Improving Elevated-Temperature Strength of an Al–Mn–Si Alloy by Strain-Induced Precipitation

Abstract

:1. Introduction

2. Materials and Methods

3. Results

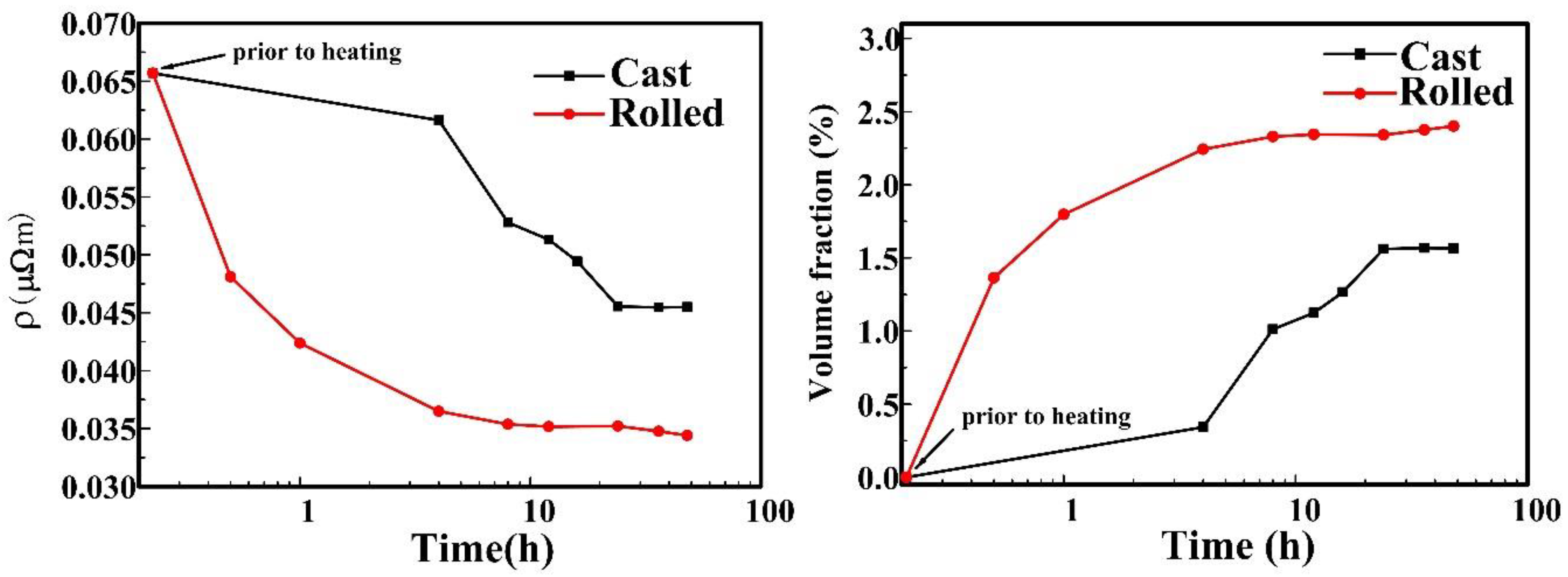

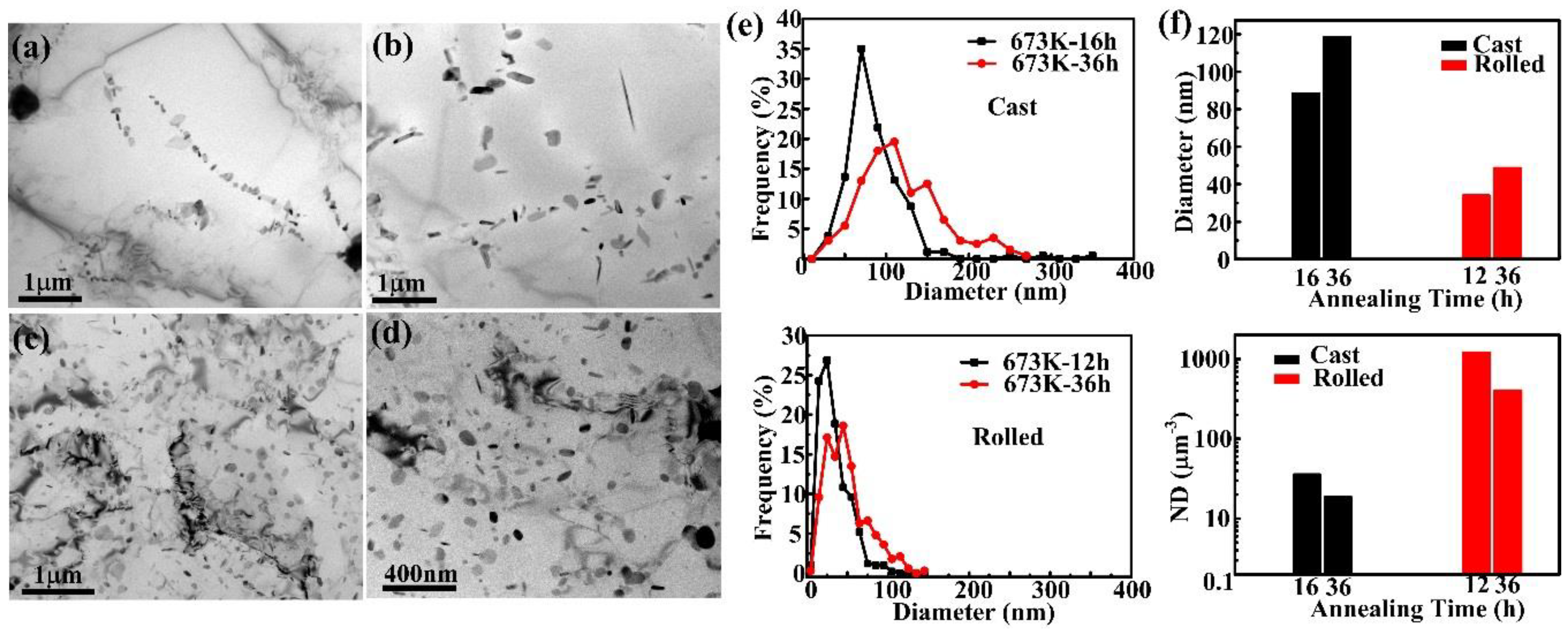

3.1. Precipitation Kinetics

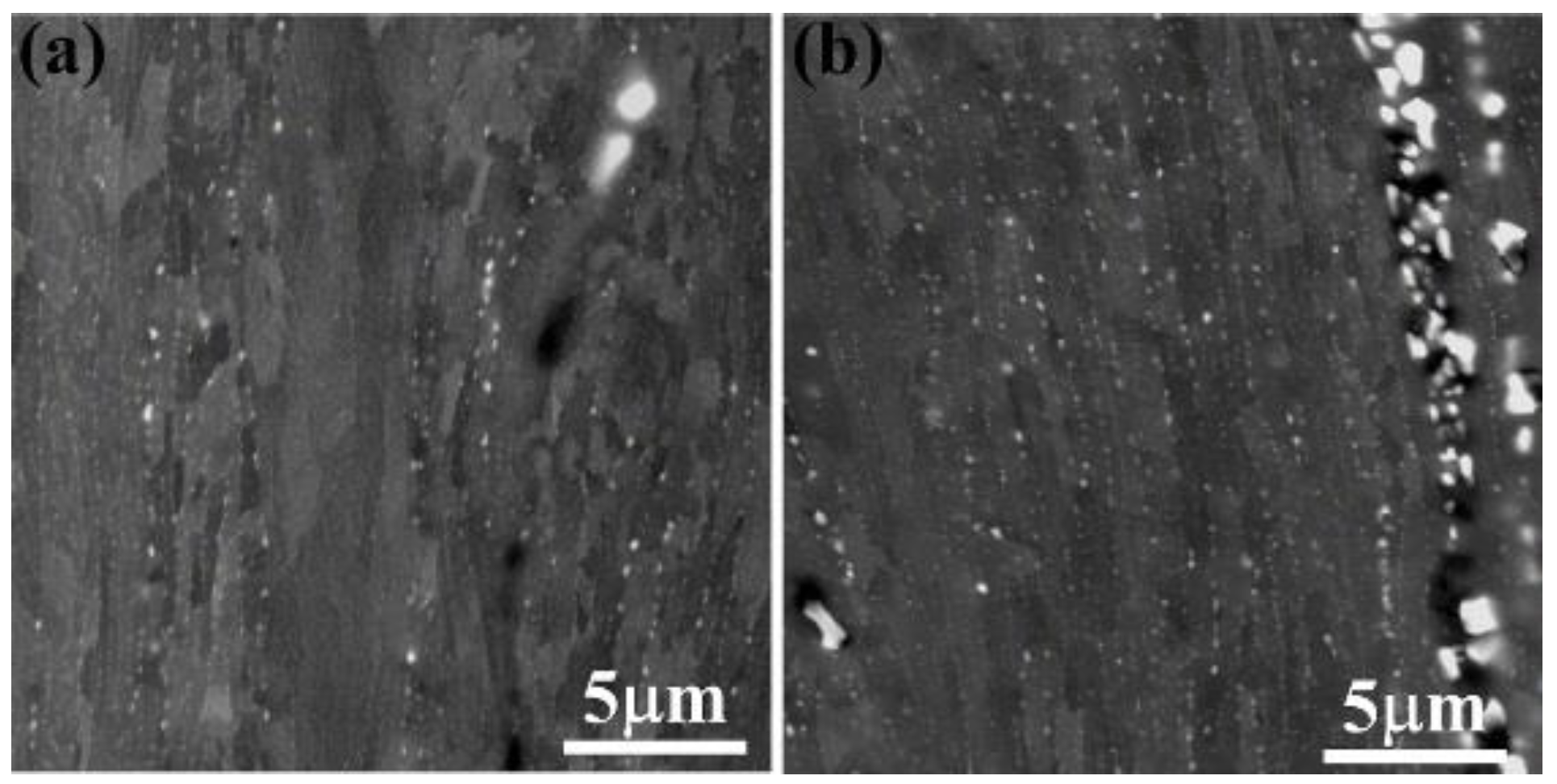

3.2. Softening of the Deformed Alloy

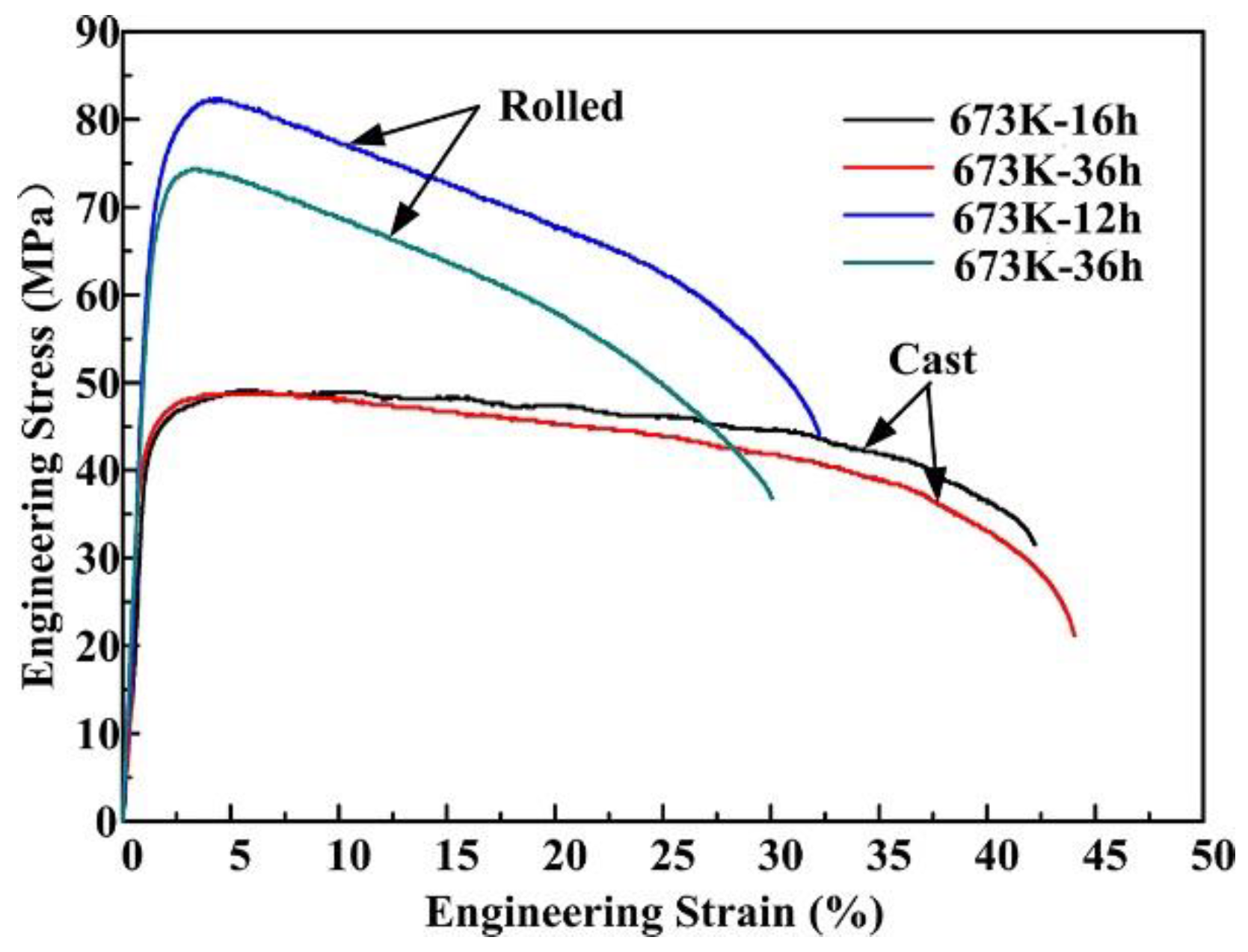

3.3. Mechanical Strength at the Elevated Temperature

4. Discussion

4.1. Thermal Stability of Strain-Induced Precipitates and Substructure

4.2. Strengthening Effect

5. Conclusions

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Kahl, S.; EkströM, H.E.; Mendoza, J. Tensile, Fatigue, and Creep Properties of Aluminum Heat Exchanger Tube Alloys for Temperatures from 293 K to 573 K (20 °C to 300 °C). Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 2014, 45, 663–681. [Google Scholar] [CrossRef]

- Liu, K.; Chen, X.-G. Development of Al-Mn-Mg 3004 alloy for applications at elevated temperature via dispersoid strengthening. Mater. Des. 2015, 84, 340–350. [Google Scholar] [CrossRef]

- Li, Y.J.; Arnberg, L. Quantitative study on the precipitation behavior of dispersoids in DC-cast AA3003 alloy during heating and homogenization. Acta Mater. 2003, 51, 3415–3428. [Google Scholar] [CrossRef]

- Li, Y.J.; Muggerud, A.M.F.; Olsen, A.; Furu, T. Precipitation of partially coherent α-Al(Mn,Fe)Si dispersoids and their strengthening effect in AA 3003 alloy. Acta Mater. 2012, 60, 1004–1014. [Google Scholar] [CrossRef]

- Muggerud, A.M.F.; Mørtsell, E.A.; Li, Y.; Holmestad, R. Dispersoid strengthening in AA3xxx alloys with varying Mn and Si content during annealing at low temperatures. Mater. Sci. Eng. A 2013, 567, 21–28. [Google Scholar] [CrossRef]

- Pettersen, T.; Li, Y.J.; Furu, T.; Marthinsen, K. Effect of Changing Homogenization Treatment on the Particle Structure in Mn-Containing Aluminium Alloys. Mater. Sci. Forum 2007, 558–559, 301–306. [Google Scholar] [CrossRef]

- Huang, H.W.; Ou, B.L. Evolution of precipitation during different homogenization treatments in a 3003 aluminum alloy. Mater. Des. 2009, 30, 2685–2692. [Google Scholar] [CrossRef]

- Wang, N.; Huang, K.; Li, Y.; Marthinsen, K. The Influence of Processing Conditions on Microchemistry and the Softening Behavior of Cold Rolled Al-Mn-Fe-Si Alloys. Metals 2016, 6, 61. [Google Scholar] [CrossRef]

- Liu, K.; Chen, X.-G. Evolution of Intermetallics, Dispersoids, and Elevated Temperature Properties at Various Fe Contents in Al-Mn-Mg 3004 Alloys. Metall. Mater. Trans. B 2016, 47, 3291–3300. [Google Scholar] [CrossRef]

- Liu, K.; Chen, X.-G. Evolution of microstructure and elevated-temperature properties with Mn addition in Al-Mn-Mg alloys. J. Mater. Res. 2017, 32, 2585–2593. [Google Scholar] [CrossRef]

- Li, Z.; Zhang, Z.; Chen, X.-G. Effect of magnesium on dispersoid strengthening of Al-Mn-Mg-Si (3xxx) alloys. Trans. Nonferrous Met. Soc. China 2016, 26, 2793–2799. [Google Scholar] [CrossRef]

