Thermal Behaviour under Service Loads of a Thermo-Active Precast Pile

Abstract

:1. Introduction

2. Materials and Methods

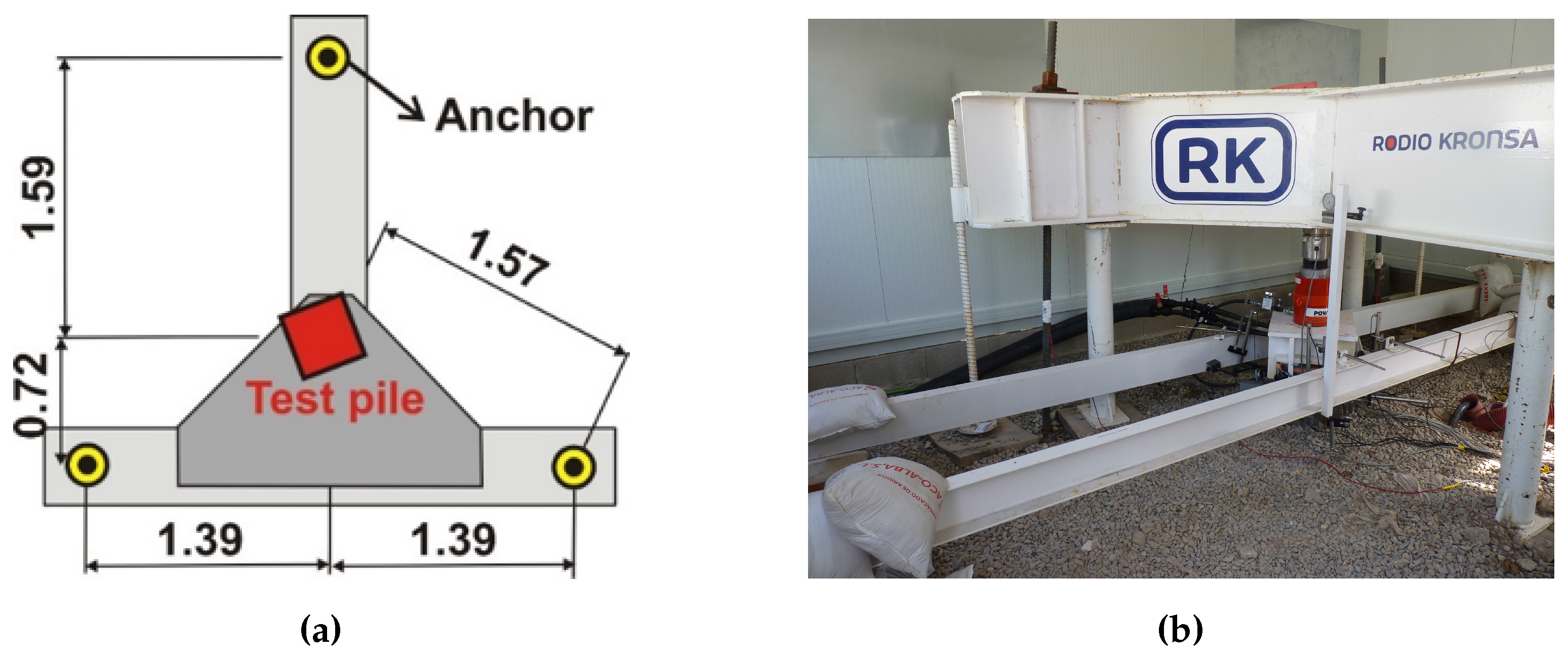

2.1. Pile Design and Construction

2.2. Experimental Set Up

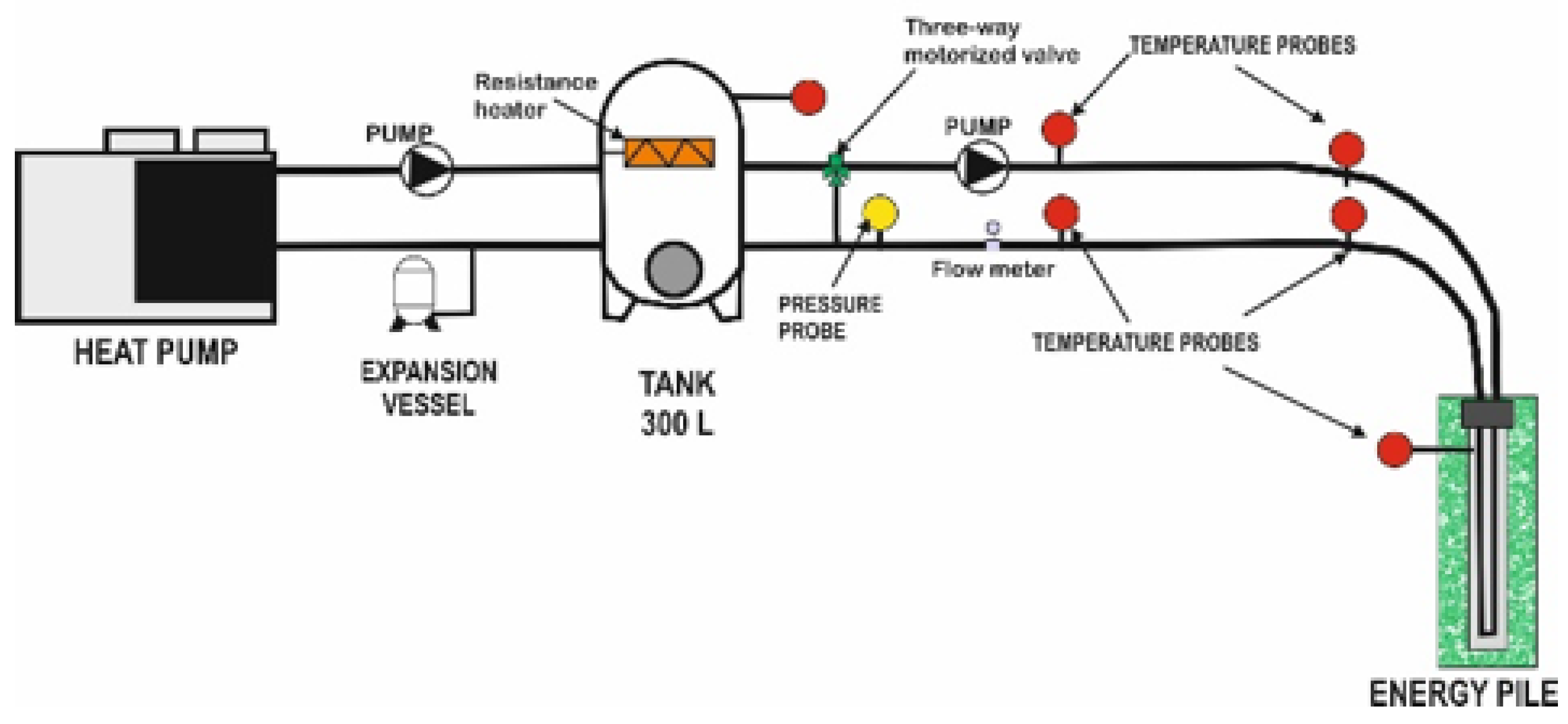

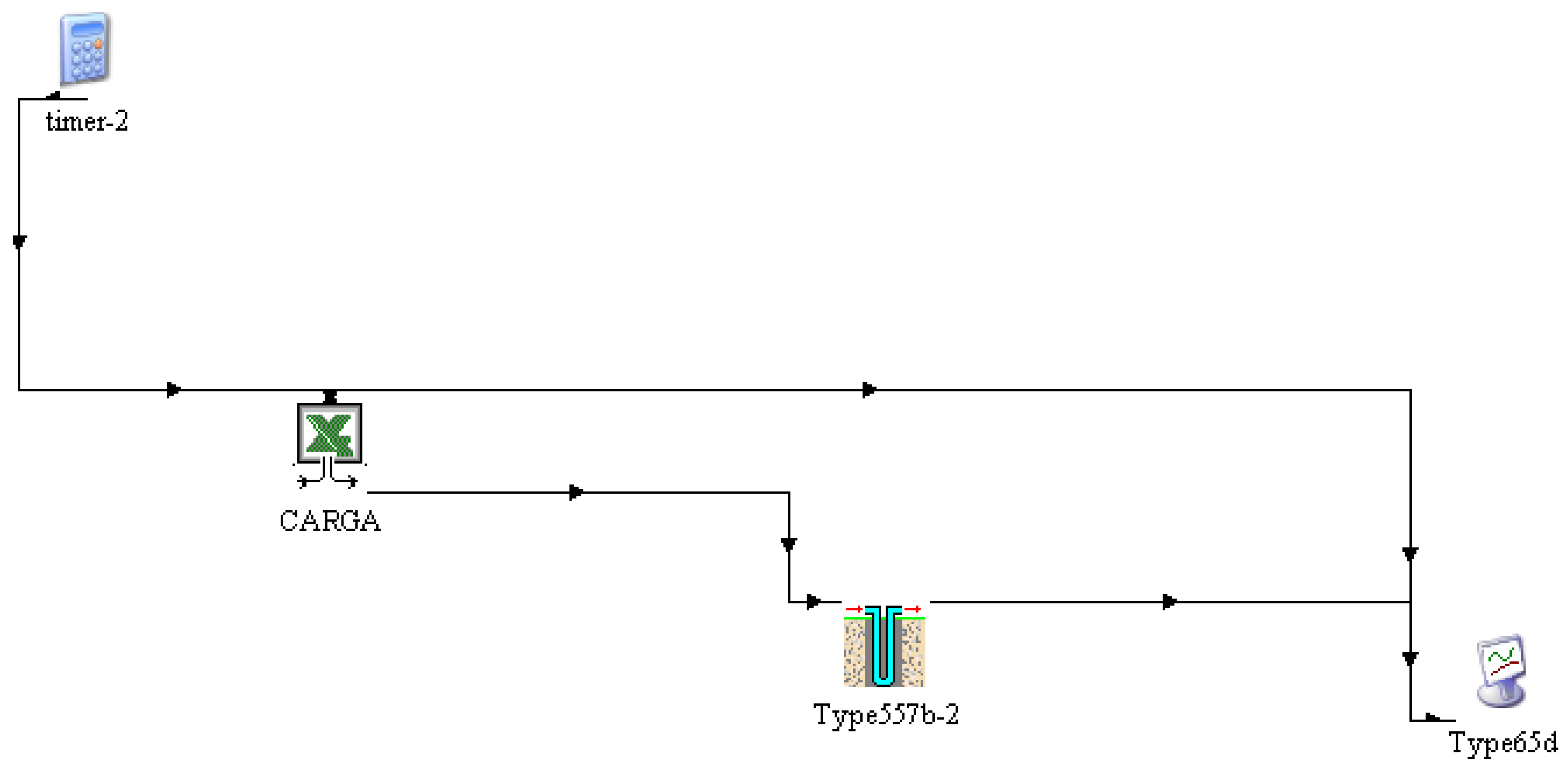

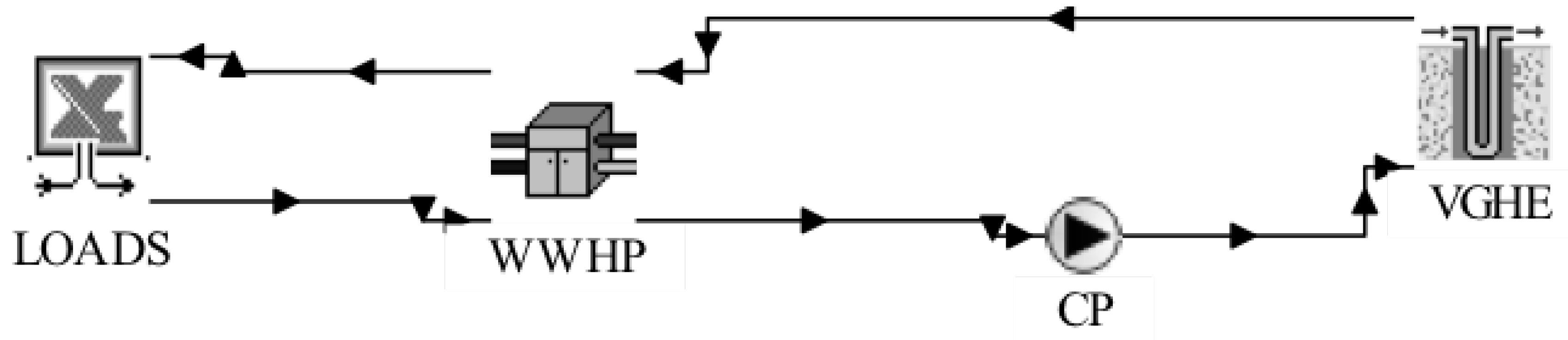

2.2.1. Thermal Loads Generating Facility

- The primary circuit, which contains the heat exchanger pipes installed in the pile, the primary circulation pump, a three-way valve for regulating the temperature of the injected water, a flow meter and various temperatures probes.

- The secondary circuit, which contains the heat pump, a storage tank equipped with a thermal resistance, an expansion vessel and the secondary circulation pump.

- Cold generation and heat generation (heat pump) and an electric resistance as auxiliary heat source.

- Regulation of the injected heat rate by means of pulse width modulation.

- Monitoring of the flow, inlet and outlet temperature and pressure.

- Remote control of the process.

- Data logging.

3. Discussion

- In the first place, an experiment was performed to characterize the pile (Section 3.1) so that it could allow to extract the main parameters (see Table 3) to carry out simulations by means of computer software later. To this end, thermal heat was injected into the energy pile regulating three different thermal leaps with constant power, simulating the behaviour of the pile in a cooling system. Subsequently, a parametric adjustment was made by a simulation of TRNSYS to validate the simulated behaviour with the measured behaviour of the test.

- Apart from the mechanical behaviour of the pile, particularly in this article, the other side is analysed: its thermal behaviour as geothermal heat exchanger. For this purpose, a service thermal load test was performed injecting heat into the heat exchanger simulating that the pile was part of a ground coupled heat exchanger of a shallow geothermal heat pump system working in cooling mode in a tertiary building (Section 3.2).

- Finally, by another TRNSYS simulation, from the data obtained in the previous experiment, the thermal behaviour of the pile was analysed compared to a conventional single U BHE (Section 3.3).

