National Deployment of Domestic Geothermal Heat Pump Technology: Observations on the UK Experience 1995–2013

Abstract

:1. Introduction

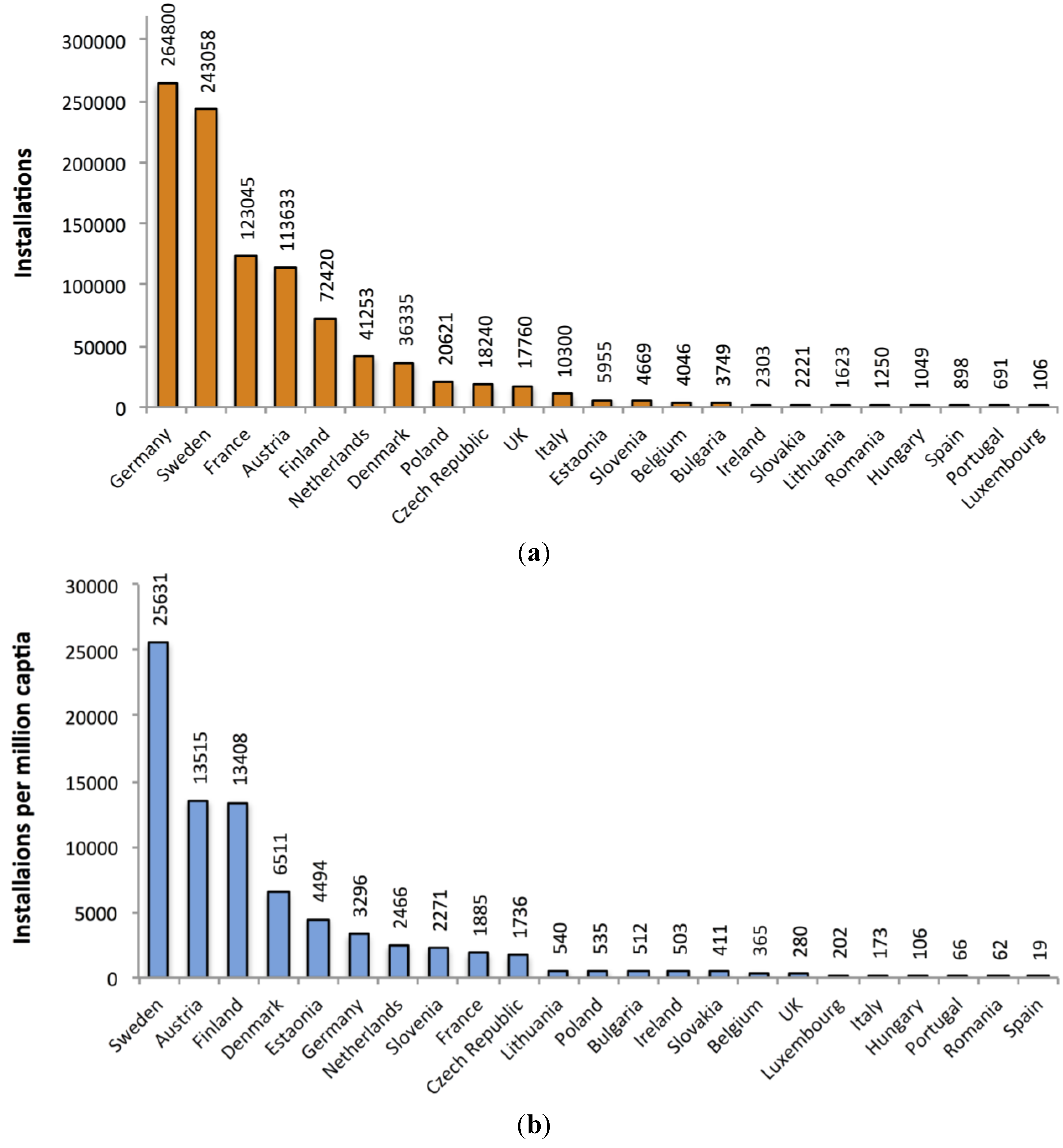

1.1. The National Context

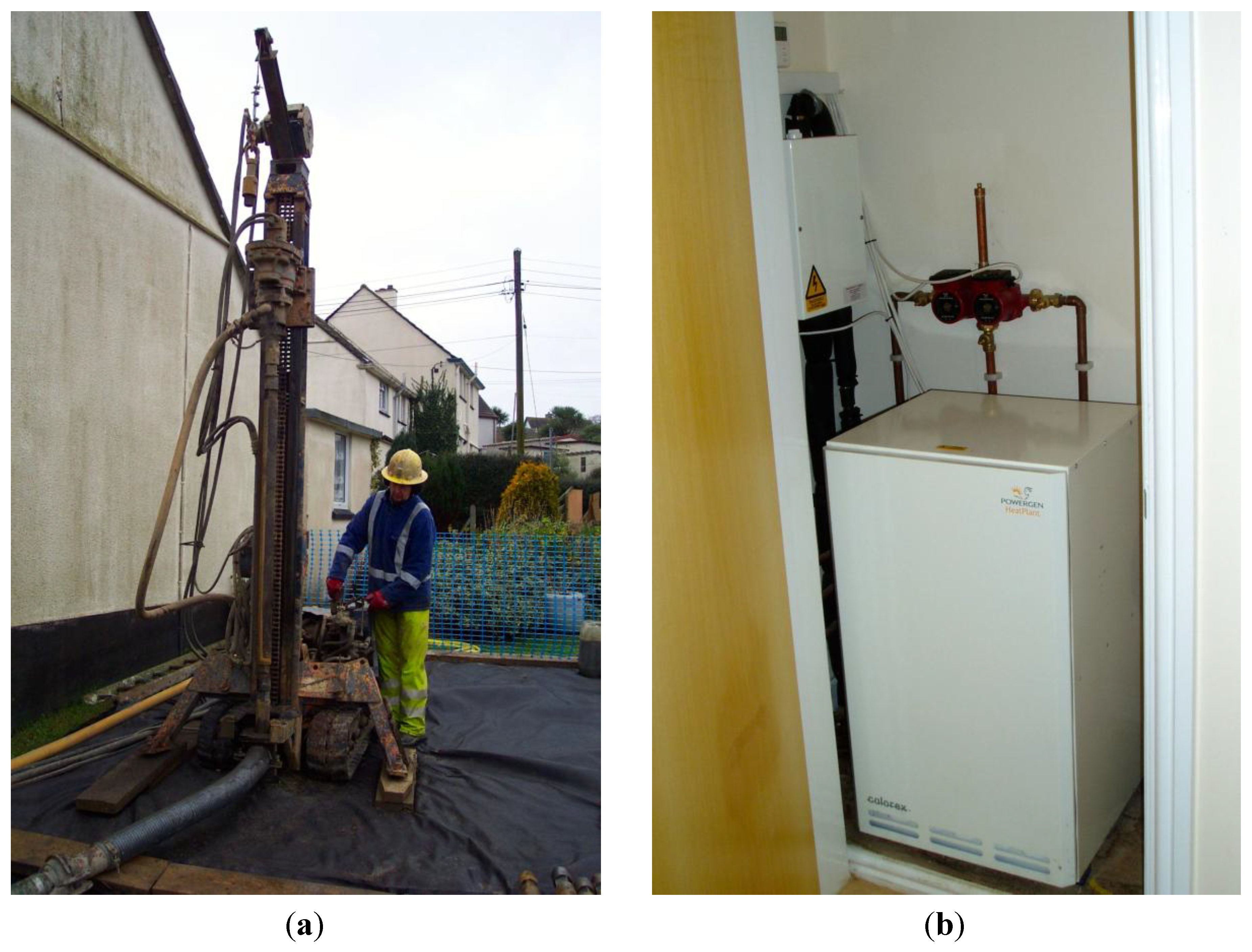

1.2. Market Development

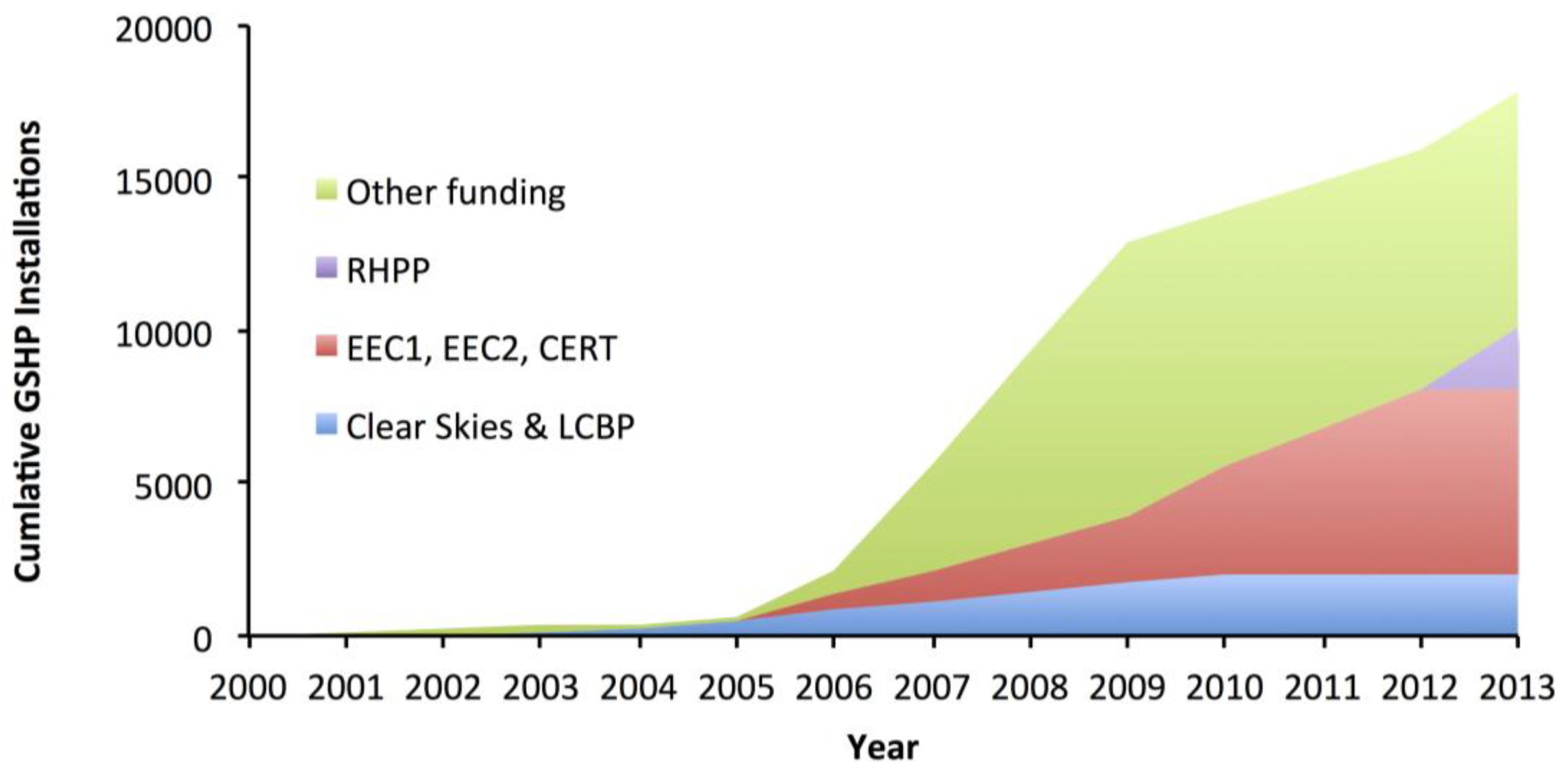

1.3. Policy and Support Programme Development

1.3.1. Capital Grant Programmes

1.3.2. Energy Supplier Obligation Programmes

1.3.3. Support Programme Outcomes

1.4. Other Supporting Measures

2. System Performance Evaluation

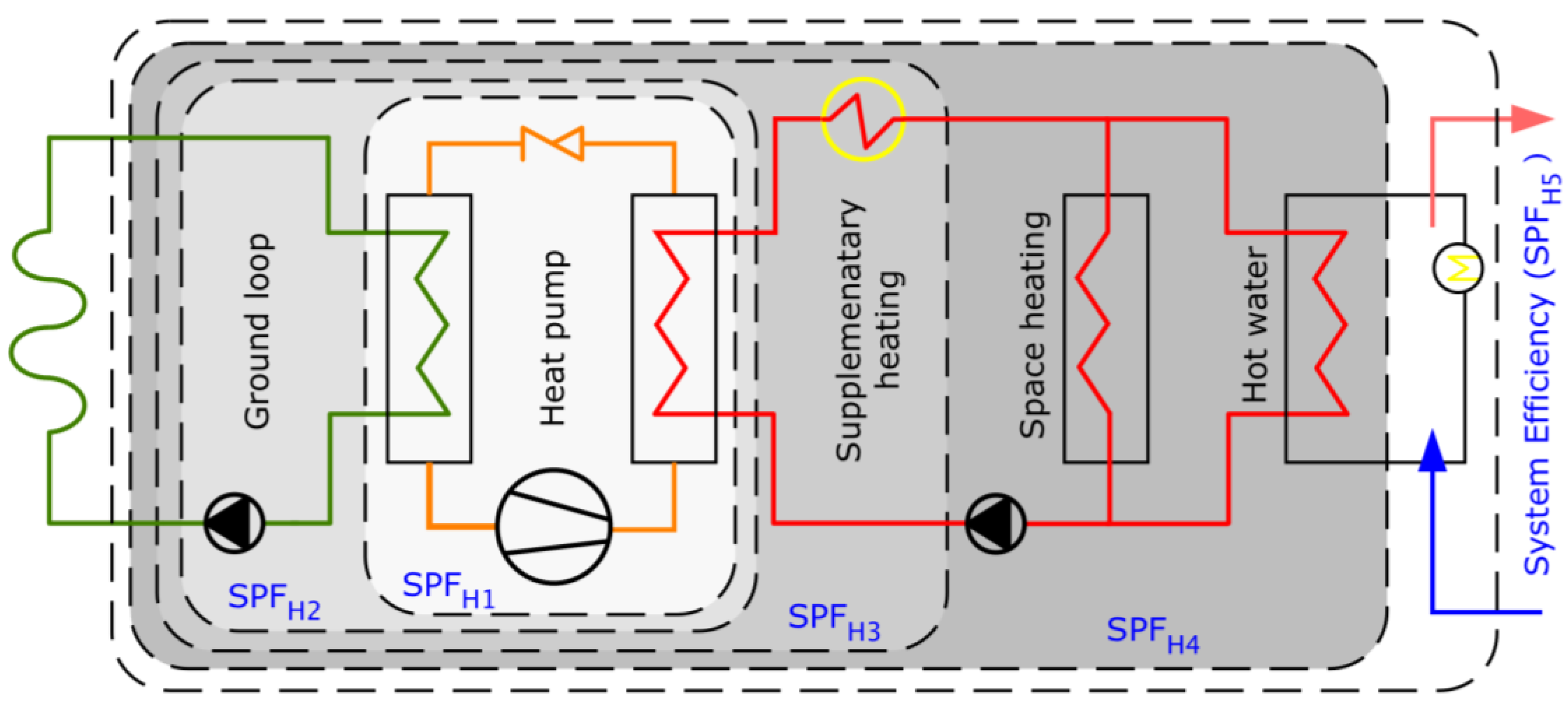

2.1. Performance Metrics and Benchmarks

2.2. National Field Trials and Monitoring Programmes

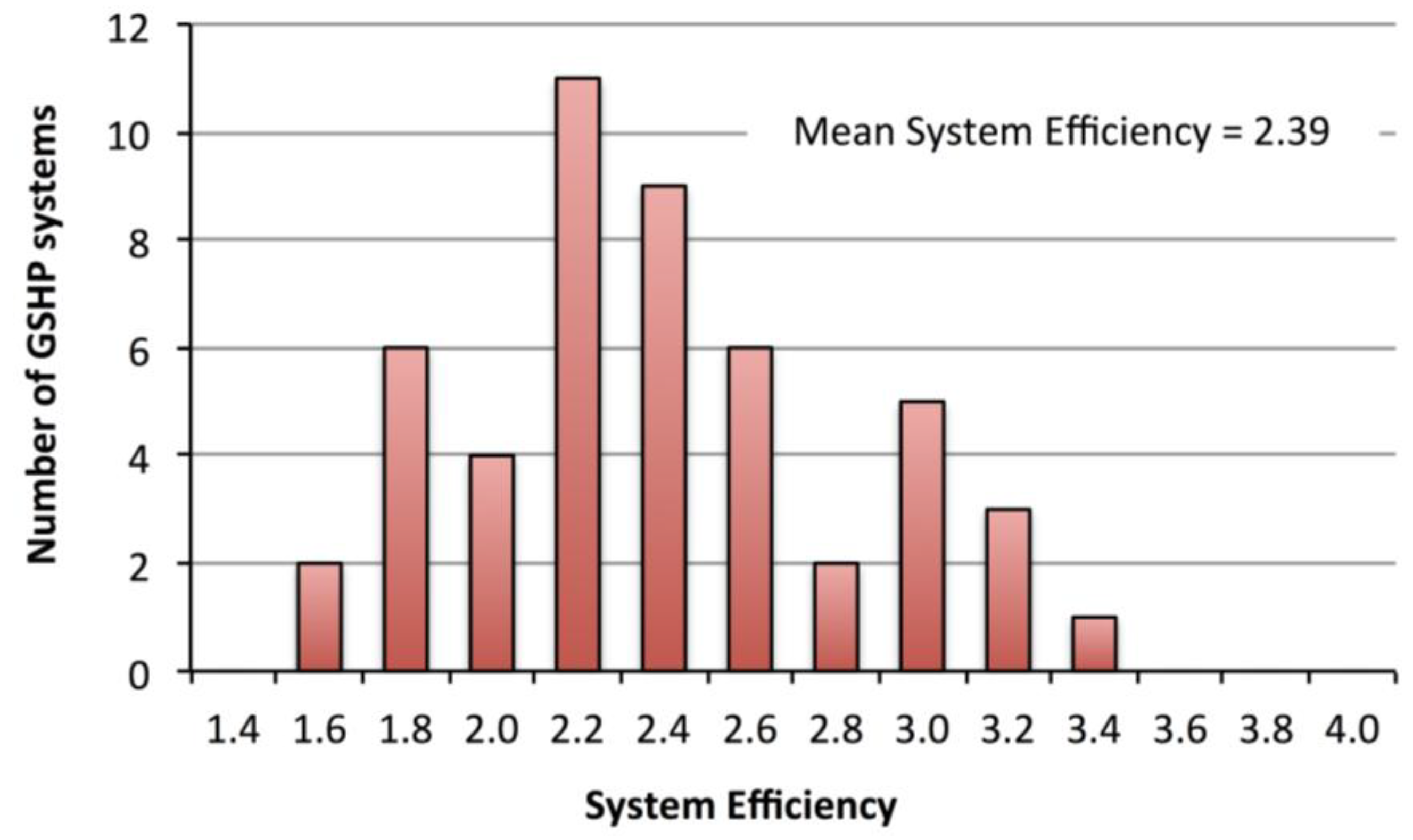

2.2.1. National Field Trial Results (Phase 1)

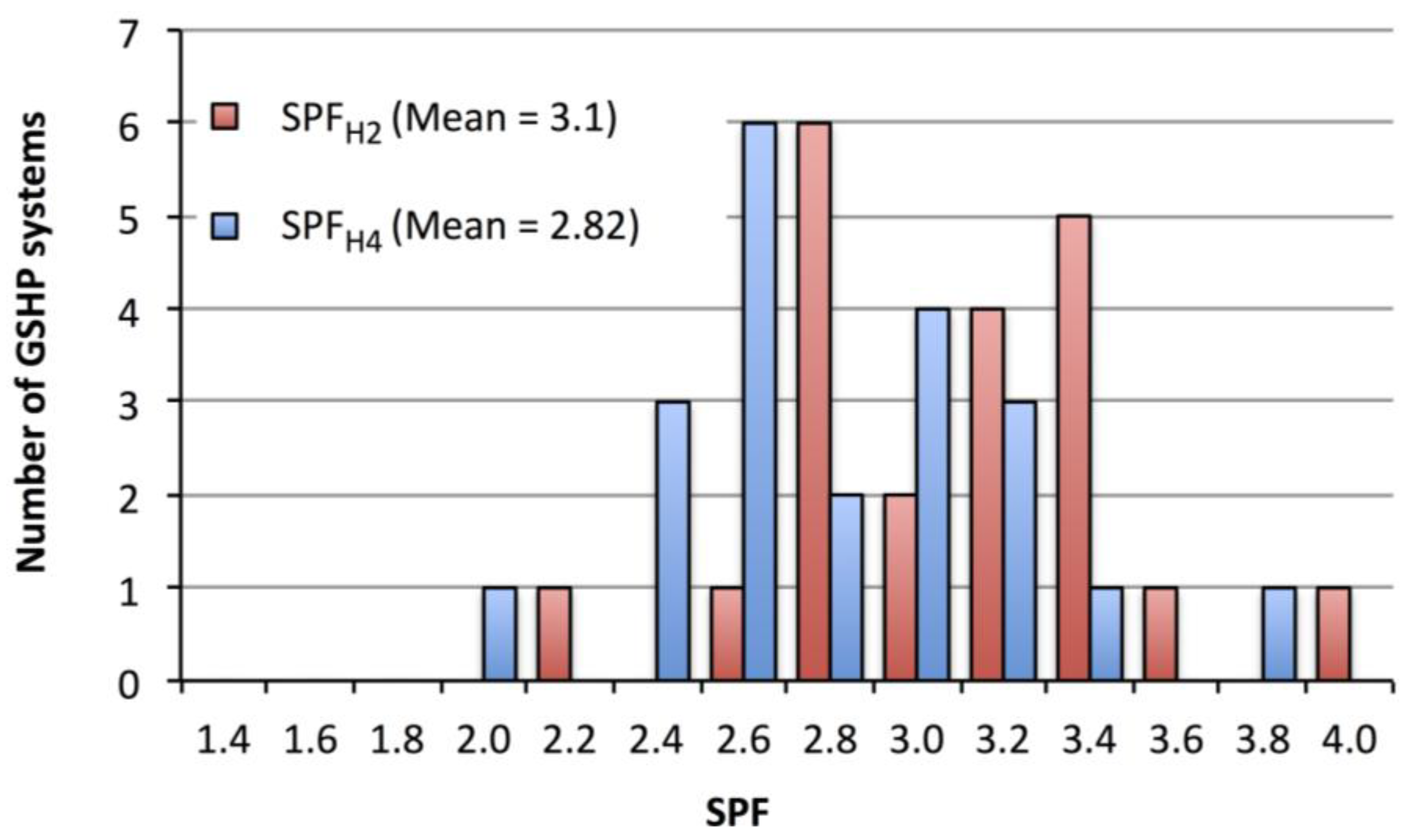

2.2.2. National Field Trial Results (Phase 2)

2.2.3. Initial RHPP Performance Data

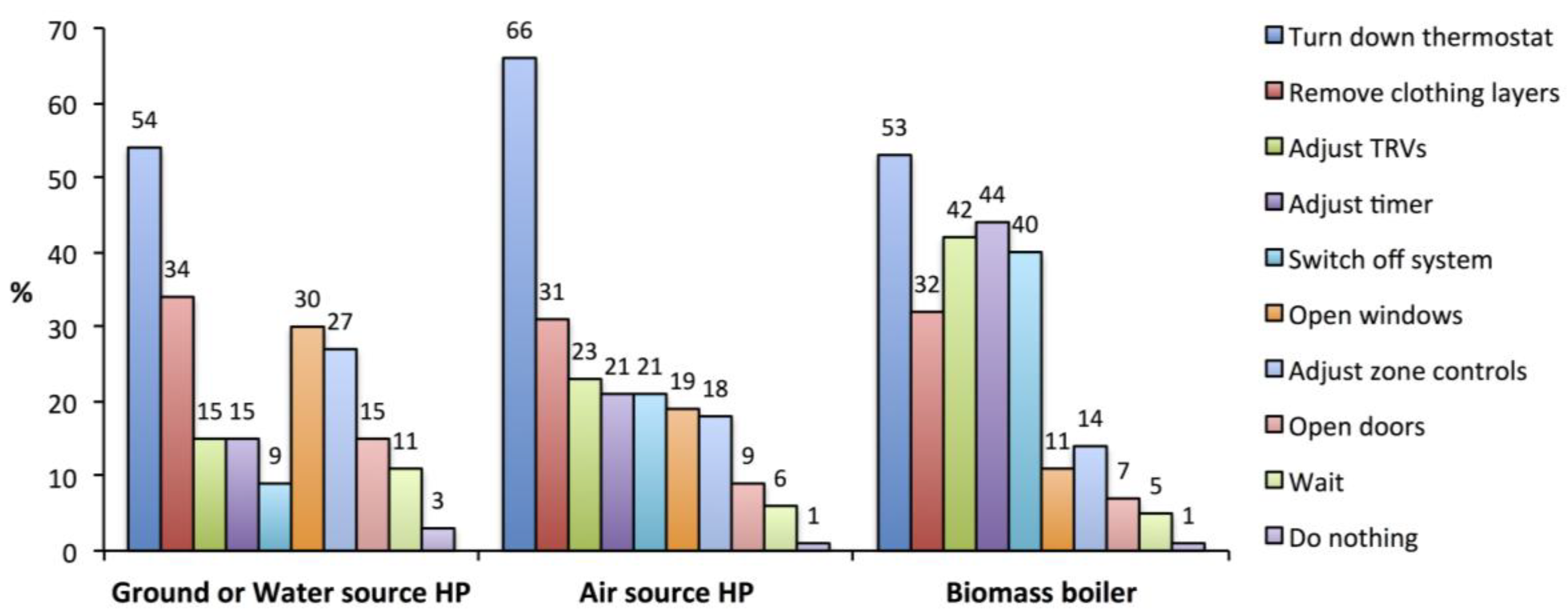

2.3. Grant Recipient Characteristics, Experiences and Behavior

3. Technology Adaptations and Development

- (1)

- Under-sizing of the heat pump;

- (2)

- Under-sizing of the ground heat exchanger;

