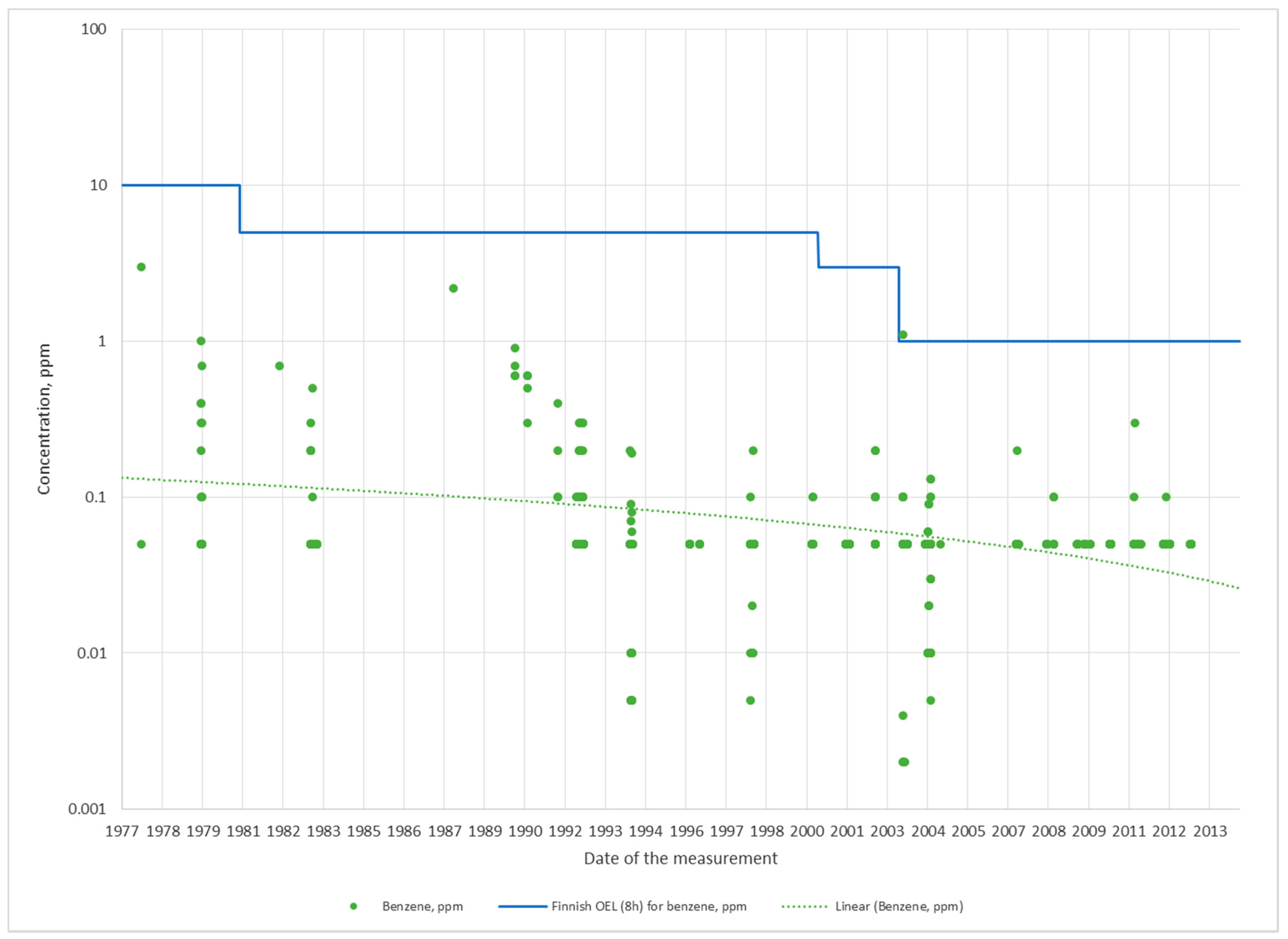

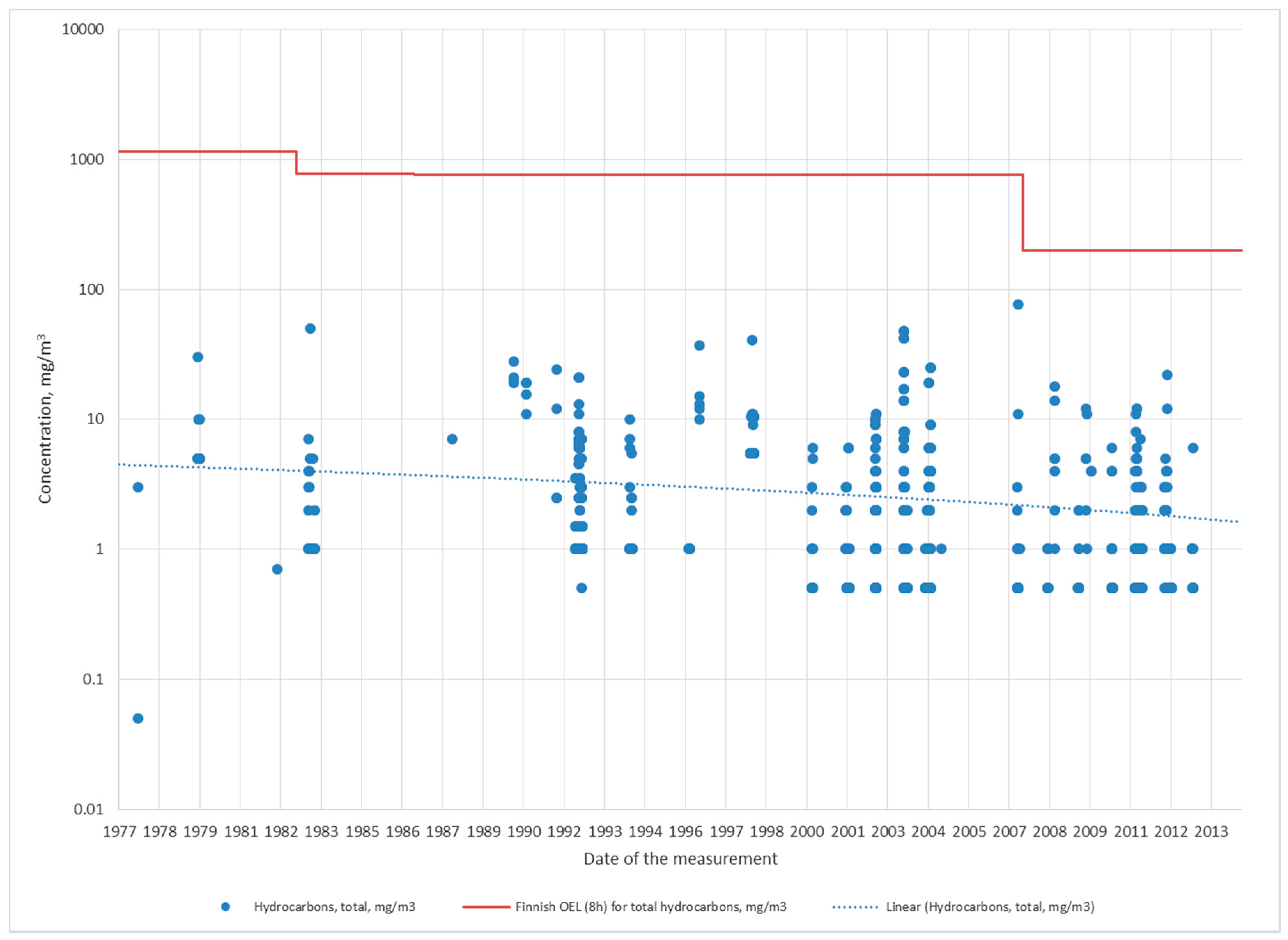

Managing Exposure to Benzene and Total Petroleum Hydrocarbons at Two Oil Refineries 1977–2014

Abstract

:1. Introduction

1.1. Exposure to Benzene and Relevant Health Implications

1.2. Background and Aims of the Study

2. Materials and Methods

2.1. The Company

2.2. Basic Exposure Monitoring Programmes, Online Monitoring of Emissions

2.3. Sample Collection and Analysis in the Present Study

2.4. Testing the Time-Dependency of the Concentration Measurement and Calculating the Change during the Measured Time Interval

2.5. Production Lines 1–5

3. Results

3.1. Production Lines 1–5

3.2. Tank Yard, Wastewater Treatment, Maintenance and Technology Center (Porvoo)

3.3. Harbour, and Distribution and Unloading Terminals (Porvoo)

3.4. Naantali: Tank Yard, Harbour, Distribution Terminal, Wastewater Treatment and Maintenance

4. Discussion

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Edokpolo, B.; Qiming, J.Y.; Connel, D. Health Risk Assessment for Exposure to Benzene in Petroleum Refinery Environments. Int. J. Environ. Res. Public Health 2015, 12, 595–610. [Google Scholar] [CrossRef] [PubMed]

- CONCAWE. Abating Fugitiva VOC Emissions More Efficiently. Concawe Rev. 2015, 24, 3–9. [Google Scholar]