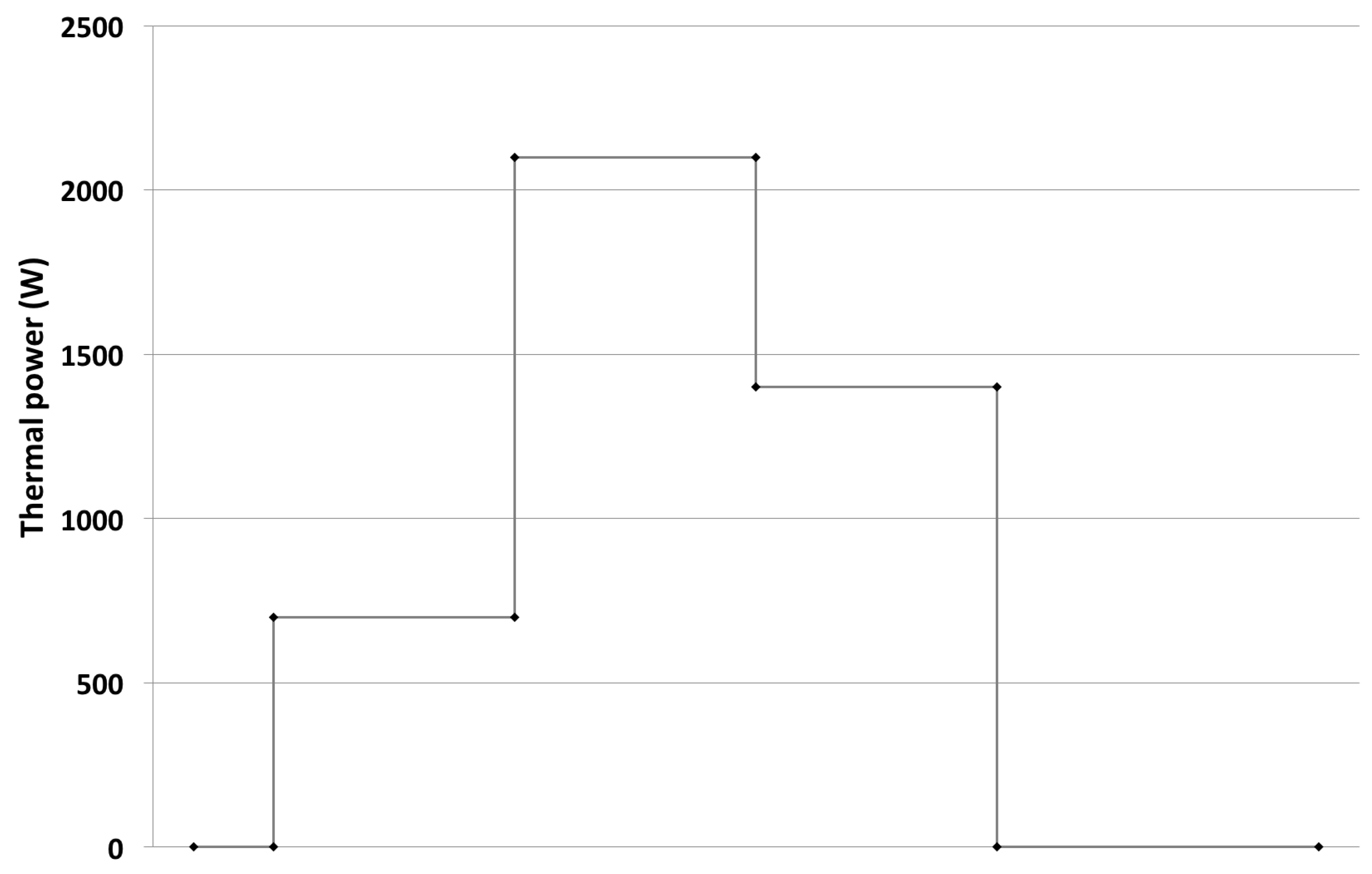

3.1. Thermal Characterization of the Pile

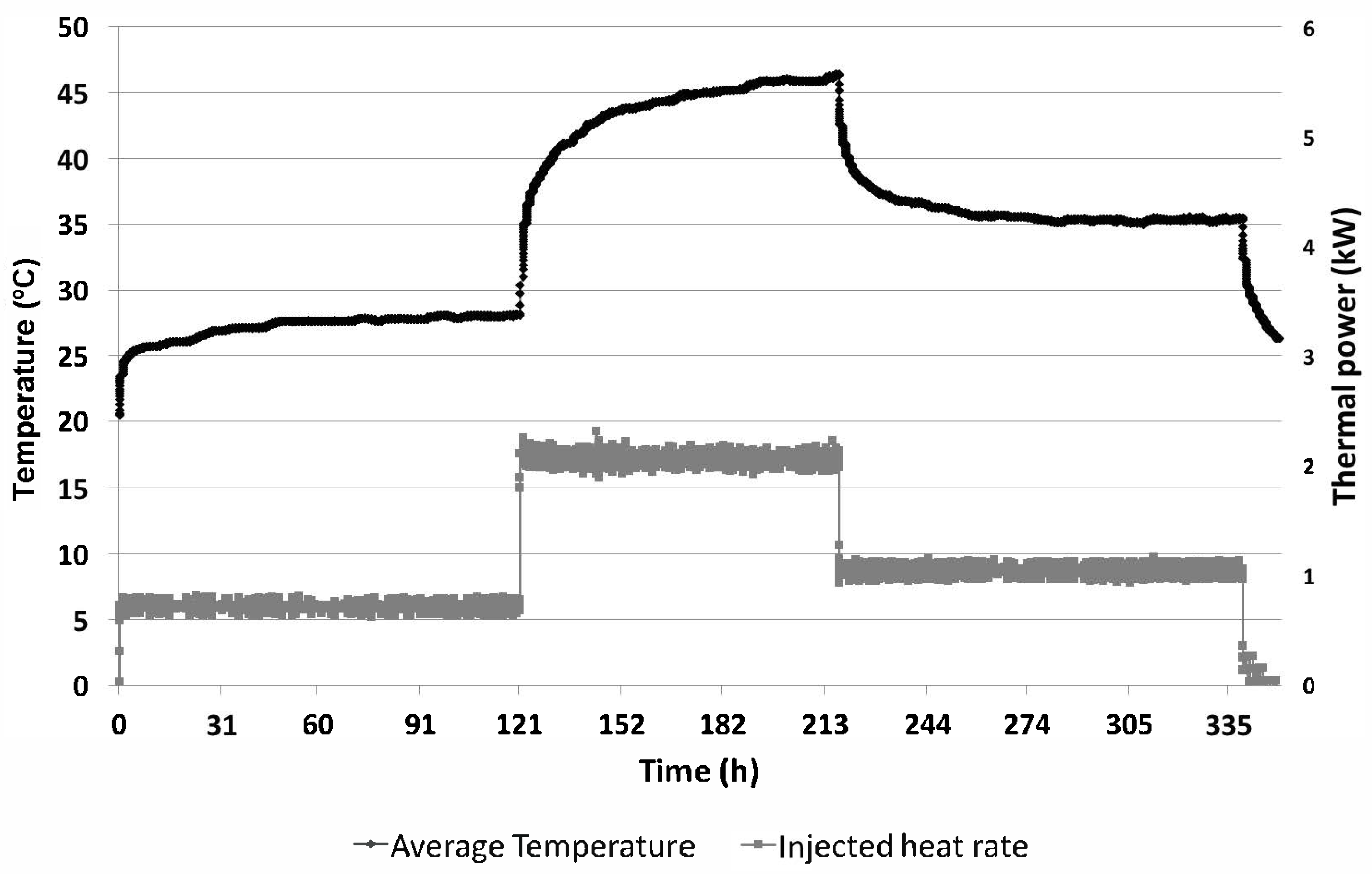

3.2. Thermal Behaviour under Service Loads

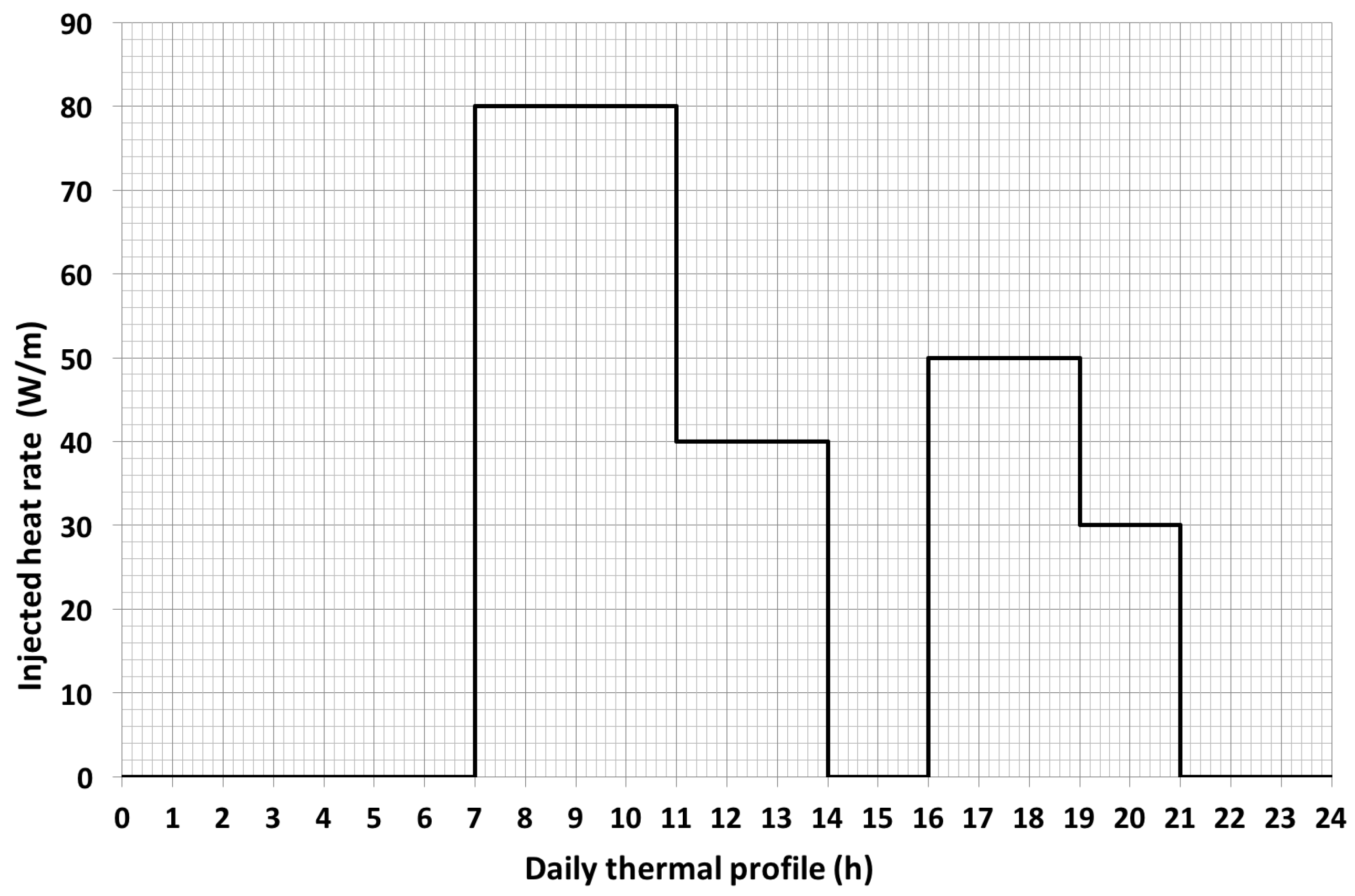

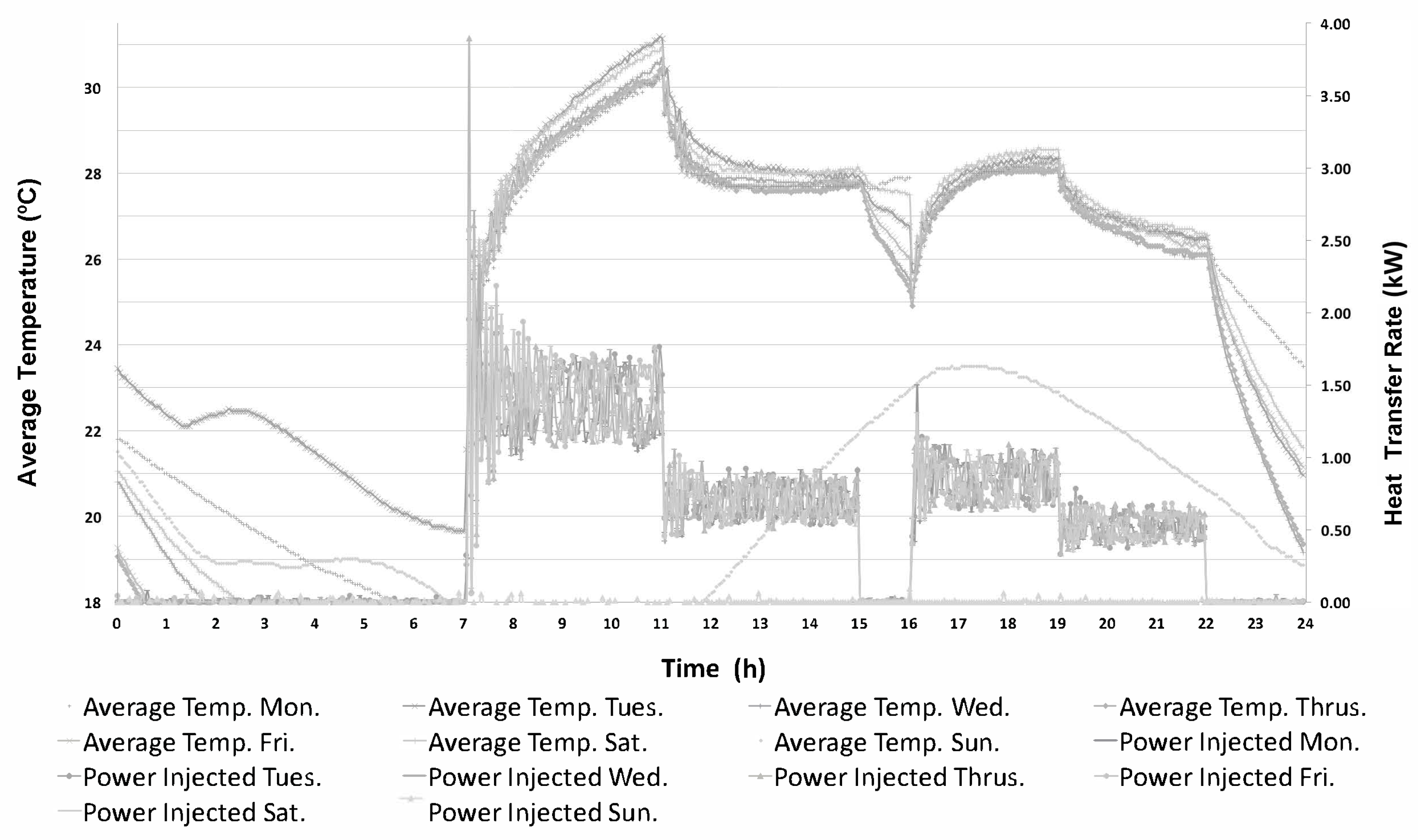

3.2.1. Daily Profile of the Test

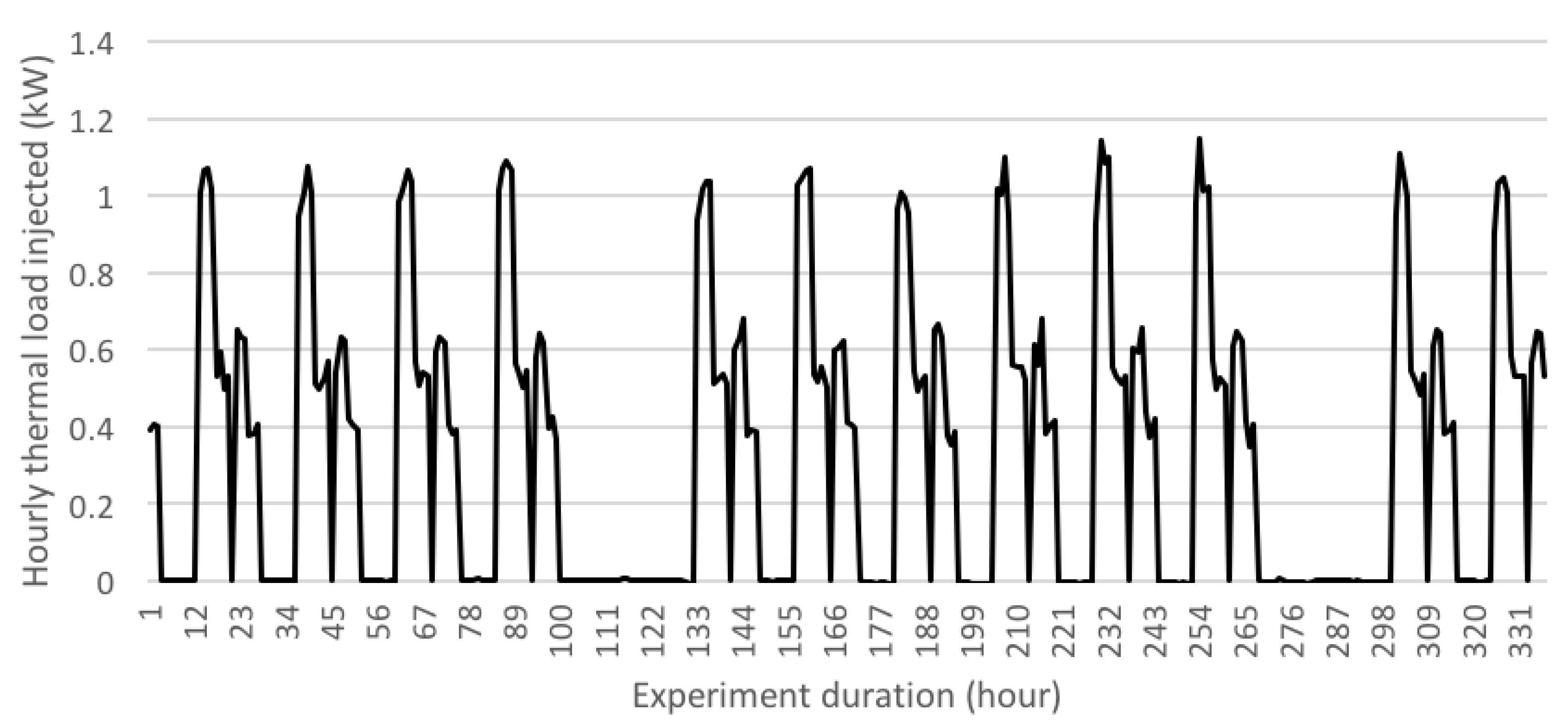

3.2.2. Test Development

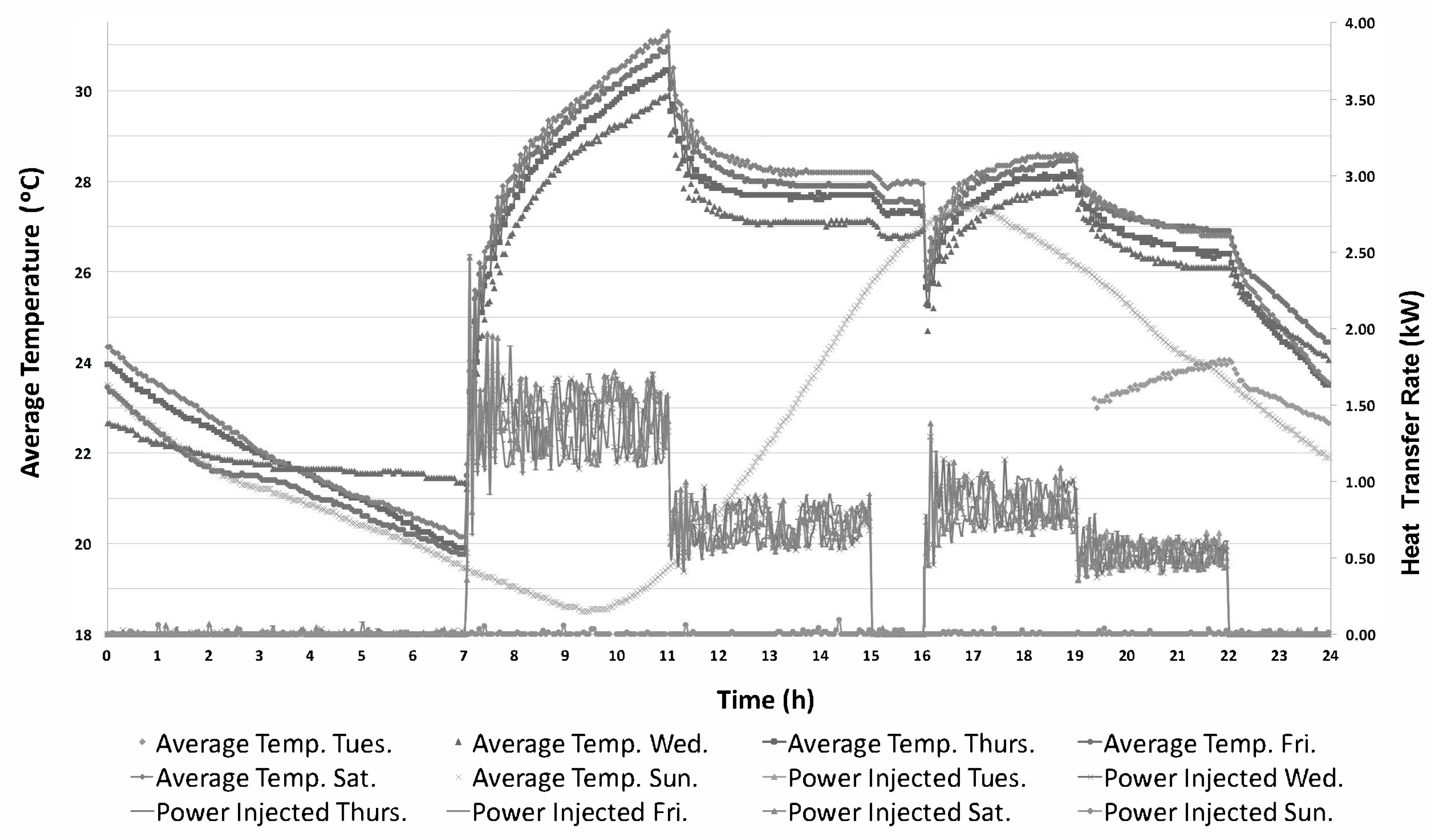

