Morphology Analysis of a Multilayer Single Pass via Novel Metal Thin-Wall Coating Forming

Abstract

:1. Introduction

2. Experimental Procedure

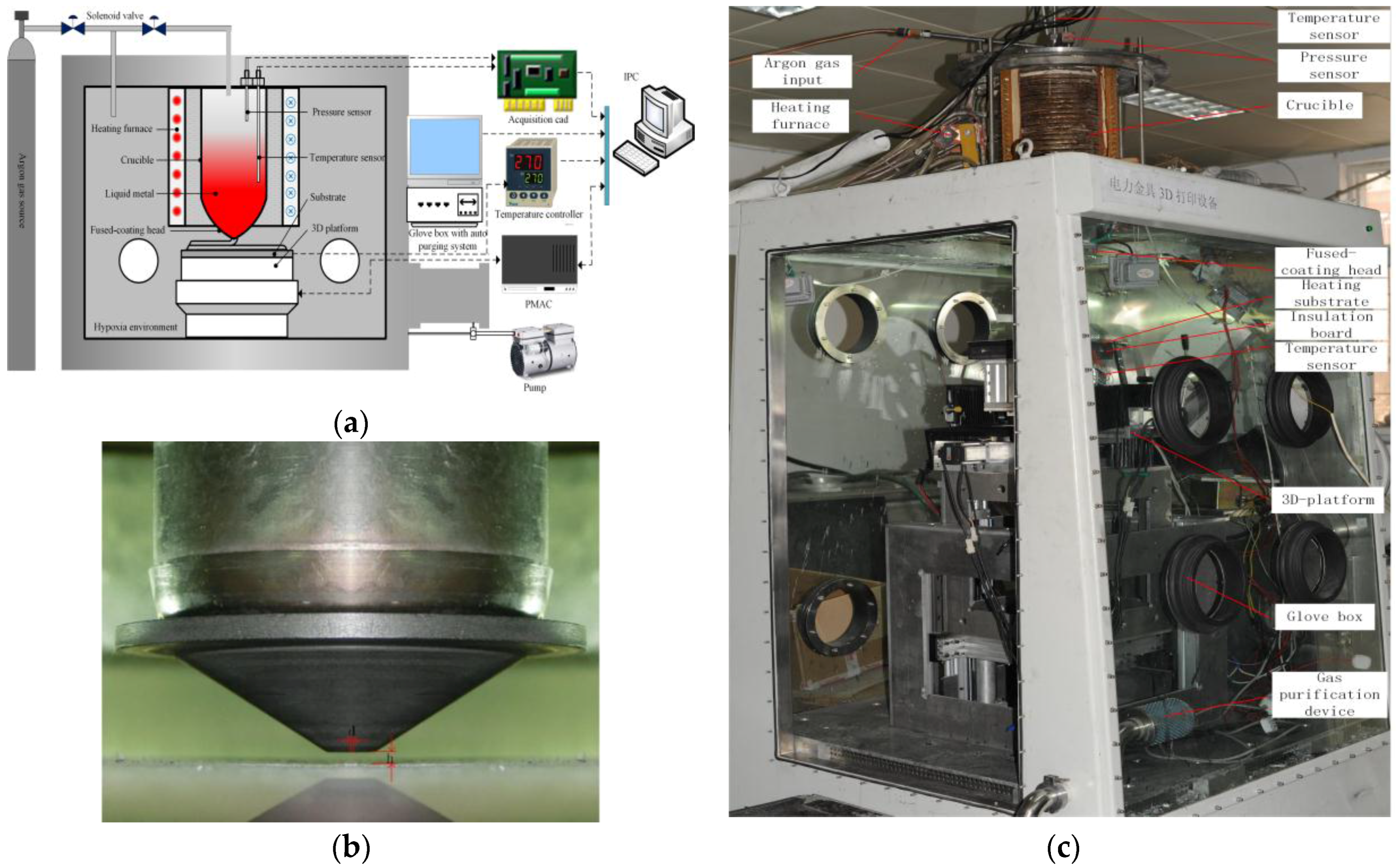