- (3)

- Poor insulation standards (pipes and tanks);

- (4)

- Flow temperature unnecessarily high;

- (5)

- Excessive pump usage (time control or number of pumps);

- (6)

- Poor control.

3.1. Technical Performance

3.2. Standards Development

3.3. System Dynamics and Control

4. Discussion

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Lund, J.; Freeston, D.; Boyd, T. Direct utilization of geothermal energy 2010 worldwide review. Geothermics 2011, 40, 159–180. [Google Scholar] [CrossRef]

- Baker, W. Off-Gas Consumers Information on Households Without Mains Gas Heating; Consumer Focus: London, UK, 2013; p. 54. [Google Scholar]

- Bayer, P.; Saner, D.; Bolay, S.; Rybach, L.; Blum, P. Greenhouse gas emission savings of ground source heat pump systems in Europe: A review. Renew. Sustain. Energy Rev. 2012, 16, 1256–1267. [Google Scholar] [CrossRef]

- Singh, H.; Muetze, A.; Eames, P. Factors influencing the uptake of heat pump technology by the UK domestic sector. Renew. Energy 2010, 35, 873–878. [Google Scholar] [CrossRef]

- Lund, J.; Freeston, D.; Boyd, T. Direct application of geothermal energy: 2005 worldwide review. Geothermics 2005, 34, 691–727. [Google Scholar] [CrossRef]

- Garnish, J.D. Geothermal Resources of the UK—Country Update Report. Trans. Geotherm. Resour. Counc. 1985, 9, International. 217–222. [Google Scholar]

- Sumner, J.A. Domestic Heat Pumps; Prism Press: London, UK, 1976. [Google Scholar]

- Curtis, R. Earth Energy in the UK. Geo Heat Cent. Bull. 2001, 23–30. [Google Scholar]

- Lund, J.; Freeston, D. World-wide direct uses of geothermal energy 2000. Geothermics 2001, 30, 29–68. [Google Scholar] [CrossRef]

- Batchelor, T.; Curtis, R.; Ledingham, P. Country update for the United Kingdom. In Proceedings of World Geothermal Congress 2005, Antalya, Turkey, 24–29 April 2005; pp. 1–5.

- Karpathy, B.Z. Heat Pumps United Kingdom World Renewables 2013 A Multi Client Study; BSRIA: Bracknell, UK, 2013. [Google Scholar]

- EurObserv’ER. Ground-Source Heat Pump Barometer. J. Des Énergies Renouv. 2011, 205, 82–101. [Google Scholar]

- EurObserv’ER. Heat Pumps Barometer; EurObsv’ER: Brussels, Belgium, 2013; p. 17. [Google Scholar]

