Conventional energy sources in the world are fast depleting and it is very important to tap the enormous potential of renewable energy sources to meet escalating energy demands. Harnessing energy from renewable energy sources can significantly reduce the carbon emissions and can contribute towards the energy generation in a sustainable way and at stable costs. Earth receives about 1.8 × 10

14 kW of energy from the sun and out of this only 60% reaches the earth’s surface [

1]. Tapping less than 1% of this available solar thermal potential is enough to stabilize the world climate by virtue of significant reduction in carbon emissions.

Solar energy can be converted into thermal energy or to electrical energy among other forms. In solar thermal technology the energy from the incident solar rays is converted in to heat and the same is utilized for different applications. Solar thermal power is more environmentally friendly as it has very little polluting emissions when compared to conventional energy generation technologies. This technology can be effectively used in regions which have high amount of direct solar radiation. Middle Eastern regions are among the potential areas of the world which receive direct high intensity solar radiation [

2,

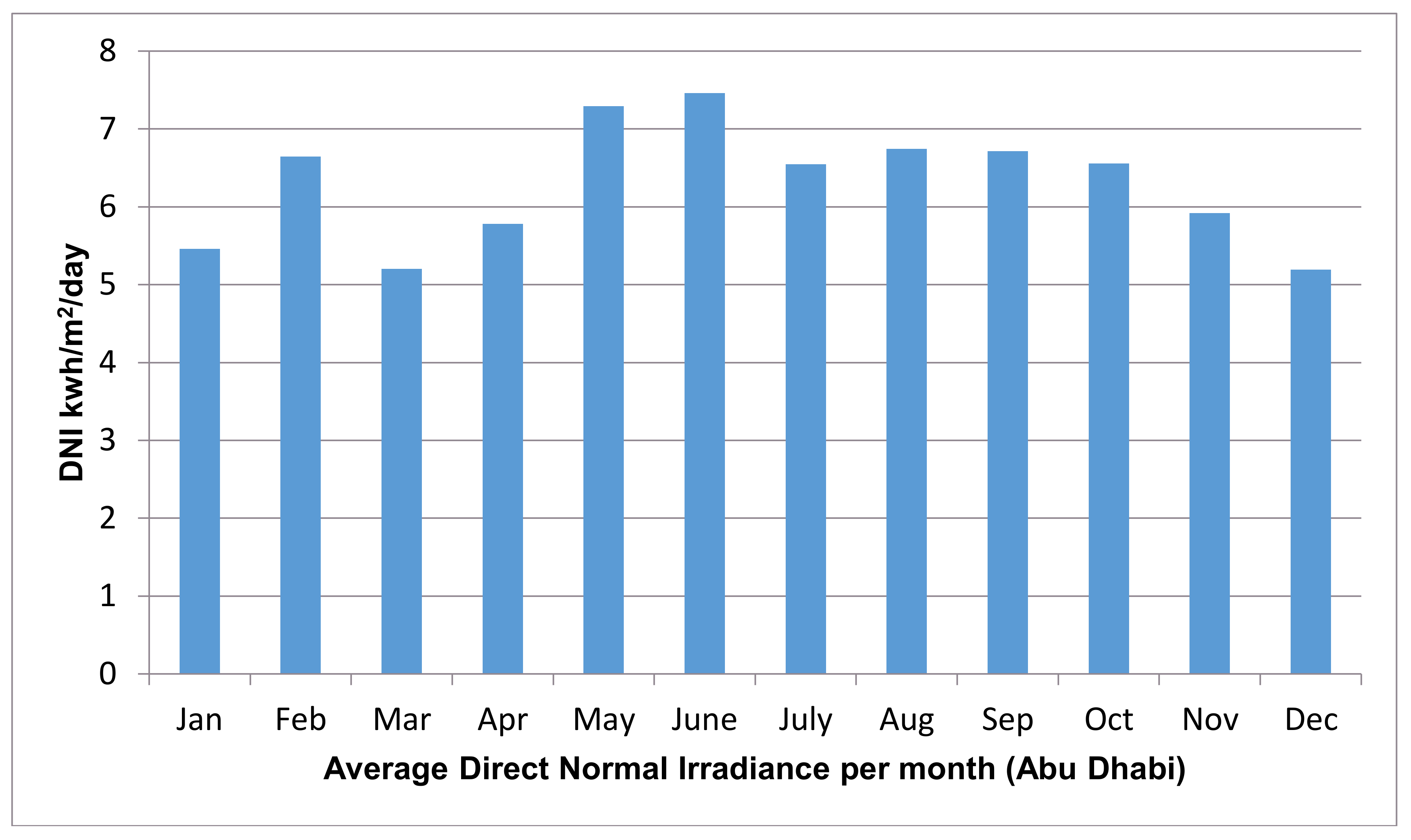

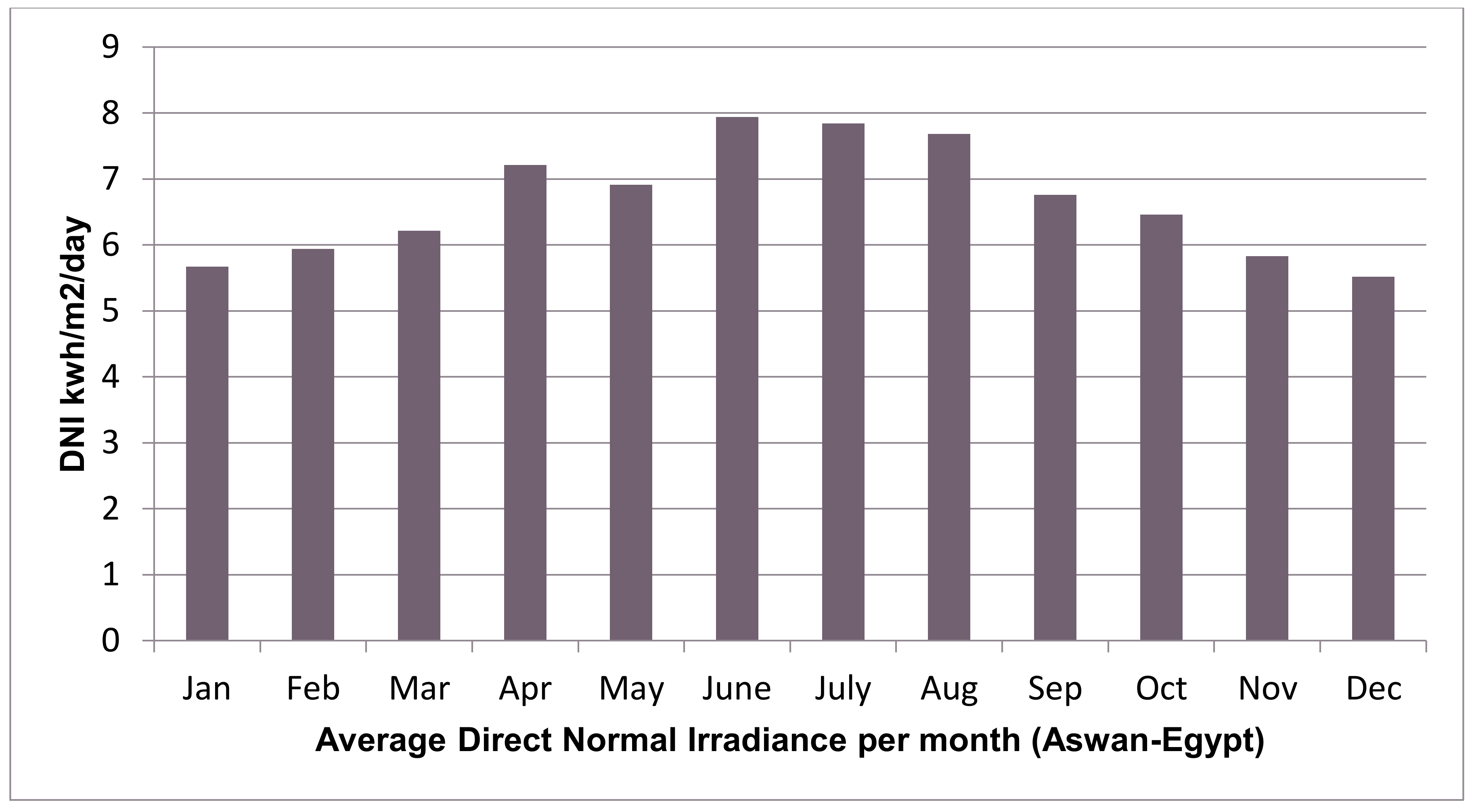

3]. The Middle East region is ideal for the installation of solar thermal plants as the region has rich solar potential combined with lot of uninhibited space. There is an increase in the average annual DNI values when moving from northern to southern parts of the Middle East. This can be attributed to the fact that the latitude decreases along this