Experimental Study on the Hygrothermal Behavior of a Coated Sprayed Hemp Concrete Wall

Abstract

:1. Introduction

2. Method of Hygrothermal Behavior Assessment of Multilayer Hemp Concrete Wall

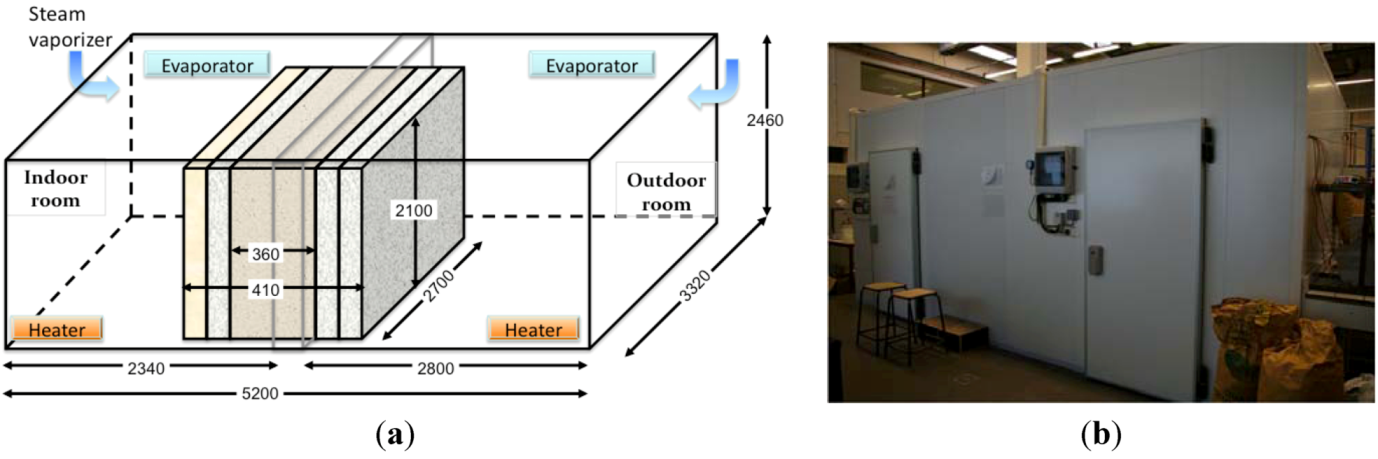

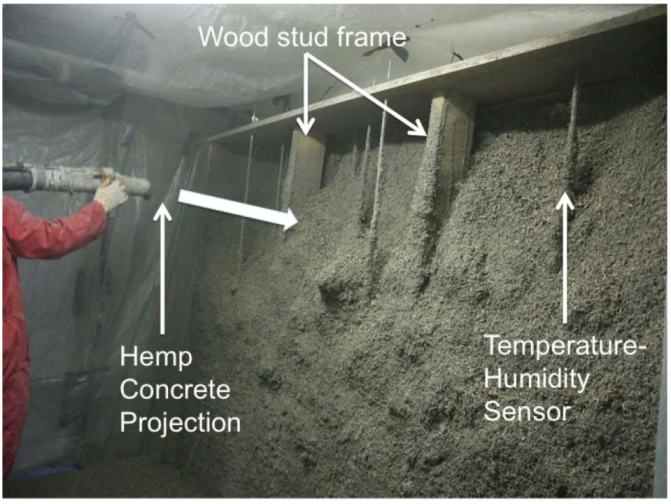

2.1. Experimental Setup: The Biclimatic Room and the Hemp Concrete Wall

| Operating parameter | Room 1 (Indoor) | Room 2 (Outdoor) | ||

| Range | Accuracy | Range | Accuracy | |

| Temperature θ | 18–27 °C | ±0.5 °C | −5–35 °C | ±1 °C |

| Relative Humidity ϕ | 30%–60% | ±2% | 30%–90% | ±2% |

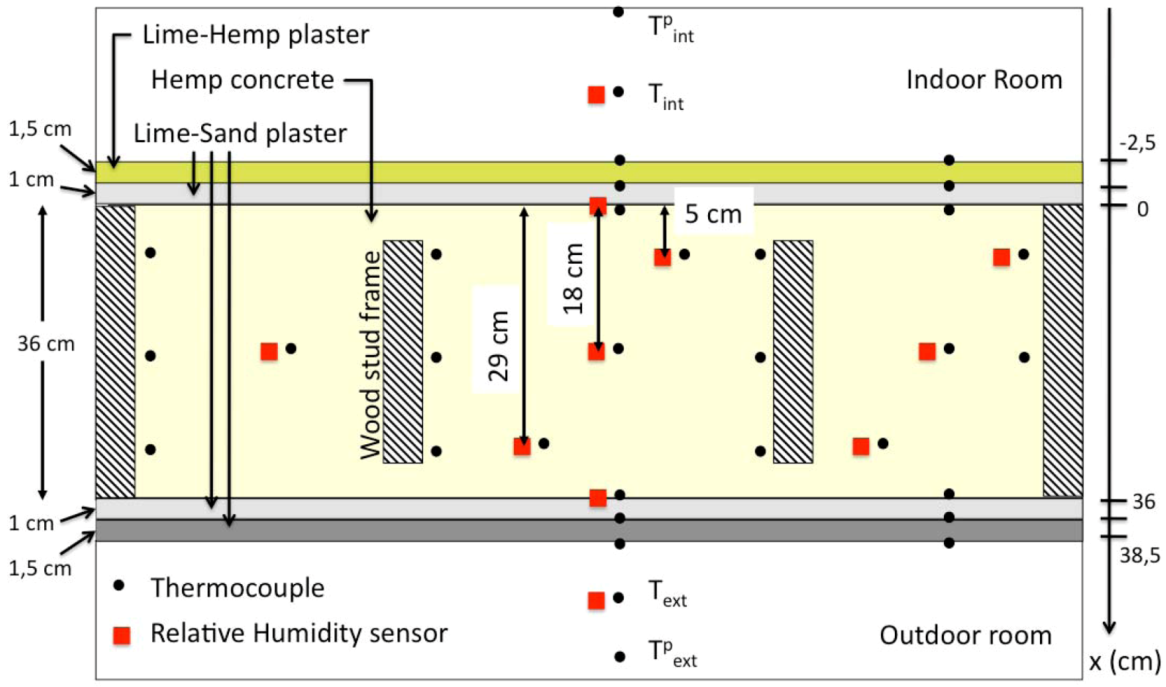

2.2. Monitoring Methods

2.3. Experimental Procedure

- Evaluate temperature and relative humidity in time and in space,

- Examine the drying stage of sprayed hemp concrete [33],

- Characterize the hygrothermal behavior of hemp concrete as function of boundary conditions,

- Investigate the influence of plasters on the hygrothermal performances of the wall.