- Curtis, R.; Ledingham, P.; Law, R.; Bennett, T. Geothermal Energy Use, Country Update for United Kingdom. In Proceedings of European Geothermal Congress 2013, Pisa, Italy, 3–7 June 2013; pp. 1–9.

- Fawcett, T. The future role of heat pumps in the domestic sector. In Proceedings of the ECEEE 2011 Summer Study, Energy Efficiency First: The Foundation of a Low-Carbon SocietyBelambra Presqu'île de Giens, City, France, 6–11 June 2011; pp. 1547–1557.

- Le Feuvre, P. Le An Investigation into Ground Source Heat Pump Technology, its UK Market and Best Practice in System Design. Master’s Thesis, Univeristy of Strathclyde, Glasgow, UK, 2007; p. 180. [Google Scholar]

- Outlook 2009 European Heat Pump Statistics; European Heat Pump Association: Brussel, Belgium, 2009; p. 39.

- Mallaburn, P.; Eyre, N. Lessons from energy efficiency policy and programmesin the UK from 1973 to 2013. Energy Effic. 2014, 7, 23–41. [Google Scholar] [CrossRef]

- Department of the Environment. This Common Inheritance: Britain’s Environmental Strategy; HMSO: London, UK, 1990; p. 291.

- Performance Inovation Unit. The Energy Review; Cabinet Office Performance and Innovation Unit: London, UK, 2002; p. 216. [Google Scholar]

- Department of Trade and Industry (DTI). Our Energy Future—Creating a Low Carbon Economy; DTI: London, UK, 2003; p. 142.

- BRE. Renewable energy grants top £5.5 million. Available online: http://www.bre.co.uk/news/Renewable-energy-grants-top-55-million-230.html (accessed on 12 June 2014).

- BRECSU. Heat Pumps in the UK—A Monitoring Report (GIR 72); BRECSU: Watford, UK, 2000; p. 16. [Google Scholar]

- Van de Ven, H. Ground-source heat pump systems, An international overview. IEA Heat Pump Cent. Newsl. 1999, 17, 10–12. [Google Scholar]

- HMG. Energy Act 2004; HM Government: London, UK, 2004; p. 296.

- Gardiner, M.; White, H.; Munziger, M.; Ray, W. Low Carbon Building Programme 2006–2011 Final Report; Department of Energy and Climate Change: London, UK, 2011; p. 169.

- Radov, D.; Klevnäs, P.; Lindovska, M. Design of the Renewable Heat Incentive Study for the Department of Energy & Climate Change. NERA Econdomic Consulting: London, UK, 2010; p. 69. [Google Scholar]

- HMG. The UK Renewable Energy Strategy; HM Government: London, UK, 2009; p. 236.

