1. Introduction

Mineral resources are the material basis of economic development. In 2014, China’s oil production was 211.41 million tons, gas production was 124.81 billion cubic meters, and production of non-petroleum oils was 8.437 billion tons [

1]. Mining promotes China’s economic development. In the past 10 years, the value of the mining industry has increased each year.

Except for in 2014, the mining industry added value accounted for more than 4% of the GDP [

2,

3,

4,

5,

6,

7,

8,

9,

10,

11,

12,

13,

14,

15,

16,

17,

18,

19,

20,

21,

22,

23,

24,

25,

26,

27,

28,

29]. In 2014, it was 58.788 trillion Yuan, nearly four times that in 2005 (

Figure 1). Among the mining industries, coal mining and washing accounted for 44.27%, petroleum and natural gas extraction accounted for 19.84%, non-ferrous metal ore mining and processing accounted for 10.80%, ferrous metal ore mining and processing accounted for 15.87%, and non-metal ore mining and processing accounted for 9.22%. Furthermore, mining cities in which the mining industry is the dominant or pillar industry accounted for 34% of cities in China [

30].

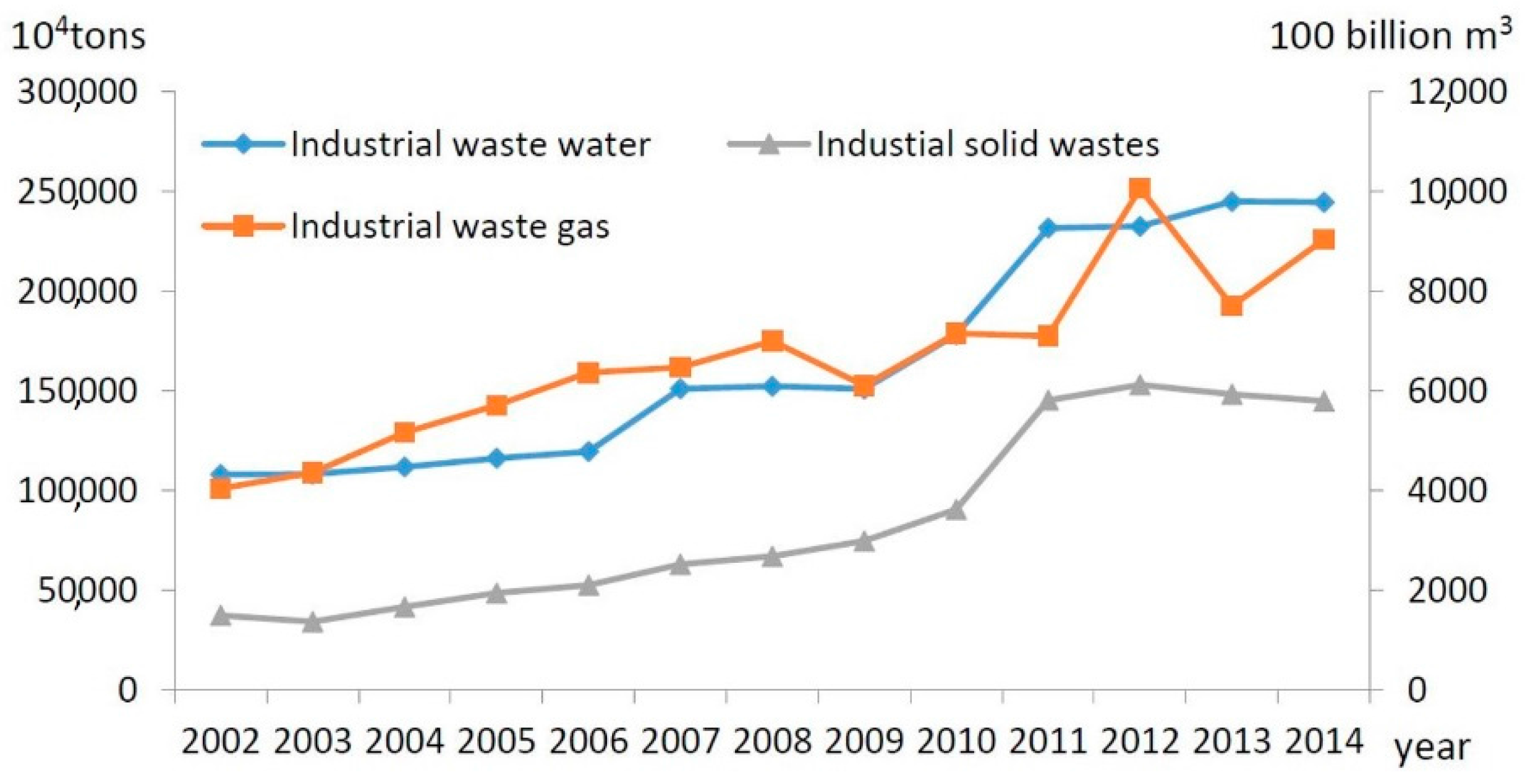

Mining activities cause great environmental disturbance. A variety of pollutants are generated in the process of ore mining. These pollutants diffuse into the surrounding environment and result in water, air and soil pollution problems. In 2014, 2531.67 million tons of industrial wastewater was discharged by the mining industry, nearly 2.2 times the 2005 amount; 903.6 billion cubic meters of industrial waste gas, nearly 1.3 times the 2005 amount; and 1449.32 million tons of industrial solid waste, nearly 3 times the 2005 amount (

Figure 2). The chemical oxygen demand (COD) and ammonia nitrogen (AN) discharged in industrial wastewater were 1857.12 million and 74.31 million tons, respectively. The industrial sulfur dioxide (SO

2) discharged in industrial waste gas was 2192.59 million tons [

31,

32,

33,

34,

35,

36,

37,

38,

39,

40,

41,

42,

43,