- Chung, E.-K.; Shin, J.-A.; Lee, B.-K.; Kwon, J.; Lee, N.; Chung, K.-J.; Lee, J.-H.; Lee, I.-S.; Kang, S.-K.; Jang, J.-K. Characteristics of Occupational Exposure to Benzene during Turnaround in the Petroleum Industries. Saf. Health Work 2010, 1, 51–60. [Google Scholar] [CrossRef] [PubMed]

- Gaffney, S.H.; Burns, A.M.; Kreider, M.L.; Unice, K.M.; Widner, T.E.; Paustenbach, D.J.; Booher, L.E.; Gelatt, R.H.; Panko, J.M. Occupational Exposure to Benzene at the ExxonMobil Refinery in Beaumont, TX (1976–2007). Int. J. Hyg. Environ. Health 2010, 213, 285–301. [Google Scholar] [CrossRef] [PubMed]

- Twerdok, L.E. Development of Toxicity Criteria for Petroleum Hydrocarbon Fractions in the Petroleum Hydrocarbon Criteria Working Group Approach for Risk-Based Management of Total Petroleum Hydrocarbons in Soil. Drug Chem. Toxicol. 1999, 22, 275–291. [Google Scholar] [CrossRef] [PubMed]

- SCOEL. Recommendation from the Scientific Committee on Occupational Exposure Limits for Benzene, European Commission Scientific Committee on Occupational Exposure Limits (SCOEL); SCOEL/SUM/140; European Commission: Brussels, Belgium, 1991. [Google Scholar]

- DECOS. Benzene, Health-Based Recommended Occupational Exposure Limit, Health Council of the Netherlands, The Hague, Publication March 2014. Available online: http://www.healthcouncil.nl/sites/default/files/benzeen_201403_0.pdf (accessed on 26 June 2015).

- Verma, D.K.; Johnson, D.M.; Shaw, M.L.; des Tombe, K. Benzene and Total Hydrocarbon Exposures in the Downstream Petroleum Industries. AIHAJ 2001, 62, 176–194. [Google Scholar] [CrossRef] [PubMed]

- Gaffney, S.H.; Panko, J.M.; Unice, K.M.; Burns, A.M.; Kreider, M.L.; Gelatt, R.H.; Booher, L.E.; Pausterbach, D.J. Occupational Exposure to benzene at the ExxonMobil Refinery in Baytown, TX (1978–2006). J. Exp. Sci. Environ. Epidemiol. 2011, 21, 169–185. [Google Scholar] [CrossRef] [PubMed]

- Panko, J.M.; Gaffney, S.H.; Burns, A.M.; Unice, K.M.; Kreider, M.L.; Booher, L.E.; Gelatt, R.H.; Marshall, J.R.; Pausterbach, D.J. Occupational Exposure to Benzene at the ExxonMobil Refinery at Baton Rouge, Louisiana (1977–2005). J. Occup. Environ. Hyg. 2009, 6, 517–529. [Google Scholar] [CrossRef] [PubMed]

- WHO. Preventing Disease through Healthy Environments. Exposure to Benzene: A Major Public Health Concern. World Health Organization (WHO). Available online: http://www.who.int/ipcs/features/benzene.pdf (accessed on 26 June 2016).

- Järnström, H.; Saarela, K. Indoor Air Quality and Emissions from Building Materials in New Buildings; Report 2281/2005; VTT Technical Research Centre of Finland Ltd.: Espoo, Finland, 2005. (In Finnish) [Google Scholar]

- Pekari, K.; Vainiotalo, S.; Heikkila, P.; Palotie, A.; Luotamo, M.; Riihimaki, V. Biological monitoring of occupational exposure to low levels of benzene. Scand. J. Work Environ. Health 1992, 18, 317–322. [Google Scholar] [CrossRef] [PubMed]

- EC. European Union Risk Assessment Report: Benzene, Ispra, Italy; European Commission Joint Research Center Institute for Health and Consumer Protection (JRC-IHCP): Brussels, Belgium, 2008. [Google Scholar]

- IARC. A Review of Human Carcinogens. In International Agency for Research on Cancer (IARC) Monograph: Chemical Agents and Related Occupations; IARC: Lyon, France, 2012; pp. 249–285. [Google Scholar]

- Lan, Q.; Zhang, L.; Li, G.; Vermeulen, R.; Weinberg, R.S.; Dosemeci, M.; Rappaport, S.M.; Shen, M.; Alter, B.P.; Wu, Y.; et al. Hematotoxicity in workers exposed to low levels of benzene. Science 2004, 306, 1774–1776. [Google Scholar] [CrossRef] [PubMed]

- Pukkala, E. Cancer Incidence among Finnish Oil Refinery Workers, 1971–1994. JOEM 1998, 40, 675–679. [Google Scholar] [CrossRef] [PubMed]

