Effect of Organic Loading on Rotating Biological Contactor Efficiency

Abstract

:Introduction

Selected Data

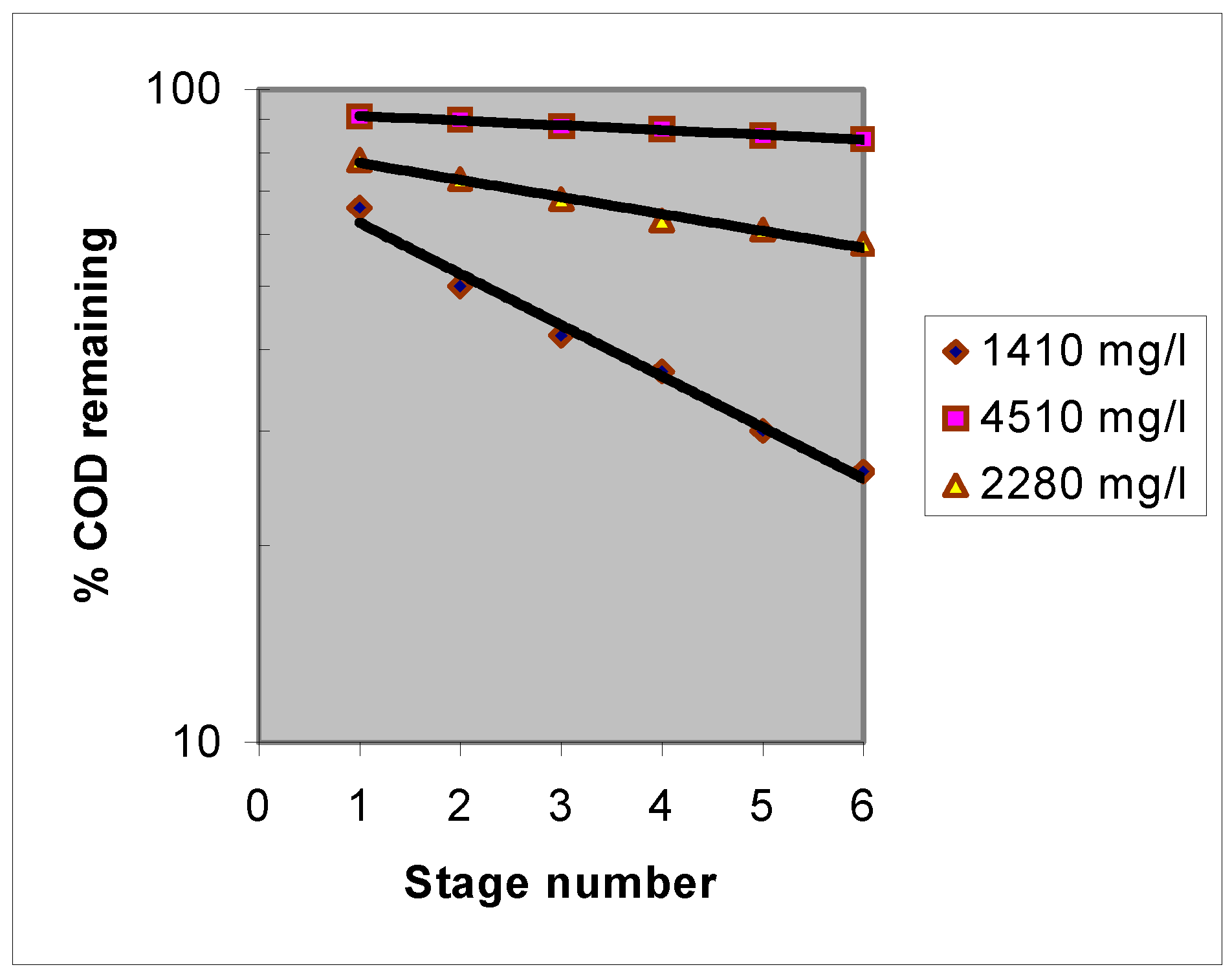

Effects of Organic Characteristics

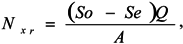

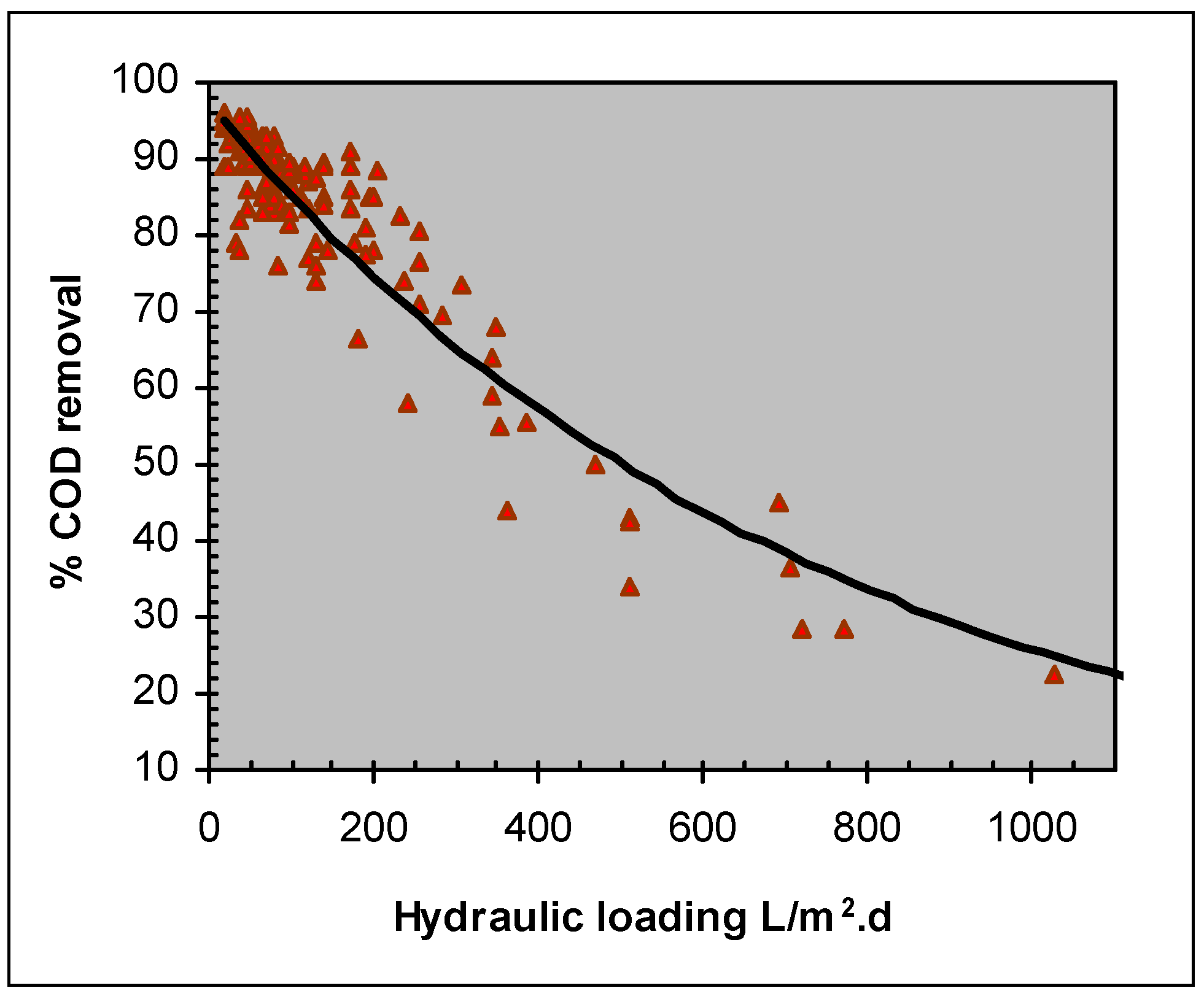

Effect of Hydraulic Loading

- Lx is the hydraulic loading applied in terms of (L/m2.d) and,

- Sr is the percent of organic removal in terms ofCOD.