direction and the region is close to the earth’s equator. Solar radiation is found to be high in the south western parts of the Middle East. Thus most of the regions in the Middle East, except for the northern parts, are highly suitable for the installation of concentrating solar power (CSP) plants. The countries like Egypt, Yemen and Saudi Arabia possess the highest exposed areas, followed by countries like U.A.E., Syria, Oman and Jordan [

4]. The Middle East region is also known for its unpredictable weather and the region experiences sand storms which vary in frequency and intensity seasonally [

5]. Deposition of dust on the solar collectors will have an adverse effect on the solar thermal power generation, which necessitates effective dust management by way of a proper maintenance schedule [

6].

Govindaraj Kumaresan et al. [

7] experimentally investigated the performance of a solar parabolic trough collector (PTC), integrated with thermal energy storage (TES). The study concluded that the PTC should be located very close to the storage system and different components of the storage system have to be insulated properly for reducing heat losses. Reddy et al. [

8] performed energy and exergetic analysis of PTC power plant by calculating the losses and efficiencies. The operating pressure for a Rankine heat engine has been optimized for maximum efficiency. Montes et al. [

9] detailed the effect of solar multiple on the annual performance of a PTC power plant employing direct steam generation. Kearney et al. [

10] carried out an investigation on the use of molten salt as the heat transfer fluid (HTF) and TES medium for a PTC solar power plant. Their feasibility study recommends the use of molten salt as HTF to minimize the levelized cost of electricity (LCOE). Martin et al. [

