Experimental Investigation of the Transpired Solar Air Collectors and Metal Corrugated Packing Solar Air Collectors

Abstract

:1. Introduction

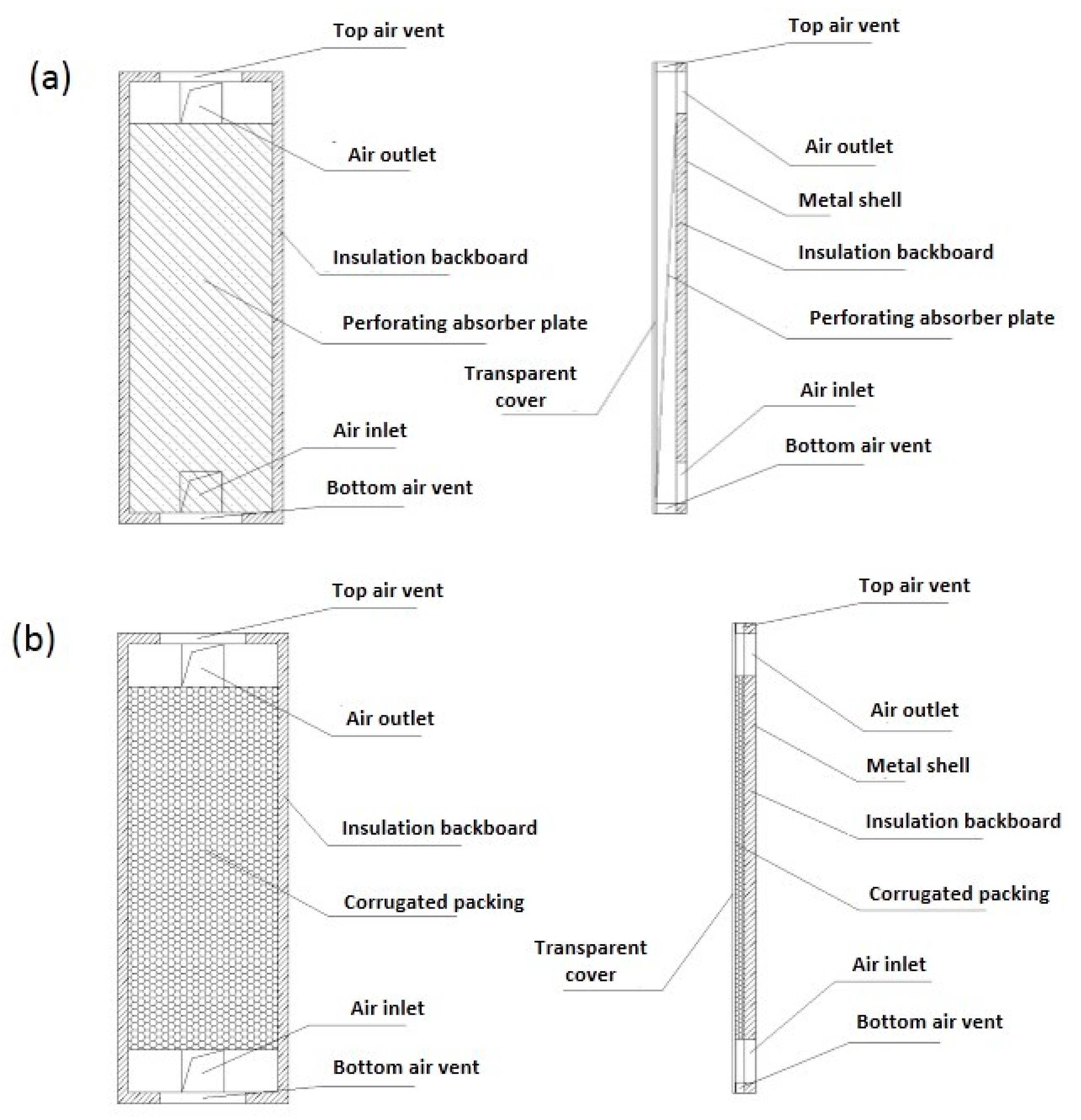

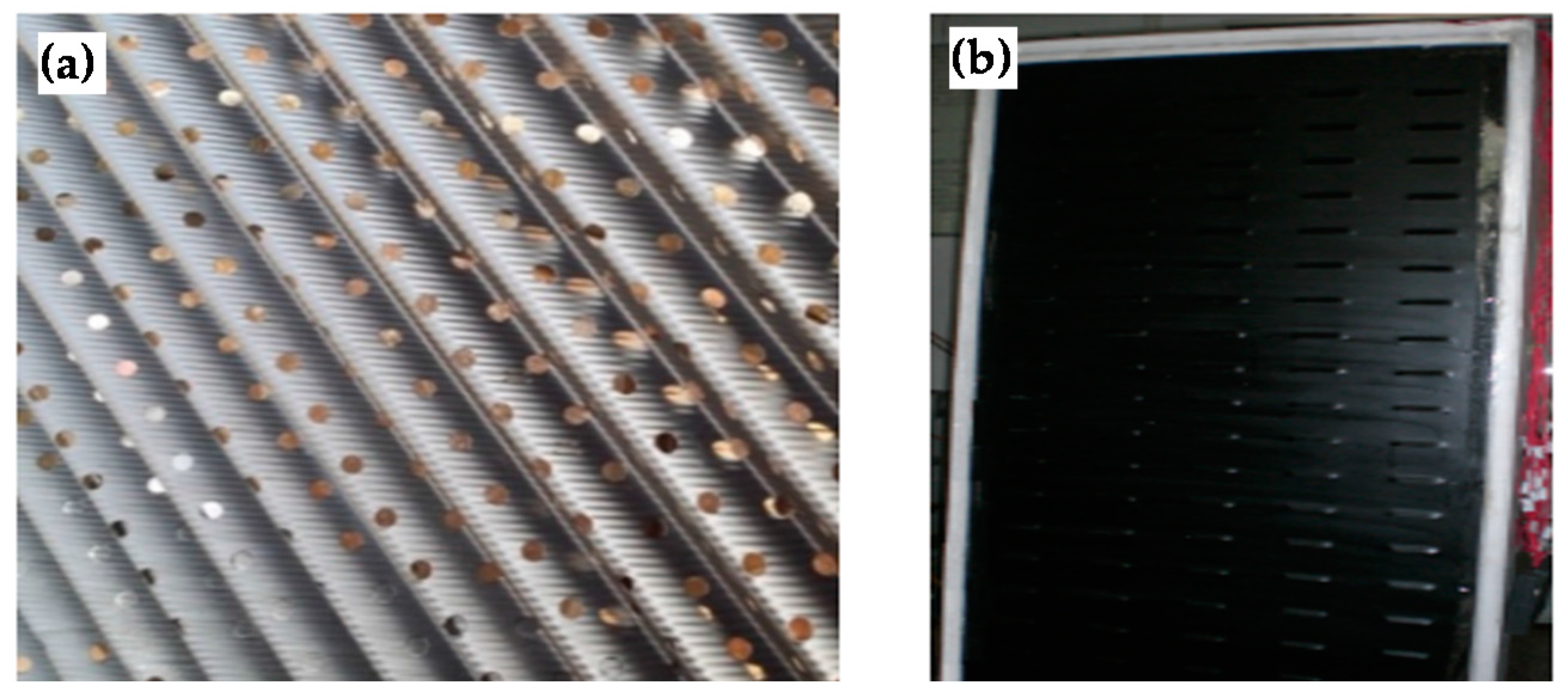

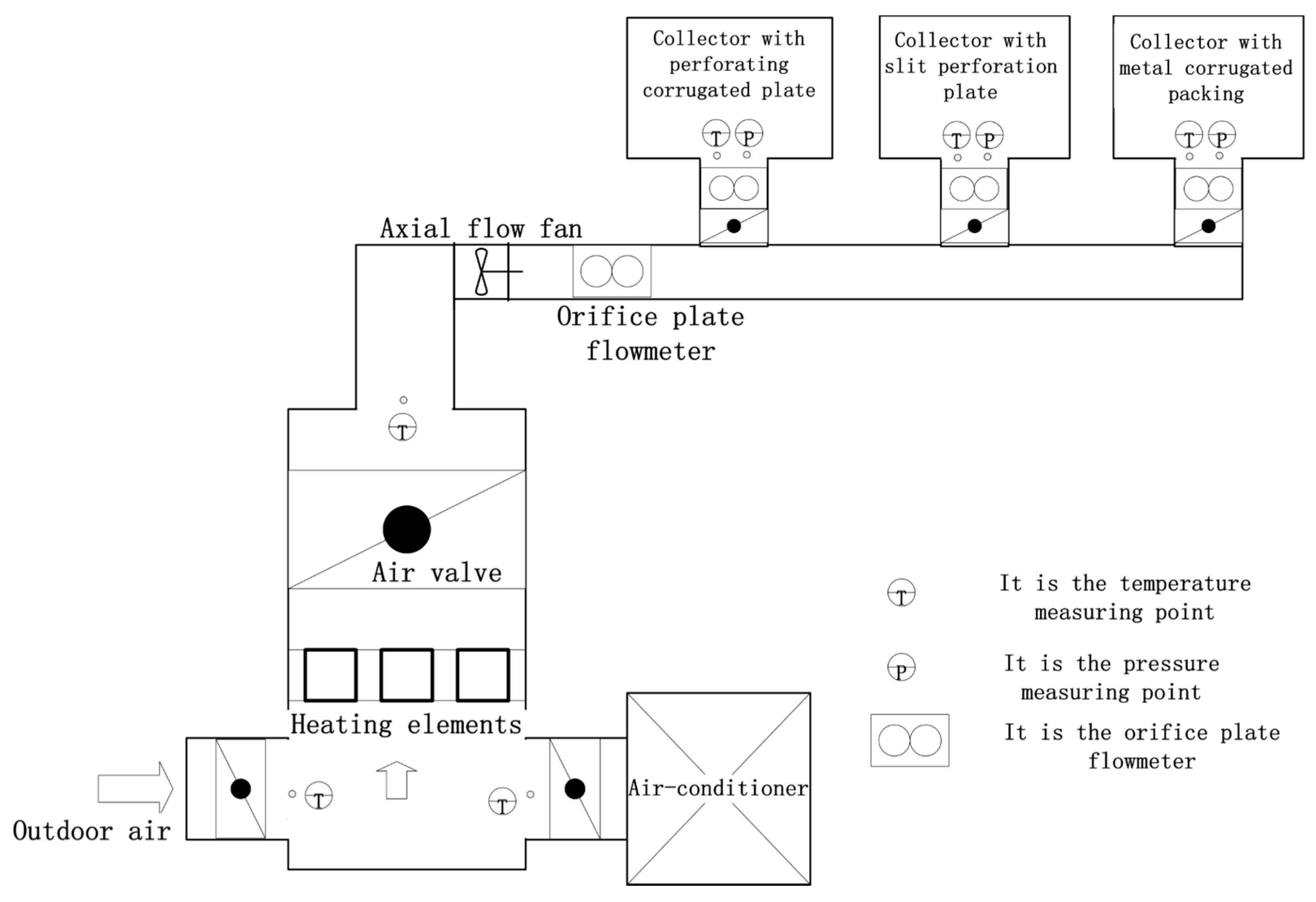

2. Experimental Setup

3. Experimental Results and Discussion

3.1. Evaluation Index