- OFGEM. Domestic Renewable Heat Incentive. Available online: https://www.ofgem.gov.uk/environmental-programmes/domestic-renewable-heat-incentive (accessed on 12 June 2014).

- Barker, G. Departmental Note: Support for Renewable Heat Technologies in the Domestic and non-Domestic Sectors; Department of Energy and Climate Change: London, UK, 2013; p. 1. [Google Scholar]

- Department of Energy and Climate Change (DECC). Renewable Heat Incentive, Consultation on Proposals for a Domestic Scheme; DECC: London, UK, 2012; p. 32.

- Rosenow, J. Energy savings obligations in the UK—A history of change. Energy Policy 2012, 49, 373–382. [Google Scholar] [CrossRef]

- Office of Gas and Electricity Markets (OFGEM). A Review of the Energy Efficiency Commitment 2002–2005; OFGEM: London, UK, 2005; p. 83.

- Office of Gas and Electricity Markets (OFGEM). A Review of the Energy Efficiency Commitment 2005–2008; OFGEM: London, UK, 2008; p. 62.

- Department of the Environment, Transport and the Regions (DETR). Quality and Choice: A Decent Home for All: The Housing Green Paper; DETR: London, UK, 2000; p. 132.

- Dewdney, P. Powergen Enters New Era of Low-Cost, Low-Carbon Heating. Available online: http://www.heatpumps.org.uk/CaseExDomestic.html (accessed on 18 August 2014).

- Calorex. Case Study, Ground Source Heat Pumps Cutting Carbon Emissions; Calorex Ltd.: Maldon, Essex, UK, 2007; pp. 16–17. [Google Scholar]

- BBC. Hot Earth to Heat Homes. Available online: http://news.bbc.co.uk/1/hi/england/1670092.stm (accessed on 12 June 2014).

- Hill, D. Ground Sourced Heat Pumps, Our experiences and where to next. In GSHPA Seminar, 2005; GSHPA: Milton Keynes, UK, 2005; pp. 1–3. [Google Scholar]

- BRE. Ground Source Heat Pumps Case Study; BRE: Watford, UK, 2004; pp. 1–4. [Google Scholar]

- Calorex. Calorex Case Study—Housing; Calorex Ltd.: Maldon, Essex, UK, 2006; p. 1. [Google Scholar]

- Office of Gas and Electricity Markets (OFGEM). A Review of the Fourth Year of the Carbon Emissions Reduction Target; OFGEM: London, UK, 2012; p. 55. [Google Scholar]

- Office of Gas and Electricity Markets (OFGEM). Energy Companies Obligation (ECO). Available online: https://www.ofgem.gov.uk/environmental-programmes/energy-companies-obligation-eco (accessed on 12 June 2014).

- Energy Savings Trust (EST). Element EnergyPotential for Microgeneration, Study and Analysis Final Report; EST: London, UK, 2005. [Google Scholar]

- Caird, S.; Potter, S.; Herring, H. Consumer Adoption and Use of Household Renewable Energy Technologies, Report DIG-10; The Open University: Milton Keynes, UK, 2007; p. 57. [Google Scholar]

- Balcombe, P.; Rigby, D.; Azapagic, A. Motivations and barriers associated with adopting microgeneration energy technologies in the UK. Renew. Sustain. Energy Rev. 2013, 22, 655–666. [Google Scholar] [CrossRef]

- Wickins, C. Preliminary Data from the RHPP Heat Pump Metering Programme; Department of Energy and Climate Change: London, UK, 2014; p. 61. [Google Scholar]

- Karpathy, Z. Heat Pump Markets UK in Europe; BSRIA: Bracknell, UK, 2012. [Google Scholar]

- DECC. Low Carbon Building Programme Householder’s Project Case Study—Ground Source Heat Pump; Department for Communities and Local Government: London, UK, 2010; p. 4.

- NEF. Ground Source Heat Pump Association Comes of Age. Available online: http://www.nef.org.uk/about-us/press-releases/ground-source-heat-pump-association-comes-of-age (accessed on 9 May 2014).

- GSHPA. GSHPA press release—Ground Source Heat Pump RHI tariff expected to double. Available online: http://www.gshp.org.uk/pdf/GSHPA_Press_Release_24_January_2013.pdf (accessed on 12 May 2014).

- Microgeneration Certification Scheme (MCS). History of the Microgeneration Certification Scheme; MCS: Watford, UK, 2013; p. 5. [Google Scholar]

- European Certified Heat Pump Installer. Available online: http://www.heatpumpcentre.org/en/newsletter/previous/Documents/HPC-news_2_2004.htm (accessed on 12 June 2014).

- BDA. BDA awarded ConstructionSkills grant for Geothermal Drilling. Available online: http://www.britishdrillingassociation.co.uk/news/BDA-awarded-ConstructionSkills-grant-for-Geothermal-Drilling (accessed on 12 June 2014).

- Wincott, N. GeoTrainet and European Wide Training Developments. In GSHPA Technical Seminar 2013; GSHPA: Milton Keynes, UK, 2013; p. 24. [Google Scholar]

- Brooke, S.B.; Matthews, D.; Willson, C. UK Literature Review for International Energy Agency (IEA) Annex 36 on Investigating the Effect of Quality of Installation and Maintenance on Heat Pump Performance; Department of Energy and Climate Change: London, UK, 2013.

- CEN. EN 14511-2, Air Conditioners, Liquid Chilling Packages and Heat Pumps with Electrically Driven Compressors for Space Heating and Cooling—Part 2: Test Conditions; CEN: Brussels, Belgium; p. 2007.

- CEN. EN 15316-4-2, Heating Systems in Buildings—Method for Calculation of System Energy Requirements and System Efficiencies—Part 4-2: Space Heating Generation Systems, Heat Pump Systems; CEN: Brussels, Belgium, 2008. [Google Scholar]

- Gleeson, C.; Lowe, R. Meta-analysis of European heat pump field trial efficiencies. Energy Build. 2013, 66, 637–647. [Google Scholar] [CrossRef]

- Stafford, A. Long-term monitoring and performance of ground source heat pumps. Build. Res. Inf. 2011, 39, 566–573. [Google Scholar] [CrossRef]

- Wemhorner, C.; Dott, R.; Afjei, T.; Huber, H.; Helfenfinger, D.; Keller, P.; Furter, R. Calculation Method for the Seasonal Performance of Heat Pump Compact Units and Validation; Swiss Federal Office of Energy: Bern, Switzerland, 2007. [Google Scholar]

- Zottl, A.; Nordman, R.; Rivière, P. SEPEMO—Common Monitoring Methodology. Eur. Heat Pump News 2011, 3, 5–6. [Google Scholar]

- European Commission. Decision (2013/114/EU) Establishing the Guidelines for Member States on Calculating Renewable Energy from Heat Pumps from Different Heat Pump Technologies pursuant to Article 5 of Directive 2009/28/EC of the European Parliament an dof the Council; Official Journal of the European Union: Brussels, Belgium, 2013; pp. 27–35. [Google Scholar]

- Dunbabin, P.; Charlick, H.; Green, R. Detailed Analysis from the Second Phase of the Energy Saving Trust’s Heat Pump Field Trial; Department of Energy and Climate Change: London, UK, 2013; p. 123.