| Operating parameter | θ [°C] | ϕ [%] | Pv [Pa] | |

|---|---|---|---|---|

| Indoor conditions | 23 | 50 | 1400 | |

| Outdoor conditions | Experiment 1 | 23 → 32 | 50 → 30 | 1400 |

| Experiment 2 | 23 → 32 | 50 | 1400 → 2360 | |

| Experiment 3 | 32 | 50 → 30 | 2360 → 1400 | |

2.4. Thermal Model

2.4.1. Heat Transfer Model

2.4.2. Boundary and Initial Conditions

3. Results and Discussion

3.1. Hygrothermal Behavior of Uncoated Hemp Concrete

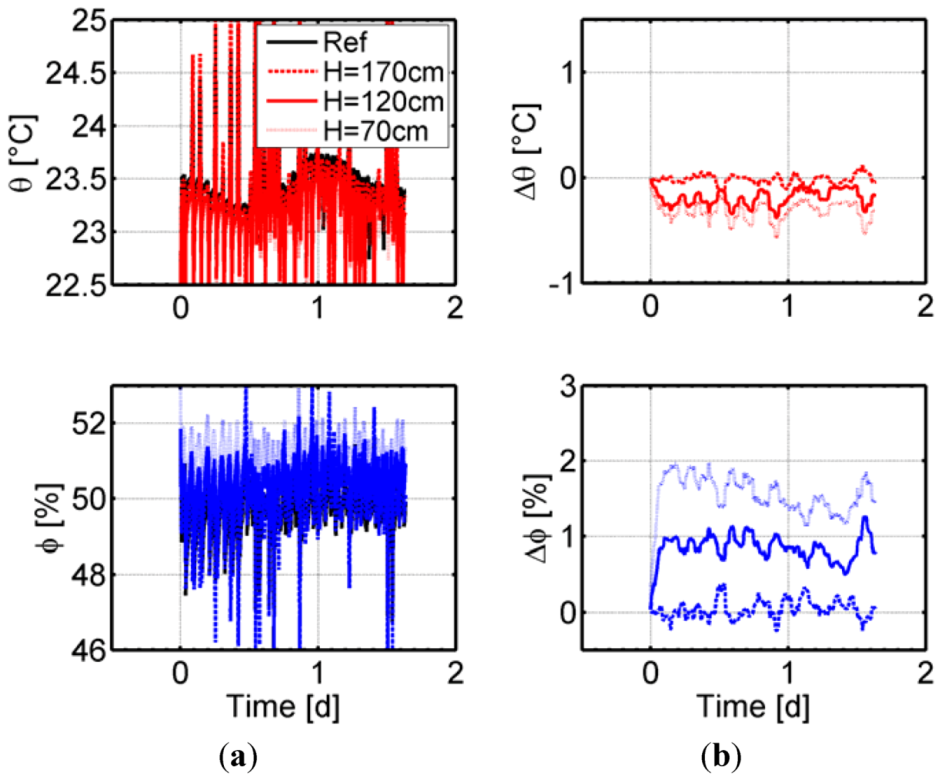

3.1.1. Evaluation of Boundary Conditions

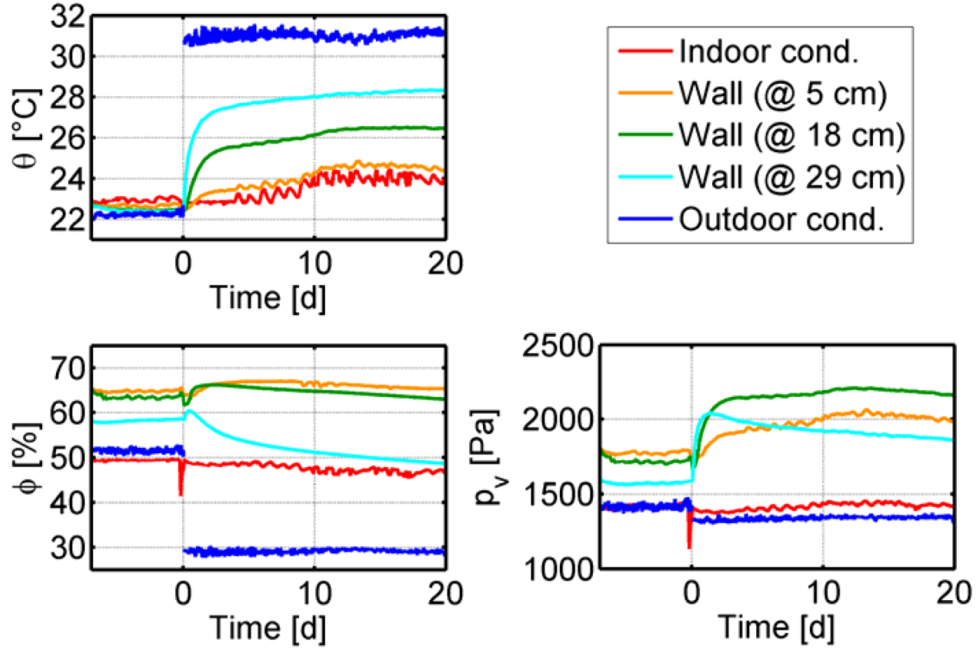

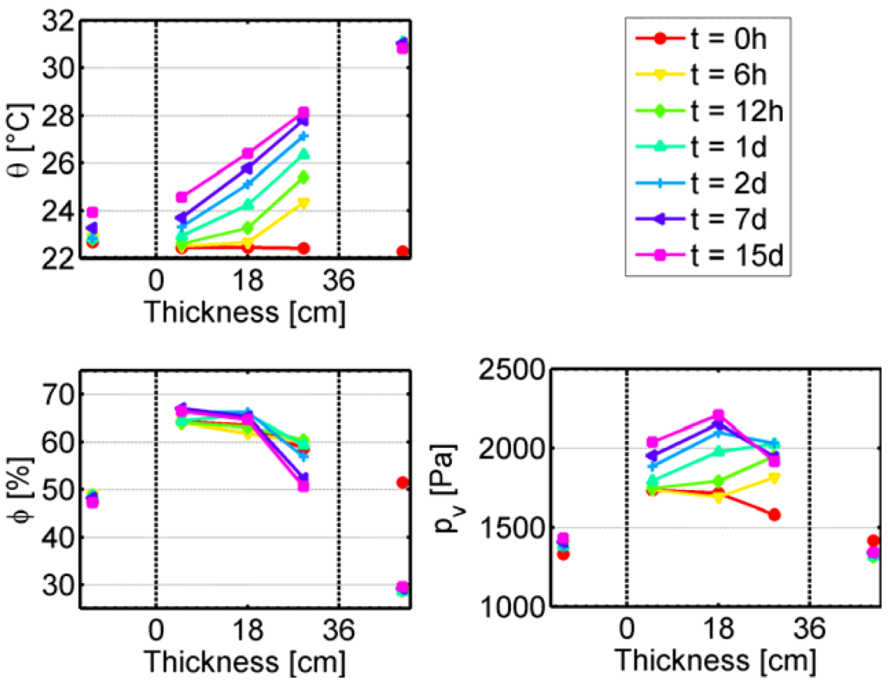

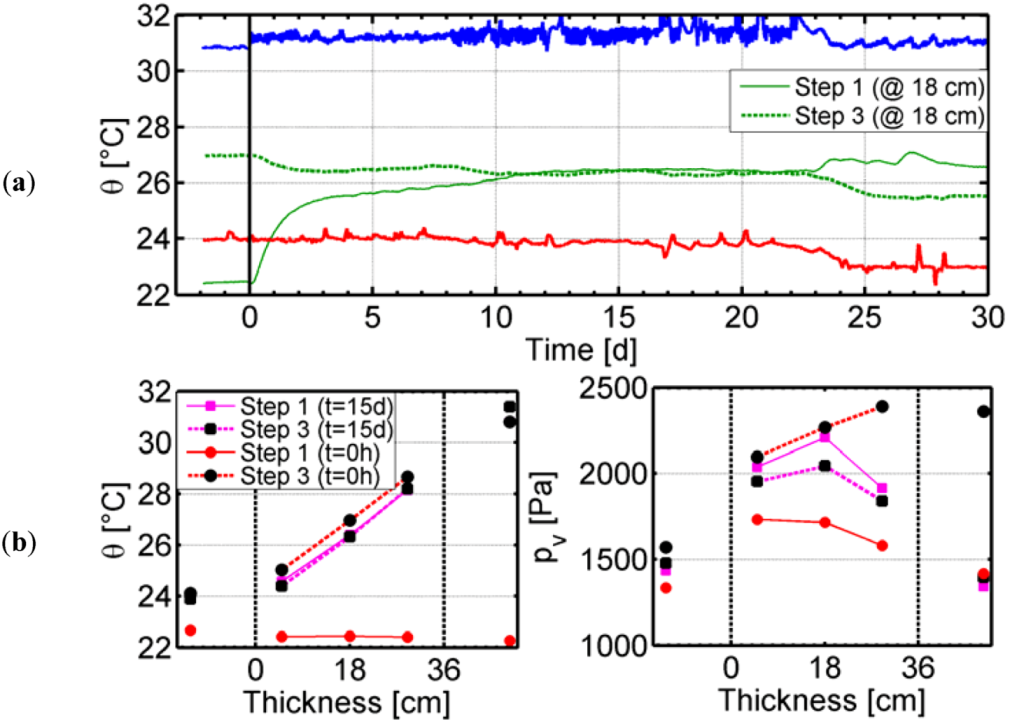

3.1.2. Experimental Response to a Temperature and Relative Humidity Gradient (Experiment 1)

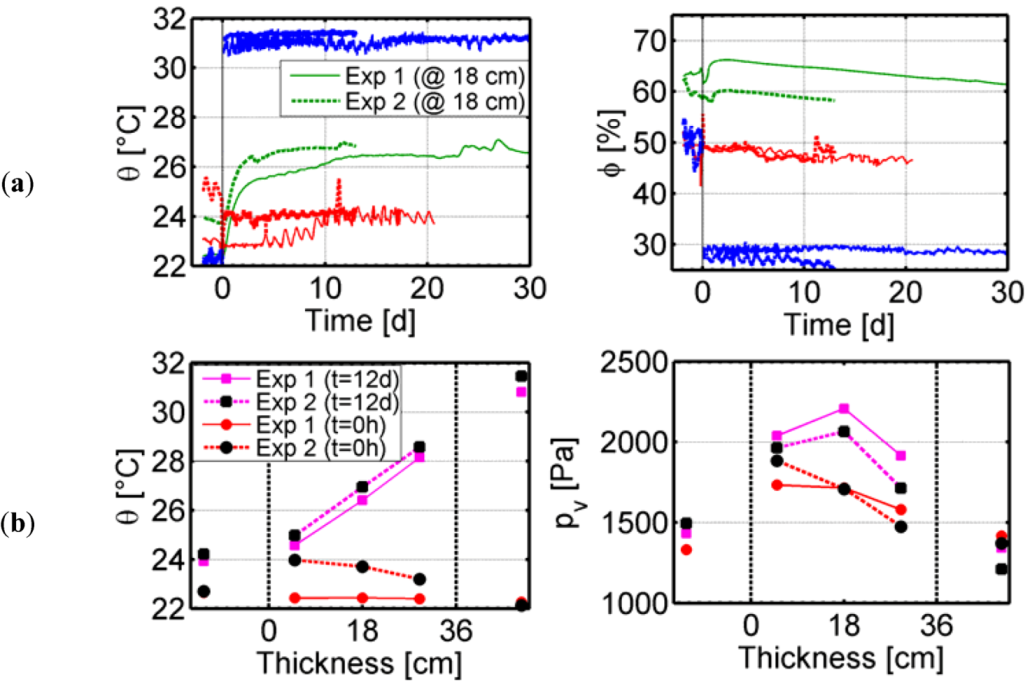

