Ground Thermal Inertia for Energy Efficient Building Design: A Case Study on Food Industry

Abstract

:1. Introduction

- (a)

- There are many constructions with different typologies of terrain use, which are used commercially by companies in this industry. It is possible to select representative constructions of different types in a same area.

- (b)

- Traditionally, wine ageing and storage was done in constructions with great thermal inertia to prevent it from being impacted by outdoor climate changes. Nowadays, the constructions for wine production are built on the surface. Subterranean cellars for the ageing of wine are only being constructed occasionally, being replaced by climate control because of the lower initial cost [12]. This change of construction techniques is the cause of an increase in energy consumption in modern wineries. In these buildings, complex air-conditioning systems are necessary in order to achieve the optimal thermal conditions [13]. The intention is to encourage the industry to go back to using energy efficient constructions.

- (c)

- The winemaking literature stresses the importance of a constant low temperature and high relative humidity inside buildings where wine is stored, in order to produce a high-quality end product and reduce wine losses [12]. In the making of quality wines the conservation and ageing process is the longest stage. In certain countries, such as United States and Australia it is the wine-maker who decides the optimum amount of cask storage time for each wine. In other countries, the time that the wine must spend in cask is regulated by law [14], as is the case in Spain, where the minimum period for red wines ranges between 24 and 60 months. Considering the time required for the aging of wine and the size of the constructions, the use of an air conditioning system implies a considerable increase in energy consumption. Therefore the principal quality of the construction should be that it assures suitable temperature and relative humidity conditions.

- (d)

- World wine production in 2009 stood at 271 millions of hectolitres [15]. The world spends 320 billion Euros on wine a year, according to industry insiders gathered at the Vinexpo trade fair, held at Bordeaux, France in June 2011. The costs of processing grape juice into wine can vary significantly, depending on the style of wine produced, e.g., early bottled wine, long-ageing wine, wine aged in barrels, etc. On average, it is estimated that producing 1 L of wine sold in a 75 cL glass bottle costs around 0.5–1.2 Euros/L [16]. Ageing wine in barrels will increase this cost. Given the importance of this sector, it is interesting to encourage it to use constructive solutions which help reduce energy consumption and lower the costs of production.

