on the Spanish Mediterranean Seaboard. Mar. Drugs 2010, 8, 2240–2251. [Google Scholar]

- Vincent, P.; Pignet, P.; Talmont, F.; Bozzi, L.; Fournet, B.; Guezennec, J.; Jeanthon, C.; Prieur, D. Production and characterization of an hydrothermal vent bacterium isolated from the polychaete annelid exopolysaccharide excreted by a deep-sea Alvinella pompejana. Appl. Environ. Microbiol. 1994, 60, 4134–4141. [Google Scholar]

- Rougeaux, H.; Talaga, P.; Carlson, R.W.; Guerzennec, J. Structural studies of an exopolysaccharide produced by Alteromonas macleodii subsp. fijiensis originating from a deep-sea hydrothermal vent. Carbohydr. Res. 1998, 312, 53–59. [Google Scholar] [CrossRef]

- Zanchetta, P.; Guezennec, J. Surface thermodynamics of osteoblasts: Relation between hydrophobicity and bone active biomaterials. Colloids Surf. B 2001, 22, 301–307. [Google Scholar] [CrossRef]

- Colliec Jouault, S.; Chevolot, L.; Helley, D.; Ratiskol, J.; Bros, A.; Sinquin, C.; Roger, O.; Fischer, A.-M. Characterization, chemical modifications and in vitro anticoagulant properties of an exopolysaccharide produced by Alteromonas infernus. Biochim. Biophys. Acta 2001, 1528, 141–151. [Google Scholar]

- Bozzi, L.; Milas, M.; Rinaudo, M. Characterization and solution properties of a new exopolysaccharide excreted by the bacterium Alteromonas sp. strain 1644. Int. J. Biol. Macromol. 1996, 18, 9–17. [Google Scholar] [CrossRef]

- Bozzi, L.; Milas, M.; Rinaudo, M. Solution and gel rheology of a new exopolysaccharide excreted by the bacterium Alteromonas sp. strain 1644. Int. J. Biol. Macromol. 1996, 18, 83–91. [Google Scholar]

- Wrangstadh, M.; Szewzyk, U.; Ostling, J.; Kjelleberg, S. Starvation-Specific Formation of a Peripheral Exopolysaccharide by a Marine Pseudomonas sp., Strain S9. Appl. Environ. Microbiol. 1990, 56, 2065–2072. [Google Scholar]

- Lim, D.J.; Kim, J.D.; Kim, M.Y.; Yoo, S.H.; Kong, J.Y. Physicochemical Properties of the Exopolysaccharides Produced by Marine Bacterium Zoogloea sp. KCCM10036. J. Microbiol. Biotechnol. 2007, 17, 979–984. [Google Scholar]

- Bramhachari, P.V.; Dubey, S.K. Production and characterization of exopolysaccharide produced by Vibrio harveyi strain VB23. Lett. Appl. Microbiol. 2006, 43, 571–577. [Google Scholar] [CrossRef]

- Muralidharan, J.; Jayachandran, S. Physicochemical analyses of the exopolysaccharides produced by a marine biofouling bacterium, Vibrio alginolyticus. Process Biochem. 2003, 38, 841–847. [Google Scholar]

- Rodrigues, C.; Bhosle, N. Exopolysaccharide production by Vibrio fischeri, a fouling marine bacterium. Biofouling 1991, 4, 301–308. [Google Scholar]

- Abu, G.O.; Weiner, R.M.; Rice, J.; Colwell, R.R. Properties of an extracellular adhesive polymer from the marine bacterium, Shewanella colwelliana. Biofouling 1991, 3, 69–84. [Google Scholar] [CrossRef]

- Urai, M.; Yoshizaki, H.; Anzai, H.; Ogihara, J.; Iwabuchi, N.; Harayama, S.; Sunairi, M.; Nakajima, M. Structural analysis of mucoidan, an acidic extracellular polysaccharide produced by a pristane-assimilating marine bacterium, Rhodococcus erythropolis PR4. Carbohydr. Resour. 2007, 342, 927–932. [Google Scholar] [CrossRef]

- Poli, A.; di Donato, P.; Abbamondi, G.R.; Nicolaus, B. Synthesis, Production, and Biotechnological Application of Exopolysaccharides and Polyhydroxyalkanoates by Archaea. Archaea 2011, 2011. [Google Scholar] [CrossRef]