3.1.3. Experimental Response to a Temperature and Vapor Pressure Gradient (Experiments 2 and 3)

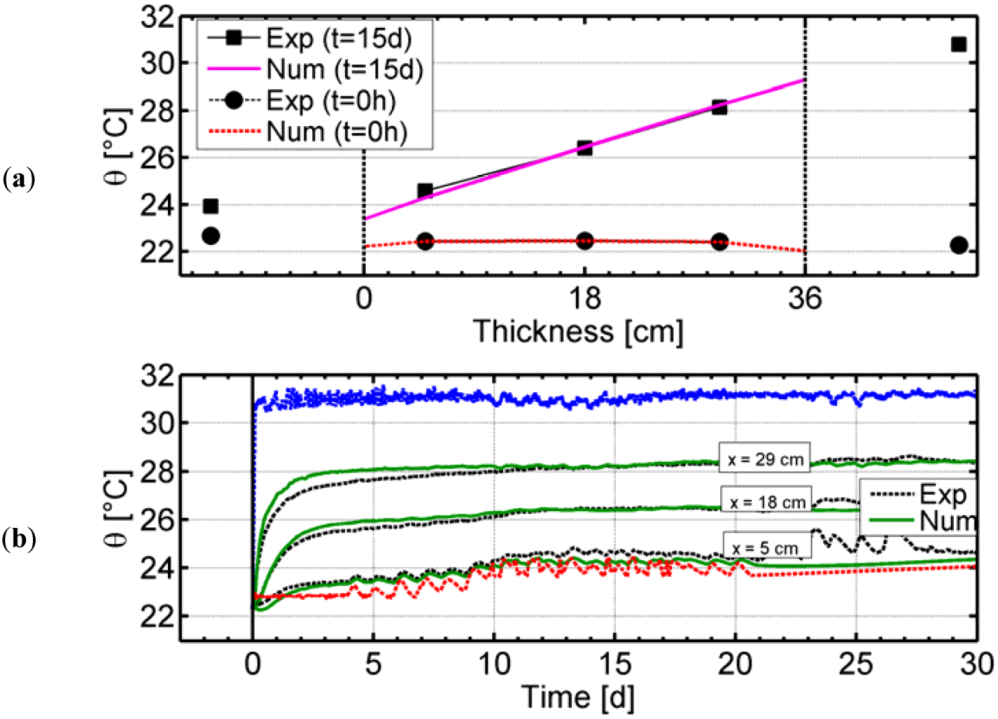

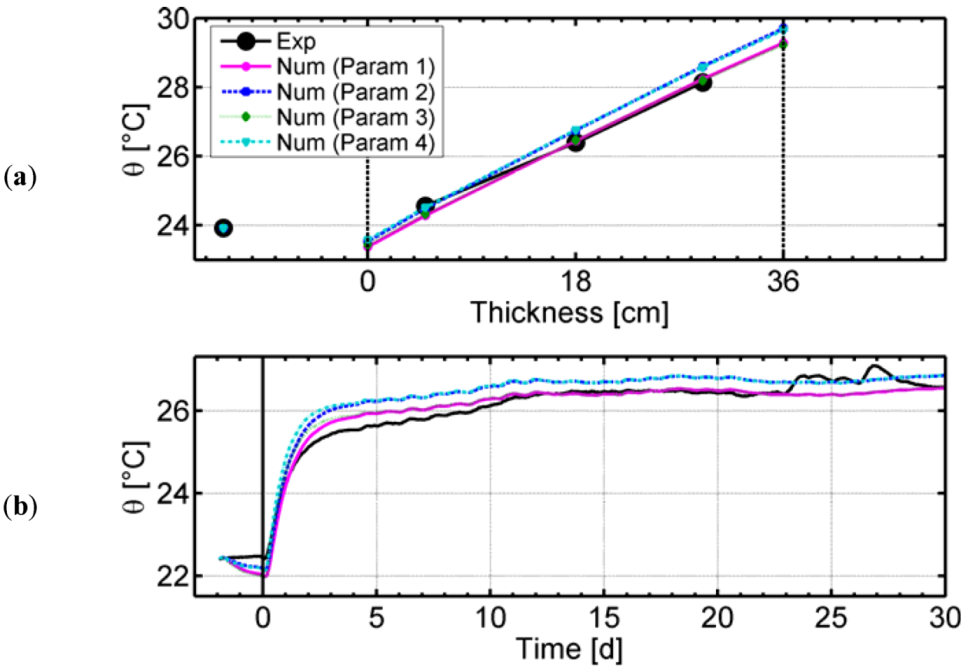

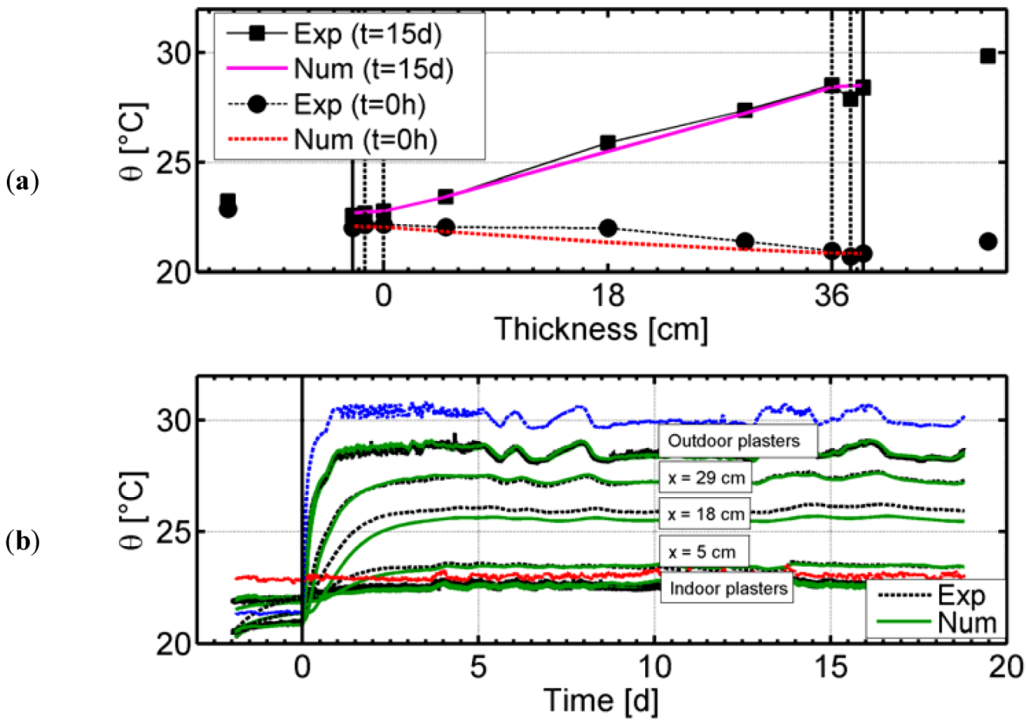

3.1.4. Comparison with Numerical Results

| Parameters | h (W·m−2·K−1) | λ (W·m−1·K−1) | a (10−7 m2·s−1) |

|---|---|---|---|

| Parameter 1 | 2 | 0.1 | 2 |

| Parameter 2 | 5 | 0.1 | 2 |