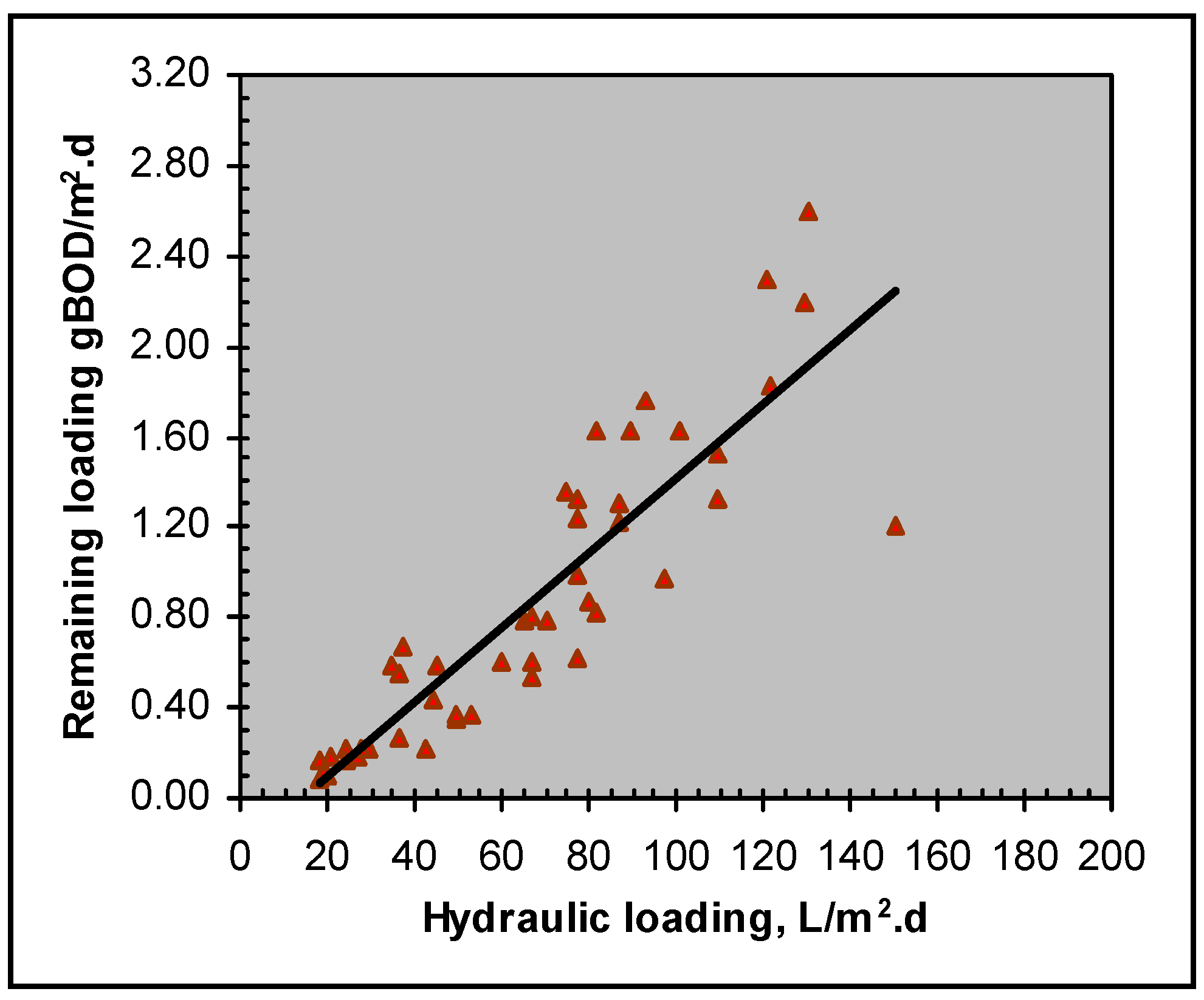

- Ne is the organic loading remaining in terms of (gBOD /m2.d)

