1. Introduction

Safety research, spanning over the past 36 years, has gradually progressed from the identification of various safety climate (SC) factors to the investigation of safety outcomes, followed by, establishing the causal relationships between SC and safety performance (SP), and examining the mediating role of various factors such as safety knowledge and motivation [

1,

2,

3,

4,

5]. Since the pioneering study of Zohar [

6], researchers started focusing on the examination of industry and organization-specific SC measures that resulted in the grouping of over fifty conceptual themes related to the construction industry (CI) [

3].

Most of the SC studies were conducted in the CI of developed (Western) countries having a homogenous cultural environment such as USA, UK and Canada [

7]. However, some of them were also carried out in the Eastern countries such as China, Singapore, Hong Kong and Australia [

8,

9,

10,

11,

12]. Surprisingly, limited attention was given to the generalization of SC studies across different cultures, languages and regions [

13]. Therefore, only a few of the SC studies could be successfully replicated across regions such as Italy [

7], China [

9], Sweden [

14] and Serbia [

15]. On the other hand, factor-structure relationships developed by Cheyne et al. [

16] for the UK and France could not be cross-validated in the Asian cultural setting of the Malaysian industry [

17]. Likewise, in another cross-cultural and cross-language research conducted in USA for Hispanic and non-Hispanic construction workers, non-equivalences were observed in the parameters and error variances of SC factor structure [

18].

The inconsistencies observed in the aforesaid cross-validation studies can be attributed to the cultural differences in risk perception, varied social and economic conditions in different regions, preferences for challenging the authority and variations in national safety regulations [

3,

19]. Realizing these variances, more cross-validation studies are suggested in different regions and cultures [

13,

19]. This study, therefore, develops an exhaustive approach to investigate the causal relationship between construction SC and SP for developing countries, in general, and Pakistan, in particular. It will disclose the variances in the influence of various SC factors on the indicators of SP. In addition, it is expected to guide the construction stakeholders to measure, monitor and improve the SP in the CI. To the authors’ knowledge, this is the first cross-validation study examining the potential linkages among the constructs of SP measurement model in the cross-cultural setting of the Pakistani CI.

1.1. Relationship between SC and SP

SC, being the robust leading indicator of safety outcome [

1,

5,

6,

7], has been expansively studied in developed countries at multiple levels such as the team, project, organization, industry and national levels. The most frequently documented SC factors in the CI include: perception of managerial commitment and employees’ involvement in safety, safety communication, safety training, safety systems and procedures, and workers’ attitude to safety and risk [

7,

10,

19,

20]. These SC factors have established a significant positive relationship with SP [

8,

21], however, consensus could not be achieved on the influence of various SC factors on SP in different industries, regions and cultures [

5,

19].

In the occupational safety research literature, SP is conceptualized as multi-dimensional [

22], however, earlier studies used only the number of accidents as an indicator of SP. Later, this indicator was refined as “number of accidents/injuries and near-misses” [

23,

24]. The advantage of using “near-miss” as a leading SP indicator is that it does not result in any injury or fatality despite the existing potential. It can also warn the management about any potential incident in a proactive way. As accidents/injuries occur infrequently and are not effective indicators of SP, a more refined measure of SP is suggested by the researchers such as “safety behavior” that is measured using safety compliance and safety participation [

1,

2,

4,

23,

25,

26].

Safety compliance comprises of core safety activities that need to be carried out by individuals to maintain a minimum level of safety at the workplace such as wearing personal protective equipment, following safety rules and complying with occupational safety regulations [

26]. Safety participation is conceived as an activity that may not directly supplement workplace safety but help in developing an environment that stimulates safety such as voluntarily joining safety training programs and helping coworkers with safety-related issues [

26,

27]. According to DeArmond et al. [

22], safety participation refers to the behaviors that are voluntary in nature, while safety compliance refers to the behaviors that are compulsory. It is worth mentioning that there is no single measure of SP that can be said to be superior to others, however, safety participation has developed a stronger positive relationship with SP as compared to safety compliance [

2].