44]. To control pollution from mining processes, 86,187.14 million Yuan were input for remediation of mine environments in 2014. Mining not only promotes economic development in China but also causes serious environmental pollution problems. The type and the degree of pollution vary depending on different mineral resources; hence, analysis of the nexus between industry development and environmental pollution for different mineral resources is important to compare their related environmental pollution problems and analyze the policies that cause the similarities and differences among them.

However, existing studies on the nexus between the mining industry and environmental pollution primarily focus on mine product consumption and energy minerals, including coal, oil and natural gas, which draw more attention due to the highlight on the greenhouse effect. Among them, the most studies are on coal consumption because it contributes more carbon per ton of oil equivalent than other resources such as oil and natural gas. These studies include Bloch et al. for China [

45], Saboori and Sulaimanfor Malaysia [

46], Tiwari et al. and Ahmad et al. for India [

47,

48] and Govindaraju and Tangfor India and China [

49]. These studies all conclude that CO

2 emission is related to coal consumption. Compared with studies on coal consumption, there are fewer studies on oil and natural gas. Alkhathlan and Javid examined the relationship between oil and natural gas consumption and CO

2 emission in Saudi Arabia from 1980 to 2011, finding that they both lead to an increase in CO

2 emissions, and the CO

2 emissions can be reduced if the energy consumption structure switches from oil to natural gas [

50]. Saboori and Sulaiman studied the relationship between natural gas and CO

2 emission. The results show that they have a positive relationship.

Although there are numerous studies on the environmental pollution resulting from mine product end consumption, studies on the environmental pollution caused by mine product production are few and focus on single minerals. Hence, it is impossible to contrast the differences in environmental pollution problems among different mineral resources or to discover the policies that cause them. For instance, Yu predicted China’s coal production environmental pollution in 2030, indicating that the turning point of the waste production per year will not occur until 2030 and the pollution caused by coal production will not increase to a great extent [

51].