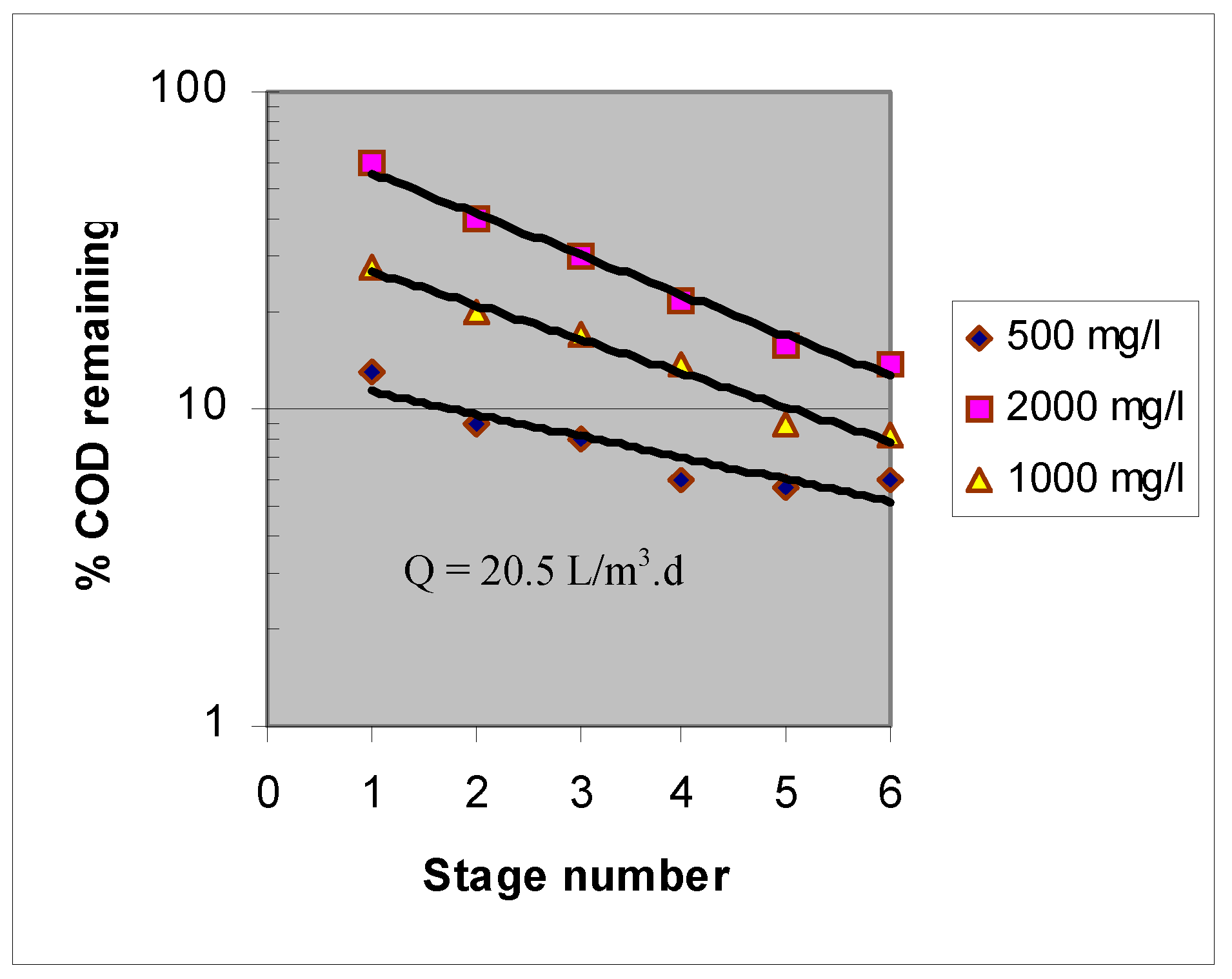

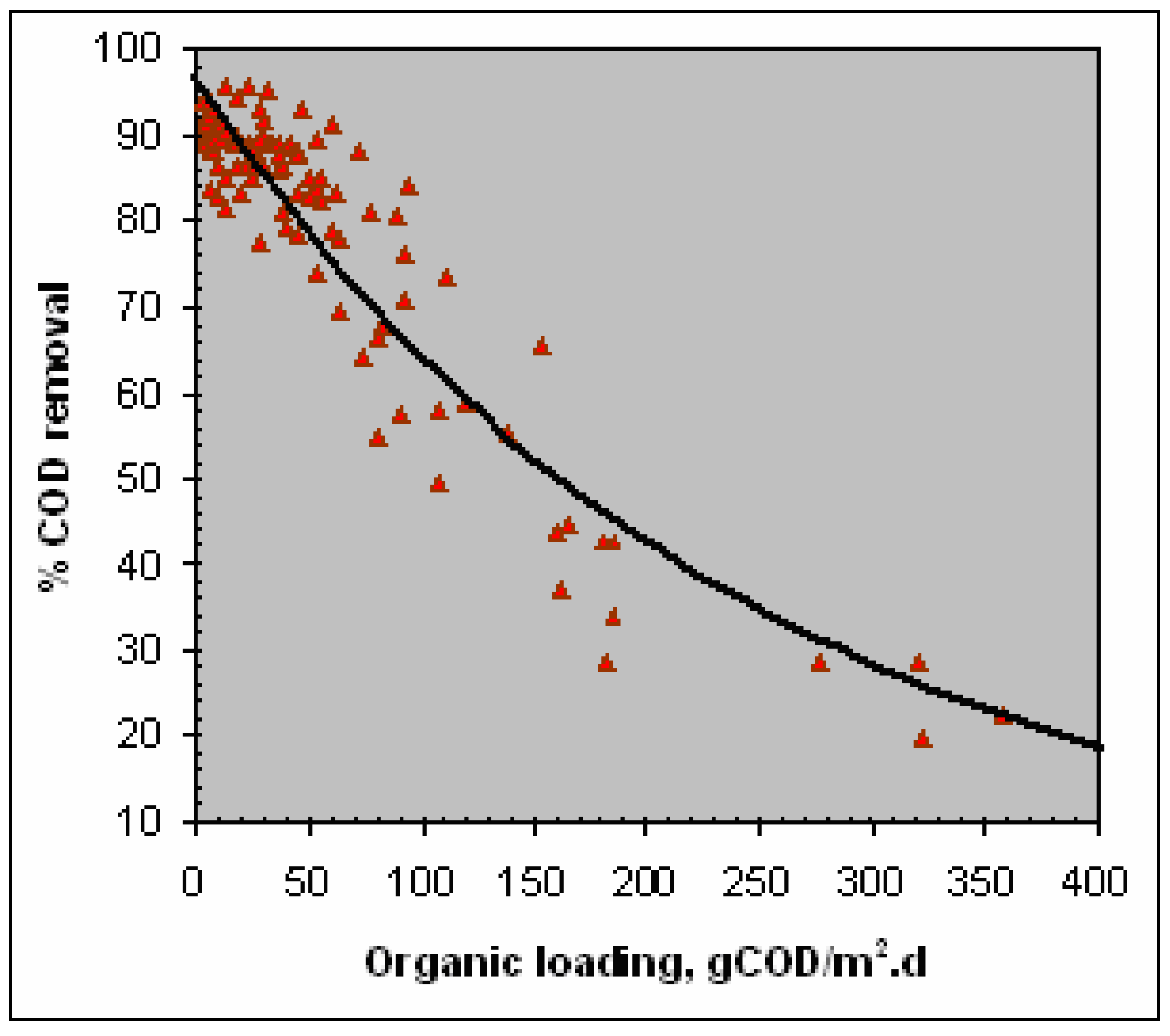

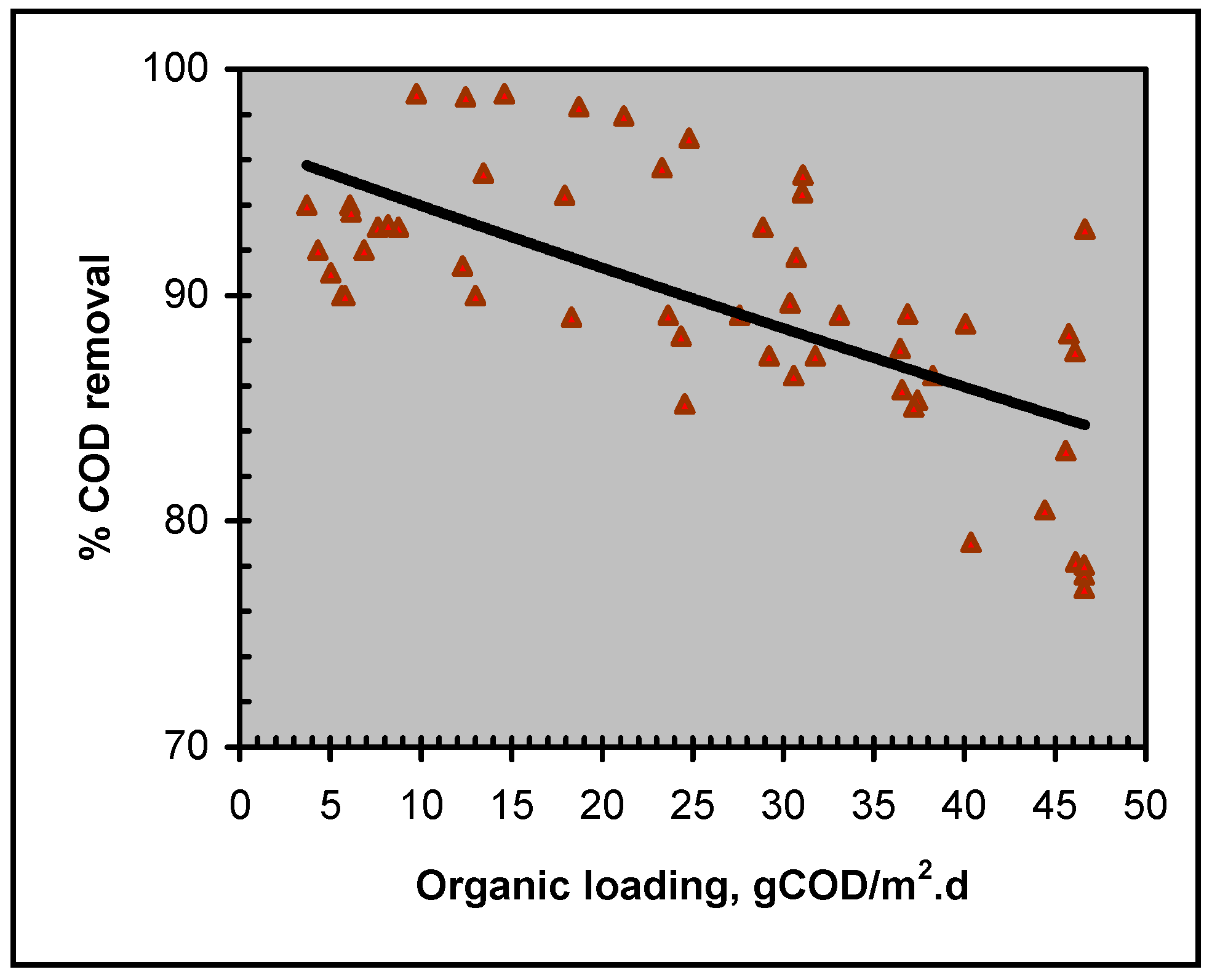

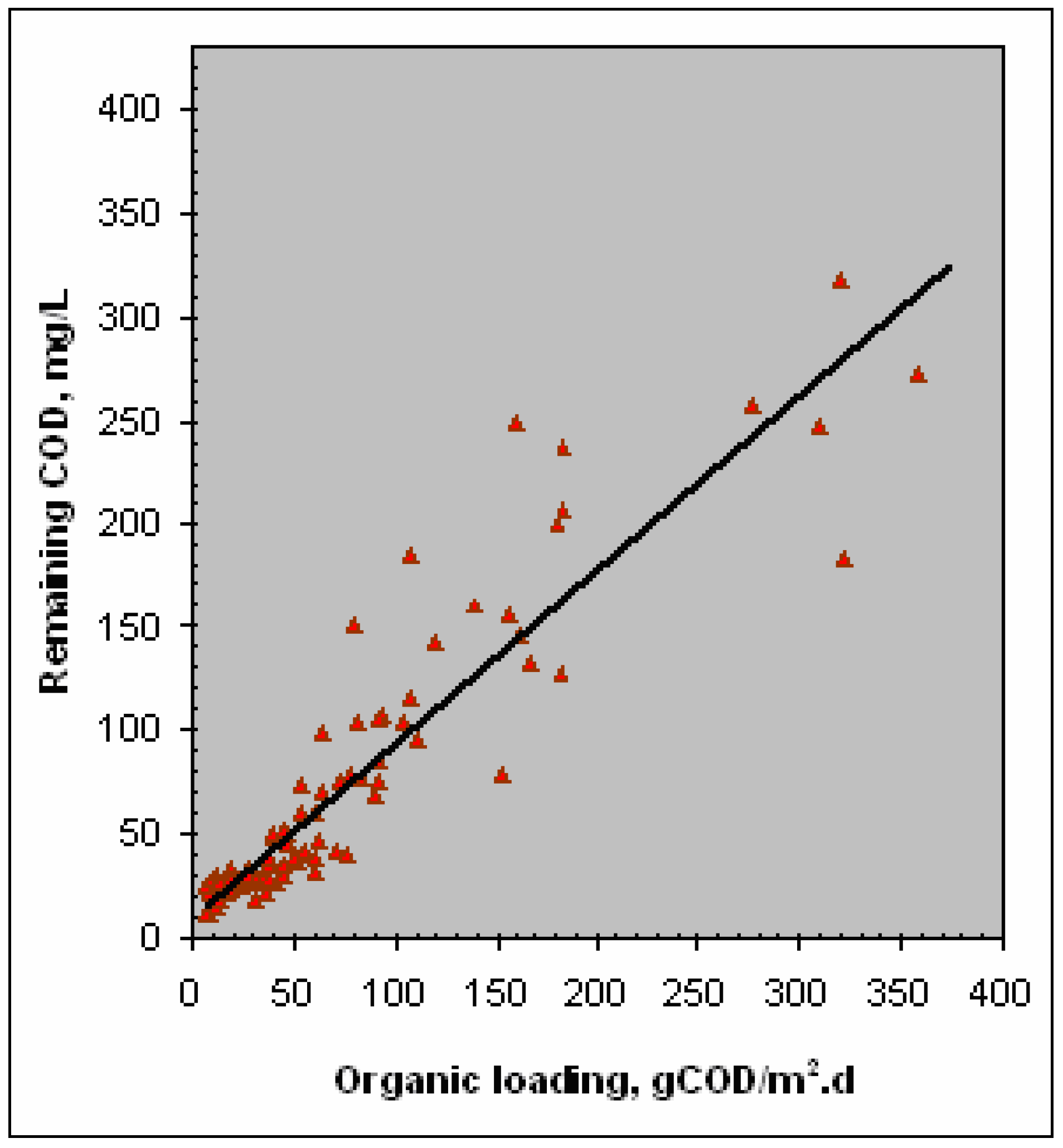

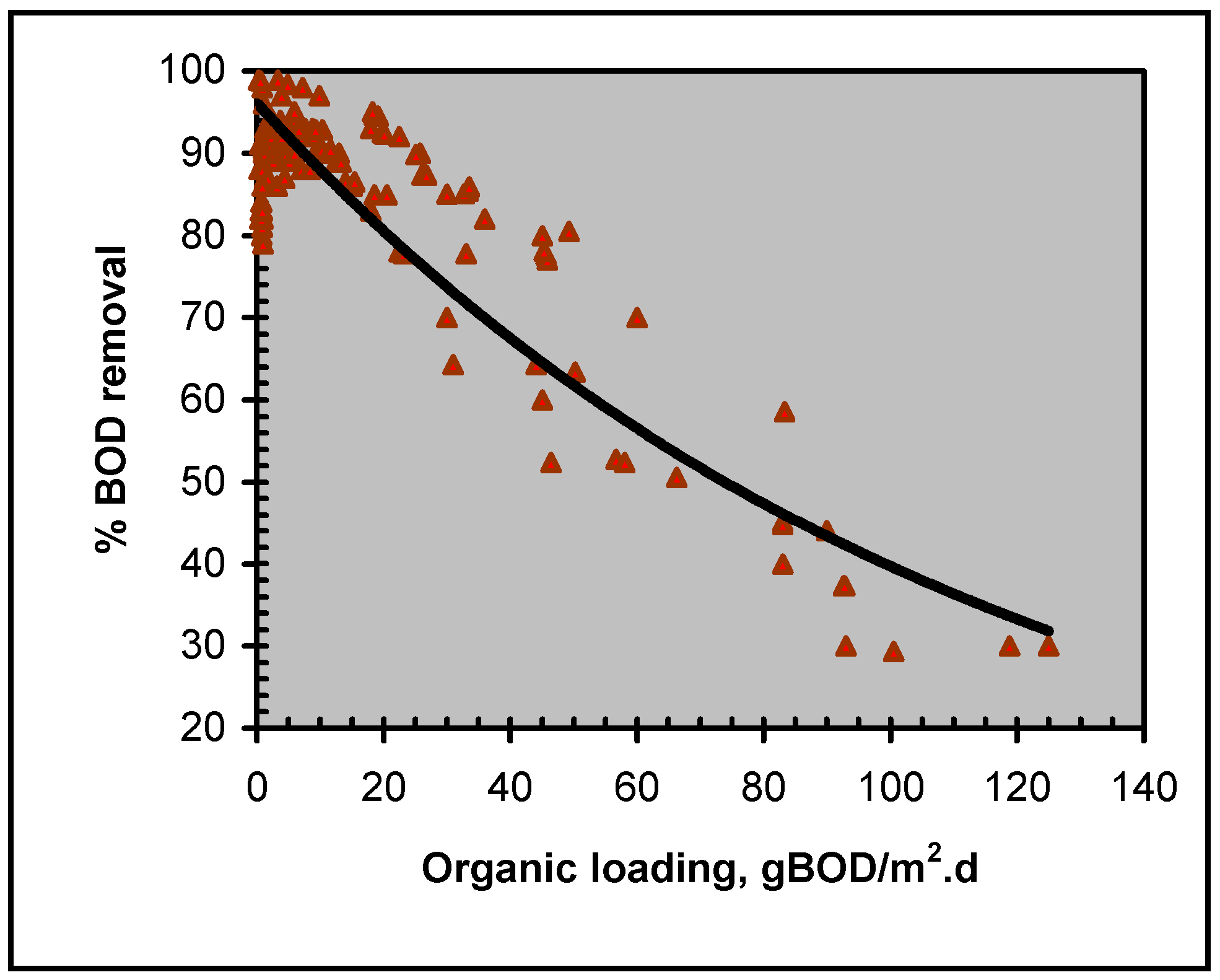

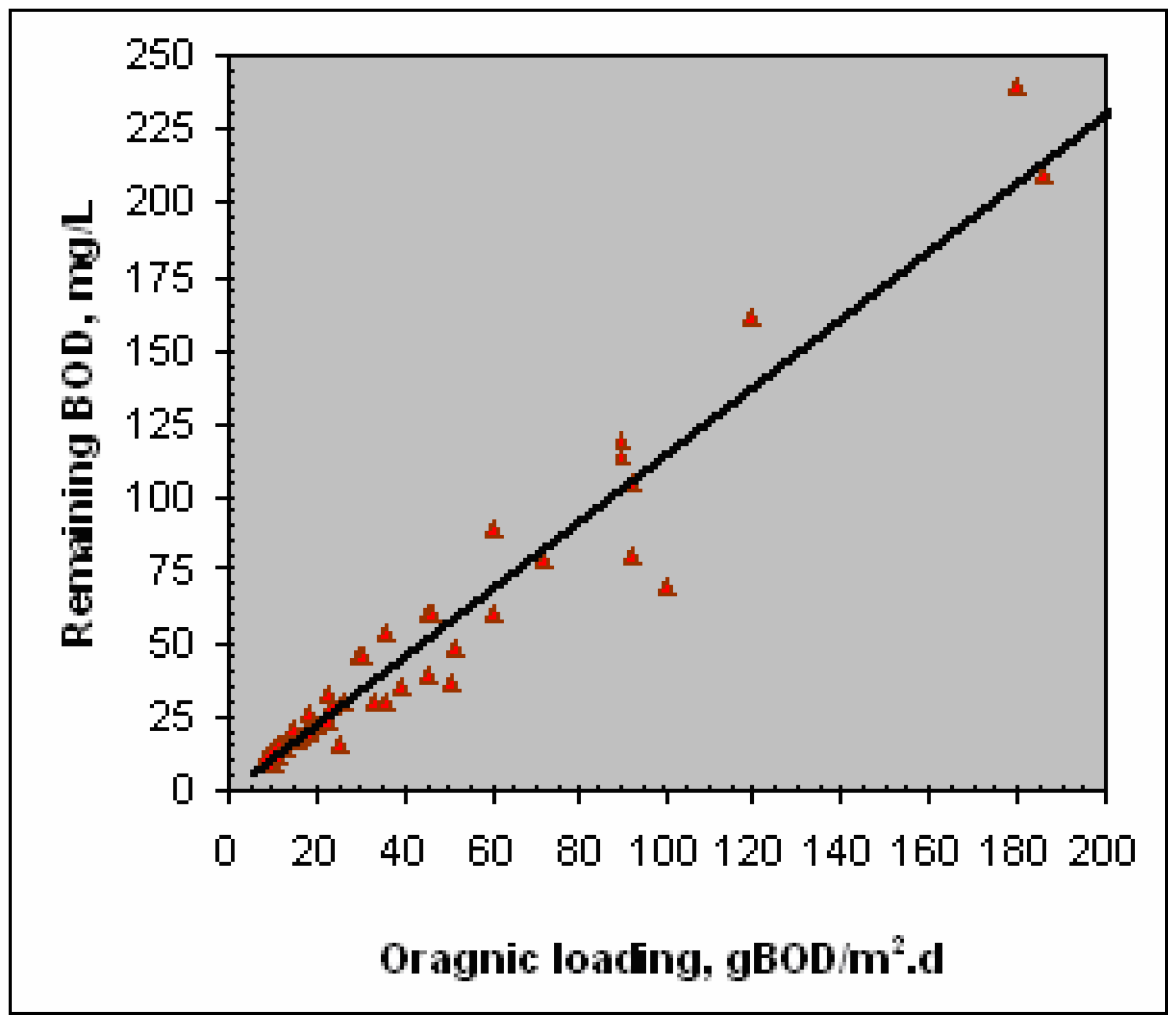

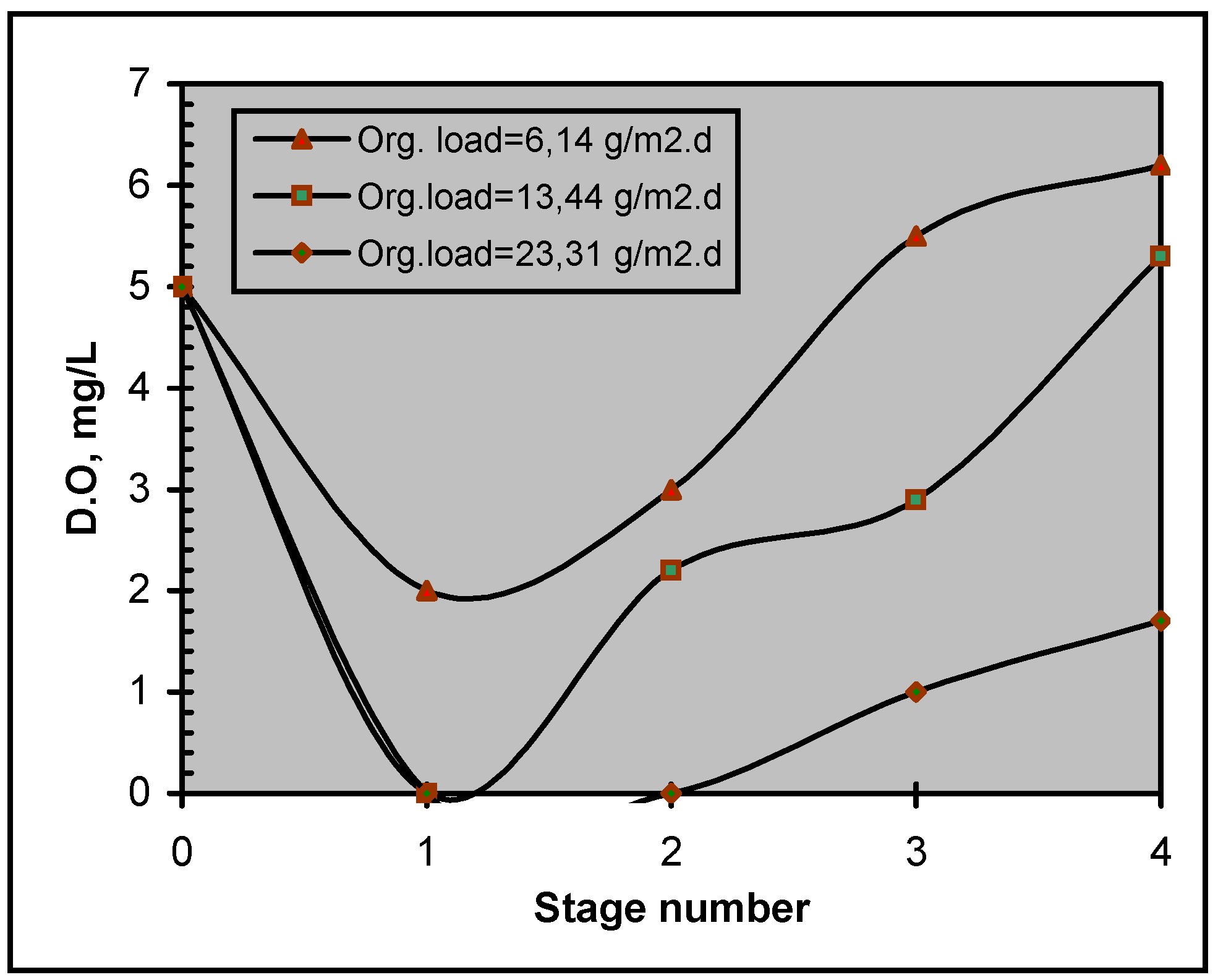

