Synthesis and Tribological Behavior of Ultra High Molecular Weight Polyethylene (UHMWPE)-Lignin Composites

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

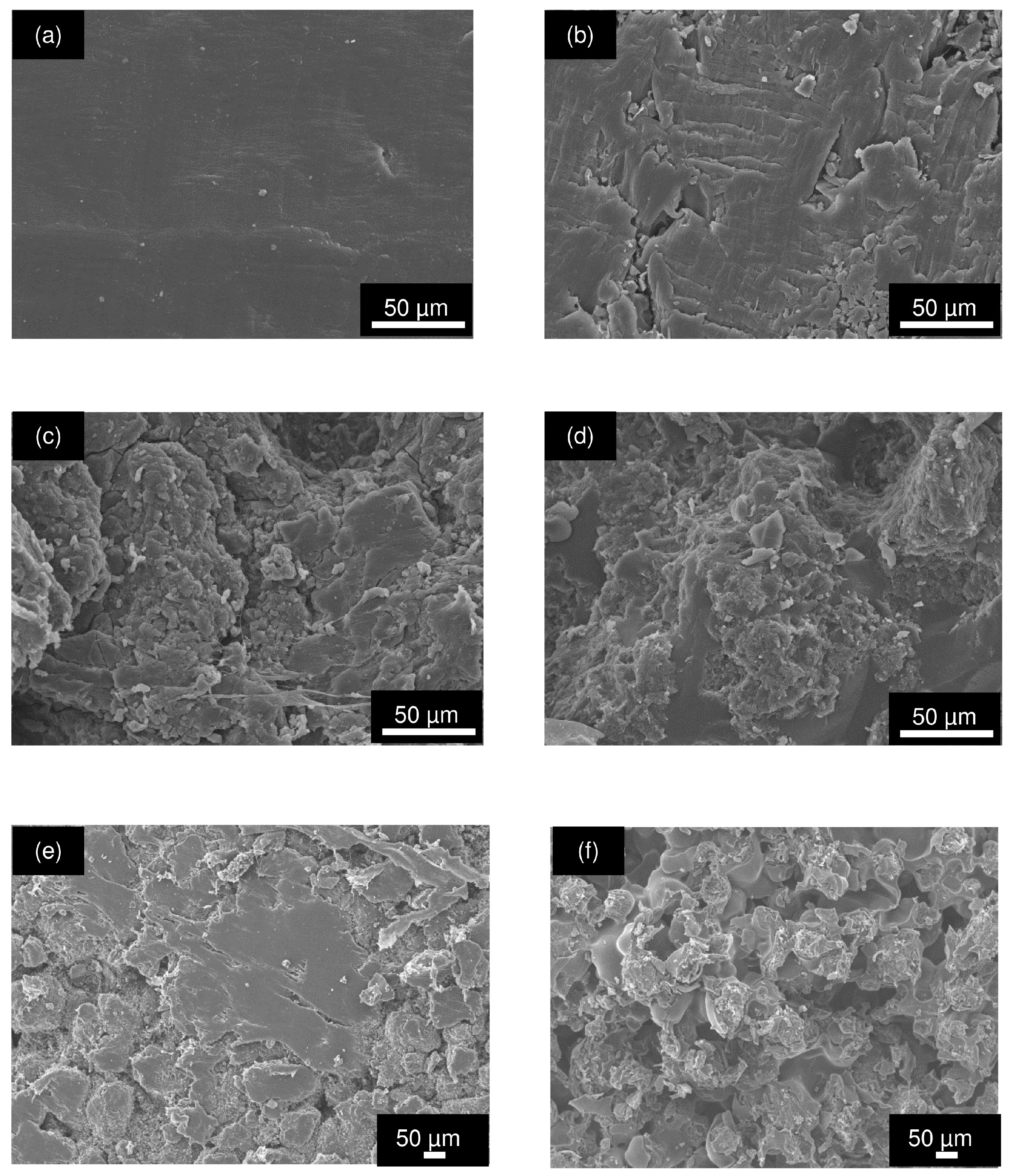

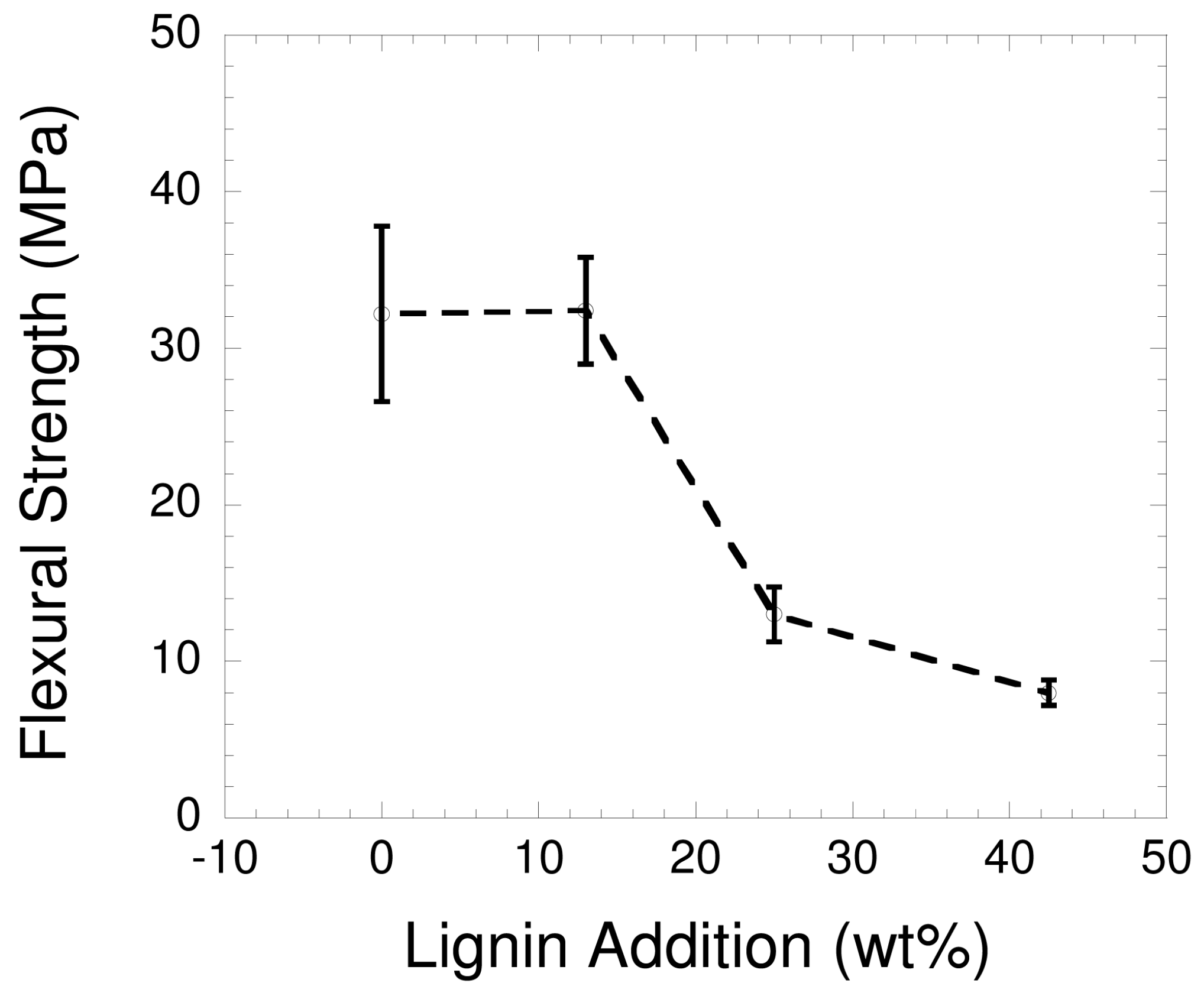

3.1. Analysis of Microstructure and Mechanical Behavior

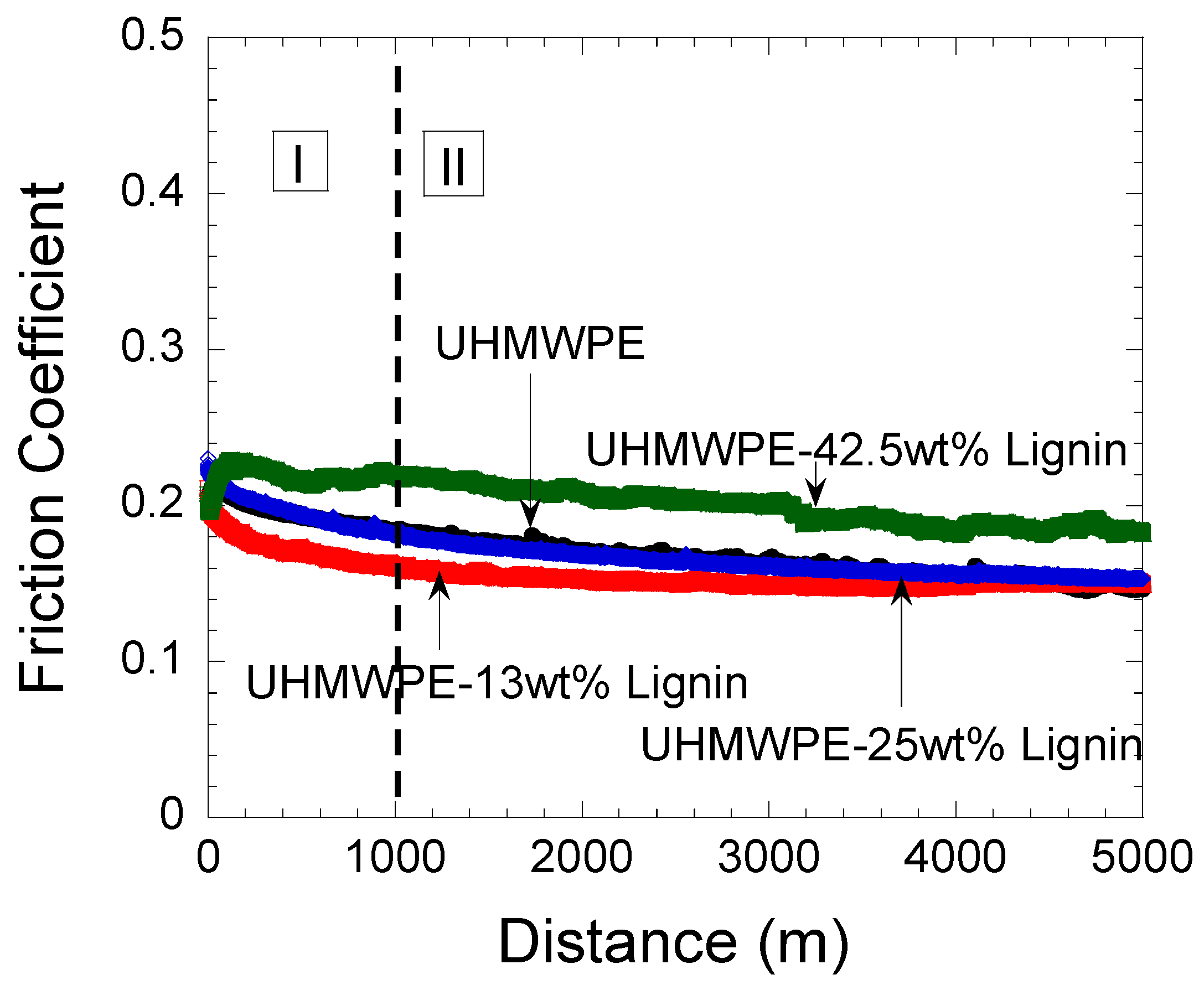

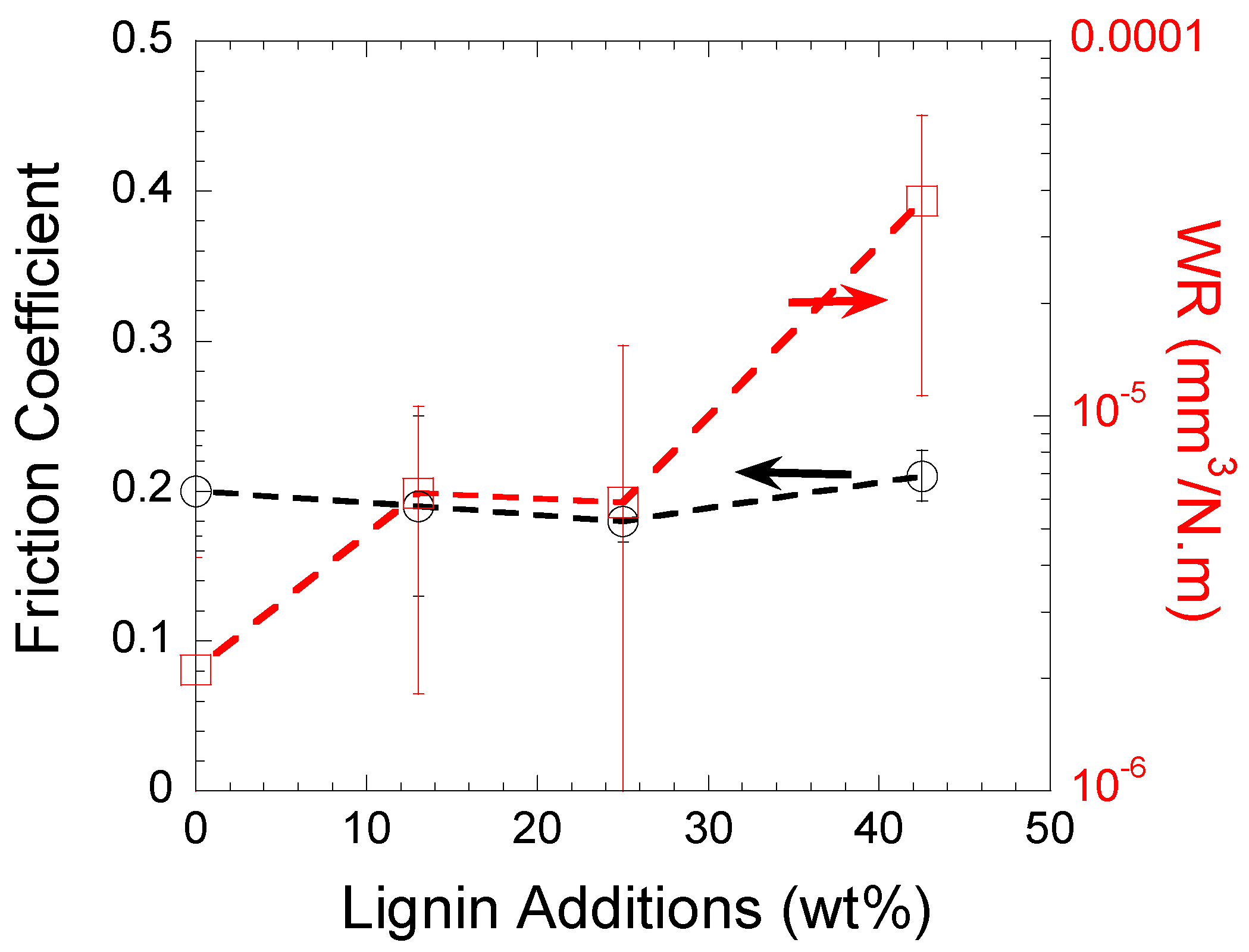