3.2. Variation of Outdoor Air Temperature and Radiation Intensity

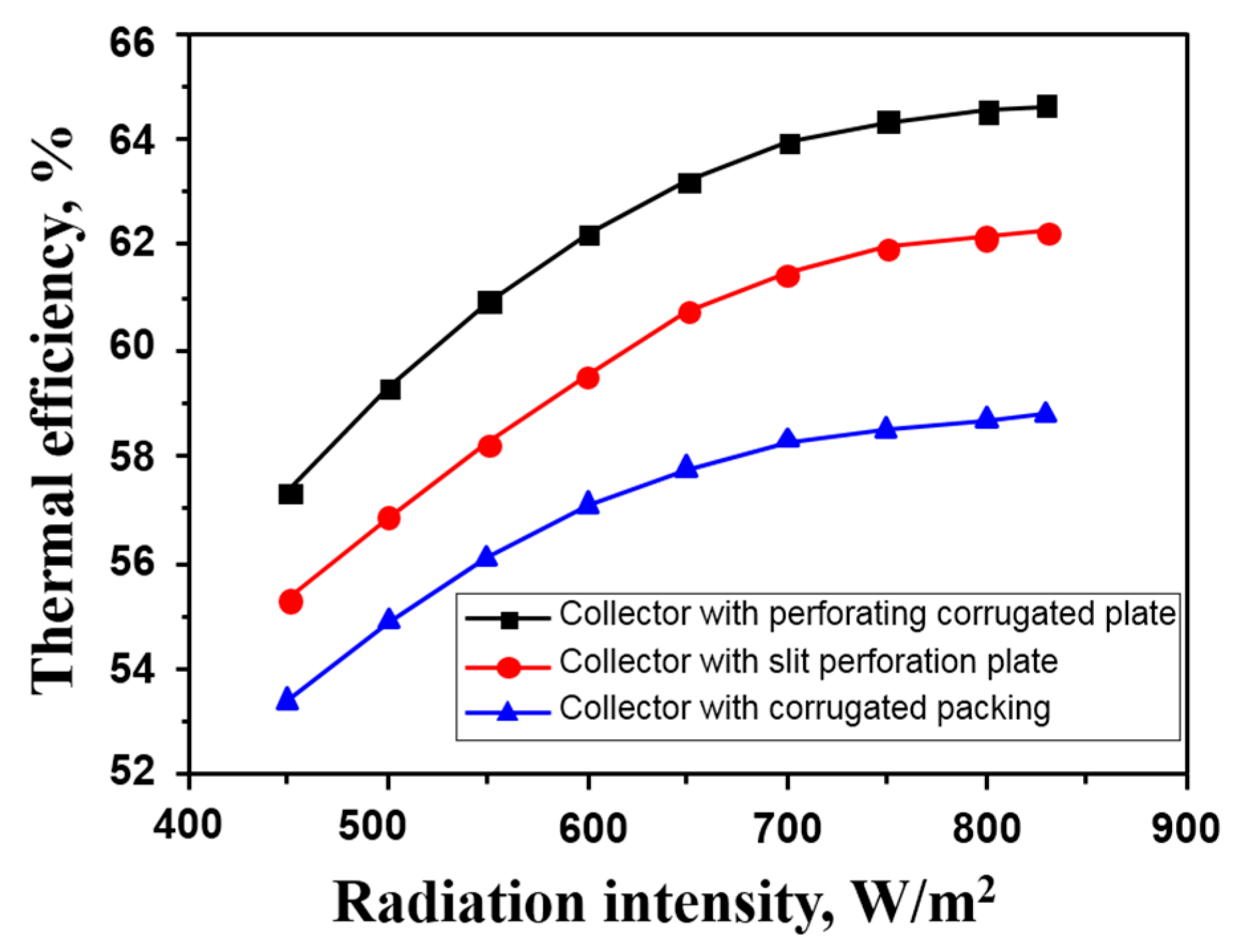

3.3. Effects of Radiation Intensity

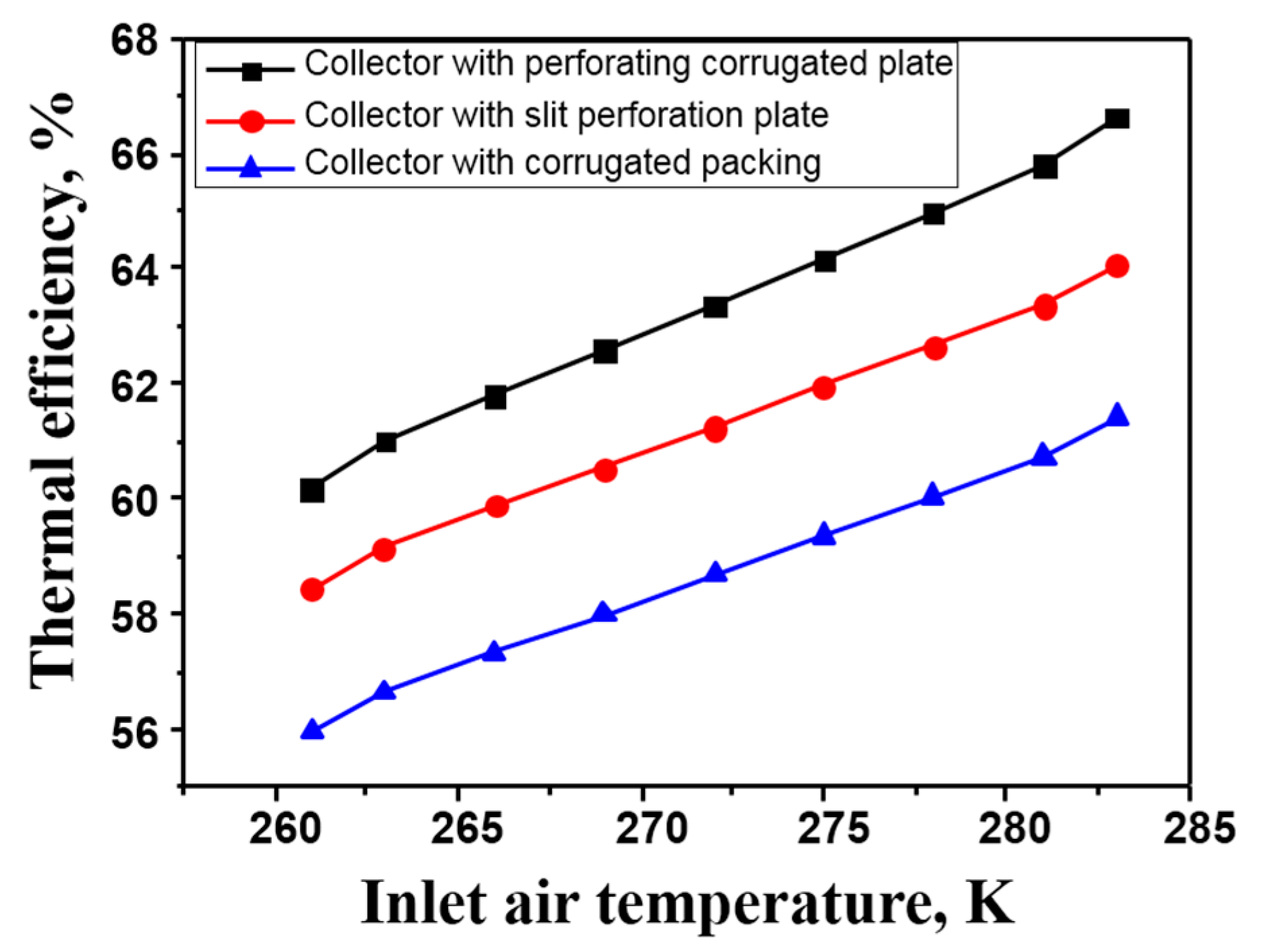

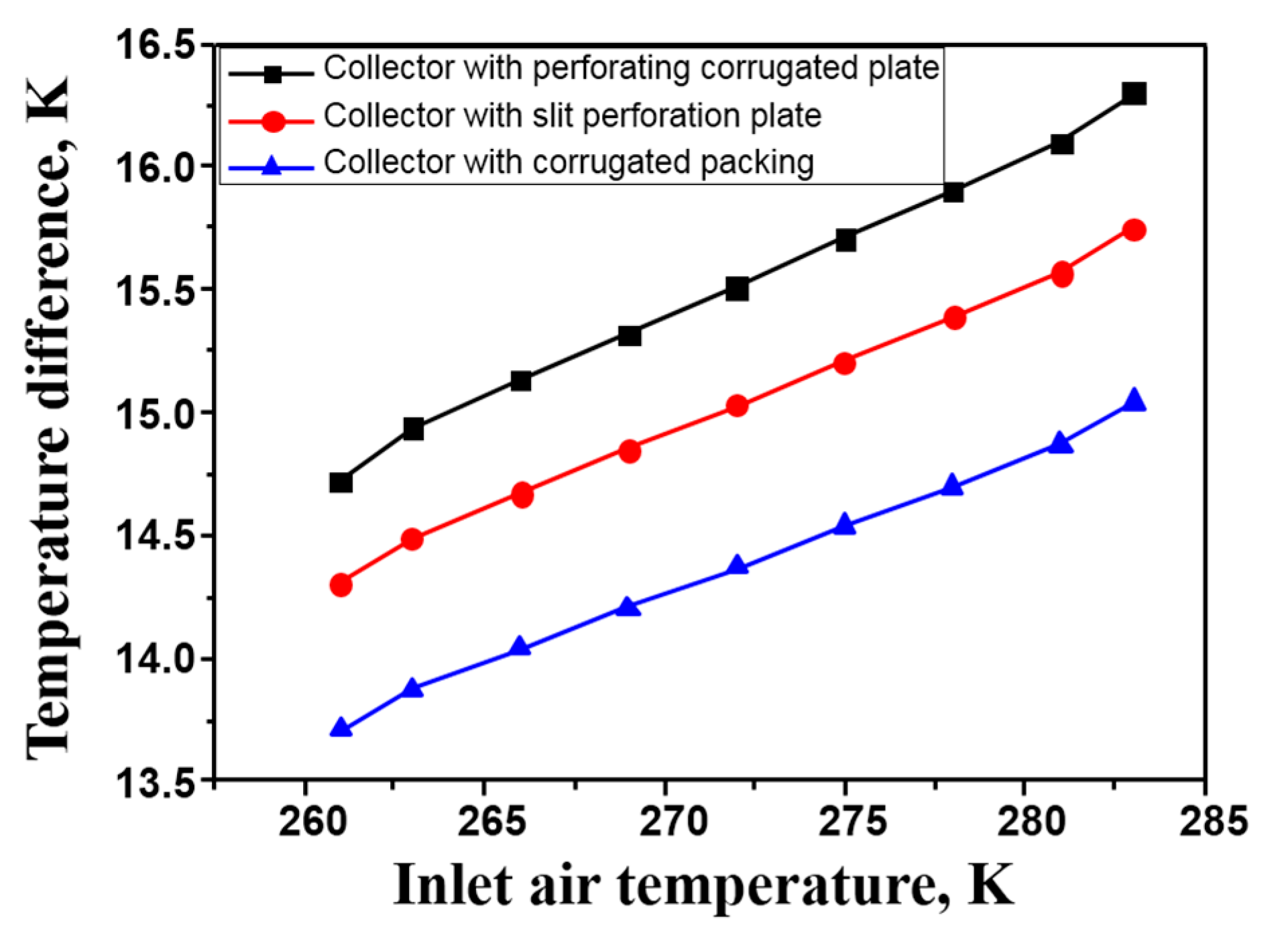

3.4. Effects of Inlet Temperature

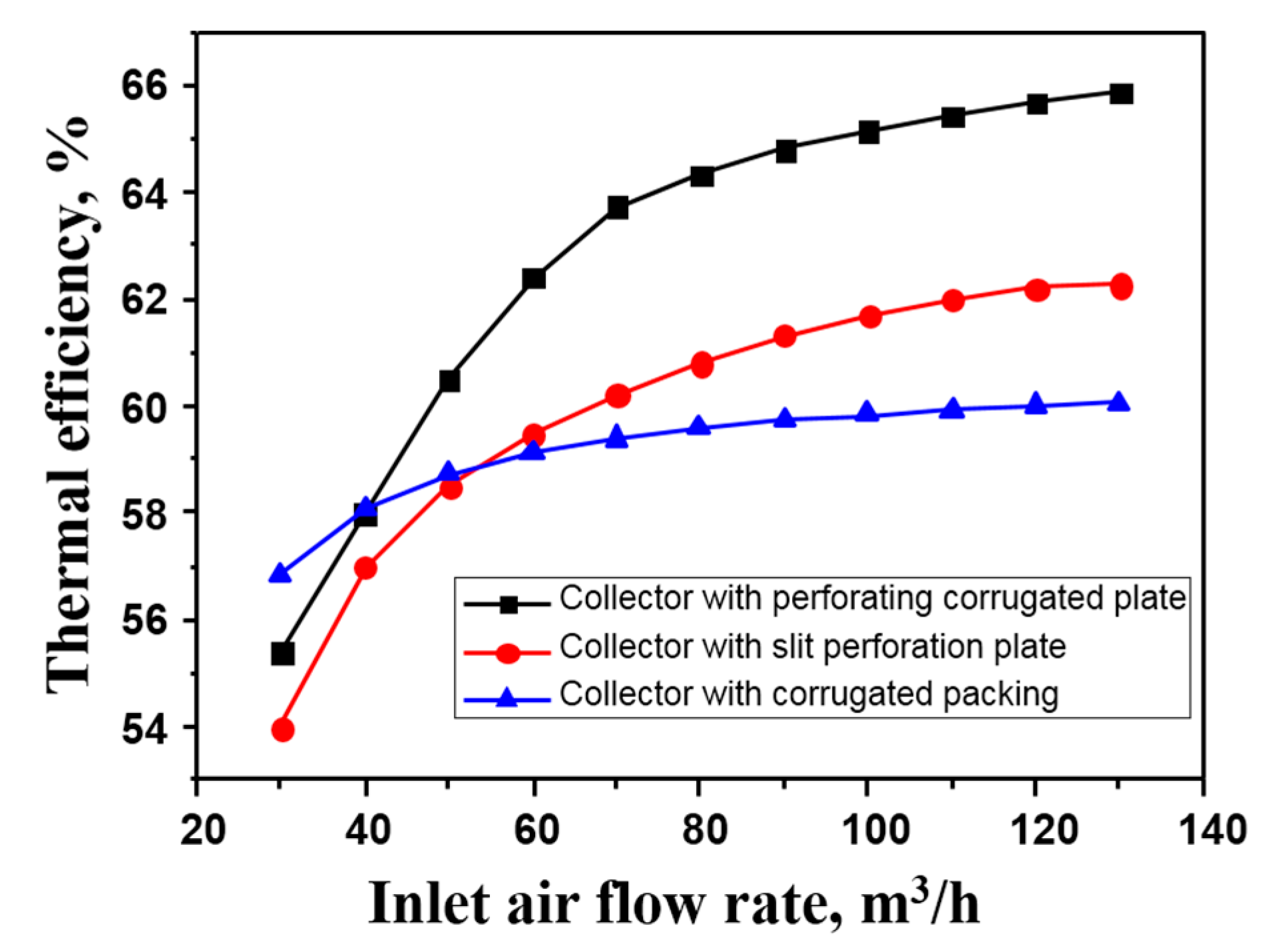

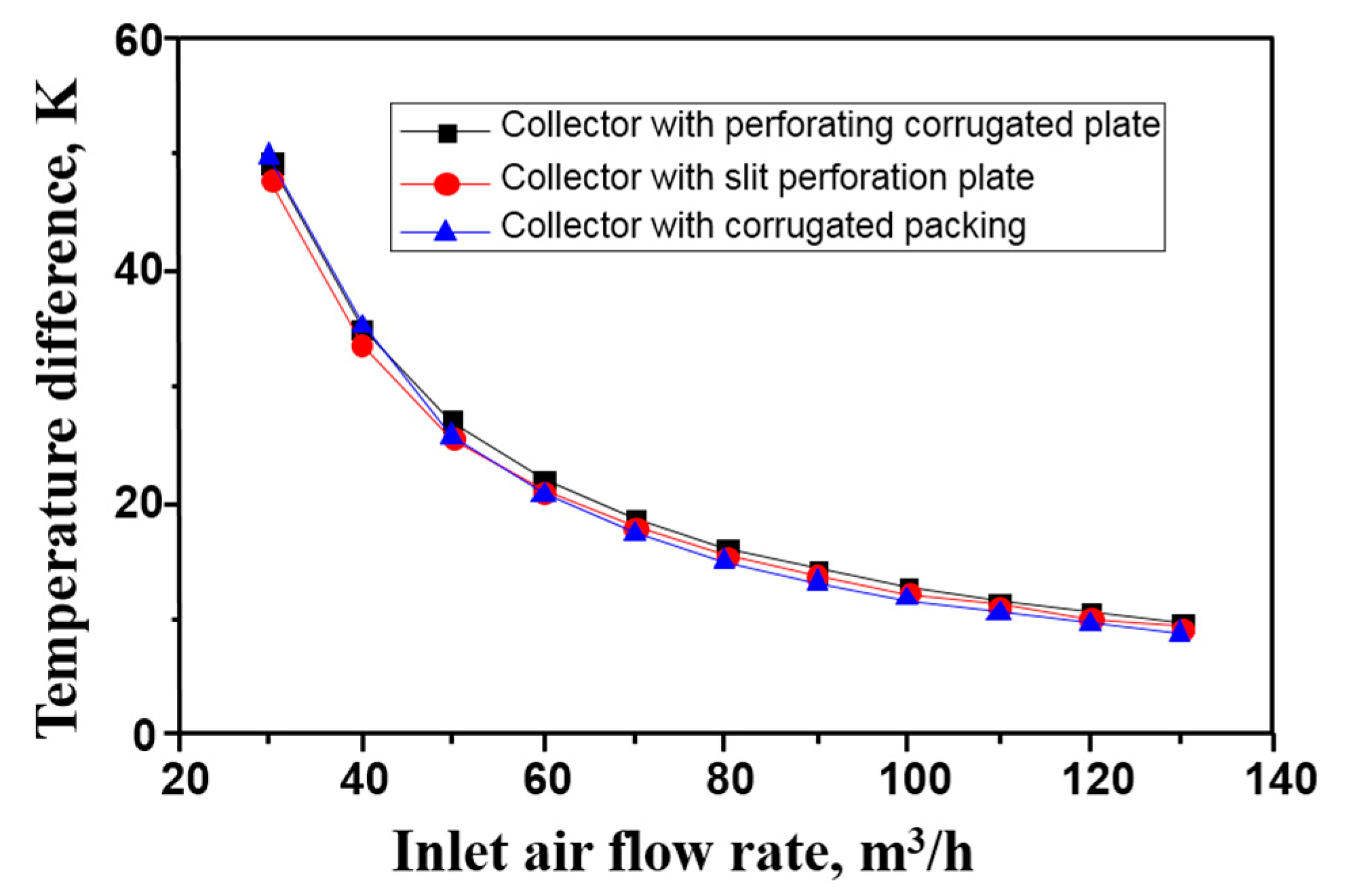

3.5. Effects of Flow Rate

3.6. Pressure Drops

3.7. Economic Analysis