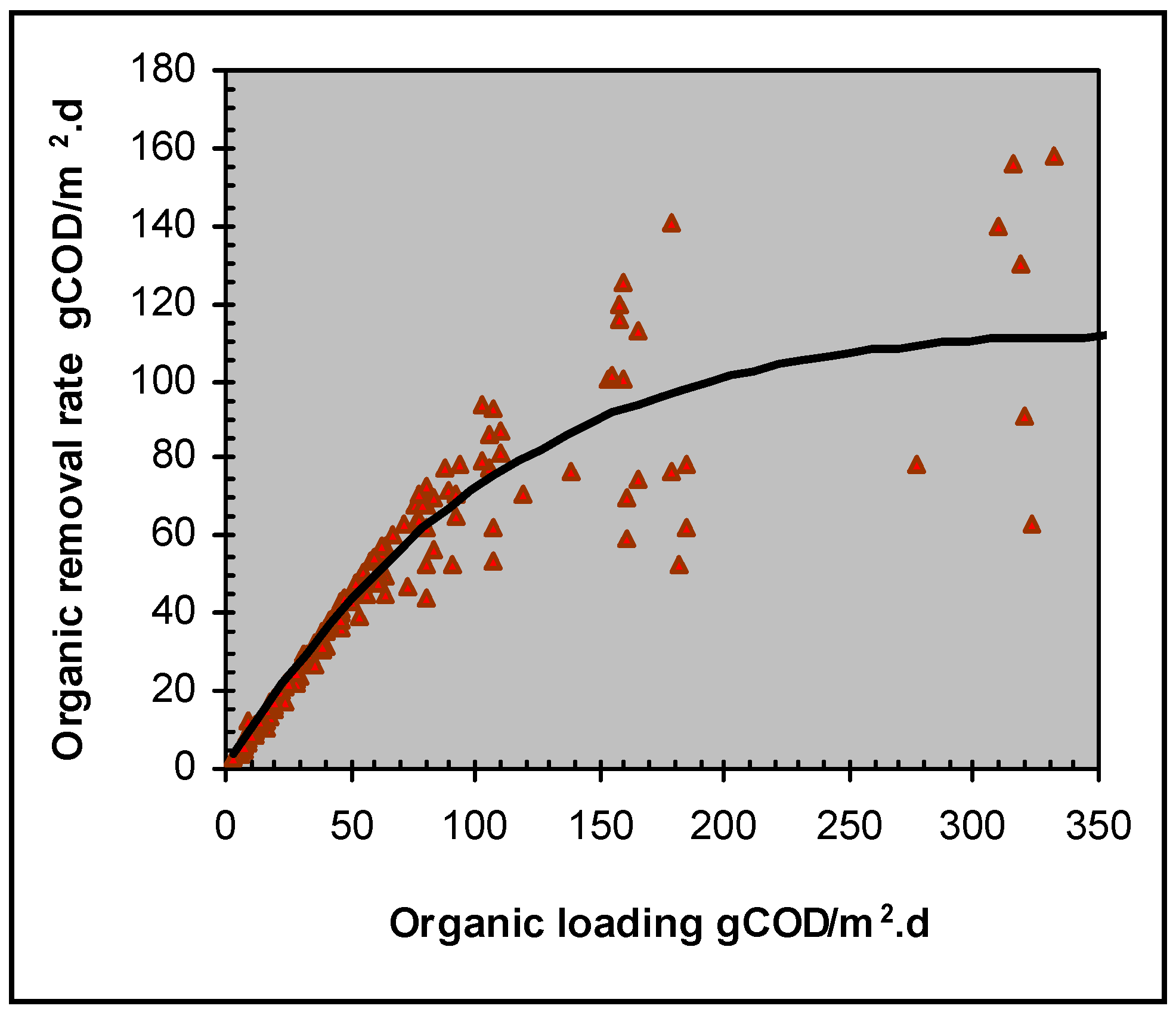

Effect of Organic Loading

- Sr is the percent removal efficiency of the system in terms of COD.

- Nx is the organic loading applied in terms of gCOD/m2.d

- Se is the concentration of organic substrate remaining in effluent from the system organic in terms of COD, (mg/l).