1.2. Construction Safety in Developing Countries

Compared to the past, the current decade is witnessing a rise in the infrastructure growth in developing countries such as Pakistan, where the share of CI in national GDP (Gross Domestic Product) [

28] has increased from 2.3% in 2012–2013 to 2.44% in 2014–2015; reflecting its consistent contribution in the country’s economic development. Although no significant increase was noticed in the employment rate of CI during the last 6 years, it suffered an increase in the percentage of injuries from 14.1% in 2013–2014 to 16.3% in 2014–2015 ([

29], p. 38). It was, therefore, ranked as the second most injury-prone industry in Pakistan, after agriculture. These accidents also resulted in cost overruns, construction delays, extended non-appearance of workers at worksites, lower productivity and conflicts between the key stakeholders in the CI [

30,

31]. More specifically, the construction companies working on building projects, despite following various safety management systems, are persistently suffering from fatal accidents, mostly due to

fall from height and

electrocution [

32,

33]. Such a situation warrants further examination of safety measures on building projects.

5. Discussion

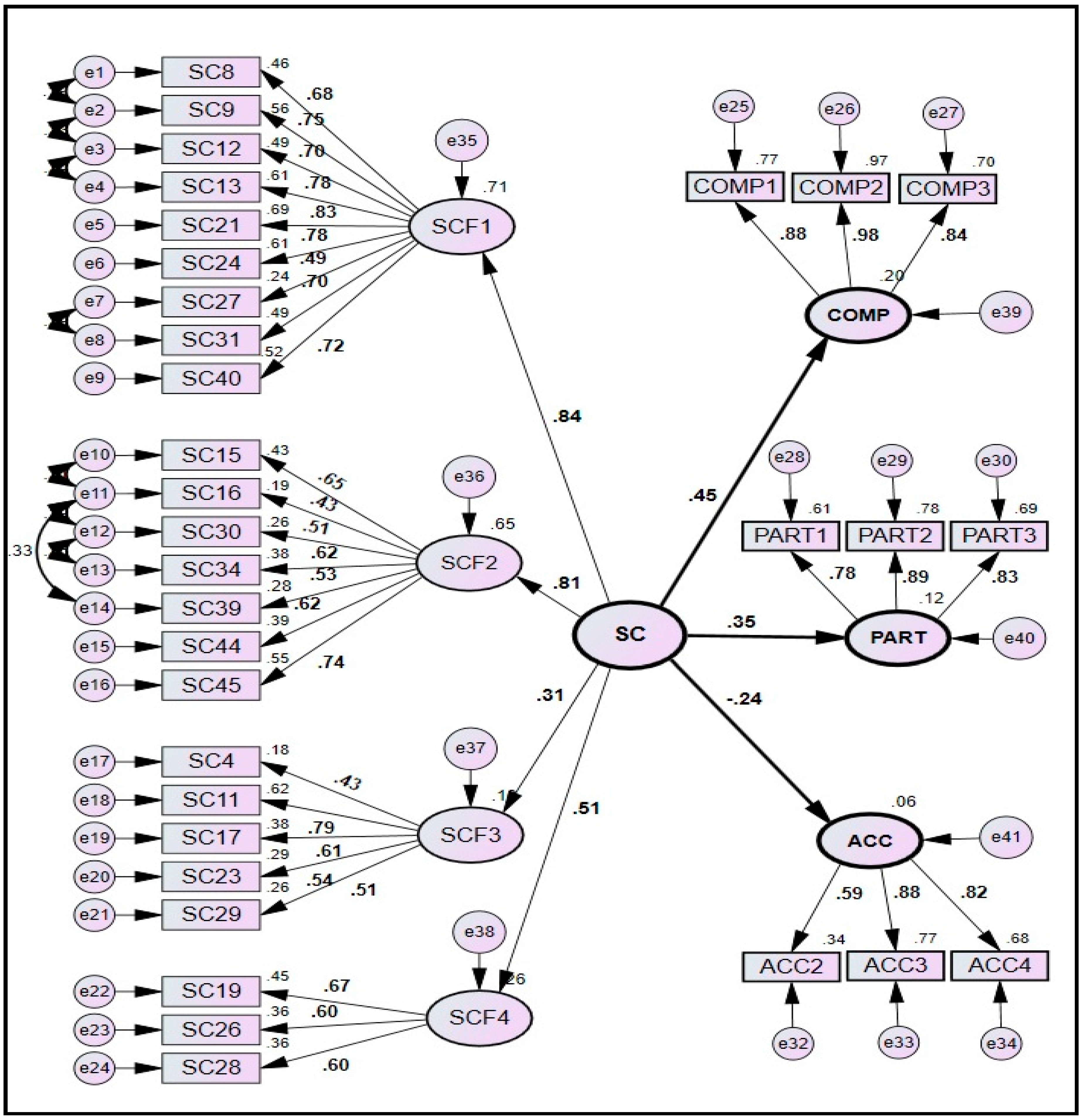

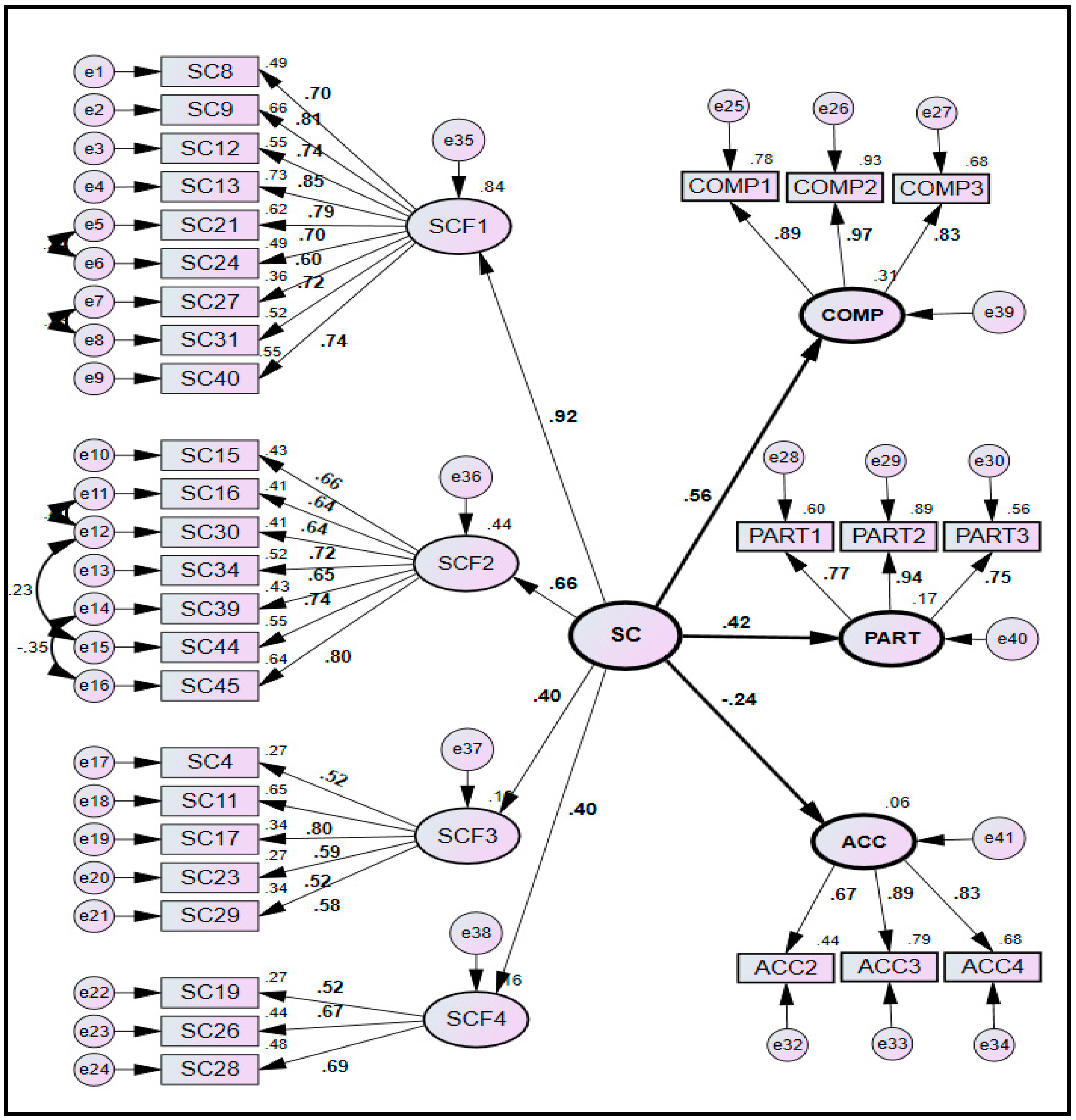

The study encompasses a systematic hybrid approach integrating the statistical techniques of EFA and CFA to validate the SP measurement model of Hong Kong construction industry in the cross-cultural setting of a developing country. In addition, it reveals the variances in the causal associations between SC factors and SP indicators. The developed model comprises of 24 items of SC grouped into four factors/constructs, and nine items of SP grouped into three indicators/constructs. The model was tested and validated using calibration and validation sub-samples (

n = 213 each) respectively. The developed model achieved the desired GOF indices, an acceptable degree of composite reliability, and convergent and discriminate validities. Resonating with the results of Hon et al. [

23], this study has confirmed the significant positive impact of SC on both the safety compliance and safety participation, and significant negative impact on the number of self-reported accidents/injuries.