- Anton, J.; Meseguer, I.; Rodriguez-Valera, F. Production of an Extracellular Polysaccharide by Haloferax mediterranei. Appl. Environ. Microbiol. 1988, 10, 2381–2386. [Google Scholar]

- Parolis, H.; Parolis, L.A.S.; Boán, I.F.; Rodríguez-Valera, F.; Widmalm, G.; Manca, M.C.; Jansson, P.-E.; Sutherland, I.W. The structure of the exopolysaccharide produced by the halophilic Archaeon Haloferax mediterranei strain R4 (ATCC 33500). Carbohydr. Resour. 1996, 295, 147–156. [Google Scholar] [CrossRef]

- Rinker, K.D.; Kelly, R.M. Growth Physiology of the Hyperthermophilic Archaeon Thermococcus litoralis: Development of a Sulfur-Free Defined Medium, Characterization of an Exopolysaccharide, and Evidence of Biofilm Formation. Appl. Environ. Microbiol. 1996, 12, 4478–4485. [Google Scholar]

- Maugeri, T.L.; Gugliandolo, C.; Caccamo, D.; Panico, A.; Lama, L.; Gambacorta, A.; Nicolaus, B. A halophilic thermotolerant Bacillus isolated from a marine hot spring able to produce a new exopolysaccharide. Biotechnol. Lett. 2002, 24, 515–519. [Google Scholar]

- Arena, A.; Maugeri, T.L.; Pavone, B.; Iannello, D.; Gugliandolo, C.; Bisignano, G. Antiviral and immunoregulatory effect of a novel exopolysaccharide from a marine thermotollerant Bacillus licheniformis. Int. Immunopharmacol. 2006, 6, 8–13. [Google Scholar] [CrossRef]

- Spanò, A.; Gugliandolo, C.; Lentini, V.; Maugeri, T.L.; Anzelmo, G.; Poli, A.; Nicolaus, B. A novel EPS-producing strain of Bacillus licheniformis isolated from a shallow vent off Panarea Island (Italy). Curr. Microbiol. 2013, 67, 21–29. [Google Scholar]

- Kambourova, M.; Mandeva, R.; Dimova, D.; Poli, A.; Nicolaus, B.; Tommonaro, G. Production and characterization of a microbial glucan, synthesized by Geobacillus tepidamans V264 isolated from Bulgarian hot spring. Carbohydr. Polym. 2009, 77, 338–343. [Google Scholar] [CrossRef]

- Radchenkova, N.; Vassilev, S.; Panchev, I.; Anzelmo, G.; Tomova, I.; Nicolaus, B.; Kuncheva, M.; Petrov, K.; Kambourova, M. Production and properties of two novel exopolysaccharides synthesized by a thermophilic bacterium Aeribacillus pallidus 418. Appl. Biochem. Biotechnol. 2013, 171, 31–43. [Google Scholar]

- Lin, M.H.; Yang, Y.L.; Chen, Y.P.; Hua, K.F.; Lu, C.P.; Sheu, F.; Lin, G.H.; Tsay, S.S.; Liang, S.M.; Wu, S.H. A novel exopolysaccharide from the biofilm of Thermus aquaticus YT-1 induces the immune response through Toll-like receptor 2. J. Biol. Chem. 2011, 286, 17736–17745. [Google Scholar]

- Ventosa, A.; Nieto, J.J.; Oren, A. Biology of moderately halophilic aerobic bacteria. Microbiol. Mol. Biol. Rev. 1998, 62, 504–544. [Google Scholar]

- Bejar, V.; Llamas, I.; Calvo, C.; Quesada, E. Characterization of exopolysaccharides produced by 19 halophilic strains of the species Halomonas eurihalina. J. Biotechnol. 1998, 61, 135–141. [Google Scholar] [CrossRef]

- Arias, S.; del Moral, A.; Ferrer, M.R.; Tallon, R.; Quesada, E.; Béjar, V. Mauran, an exopolysaccharide produced by the halophilic bacterium Halomonas maura, with a novel composition and interesting properties for biotechnology. Extremophiles 2003, 7, 319–326. [Google Scholar] [CrossRef]

- Quesada, E.; Valderrama, M.J.; Béjar, V.; Ventosa, A.; Gutiérrez, M.C.; Ruiz-Berraquero, F.; Ramos-Cormenzana, A. Volcaniella eurihalina gen. nov., sp. nov., a moderately halophilic non motile gram-negative rod. Int. J. Syst. Evolut. Microbiol. 1990, 40, 261–267. [Google Scholar]