This paper uses the vector autoregression (VAR) model to analyze the water, air and solid pollution problems in coalmining and washing, petroleum and natural gas extraction, and non-ferrous metal ore, ferrous metal ore, and non-metal ore mining and processing. Through the establishment of the dynamic relationship between the gross industrial output value and the pollutant discharged in these five types of mining industries, the environmental pollution problems among them are compared and the policies that cause similarities and differences are analyzed. The VAR model has the following two characteristics. First, the estimation of traditional economic methods are based on economic theory and the theory cannot always rigorously describe the dynamic links among variables [

52]. Compared with traditional econometric methods, the VAR model does not rely on these “incredible” economic assumptions. Second, the endogenous variables can appear on the right side of the equations well as be placed on the left side of the equation. This is complex for model to estimate and infer the relationship between variables [

53]. Nevertheless, it is unnecessary to identify the endogenous and exogenous variables in the VAR model. Hence, it is used by many researchers [

54,

55,

56] and is adopted in this paper to analyze the issue.

4. Discussion

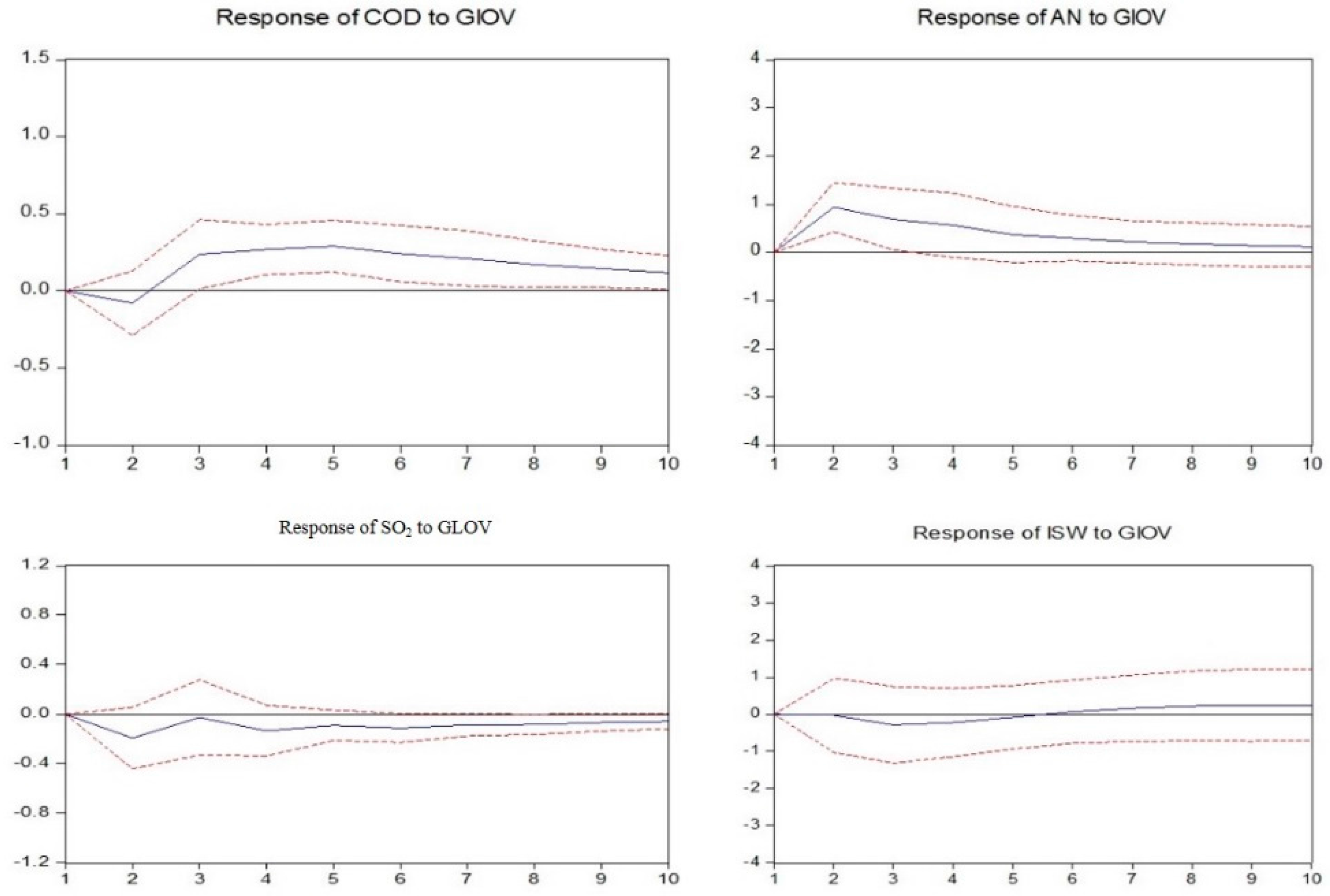

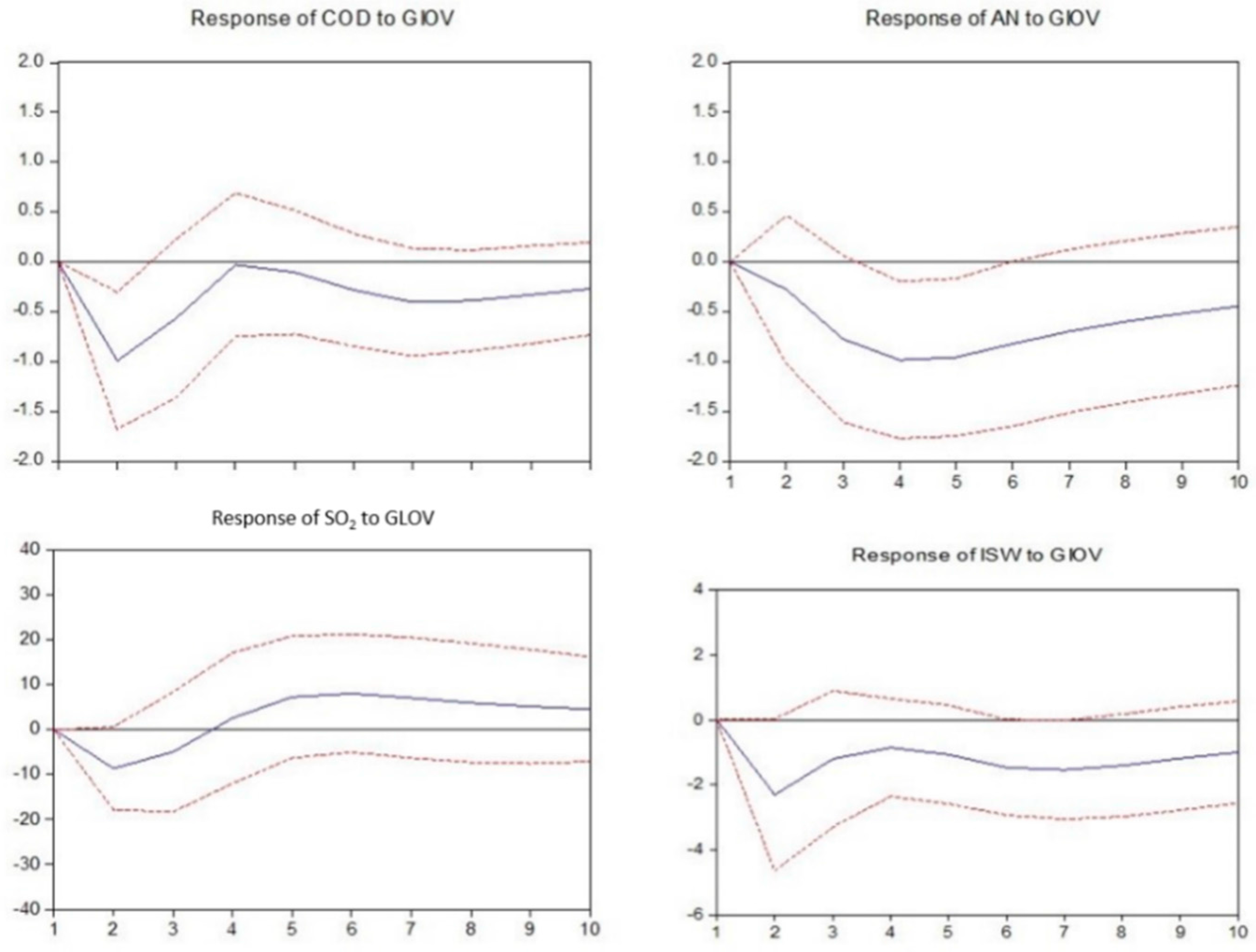

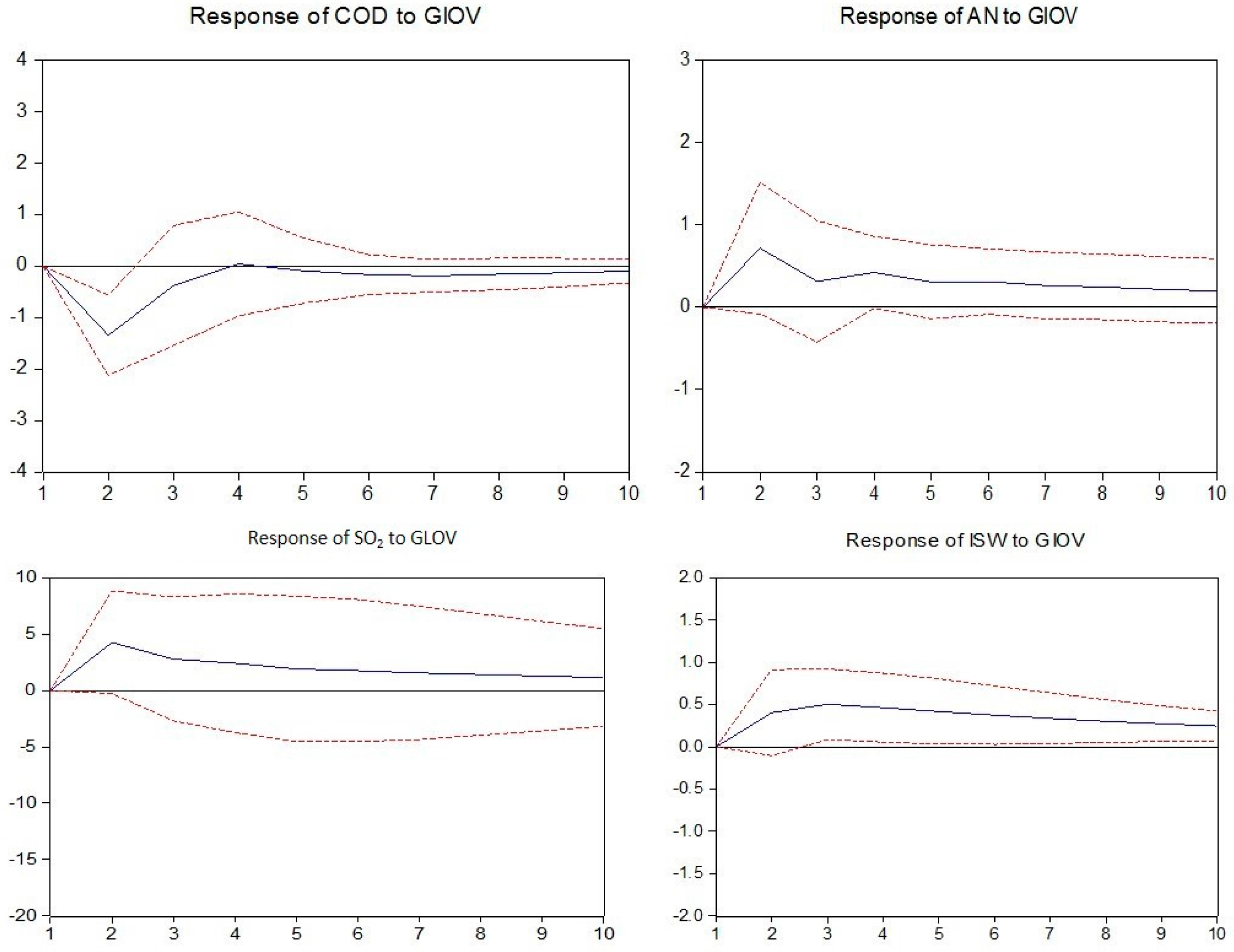

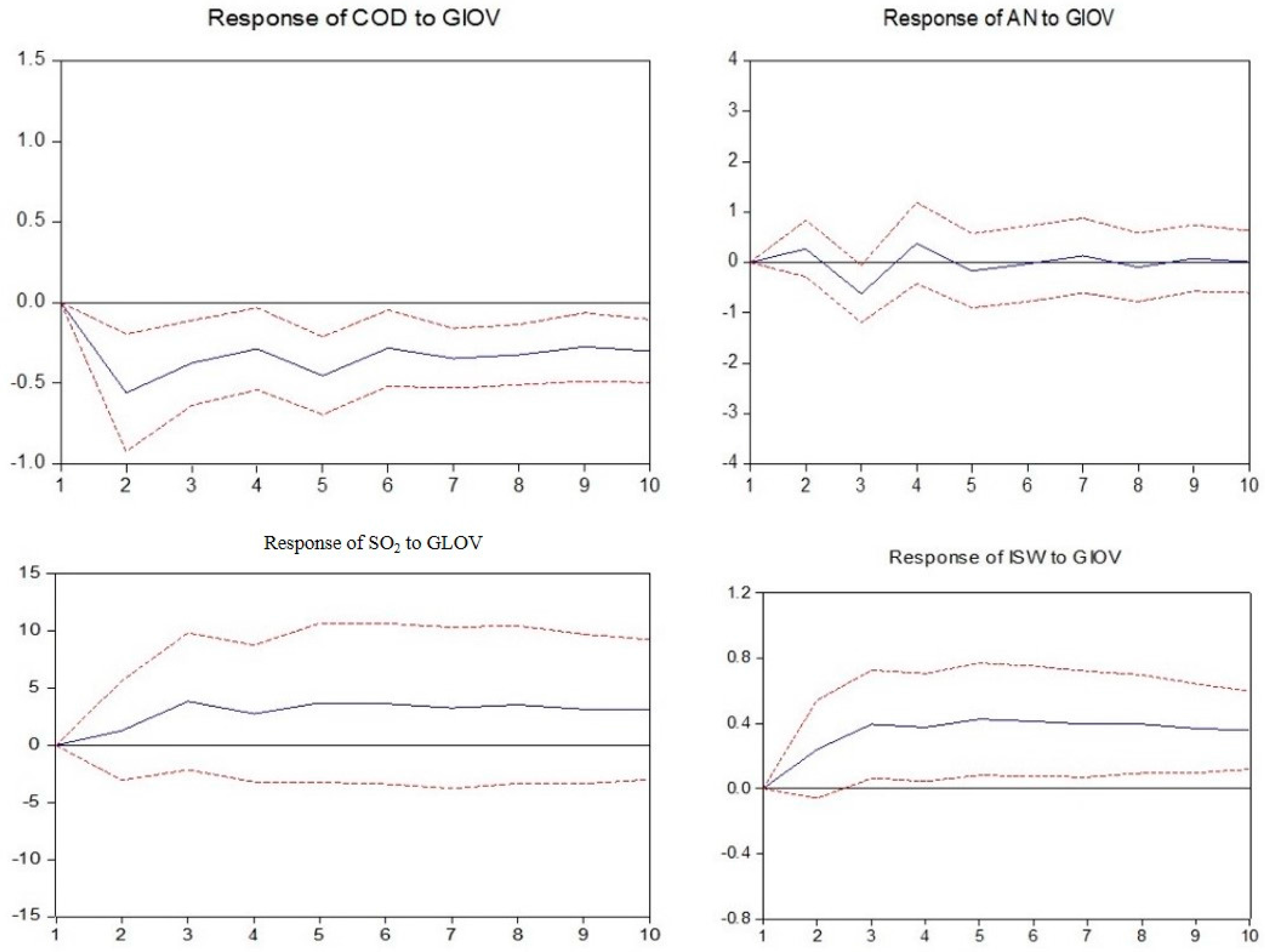

According to the above empirical results, we come to the conclusion that in terms of water pollution, the discharge of COD decreased in coal mining and washing in the short-term but increased in the long-term, whereas it increased in the other industries. The discharge of AN decreased only in petroleum and natural gas extraction and increased in the others. This phenomenon is due to the limiting effect of weak emission standards for mining wastewater and because AN was not used as an indicator for wastewater treatment until 2011 [