2. Materials and Methods

2.1. Representative Constructions

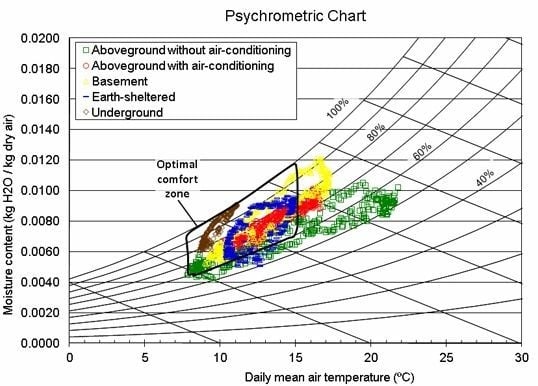

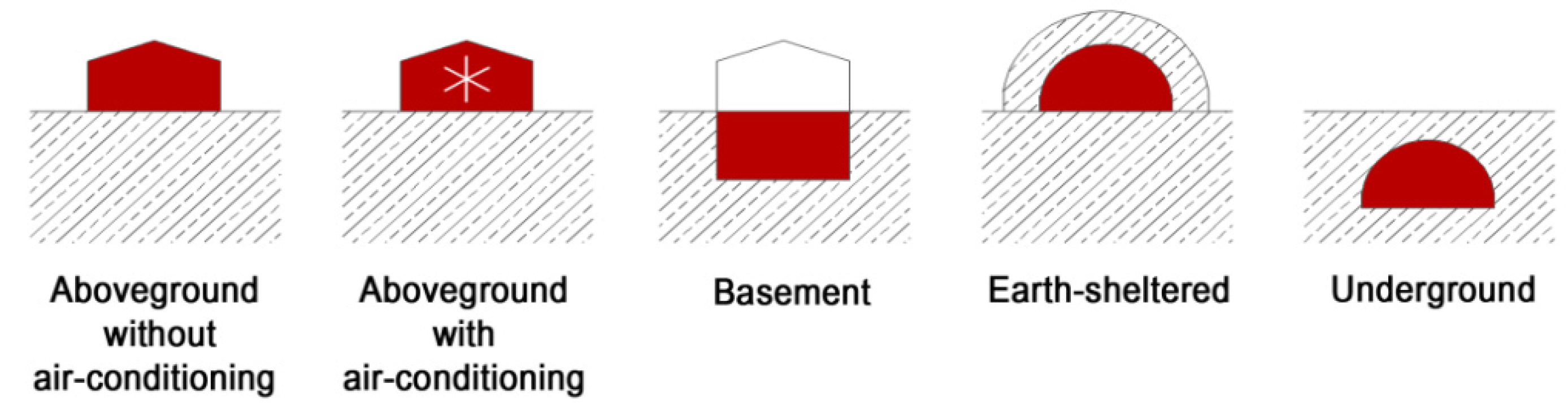

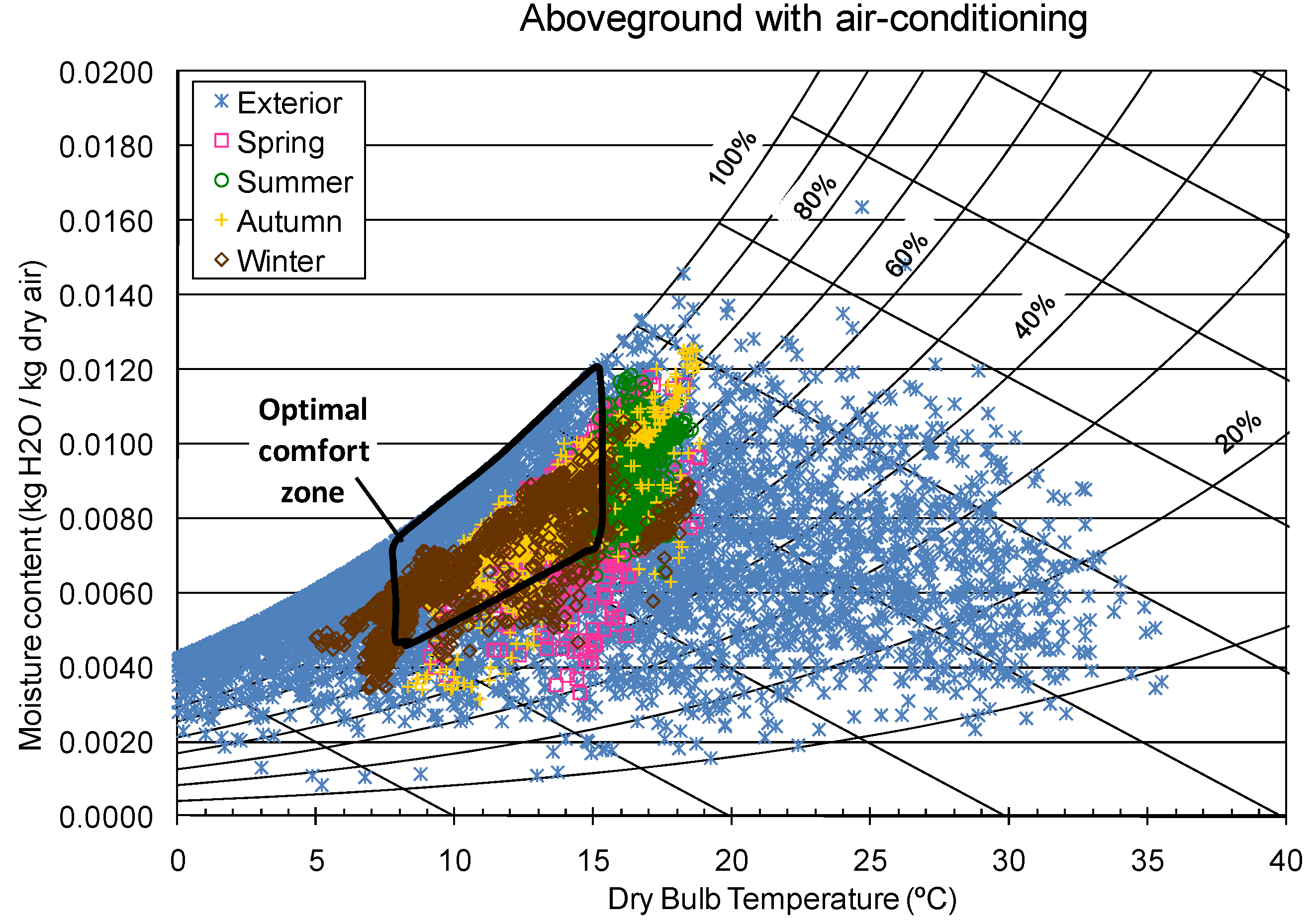

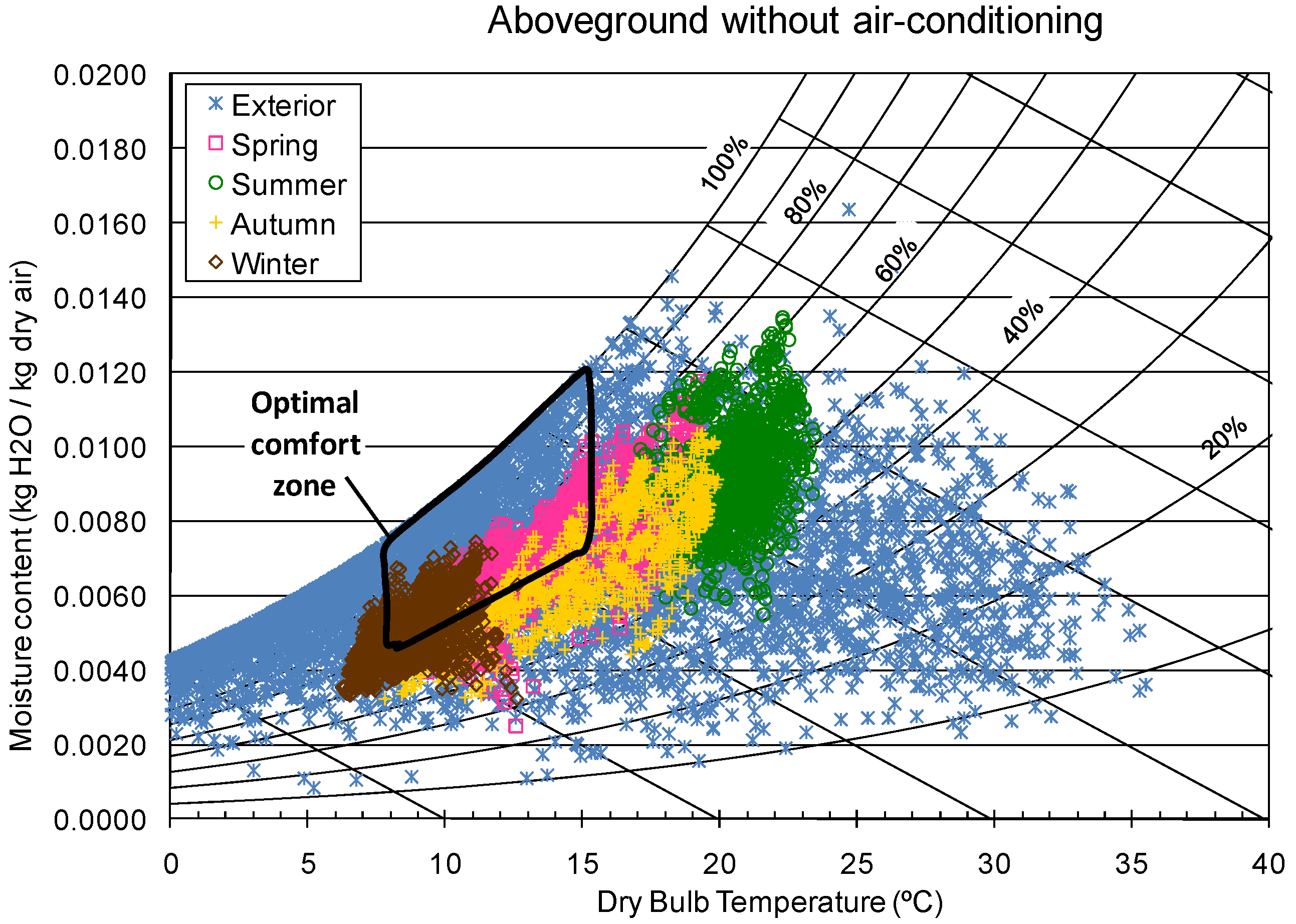

- Aboveground: the construction is on flat ground, similar to other agricultural and industrial facilities. This category of cask cellar includes wine-production facilities equipped with an air-conditioning system in order to control the relative humidity and temperature conditions.