3.2.3. Analysis of Results

- Tinitial = temperature at the start of a day

- ΔT(t) = fluctuation due to the applied thermal demand

3.3. Energy Pile Performance Analysis in Comparison with a Single U BHE

- =

- hourly thermal loads

- =

- heat pump capacity at current conditions. The initial conditions were assumed as 20 C of pipes water temperature and a pipes volume of 0.3

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

Abbreviations

| kW | kilowatt |

| t | tonne |

| EP | Energy Pile |

| TRT | Thermal Response Test |

| GSHPA | Ground Source Heat Pump Association |

| BHE | Borehole Heat Exchanger |

| Thermal resistance of the borehole | |

| PF | Performance Factor |

| SPF | Season Performance Factor |

References

- Olgun, C.G.; Ozudogru, T.Y.; Abdelaziz, S.L.; Senol, A. Long-term performance of heat exchanger piles. Acta Geotech. 2015, 10, 553–569. [Google Scholar] [CrossRef]

- Sutman, M.; Olgun, C.G.; Brettmann, T. Full-Scale Field Testing of Energy Piles. In Proceedings of the IFCEE, San Antonio, TX, USA, 17–21 March 2015; Available online: http://ascelibrary.org/doi/pdf/10.1061/9780784479087.148 (accessed on 28 August 2017).

