Evaluating Heat Flux Profiles in Aluminum Reheating Furnace with Regenerative Burner

Abstract

:1. Introduction

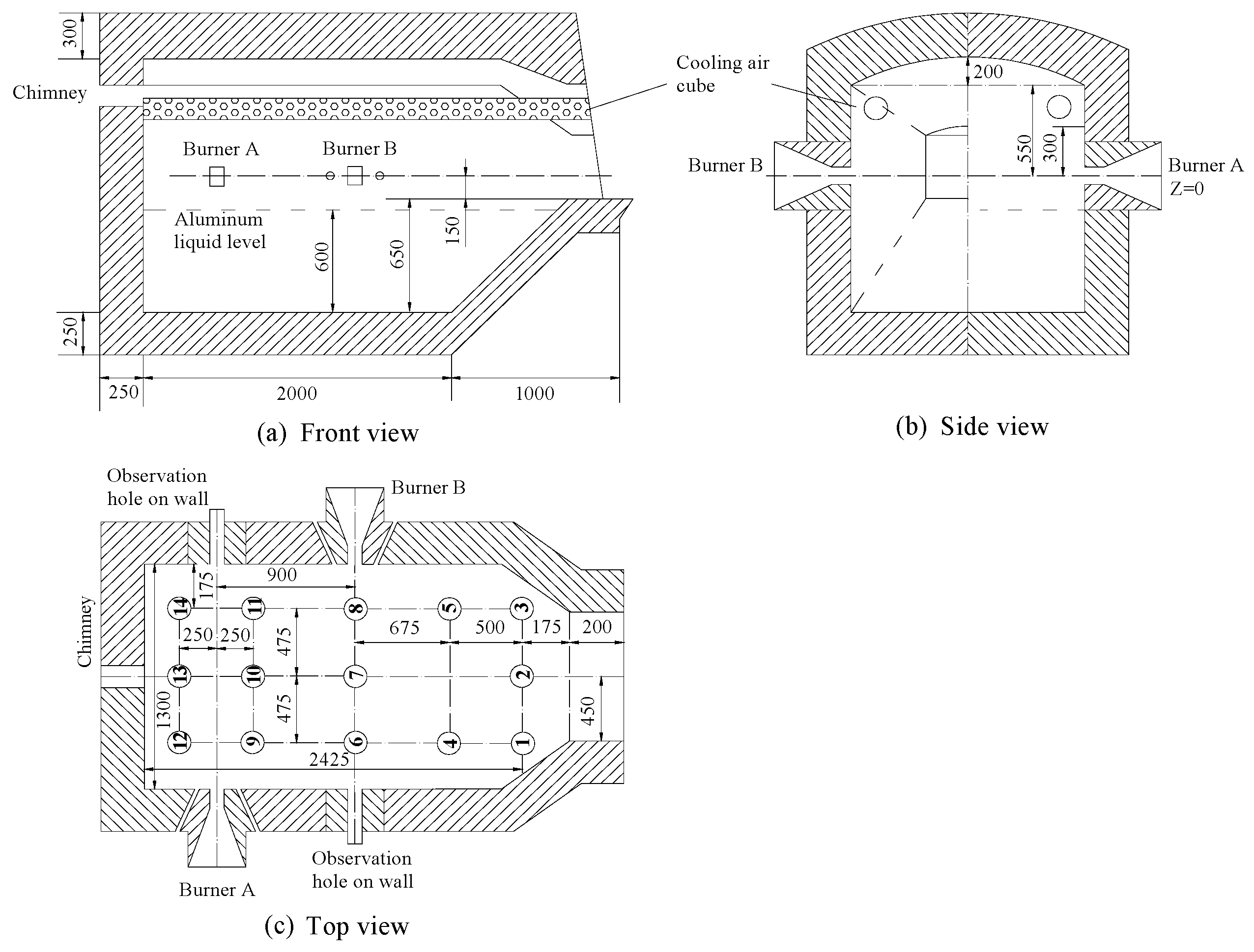

2. Experiment Test Facility

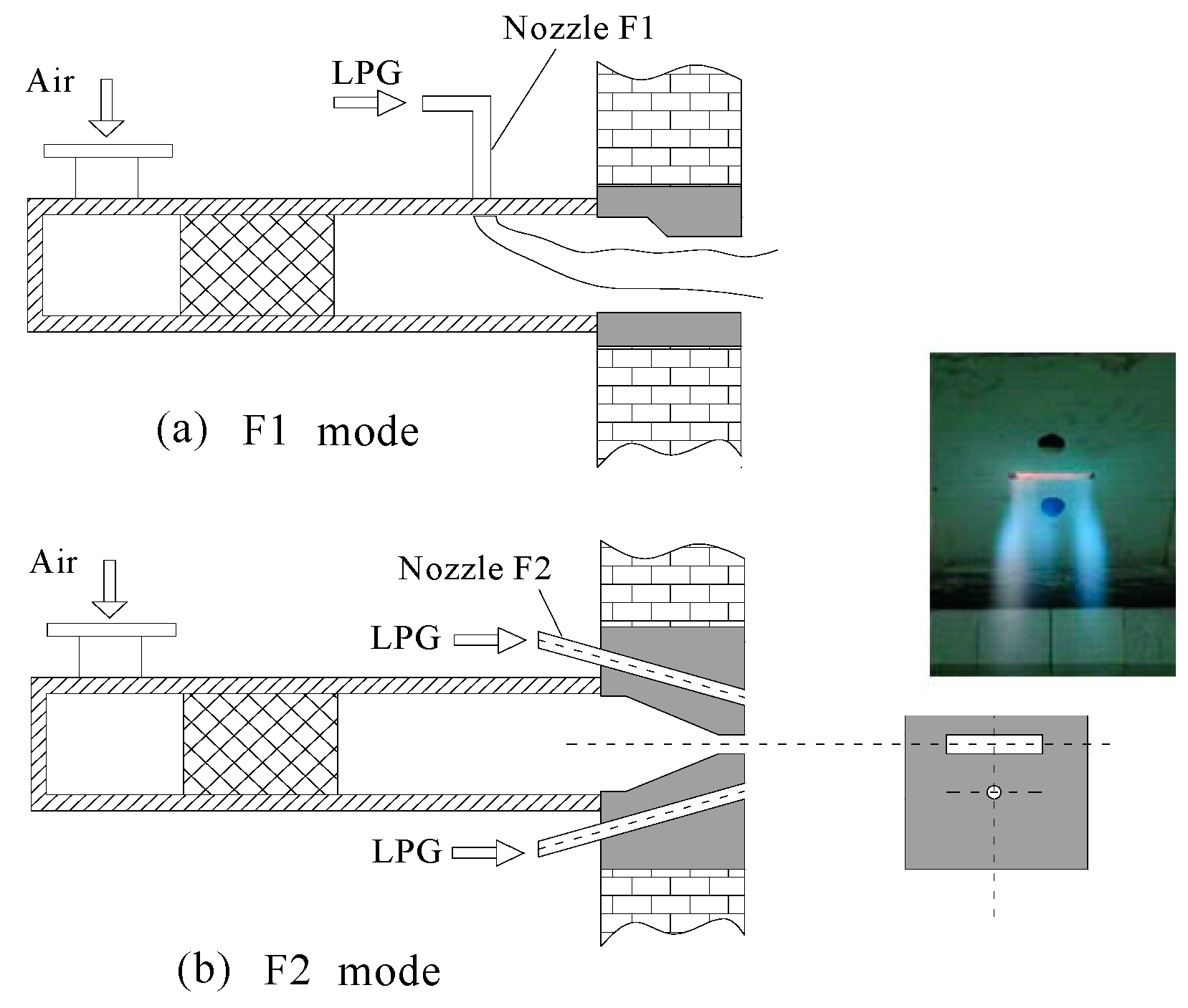