| Parameter 3 | 2 | 0.13 | 2.5 |

| Parameter 4 | 5 | 0.13 | 2.5 |

3.2. Hygrothermal Behavior of Coated Hemp Concrete

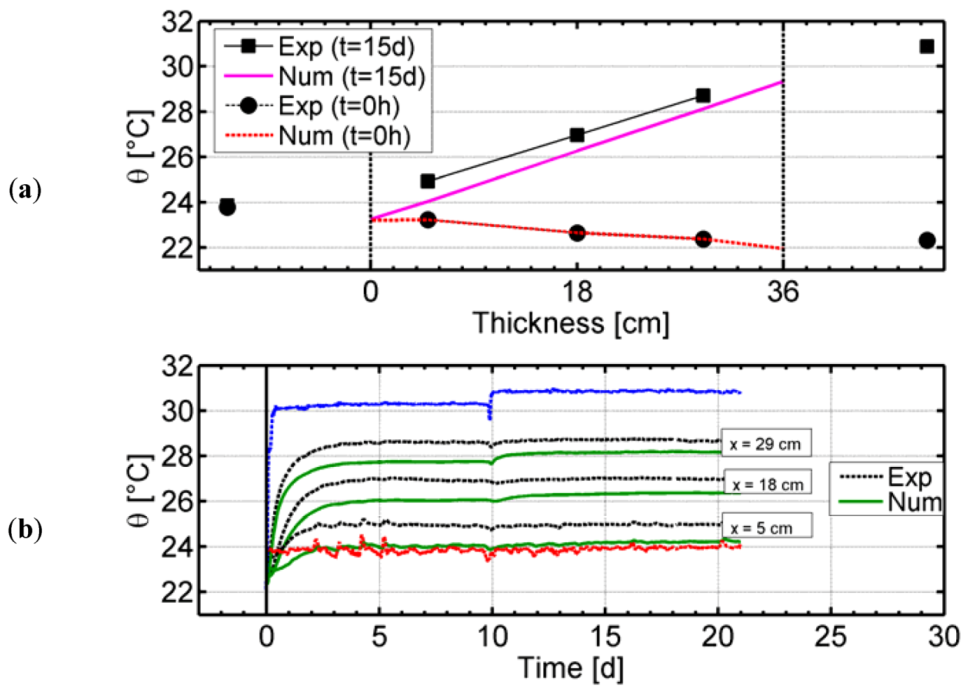

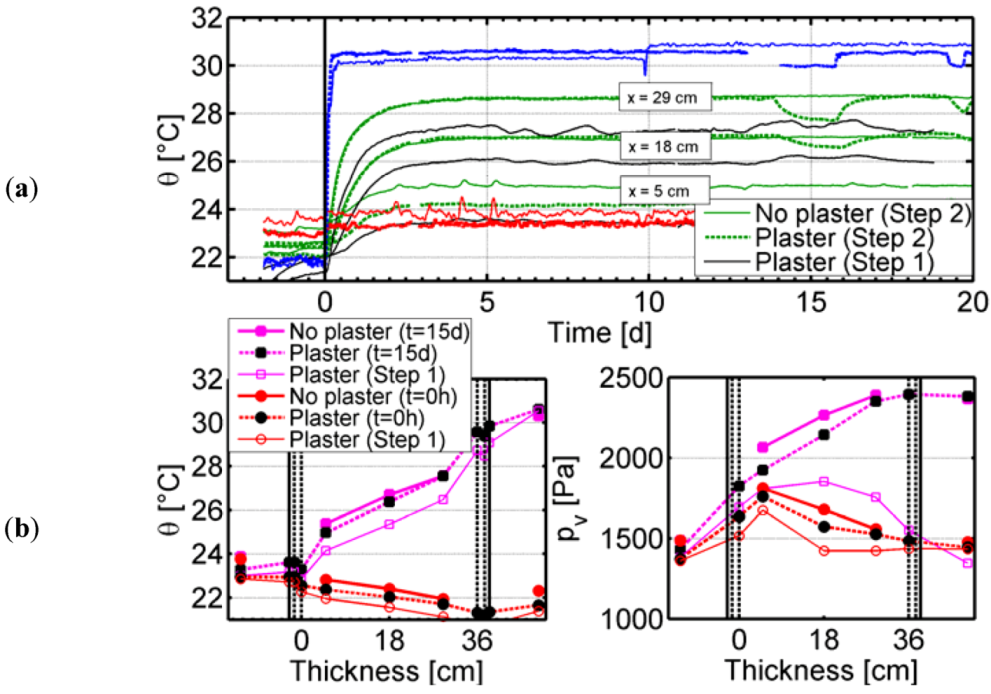

3.2.1. Experimental Response to a Temperature and Relative Humidity Gradient

| Material | Density

(kg.m−3) | Thermal conductivity (W·m−1·K−1) | Thermal diffusivity (10−7 m2·s−1) |