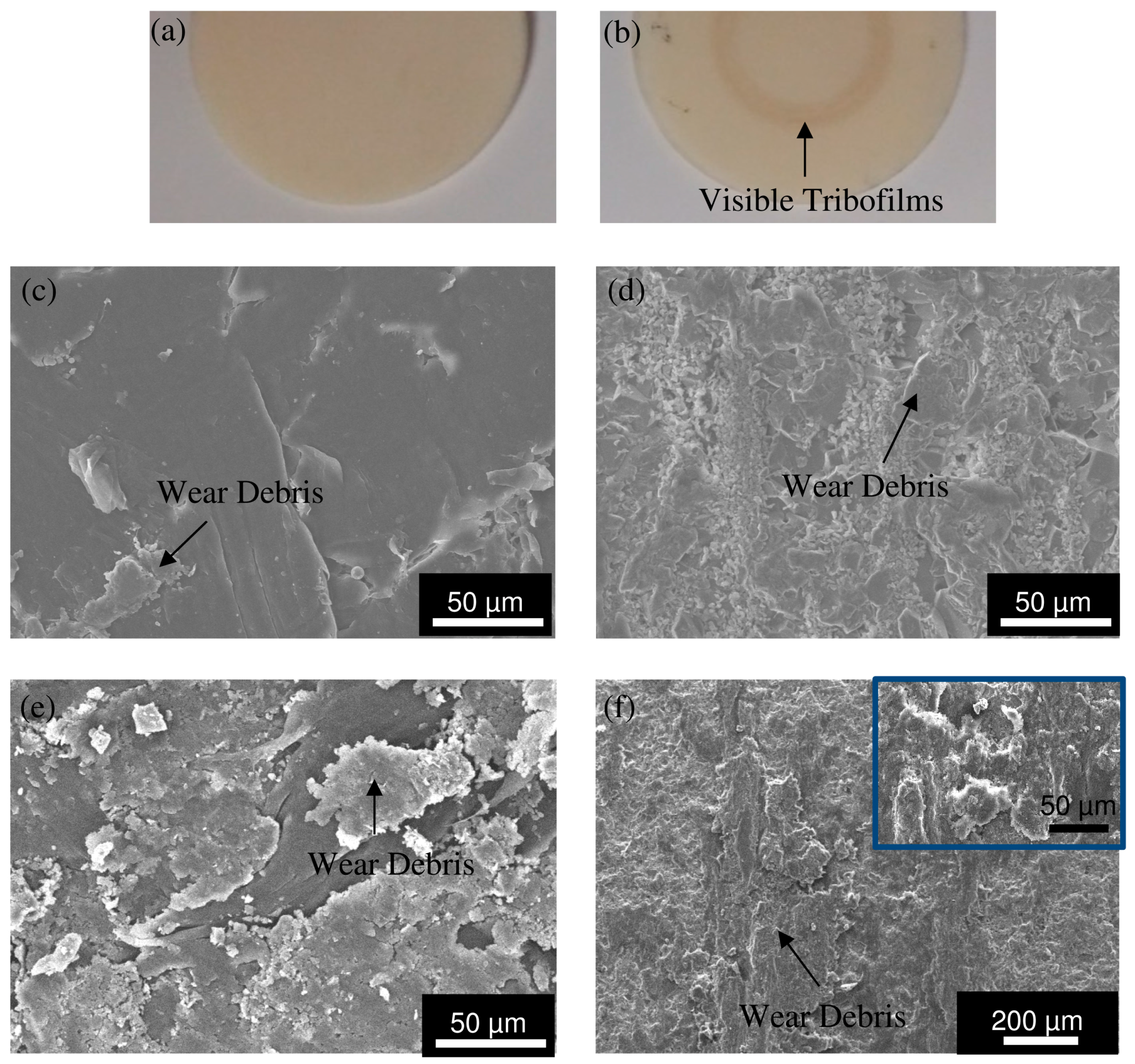

3.2. Tribological Behavior

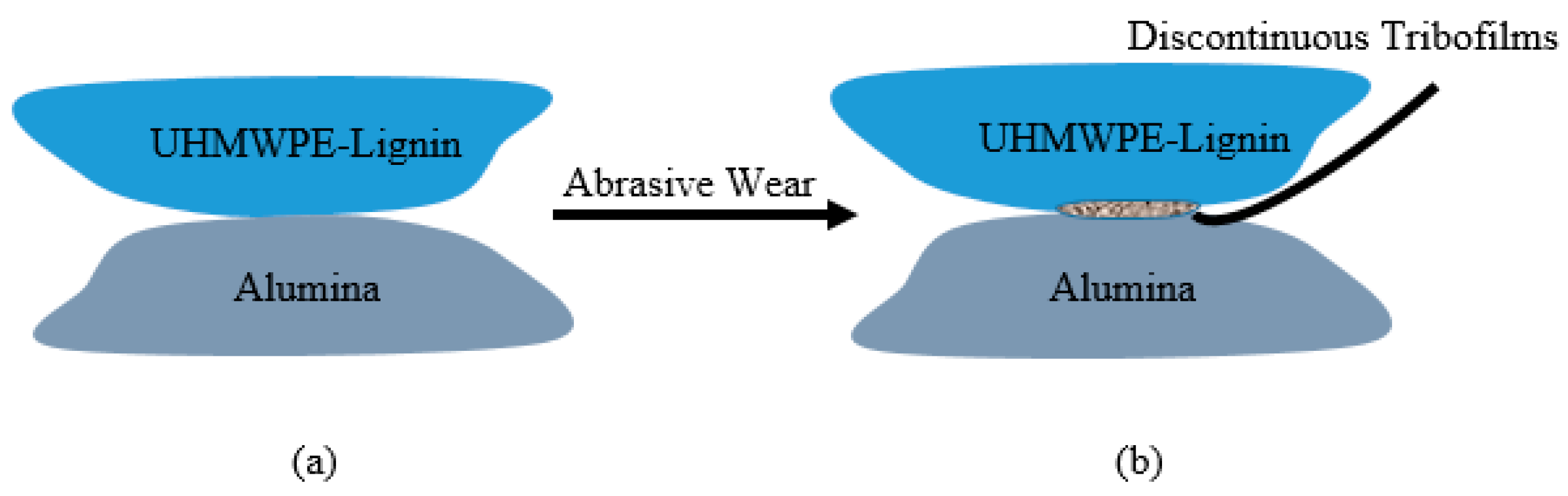

3.3. Fundamentals of Tribofilm Formation

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Knauf, M.; Moniruzzaman, M. Lignocellulosic biomass processing: A perspective. Int. Sugar J. 2004, 106, 147–150. [Google Scholar]