- Anttila, A.; Pokhrel, A.; Heikkilä, P.; Viinanen, R. Kidney Cancer Risk in Oil Refining in Finland—A Nested Case-Referent Study. JOEM 2015, 57, 68–72. [Google Scholar] [PubMed]

- OHSAS. Occupational Health and Safety Management Systems—Requirements; BS OHSAS Standard 18001:2007; BSI (British Standards Institution): London, UK, 2007. [Google Scholar]

- EPA. Leak Detection and Repair, a Best Practices Guide. United States Environmental Protection Agency (EPA), 2007. Available online: http://www2.epa.gov/sites/production/files/2014-02/documents/ldarguide.pdf (accessed on 26 June 2016).

- EPA. Handbook, Control Techniques for Fugitive VOC Emissions from Chemical Process Facilities. United States Environmental Protection Agency (EPA), 1994. Available online: http://nepis.epa.gov/Adobe/PDF/30004M36.PDF (accessed on 26 June 2016).

- Warner, R.M. Applied Statistics. From Bivariate to Multivariate Techniques, 2nd ed.; Sage Publications Inc.: Thousand Oaks, CA, USA; University of New Hampshire: Durham, NH, USA, 2013. [Google Scholar]

- Kauppinen, T.; Uuksulainen, S.; Saalo, A.; Mäkinen, I. Trends of Occupational Exposure to Chemical Agents in Finland in 1950–2020. Ann. Occup. Hyg. 2013, 57, 593–609. [Google Scholar] [PubMed]

- Carter, M.; Claydon, M.; Giacopetti, D.; Money, C.; Pizzella, G.; Margary, A.; Viinanen, R. A Survey of European Gasoline Exposures for the Period 1999–2001; CONCAWE Report nr. 9 2002; European Oil Company Organisation for Environment, Health and Safety (CONCAWE): Brussels, Belgium, 2002. [Google Scholar]

- Crump, K.; Allen, B. Quantitative Estimates of Risk of Leukemia from Occupational Exposure to Benzene. Occupational Safety and Health Administration, Docket H-059B. J. Clin. Epidemiol. 1987, 40 (Suppl. S2), 101S–111S, [As cited in: Cody, R.R.; Strawderman, W.W.; Kipen, H.M. Hematologic effects of benzene. J. Occup. Med. 1993, 35, 776–782]. [Google Scholar]

- ACGIH. Benzene: TLV(R) Chemical Substances 7th Edition Documentation; American Conference of Governmental Industrial Hygienists (ACGIH): Cincinnati, OH, USA, 2001; pp. 1–24. [Google Scholar]

- OHSAS. Guide to Achieving Effective Occupational Health and Safety Performance; BS OHSAS Standard 18004:2008; BSI (British Standards Institution): London, UK, 2008. [Google Scholar]

- Harris, R.; Cralley, L.J.; Cralley, L.V. Rationale in Patty’s Industrial Hygiene and Toxicology, Vol. III, Part A, Theory and Rationale of Industrial Hygiene Practice: The Work Environment, 3rd ed.; John Wiley & Sons, Inc.: New York, NY, USA, 1994; pp. 1–26. [Google Scholar]

- Collins, J.J.; Ireland, B.; Buckley, C.F.; Shepperly, D. Lymphohaematopoeitic cancer mortality among workers with benzene exposure. Occup. Environ. Med. 2003, 60, 676–679. [Google Scholar] [CrossRef] [PubMed]

| Year | OEL8h | |

|---|---|---|

| TPH Compounds (mg/m3) | Benzene (ppm) | |

| 2014 | 200 | 1 |

| 2012 | 200 | 1 |

| 2009 | 200 | 1 |

| 2007 | 200 a | 1 |

| 2005 | 770 | 1 |

| 2002 | 770 | 1 |

| 2000 | 770 | 1 |

| 1998 | 770 | 5 |

| 1996 | 770 | 5 |

| 1993 | 770 | 5 |

| 1987 | 770 b | 5 f |

| 1981 | 780 c | 5 |

| 1977 | 1150 | 10 |

| 1972 | 1150 d | 10 |

| 1960 | 2000 e | 25 |

| Unit (Number of Presently Exposed Workers in Brackets) | Exposure Agent | Timespan | Number of Measurements | Measurements > OEL (%) | P (Critical 3 Value of ρx,y) | R2 (Coefficient of Determination) | Pearson Correlation (ρx,y) | ρx,y ≥ P | Reduction (%) | Starting Point 4 (mg/m3 or ppm) | End Point 5 (mg/m3 or ppm) | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | Porvoo harbour and ships | Benzene | 1977–2014 | 659 | 1 | 0.076 | 0.0175 | 0.132 | true | 49 | 2.75 | 1.41 |

