1. Introduction

Thermal insulation of walls is regarded as a medium to highly cost-effective energy upgrade measure in buildings retrofits. In Greece, for instance, which lies at the southern part of Europe, insulation of external walls may cut the heating energy consumption down by 50% [

1] and achieve pay-back in a range of ten years [

2,

3]. In this framework, a tremendous potential of energy savings is formulated, considering that a great part of buildings were built before the two successive oil price crises in the 1970s and hence are insufficiently insulated. For instance, in Greece, only half of the dwellings have some kind of envelope thermal insulation [

4]. Some issues arise when retrofitting for insulation, with the principal being: the exact placement of the insulation (outside, inside, in cavity), the selection of insulation material and the required thickness for the insulating layer, with the last two interfering with each other. Insulation at buildings’ envelopes is regarded considering cost-effectiveness, as we observe a critical thickness after which the achievable energy cost savings do not pay back the further increment in insulation cost. In this sense, an optimum (and at the same time, economically maximum) insulation thickness (

OIT) is introduced.

Optimum insulation thickness can be the outcome of detailed simulation [

5]. Simplified analytical relations have also been proposed to the same aim, allowing the extraction of more general results, with limited accuracy however, as imposed by mathematical simplicity requirements. A great number of works on the determination of

OIT have been elaborated in the past. An extended review on this topic is given in [

6] and is not repeated here for economy of space. The problem of finding

OIT is coped with the minimization of life cycle heating (and/or cooling) costs needed to compensate for the heat losses (and/or gains) through the considered fabric element. Both energy (fuel) and capital (insulation cost) expenses are accounted for and the issue renders to a single-objective optimization problem (minimization of the net present value of global costs):

where

is the present worth factor for an

N years’ constant annual cash flow and a discount rate of

r.

Based on the above criterion, the researchers follow one of two distinguished alternative methods to find OIT, the first being a detailed simulation and the second an analytical relation based on simplification of the degree-days method. The application of detailed simulation leads to more accurate results by considering the effect of many factors. Nevertheless, the arising conclusions are site and case specific and, for this reason, of limited value to the designers/engineers. On the other hand, the proposed analytical relation ignores important factors, such as the effect of the insulation on the base temperature of the heated space and in this context it is set here under questionable accuracy.

Several researchers applied degree-days [

7,

8,

9,

10] and concluded to the same simple and explicit relation for the

OITH (the subscript

H denotes the assumption of heating operation only):

where

DDH are the heating degree-days,

CF the cost of fuel,

HU its calorific value,

nHS the efficiency of the heating system,

kINS the thermal conductivity of the insulation material,

CINS the cost of insulation and

RW the initial thermal resistance of the wall (coefficient 293.94 stands for conversion of

Watt-days to

Joule).

On the other hand, Kayfeci et al. [

11] found that the optimum insulation thickness may also depend on the cooling degree-days

DDC and the coefficient of performance of the cooling equipment

COP. In the same context, Bolatturk [

12] proposed two alternative values for

OIT one for the heating and one for the cooling operation, while Kurekci [

13] proposed furthermore an

OITY considering an all year around operation. In the same framework, a general relation to estimate

OITY, through considering both the heating and cooling energy needs, was proposed [

13,

14,

15]:

where

CE is the cost of electricity.

Although very simple and fast in estimating

OIT, the degree-days concept and the subsequent simplified relations, Equations (2) and (3), have been criticized for inconvenience, by ignoring the effect of solar radiation and thermal mass [

15,

16]. Actually, there are a few other parameters that have also been confirmed as affecting