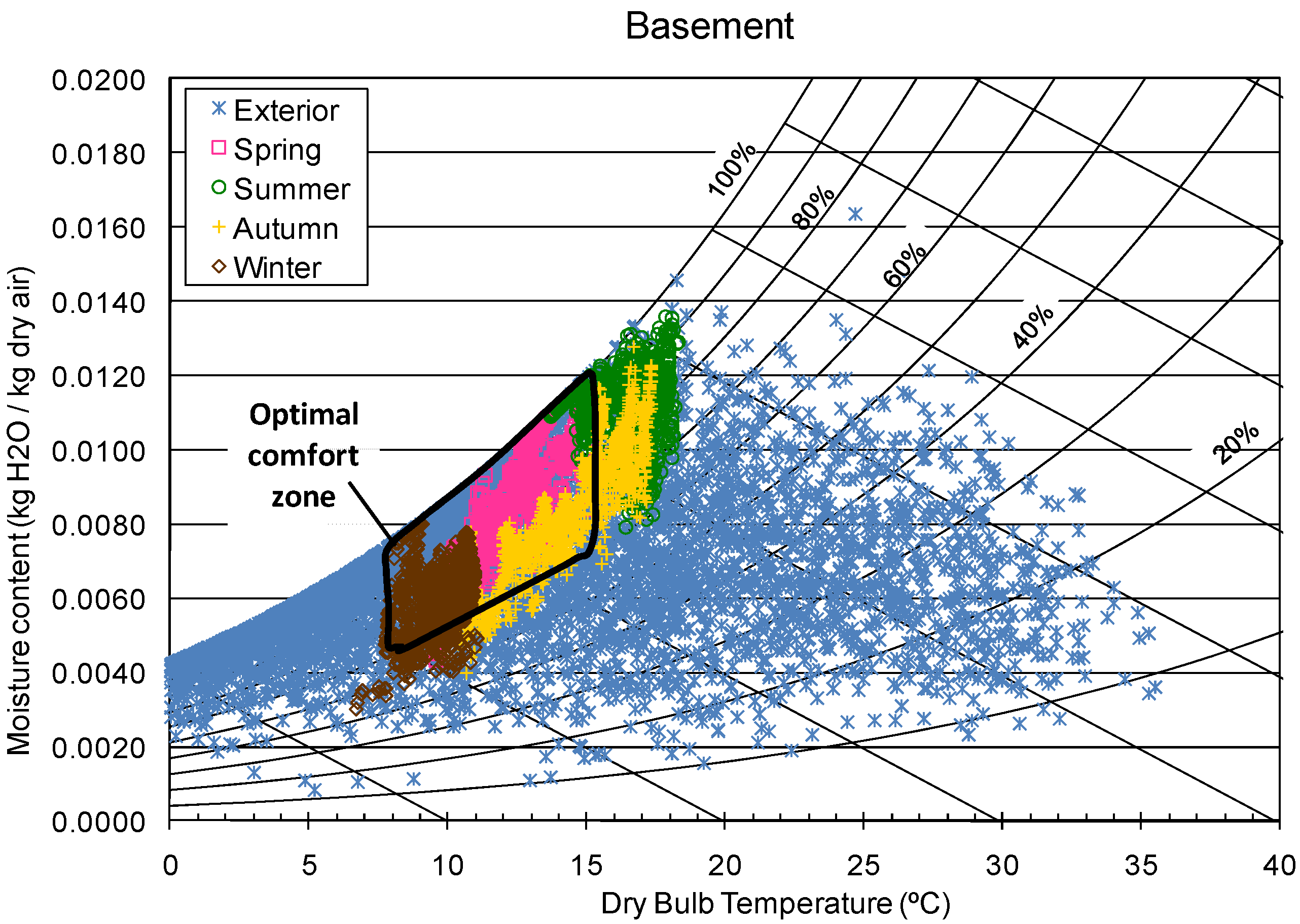

- Basement: the construction is just below ground level, creating a cellar below the other facilities. All four walls are thus in contact with the surrounding earth.