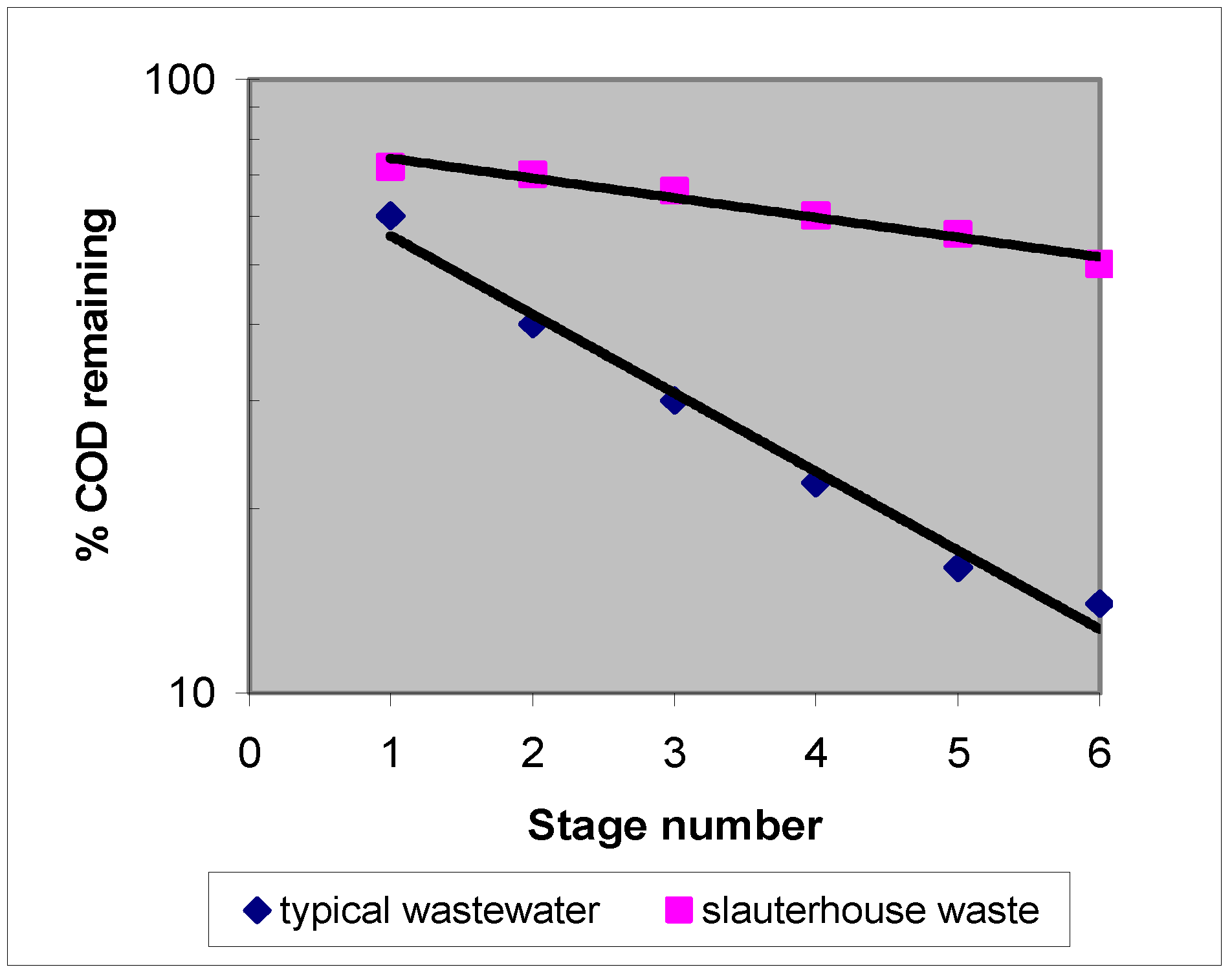

- Nxr is the removed loading in terms of gCODr/m2.d, which can be represented as:

- So: influent COD in (mg/l);

- Se: effluent or remaining COD in (mg/l);

- Q: flow rate (m3/d) and;

- A is the surface area of the contactor (m2).

Conclusions

- (1)