2.1. Furnace with Regenerative Burners

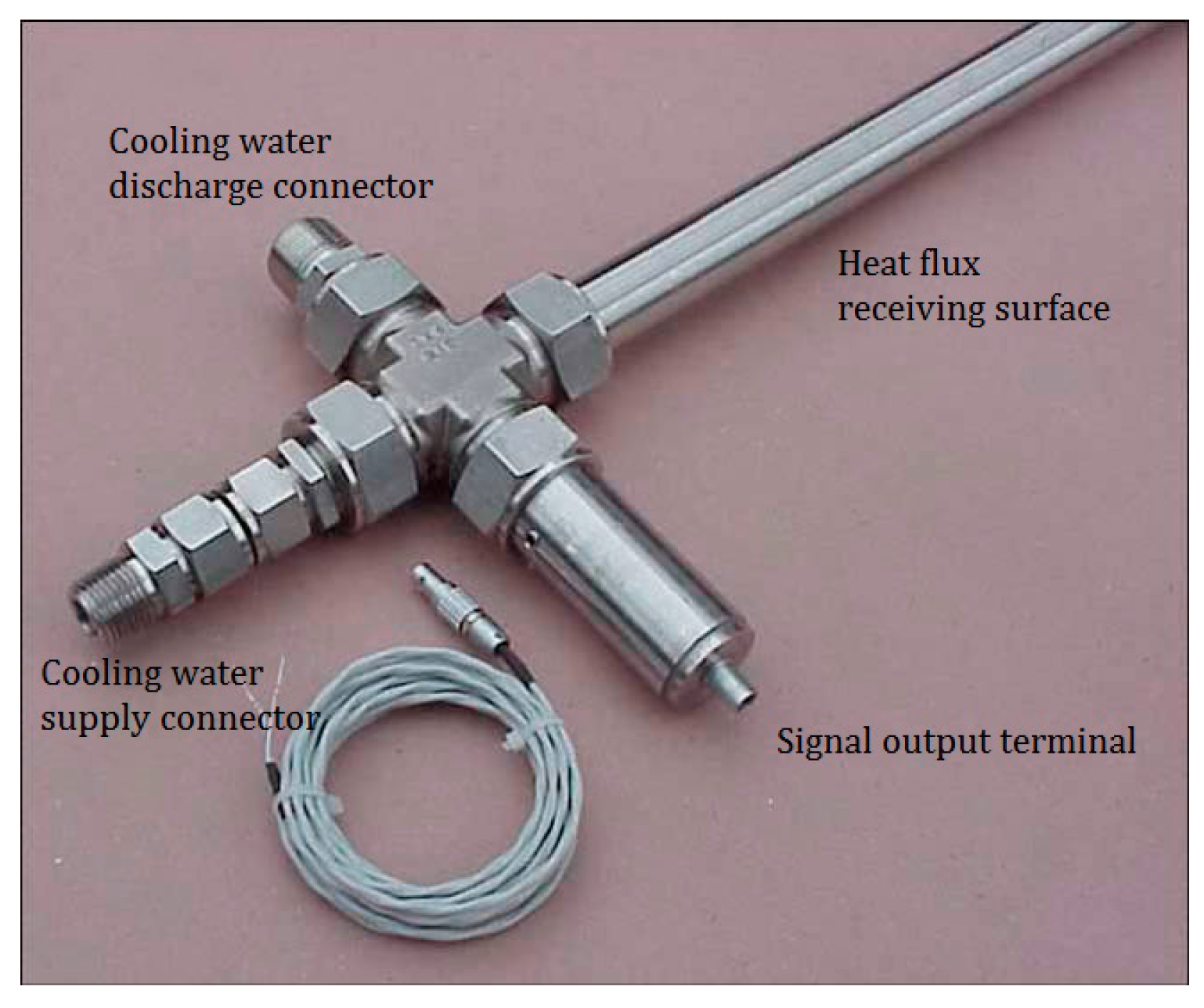

2.2. Measurement Program

2.3. Experiment Uncertainty Analysis

2.4. Experimental Conditions

3. Results and Discussion

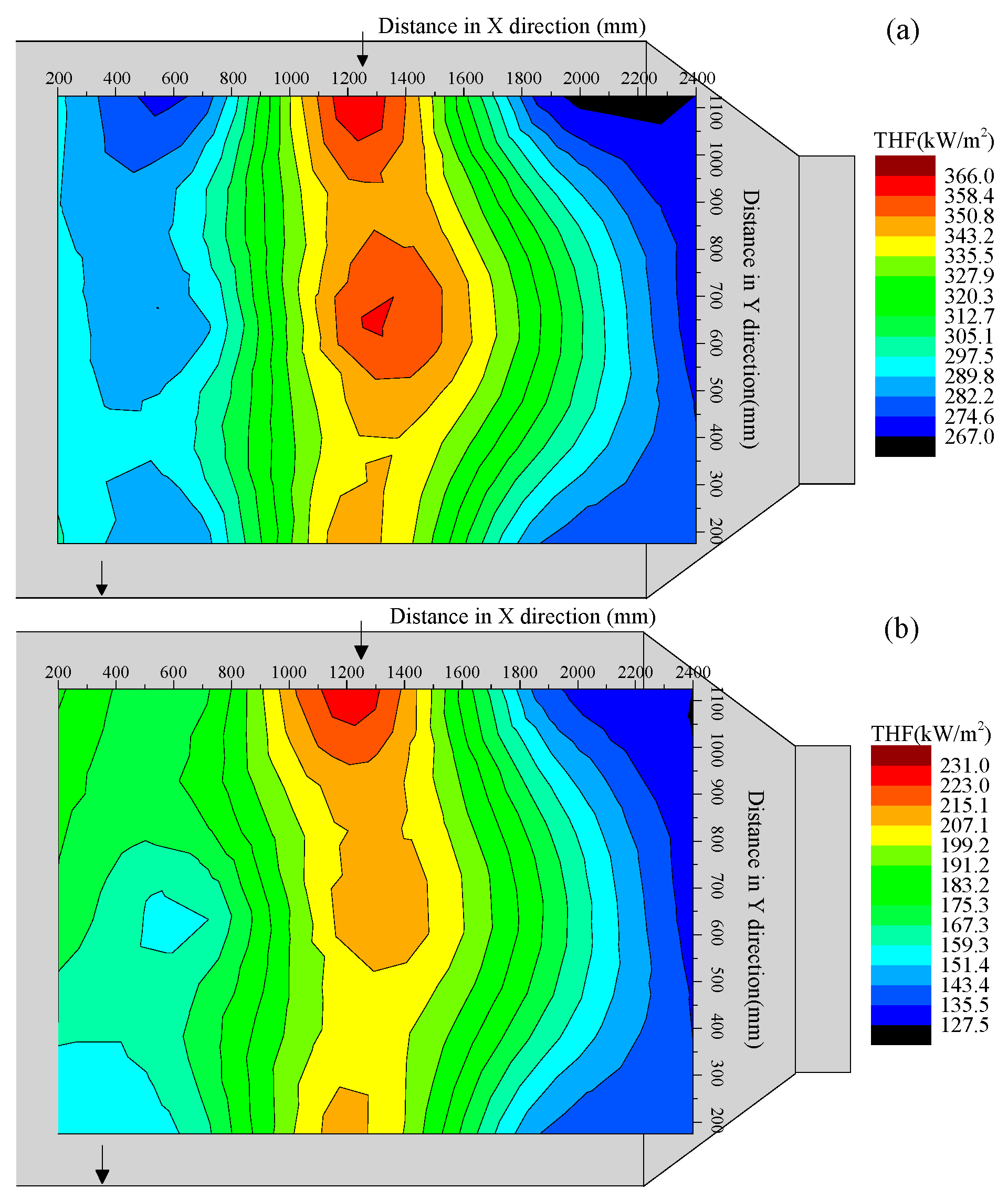