Considering the importance given to near-misses in previous studies for forecasting the potential accidents/injuries, the “number of near-misses (ACC1)” was initially included in the hypothesized model as one of the observed variables to measure the SP indicator of ‘number of self-reported accidents/injuries and near-misses (ACC)’ [

23]. Notwithstanding, ACC1 could not be retained in the final SEM model due to its lower standardized path coefficient (0.37). Consequently, the related SP indicator was renamed as “number of self-reported accidents/injuries”. Its deletion has not only enhanced the Cronbach’s coefficient alpha value of SP scale from 0.68 to 0.703 (

Table 2) but resulted in achieving the desired GOF indices for SEM model. Given the above, it is suggested to further investigate the applicability of observed variable of ACC1 in measuring the SP in other regions and cultures, so as to eventually include or exclude it from SP measurement model.

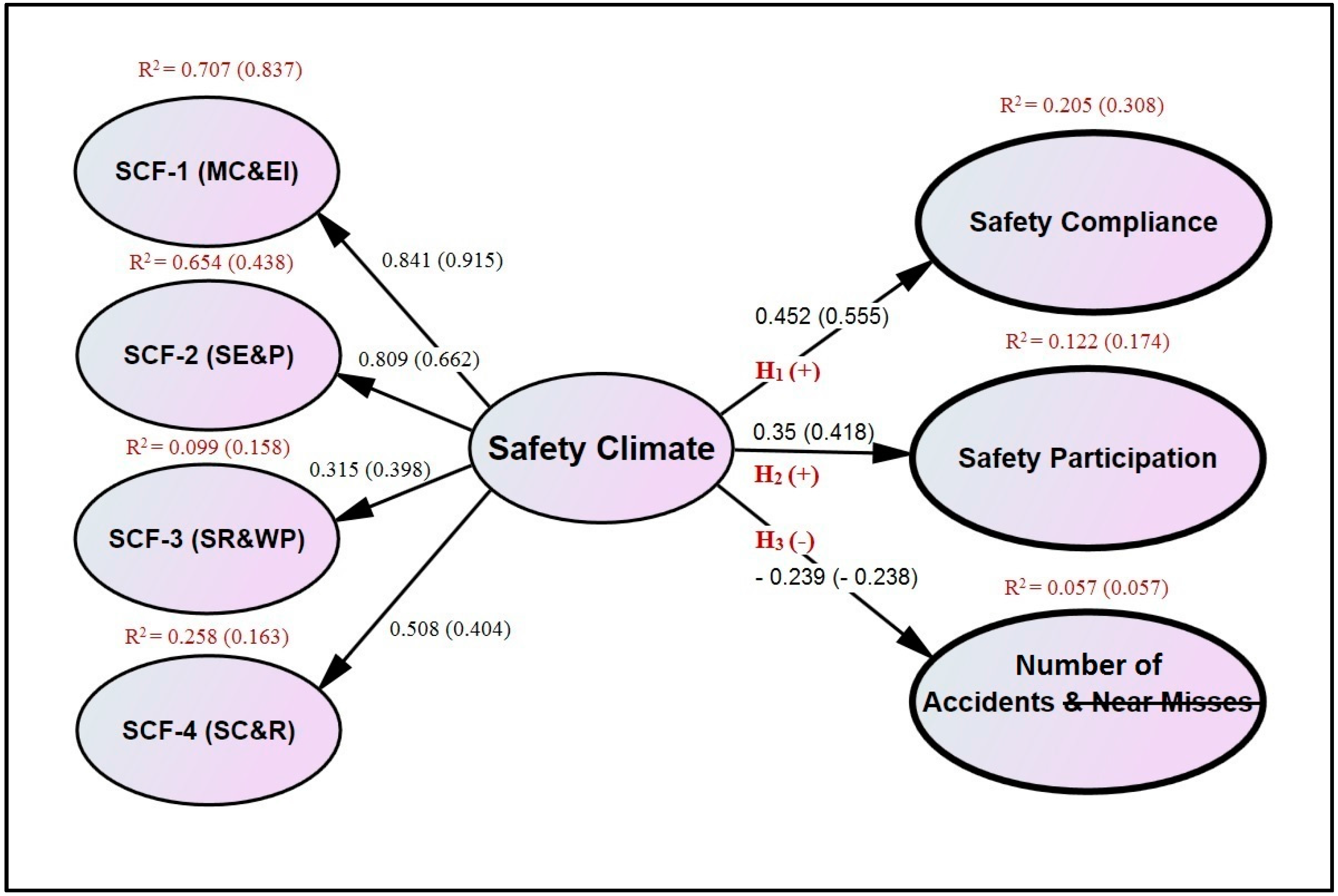

The findings have deviated, to an extent, from the past studies conducted in different regions. For instance, the SP should be immensely influenced by safety participation than the safety compliance [

1,

2,

60]; however, this perception was confronted in this study, as safety compliance has established a stronger positive impact (0.452) on SP than the safety participation (0.35). Moreover, “number of accidents/injuries” was quantified to have the weakest influence (−0.239) on SC among all the three SP indicators. It is, however, inconsistent with the findings of Hon et al. [

23] that could develop the weakest influence of safety participation on SC. These variances in the impact of various SP indicators confirm the necessity of investigating the safety behavior in the cross-cultural and cross-regional environment, especially in the developing countries.

The study has evaluated the relationships between each factor of SC and perceived SP. As presented in

Figure 1, SC factor of MC&EI has developed the strongest relationship (0.841) with perceived SP, followed by SE&P (0.809), SC&R (0.508) and SR&WP (0.315). This finding is almost in line with the study of Choudhry et al. [

8]. However, it contrasts with the study of Hon et al. [

23] that has derived a 3-factor structure, and developed the strongest relationship of perceived SP with the factor of SR&WP as compared to MC&EI. Moreover, the study has identified SE&P as a novel and second most influential SC factor. In the past studies [

9,

10,

14,

35,