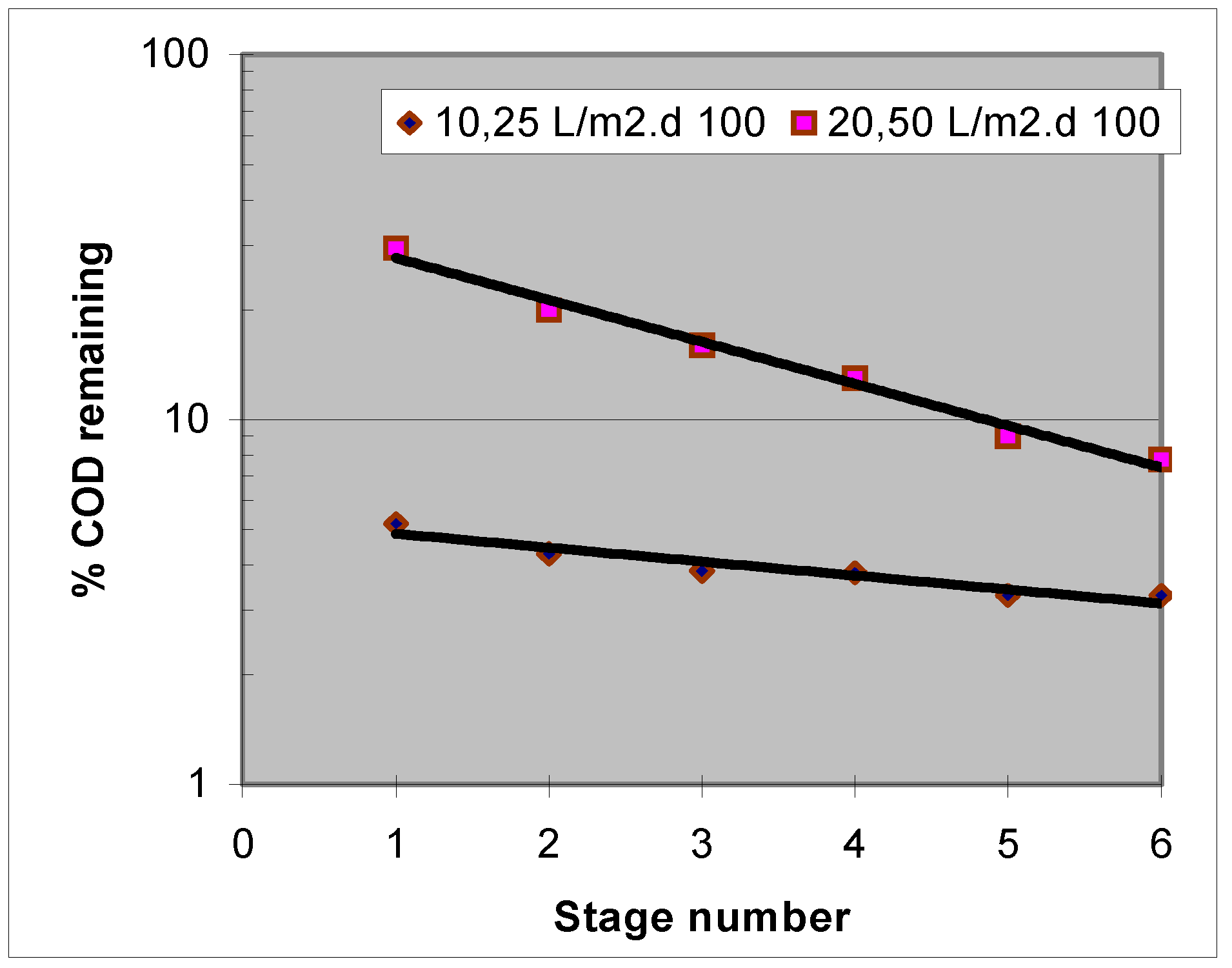

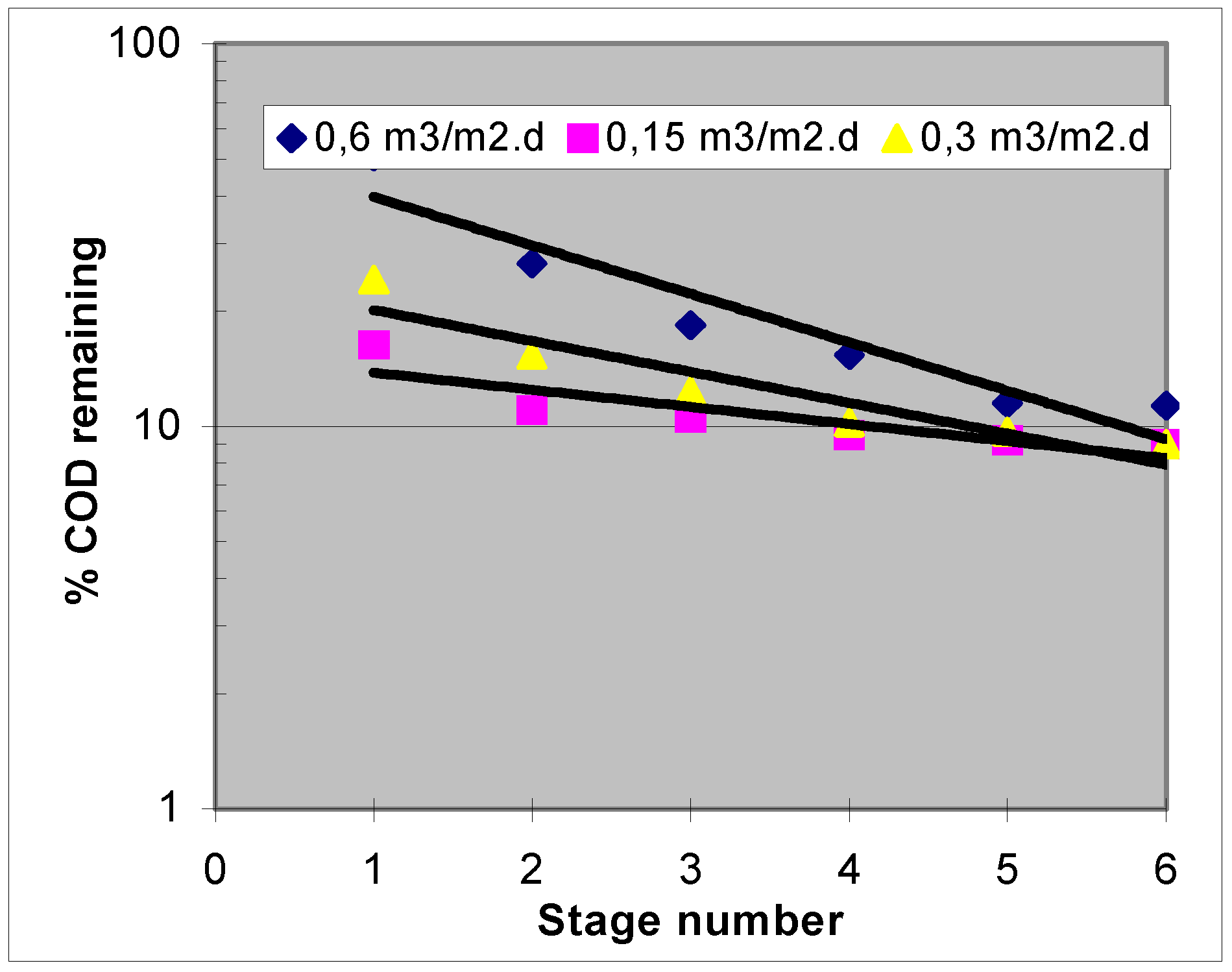

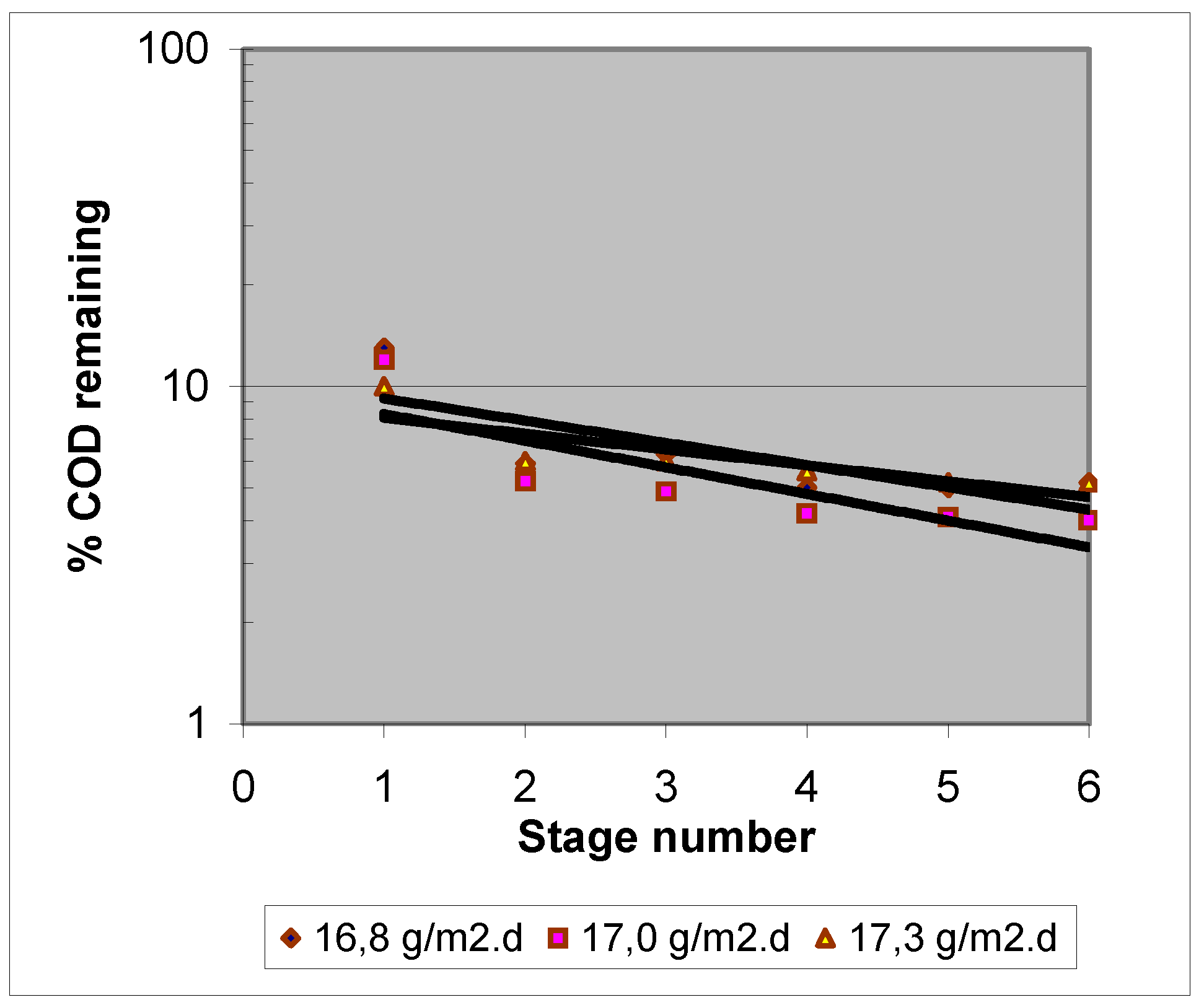

- The majority of COD removal occurs in the first stages of rotating biological contactor systems. The COD removal in the first stages ranging between (40-85 %) depending on the organic loading applied. However, each of the type of wastewater and flow rate is also influence on the system efficiency but their impact can be combined by the effect of organic loading.