| (50–100) | Hydrocarbons | 1977–2014 | 659 | 0 | 0.076 | 2.00 × 10−7 | 0.000 | false | ±0 | 4.00 1 | 4.00 1 | |

| 2 | Porvoo distribution terminal | Benzene | 1977–2011 | 368 | 7 | 0.102 | 0.1082 | 0.329 | true | >99 | 4.37 | <0.10 2 |

| (10–20) | Hydrocarbons | 1977–2011 | 368 | 1 | 0.102 | 0.1569 | 0.396 | true | >99 | 245 | <0.10 2 | |

| 3 | Porvoo unloading terminal | Benzene | 1998–2014 | 77 | 1 | 0.224 | 0.0039 | 0.062 | false | ±0 | <0.10 1,2 | <0.10 1,2 |

| (20–50) | Hydrocarbons | 1998–2014 | 77 | 0 | 0.224 | 0.0039 | 0.062 | false | ±0 | 5.00 1 | 5.00 1 | |

| 4 | Porvoo. production line 1 | Benzene | 1977–2014 | 366 | 0 | 0.103 | 0.0485 | 0.220 | true | 54 | 0.24 | 0.11 |

| (100–150) | Hydrocarbons | 1977–2014 | 366 | 0 | 0.103 | 0.0533 | 0.231 | true | 65 | 3.90 | 1.36 | |

| 5 | Porvoo. production line 2 | Benzene | 1977–2014 | 231 | 0 | 0.129 | 0.0264 | 0.162 | true | 15 | 0.08 | 0.07 |

| (100–150) | Hydrocarbons | 1977–2014 | 231 | 0 | 0.129 | 0.0259 | 0.161 | true | >99 | 1.87 | <0.10 | |

| 6 | Porvoo. production line 3 | Benzene | 1977–2011 | 718 | 0 | 0.073 | 0.0428 | 0.207 | true | 71 | 0.13 | <0.10 2 |

| (100–150) | Hydrocarbons | 1977–2011 | 718 | 0 | 0.073 | 0.0120 | 0.110 | true | 42 | 5.57 | 3.23 | |

| 7 | Porvoo. production line 4 | Benzene | 2009–2013 | 42 | 0 | 0.304 | 2.00 × 10−13 | 0.000 | false | ±0 | <0.10 1,2 | <0.101 ,2 |

| (100–150) | Hydrocarbons | 2009–2013 | 42 | 0 | 0.304 | 0.0312 | 0.177 | false | ±0 | 0.50 1 | 0.50 1 | |

| 8 | Porvoo. tank yard | Benzene | 1977–2014 | 175 | 1 | 0.148 | 0.0027 | 0.052 | false | ±0 | 0.10 1 | 0.10 1 |

| (50–100) | Hydrocarbons | 1977–2014 | 175 | 1 | 0.148 | 4.00 × 10−5 | 0.006 | false | ±0 | 2.00 1 | 2.00 1 | |

| 9 | Porvoo. wastewater treatment | Benzene | 1979–2014 | 726 | 4 | 0.073 | 0.0523 | 0.229 | true | >99 | 4.48 | <0.10 |

| (20–50) | Hydrocarbons | 1979–2014 | 726 | 0 | 0.073 | 0.0068 | 0.082 | true | 55 | 19.85 | 8.90 | |

| 10 | Porvoo. maintenance | Benzene | 1977–2008 | 38 | 0 | 0.320 | 0.0248 | 0.157 | false | ±0 | <0.10 1,2 | <0.10 1,2 |

| (100–150) | Hydrocarbons | 1977–2008 | 38 | 0 | 0.320 | 0.3647 | 0.604 | true | >−99 | <0.10 2 | 6.67 | |

| 11 | Porvoo. Technology center | Benzene | 1975–2014 | 222 | 0 | 0.132 | 0.0490 | 0.221 | true | 65 | 0.43 | 0.14 |

| (20–50) | Hydrocarbons | 1975–2014 | 222 | 1 | 0.132 | 0.0174 | 0.132 | true | >−99 | 1.22 | 69.19 | |

| 12 | Naantali. production line 5 | Benzene | 1981–2011 | 504 | 1 | 0.087 | 0.0449 | 0.212 | true | 58 | 0.21 | <0.10 2 |

| (50–100) | Hydrocarbons | 1981–2011 | 635 | 0 | 0.078 | 0.1101 | 0.332 | true | 98 | 69.25 | 1.25 | |

| 13 | Naantali. tank yard | Benzene | 1981–2011 | 158 | 1 | 0.156 | 0.0827 | 0.288 | true | 76 | 0.57 | 0.14 |

