On a Long Term Strategy for the Success of Nuclear Power

Abstract

:1. Introduction

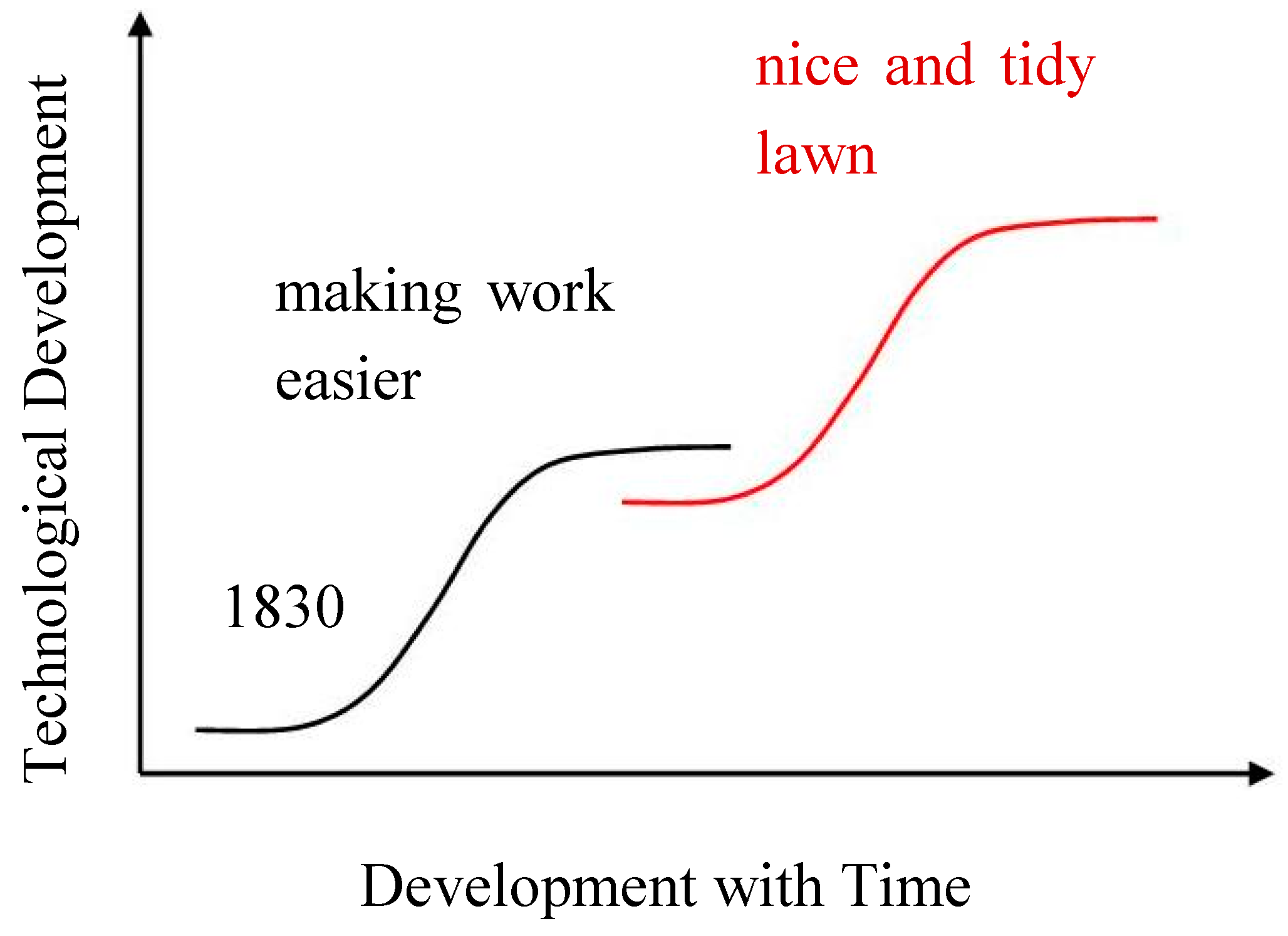

Excursion: “The Lawn Mower Problem”