36], SC statements related to this factor were generally distributed among other factors such as management commitment, safety regulations and safety promotion. However, two recent studies identified nearly similar SC factors, namely ‘supervisory care promotion’ and “positive feedback and safety recognition” [

61,

62]. The emergence of SE&P as a new SC factor also verifies the influence of regional and cultural values on SC. Hence, a SC scale must be validated in the country of intended use [

17].

Considering the path coefficients of all SC factors (

Figure 2) and their respective percentage of variances (

Table 3), it can be concluded that a focus on the factors of MC&EI and SE&P can have a greater impact on SP. Similarly, relatively lower mean values of the factors of MC&EI and SR&WP demand stakeholder’s special attention (

Table 1 and

Table 5). Despite having a relatively lower mean value, the factor of MC&EI achieved the strongest impact on SC (0.841); thus signifying that a little attention by the higher management will enhance the SP enormously. It can be supplemented with an enhanced employees’ involvement through various incentive schemes and by inculcating the sense of responsibility among its employees [

63]. The corresponding variables of this factor can also be considered for potential improvements. For instance; SC21, measuring the safety communication between the higher management and the workers, achieved the highest path coefficient of 0.832 (mean = 2.81) among all the observed variables of MC&EI factor (

Figure 2). It indicates that a focus on SC21 can greatly impact the factor of MC&EI, and the overall SC and SP. This factor can also be improved by ensuring that people always wear their PPE, and by providing sufficient resources, equipment and safety training to the workers [

23].

Similarly, the lowest mean value of SR&WP factor (2.42) speaks of the appalling situation in the CI of Pakistan where implementation of appropriate safety rules and regulations is lacking and unsafe work practices are not uncommon. One of the main reasons for the lack of compliance to safety instructions is that employees do not see the utility of these safety rules and procedures [

60]. The respondents had also expressed their concern that some safety rules and work procedures are obsolete and incompatible to the site constrictions [

64]. Thus, it is vital for the organizations to effectively communicate the importance of safety rules to their employees. In addition, there is a need to develop and implement the standardized safety rules and regulations that commensurate with the rapid advancement in the construction methods [

4,

65].