3.1. Heat Flux Profile at Burner Horizontal Plane

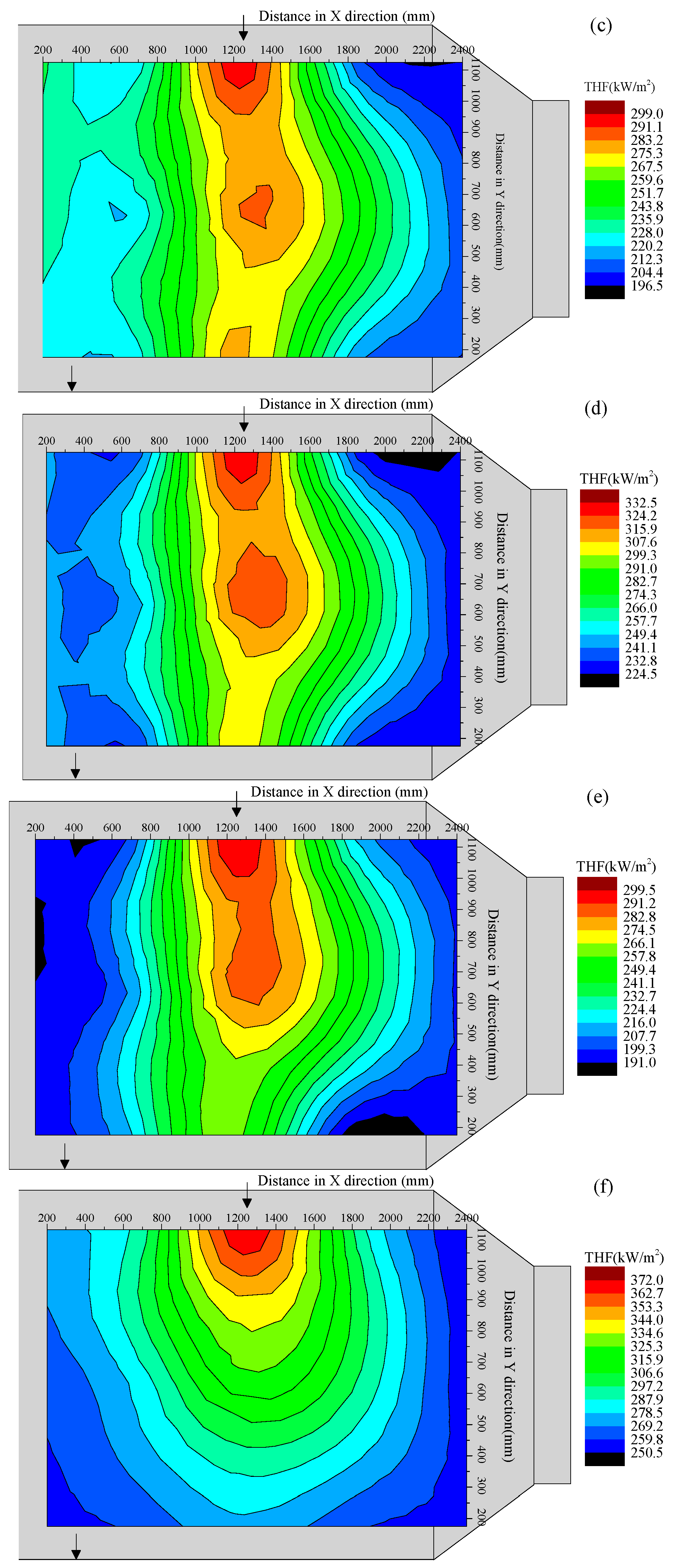

3.1.1. Total Heat Flux (THF) Profile

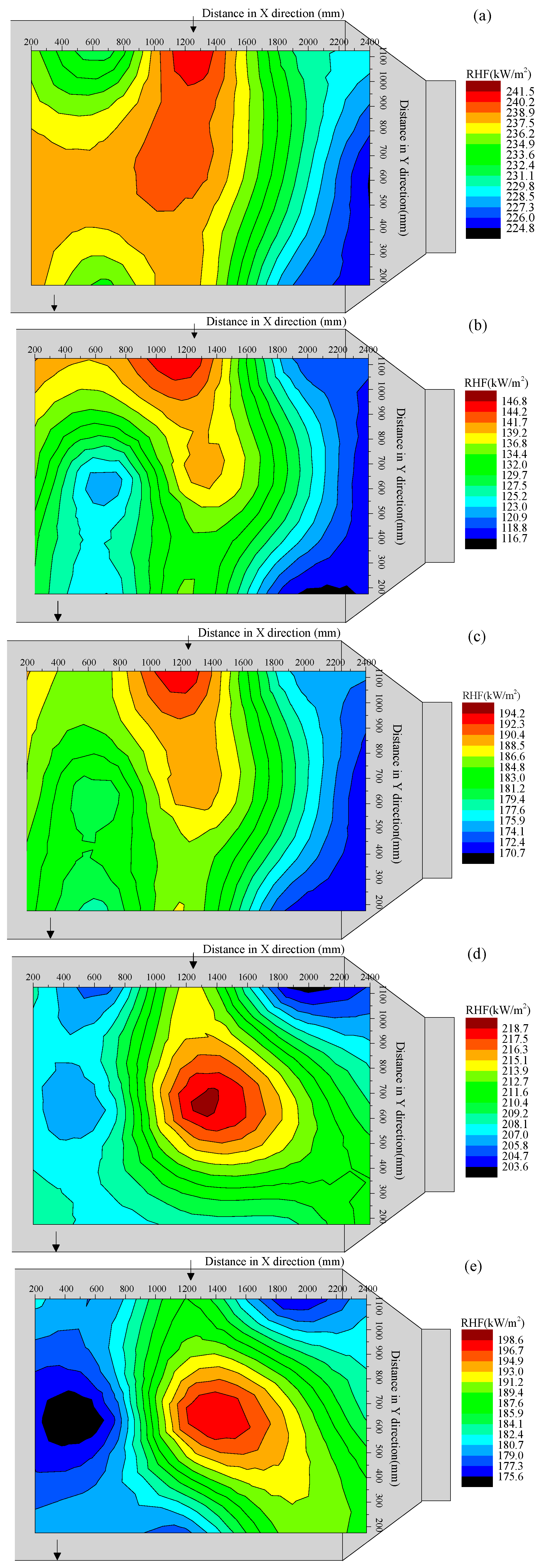

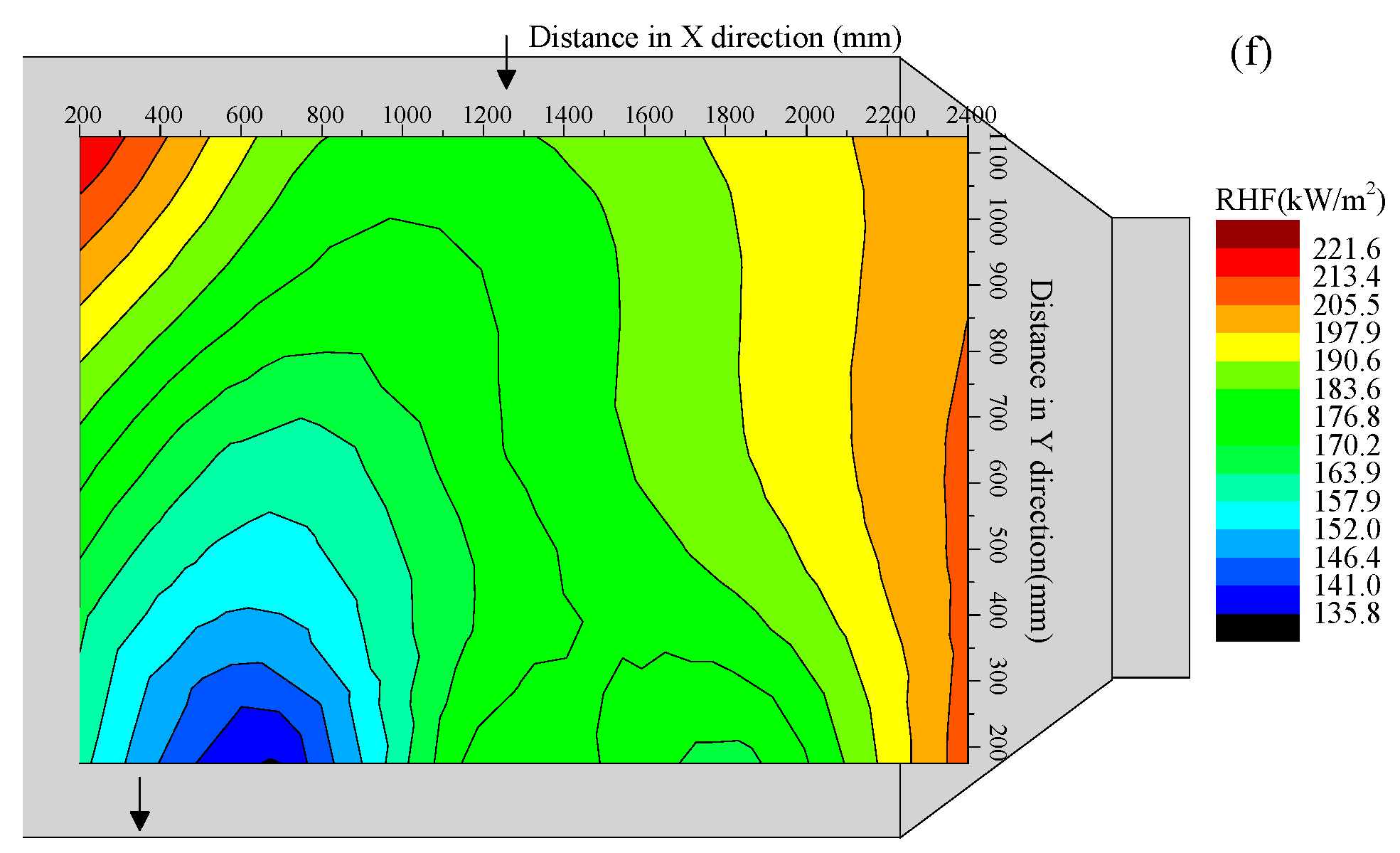

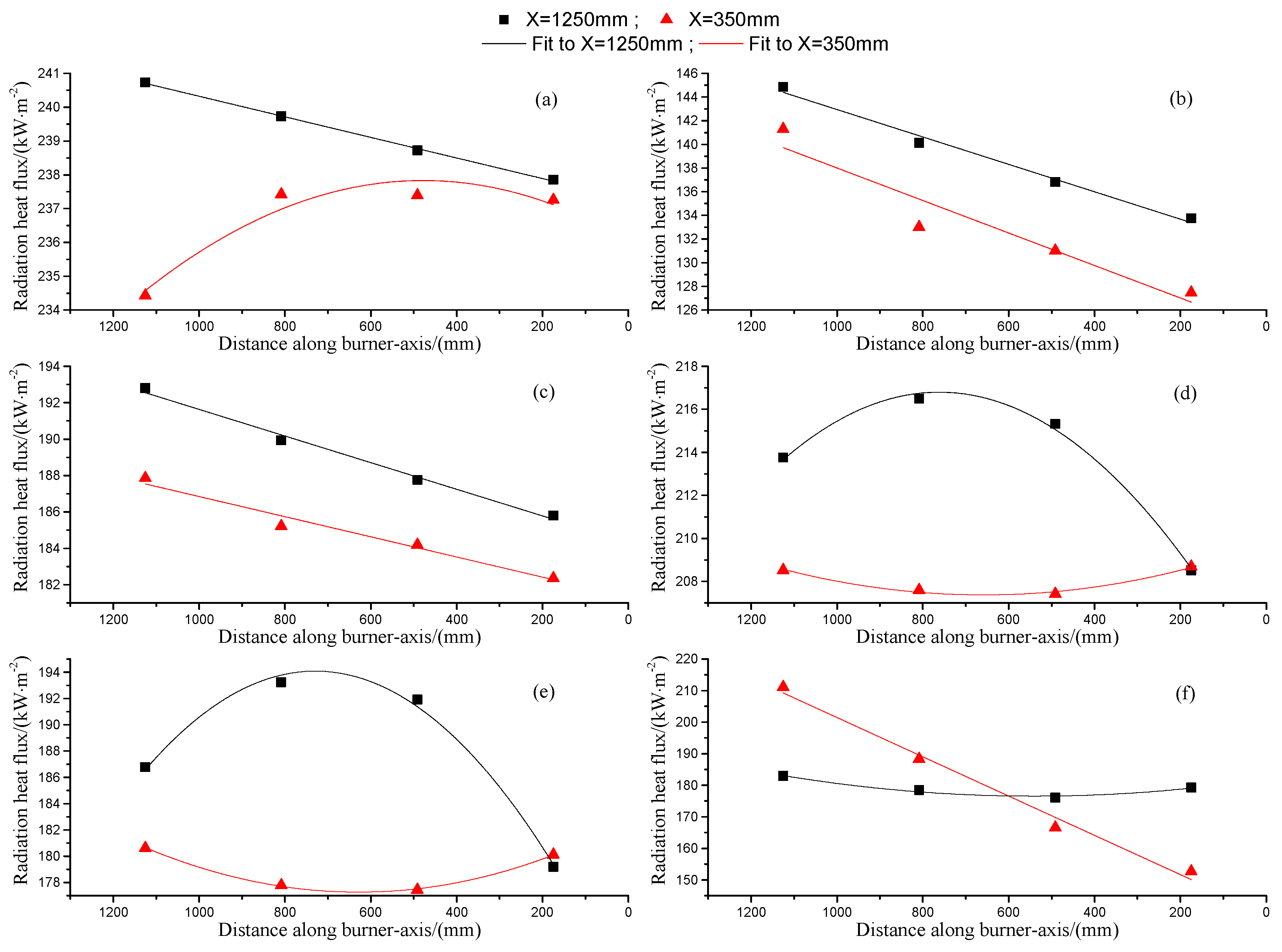