- Liu, K.; Ma, H.; Chen, X.G. Enhanced elevated-temperature properties via Mo addition in Al-Mn-Mg 3004 alloy. J. Alloys Compd. 2017, 694, 354–365. [Google Scholar] [CrossRef] [Green Version]

- Li, Z.; Zhang, Z.; Chen, X.-G. The Influence of Cu Addition on Dispersoid Formation and Mechanical Properties of Al-Mn-Mg 3004 Alloy. Metals 2018, 8, 155. [Google Scholar] [CrossRef]

- Shojaei, K.; Sajadifar, S.V.; Yapici, G.G. On the mechanical behavior of cold deformed aluminum 7075 alloy at elevated temperatures. Mater. Sci. Eng. A 2016, 670, 81–89. [Google Scholar] [CrossRef]

- Orozco-Caballero, A.; Menon, S.K.; Cepeda-Jiménez, C.M.; Hidalgo-Manrique, P.; McNelley, T.R.; Ruano, O.A.; Carreño, F. Influence of microstructural stability on the creep mechanism of Al-7wt.% Si alloy processed by equal channel angular pressing. Mater. Sci. Eng. A 2014, 612, 162–171. [Google Scholar] [CrossRef] [Green Version]

- Zhao, Q.; Zhang, H.; Zhang, X.; Qiu, F.; Jiang, Q. Enhanced elevated-temperature mechanical properties of Al-Mn-Mg containing TiC nano-particles by pre-strain and concurrent precipitation. Mater. Sci. Eng. A 2018, 718, 305–310. [Google Scholar] [CrossRef]

- Zhao, Q.; Zhang, H.; Qiu, F.; Jiang, Q. Strain-induced precipitation kinetics during non-isothermal annealing of Al-Mn alloys. J. Alloys Compd. 2018, 735, 2275–2280. [Google Scholar] [CrossRef]

- Lifshitz, I.M.; Slyozov, V.V. The kinetics of precipitation from supersaturated solid solutions. J. Phys. Chem. Solids 1961, 19, 35–50. [Google Scholar] [CrossRef]

- Du, Y.; Chang, Y.A.; Huang, B.; Gong, W.; Jin, Z.; Xu, H.; Yuan, Z.; Liu, Y.; He, Y.; Xie, F.-Y. Diffusion coefficients of some solutes in fcc and liquid Al: Critical evaluation and correlation. Mater. Sci. Eng. A 2003, 363, 140–151. [Google Scholar] [CrossRef]

- Nes, E.; Ryum, N.; Hunderi, O. On the Zener drag. Acta Metall. 1985, 33, 11–22. [Google Scholar] [CrossRef]

- Brown, L.M.; Ham, R.K. Dislocation-particle interactions. In Strengthening Methods in Crystals; Kelly, A., Nicholson, R.B., Eds.; Elsevier: Amsterdam, The Netherlands, 1971; pp. 9–135. [Google Scholar]

- Zhao, Q.; Holmedal, B.; Li, Y. Influence of dispersoids on microstructure evolution and work hardening of aluminium alloys during tension and cold rolling. Philos. Mag. 2013, 93, 2995–3011. [Google Scholar] [CrossRef]

- Arzt, E. Size effects in materials due to microstructural and dimensional constraints: A comparative review. Acta Mater. 1998, 46, 5611–5626. [Google Scholar] [CrossRef]

- Arzt, E. Creep of Dispersion Strengthened Materials: A Critical Assessment. Res. Mech. 1991, 31, 399–453. [Google Scholar]

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Y.; Jin, W.; Hao, X.; Qiu, F.; Zhao, Q. Improving Elevated-Temperature Strength of an Al–Mn–Si Alloy by Strain-Induced Precipitation. Metals 2018, 8, 446. https://doi.org/10.3390/met8060446

Zhang Y, Jin W, Hao X, Qiu F, Zhao Q. Improving Elevated-Temperature Strength of an Al–Mn–Si Alloy by Strain-Induced Precipitation. Metals. 2018; 8(6):446. https://doi.org/10.3390/met8060446

Chicago/Turabian StyleZhang, Yangyang, Wei Jin, Xuanzhang Hao, Feng Qiu, and Qinglong Zhao. 2018. "Improving Elevated-Temperature Strength of an Al–Mn–Si Alloy by Strain-Induced Precipitation" Metals 8, no. 6: 446. https://doi.org/10.3390/met8060446