The unsuccessful cross-validation of Hon et al. [

23] in Pakistani CI and deviation in the existing factor structure are in line with past two studies [

17,

18], as these studies could not be cross-validated in the developing country of Malaysia and for non-Hispanic construction workers in USA. The variances observed in the cross-validation studies can be attributed to the differences in the: workers’ safety awareness, level of education and safety training, job insecurity, competence of higher management and supervisors, subcontracting practices, effectiveness of the safety regulatory authority, and most importantly, workers propensity towards safety compliance and their risk taking behaviour [

17,

18,

37,

66,

67]. Hence, similar SC factors should not be expected in different countries as well as industries.

5.1. Significance and Practical Implications

The study has several theoretical and practical contributions. First, it contributes to the body of knowledge by opposing the prevailing perception that safety participation, compared to safety compliance, has a stronger influence on SP; Second, it discusses the differences observed in the impact of various SC factors on SP in a developing country; Third, it has discovered SE&P as a novel SC factor comprising of seven SC items; this factor might have been split among other SC factors in previous studies. Fourth, although this study was conducted in Pakistani CI, the developed model is expected to measure the SP in developing countries sharing similar work environment. Fifth, an in-depth understanding of the significant SC factors and their respective dimensions may help the key stakeholders in making their construction sites safer. Finally, a comprehensive methodology was presented that can be replicated in other industries and regions.

5.2. Limitations and Future Directions

First, the cross-sectional design of the study precludes any conclusion regarding the causality. The second limitation concerns the use of self-reported SP data collected from the building projects in Pakistan; hence, caution must be exercised while generalizing the study results to other developing countries. The results were also dependent on the respondent’s candid opinion and the surveys were not personally administered at some of the construction sites. Nevertheless, this research offers a valuable starting point for future safety interventions in developing countries. As the employees’ perceptions can change over time, a longitudinal study can examine the steadiness of the developed model for developing countries. Realizing the varied influence of cultural and regional aspects and the discovery of SE&P as a novel SC factor, potential differences in safety related perceptions need to be further investigated in other developing regions and cultures [

7]. Besides, a multi-level investigation of SC factors is suggested so that the safety behaviour of those employees can be enhanced who are engaged for the subcontracted works in the Pakistani CI [

37].

6. Conclusions

This study has hypothesized and cross-validated the complex associations of three indicators of SP with twenty-four observed variables and four first-order latent factors of SC in a developing region. It is the first study of its kind that has tested an existing model of SC and SP in the CI of Pakistan and reported the inconsistencies in the interrelationships among the model constructs. A developed questionnaire was used to gather the information (n = 426) on variables of interest from forty under-construction multi-storey building projects. EFA was carried out on calibration sub-sample to identify the factors of SC and SP. The extracted SC factors include MC&EI, SE&P, SR&WP and SC&R whereas SP indicators include safety compliance, safety participation and “number of self-reported accidents/injuries”. To test and validate the hypothesized SP measurement model, CFA was conducted on both the calibration and validation sub-samples using AMOS. CFA results offered a perfect understanding of the causal relationship among various constructs of SC and SP. As the developed model achieved the desired GOF indices, construct reliability, and convergent and divergent validities, it is expected to concisely measure the construction SP in the developing countries sharing similar work environment.

The study has confirmed the initial three hypotheses whereas the fourth hypothesis was rejected. It has developed a significant positive impact of SC on both the safety compliance and safety participation, and significant negative impact on the “number of self-reported accidents/injuries” (excluding the near-misses). The “number of near-misses” could not be retained in SP measurement model due to a relatively lower value of standardized path coefficient. In contrast with previous studies, safety compliance has established the strongest positive impact on SP than the safety participation and “number of accidents/injuries”. Similarly, SC factor of MC&EI developed the strongest relationship with perceived SP, followed by SE&P, SC&R and SR&WP. The lowest mean value of SR&WP painted the unpleasant enactment of safety rules and procedures in the CI of Pakistan. Furthermore, the study disclosed SE&P as a novel and second most influential SC factor.

Given the above, construction stakeholders are suggested to focus more on safety compliance for achieving an enhanced SP. In addition, employees need to be motivated to comply with obligatory safe procedures and work practices. Such efforts can be supplemented by inculcating a higher degree of self-motivation among the employees through various incentives to enhance their safety participation. Though safety participation will not contribute directly to personal safety, it will nurture the culture of voluntary participation in the organization. Moreover, there is a need to focus on the factors of MC&EI and SE&P as they can significantly enhance the SP. It is suggested to develop, implement and regularly update the standardized safety rules and regulations matching the rapid technological advancement in the CI.