4. Conclusions

- (1)

- As the effects of jet impingement of the air through the perforating corrugated plate and the enlarging of heat transfer area, the thermal performance of the solar air collector with perforating corrugated plate is higher than the other collectors.

- (2)

- The flow rate of inlet air has significant effects on the thermal comfort of buildings in cold and severe cold regions. The experimental results indicate that the inlet air flow rate should be lower than 45 m3/h to satisfy the thermal comfort of buildings in severe cold regions.

- (3)

- The correlations between the friction factor and Reynolds number of the three collectors are fitted with the experimental results. The dynamics analysis results indicate that the pressure drop of the collector with slit-perforated plate was the least and the pressure drop of the collector with corrugated packing was the most.

- (4)

- Although the pressure drop and power consumption of the collector with perforating corrugated plate was a little larger than the collector with slit-perforated plate while the air flow rate is the same, the operation cost is lower for its better thermal performance. Therefore, the collector with perforating corrugated plate was more suitable for use in the cold and severe cold regions.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Vaziri, R.; Ilkan, M.; Egelioglu, F. Experimental performance of perforated glazed solar air heaters and unglazed transpired solar air heater. Sol. Energy 2015, 119, 251–260. [Google Scholar] [CrossRef]

- Altfeld, K.; Leiner, W.; Fiebig, M. Second law optimization of flat-plate solar air heaters. Sol. Energy 1988, 41, 127–132. [Google Scholar] [CrossRef]

- Ekechukwu, O.V.; Norton, B. Review of solar-energy drying systems III: Low temperature air-heating solar collectors for crop drying applications. Energy Convers. Manag. 1990, 40, 657–667. [Google Scholar] [CrossRef]