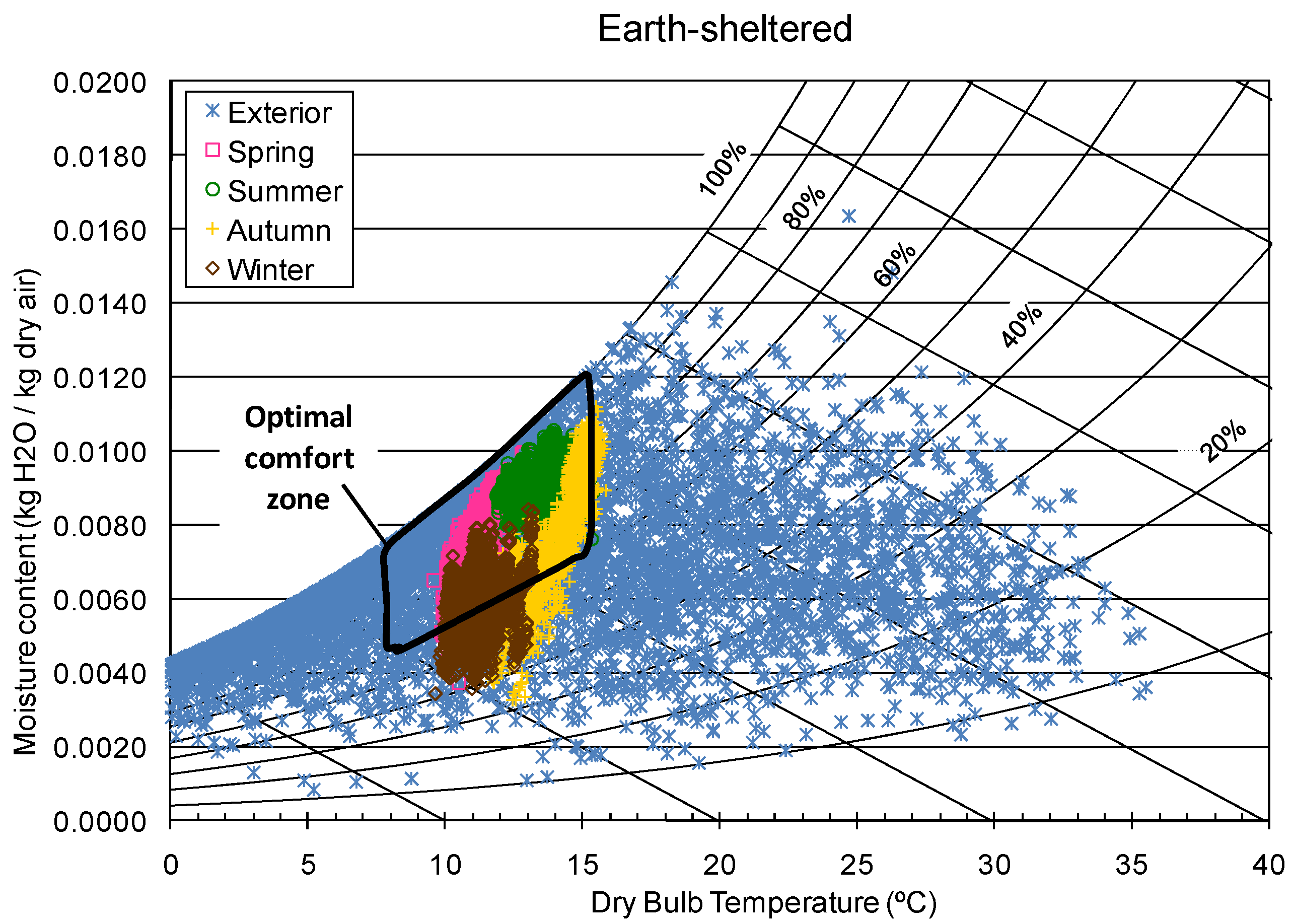

- Earth-sheltered: the construction is on ground level but completely sheltered, as it is under earth to recreate the conditions of an underground cask cellar.