- (2)

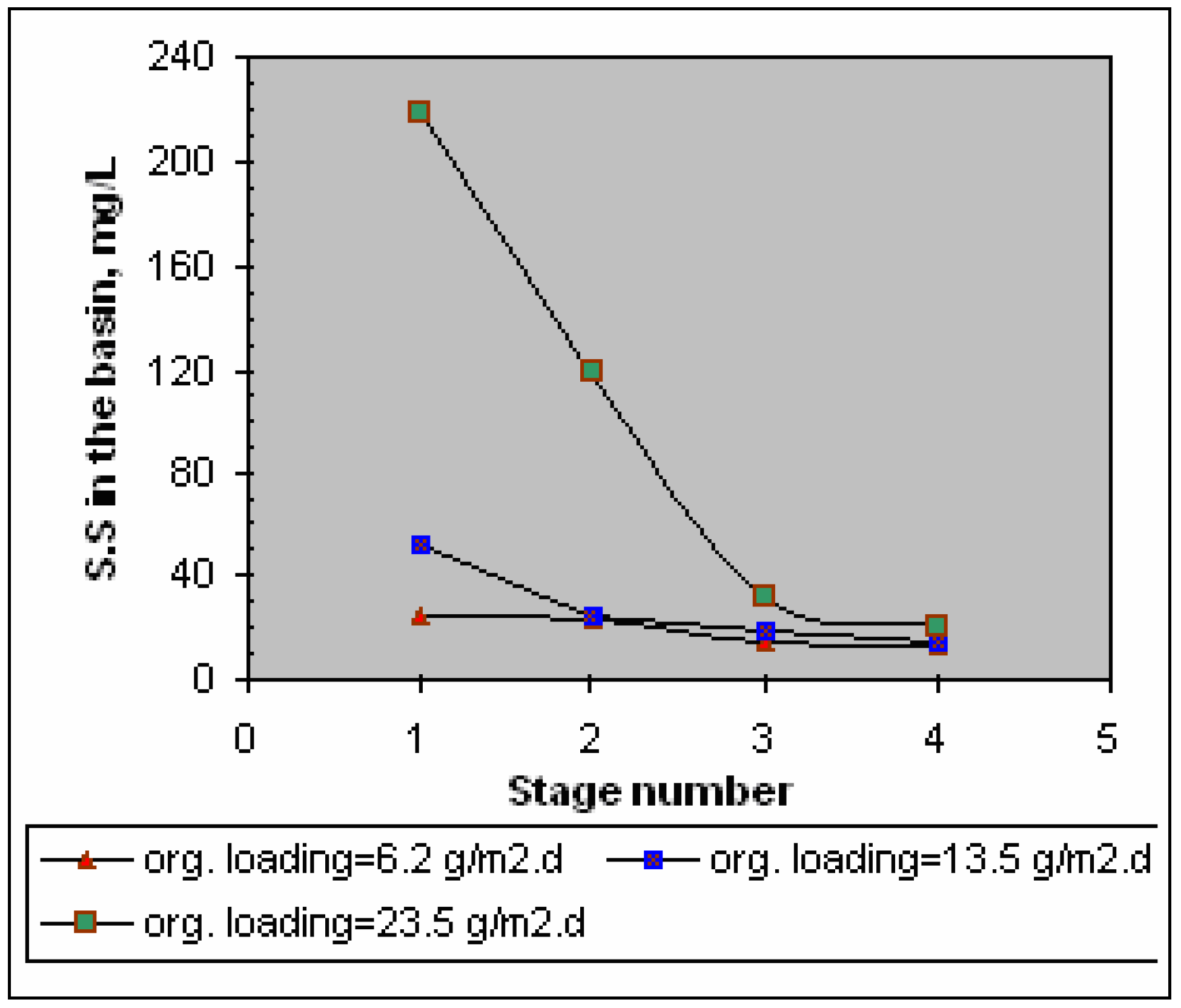

- There is a strong correlation between the organic loading applied and the concentration of the suspended solids present in the rotating biological contactor basins. At higher loadings, higher concentration is noted. At a loading of about, (24 g/m2.d) suspended solids were 225, 125, 35, and 25 mg/L at the first, second, third and, the fourth stage respectively.

- (3)

- To achieve an effluent quality of: BOD ≤ 25 mg/L, COD ≤ 60 mg/L, the system should be operated on organic loading rates of (22 gBOD /m2.d and 65 gCOD g/m2.d) respectively.

- (4)

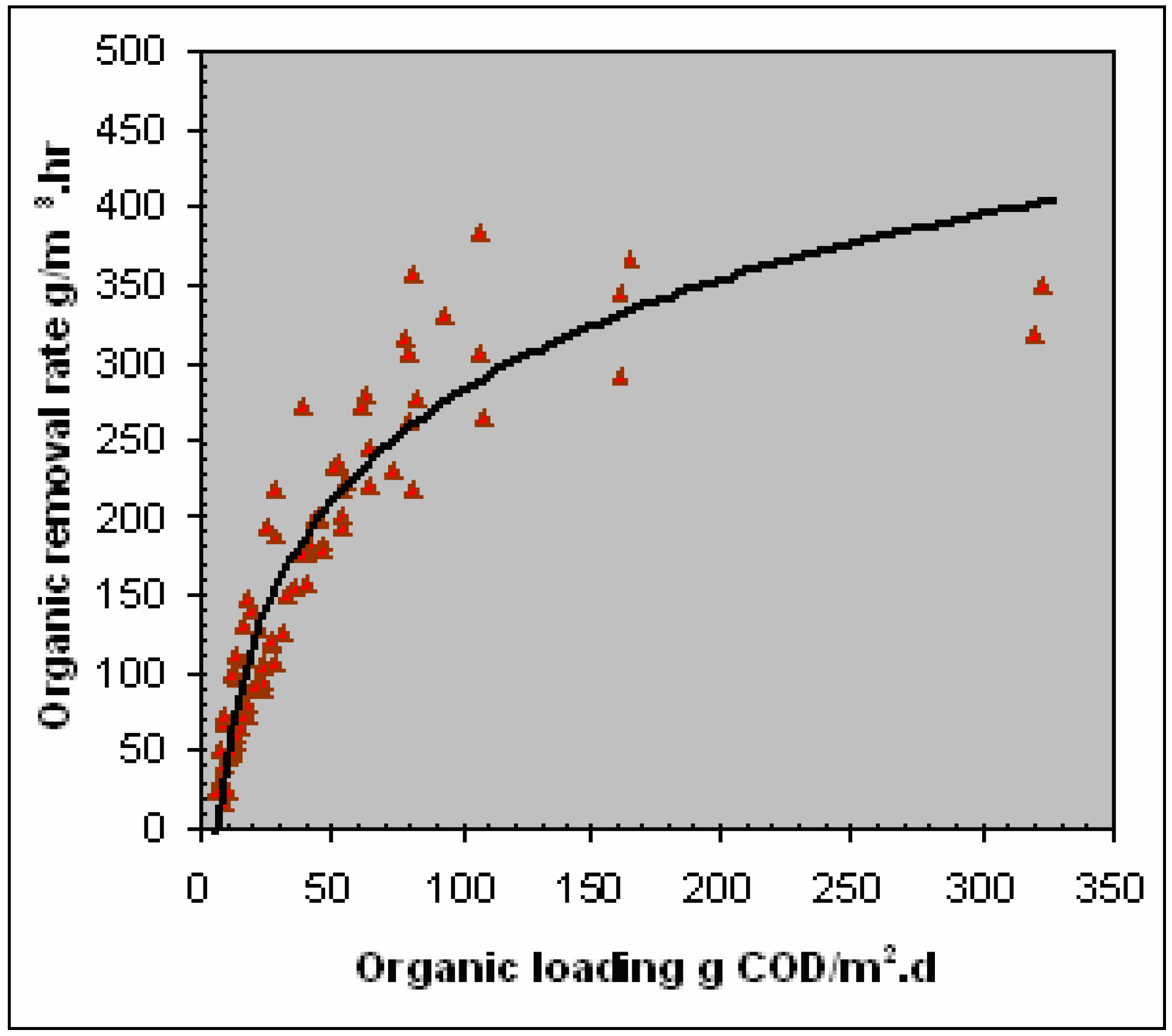

- Substrate utilization rate (organic removal rate) increases with increasing the organic loading to such limit which after it, increasing the load has no or limited impact on the removal rate. For rotating biological contactor systems, that treating domestic wastewater, the value of organic loading that at which the maximum removal rate is obtained was (150 g/m2.d). The volumetric and surface removal rates which correspond to this load were (320 gCOD/m3.d) and (100 gCOD/m2.d) respectively.

- (5)

- For nitrification, the rotating biological contactor systems should be designed to work on a level of loading not more than (10 gCOD/m2.d) and, the reactor volume should be designed to achieve a hydraulic loading of about (40 L/m2.d) or less.