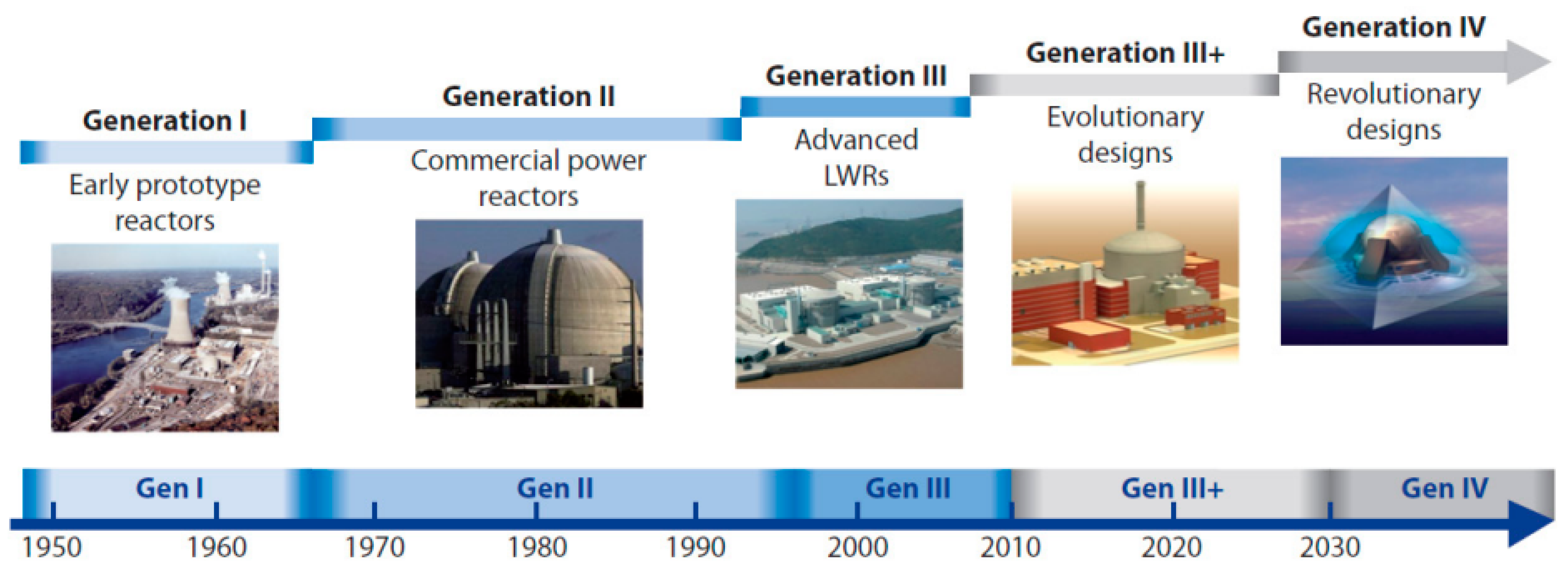

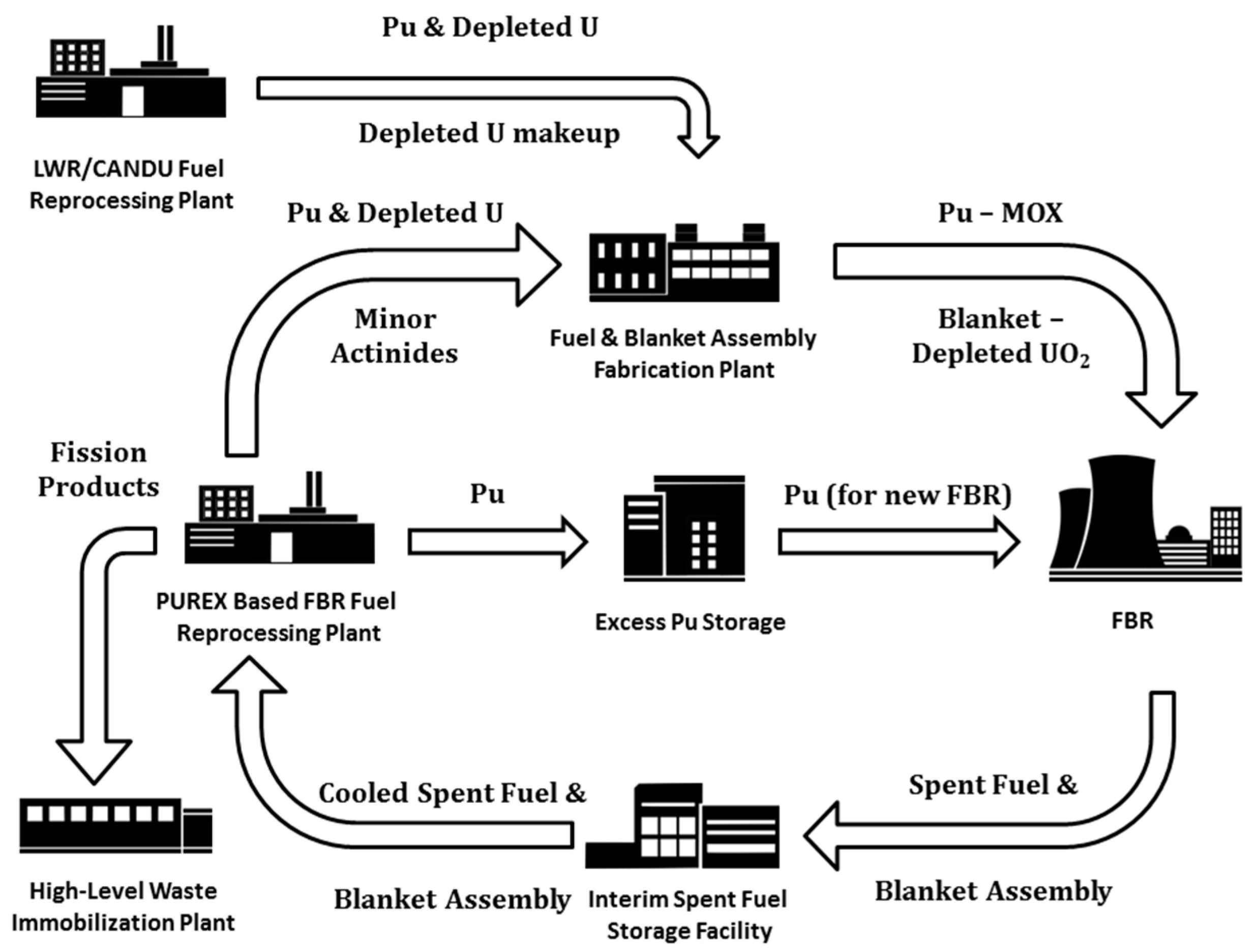

2. Development of Nuclear Reactor Technologies

2.1. Historic Development

- Demonstration of a continuing chain reaction and its potential application

- Generation of material for military purposes and/or commercial/medical applications

- Energy generation from the chain reaction, either as electricity, most desirable, or heat