- Underground: the construction has been dug straight out of the soil.

2.2. Monitoring the Constructions

2.3. Quantification of the Construction Effectiveness to Decrease Outdoors Variations

2.4. Hygrometric Conditions and Interior Comfort

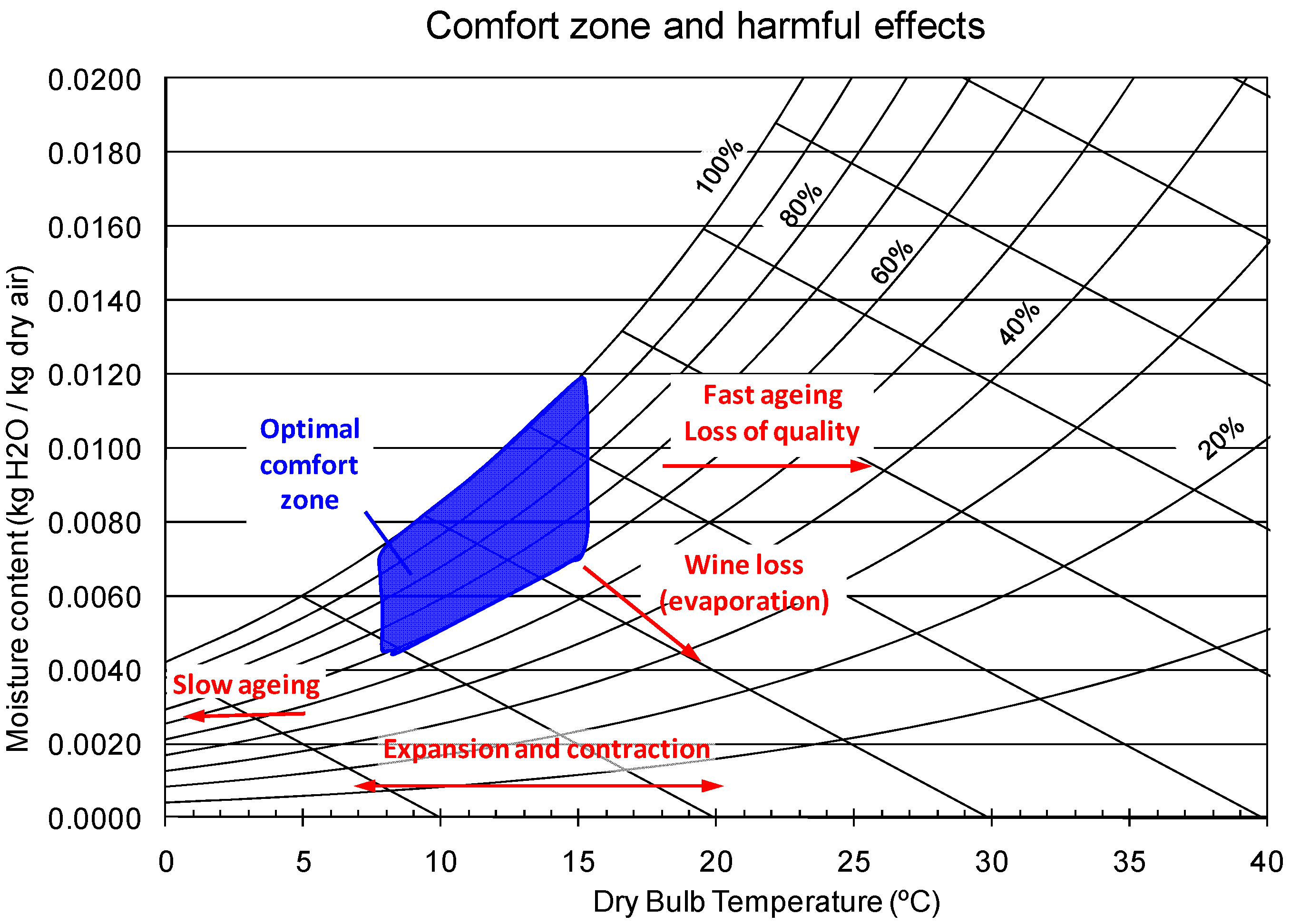

- High temperatures above 18–20 °C make the wine age more rapidly, with the consequent loss of quality.