|---|---|---|---|

| Lime-Hemp plaster (interior finishing plaster) | 990 | 0.23 | 2.41 |

| Lime-Sand plaster (interior coarse plaster) | 1660 | 0.58 | 4.31 |

| Hemp concrete | 440 | 0.1 | 2.00 |

| Lime-Sand plaster (exterior coarse plaster) | 1590 | 0.39 | 3.03 |

| Lime-Sand plaster (exterior finishing plaster) | 1600 | 0.39 | 2.94 |

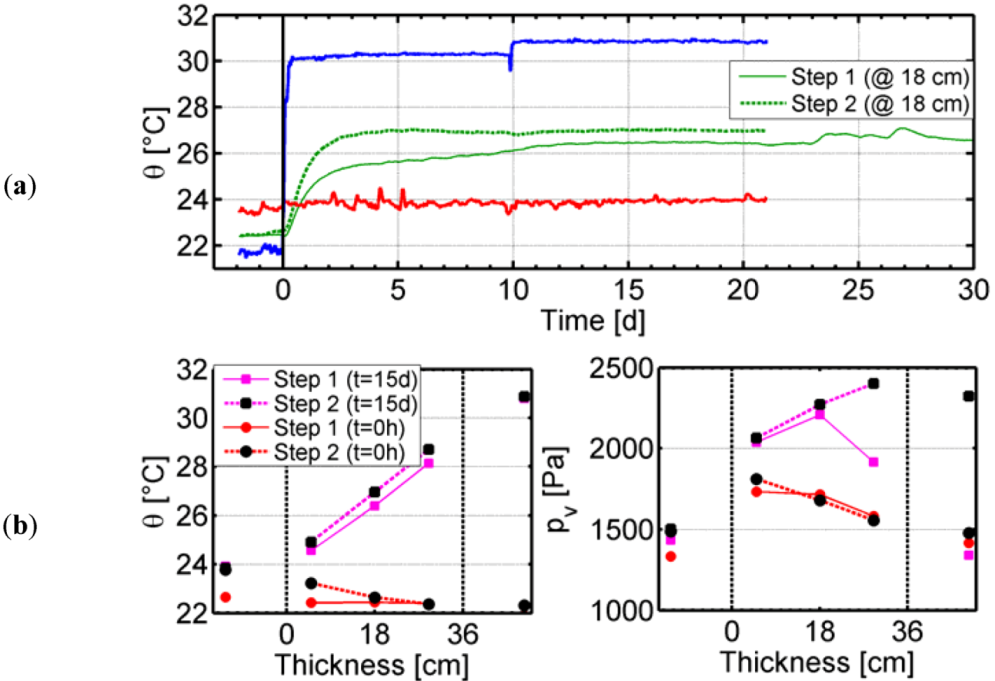

3.2.2. Experimental Response to a Temperature and Vapor Pressure Gradient

4. Conclusions

Acknowledgments

References

- Osanyintola, O.F.; Simonson, C.J. Moisture buffering capacity of hygroscopic building materials: Experimental facilities and energy impact. Energy Build. 2006, 38, 1270–1282. [Google Scholar] [CrossRef]

- Steeman, M.; Janssens, A.; De Paepe, M. Performance evaluation of indirect evaporative cooling using whole-building hygrothermal simulations. Appl. Therm. Eng. 2009, 29, 2870–2875. [Google Scholar] [CrossRef]

- Woloszyn, M.; Kalamees, T.; Abadie, M.O.; Steeman, M.; Kalagsidis, S.A. The effect of combining a relative-humidity-sensitive ventilation system with the moisture-buffering capacity of materials on indoor climate and energy efficiency of buildings. Build. Environ. 2009, 44, 515–524. [Google Scholar] [CrossRef]

- Simonson, C.J.; Salonvaara, M.; Ojanen, T. The effects of structures on indoor humidity—Possibility to improve comfort and perceived air quality. Indoor Air 2002, 12, 243–251. [Google Scholar] [CrossRef]

- El Diasty, R.; Fazio, P.; Budaiwi, I. Modelling of indoor air humidity: The dynamic behavior within an enclosure. Energy Build. 1992, 19, 61–73. [Google Scholar] [CrossRef]

- Woloszyn, M.; Rode, C. Tools for performance simulation of heat, air and moisture conditions of whole buildings. Build. Simul. 2008, 1, 5–24. [Google Scholar] [CrossRef]

- Hagentoft, C.E.; Kalagasidis, S.A.; Adl-Zarrabi, B.; Roels, S.; Carmeliet, J.; Hens, H.; Grunewald, J.; Funk, M.; Becker, R.; Shamir, D.; Adan, O.; Brocken, H.; Kumaran, K.; Djebbar, R. Assessment method of numerical prediction models for combined heat, air and moisture transfer in building components: Benchmarks for one-dimensional cases. J. Therm. Env. Build. Sci. 2004, 27, 327–352. [Google Scholar]

- Hagentoft, C.E. Heat, air and moisture transfer through new and retrofitted insulated envelope parts. Task 5: Performances and practice. In Final Report of IEA Annex 24; Katholieke Universiteit Leuven: Leuven, Belgium, 1998. [Google Scholar]