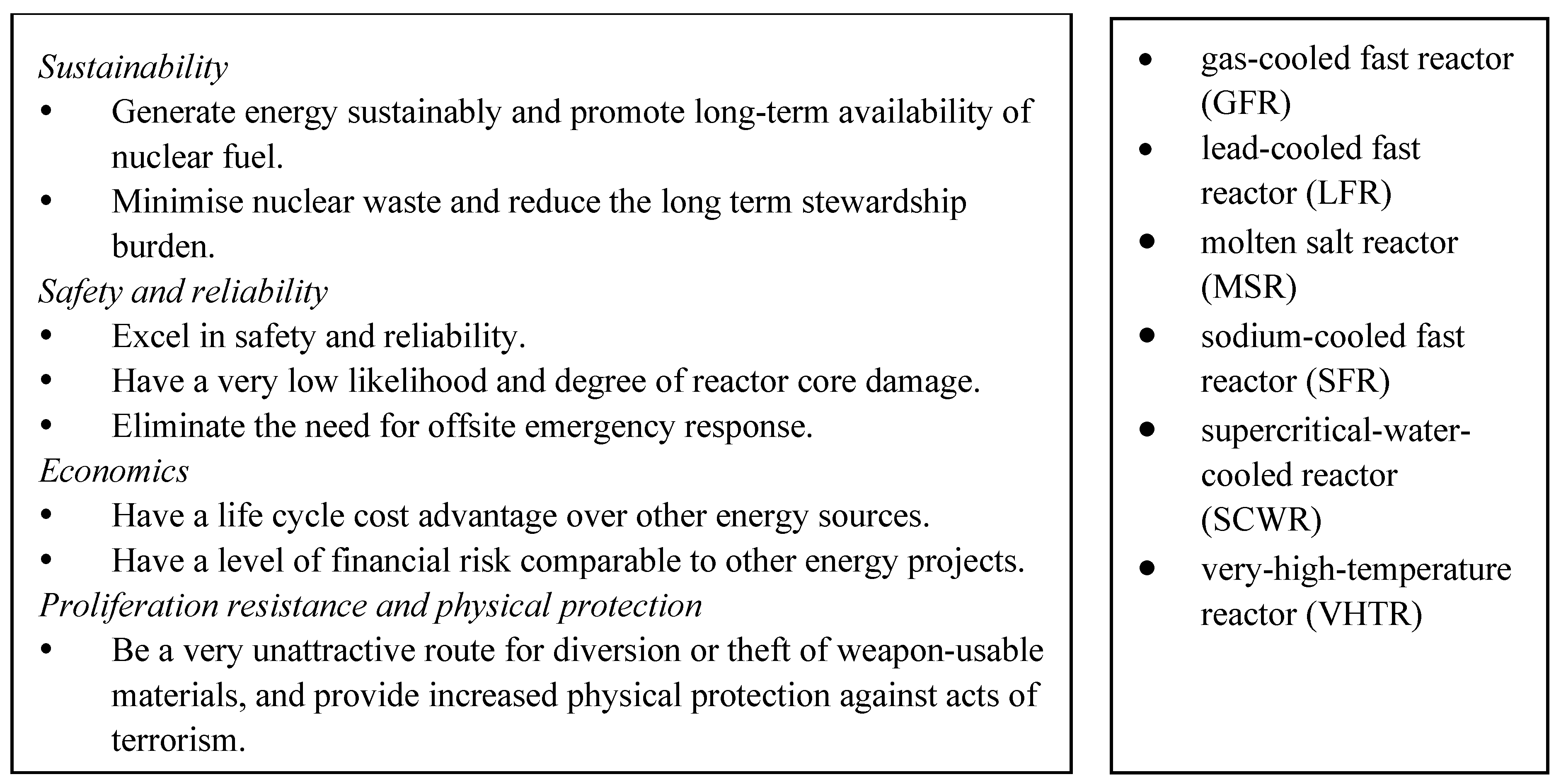

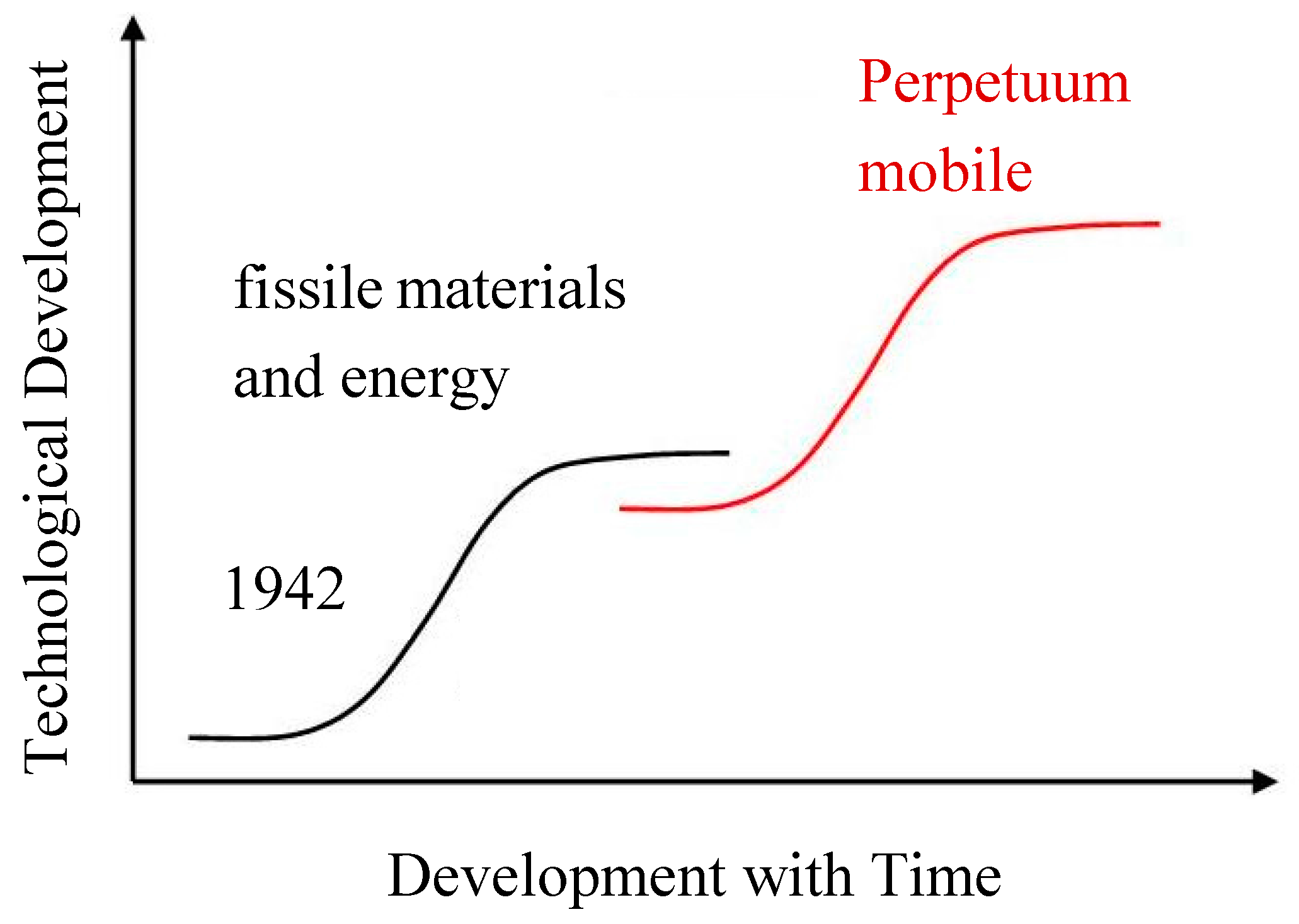

2.2. Strategic Development for the Future

- No resources requested

- No waste produced

- Highly economic, reliable, safe and secure

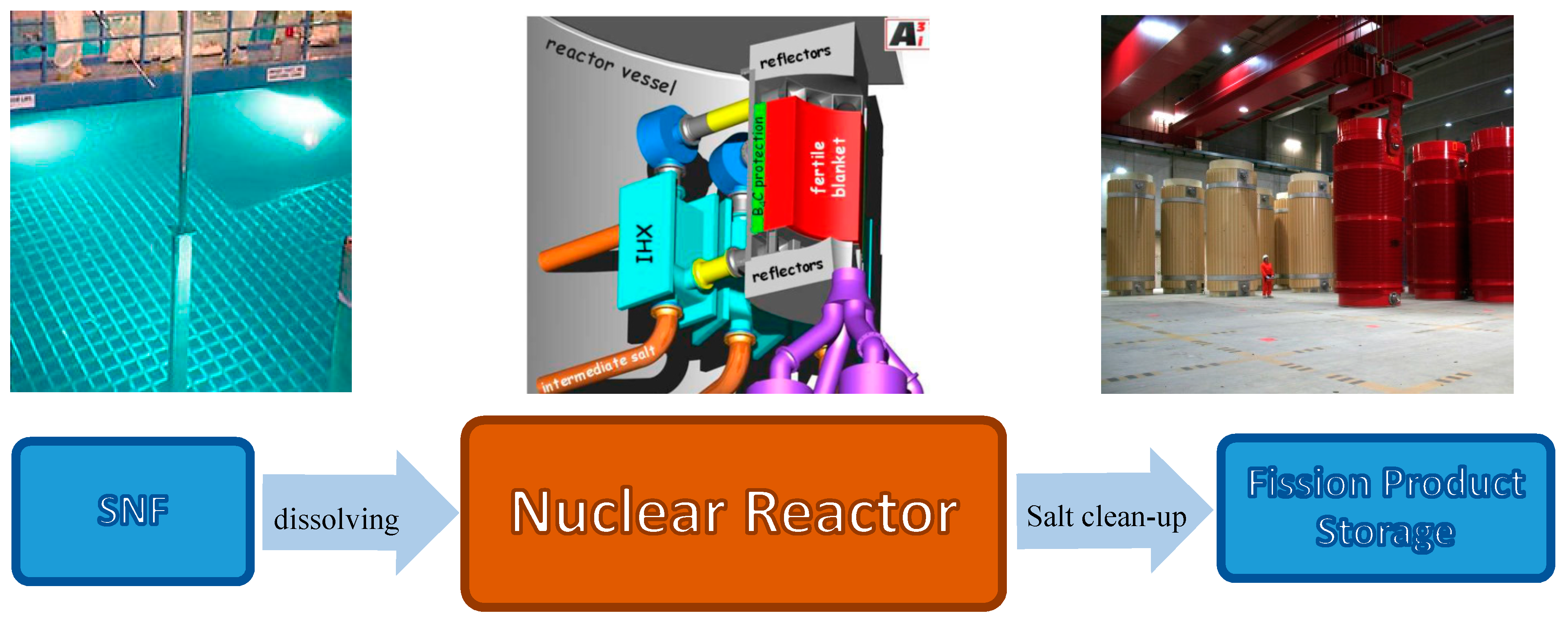

3. Results

3.1. Initial Core

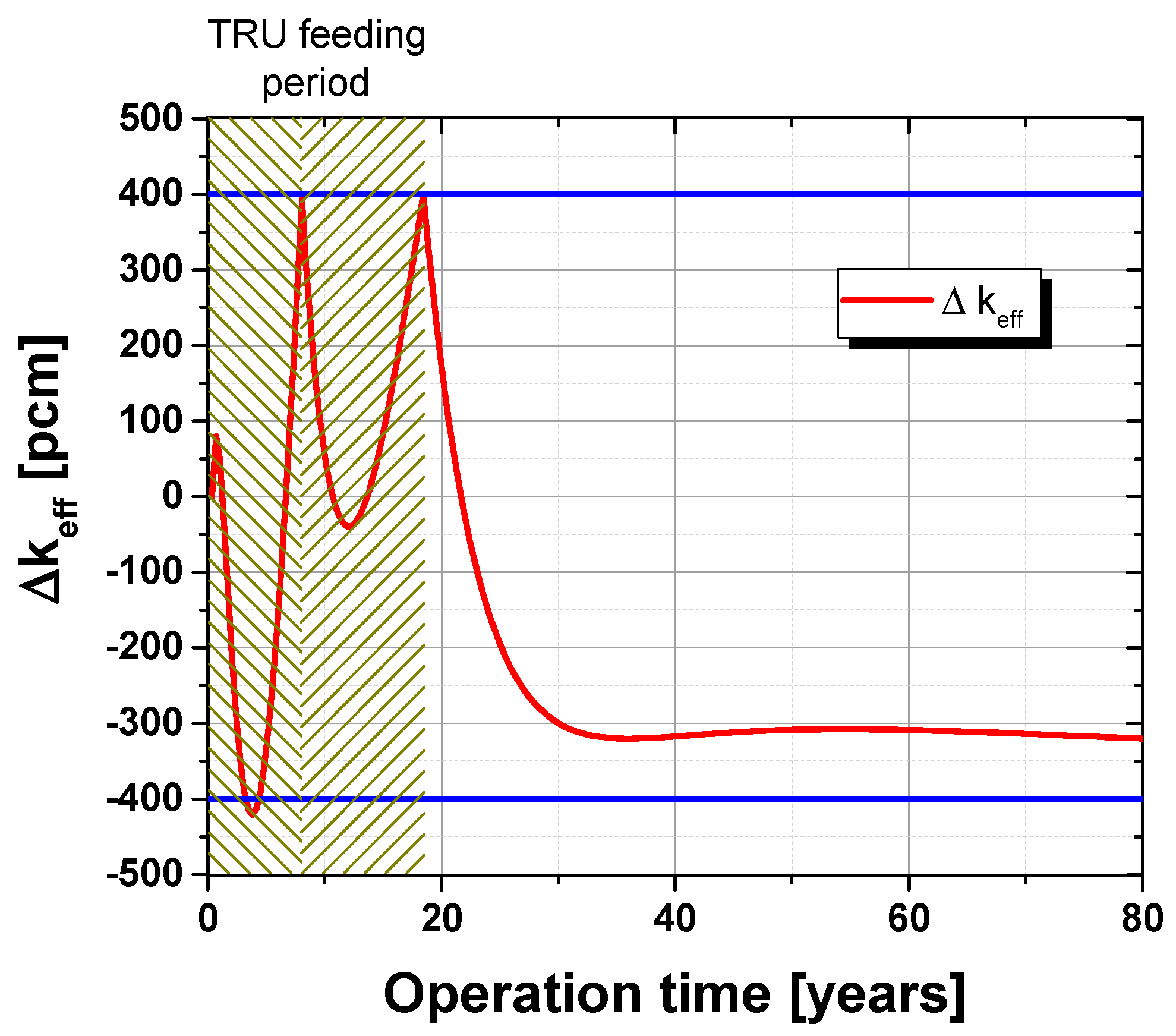

3.2. Simulation over Lifetime

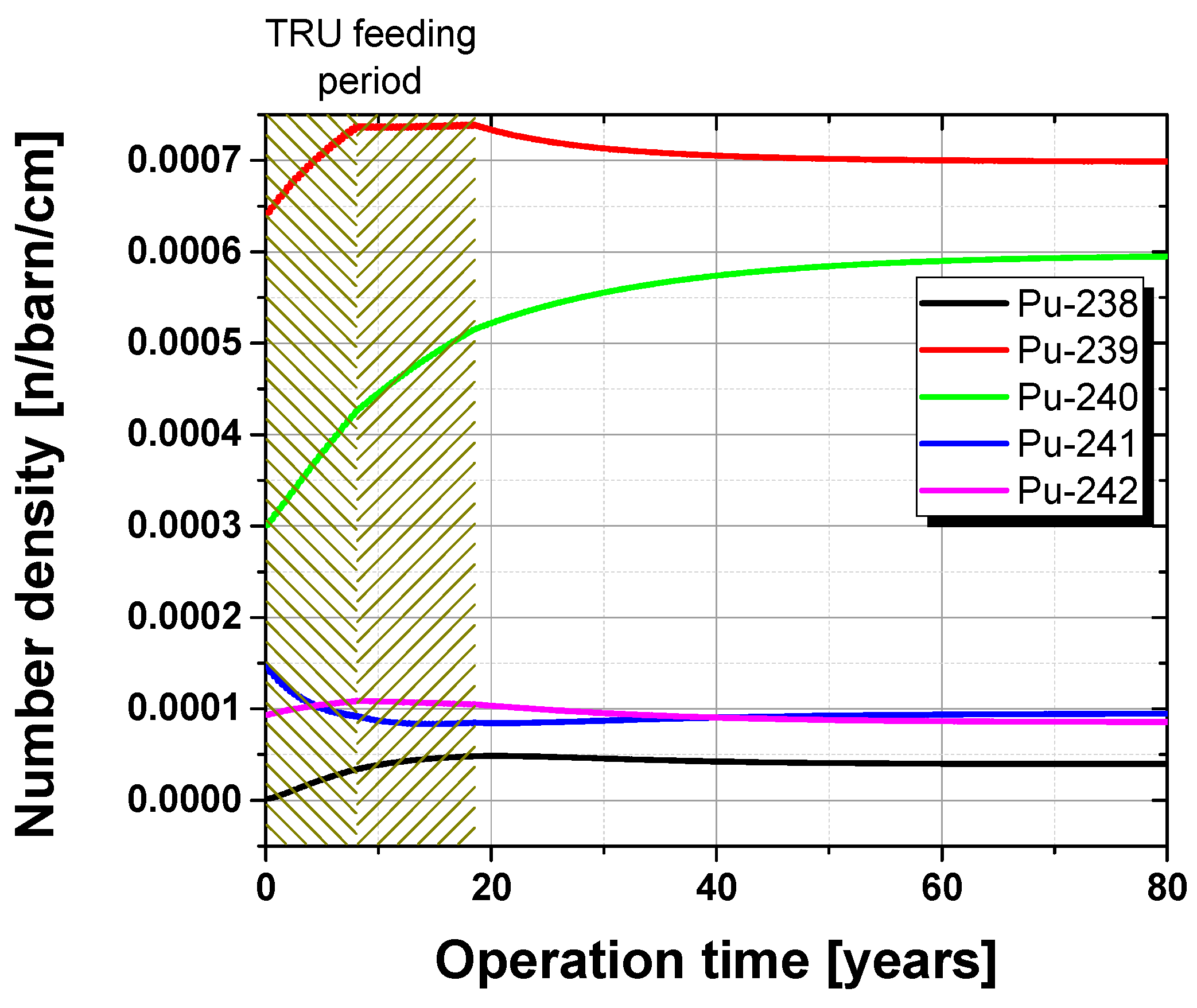

3.3. Isotopic Contents

4. Discussion

4.1. Not an Unlimited Energy Source!

4.2. Challenges for R&D

- Engineering:

- Optimization of burning used LWR fuel, i.e., demonstration of principles with validation

- Optimization of reactor design, i.e., better than EVOL

- ○

- Fully understanding the fluid dynamics under both normal and accidental conditions

- ○

- Componentry for molten salt system including in service inspection and repair

- Development of materials or engineering solutions capable of operating under such extreme conditions, e.g., high temperature, significant radiation damage, corrosive environment

- Chemistry and Thermodynamics:

- Optimization of salt purification, i.e., removal of fission products from within the liquid phase

- Design, implementation and capture of volatile fission products, helping to keep the liquid phase pure

- Preparing the fuel—choosing the optimal method for converting used LWR fuel in to a form sufficient for use within the reactor

- Appreciation of the chemical thermodynamics, and limitations in using molten salts with high levels of actinide loading

- Safety:

- Develop the safety methodology and implementation protocols for such a novel liquid reactor design

- Assurance in safety of such a co-located site, i.e., both reactor and reprocessing

- Others:

- Economic viability, ensuring the reactor is economically viable and competitive with current technology

- Ensure the public acceptance of such a new technology, without which the reactor is unviable

- Development, verification, and validation of an integrated computer simulation environment incorporating reactor physics, salt chemistry, process engineering, thermodynamics, and material behavior