- Quesada, E.; Béjar, V.; Calvo, C. Exopolysaccharide production by Volcaniella eurihalina. Experientia 1993, 49, 1037–1041. [Google Scholar] [CrossRef]

- Quesada, E.; Béjar, V.; Del Moral, A.; Ferrer, M.R.; Calvo, C.; Llamas, I.; Martinez-Checa, F.; Arias, S.; Ruiz-Garcìa, C.; Martinez-Cánovas, J.; et al. Moderately halophilic exopolysaccharide-producing bacteria. In Halophilic Microorganisms; Ventosa, A., Ed.; Springer-Verlag: Heidelberg, Germany, 2004; pp. 297–314. [Google Scholar]

- Martínez-Cánovas, M.J.; Quesada, E.; Llamas, I.; Béjar, V. Halomonas ventosae sp. nov., a moderately halophilic, denitrifying, exopolysaccharide-producing bacterium. Int. J. Syst. Evolut. Microbiol. 2004, 54, 733–737. [Google Scholar] [CrossRef]

- Bouchotroch, S.; Quesada, E.; Izquierdo, I.; Rodriguez, M.; Béjar, V. Bacterial exopolysaccharide produced by newly discovered bacteria belonging to the genus Halomonas, isolated from hypersaline habitats in Morocco. J. Ind. Microbiol. Biotechnol. 2000, 24, 374–378. [Google Scholar] [CrossRef]

- Bouchotroch, S.; Quesada, E.; del Moral, A.; Llamas, I.; Bejar, V. Halomonas maura sp. nov. a novel moderately halophilic, exopolysaccharide-producing bacterium. Int. J. Syst. Evolut. Microbiol. 2001, 51, 1625–1632. [Google Scholar] [CrossRef]

- Poli, A.; Esposito, E.; Orlando, P.; Lama, L.; Giordano, A.; de Appolonia, F.; Nicolaus, B.; Gambacorta, A. Halomonas alkaliantarctica sp. nov., isolated from saline lake Cape Russell in Antarctica, an alkalophilic moderately halophilic, exopolysaccharide-producing bacterium. Syst. Appl. Microbiol. 2007, 30, 31–38. [Google Scholar] [CrossRef]

- Sameera, V. Novel techniques in the production of industrially imperative products. J. Microb. Biochem. Technol. 2011, R1. [Google Scholar] [CrossRef]

- Silvi, S.; Barghini, P.; Aquilanti, A.; Juarez-Jimenez, B.; Fenice, M. Physiologic and metabolic characterization of a new marine isolate (BM39) of Pantoea sp. producing high levels of exopolysaccharide. Microb. Cell Fact. 2013, 12. [Google Scholar] [CrossRef]

- Lee, I.Y.; Seo, W.T.; Kim, G.J.; Kim, M.K.; Ahn, S.G.; Kwon, G.S.; Park, Y.H. Optimization of fermentation conditions for production of exopolysaccharide by Bacillus polymyxa. Bioprocess Eng. 1997, 16, 71–75. [Google Scholar] [CrossRef]

- Lee, H.K.; Chun, J.; Moon, E.Y.; Ko, S.H.; Lee, D.S.; Lee, H.S.; Bae, K.S. Hahella chejuensis gen. nov., sp. nov., an extracellular-polysaccharide-producing marine bacterium. Int. J. Syst. Evolut. Microbiol. 2001, 51, 661–666. [Google Scholar]

- Ramırez-Castillo, M.L.; Uribelarrea, J.L. Improved process for exopolysaccharide production by Klebsiella pneumoniae sp. Pneumoniae by a fed-batch strategy. Biotechnol. Lett. 2004, 26, 1301–1306. [Google Scholar] [CrossRef]

- Fialho, A.M.; Moreira, L.M.; Granja, A.; Popescu, A.O.; Hoffmann, K.; Sá-Correia, I. Occurrence, production, and applications of gellan: Current state and perspectives. Appl. Microbiol. Biotechnol. 2008, 79, 889–900. [Google Scholar] [CrossRef]

- Marx, J.G.; Carpenter, S.D.; Deming, J.W. Production of cryoprotectant extracellular polysaccharide substances (EPS) by the marine psychrophilic bacterium Colwellia psychrerythraea strain 34H under extreme conditions. Can. J. Microbiol. 2009, 55, 63–72. [Google Scholar] [CrossRef]