11] used a mathematical programming technique to optimize the operation of a CSP plant employing regenerative Rankine cycle for a site in Spain. A simulation model for predicting the electrical output of a 50 MWe PTC power plant was developed by Garcia et al. [

12]. The model results were compared with the experimental data of a power plant operating in Spain. A feasibility study for the installation of PTC power plant in the island of Cyprus was carried out by Poullikkas et al. [

13]. The study was performed by varying different parameters such as plant capacity, capital investment and operating hours of the plant. Larrain et al. [

14] developed a thermodynamic model to evaluate the performance of a 100 MWe hybrid PTC plant in Chile. Boukelia et al. [

15] presented a comparative study on the performance of different configurations of PTC plants operating with two different HTF fluids. The same authors [

16] carried out feasibility analysis and optimization of PTC plants equipped with integrated TES and fuel backup system (FBS) for Algerian conditions. The outcome of the study recommends the installation of CSP plants in arid and semi-arid regions of Algeria. Abbas et al. [

17] carried out performance assessment of a 100 MWe PTC solar power plant for feasible locations in Algeria. An experimental investigation on the performance of a PTC system under Tunisian climatic conditions has been conducted by Mohamed Chafie et al. [

18]. Reddy and Kumar [

19] presented a techno-economic feasibility analysis of PTC plant for different locations in India. Deepak et al. [