2.1. Experimental System

2.2. Arrangement of the Experiments

3. Results and Discussion

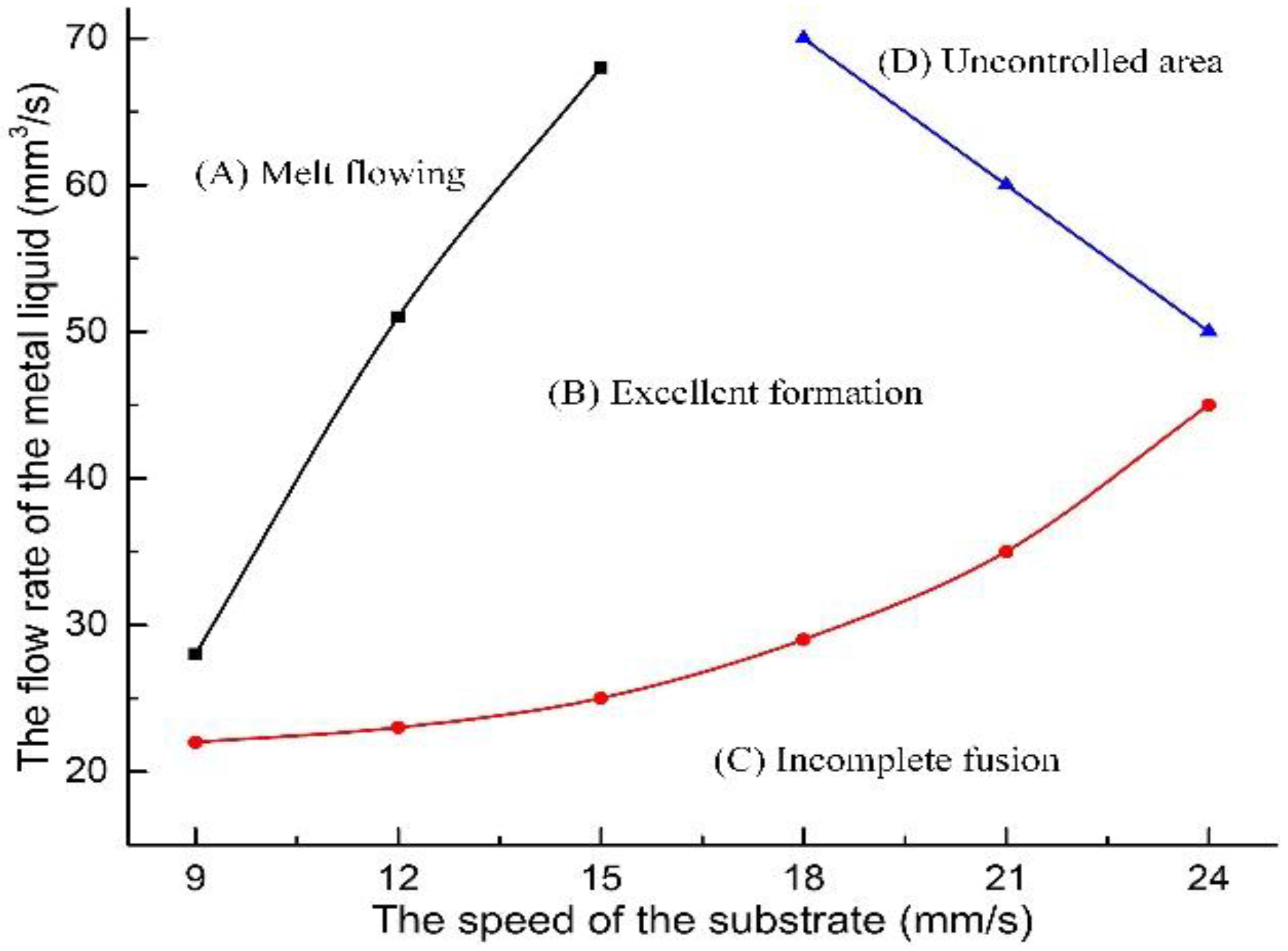

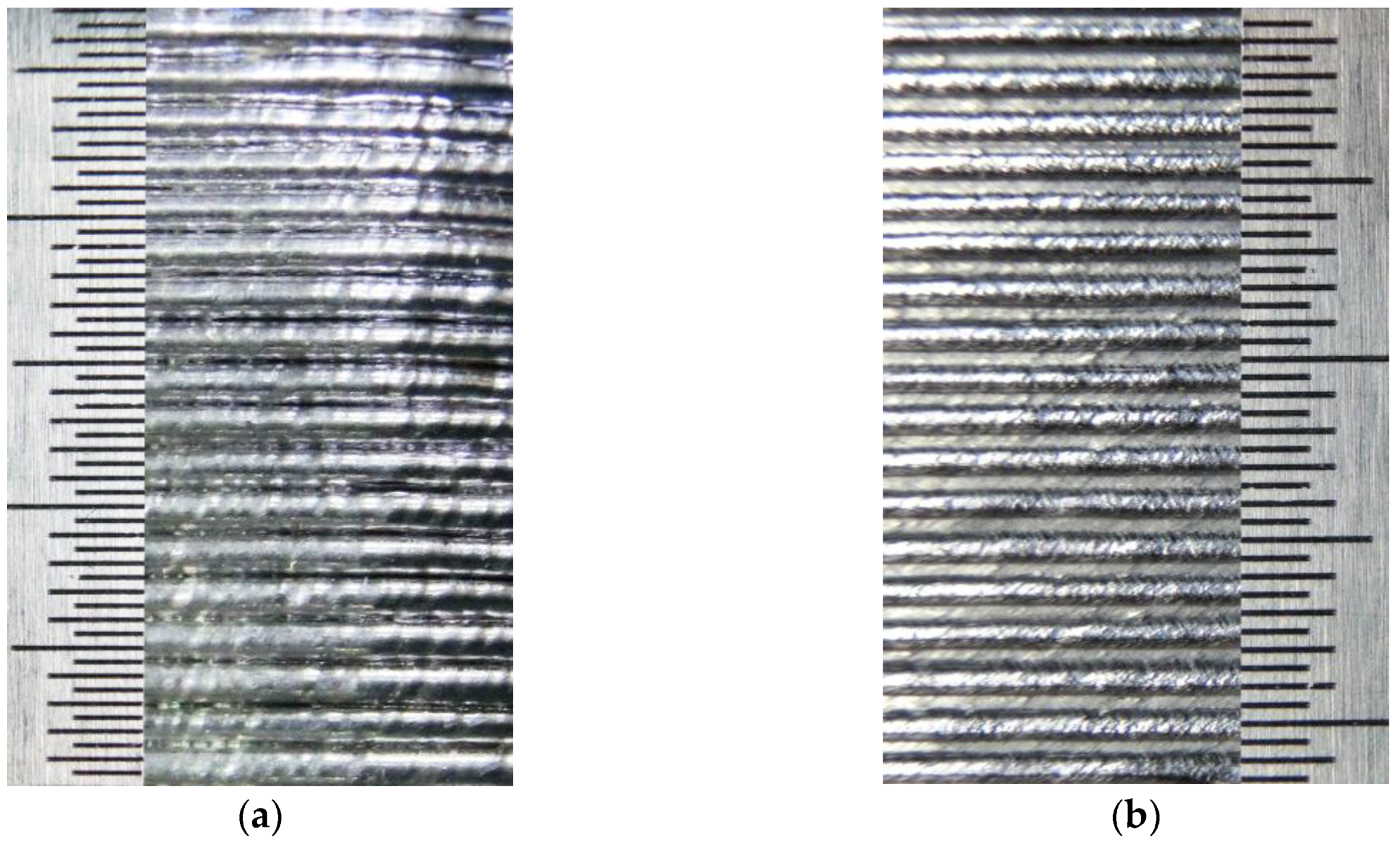