59]. Although the maximum permissible discharge concentrations of COD and AN are clear in the Integrated Wastewater Discharge Standard [

60], to which discharged mining wastewater refers, the following two deficiencies limit the effects of the standard. First, the Integrated Wastewater Discharge Standard is not specific to each industrial sector. The maximum permissible discharge concentrations in this standard are applied to the whole mining industry. The fact that the degree of pollution varies depending on different types of mineral resources has not been considered. Second, the maximum permissible discharge concentrations adopted in 1996 are too high to efficiently control the pollutants. However, COD has been taken as an indicator of sewage treatment in the China Environmental Protection plan, but AN was not used until 2011. Hence, the weak limiting effect of emission standards and the indicators for wastewater treatment that are not specific to each industrial sector caused a decrease in the COD in all types of mining industries (for coal mining and washing, it only decreased in the short-term), but the AN increased in most mining industries except for petroleum and natural gas extraction. The reason for the increase in COD from coal mining and washing in the long-term after decreasing in the short-term is that tactic of increasing production, which is adopted by most coal enterprises to compensate for losses caused by falling coal prices, leads to an increase in the COD discharged per gross industrial output value. The reason the AN only decreased in petroleum and natural gas extraction is that a great deal of industrial wastewater in which the COD is not treated is injected into the oil field. Furthermore, the injection rate is greater than 90%, and this rejected wastewater is not counted as discharged wastewater. Hence, the AN in petroleum and natural gas extraction decreased.

In terms of air pollution, the industrial SO

2 decreased in coal mining and washing, decreased in the short term in petroleum and natural gas extraction, but increased in the long-term and increased in the other three mining industries. The reason for this phenomenon is that the effect of the Integrated Emission Standard of Air Pollutants, to which mining waste gas refers, is not strong due to the same deficiencies as in the Integrated Wastewater Discharge Standard [

61]. However, the Discharge Standard for Coal Industry [

62] lowered the maximum permissible discharge concentration of industrial SO

2, causing the industrial SO

2 to decrease in coal mining and washing. In addition, the comprehensive utilization of coal gangue decrease the industrial SO

2 to some extent. A large number of coal gangue are produced and are piled up [

63]. The coal gangue piles are prone to spontaneous combustion, which is hazardous to environment by discharge the harmful gas including sulfur dioxide. With the increasing awareness of environmental protection and comprehensive utilization of resources in China, the coal gangue is used for power generation and making bricks, etc. This change makes the gangue piles turned into man-made eco-park and decrease the amount of sulfur dioxide discharged [

64,

65]. The reason the industrial SO

2 decreased in the short-term in petroleum and natural gas extraction is that the industrial SO

2 is mainly produced from natural gas purification plant tail gas and policies were introduced to encourage enterprises to improve the recovery and utilization of industrial SO

2 in the tail gas of these purification plants. Nevertheless, the costs of tail gas treatment and the maximum permissible discharge concentrations for the extraction of petroleum and natural gas are too high. To pursue economic benefits, tail gas treatment equipment is the optimal choice for enterprises. This caused the industrial SO

2 increase in the long-term in petroleum and natural gas extraction.