| (20–50) | Hydrocarbons | 1981–2011 | 164 | 1 | 0.153 | 0.0555 | 0.236 | true | 92 | 155 | 11.71 | |

| 14 | Naantali. distribution terminal | Benzene | 1981–2013 | 86 | 1 | 0.212 | 0.0168 | 0.130 | false | ±0 | 19.00 1 | 19.00 1 |

| <10 | Hydrocarbons | 1981–2013 | 86 | 0 | 0.212 | 0.0616 | 0.248 | true | 85 | 85.15 | 12.88 | |

| 15 | Naantali. harbour | Benzene | 1981–2011 | 26 | 0 | 0.388 | 0.2249 | 0.474 | true | >99 | 0.27 | <0.10 2 |

| (10–20) | Hydrocarbons | 1981–2011 | 26 | 0 | 0.388 | 0.1183 | 0.344 | false | ±0 | 36.00 1 | 36.00 1 | |

| 16 | Naantali. wastewater treatment | Benzene | 1981–2014 | 121 | 2 | 0.179 | 0.2411 | 0.491 | true | >99 | 1.40 | <0.10 2 |

| (10–20) | Hydrocarbons | 1981–2014 | 121 | 2 | 0.179 | 0.2648 | 0.515 | true | >99 | 345 | <0.10 2 | |

| 17 | Naantali. maintenance | Benzene | 1980–2011 | 59 | 0 | 0.256 | 0.0497 | 0.223 | false | ±0 | <0.10 1,2 | <0.10 1,2 |

| (20–50) | Hydrocarbons | 1980–2011 | 65 | 0 | 0.244 | 0.0638 | 0.253 | true | >99 | 247.92 | <0.10 2 |

| Unit (Number of Presently Exposed Workers in Brackets) | Exposure Agent | Timespan | Number of Measurements | Measurements > OEL (%) | P (Critical 3 Value of ρx,y) | R2 (Coefficient of Determination) | Pearson Correlation (ρx,y) | ρx,y ≥ P | Reduction (%) | Starting Point 4 (mg/m3 or ppm) | End Point 5 (mg/m3 or ppm) | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | Porvoo harbour and ships | Benzene | 1977–2014 | 189 | 3 | 0.143 | 0.048 | 0.2191 | true | 43 | 2.96 | 1.69 |

| (50–100) | Hydrocarbons | 1977–2014 | 189 | 0 | 0.143 | 3.00 × 10−6 | 0.0017 | false | - | 4.00 1 | 4.00 1 | |

| 2 | Porvoo distribution terminal | Benzene | 1977–2011 | 121 | 2 | 0.179 | 0.1122 | 0.3350 | true | 51 | 0.20 | <0.10 2 |

| (10–20) | Hydrocarbons | 1977–2011 | 121 | 0 | 0.179 | 0.169 | 0.4111 | true | >99 | 116.56 | <0.10 2 | |

| 3 | Porvoo unloading terminal | Benzene | 1998–2014 | 38 | 0 | 0.320 | 0.0032 | 0.0566 | false | - | <0.10 1,2 | <0.10 1,2 |

| (20–50) | Hydrocarbons | 1998–2014 | 38 | 0 | 0.320 | 3.00 × 10−5 | 0.0055 | false | - | 5.00 1 | 5.00 1 | |

| 4 | Porvoo. production line 1 | Benzene | 1977–2014 | 90 | 0 | 0.207 | 0.0373 | 0.1931 | false | - | <0.10 1,2 | <0.10 1,2 |

| (100–150) | Hydrocarbons | 1977–2014 | 90 | 0 | 0.207 | 0.0047 | 0.0686 | false | - | 1.00 1 | 1.00 1 | |

| 5 | Porvoo. production line 2 | Benzene | 1977–2014 | 86 | 0 | 0.212 | 1.00 × 10−13 | 0.0000 | false | - | <0.10 1,2 | <0.10 1,2 |

| (100–150) | Hydrocarbons | 1977–2014 | 86 | 0 | 0.212 | 0.0024 | 0.0490 | false | - | 1.00 1 | 1.00 1 | |

| 6 | Porvoo. production line 3 | Benzene | 1977–2011 | 165 | 0 | 0.153 | 0.006 | 0.0775 | false | - | <0.10 1,2 | <0.10 1,2 |

| (100–150) | Hydrocarbons | 1977–2011 | 165 | 0 | 0.153 | 0.0049 | 0.0700 | false | - | 1.50 1 | 1.50 1 | |