- Sjöström, E. Wood Chemistry. Fundamentals and Applications; Academic Press: San Diego, CA, USA, 1993. [Google Scholar]

- Gordobil, Q.; Moriana, R.; Zhang, L.; Labidi, J.; Sevastyanova, O. Assessment of technical lignins for uses in biofuels and biomaterials: Structure-related properties, proximate analysis and chemical modification. Ind. Crop. Prod. 2016, 83, 155–165. [Google Scholar]

- Hu, T.Q. Chemical Modification, Properties and Usage of Lignin, 1st ed.; Springer: New York, NY, USA, 2002. [Google Scholar]

- Christopher, L.P. Integrated Forest Biorefineries, Challenges and Opportunities; RSC Green Chemistry Series; RSC Publishing: London, UK, 2012; p. 32. [Google Scholar]

- Song, P.; Cao, Z.; Fu, S.; Fang, Z.; Wu, Q.; Ye, J. Thermal degradation and flame retardancy properties of ABS/lignin: Effects of lignin content and reactive compatibilization. Thermochim. Acta 2011, 518, 59–65. [Google Scholar] [CrossRef]

- Perlack, R.D.; Stokes, B.J. U.S. Billion-Ton Update: Biomass Supply for a Bioenergy and Bioproducts Industry; ORNL/TM-2011/224; Oak Ridge National Laboratory: Oak Ridge, TN, USA, 2011; 227p. [Google Scholar]

- Singh, R.; Singh, S.; Trimukhe, K.D.; Pandare, K.V.; Bastawade, K.B.; Gokhale, D.V.; Varma, A.J. Lignin-carbohydrate complexes from sugarcane bagasse: Preparation, purification, and characterization. Carbohydr. Polym. 2005, 62, 57–66. [Google Scholar] [CrossRef]

- Duval, A.; Lawoko, M. A review on lignin-based polymeric, micro- and nano-structured materials. React. Funct. Polym. 2014, 85, 78–96. [Google Scholar] [CrossRef]