In terms of solid pollution, the industrial solid waste discharged decreased in petroleum and natural gas extraction, decreased in coal mining and washing in the short-term but increased in the long-term and increased in the three other types of mining industries. This phenomenon occurs because some of the Chinese government’s policies to promote the comprehensive utilization ratio of the industrial solid wastes were only implemented in coal mining and washing and petroleum and natural gas extraction. The comprehensive utilization of 17% of coal gangue is required [

66], and a 100% resource utilization ratio of oily sludge is required [

67]. Furthermore, the enterprises that sell the coal gangue or oily sludge they produce and those that yield products made of coal gangue or oily sludge can return 50% value-added tax [

68]. These policies decreased the industrial solid waste in petroleum and natural gas extraction and in coal mining and washing in the short-term. However, the tactic of increasing production, which is adopted by most coal enterprises to compensate for losses caused by falling coal prices, caused the increase in industrial solid waste in the long-term. In addition to the above three points, the uniformity of the pollution control policies and standards reduce the effect of pollution prevention to some extent because there are diversities in the level of economic development, industrial structure, environmental carrying capacity, etc., among the provinces [

69,

70,

71]. Firstly, although the uniform pollution control policies and standards are stipulated by the central government, the responsibilities of local governments are not clear for environment pollution, and further how such responsibilities are evaluated [

72]. In order to economic development, local governments,especially who face difficulty in economic development, are inclined to neglect their responsibilities for protecting local environment, and finally make the effects of uniform pollution control policies and standards unobvious [

73,

74,

75]. Worse still, local governments may reduce the collection of emission fees to protect the profits of local companies [

76]. For example, the industrial structure of Shanxi Province is single due to heavily dependent on coal industry. When the coal prices are low, it is a challenge for Shanxi Province to solve environmental problems according to the uniform policies and standards. Secondly, the diversities of environment carrying capacities among provinces can make the different environmental disturbance caused by the same amount of pollution discharged [

77,

78,

79,

80]. Therefore, the implementation of the uniform pollution control policies and standards is not rational. It can destruct the environment in ecologically fragile regions due to the low pollutant control polices and standards, which are suitable for regions with high environment carrying capacities. For example, the forest coverage rate and rainfall are low in northwest China, in which most province are environmental fragile. The environment can be construct if these provinces implement the same pollution control policies and standards as other regions.

5. Conclusions

Using a time series from 2001 to 2014, this paper investigated the nexus between industry development and environmental pollution in coal mining and washing, petroleum and natural gas extraction and non-ferrous metal ore, ferrous metal ore and non-metal ore mining and processing in China, considering the dynamic changes within the VAR model. The results are as follows.

The pertinence of standards for the discharge of industrial wastewater and industrial waste gas is not strong and the maximum permissible discharge concentrations in these standards are too high. These two problems limit the effect of the standards in most mineral industries. Hence, to reduce the discharge of pollutants in industrial wastewater and waste gas, niche targeting standards for industrial wastewater and the waste gas should be adopted and the maximum permissible discharge concentrations in the standards should be lowered for different mining industries according to the characteristics of pollutants in each mining industry.

Tax reduction policies to promote the comprehensive utilization of industrial solid waste in coal mining and washing and petroleum and natural gas extraction are effective. However, these policies are not adopted in other mining industries. Hence, to reduce the discharge of industrial solid waste in non-ferrous metal ore, ferrous metal ore and non-metal ore mining and processing, the enterprises that sell the industrial solid waste they produce and those that yield products made of industrial solid waste can return a part of the value-added tax in these three mining industries.

The tactic of increasing production, used by many coal enterprises, led to increases in the COD and industrial solid waste discharged in the long-term in this industry. Hence, to manage the problem of overcapacity of coal enterprises, the production of coal enterprises should be controlled within a reasonable range by the Chinese government. Policies should also be adopted to encourage coal enterprises to extend the industrial chain by developing the coal chemical and coal gasification industries, which can increase the added value of the product to compensate for losses caused by falling prices.

The current uniform pollution control policies and standards have a shortage that they do not consider the diversity among different provinces. The diversity can reduce the effect of pollution prevention. Hence, the different pollution control policies and standards should be stipulated according to the level of economic development, industrial structure, environmental carrying capacity, etc., among provinces. Appropriately raise pollution control polices and standards in environmental fragile regions. Meanwhile, responsibilities of local governments for environment pollution should be determined and the method should be stipulated to evaluate the responsibilities.