20] analyzed the performance of a 100 MWe PTC plant for the location of Udaipur in India. Mezher et al. [

21] presented various renewable energy initiatives of U.A.E. and evaluated the benefits of introducing CSP plants in to the energy mix of the country. Shouman et al. [

22] described a strategic road map for the introduction of CSP technology in Egypt. Aidin et al. [

23] presented an economic modeling of a 25 MWe PTC solar power plant operating in Iran. The influence of storage system on plant operating hours was also investigated for different load conditions. Mohammed et al. [

24] proposed a prototype of a 50 MWe CSP plant in Jordan and carried out an economic feasibility analysis of the plant. The study concludes that the southern location of Jordan has enormous potential for the installation of CSP plants.

From these literature reviews, it is evident that majority of the research work on design and performance assessment and optimization of PTC solar power plants is carried out for locations in USA, Europe, Algeria, Tunisia and India. The literature available on the application of PTC CSP technology in the Middle Eastern region is rather restricted to only an initial assessment of the benefits of implementation of CSP plants and economic feasibility analysis. There are very few research works available which concentrate on design, performance analysis and optimization of the PTC solar power plants for feasible locations in the Middle East. The research on this aspect is highly significant as there is a high demand to tap the abundant renewable energy sources in the region to meet growing energy demands. Moreover, this is essential for the future development of the Middle East region as it reduces the dependency on fossil fuels and eliminates the problems associated with air pollution and greenhouse gases. Hence, this research is carried out to design, analyze and optimize the performance of a commercial 100 MWe parabolic trough collector solar power plant with TES for feasible locations in the Middle East region. The thermodynamic aspect and annual performance of the proposed plant will also be analyzed in the work.

Concentrating Solar Power (CSP) Technology

CSP technology is a solar thermal power generation technology that concentrates the heat from the solar radiation in to a small area for generating power. CSP-based technology is found to be suitable for regions with high DNI.