- Mancuso Nichols, C.; Bowman, J.P.; Guezennec, J. Effects of Incubation Temperature on Growth and Production of Exopolysaccharideby an Antarctic Sea Ice Bacterium Grown in Batch Culture. Appl. Environ. Microbiol. 2005, 71, 3519–3523. [Google Scholar] [CrossRef]

- Ko, S.H.; Lee, H.S.; Park, S.H.; Lee, H.K. Optimal conditions for the Production of Exopolysaccharide by Marin Microorganism Hahella chejuensis. Biotechnol. Bioprocess Eng. 2000, 5, 181–185. [Google Scholar] [CrossRef]

- Al-Nahas, M.O.; Darwish, M.M.; Ali, A.E.; Amin, M.A. Characterization of an exopolysaccharide-producing marine bacterium, isolate Pseudoalteromonas sp. AM. Afr. J. Microbiol. Res. 2011, 5, 3823–3831. [Google Scholar]

- Liu, S.B.; Qiao, L.P.; He, H.L.; Zhang, Q.; Chen, X.L.; Zhou, W.Z.; Zhou, B.C.; Zhang, Y.Z. Optimization of Fermentation Conditions and Rheological Properties of Exopolysaccharide Produced by Deep-Sea Bacterium Zunongwangia profunda SM-A87. PLoS One 2011, 6, e26825. [Google Scholar]

- Samain, E.; Milas, M.; Bozzi, L.; Dubreucq, M.; Rinaudo, M. Simultaneous production of two different gel-forming exopolysaccharides by an Alteromonas strain originating from deep-sea hydrothermal vents. Carbohydr. Polym. 1997, 34, 235–241. [Google Scholar] [CrossRef]

- Dubreucq, G. Contribution à l’étude Structural d’un Polysaccharide Excrete par la Bacteria Alteromonas sp. 1644 Isolée du Milieu Hydrothermal Profound. Ph.D. Thesis, Université des Sciences et Technologies de Lille, Villeneuve d’Ascq, France, 1996. [Google Scholar]

- Rinker, K.D.; Kelly, R.M. Effect of carbon and nitrogen sources on growth dynamics and exopolysaccharide production for the hyperthermophilic archaeon Thermococcus litoralis and bacterium Thermotoga maritima. Biotechnol. Bioeng. 2000, 69, 537–547. [Google Scholar] [CrossRef]

- Lapaglia, C.; Hartzell, P.L. Stress-Induced Production of Biofilm in the Hyperthermophile Archaeoglobus fulgidus. Appl. Environ. Microbiol. 1997, 63, 3158–3163. [Google Scholar]

- Nicolaus, B.; Lama, L.; Panico, A.; Schiano Moriello, V.; Romano, I.; Gambacorta, A. Production and characterization of exopolysaccharides excreted by thermophilic bacteria from shallow, marine hydrothermal vents of flegrean areas (Italy). Syst. Appl. Microbiol. 2002, 25, 319–325. [Google Scholar] [CrossRef]

- More, T.T.; Yan, S.; Hoang, N.V.; Tyagi, R.D.; Surampalli, R.Y. Bacterial polymer production using pre-treated sludge as raw material and its flocculation and dewatering potential. Bioresour. Technol. 2012, 121, 425–431. [Google Scholar]

- Razack, A.S.; Velayutham, V.; Thangavelu, V. Medium optimization for the production of exopolysaccharide by Bacillus subtilis using synthetic sources and agro wastes. Turk. J. Biol. 2013, 37, 280–288. [Google Scholar]

- Küçükaşik, F.; Kazak, H.; Güney, D.; Finore, I.; Poli, A.; Yenigün, O.; Nicolaus, B.; Toksoy, E.O. Molasses as Fermentation Substrate for Levan production by Halomonas sp. Appl. Microbiol. Biotechnol. 2011, 89, 1729–1740. [Google Scholar]

- Han, Y.W.; Watson, M.A. Production of microbial levan from sucrose, sugarcane juice and beet molasses. J. Ind. Microbiol. Biotechnol. 1992, 9, 257–260. [Google Scholar]

- Banik, R.M.; Santhiagu, A.; Upadhyay, S.N. Optimization of nutrients for gellan gum production by Sphingomonas paucimobilis ATCC-31461 in molasses based medium using response surface methodology. Bioresour. Technol. 2007, 98, 792–797. [Google Scholar] [CrossRef]