- Very low temperatures, below 4–5 °C, sustained over long periods mean that the wine will age slowly.

- The relative humidity must be high so as to reduce losses due to evaporation, provided that the appearance of harmful mould can be ruled out. Therefore we can recommend high relative humidity to reduce the evaporation losses, provided that the ventilation is adequate.

- The annual interval and temperature variations should not be high as contraction and expansion phenomena affect the handling and quality of the wine.

3. Results and Discussion

3.1. Quantification of the Construction Effectiveness

| Mean Daily Temperature (°C) | ||||||

|---|---|---|---|---|---|---|

| Outside | Inside | |||||

| Aboveground Without air-conditioning | Aboveground With air-conditioning | Basement | Earth-sheltered | Underground | ||

| Annual mean | 11.2 | 14.4 | 13.6 | 13.2 | 12.5 | 9.9 |

| Annual max. | 24.4 | 21.8 | 16.9 | 17.3 | 14.9 | 11.1 |

| Annual min. | −1.1 | 7.8 | 9.6 | 8.9 | 10.3 | 8.6 |

| Annual interval | 25.5 | 14.0 | 7.3 | 8.4 | 4.6 | 2.5 |

| Construction Effectiveness | |||||

|---|---|---|---|---|---|

| Aboveground without air-conditioning | Aboveground with air-conditioning | Basement | Earth-sheltered | Underground | |

| Decrement factor | 0.55 | 0.29 | 0.33 | 0.18 | 0.10 |

| Time lag (days) | 1 | −30 | 38 | 58 | 51 |

| Mean of Daily Temperature Interval (°C) | |||||

|---|---|---|---|---|---|

| Outside | Aboveground Without air-conditioning | Aboveground With air-conditioning | Basement | Earth-sheltered | Underground |

| 12.1 | 0.7 | 1.0 | 0.1 | 0.2 | 0.1 |

3.2. Hygrothermal Conditions and Interior Comfort: Particular Case of Wine

| Hourly Mean Values within Optimal Comfort Interval (8–15 °C; >60%RH) as Percentage of the Period (%) | ||||||

|---|---|---|---|---|---|---|

| Period | Outside | Aboveground without air-conditioning | Aboveground with air-conditioning | Basement | Earth-sheltered | Underground |

| Spring | 33% | 52% | 61% | 96% | 97% | 100% |

| Summer | 18% | 0% | 20% | 7% | 96% | 100% |

| Autumn | 30% | 18% | 84% | 49% | 61% | 100% |

| Winter | 11% | 56% | 66% | 87% | 67% | 100% |

| 06–09 | 23% | 31% | 58% | 58% | 80% | 100% |

4. Conclusions

Acknowledgments

References

- Labs, K. Regional analysis of ground and aboveground climate: Conclusion. Undergr. Space 1981, 7, 37–65. [Google Scholar]

- Wang, F.; Liu, Y. Thermal environment of the courtyard style cave dwelling in winter. Energy Build. 2002, 34, 985–1001. [Google Scholar] [CrossRef]

- Al-Temeemi, A.A.; Harris, D.J. A guideline for assessing the suitability of earth-sheltered mass-housing in hot-arid climates. Energy Build. 2004, 36, 251–260. [Google Scholar] [CrossRef]

- Anselm, A.J. Passive annual heat storage principles in earth sheltered housing, a supplementary energy saving system in residential housing. Energy Build. 2008, 40, 1214–1219. [Google Scholar] [CrossRef]

- Choi, S.O.; Park, H.D.; Park, Y.J.; Kim, H.Y.; Jang, H.D. Test running of an underground food storage cavern in Korea. Tunn. Undergr. Space Technol. 2000, 15, 91–95. [Google Scholar] [CrossRef]

- Dunkel, F.V. Underground and earth sheltered food storage—Historical, geographic, and economic-considerations. Undergr. Space 1985, 9, 310–315. [Google Scholar]