3.1. Preliminary Experiments to Determine the Process Window of SLSP

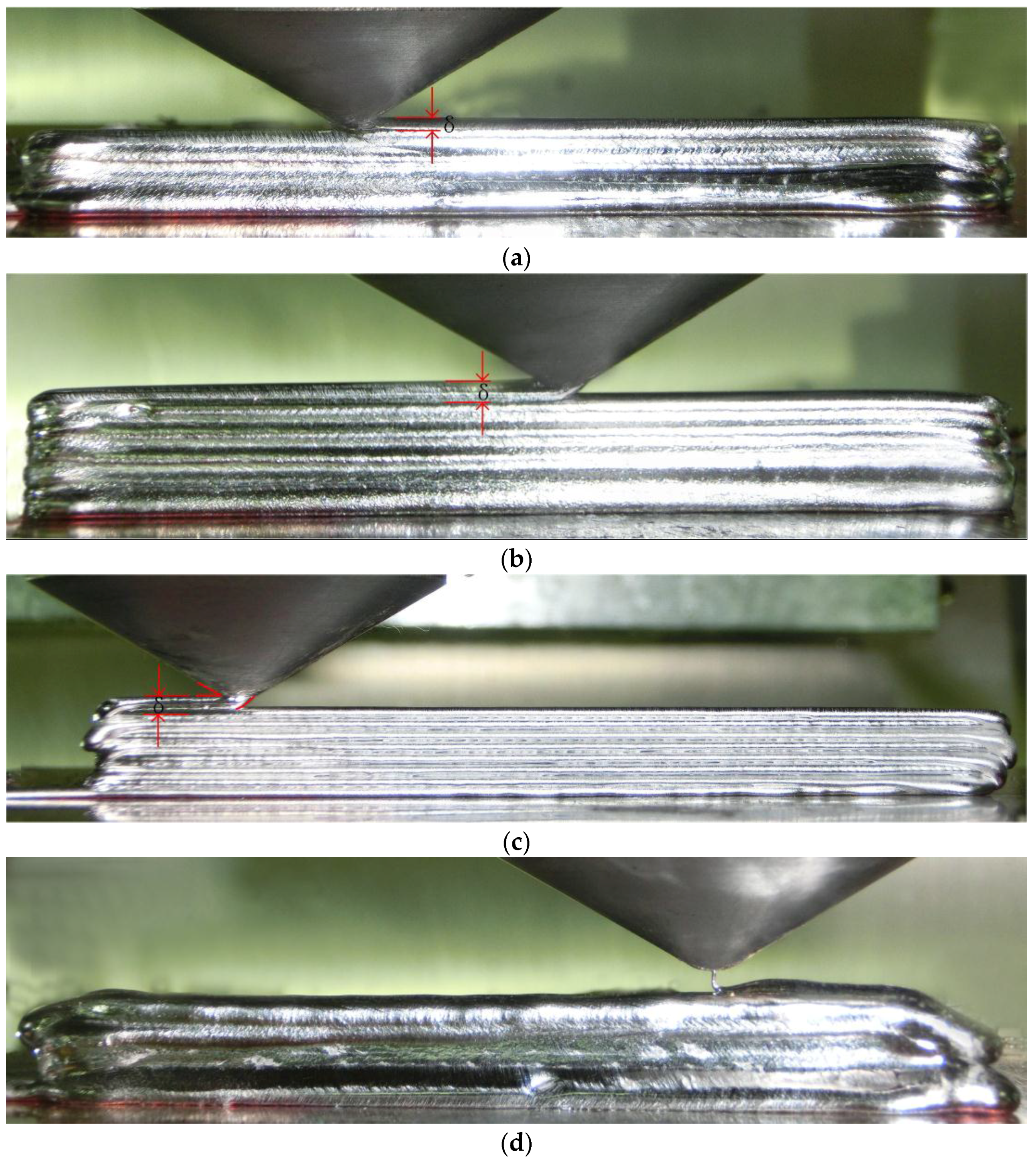

3.2. Influence of the Distance between the Nozzle and the Top Surface of the Previous Layer