- Kalogiannis, S.G.; Iakovidou, M.; Liakopoulou-Kyriakides, D.A.; Skaracis, G.N. Optimization of xanthan gum production by Xantomonas campestris grown in molasses. Process Biochem. 2003, 39, 249–256. [Google Scholar] [CrossRef]

- Plackett, R.L.; Burman, J.P. The design of optimum multifactorial experiments. Biometrika 1946, 33, 305–325. [Google Scholar]

- Qiang, L.; Yumei, L.; Sheng, H.; Yingzi, L.; Dongxue, S.; Dake, H.; Jiajia, W.; Yanhong, Q.; Yuxia, Z. Optimization of Fermentation Conditions and Properties of an Exopolysaccharide from Klebsiella sp. H-207 and Application in Adsorption of Hexavalent Chromium. PLoS One 2013, 8, e53542. [Google Scholar] [CrossRef]

- Jathore, N.R.; Bule, M.V.; Tilay, A.V.; Annapure, U.S. Microbial Levan from Pseudomonas fluorescens: Characterization and Medium Optimization for Enhanced Production. Food Sci. Biotechnol. 2012, 21, 1045–1053. [Google Scholar] [CrossRef]

- Qin, Q.L.; Zhang, X.Y.; Wang, X.M.; Liu, G.M.; Chen, X.L.; Xie, B.B.; Dang, H.Y.; Zhou, B.C.; Yu, J.; Zhang, Y.Z. The complete genome of Zunongwangia profunda SM-A87 reveals its adaptation to the deep-sea environment and ecological role in sedimentary organic nitrogen degradation. Genomics 2010, 11. [Google Scholar] [CrossRef]

- Qin, Q.L.; Li, Y.; Zhang, Y.J.; Zhou, Z.M.; Zhang, W.X.; Chen, X.L.; Zhang, X.Y.; Zhou, B.C.; Wang, L.; Zhang, Y.Z. Comparative genomics reveals a deep-sea sediment-adapted life style of Pseudoalteromonas sp. SM9913. Int. Soc. Microb. Ecol. J. 2011, 5, 274–284. [Google Scholar]

- Hou, S.; Saw, J.H.; Lee, K.S.; Freitas, T.A.; Belisle, C.; Kawarabayasi, Y.; Donachie, S.P.; Pikina, A.; Galperin, M.Y.; Koonin, E.V.; et al. Genome sequence of the deep-sea gamma-proteobacterium Idiomarina loihiensis reveals amino acid fermentation as a source of carbon and energy. Proc. Natl. Acad. Sci. USA 2004, 101, 18036–18041. [Google Scholar] [CrossRef]

- Martinez, E.I.; Cuadrado, A.M.; Auria, G.D.; Mira, A.; Ferriera, S.; Johnson, J.; Friedman, R.; Valera, F.R. Comparative genomics of two ecotypes of the marine planktonic copiotroph Alteromonas macleodii suggests alternative lifestyles associated with different kinds of particulate organic matter. Int. Soc. Microb. Ecol. J. 2008, 2, 1194–1212. [Google Scholar]

- Rehm, B.H.A. (Ed.) Microbial Production of Biopolymers and Polymer Precursors: Applications and Perspectives; Caister Academic Press: Massey, New Zealand, 2009.

- Bae, S.O.; Sugano, Y.; Ohi, K.; ShodaBae, M. Features of bacterial cellulose synthesis in a mutant generated by disruption of the diguanylate cyclase 1 gene of Acetobacter xylinum BPR 2001. Appl. Microbiol. Biotechnol. 2004, 65, 315–322. [Google Scholar]

© 2014 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/3.0/).

Share and Cite

Finore, I.; Di Donato, P.; Mastascusa, V.; Nicolaus, B.; Poli, A. Fermentation Technologies for the Optimization of Marine Microbial Exopolysaccharide Production. Mar. Drugs 2014, 12, 3005-3024. https://doi.org/10.3390/md12053005

Finore I, Di Donato P, Mastascusa V, Nicolaus B, Poli A. Fermentation Technologies for the Optimization of Marine Microbial Exopolysaccharide Production. Marine Drugs. 2014; 12(5):3005-3024. https://doi.org/10.3390/md12053005

Chicago/Turabian StyleFinore, Ilaria, Paola Di Donato, Vincenza Mastascusa, Barbara Nicolaus, and Annarita Poli. 2014. "Fermentation Technologies for the Optimization of Marine Microbial Exopolysaccharide Production" Marine Drugs 12, no. 5: 3005-3024. https://doi.org/10.3390/md12053005