- Van Belleghem, M.; Steeman, M.; Willockx, A.; Janssens, A.; De Paepe, M. Benchmark experiments for moisture transfer modelling in air and porous materials. Build. Environ. 2011, 46, 884–898. [Google Scholar] [CrossRef]

- Carmeliet, J.; Derome, D. Temperature driven inward vapor diffusion under constant and cyclic loading in small-scale wall assemblies: Part 1 experimental investigation. Build. Environ. 2012, 48, 48–56. [Google Scholar] [CrossRef]

- Rode, C.; Salonvaara, M.; Ojanen, T.; Simonson, C.; Grau, K. Integrated hygrothermal analysis of ecological buildings. In Proceedings of the 2nd International Building Physics Conference, Leuven, Belgium, 14 September 2003.

- Pavlík, Z.; Cerny, R. Hygrothermal performance study of an innovative interior thermal insulation system. Appl. Therm. Eng. 2009, 29, 1941–1946. [Google Scholar] [CrossRef]

- Kalamees, T.; Vinha, J. Hygrothermal calculations and laboratory tests on timber-framed wall structures. Build. Environ. 2003, 38, 689–697. [Google Scholar] [CrossRef]

- Belarbi, R.; Qin, M.; Aït-Mokhtar, A.; Nilsson, L.O. Experimental and theoretical investigation of non-isothermal transfer in hygroscopic building materials. Build. Environ. 2008, 43, 2154–2162. [Google Scholar] [CrossRef]

- Yang, X.; Vera, S.; Rao, J.; Ge, H.; Fazio, P. Full-scale experimental investigation of moisture buffering effect and indoor moisture distribution. In Proceedings of the Building X Conference, Clearwater Beach, FL, USA, 2–7 December 2007.

- Woolley, T.; Thompson, H.; McGrogan, T.; Alexander, M. The role of low impact building materials in sustainable construction: The potential for hemp. In Proceedings of the Sustainable Building Conference, Stellenbosch, South Africa, 13–18 September 2004.

- Bevan, R.; Woolley, T. Hemp Lime Construction: A Guide to Building with Hemp Lime Composites; IHS/BRE Press: Bracknell, Berkshire, UK, 2008. [Google Scholar]

- Evrard, A.; De Herde, A. Hygrothermal performance of lime-hemp wall assemblies. J. Build. Phys. 2010, 34, 5–25. [Google Scholar] [CrossRef]

- Garnier, C.; Pretot, S.; Collet, F. Life cycle assessment of a hemp concrete wall manufactured by spraying. In Proceedings of The Second International Conference on Building Energy and Environment, Boulder, CO, USA, 1–4 August 2012.