- Mazarron, F.R.; Canas, I. Exponential sinusoidal model for predicting temperature inside underground wine cellars from a Spanish region. Energy Build. 2008, 40, 1931–1940. [Google Scholar] [CrossRef]

- Mazarrón, F.R.; Cañas, I. Seasonal analysis of the thermal behaviour of traditional underground wine cellars in Spain. Renew. Energy 2009, 34, 2484–2492. [Google Scholar] [CrossRef]

- Canas, I.; Mazarron, F.R. The effect of traditional wind vents called zarceras on the hygrothermal behaviour of underground wine cellars in Spain. Build. Environ. 2009, 44, 1818–1826. [Google Scholar] [CrossRef]

- Garg, N.K.; Oreszczyn, T. Energy efficiency in building envelopes through ground integration. Sol. Energy 1994, 53, 427–430. [Google Scholar] [CrossRef]

- Sterling, R.L.; Meixel, G.D.; Dunkel, F.; Fairhurst, C. Underground-storage of food. Undergr. Space 1983, 7, 257–262. [Google Scholar]

- Martin, S.; Canas, I. A comparison between underground wine cellars and aboveground storage for the aging of Spanish wines. Trans. ASABE 2006, 49, 1471–1478. [Google Scholar] [CrossRef]

- Guerrero, I.C.; Ocana, S.M. Study of the thermal behaviour of traditional wine cellars: The case of the area of “Tierras Sorianas del Cid” (Spain). Renew. Energy 2004, 30, 43–55. [Google Scholar] [CrossRef]

- Garde-Cerdán, T.; Ancín-Azpilicueta, C. Review of quality factors on wine ageing in oak barrels. Trends Food Sci. Technol. 2006, 17, 438–447. [Google Scholar] [CrossRef]

- OIV. Assessment on the World Vitiviniculture Situation in 2010; Organisation Internationale de la Vigne et du Vin: Paris, France, 2010. [Google Scholar]

- Food and Agriculture Organization (FAO). Agribusiness Handbook: Grapes Wine; Investment Centre Division, FAO: Rome, Italy, 2009. [Google Scholar]

- Kontoleon, K.J.; Eumorfopoulou, E.A. The influence of wall orientation and exterior surface solar absorptivity on time lag and decrement factor in the Greek region. Renew. Energy 2008, 33, 1652–1664. [Google Scholar] [CrossRef]

- Asan, H. Investigation of wall’s optimum insulation position from maximum time lag and minimum decrement factor point of view. Energy Build. 2000, 32, 197–203. [Google Scholar] [CrossRef]

- De Adana, M.R.; Lopez, L.M.; Sala, J.M. A Fickian model for calculating wine losses from oak casks depending on conditions in ageing facilities. Appl. Therm. Eng. 2005, 25, 709–718. [Google Scholar] [CrossRef]

- Ough, C.S. Tratado Básico de Enología; Acribia: Zaragoza, Spain, 1996. [Google Scholar]

- Troost, G. Tecnología del Vino; Omega: Barcelona, Spain, 1985. [Google Scholar]

- Atanasova, V.; Fulcrand, H.; Cheynier, V.; Moutounet, M. Effect of oxygenation on polyphenol changes occurring in the course of wine-making. Anal. Chim. Acta 2002, 458, 15–27. [Google Scholar] [CrossRef]

© 2012 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/3.0/).

Share and Cite

Mazarrón, F.R.; Cid-Falceto, J.; Cañas, I. Ground Thermal Inertia for Energy Efficient Building Design: A Case Study on Food Industry. Energies 2012, 5, 227-242. https://doi.org/10.3390/en5020227

Mazarrón FR, Cid-Falceto J, Cañas I. Ground Thermal Inertia for Energy Efficient Building Design: A Case Study on Food Industry. Energies. 2012; 5(2):227-242. https://doi.org/10.3390/en5020227

Chicago/Turabian StyleMazarrón, Fernando R., Jaime Cid-Falceto, and Ignacio Cañas. 2012. "Ground Thermal Inertia for Energy Efficient Building Design: A Case Study on Food Industry" Energies 5, no. 2: 227-242. https://doi.org/10.3390/en5020227