5. Materials and Methods

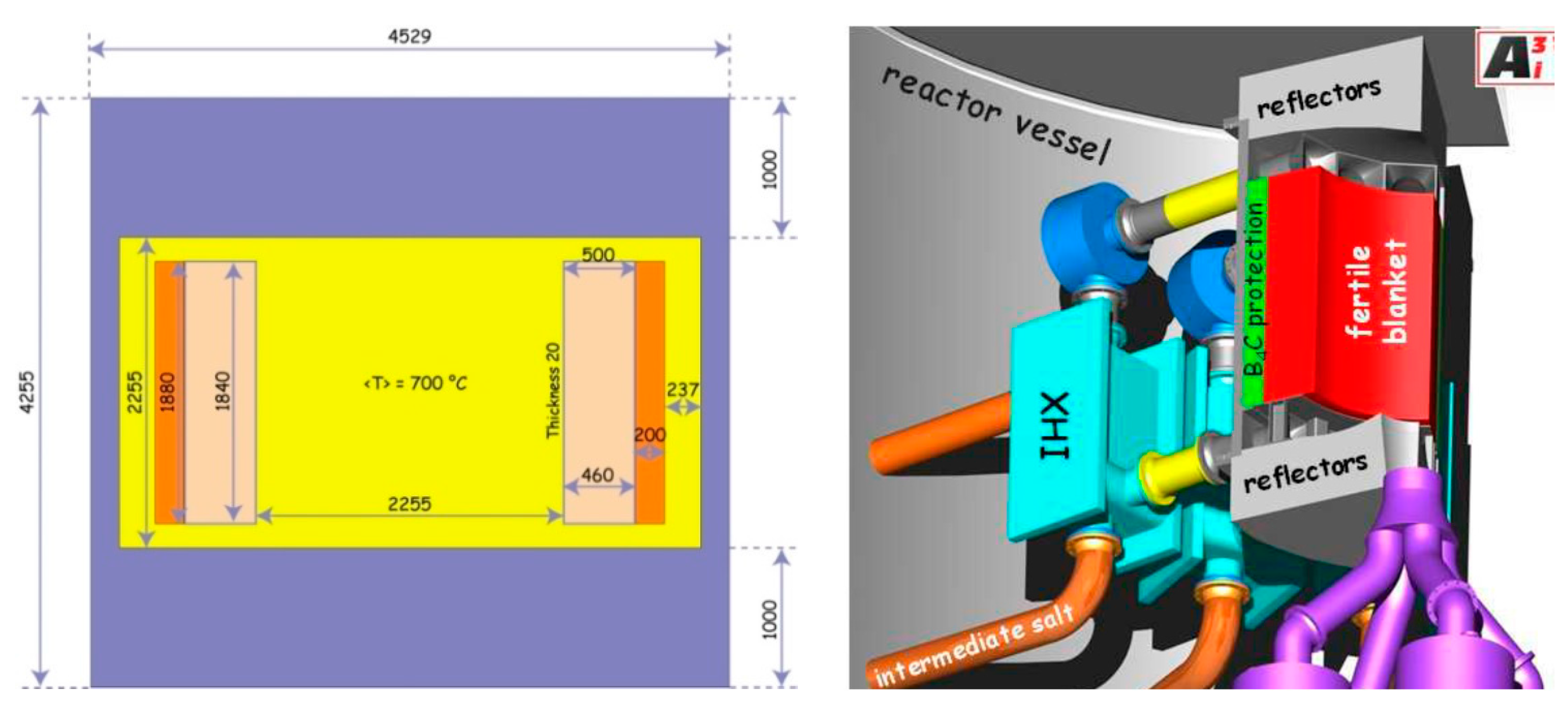

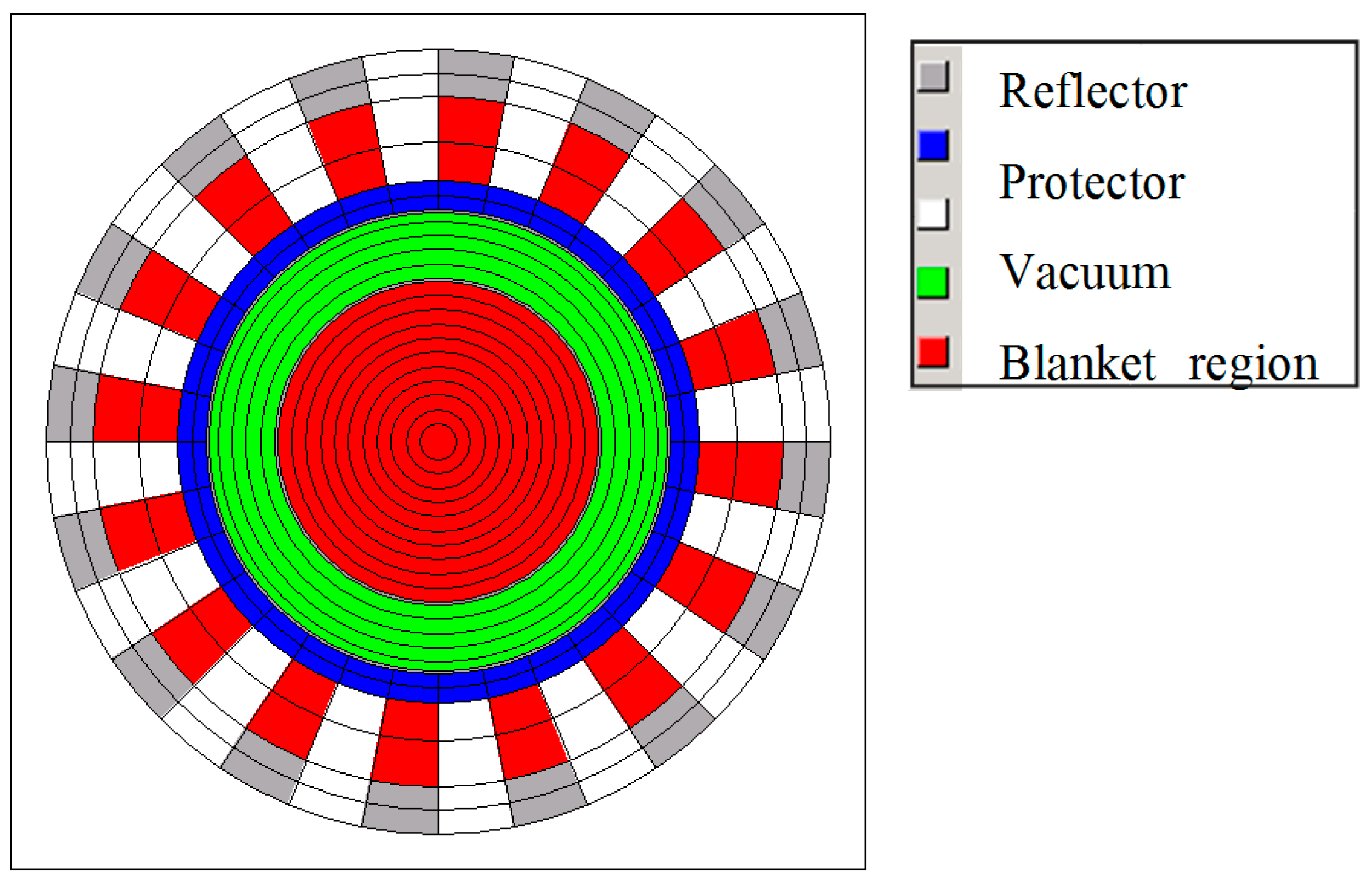

5.1. Reference Configuration

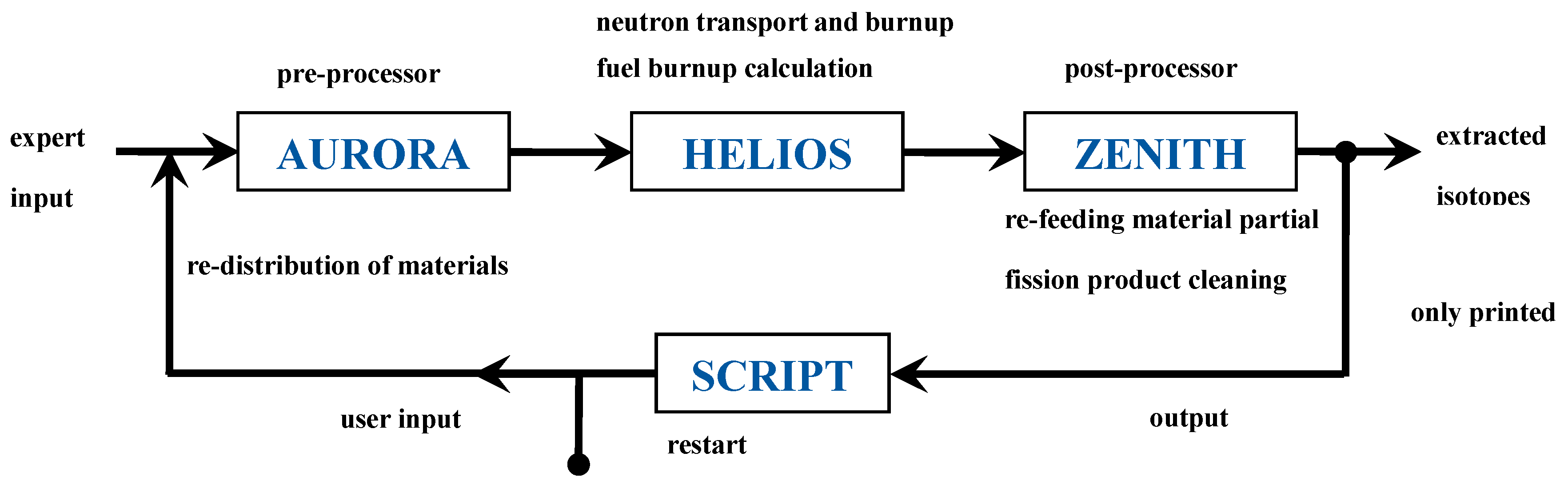

5.2. Modelling and Calculation Tool

6. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

Abbreviations

| MSR | Molten Salt Reactor |

| MSFR | Molten Salt Fast Reactor |

| LWR | Light Water Reactor |

| iMAGINE | Visionary Molten Salt Fast Reactor Concept operating on spent nuclear fuel |

| SNF | Spent Nuclear Fuel |

| TRU | Transuranium—all elements with an atomic number higher than 92 |

| HM | heavy metal—all elements with an atomic number higher than 90, typically the base to account for fissile materials in the reactor |

| HEU | Highly enriched Uranium—typically uranium with more than 20% U-235 content |

| MWth | Megawatt thermal |

| GWe | Gigawatt electric |

| GWd/tHM | Gigawattdays per ton of heavy metal—measure for the burnup of nuclear material in a reactor |

| MWd/tHM | Megawattdays per ton of heavy metal |

| GenIV | Reactor systems of the 4th generation as defined by the Generation IV International Forum |

| NEA | Nuclear energy Agency of the OECD |

| IAEA | International Atomic Energy Agency of the United Nations |

| Δ͞keff | difference from the critical reactor status, typically measured in pcm (percent mille) |

| LiF | Lithiumfluoride |

| SNFF4 | Spent Nuclear Fuel Tetrafluoride |

| UF4 | Uranium Tetrafluoride |

| EVOL | European project for the development of a molten salt fast reactor |

| BREST | Russian innovative reactor concept with lead coolant |

| INDE | Integrated Nuclear Digital Environment |

| R&D | Research and Development |

| TRL | Technical readiness level |

| HELIOS | Reactor physics code package of Studsvik Scandpower |

| AURORA | pre-processor of the HELIOS package |

| ZENITH | post-processor of the HELIOS package |

| SERPENT | Reactor physics package based on the Monte Carlo method |

| ENDF/B VII | Nuclear data library |

References

- Rogers, E.M. Diffusion of Innovations, 5th ed.; Paperback; Free Press: New York, NY, USA, 2003. [Google Scholar]