| 7 | Porvoo. production line 4 | Benzene | 2009–2013 | 22 | 0 | 0.423 | 3.00 × 10−13 | 0.0000 | false | - | <0.10 1,2 | <0.10 1,2 |

| (100–150) | Hydrocarbons | 2009–2013 | 22 | 0 | 0.423 | 0.0435 | 0.2086 | false | - | 0.50 1 | 0.50 1 | |

| 8 | Porvoo. tank yard | Benzene | 1977–2014 | 142 | 1 | 0.165 | 0.002 | 0.0447 | false | - | 0.10 1 | 0.10 1 |

| (50–100) | Hydrocarbons | 1977–2014 | 142 | 1 | 0.165 | 0.0021 | 0.0458 | false | - | 2.30 1 | 2.30 1 | |

| 9 | Porvoo. wastewater treatment | Benzene | 1979–2014 | 211 | 0 | 0.135 | 0.0563 | 0.2373 | true | 85 | 0.67 | <0.10 2 |

| (20–50) | Hydrocarbons | 1979–2014 | 211 | 0 | 0.135 | 0.0004 | 0.0200 | false | - | 2.00 1 | 2.00 1 | |

| 10 | Porvoo. maintenance | Benzene | 1977–2008 | 38 | 0 | 0.320 | 0.0248 | 0.1575 | false | - | <0.10 1,2 | <0.10 1,2 |

| (100–150) | Hydrocarbons | 1977–2008 | 38 | 0 | 0.320 | 0.3647 | 0.6039 | true | >−99 | <0.10 2 | 6.67 | |

| 11 | Porvoo. Technology center | Benzene | 1975–2014 | 114 | 0 | 0.184 | 0.0087 | 0.0933 | false | - | <0.10 1,2 | <0.10 1,2 |

| (20–50) | Hydrocarbons | 1975–2014 | 114 | 1 | 0.184 | 0.0158 | 0.1257 | false | - | 4.50 1 | 4.50 1 | |

| 12 | Naantali. production line 5 | Benzene | 1981–2011 | 129 | 0 | 0.173 | 0.0351 | 0.1873 | true | 5 | 0.11 | <0.10 2 |

| (50–100) | Hydrocarbons | 1981–2011 | 143 | 0 | 0.164 | 0.027 | 0.1643 | true | 86 | 31.65 | 4.48 | |

| 13 | Naantali. tank yard | Benzene | 1981–2011 | 56 | 2 | 0.263 | 0.0703 | 0.2651 | true | 82 | 0.55 1 | <0.10 1,2 |

| (20–50) | Hydrocarbons | 1981–2011 | 56 | 0 | 0.263 | 0.1738 | 0.4169 | true | >99 | 75.45 | <0.10 2 | |

| 14 | Naantali. distribution terminal | Benzene | 1981–2013 | 27 | 0 | 0.381 | 0.2002 | 0.4474 | true | 76 | 0.41 | <0.10 2 |

| <10 | Hydrocarbons | 1981–2013 | 27 | 0 | 0.381 | 0.3087 | 0.5556 | true | >99 | 178.06 | <0.10 2 | |

| 15 | Naantali. harbour | Benzene | 1981–2011 | 7 | 0 | 0.754 | 0.2543 | 0.5043 | false | - | 0.10 1 | 0.10 1 |

| (10–20) | Hydrocarbons | 1981–2011 | 7 | 0 | 0.754 | 0.0818 | 0.2860 | false | - | 64.00 1 | 64.00 1 | |

| 16 | Naantali. wastewater treatment | Benzene | 1981–2014 | 21 | 5 | 0.433 | 0.5588 | 0.7475 | true | 96 | 2.84 | <0.10 2 |

| (10–20) | Hydrocarbons | 1981–2014 | 21 | 10 | 0.433 | 0.6374 | 0.7984 | true | >99 | 842.76 | <0.10 2 | |

| 17 | Naantali. maintenance | Benzene | 1980–2011 | 58 | 0 | 0.259 | 0.0544 | 0.2332 | false | - | <0.10 1,2 | <0.10 1,2 |

| (20–50) | Hydrocarbons | 1980–2011 | 64 | 0 | 0.246 | 0.0662 | 0.2573 | true | >99 | 54.72 | <0.10 2 |

| Unit | Number of Measurements | Median, Air Concentrations (ppm) | Average, Air Concentrations (ppm) | 95% Percentile, Air Concentration 2 (ppm) | 95% Percentile, Exposure 2 (ppm) |