- Li, B.J.; You, S.J.; Ye, T.Z.; Zhang, H.; Li, X.L.; Li, C. Mathematical modeling and experimental verification of vacuum glazed transpired solar collector with slit-like perforations. Renew. Energy 2014, 69, 43–49. [Google Scholar] [CrossRef]

- Li, X.L.; Li, C.; Li, B.J. Net heat gain assessment on a glazed transpired solar air collector with slit-like perforations. Appl. Therm. Eng. 2016, 99, 1–10. [Google Scholar] [CrossRef]

- Kutscher, C.; Dymond, C. Development of a flow distribution and design model for transpired solar collectors. Sol. Energy 1997, 60, 291–300. [Google Scholar]

- Decker, G.W.E.V.; Hollands, K.G.T.; Brunger, A.P. Heat-exchange relations for unglazed transpired solar collectors with circular holes on a square or triangular pitch. Sol. Energy 2001, 71, 33–45. [Google Scholar] [CrossRef]

- Kumar, A.; Saini, R.P.; Saini, J.S. Development of correlations for Nusselt number and friction factor for solar air heater with roughened duct having multi v-shaped with gap rib as artificial roughness. Renew. Energy 2013, 58, 151–163. [Google Scholar] [CrossRef]

- Nowzari, R.; Aldabbagh, L.; Egelioglu, F. Single and double pass solar air heaters with partially perforated cover and packed mesh. Energy 2014, 73, 694–702. [Google Scholar] [CrossRef]

- Saxena, A.; Varun; El-Sebaii, A.A. A thermodynamic review of solar air heaters. Renew. Sustain. Energy Rev. 2015, 43, 863–890. [Google Scholar] [CrossRef]

- Gao, L.X.; Bai, H.; Mao, S.F. Potential application of glazed transpired collectors to space heating in cold climates. Energy Convers. Manag. 2014, 77, 690–699. [Google Scholar] [CrossRef]

- Zheng, W.; Li, B.; Zhang, H.; You, S.; Li, Y.; Ye, T. Thermal characteristics of a glazed transpired solar collector with perforating corrugated plate in cold regions. Energy 2016, 109, 781–790. [Google Scholar] [CrossRef]

- Bhushan, B.; Singh, R. Thermal and thermohydraulic performance of roughened solar air heater having protruded absorber plate. Sol. Energy 2012, 86, 3388–3396. [Google Scholar] [CrossRef]

- Chauhan, R.; Thakur, N.S. Investigation of the thermohydraulic performance of impinging jet solar air heater. Energy 2014, 68, 255–261. [Google Scholar] [CrossRef]

- El-Khawajah, M.; Aldabbagh, L.; Egelioglu, F. The effect of using transverse fins on a double pass flow solar air heater using wire mesh as an absorber. Sol. Energy 2011, 85, 1479–1487. [Google Scholar] [CrossRef]

- Moffat, R.J. Describing the experimental uncertainties in experimental results. Exp. Therm. Fluid Sci. 1988, 1, 3–17. [Google Scholar] [CrossRef]

- Kutcher, C.F. Heat exchange effectiveness and pressure drop for air flow through perforated plates with and without crosswind. J. Heat Transf. Trans. ASME 1994, 116, 391–399. [Google Scholar] [CrossRef]

| Instruments | Accuracy | Instruments | Accuracy |

|---|---|---|---|

| K-type thermocouples | ±0.75%t °C | Microelectronic pressure gauge | ±(2% + 0.25) |

| Radiometer | ±2% | ||

| Flowmeter | ±3% | Hot-wire anemometer | ±0.02 m/s |

| Solar Air Collector | Initial Cost | Operating Cost | Life Cycle Cost |

|---|---|---|---|

| Perforating corrugated plate | 3500 RMB | 7500 RMB | 11,000 RMB |

| Slit-perforated plate | 3000 RMB | 9000 RMB | 12,000 RMB |

| Corrugated packing | 3100 RMB | 10,300 RMB | 13,400 RMB |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license ( http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zheng, W.; Zhang, H.; You, S.; Fu, Y. Experimental Investigation of the Transpired Solar Air Collectors and Metal Corrugated Packing Solar Air Collectors. Energies 2017, 10, 302. https://doi.org/10.3390/en10030302

Zheng W, Zhang H, You S, Fu Y. Experimental Investigation of the Transpired Solar Air Collectors and Metal Corrugated Packing Solar Air Collectors. Energies. 2017; 10(3):302. https://doi.org/10.3390/en10030302

Chicago/Turabian StyleZheng, Wandong, Huan Zhang, Shijun You, and Yindan Fu. 2017. "Experimental Investigation of the Transpired Solar Air Collectors and Metal Corrugated Packing Solar Air Collectors" Energies 10, no. 3: 302. https://doi.org/10.3390/en10030302