- Murphy, K.D.; McCartney, J.S.; Henry, K.S. Evaluation of thermo-mechanical and thermal behavior of full-scale energy foundations. Acta Geotech. 2015, 10, 179–195. [Google Scholar] [CrossRef]

- Abdelaziz, S.L.; Ozudogru, T.Y. Selection of the design temperature change for energy piles. Appl. Therm. Eng. 2016, 107, 1036–1045. [Google Scholar] [CrossRef]

- Suryatriyastuti, M.E.; Mroueh, H.; Burlon, S. Numerical Analysis of the Bearing Capacity of Thermoactive Piles under Cyclic Axial Loading. In Energy Geostructures; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2013; pp. 139–155. [Google Scholar]

- Ground Source Heat Pump Association. Thermal Pile: Design, Installation & Materials Standards; Issue 1.0; Standard, Ground Source Heat Pump Association: Stillwater, OK, USA, 2012. [Google Scholar]

- De Santiago, C.; de Santayana, F.P.; de Groot, M.; Urchueguía, J.F.; Badenes, B.; Magraner, T.; Arcos, J.; Martín, F. Thermo-mechanical behavior of a thermo-active precast pile. Bulg. Chem. Commun. 2016, 48, 41–54. [Google Scholar]

- Dirección General de Vivienda. Código Técnico de la Edificación—Documento Básico de Seguridad Estructural; Standard, Ministerio de Fomento del Gobierno de España: Oviedo, Spain, 2009. [Google Scholar]

- De Groot, M.; de Santiago, C.; Pardo, F.; Arcos, J.L.; Martín, F.; Urchueguía, J.F.; Badenes, B. Heating and cooling an energy pile under working load in Valencia. In Proceedings of the European Geothermal Congress, Pisa, Italy, 3–7 July 2013. [Google Scholar]

- Badenes, B.; de Santiago, C.; Nope, F.; Magraner, T.; Urchueguía, J.F.; de Groot, M.; de Santayana, F.P.; Arcos, J.L.; Martín, F. Thermal characterization of a geothermal precast pile in Valencia (Spain). In Proceedings of the European Geothermal Congress, Strasbourg, France, 14–19 September 2016. [Google Scholar]

- Solar Energy Laboratory. TRNSYS 16. A Transient System Simulation Program; Licensed Department Física Aplicada—Universitat Politècnica de València: València, Spain, 2004. [Google Scholar]

- Magraner, T.; Montero, A.; Quilis, S.; Urchueguia, J. Comparison between design and actual energy performance of a HVAC-ground coupled heat pump system in cooling and heating operation. Energy Build. 2010, 42, 1394–1401. [Google Scholar] [CrossRef]

| Parameter | Value |

|---|---|

| Pile Length (m) | 17.4 |

| Square cross section side (m) | 0.35 |

| Active pipe length (m) | 17 |

| Heat exchanger type | Double U |

| Number of pipes | 4 |

| PE Pipe Outer Diameter (m) | 25.0 |

| PE Pipe Inner Diameter (m) | 20.6 |

| Parameter | Test 1 | Test 2 | Test 3 |

|---|---|---|---|

| Temperature step | 1 C | 3 C | 1.5 C |

| Flow rate | 0.6 /h | 0.6 /h | 0.6 /h |

| (10 L/min) | (10 L/min) | (10 L/min) | |

| Fluid (m) | Water | Water | Water |

| Injected heat | 700 W | 2100 W | 1050 W |

| Heat injection rate | 40 W/m | 120 W/m | 60 W/m |

| Duration | 5 days | 5 days | 5 days |

| Parameter | Value |

|---|---|

| EP Parameters | |

| Number of boreholes | 1 |

| Borehole depth | 17.4 m |

| Equivalent borehole radius | 0.197 m |

| Borehole thermal resistance | 0.16 mK/W = 0.044 m·K·h/kJ |

| Fluid parameters | |

| Specific heat capacity of fluid | 4.18 kJ/kg·K |

| Fluid density | 1000 kg/ |

| Ground parameters | |

| Average ground temperature | 20 C |

| Storage thermal conductivity | 2.7 W/mK |

| Storage heat capacity | 2200 kJ/ K |

| Storage volume | 2000 K |

| Parameter | Value |

|---|---|

| Borehole Heat Exchanger Parameters | |

| Number of boreholes | 1 |

| Borehole depth | 17.4 m |

| Borehole radius | 0.120 m |

| Outer radius of U-tube pipe | 0.016 m |

| Inner radius of U-tube pipe | 0.0131 m |

| Filling thermal conductivity | 2.1 W/mK |

| Pipe thermal conductivity | 0.42 W/mK |

| Reference borehole flow rate | 420 kg/hr |

| Ground Parameters | |

| Undisturbed ground temperature | 18 C |

| Storage thermal conductivity | 2.7 W/mK |

| Storage heat capacity | 2200 kJ/ K |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Badenes, B.; Magraner, T.; De Santiago, C.; Pardo de Santayana, F.; Urchueguía, J.F. Thermal Behaviour under Service Loads of a Thermo-Active Precast Pile. Energies 2017, 10, 1315. https://doi.org/10.3390/en10091315

Badenes B, Magraner T, De Santiago C, Pardo de Santayana F, Urchueguía JF. Thermal Behaviour under Service Loads of a Thermo-Active Precast Pile. Energies. 2017; 10(9):1315. https://doi.org/10.3390/en10091315

Chicago/Turabian StyleBadenes, Borja, Teresa Magraner, Cristina De Santiago, Fernando Pardo de Santayana, and Javier F. Urchueguía. 2017. "Thermal Behaviour under Service Loads of a Thermo-Active Precast Pile" Energies 10, no. 9: 1315. https://doi.org/10.3390/en10091315