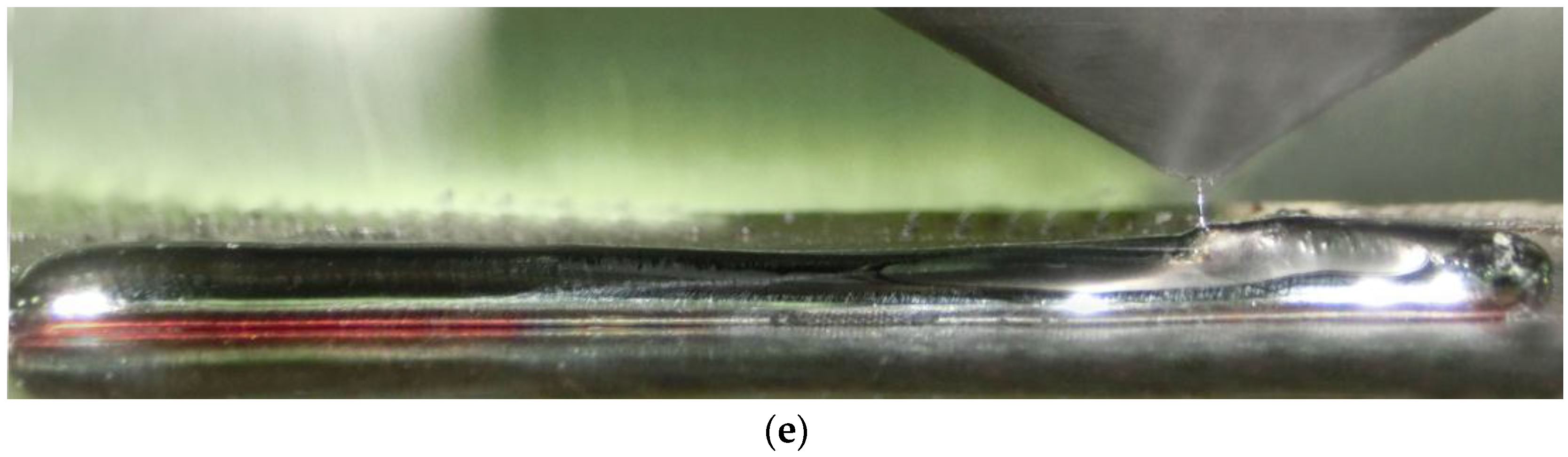

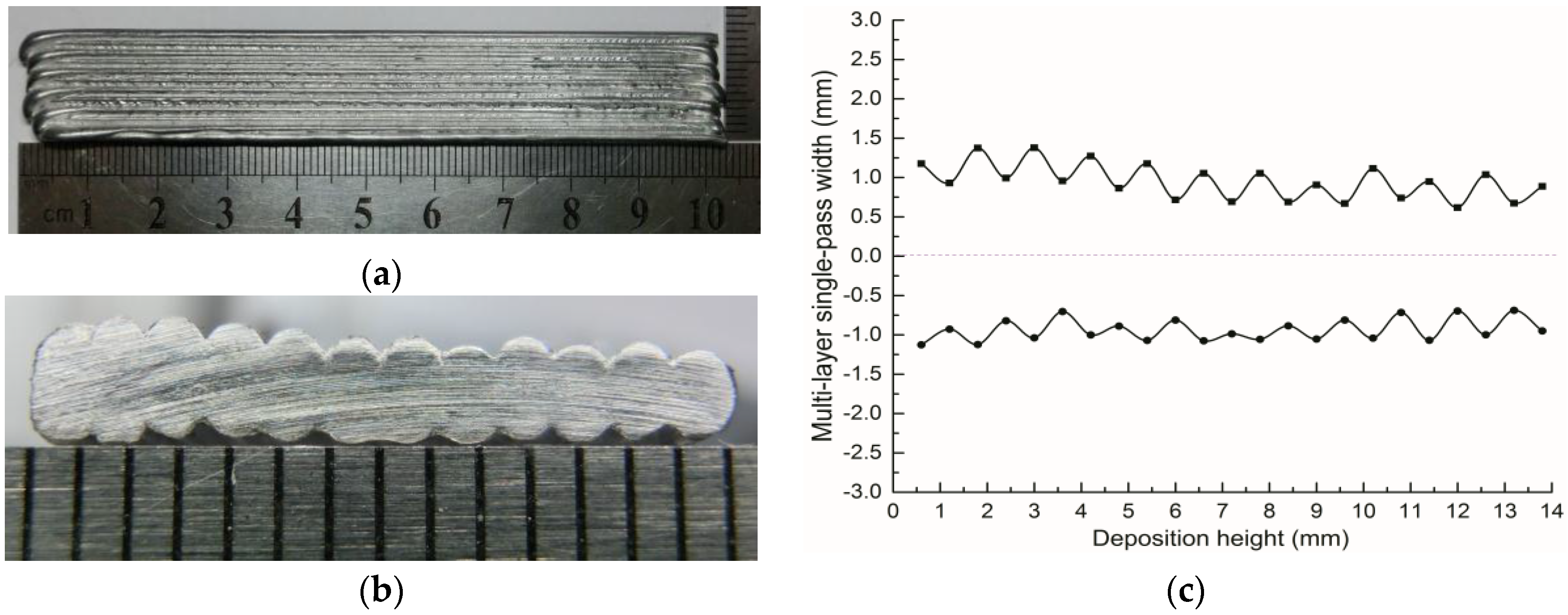

3.3. Waviness and Cross-Section Morphology Analysis of Thin-Walled Specimens

4. Conclusions

- The MCMAM technology is considered an economical and effective forming process. The forming efficiency of the MCMAM up to 50 mm3/s (viz. 1490 g/h) is doubled, compared to the metal droplet deposition.