- Energy Saving Trust (EST). The Heat is on: Heat Pump Field Trials Phase 2; EST: London, UK, 2013; p. 40. [Google Scholar]

- Greening, B.; Azapagic, A. Domestic heat pumps: Life cycle environmental impacts and potential implications for the UK. Energy 2012, 39, 205–217. [Google Scholar] [CrossRef]

- Johnson, E. Air-source heat pump carbon footprints: HFC impacts and comparison to other heat sources. Energy Policy 2011, 39, 1369–1381. [Google Scholar] [CrossRef]

- European Commission. Directive 2009/28/EC of the European Parliament and of the Council of 23 April 2009 on the Promotion of the Use of Energy from Renewable Sources and Amending Subsequently Replealing Directives 2001/77/EC and 2003/30/EC; Official Journal of the European Union: Brussels, Belgium, 2009; pp. 16–62. [Google Scholar]

- Orr, G.; Lelyveld, T.; Burton, S. Final Report : In-situMonitoring of Efficiencies of Condensing Boilers and Use of Secondary Heating; Gastec at CRE: Cheltenham, UK, 2009; p. 44. [Google Scholar]

- Energy Saving Trust (EST). Getting Warmer: A Field Trial of Heat Pumps; EST: London, UK, 2010. [Google Scholar]

- Dunbabin, P.; Wickins, C. Detailed Analysis from the First Phase of the Energy Saving Trust’s Heat Pump Field Trial; Department of Energy and Climate Change: London, UK, 2012. [Google Scholar]

- Microgeneration Certification Scheme (MCS). Microgeneration Installation Standard: MIS 3005, Requirements for Contractors Undertaking the Supply, Design, Installation, Set to Work Commissioning and Handover of Microgeneration Heat Pump Systems, Version 3.1; MCS: Watford, UK, 2008; pp. 1–47. [Google Scholar]

- Caird, S.; Roy, R.; Potter, S. Domestic heat pumps in the UK: User behaviour, satisfaction and performance. Energy Effic. 2012, 5, 283–301. [Google Scholar] [CrossRef]

- Roy, R.; Caird, S. Diffusion, User Experiences and Performance of UK Domestic Heat Pumps. Energy Sci. Technol. 2013, 6, 14–23. [Google Scholar]

- Stafford, A.; Lilley, D. Predicting in situ heat pump performance: An investigation into a single ground-source heat pump system in the context of 10 similar systems. Energy Build. 2012, 49, 536–541. [Google Scholar] [CrossRef] [Green Version]

- Boait, P.; Fan, D.; Stafford, A. Performance and control of domestic ground-source heat pumps in retrofit installations. Energy Build. 2011, 43, 1968–1976. [Google Scholar] [CrossRef]

- DECC AECOM. Analysis of Customer Data from Phase One of the Renewable Heat Premium Payments (RHPP) Scheme; Department of Energy and Climate Change: London, UK, 2013; p. 110.

- Energy Saving Trust. RHPP RSL Fast Track Competition Winners 2013–2014. Available online: http://www.energysavingtrust.org.uk/Generating-energy/Getting-money-back/Renewable-Heat-Premium-Payment-RHPP-Social-Landlords-Competition-Phase-Two-Extensions-2013-14/RHPP-RSL-Fast-Track-Competition-Winners-2013-2014 (accessed on 19 May 2014).

- Office for National Statistics. Home ownership and renting in England and Wales—Detailed Characteristics. Available online: http://www.ons.gov.uk/ons/rel/census/2011-census/detailed-characteristics-on-housing-for-local-authorities-in-england-and-wales/short-story-on-detailed-characteristics.html (accessed on 22 June 2014).

- Office for National Statistics. Annual Survey of Hours and Earnings, 2013 Provisional Results; Office for National Statistics: London, UK, 2013; pp. 1–45.

- Delta Energy & Environment. Heat Pumps in the UK: How Hot Can They Get? Delta Energy and Environment: Edinburgh, UK, 2011; p. 8. [Google Scholar]

- Stenlund, M.; Axell, M. Residential Ground-Source Heat Pump Systems—Results from a Field Study in Sweden; SP Swedish Technical Research Institute: Borås, Sweden, 2007; pp. 1–10. [Google Scholar]

- Pederson, S.; Jacobsen, E. Approval of Systems Entitled to Subsidies. Measurements Data Collection and Dissemination; Danish Technological Institute: Taastrup, Denmark, 2011; p. 12. [Google Scholar]

- Nordman, R.; Andersson, K.; Axell, M.; Lindahl, M. Calculation Methods for SPF for Heat Pump Systems for Comparison, System Choice and Dimensioning; SP Swedish Technical Research Institute: Borås, Sweden, 2010; p. 82. [Google Scholar]

- Russ, C.; Miara, M.; Platt, M.; Günther, D.; Kramer, T.; Dittmer, H.; Lechner, T.; Kurz, C. Feldmessung Wärmepumpen im Gebäudebestand; Fraunhofer ISE: Freiburg, Germany, 2010; pp. 1–21. (In German) [Google Scholar]

- Miara, M.; Gunther, D.; Kramer, T.; Oltersdorf, T.; Wapler, J. Messtechnische Untersuchung von Wärmepumpenanlagen zur Analyse und Bewertung der Effizienz im realen Betrieb; Fraunhofer ISE: Freiburg, Germany, 2011; p. 154. (In German) [Google Scholar]

- Microgeneration Certification Scheme (MCS). MCS 022: Ground Heat Exchanger Look-up Tables, Supplementary Material to MIS 3005, Issue 1.0; MCS: Watford, UK, 2011; pp. 1–22. [Google Scholar]