- Malik, F. Strategy—Navigating the Complexity of the World; Campus Verlag: Frankfurt, Germany; New York, NY, USA, 2013. [Google Scholar]

- A History of the World: The World’s First Lawnmower. Available online: http://www.bbc.co.uk/ahistoryoftheworld/objects/NI2ZjBwpTcqYdtpXFnIzUQ (accessed on 23 June 2017).

- Achievements: Reactors Designed by Argonne National Laboratory. Available online: http://www.ne.anl.gov/About/reactors/early-reactors.shtml (accessed on 6 April 2016).

- Technology Roadmap Update for Generation IV Nuclear Energy Systems, January 2014. Available online: https://www.gen-4.org/gif/upload/docs/application/pdf/2014-03/gif-tru2014.pdf (accessed on 6 April 2016).

- World Energy Council: Energy Trilemma Index. Available online: https://trilemma.worldenergy.org/ (accessed on 5 April 2017).

- Outline History of Nuclear Energy. (Updated March 2014). Available online: http://www.world-nuclear.org/information-library/current-and-future-generation/outline-history-of-nuclear-energy.aspx (accessed on 7 April 2016).

- Hyman, G. Rickover. Available online: http://www.globalsecurity.org/military/agency/navy/rickover.htm (accessed on 5 April 2017).

- Roehrlich, E. 60 Years of “Atoms for Peace”. Available online: https://www.iaea.org/newscenter/news/60-years-atoms-peace (accessed on 21 June 2016).

- Eisenhower, D.D. Atoms for Peace Speech, 470th Plenary Meeting of the United Nations General Assembly. Available online: https://www.iaea.org/about/history/atoms-for-peace-speech (accessed on 24 May 2017).

- Nash, K.L.; Nilsson, M. Introduction to the Reprocessing and Recycling of Spent Nuclear Fuels. In Reprocessing and Recycling of Spent Nuclear Fuel; Taylor, R., Ed.; Woodhead Publishing Series in Energy 79; Elsevier: Oxford, UK, 2015. [Google Scholar]

- Barnham, K.W.J.; Hart, D.; Nelson, J.; Stevens, R.A. Did civil reactors supply plutonium for weapons? Nature 2000, 407, 833–834. [Google Scholar] [CrossRef] [PubMed]

- Barnham, K.W.J.; Hart, D.; Nelson, J.; Stevens, R.A. Production and destination of British civil plutonium. Nature 1985, 317, 213–217. [Google Scholar] [CrossRef]

- RBMK Reactors. Available online: http://www.world-nuclear.org/information-library/nuclear-fuel-cycle/nuclear-power-reactors/appendices/rbmk-reactors.aspx (accessed on 15 June 2016).

- Cerullo, N.; Lomonaco, G. Generation IV reactor designs, operation and fuel cycle. In Nuclear Fuel Cycle Science and Engineering; Crossland, I., Ed.; Woodhead Publishing Limited: Cambridge, UK, 2012; pp. 333–395. [Google Scholar] [CrossRef]

- Carré, F. The Nuclear Fuel Cycle: Key to Generation IV Nuclear Energy Systems’ Sustainability and Transition from LWRs, ANS Annual Meeting. Available online: http://web.mit.edu/nse/pdf/news/2007/07_ansannualmtg/ANS_07%20(Carre).pdf (accessed on 5 May 2017).

- Trends towards Sustainability in the Nuclear Fuel Cycle; NEA No. 6980; Nuclear Development: Paris, France, 2011.

- Assessment of Nuclear Energy Systems Based on a Closed Nuclear Fuel Cycle with Fast Reactors; A Report of the International Project on Innovative Nuclear Reactors and Fuel Cycles (INPRO), IAEA-TECDOC-1639; International Atomic Energy Agency: Vienna, Austria, 2010.

- Merk, B.; Stanculescu, A.; Chellapandi, P.; Hill, R. Progress in reliability of fast reactor operation and new trends to increased inherent safety. Appl. Energy 2015, 147, 104–116. [Google Scholar] [CrossRef]

- MacPherson, H.G. The Molten Salt Reactor Adventure. Nucl. Sci. Eng. 1985, 90, 374–380. [Google Scholar] [CrossRef]

- Myung-Seung, Y.; Choi, H.B.; Jeong, C.J. The status and prospect of DUPIC fuel technology. Nucl. Eng. Technol. 2006, 38, 359–374. [Google Scholar]

- Wigeland, R.; Taiwo, T.; Ludewig, H.; Todosow, M.; Halsey, W.; Gehin, J.; Jubin, R.; Buelt, J.; Stockinger, S.; Jenni, K.; et al. Nuclear Fuel Cycle Evaluation and Screening—Final Report, INL/EXT-14-31465, FCRD-FCO-2014-000106. Available online: https://fuelcycleevaluation.inl.gov/Shared%20Documents/ES%20Main%20Report.pdf (accessed on 24 May 2017).

- Kim, T.K.; Taiwo, T.A.; Wigeland, R.A.; Dixon, B.W.; Gehin, J.C.; Todosow, M. Mass Flow Data Comparison for Comprehensive Fuel Cycle Options. In Proceedings of the Actinide and Fission Product Partitioning and Transmutation Thirteenth Information Exchange Meeting, Seoul, Korea, 23–26 September 2014. [Google Scholar]

- Merk, B.; Rohde, U.; Glivici-Cotruta, V.; Litskevich, D.; Scholl, S. On the Molten Salt Fast Reactor for Applying an Idealized Transmutation Scenario for the Nuclear Phase Out. PLoS ONE 2014, 9, e92776. [Google Scholar] [CrossRef] [PubMed]

- Merk, B.; Litskevich, D. Transmutation of All German Transuranium under Nuclear Phase out Conditions—Is This Feasible from Neutronic Point of View? PLoS ONE 2015, 10, e0145652. [Google Scholar] [CrossRef] [PubMed]

- Merk, B.; Litskevich, D. On the Burning of Plutonium Originating from Light Water Reactor Use in a Fast Molten Salt Reactor—A Neutron Physical Study. Energies 2015, 8, 12557–12572. [Google Scholar] [CrossRef]

- EVOL (Project No. 249696) FINAL REPORT. Available online: http://cordis.europa.eu/docs/results/249/249696/final1-final-report-f.pdf (accessed on 23 June 2017).