3.1.2. Radiation Heat Flux (RHF) Profile

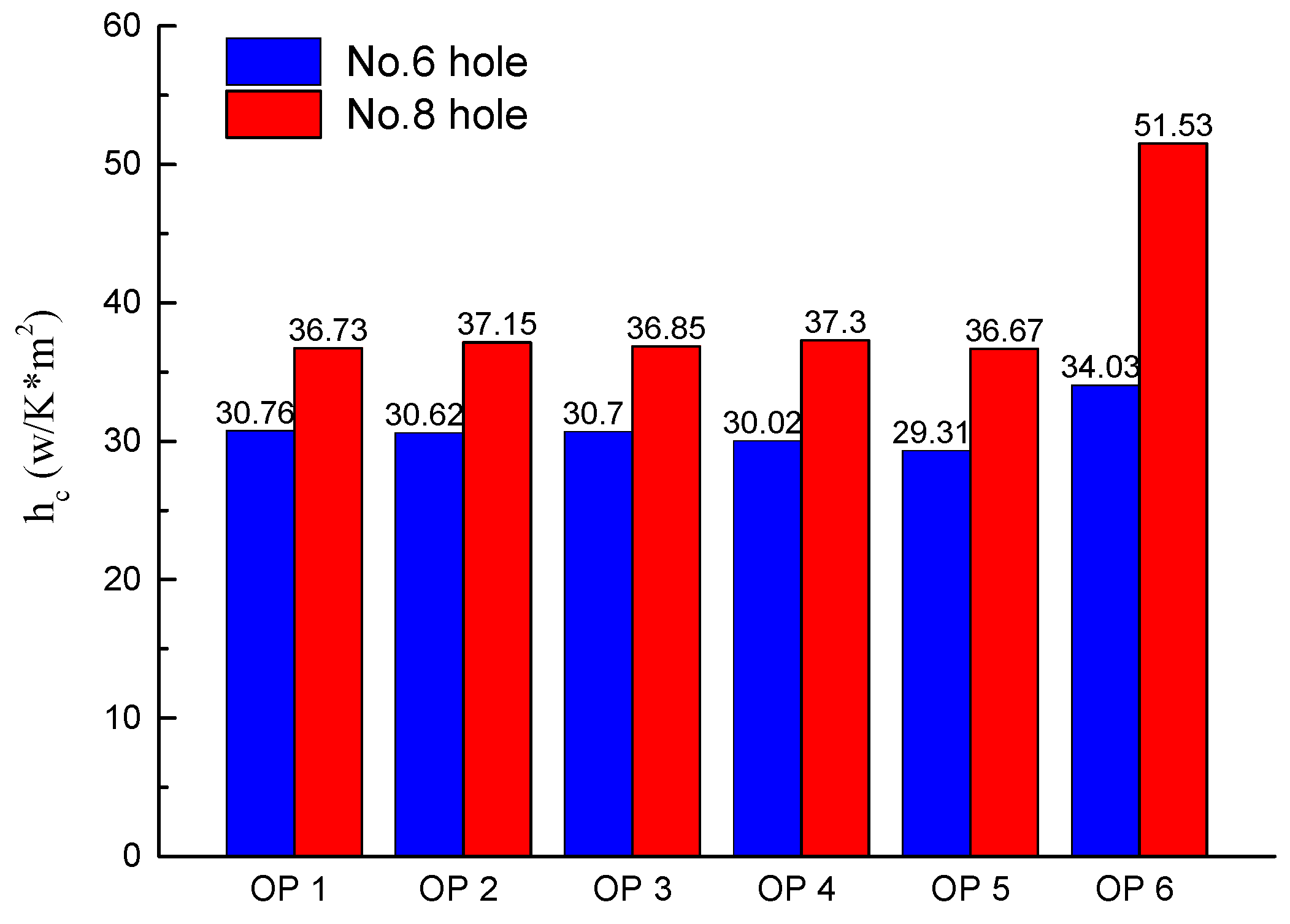

3.1.3. CHT Coefficient of Flame

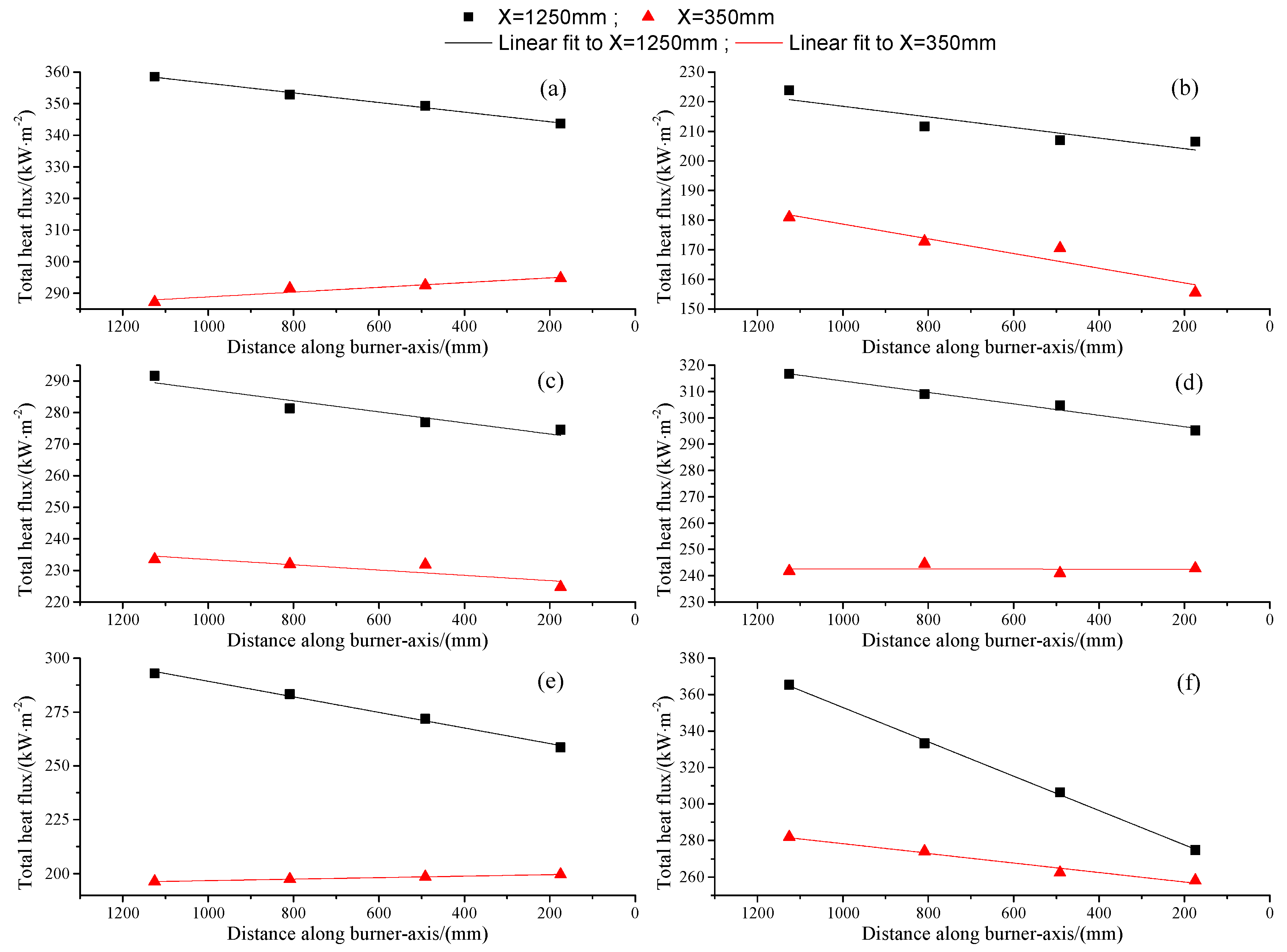

3.2. Nonlinear Surface Fitting of THF Profile at Burner Horizontal Plane

3.3. Heat Flux Proportion at Three Horizontal Levels

4. Conclusions

- The maximum and average THF increased (64.5% and 65.1%) as furnace temperature increased from 900 to 1100 °C. Increasing the excess air ratio from 1.2 to 1.3 at 1100 K furnace temperature enlarged the maximum and average THF (22.8% and 23.4%), the high THF area and reduced the flame volume. Conventional combustion resulted in lower average THF (8.3%) and smaller combustion space than flameless combustion.