References

- Al-Ahmady, K. K. Development of new technology for rotating biological contactors for wastewater treatment. Ph.D. Thesis, St. Petersburg state university of architecture and civil engineering, Russia, 2003; pp. 86–95. [Google Scholar]

- Antonie, R. L.; Kluge, L. D.; Mielke, J. H. Evaluation of rotating disk wastewater treatment plant. J. Water Pollut. Control Fed. 1974, 46, 498–511. [Google Scholar]

- Barger, R.; Dawson, D. Factors affecting rotating biological contactor biomass weight through seasonal variations. In Abst. Tech. Pap. 64th Annu. Conf., Water Pollut. Control Fed., Toronto, Can; 1991. [Google Scholar]

- Bintanja, H. H. J.; Van Der Erve, J. J. V. M.; Boelhouwer, C. Oxygen transfer in a rotating disc treatment plant. Water Res. (G.B.) 1975, 9, 1147–1153. [Google Scholar] [CrossRef]

- Chesner, W. H.; Ionnone, T. T. I. Current status of municipal wastewater treatment with rotating biological contactor technology in the USA. In Proc. 1st Nat. Symp./Workshop on Rotating Biological Contactor Technol, University of Pittsburgh, Champion, Pa. Smith, E. D., Ed.; 1980; pp. 53–58. [Google Scholar]

- Chung, J. C.; Storm, P. F. Microbiological study of ten New Jersey rotating biological contactor wastewater treatment plants. Res. J. Water Pollut. Control Fed. 1991, 63, 35–43. [Google Scholar]

- Clark, J. A.; et al. Performance of a rotating biological contactor under varying wastewater flow. J. Water Pollut. Control Fed. 1978, 50, 896–911. [Google Scholar]

- dAntonio, G.; Mendia, L.; Pirozzi, F.; Polese, A. Rotating biological contactor–solid contact system for the treatment of wastewater from small communities. Wat. Sci. Technol. (G.B.) 1997, 35, 109–115. [Google Scholar]

- DuPont, R. R.; McKinney, R. E. Data evaluation of a municipal installation, Kirksville, Missouri. In Proc. 1st Nat. Symp./Workshop on Rotating Biological Contactor Technol., University of Pittsburgh, Champion, Pa. Smith, E. D., Ed.; 1980; pp. 205–217. [Google Scholar]

- Eckenfelder, W. W.; Vandevenne, L. A design approach for rotating biological contactor treating industrial wastewaters. In Proc. 1st Nat. Symp./Workshop on Rotating Biological Contactor Technol., University of Pittsburgh, Champion, Pa. Smith, E. D., Ed.; 1980; pp. 1065–1077. [Google Scholar]

- Famularo, J.; Muller, J. A.; Mulligan, T. Application of mass transfer to rotating biological contactors. J. Water Pollut. Control Fed. 1978, 50, 653–671. [Google Scholar]

- Filion, M. P.; Murphy, K. L.; Stephenson, J. P. Performance of a rotating biological contactor under transient loading conditions. J. Water Pollut. Control Fed. 1979, 51, 1925–1933. [Google Scholar]

- Friedman, A. A.; Robbins, R. C. Wood: “Effect of disk rotational speed on biological contactor efficiency”. J. Water Pollut. Control Fed. 1979, 51, 11. 2678–2690. [Google Scholar]

- Greaves, F. E.; Thorp, B.; Critchley, R. F. Operational performance of package sewage treatment plants in north west England. Wat. Sci. Technol. (G.B.) 1990, 22, 25–32. [Google Scholar]

- Hitdlebugh, J. A.; Miller, R. D. Full- scale rotating biological contactor for secondary treatment and nitrification. In Proc. 1st Nat. Symp./Workshop on Rotating Biological Contactor Technol., Champion, Pa. 1980; 1, pp. 269–278. [Google Scholar]

- Kim, B. J.; Molof, A. H. The scale-up and limitation of physical oxygen transfer in rotating biological contactors. Wat. Sci. Technol. (G.B.) 1982, 14, 569–574. [Google Scholar]

- Kyu-Hong, Ahn; Chang, Joe-Soo. Performance evaluation of compact rotating biological contactor – settling tank. Wat. Sci. Technol. (G.B.) 1991, 23, 1467–1485. [Google Scholar]

- Lehman, P. L. Start-up and operating characteristics of an rotating biological contactor facility in a cold climate. J. Water Pollut. Control Fed. 1983, 55, 1233–1238. [Google Scholar]

- Leitdlebaugh, I. A.; Miller, R. D. Operational problems with rotating biological contactors. Water Pollut. Control Fed. 1981, 53, 1283–1288. [Google Scholar]

- Liu, Y.; Capdeville, B. Specific activity of nitrifying biofilm in water nitrification process. Water Res. (G.B.) 1996, 30, 1645–1650. [Google Scholar] [CrossRef]

- Marsh, D. Copuled trickling filter – rotating biological contactor for nitrification process. Water Pollut. Control Fed. 1981, 53, 1469–1480. [Google Scholar]

- Masuda, S.; Watanabe, Y.; Ishiguro, M. Biofilm properties and simultaneous nitrification and denitrification in aerobic rotating biological contactors. Wat. Sci. Technol. (G.B.) 1991, 23, 1355–1363. [Google Scholar]

- Mathys, R. G.; Branion, R. M. R.; Lo, K.V.; Anderson, K. B.; Leyen, P.; Louie, D. Wastewater treatment using a rotating biological contactor. Water Qual. Res. J. Can. 1997, 32, 771–779. [Google Scholar]

- Metcalf and Eddy, Inc. Wastewater engineering, Treatment, Disposal, and Reuse, 4nd ed.; McGraw-Hill Book Co.: New York, NY, 2002; Volume Ch. 9, pp. 930–940. [Google Scholar]

- Mueller, J. A.; Paquin, P.; Famularo, J. Analysis and design of rotating biological contactors. In Proc. 1st Nat. Symp./Workshop on Rotating Biological Contactor Technol., University of Pittsburgh, Champion, Pa. Smith, E. D., Ed.; 1980; pp. 921–928. [Google Scholar]

- Okabe, S.; Oozawa, Y.; Hirata, K.; Watanabe, Y. Relationship between population dynamic of nitrifiers in biofilms and reactor performance at various C: N ratios. Water Res. (G.B.) 1996, 30, 1563–1572. [Google Scholar] [CrossRef]

- Pano, A.; Middlebrook, J. Kinetic of carbon and ammonia nitrogen removal in RBC. J. Water Pollut. Control Fed. 1983, 55, 956–965. [Google Scholar]

- Paolini, A. E.; Variali, G. Kinetic consideration on the performance of activated sludge reactors and rotating biological contactors. Water Res. (G.B.) 1982, 16, 155–160. [Google Scholar] [CrossRef]

- Pescod, N. B.; Norton, T. S. Treatment of strong organic wastewater using aerobic and anaerobic packed-cage rotating biological contactors. In Paper presented at the 2nd Int. conf. Fixed-Film Biological Processes, Arlington; July 1984; pp. 299–318. [Google Scholar]

- Poon, P. C.; Chao, Ya-Len; Micucki, W. J. Factors controlling rotating biological contactor performance. J. Water Pollut. Control Fed. 1979, 51, 601–611. [Google Scholar]

- Sagy, M.; Kott, Y. Efficiency of rotating biological contactor in removing pathogenic bacteria from domestic sewage. Water Res. (G.B.) 1990, 24, (9), 1125–1128. [Google Scholar] [CrossRef]

- Spengel, D. B.; Dzombak, A. D. Biokinetic modeling and scale-up considerations for rotating biological contactors. Res. J. Water Pollut. Control Fed. 1992, 64, (3), 223–235. [Google Scholar]

- Stover, E. L.; Kincannon, D. F. Evaluating rotating biological contactor performance. Water and Sew. Works 1976, 123, 88–91. [Google Scholar]

- Tanaka, K.; Oshima, A.; Rittman, B. E. Performance evaluation of rotating biological contactor process. Wat. Sci. Technol. 1987, 19, 483–494. [Google Scholar]

- Tanaka, K.; Tada, M.; Ito, M.; Shimizu, N. Performance analysis of the rotating biological contactor process based on particle fraction and improvement of final effluent quality. Wat. Sci. Technol. (G.B.) 1991, 23, 1457–1466. [Google Scholar]

- Ware, J. A.; Pescod, M. B.; Storch, B. Evaluation of alternatives to conventional disc support media for rotating biological contactors. Wat. Sci. Technol. (G.B.) 1990, 22, (2), 113–117. [Google Scholar]

- Watanabe, Y.; Lee, C.; Koike, M.; Ishiguro, M. Nitrification kinetics and simultaneous removal of biomass and phosphorus in rotating biological contactors. Wat. Sci. Technol. (G.B.) 1990, 22, (2), 169–178. [Google Scholar]

- Weng, C.; Molof, A. H. Nitrification in the biological fixed film rotating disk systems. J. Water Pollut. Control Fed. 1974, 46, 1674–1685. [Google Scholar]

- Wilson, R. W. Scale-up in rotating biological contactor design. J. Water Pollut. Control Fed. 1980, 52, 610–620. [Google Scholar]

- Wu, Y. C.; Smith, ED, D.; Chen, C. Y. Temperature effects on rotating biological contactor scale-up. J. of the Environ. Engin. Div. 1983, 109, 321–726. [Google Scholar] [CrossRef]

© 2005 MDPI. All rights reserved.

Share and Cite

Al-Ahmady, K.K. Effect of Organic Loading on Rotating Biological Contactor Efficiency. Int. J. Environ. Res. Public Health 2005, 2, 469-477. https://doi.org/10.3390/ijerph2005030012

Al-Ahmady KK. Effect of Organic Loading on Rotating Biological Contactor Efficiency. International Journal of Environmental Research and Public Health. 2005; 2(3):469-477. https://doi.org/10.3390/ijerph2005030012

Chicago/Turabian StyleAl-Ahmady, Kossay K. 2005. "Effect of Organic Loading on Rotating Biological Contactor Efficiency" International Journal of Environmental Research and Public Health 2, no. 3: 469-477. https://doi.org/10.3390/ijerph2005030012