- Acatech. Partitioning and Transmutation of Nuclear Waste. Opportunities and Risks in Research and Application; Acatech POSITION PAPER; Acatech: Munich, Germany, 2014. [Google Scholar]

- Final Report Summary—EVOL (Evaluation and Viability of Liquid Fuel Fast Reactor System). Available online: http://cordis.europa.eu/result/rcn/159411_en.html (accessed on 5 May 2017).

- Molten Salt Fast Reactor, EVOL Reference Configuration. Available online: http://cordis.europa.eu/docs/results/249/249696/final1-final-report-f.pdf (accessed on 23 June 2017).

- Engel, J.R.; Grimes, W.R.; Rhoades, W.A.; Dearing, J.F. Molten-Salt Reactors for Efficient Nuclear Fuel Utilization Without Plutonium Separation, ORNL/TM-6413, August 1978. Available online: http://web.ornl.gov/info/reports/1978/3445603227167.pdf (accessed on 15 July 2015).

- Poinssot, Ch.; Bourg, S.; Ouvrier, N.; Combernoux, N.; Rostaing, C.; Vargas-Gonzalez, M.; Bruno, J. Assessment of the environmental footprint of nuclear energy systems. Comparison between closed and open fuel cycles. Energy 2014, 69, 199–211. [Google Scholar] [CrossRef]

- Merk, B.; Litskevich, D.; Bankhead, M.; Taylor, R.J. An Innovative Way of Thinking Nuclear Waste Management—Neutron Physics of a Reactor Directly Operating on SNF, OECD/NEA Actinide and Fission Product Partitioning and Transmutation. In Proceedings of the 14th Information Exchange Meeting, Hilton San Diego Mission Valley, San Diego, CA, USA, 17–20 October 2016. [Google Scholar]

- Adamov, E.O.; Pershukov, V.A. Project Proryv (Breakthrough). In Proceedings of the VII International Forum ATOMEXPO, Moscow, Russia, 30 May 2016. [Google Scholar]

- Ignatiev, V.; Feynberg, O.; Merzlyakov, A.; Surenkov, A.; Zagnitko, A.; Afonichkin, V.; Bovet, A.; Khokhlov, V.; Subbotin, V.; Fazilov, R.; et al. Progress in Development of MOSART Concept with Th Support. In Proceedings of the 2012 International Congress on Advances in Nuclear Power Plants (ICAPP’12), Chicago, IL, USA, 24–28 June 2012. [Google Scholar]

- Safety Assessment of the Molten Salt Fast Reactor. Available online: http://samofar.eu/ (accessed on 23 June 2017).

- Patterson, E.A.; Taylor, R.J.; Bankhead, M. A framework for an integrated nuclear digital environment. Prog. Nucl. Energy 2016, 87, 97–103. [Google Scholar] [CrossRef]

- Madic, C. From the Reactor to Waste Disposal: The Back-End of the Nuclear Fuel Cycle, Biological Assessment of Occupational Exposure to Actinides, Versailles, France, 1988. Available online: http://www.iaea.org/inis/collection/NCLCollectionStore/_Public/20/005/20005325.pdf?r=1 (accessed on 18 April 2016).

- Feiveson, H.; Mian, Z.; Rama, M.V.; von Hippel, F. Spent Fuel from Nuclear Power Reactors—An Overview of a New Study in the International Panel on Fissile Materials, Draft for Discussion. June 2011. Available online: http://fissilematerials.org/library/ipfm-spent-fuel-overview-june-2011.pdf (accessed on 18 April 2016).

- Fissile Material Stocks, International Panel on Fissile Materials. Available online: http://fissilematerials.org/ (accessed on 18 April 2016).

- Costing of Spent Nuclear Fuel Storage, IAEA Nuclear Energy Series Technical Reports No. NF-T-3.5, IAEA 2009. Available online: https://www.iaea.org/sites/default/files/costingfuel0909.pdf (accessed on 30 August 2016).

- Merk, B.; Konheiser, J. Shielding Studies on an Advanced Molten Salt Fast Reactor Design. Ann. Nucl. Energy 2014, 64, 441–448. [Google Scholar] [CrossRef]

- Merk, B. Molten Salt Reactor Study. Available online: http://datacat.liverpool.ac.uk/id/eprint/151 (accessed on 23 June 2017).

- Kozlowski, T.; Downar, T.J. OECD/NEA AND U.S. NRC PWR MOX/UO2 Core Transient Benchmark. OECD NEA, Final Spec. 2003. Available online: http://www.nea.fr/science/wprs/MOX-UOX-transients/benchmark_documents/specifications/mox_bench_spec.pdf (accessed on 23 June 2017).

- HELIOS-2 Methods, Version 2.1; SSP-11/452 Rev 1; Studsvik Scandpower: Waltham, MA, USA, 2011.

- Villarino, E.A.; Stammler, R.J.J.; Ferri, A.; Casal, J.J. HELIOS: Angularly dependent collision probabilities. Nucl. Sci. Eng. 1992, 112, 16–31. [Google Scholar] [CrossRef]

- Rachamin, R.; Wemple, C.; Fridman, E. Neutronic analysis of SFR core with HELIOS-2, Serpent, and DYN3D codes. Ann. Nucl. Energy 2013, 55, 194–204. [Google Scholar] [CrossRef]

- Brovchenko, M. Neutronic Benchmark of the Molten Salt Fast Reactor in the Frame of the EVOL and MARS Collaborative Projects. Ann. Nucl. Energy 2015. submitted. [Google Scholar]

- Mikityuk, K. Core Safety (ESNII + WP6). In Proceedings of the European Nuclear Gen II, III, IV Days, Brussels, Belgium, 17–19 March 2015. [Google Scholar]

| Isotope | Unload | Load |

|---|---|---|

| Pu-238 | 2.6% | 3.1% |

| Pu-239 | 46.1% | 52.5% |

| Pu-240 | 39.4% | 24.6% |

| Pu-241 | 6.3% | 12.2% |

| Pu-242 | 5.6% | 7.7% |

| Pufiss | 52.4% | 64.7% |

| Isotope | Concentration |

|---|---|

| Np 237 | 6.30% |

| Pu 238 | 2.70% |

| Pu 239 | 45.90% |

| Pu 240 | 21.50% |

| Pu 241 | 10.70% |

| Pu 242 | 6.70% |

| Am 241 | 3.40% |

| Am 243 | 1.90% |

| Cm 244 | 0.80% |

| Cm 245 | 0.10% |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Merk, B.; Litskevich, D.; Whittle, K.R.; Bankhead, M.; Taylor, R.J.; Mathers, D. On a Long Term Strategy for the Success of Nuclear Power. Energies 2017, 10, 867. https://doi.org/10.3390/en10070867

Merk B, Litskevich D, Whittle KR, Bankhead M, Taylor RJ, Mathers D. On a Long Term Strategy for the Success of Nuclear Power. Energies. 2017; 10(7):867. https://doi.org/10.3390/en10070867

Chicago/Turabian StyleMerk, Bruno, Dzianis Litskevich, Karl R. Whittle, Mark Bankhead, Richard J. Taylor, and Dan Mathers. 2017. "On a Long Term Strategy for the Success of Nuclear Power" Energies 10, no. 7: 867. https://doi.org/10.3390/en10070867