- Colinart, T.; Glouannec, P.; Chauvelon, P. Influence of the setting process and the formulation on the drying of hemp concrete. Constr. Build. Mater. 2012, 30, 372–380. [Google Scholar] [CrossRef]

- Cerezo, V. Proprietes Mecaniques, Thermiques et Acoustiques d’un Materiau à Base de Particules Vegetales: Approche Experimentale et Modelisation Theorique (in French). Ph.D. Dissertation, ENTPE (Ecole Nationale des Travaux publics de l’Etat), Lyon, France, 16 June 2005. [Google Scholar]

- Evrard, A. Transient Hygrothermal Behavior of Lime-Hemp Materials. Ph.D. Dissertation, Universite Catholique de Louvain, Louvain, Belgium, 5 March 2008. [Google Scholar]

- Collet, F. Caracterisation Hydrique et Thermique de Materiaux de Genie Civil à Faibles Impacts Environnementaux (in French). Ph.D. Dissertation, INSA (The Institut National des Sciences Appliquées), Rennes, France, 14 December 2004. [Google Scholar]

- Samri, D. Analyse Physique et Caracterisation Hygrothermique des Materiaux de Construction: Approche Experimentale et Modelisation Numerique (in French). Ph.D. Dissertation, ENTPE, Lyon, France, 21 October 2008. [Google Scholar]

- Pierre, T.; Colinart, T.; Glouannec, P. Measurements of thermal properties of biosourced building materials. In Proceedings of the 18th Symposium on Thermophysical Properties, Boulder, CO, USA, 24–29 June 2012.

- Collet, F.; Pretot, S. Experimental investigation of moisture buffering capacity of sprayed hemp concrete. Constr. Build. Mater. 2012, 36, 58–65. [Google Scholar] [CrossRef]

- Shea, A.; Lawrence, M.; Walker, P. Hygrothermal performance of an experimental hemp-lime building. Constr. Build. Mater. 2012, 36, 270–275. [Google Scholar] [CrossRef]

- Tran Le, A.D.; Maalouf, C.; Mai, T.H.; Wurtz, E.; Collet, F. Transient hygrothermal behavior of a hemp concrete building envelope. Energy Build. 2010, 30, 1797–1806. [Google Scholar]

- Maalouf, C.; Tran Le, A.D.; Lachi, M.; Wurtz, E.; Mai, T.H. Effect of moisture transfer on thermal inertia in simple layer walls: Case of a vegetal fibre material. Math. Mod. Meth. Appl. Sci. 2011, 5, 33–47. [Google Scholar]

- Maalouf, C.; Tran Le, A.D.; Lachi, M.; Wurtz, E.; Mai, T.H. Effect of moisture transfer on heat energy storage in simple layer walls: Case of a vegetal fibre material. Math. Mod. Meth. Appl. Sci. 2011, 5, 1127–1134. [Google Scholar]

- LIMATB Website. Available online: http://web.univ-ubs.fr/limatb (accessed on 17 January 2013).

- Elfordy, S.; Lucas, F.; Tancret, F.; Scudeller, Y.; Goudet, L. Mechanical and thermal properties of lime and hemp concrete (“hempcrete”) manufactured by a projection process. Constr. Build. Mater. 2008, 22, 2116–2123. [Google Scholar] [CrossRef]

- Glouannec, P.; Chauvelon, P.; Colinart, T.; Le Bideau, P.; Zaknoune, A.; Jameline, N. Experimental and numerical studies of the drying of hemp concrete. In Proceedings of the 17th International Drying Symposium, Magdeburg, Germany, 3–6 October 2010.

- Hedenblad, G. Measurement of moisture in high performance concrete. In Proceedings of Nordic Concrete Federation Mini-Seminar “Moisture Measurement in Concrete Constructions Exposed to Temperature and Moisture Variations”, Otaniemi, Espoo, Finland; 22 August 1997. [Google Scholar]

- Peuhkuri, R.; Rode, C.; Hansen, K.K. Non-isothermal moisture transport through insulation materials. Build. Environ. 2008, 43, 811–822. [Google Scholar] [CrossRef]

- Hens, H. Building Physics—Heat, Air and Moisture: Fundamentals and Engineering Methods with Examples and Exercises; Ernst & Sohn: Berlin, Germany, 2007. [Google Scholar]

© 2013 by the authors; licensee MDPI, Basel, Switzerland. This article is an open-access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/3.0/).

Share and Cite

Colinart, T.; Glouannec, P.; Pierre, T.; Chauvelon, P.; Magueresse, A. Experimental Study on the Hygrothermal Behavior of a Coated Sprayed Hemp Concrete Wall. Buildings 2013, 3, 79-99. https://doi.org/10.3390/buildings3010079

Colinart T, Glouannec P, Pierre T, Chauvelon P, Magueresse A. Experimental Study on the Hygrothermal Behavior of a Coated Sprayed Hemp Concrete Wall. Buildings. 2013; 3(1):79-99. https://doi.org/10.3390/buildings3010079

Chicago/Turabian StyleColinart, Thibaut, Patrick Glouannec, Thomas Pierre, Philippe Chauvelon, and Anthony Magueresse. 2013. "Experimental Study on the Hygrothermal Behavior of a Coated Sprayed Hemp Concrete Wall" Buildings 3, no. 1: 79-99. https://doi.org/10.3390/buildings3010079