|---|---|---|---|---|---|

| Porvoo, production line 1 | 160 | <0.10 2 | <0.10 2 | 0.10/<0.10 | <0.10 |

| Porvoo, production line 2 | 60 | <0.10 2 | <0.10 2 | 0.10/<0.10 | <0.10 |

| Porvoo, production line 3 | 193 | <0.10 2 | 0.19 2 | 0.30/<0.10 | <0.10 |

| Porvoo, production line 4 | 42 | <0.10 2 | <0.10 2 | <0.10/<0.10 | <0.10 |

| Naantali, production line 5 | 134 | <0.10 2 | <0.10 2 | 0.10/<0.10 | <0.10 |

| Porvoo, tank yard | 328 | <0.10 1 | 1.0 1 | 0.20/- | - |

| Porvoo, wastewater treat. | 981 | 0.10 1 | 5.0 1 | 0.10/<0.10 | <0.10 |

| Porvoo, maintenance | 75 | <0.10 1 | 0.73 1 | <0.10/0.10 | <0.10 |

| Porvoo, Technology center | 306 | 0.10 1 | 0.20 1 | <0.10/<0.10 | 0.10 |

| Porvoo harbour and ships | 840 | <0.10 1 | 0.83 1 | 0.40/0.45 | 0.45 |

| Porvoo distr. terminal | 718 | 0.30 1 | 2.0 1 | <0.10/<0.10 | <0.10 |

| Porvoo unloading terminal | 188 | <0.10 1 | 1.1 1 | 0.20/<0.10 | <0.10 |

| Naantali, tank yard | 212 | 0.10 1 | 0.52 1 | 0.18/0.27 | 0.27 |

| Naantali, distr. terminal | 243 | <0.10 1 | 0.27 1 | 0.10/<0.10 | <0.10 |

| Naantali, harbour | 46 | <0.10 1 | 0.20 1 | -/- | - |

| Naantali, wastew. treat. | 167 | <0.10 1 | 0.35 1 | 0.14/- | - |

| Naantali, maintenance | 81 | <0.10 1 | 0.14 1 | -/- | - |

| Unit | Number of Measurements | Median, Air Concentrations (ppm) | Average, Air Concentrations (ppm) | 95% Percentile, Air Concentration 2 (mg/m3) | 95% Percentile, Exposure 2 (mg/m3) |

|---|---|---|---|---|---|

| Porvoo, production line 1 | 168 | 1 2 | 9 2 | 39/15 | 15 |

| Porvoo, production line 2 | 65 | 1 2 | 3 2 | 10/6 | 6 |

| Porvoo, production line 3 | 198 | 1 2 | 4 2 | 79/3 | 3 |

| Porvoo, production line 4 | 42 | 0.5 2 | 2 2 | 6/5 | 5 |

| Naantali, production line 5 | 134 | 4 2 | 28 2 | 92/62 | 62 |

| Porvoo, tank yard | 328 | 2 1 | 32 1 | 76/- | - |

| Porvoo, wastewater treat. | 981 | 2 1 | 33 1 | 4/4 | 4 |

| Porvoo, maintenance | 75 | 1 1 | 19 1 | 17/17 | 17 |

| Porvoo, Technology center | 306 | 4 1 | 35 1 | 386 3/33 | 33 |

| Porvoo harbour and ships | 840 | 4 1 | 18 1 | 56/18 | 18 |

| Porvoo distr. terminal | 718 | 24 1 | 129 1 | 17/2 | 2 |

| Porvoo unloading terminal | 188 | 5 1 | 40 1 | 96/44 | 44 |

| Naantali, tank yard | 212 | 30 1 | 157 1 | 56/51 | 51 |

| Naantali, distr. terminal | 243 | 24 1 | 174 1 | 477/2 | 2 |

| Naantali, harbour | 46 | 35 1 | 147 1 | -/- | - |

| Naantali, wastew. treat. | 167 | 10 1 | 89 1 | 75/- | - |

| Naantali, maintenance | 81 | 37 1 | 10 1 | -/- | - |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tuomi, T.; Veijalainen, H.; Santonen, T. Managing Exposure to Benzene and Total Petroleum Hydrocarbons at Two Oil Refineries 1977–2014. Int. J. Environ. Res. Public Health 2018, 15, 197. https://doi.org/10.3390/ijerph15020197

Tuomi T, Veijalainen H, Santonen T. Managing Exposure to Benzene and Total Petroleum Hydrocarbons at Two Oil Refineries 1977–2014. International Journal of Environmental Research and Public Health. 2018; 15(2):197. https://doi.org/10.3390/ijerph15020197

Chicago/Turabian StyleTuomi, Tapani, Henna Veijalainen, and Tiina Santonen. 2018. "Managing Exposure to Benzene and Total Petroleum Hydrocarbons at Two Oil Refineries 1977–2014" International Journal of Environmental Research and Public Health 15, no. 2: 197. https://doi.org/10.3390/ijerph15020197