- Thakur, V.K.; Thakur, M.K.; Raghavan, P.; Kessler, M.R. Progress in Green Polymer Composites from Lignin for Multifunctional Applications: A Review. ACS Sustain. Chem. Eng. 2014, 2, 1072–1092. [Google Scholar] [CrossRef]

- Doherty, W.O.S.; Mousavioun, P.; Fellows, C.M. Value-adding to cellulosic ethanol: Lignin polymers. Ind. Crop. Prod. 2011, 33, 259–276. [Google Scholar] [CrossRef] [Green Version]

- Kharade, A.Y.; Kale, D.D. Lignin-Filled Polyolefins. J. Appl. Polym. Sci. 1999, 72, 1321–1326. [Google Scholar] [CrossRef]

- Alexy, P.; Kosıkova, B.; Podstranska, G. The effect of blending lignin with polyethylene and polypropylene on physical properties. Polymer 2000, 41, 4901–4908. [Google Scholar] [CrossRef]

- Toriz, G.; Denes, F.; Young, R.A. Lignin-Polypropylene Composites. Part 1: Composites from Unmodified Lignin and Polypropylene. Polym. Compos. 2002, 23, 806–813. [Google Scholar] [CrossRef]

- Spiridon, I.; Leluk, K.; Resmerita, A.M.; Darie, R.N. Evaluation of PLA–lignin bioplastics properties before and after accelerated weathering. Compos. Part B 2015, 69, 342–349. [Google Scholar] [CrossRef]

- Li, J.; He, Y.; Inoue, Y. Thermal and mechanical properties of biodegradable blends of poly(l-lactic acid) and Lignin. Polym. Int. 2003, 52, 949–955. [Google Scholar] [CrossRef]

- Gordobila, O.; Delucis, R.; Egüésa, I.; Labidia, J. Kraft lignin as filler in PLA to improve ductility and thermal properties. Ind. Crop. Prod. 2015, 72, 46–53. [Google Scholar] [CrossRef]

- Kadla, J.F.; Kubo, S. Miscibility and Hydrogen Bonding in Blends of Poly(ethylene oxide) and Kraft Lignin. Macromolecules 2003, 36, 7803–7811. [Google Scholar] [CrossRef]

- Kubo, S.; Kadla, J.F. Kraft Lignin/Poly(ethylene oxide) Blends: Effect of Lignin Structure on Miscibility and Hydrogen Bonding. J. Appl. Polym. Sci. 2005, 98, 1437–1444. [Google Scholar] [CrossRef]

- Thielemans, W.; Can, E.; Morye, S.S.; Wool, R.P. Novel Applications of Lignin in Composite Materials. J. Appl. Polym. Sci. 2002, 83, 323–331. [Google Scholar] [CrossRef]

- Kosıkova, B.; Gregorova, A.; Osvald, A.; Krajcovicova, J. Role of Lignin Filler in Stabilization of Natural Rubber–Based Composites. J. Appl. Polym. Sci. 2007, 103, 1226–1231. [Google Scholar] [CrossRef]

- Thielemans, W.; Wool, R.P. Lignin Esters for Use in Unsaturated Thermosets: Lignin Modification and Solubility Modeling. Biomacromolecules 2005, 6, 1895–1905. [Google Scholar] [CrossRef] [PubMed]

- Sailaja, R.R.N.; Deepthi, M.V. Mechanical and thermal properties of compatibilized composites of polyethylene and esterified lignin. Mater. Des. 2010, 31, 4369–4379. [Google Scholar] [CrossRef]

- Nirmal, U.; Hashim, J.; Ahmad, M.M.H.M. A review on tribological performance of natural fibre polymeric composites. Tribol. Int. 2015, 83, 77–104. [Google Scholar] [CrossRef]

- Omrani, E.; Menezes, P.L.; Rohatgi, P.K. State of the art on tribological behavior of polymer matrix composites reinforced with natural fibers in the green materials world. Eng. Sci. Technol. 2016, 19, 717–736. [Google Scholar] [CrossRef]

- Guofang, G.; Huayong, Y.; Xin, F. Tribological properties of kaolin filled UHMWPE composites in unlubricated sliding. Wear 2004, 256, 88–94. [Google Scholar] [CrossRef]