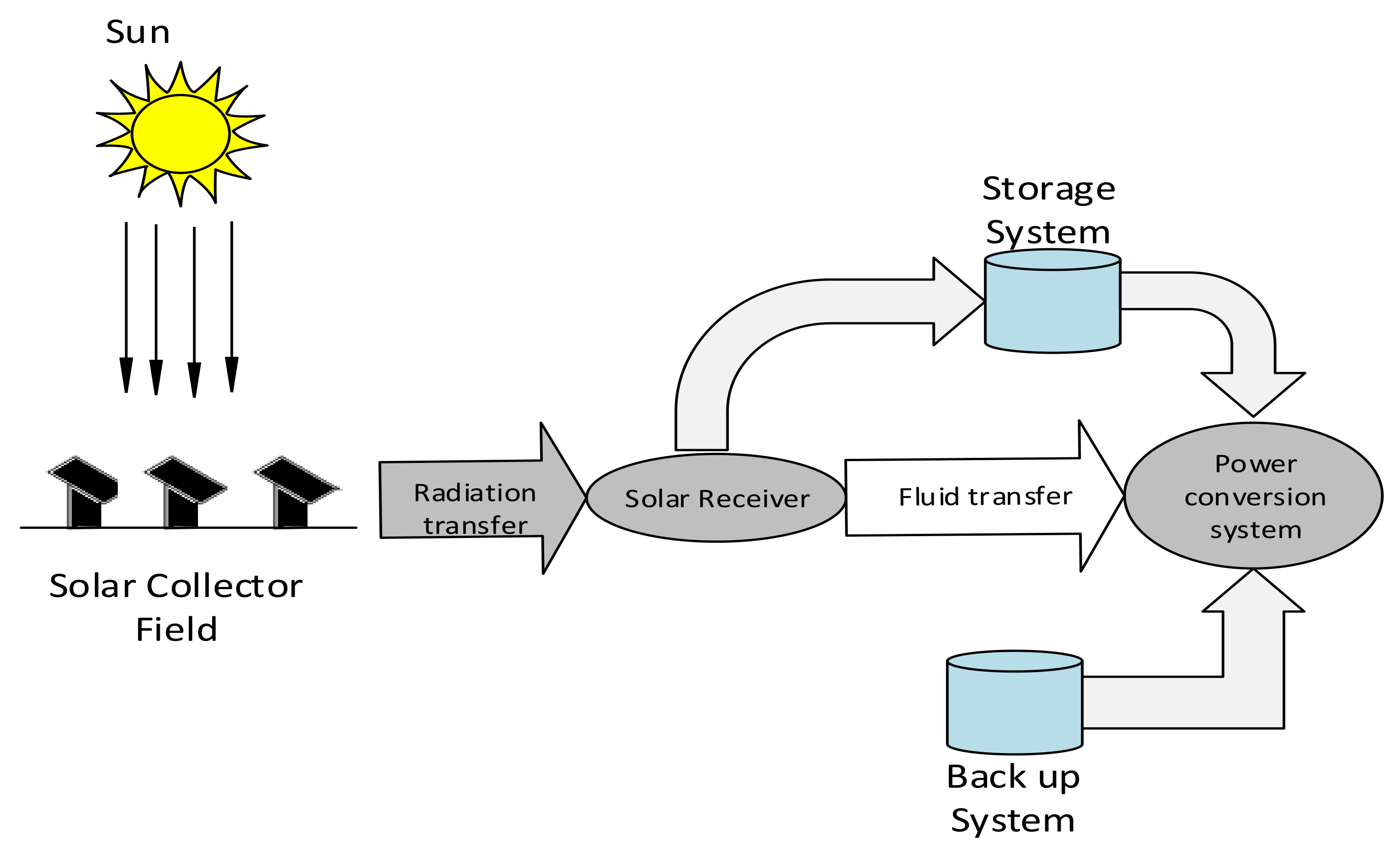

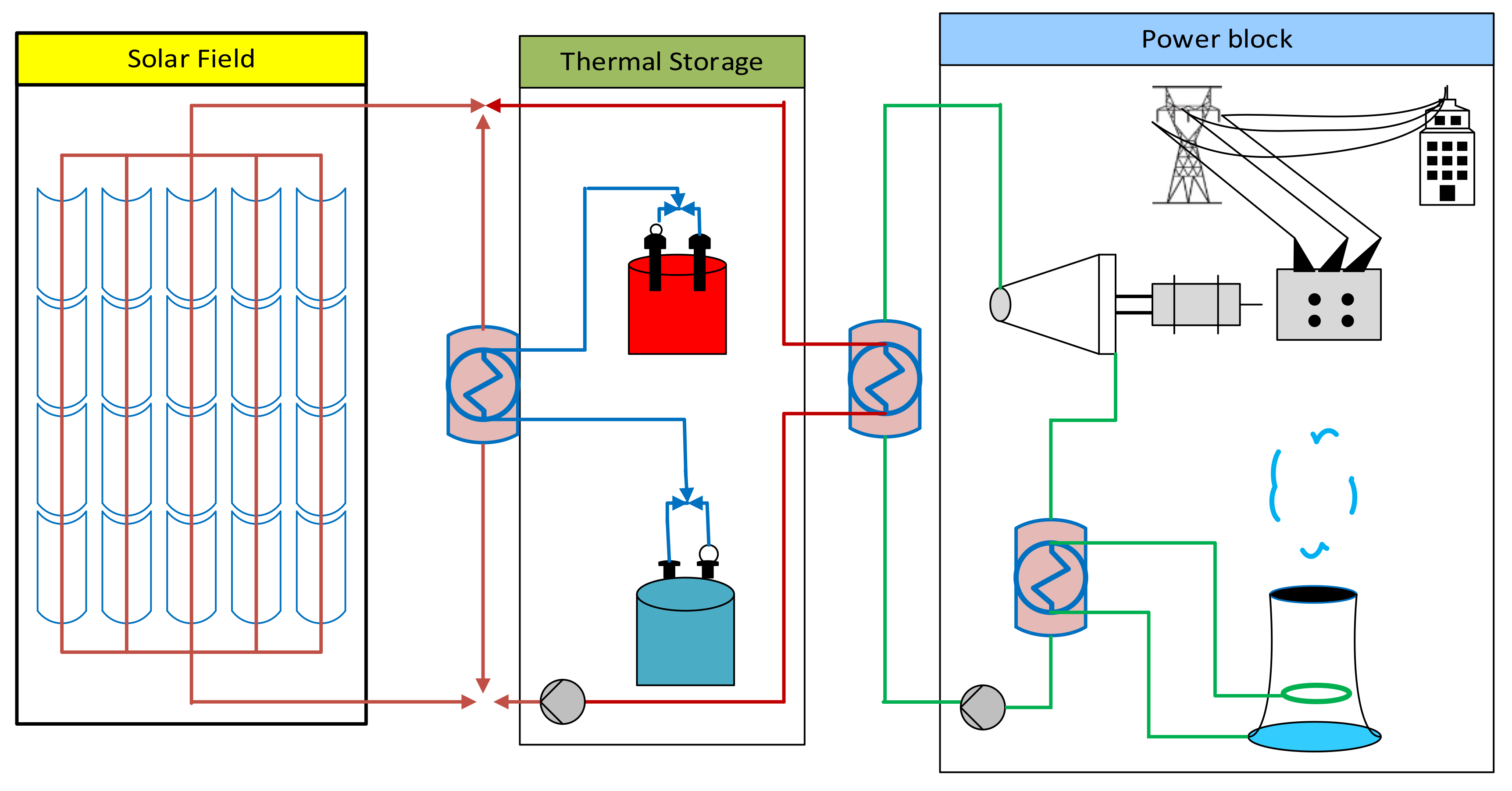

Figure 1 shows the fundamental principle of solar thermal power generation, which is comprised of four main sub-systems, namely solar collector field, solar receiver, storage and/or back up system, and power conversion system. Solar collector field consists of an array of mirrors or reflectors that collect the solar radiation and focus it onto a receiver tube. The receiver tube with a thermal energy carrier absorbs the heat from the concentrated solar energy which can be used directly or with the help of a secondary circuit to generate power. A certain amount of heat is lost during the energy conversion process. Also, a part of the solar radiation is reflected back and does not even reach the absorber. Hence the choice of an appropriate solar collector is very important to suit the application requirement and to attain the desired temperature level [

25]. Most of the commercial CSP plant designs incorporate TES systems for generating power in the absence of sunshine [

26]. According to the focus geometry, CSP systems can be classified as point-focus concentrators and line-focus concentrators. Solar Tower systems and parabolic dishes uses point focus concentrators whereas PTC’s and linear Fresnel collectors employ line-focus concentrators [

27].