- The layer thickness is one of the major factors, influencing the forming morphology. The forming morphology of the thin-wall specimen is relatively the best when the layer thickness is set to 1.2 mm, and the metallurgical bonding of the adjacent layers can be obtained.

- The waviness was used to analyze the forming morphology of the thin-walled specimen. The values of the surface waviness indexes are Wa = 0.9448, Wq = 0.963, and Wz = 0.303 when the layer thickness is 1.2 mm.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Beaman, J.J.; Deckard, C.R. Selective Laser Sintering with Assisted Powder Handling. U.S. Patent 4938816, 1990. [Google Scholar]

- Arcella, F.G.; Froes, F.H. Producing titanium aerospace components from powder using laser forming. JOM 2000, 52, 2–30. [Google Scholar] [CrossRef]

- Clare, A.T.; Chalker, P.R.; Davies, S.; Sutcliffe, C.J.; Tsopanos, S. Selective laser melting of high aspect ratio 3D nickel–titanium structures two way trained for MEMS applications. Int. J. Mech. Mater. Des. 2008, 4, 181–187. [Google Scholar] [CrossRef]

- Aiyiti, W. Investigation of the overlapping parameters of MPAW-based rapid prototyping. Rapid Prototyp. J. 2006, 12, 165–172. [Google Scholar] [CrossRef]

- Xiong, J.; Zhang, G.; Zhang, W. Forming appearance analysis in multi-layer single-pass GMAW-based additive manufacturing. Int. J. Adv. Manuf. Technol. 2015, 80, 1767–1776. [Google Scholar] [CrossRef]

- Heralic, A.; Christiansson, A.K.; Ottosson, M.; Lennartson, B. Increased stability in laser metal wire deposition through feedbackfrom optical measurements. Opt. Lasers Eng. 2010, 48, 478–485. [Google Scholar] [CrossRef]

- Xiong, J.; Zhang, G. Adaptive control of deposited height in GMAW-based layer additive manufacturing. J. Mater. Process. Technol. 2014, 214, 962–968. [Google Scholar] [CrossRef]

- Mireles, J.; Espalin, D.; Roberson, D.A.; Zinniel, B.; Medina, F.; Wicker, R. Fused Deposition Modeling of Metals. In Proceedings of the Solid Freeform Fabrication Symposium, Austin, TX, USA, 6–8 August 2012; pp. 836–845.

- Yao, Y.; Gao, S.; Cui, C. Rapid prototyping based on uniform droplet spraying. J. Mater. Process. Technol. 2004, 146, 389–395. [Google Scholar]

- Du, J.; Wei, Z.; Wang, X.; Fang, X.; Zhao, G. A novel high-efficiency methodology for metal additive manufacturing. Appl. Phys. A 2016, 122, 945. [Google Scholar] [CrossRef]

| Property and Parameter | Value |

|---|---|

| Coating head temperature | 270 °C |

| Heating substrate | 90 °C |

| Argon mass flowmeter | 20–70 mm3/s |

| Deposition velocity | 9–24 mm/s |

| Initial distance | 1.6 mm |

| Layer thickness | 0.9–2.1 mm |

| Coating nozzle | 0.3 mm |

| Pressure | 100 KPa |

| Glove box | Ar (99.999%) (20 ppm) |

| Size of copper-clad substrate | 300 mm × 200 mm × 10 mm |

| SLSP deposited length | 130 mm |

| multilayer single pass deposited length | 100 mm |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, X.; Du, J.; Wei, Z.; Fang, X.; Zhao, G.; Bai, H.; Liu, W.; Ren, C.; Yao, Y. Morphology Analysis of a Multilayer Single Pass via Novel Metal Thin-Wall Coating Forming. Metals 2016, 6, 313. https://doi.org/10.3390/met6120313

Wang X, Du J, Wei Z, Fang X, Zhao G, Bai H, Liu W, Ren C, Yao Y. Morphology Analysis of a Multilayer Single Pass via Novel Metal Thin-Wall Coating Forming. Metals. 2016; 6(12):313. https://doi.org/10.3390/met6120313

Chicago/Turabian StyleWang, Xin, Jun Du, Zhengying Wei, Xuewei Fang, Guangxi Zhao, Hao Bai, Wei Liu, Chuanqi Ren, and Yunfei Yao. 2016. "Morphology Analysis of a Multilayer Single Pass via Novel Metal Thin-Wall Coating Forming" Metals 6, no. 12: 313. https://doi.org/10.3390/met6120313