- Pettarin, V.; Churruca, M.J.; Felhos, D.; Karger-Kocsis, J.; Frontini, P.M. Changes in tribological performance of high molecular weight high density polyethylene induced by the addition of molybdenum disulphide particles. Wear 2010, 269, 31–45. [Google Scholar] [CrossRef]

- Gupta, S.; Riyad, M.F. Synthesis and tribological behavior of novel UHMWPE-Ti3SiC2 composites. Polym Compos. 2016. [Google Scholar] [CrossRef]

- Meyers, M.A.; Chawla, K.K. Mechanical Behavior of Materials; Prentice-Hall: Upper Saddle River, NJ, USA, 1999. [Google Scholar]

- Wang, Y.Q.; Li, J. Sliding wear behavior and mechanism of ultra-high molecular weight polyethylene. Mater. Sci. Eng. 1999, A266, 155–160. [Google Scholar] [CrossRef]

- Bahadur, S. The development of transfer layers and their role in polymer tribology. Wear 2000, 245, 92–99. [Google Scholar] [CrossRef]

- Yu, L.; Bahadur, S. An investigation of the friction and wear behaviors of ceramic particle filled polyphenylene sulfide composites. Wear 1998, 214, 54–63. [Google Scholar] [CrossRef]

| Surface | Countersurface | Filler | Conditions | WR (mm3/N.m) | µ | Reference |

|---|---|---|---|---|---|---|

| 0 | 11 × 10−6 | 0.3 | [26] | |||

| 11 wt. % Kaolin (mixing) | 9 × 10−6 | 0.31 | ||||

| ASTM 1045 Steel (Ring) | UHMWPE (Block) | 26.5 wt. % Kaolin (mixing) | Block-on-Ring, 105 N, and 0.42 m/s | 11 × 10−6 | 0.31 | |

| 11 wt. % Kaolin (polymerization) | 6 × 10−6 | 0.28 | ||||

| 26.5 wt. % Kaolin (polymerization) | 7 × 10−6 | 0.31 | ||||

| 0 | 30 µm2/N ‡ | 0.1 | ||||

| 7 wt. % MoS2 | 3 µm2/N ‡ | 0.1 | [27] | |||

| 9SMnPb28k type steel | UHMWPE (Plate) | 9 wt. % MoS2 | Roller-on-Plate, 40 N, and 0.25 m/s | 0.5 µm2/N ‡ | 0.1 | |

| (Roller) | 17 wt. % MoS2 | 20 µm2/N ‡ | 0.12 | |||

| 25 wt. % MoS2 | 70 µm2/N ‡ | 0.18 | ||||

| UHMWPE | 0 | 1.5 × 10−6 | 0.22 | |||

| UHMWPE-5% Ti3SiC2 (Tab) | Alumina (Disc) | 5 vol % Ti3SiC2 | Tab-on-Disc, 5 N, 50 cm/s | 2 × 10−6 | 0.19 | [28] |

| UHMWPE-20% Ti3SiC2 (Tab) | 20 vol % Ti3SiC2 | 3.4 × 10−6 | 0.22 | |||

| UHMWPE-35% Ti3SiC2 (Tab) | 35 vol % Ti3SiC2 | 12 × 10−6 | 0.20 |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gupta, S.; Riyad, M.F.; Ji, Y. Synthesis and Tribological Behavior of Ultra High Molecular Weight Polyethylene (UHMWPE)-Lignin Composites. Lubricants 2016, 4, 31. https://doi.org/10.3390/lubricants4030031

Gupta S, Riyad MF, Ji Y. Synthesis and Tribological Behavior of Ultra High Molecular Weight Polyethylene (UHMWPE)-Lignin Composites. Lubricants. 2016; 4(3):31. https://doi.org/10.3390/lubricants4030031

Chicago/Turabian StyleGupta, Surojit, M. F. Riyad, and Yun Ji. 2016. "Synthesis and Tribological Behavior of Ultra High Molecular Weight Polyethylene (UHMWPE)-Lignin Composites" Lubricants 4, no. 3: 31. https://doi.org/10.3390/lubricants4030031