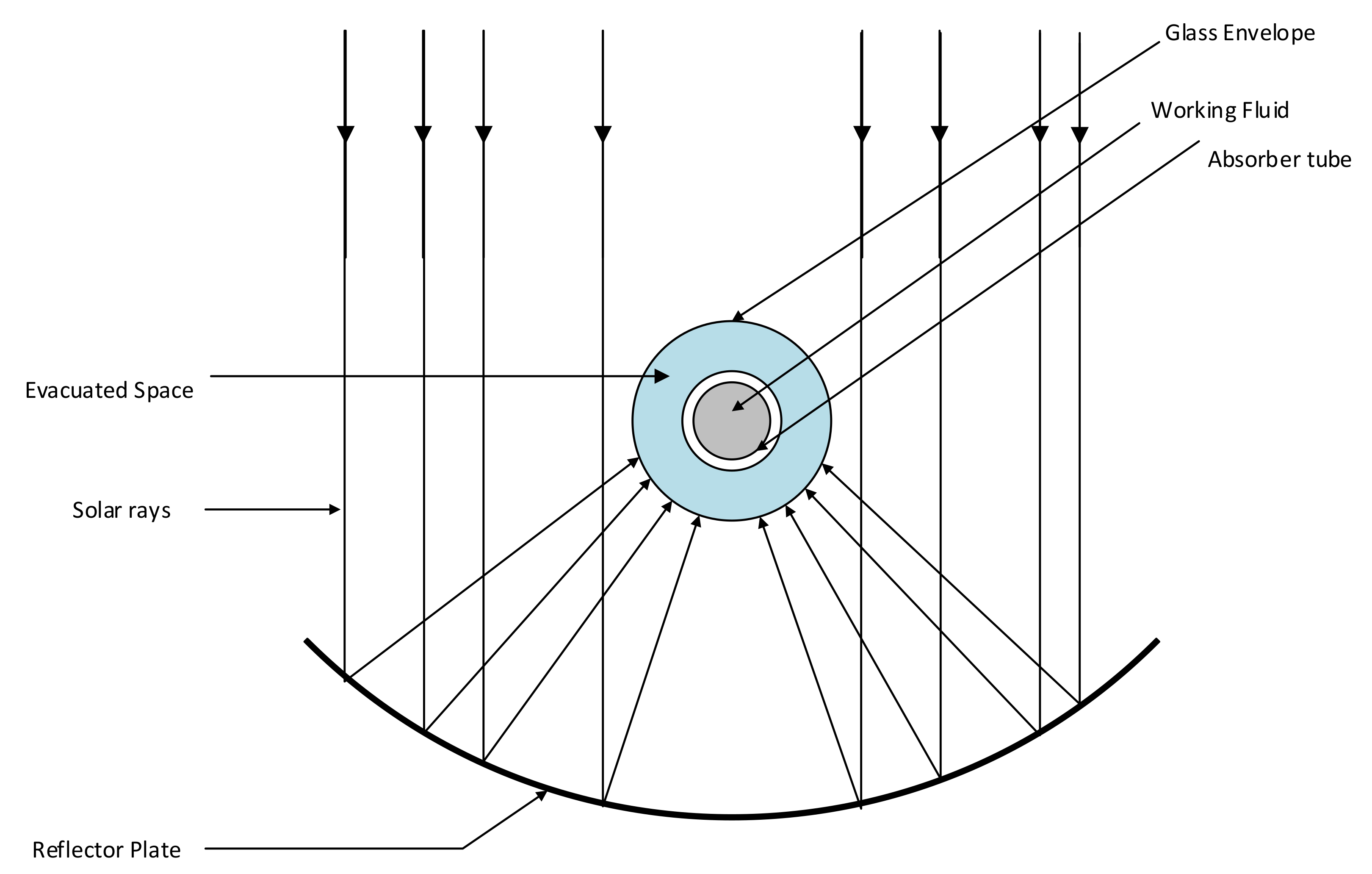

Figure 2 shows the cross sectional view of a Parabolic Trough Collector. The absorber tube consists of a metal tube with a glass envelope covering it. The region between the glass envelope and metal tube is filled with either air or vacuum so as to allow for thermal expansion and reduction of convective heat losses. Direct solar radiation is focused on to the focal line of the collector axis. The collector assembly incorporates single-axis tracking mechanism to ensure that the solar beam falls parallel to its axis.

Parabolic Trough collectors can only use the direct component of solar radiation, that is, direct normal irradiance (DNI). Parabolic Trough-based CSP projects are very popular in countries like Spain and the USA where they are used for medium- to large-scale power generation. PTC solar power plants are the most commercially established among the power plants operating with CSP technology [

28,

29]. Parabolic trough Collector is selected for the CSP plant design analysed in this work as they have superior heat absorption rate when compared to flat plat collectors.