- The maximum and average RHF were enhanced (25.6% and 30.8%) by elevated furnace temperatures (900 to 1100 °C), and 23.8% and 27.0% by magnified excess air ratio (1.2 to 1.3). Although an increase in excess air ratio contributed to the maximum RHF, it also caused the heat flux gradient to enlarge. The RHF distribution of flameless combustion was more homogeneous than that of conventional combustion.

- A variation of furnace temperature and excess air ratio had mildly effect (above 20%) on convection coefficient, but combustion mode was in contrast (51.4%).

- The estimated model of the heat flux distribution from the measured heat flux at the whole burner plane agreed with the fitted line of the axis of burner B.

- The RHF of three horizontal levels occupied about 80% of the total heat flux. Heat flux tended to concentrate on the top of the furnace.

Acknowledgments

Author Contributions

Conflicts of Interest

Appendix A

| Coefficient | OP1 | OP2 | OP3 | OP4 | OP5 | Coefficient | OP6 |

|---|---|---|---|---|---|---|---|

| q0 | 244.6823 | 134.0883 | 190.4299 | 201.068 | 176.2513 | q0 | 250.34332 |

| A1 | −2.22729 | −1.35071 | −1.79064 | −1.80963 | −1.43322 | A | 126.79834 |

| A2 | 0.00594 | 0.00366 | 0.0048 | 0.0049 | 0.0038 | xc | 1214.22684 |

| A3 | −6.6 × 10−6 | −4.2 × 10−6 | −5.4 × 10−6 | −5.6 × 10−6 | −4.3 × 10−6 | w1 | 417.5452 |

| A4 | 3.11 × 10−9 | 2 × 10−9 | 2.55 × 10−9 | 2.68 × 10−9 | 2.12 × 10−9 | yc | 1022.544 |

| A5 | −5.2 × 10−13 | −3.4 × 10−13 | −4.3 × 10−13 | −4.6 × 10−13 | −3.6 × 10−13 | w2 | 443.1504 |

| B1 | 0.05254 | 0.04959 | 0.04932 | 0.05302 | 0.05323 | ||

| B2 | −6.8 × 10−6 | 6.3 × 10−6 | −1.3 × 10−6 | −1.3 × 10−6 | 1.8 × 10−6 | ||

| B3 | −8.8 × 10−5 | −4.7 × 10−5 | −6.7 × 10−5 | −7.3 × 10−5 | −6.2 × 10−5 | ||

| B4 | 2.1 × 10−7 | 1.1 × 10−7 | 1.6 × 10−7 | 1.7 × 10−7 | 1.5 × 10−7 | ||

| B5 | −1.2 × 10−10 | −6.2 × 10−11 | −8.9 × 10−11 | −9.7 × 10−11 | −8.2 × 10−11 |

References

- Steinboeck, A.; Wild, D.; Kugi, A. Energy-efficient control of continuous reheating furnaces. IFAC Proc. Vol. 2013, 46, 359–364. [Google Scholar] [CrossRef]

- Marion, M.; Hirz, R.P.; Grote, F.; Weber, S.; Winning, G.; Adler, W.; Bender, W. Increase of energy efficiency of reheating furnaces in forging mills. Stahl Und Eisen 2008, 128, 29–33. [Google Scholar]

- Xing, F.; Kumar, A.; Huang, Y.; Chan, S.N.; Ruan, C.; Gu, S.; Fai, X.L. Flameless combustion with liquid fuel: A review focusing on fundamentals and gas turbine application. Appl. Energy 2017, 197, 28–51. [Google Scholar] [CrossRef]

- Mahdi, Y.; Ann, F.; Thierry, G. Impact of size and temperature on the hydrodynamics of chemical combustion. Appl. Energy 2015, 157, 416–421. [Google Scholar]

- Bhuiyan, A.A.; Blicblau, A.S.; Sadrul Islam, A.K.M.; Naser, J. A review on thermo-chemical characteristics of coal/biomass co-firing in industrial furnace. J. Energy Inst. 2016, in press. [Google Scholar] [CrossRef]

- Chiara, G.; Giovanni, C.; Leonardo, T. Numerical investigation of oxy-natural-gas combustion in a semi-industrial furnace: Validation of CFD sub-models. Fuel 2013, 109, 445–460. [Google Scholar]

- Zhang, R.Q.; Yang, H.R.; Hu, N.; Lu, J.F.; Wu, Y.X. Experimental investigation and model validation of the heat flux profile in a 300 MW CFB boiler. Powder Technol. 2013, 246, 31–40. [Google Scholar] [CrossRef]

- Xu, L.J.; Cheng, L.M.; Cai, Y.; Liu, Y.Q.; Wang, Q.H.; Luo, Z.Y.; Ni, M.J. Heat flux determination based on the waterwall and gas–solid flow in a supercritical CFB boiler. Appl. Therm. Eng. 2016, 99, 703–712. [Google Scholar] [CrossRef]

- Roldán, M.I.; Monterreal, R. Heat flux and temperature prediction on a volumetric receiver installer in a solar furnace. Appl. Energy 2014, 120, 65–74. [Google Scholar] [CrossRef]

- Robin, P.M.; Shaun, M.F.; Zuzana, G.; Juraj, L. An experimental-numerical method for estimating heat transfer in a Bridgman furnace. Appl. Therm. Eng. 2014, 67, 61–71. [Google Scholar]

- Gimelli, A.; Muccillo, M.; Sannino, R. Optimal design of modular cogeneration plants for hospital facilities and robustness evaluation of the results. Energy Convers. Manag. 2017, 134, 20–31. [Google Scholar] [CrossRef]

- Kang, Y.H.; Wang, Q.H.; Lu, X.F.; Ji, X.Y.; Wang, H.; Guo, Q.; Chen, Y.; Yan, J.; Zhou, H.L. Experimental and theoretical study on radiative heat transfer characteristics of dimethyl ether jet diffusion flame. Fuel 2015, 158, 684–696. [Google Scholar] [CrossRef]