- Microgeneration Certification Scheme (MCS). MCS 021: Heat Emitter Guide for Domestic Heat Pumps, Issue 1.0; MCS: Watford, UK, 2013; p. 9. [Google Scholar]

- GeoEnergy. MCS Procedure and Charts for Designing the Hydraulics and Associated Pumping Power of Closed Loop GSHP Systems under MCS; MCS: Watford, UK, 2012; p. 39. [Google Scholar]

- Green, R.; Knowles, T. The Effect of Thermostatic Radiator Valves on Heat Pump Performance; EA Technology Consulting: Chester, UK, 2011; p. 21. [Google Scholar]

- Charlick, H. Investigation of the Interaction between Hot Water Cylinders, Buffer Tanks and Heat Pumps; Kiewa GASTEC at CRE: Cheltenham, UK, 2013. [Google Scholar]

- Hellström, G.; Sanner, B. Software for dimensioning of deep boreholes for heat extraction. Proc. CALORSTOCK 1994, 94, 195–202. [Google Scholar]

- Spitler, J.D. GLHEPRO—A design tool for commercial ground loop heat exchangers. In Proceedings of the Fourth International Heat Pumps in Cold Climates Conference, Aylmer, QC, Canada, 17–18 August 2000; p. 16.

- Gaia Geothermal LLC. Ground Loop Design User’s Guide. Available online: http://www.groundloopdesign.com/downloads/GLD_2.x/manual.pdf (accessed on 21 August 2014).

- Verein Deutscher Ingenieure. VDI-Richtlinie 4640: Thermische Nutzung des Untergrundes–Blatt 2: Erdgekoppelte Wärmepumpenanlagen; Beuth Verlag: Berlin, Germany, 2001. [Google Scholar]

- Curtis, R.; Pine, T.; Wickins, C. Development of new ground loop sizing tools for domestic GSHP installations in the UK. In Proceedings of European Geothermal Congress 2013, Pisa, Italy, 3–7 June 2013; pp. 1–10.

- International Ground Source Heat Pump Association (IGSHPA). CLGS Ground Heat Exchanger Design Program; IGSHPA: Stillwater, OK, USA, 2005. [Google Scholar]

- Schein, J.; Bushby, S.T. A heirarchical rule-based fault detection and diagnostic method for HVAC systems. HVAC&R Res. 2006, 12, 115–126. [Google Scholar]

- Zogg, D. Fault Diagnosis for Heat Pump Systems. Ph.D. Thesis, Swiss Federal Insitute of Technology (ETH), Zurich, Switzerland, 2002. [Google Scholar]

- Curtis, R.; Pine, T. Effects of Cycling on Domestic GSHPs Supporting Analysis to EA Technology Simulation/Modelling; Mimer Geoenergy: Falmouth, UK, 2012; p. 28. [Google Scholar]

- Heffernan, W.; Watson, N. Harmonic performance of heat-pumps. J. Eng. 2013, 25, 1–14. [Google Scholar]

- Connor, P.; Bürger, V.; Beurskens, L.; Ericsson, K.; Egger, C. Devising renewable heat policy: Overview of support options. Energy Policy 2013, 59, 3–16. [Google Scholar] [CrossRef]

- Department of Energy and Climate Change (DECC). The Future of the Energy Company Obligation; DECC: London, UK, 2014; p. 63.

- Department of Energy and Climate Change (DECC). The Green Deal, A Summary of the Government’s Proposals; DECC: London, UK, 2010; p. 22.

- HMG. The Building Regulations, Conservation of Fuel and Power Approved Document Part L1A (2013 version); HM Government: London, UK, 2013; p. 48.

- Department for Communities and Local Government (DCLG). Code for Sustainable Homes, A Step-Change in Sustainable Home Building Practice; DCLG: London, UK, 2006; p. 31.

- Department for Communities and Local Government (DCLG). The Code for Sustainable Homes, Case Studies Volume 2; DCLG: London, UK, 2010; Volume 2, p. 50.

- Department for Communities and Local Government (DCLG). Housing Standards Review; DCLG: London, UK, 2013; p. 88.

- The Committee on Climate Change (CCC). The Fourth Carbon Budget, Reducing Emissions through the 2020s; CCC: London, UK, 2010. [Google Scholar]

- Strbac, G.; Gan, C.K.; Aunedi, M.; Stanojevic, V.; Djapic, P.; Dejvises, J.; Mancarella, P.; Hawkes, A.; Pudjianto, D.; Openshaw, D.; et al. Benefits of Advanced Smart Metering for Demand Response based Control of Distribution Networks; Imperial College London: London, UK, 2010; p. 49. [Google Scholar]

- Department for Communities and Local Government (DCLG). National Renewable Energy Action Plan for the United Kingdom; DCLG: London, UK, 2009; p. 160.

- Radov, D.; Klevnäs, P.; Lindovska, M.; Abu-Ebid, M.; Barker, N.; Stabaugh, J. The UK Supply Curve for Renewable Heat; NERA Economic Consulting: London, UK, 2009; Volume 689, p. 155. [Google Scholar]

- Frontier Economics Element Energy. Pathways to High Penetration of Heat Pumps; Frontier Economics Ltd.: London, UK, 2013; p. 147. [Google Scholar]

- Guzeleva, D. Challenges in the UK network. In IET Seminar, Integrating Renewable Energy to the Grid: Optimising and Securing the Network; IET: London, UK, 2014. [Google Scholar]

- Sugden, L. Smart Grids create new opportunities for heat pumps. REHVA J. 2012, 20–22. [Google Scholar]

- Karlsson, F.; Axell, M.; Fahlén, P. Heat Pump Systems in Sweden—Country Report for IEA HPP Annex 28; SP Swedish Technical Research Institute: Borås, Sweden, 2003; pp. 1–29. [Google Scholar]

© 2014 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/3.0/).

Share and Cite

Rees, S.; Curtis, R. National Deployment of Domestic Geothermal Heat Pump Technology: Observations on the UK Experience 1995–2013. Energies 2014, 7, 5460-5499. https://doi.org/10.3390/en7085460

Rees S, Curtis R. National Deployment of Domestic Geothermal Heat Pump Technology: Observations on the UK Experience 1995–2013. Energies. 2014; 7(8):5460-5499. https://doi.org/10.3390/en7085460

Chicago/Turabian StyleRees, Simon, and Robin Curtis. 2014. "National Deployment of Domestic Geothermal Heat Pump Technology: Observations on the UK Experience 1995–2013" Energies 7, no. 8: 5460-5499. https://doi.org/10.3390/en7085460