- Hashimoto, N.; Watanabe, H. Numerical analysis on effect of furnace scale on heat transfer mechanism of coal particles in pulverized coal combustion field. Fuel Process. Technol. 2016, 145, 20–30. [Google Scholar] [CrossRef]

- Zhang, D.L.; Meng, C.W.; Zhang, H.; Liu, P.Y.; Li, Z.H.; Wu, Y.X.; Lu, J.F.; Zhou, W.; Ran, S.M.; Zhang, D.H. Studies on heat flux distribution on the membrane walls in a 600 MW supercritical arch-fired boiler. Appl. Therm. Eng. 2016, 103, 264–273. [Google Scholar] [CrossRef]

- Fan, Q.W.; Hui, S.E.; Zhou, Q.L.; Chen, X.; Zhao, Q.X.; Xu, T.M. Experimental study on the heat flux distribution of a laboratory-scale wall-fired furnace. Energy Fuels 2010, 24, 5369–5377. [Google Scholar] [CrossRef]

- Silva, R.C.; Krautz, H.J. Experimental studies on heat transfer of oxy-coal combustion in a large-scale laboratory furnace. Appl. Therm. Eng. 2015, 82, 82–97. [Google Scholar] [CrossRef]

- Wang, J.M.; Xu, P.; Yan, H.J.; Zhou, J.M.; Li, S.X.; Gui, G.C.; Li, W.K. Burner effects on melting process of regenerative aluminum melting furnace. Trans. Nonferrous Met. Soc. China 2013, 23, 3125–3136. [Google Scholar] [CrossRef]

- Sadegh, S.K.; David, P.; Fredirk, N.; Filip, J. Heat transfer in a 4-MWth circulating fuildized bed furnace operated under oxy-fired and air-fired conditions: Modeling and measurements. Int. J. Greenh. Gas Control 2015, 37, 264–273. [Google Scholar]

- Erfan, K.; Mahdi, P.; Mohammad, H.P. Effects of excess air and preheating on the flow pattern and efficiency of the radiative section of a fired heater. Appl. Therm. Eng. 2016, 105, 537–548. [Google Scholar]

- Karimi, H.J.; Saidi, M.H. Heat transfer and energy analysis of a pusher type reheating furnace using oxygen enhanced air for combustion. J. Iron Steel Res. 2010, 17, 12–17. [Google Scholar] [CrossRef]

- Jang, J.H.; Lee, D.E.; Kim, C.M.; Kim, M.Y. Prediction of furnace heat transfer and its influence on the steel slab heating and skid mark formation in a reheating furnace. Iron Steel Inst. J. Int. 2008, 48, 1325–1330. [Google Scholar] [CrossRef]

- Wikstrom, P.; Blasiak, W.; Berntsson, F. Estimation of the transient surface temperature, heat flux and effective heat transfer coefficient of a slab in an industrial reheating furnace by using an inverse method. Steel Res. Int. 2007, 78, 63–70. [Google Scholar] [CrossRef]

- Rafidi, N.; Blasiak, W. Heat transfer characteristics of HiTAC heating furnace using regenerative burners. Appl. Therm. Eng. 2006, 26, 2027–2034. [Google Scholar] [CrossRef]

- Bideau, P.L.; Ploteau, J.P.; Glouannec, P. Heat flux estimation in an infrared experimental furnace using an inverse method. Appl. Therm. Eng. 2009, 29, 2977–2982. [Google Scholar] [CrossRef]

- Sankar, G.; Rao, A.C.; Seshadri, P.S.; Balasubramanian, K.R. Techniques for measurement of heat flux in furnace waterwalls of boilers and prediction of heat flux—A review. Appl. Therm. Eng. 2016, 103, 1470–1479. [Google Scholar] [CrossRef]

- Murthy, A.V. Characterization of an ellipsoidal radiometer. J. Res. Natl. Inst. Stand. Technol. 2003, 108, 115–124. [Google Scholar] [CrossRef] [PubMed]

- Li, A.; Gao, X.P. A method to calculate wall heat fluxes of electrical equipments based on overdetermined linear equation. Appl. Therm. Eng. 2011, 114, 428–443. [Google Scholar] [CrossRef]

- Holman, S.W. Discussion of the Precision of Measurements: With Examples Taken Mainly from Physics and Electrical Engineering; Brunton Press: Louisville, CO, USA, 2007. [Google Scholar]

| Element | Cu | Mg | Si | Fe | Mn | Ni | Zn | Ca | Al |

|---|---|---|---|---|---|---|---|---|---|

| wt % | 1.638 | 0.251 | 10.603 | 0.78 | 0.202 | 0.055 | 0.916 | 0.005 | 85.309 |

| Case | Gas Velocity (m/s) | Excess Air Ratio | Furnace Temperature (°C) | Mode |

|---|---|---|---|---|

| OP1 | 90 | 1.2 | 1100 | F2 |

| OP2 | 90 | 1.2 | 900 | F2 |

| OP3 | 90 | 1.2 | 1000 | F2 |

| OP4 | 90 | 1.25 | 1100 | F2 |

| OP5 | 90 | 1.3 | 1100 | F2 |

| OP6 | 90 | 1.2 | 850 | F1 |

| Heat Flux | OP | Equation Form | R-sq (adj) |

|---|---|---|---|

| THF | OP1 | Q = Q0 + A1 x + A2 x2 + A3 x3 + A4 x4 + A5 x5 + B1 y + B2 y2 + B3 y3 + B4 y4 + B5 y5 | 0.911 |

| OP2 | 0.897 | ||

| OP3 | 0.881 | ||

| OP4 | 0.913 | ||

| OP5 | 0.876 | ||

| OP6 | Q = Q0 + A/((1 + ((x − xc)/w1)2) × (1 + ((y − yc)/w2)2)) | 0.958 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, H.; Deng, S. Evaluating Heat Flux Profiles in Aluminum Reheating Furnace with Regenerative Burner. Energies 2017, 10, 562. https://doi.org/10.3390/en10040562

Zhang H, Deng S. Evaluating Heat Flux Profiles in Aluminum Reheating Furnace with Regenerative Burner. Energies. 2017; 10(4):562. https://doi.org/10.3390/en10040562

Chicago/Turabian StyleZhang, Hang, and Shengxiang Deng. 2017. "Evaluating Heat Flux Profiles in Aluminum Reheating Furnace with Regenerative Burner" Energies 10, no. 4: 562. https://doi.org/10.3390/en10040562