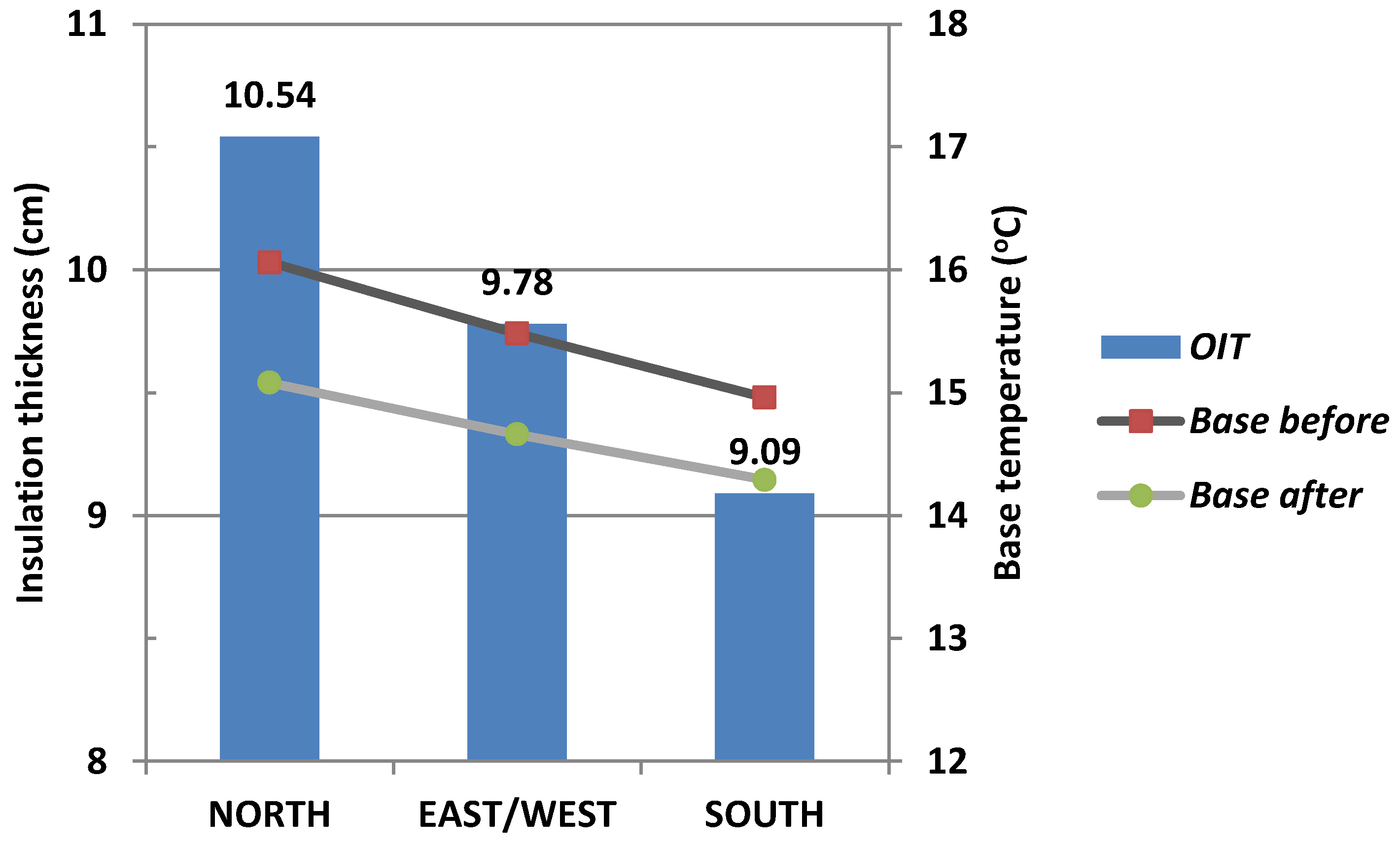

OIT significantly, but are not included yet in the above relations. For instance, wall orientation was found to affect

OIT by 0.5 cm for cold climates like the one in Elazig, Turkey (2653 heating degree-days) [

17] up to 1.6 cm in warmer climates such as in Tunis (550 heating degree-days) [

15]. Yuan et al. [

18] investigated the optimum combination of external surface reflectivity and insulation thickness for several cities all over Japan thus demonstrating the effect of reflectivity on

OIT. Other researchers examined alternatively the effect of external surface absorptance [

17] and color [

18] on

OIT. In [

16] it was examined the effect of shading on

OIT, and demonstrated that full shading may decrease

OIT by 3–3.5 cm (for a solar absorptance of 0.6). The significant effect of indoor temperature on

OIT was also demonstrated [

15], with the latter increasing remarkably with the winter base temperature. Other researchers investigated the effect of glazing area on

OIT [

19]; although they found that this does primarily affect the thermal load and consequently the achievable energy savings, it has a smaller effect on

OIT which however can still reach up to 10% for the warmer areas of Turkey (region 1 of the Country’s climatic zones). For any of the above reasons, the proposed simplified analytical relations may prove inaccurate, when comparing their results to more accurately calculated

OIT by using, for instance, Complex Finite Fourier Transform [

15]. In this context, the need for amending the above relations, by incorporating additional parameters that proved to be of similar importance, arises.

In the previous publications on

OIT, the optimization problem is regularly considered as an isolated one, focusing on the fabric element, and thus ignoring other data of the heated space which this element belongs to, such as the thermal transmittance of its other elements, the heat and the solar gains of the space, the thermal capacitance of the space etc. Only relatively recently, researchers took into consideration other data of the heated space [

19]. As a consequence they found that insulation is more effective (energy savings are larger and payback period is shorter, for the same insulation thickness) in buildings with smaller window areas. In their calculations they assumed a monthly time step and a utilization factor for the gains. More specifically, they investigated the effects of an alteration of the glazing percentage from 10% to 50% of the wall area and indicated that optimum insulation thickness varies between 0.036 and 0.087 m (for extruded polystyrene foam and use of natural gas). In this way they indicated that

OIT should not be examined by considering the fabric element alone, but through considering the integration of the latter to the heated space as well, without however concluding to any mathematical expression.

Although having indicated the dependence of

OIT on characteristics of the heated space, the above researchers have not concluded to any relations that could be used as a guide to this aim. A comprehensive parametric analysis has been elaborated to this aim [

20] but it was entirely based on Equation (3) ignoring in this context other parameters of the heated space that also affect

OIT. In the present work we exactly assume thermal insulation of a fabric element as a more generalized issue, by considering it as an interfering with the heated space element. As a consequence, we investigate the effects of factors not included within the previously suggested relations, like the total heat losses coefficient of the space, the heat gains and all relevant parameters affecting these quantities. To keep our approach simple and broadly applicable, we also attempt to solve the problem analytically.

3. Commentary on the Most Important Factors that Affect Optimum Insulation Thickness

Optimum insulation thickness is a function of the building type, shape, orientation, construction materials, climatic conditions, insulation material and cost, energy type and cost, and the type and efficiency of air-conditioning system. Some of these factors are shortly commented below.

Heating degree-days: This is obviously the most important factor. High value of heating degree-days leads to greater achievable energy cost savings by applying insulation, and in this sense it is worth adding thicker layers of insulation. As a consequence, higher value of heating degree-days is reasonably expected to result in a greater optimum insulation thickness.

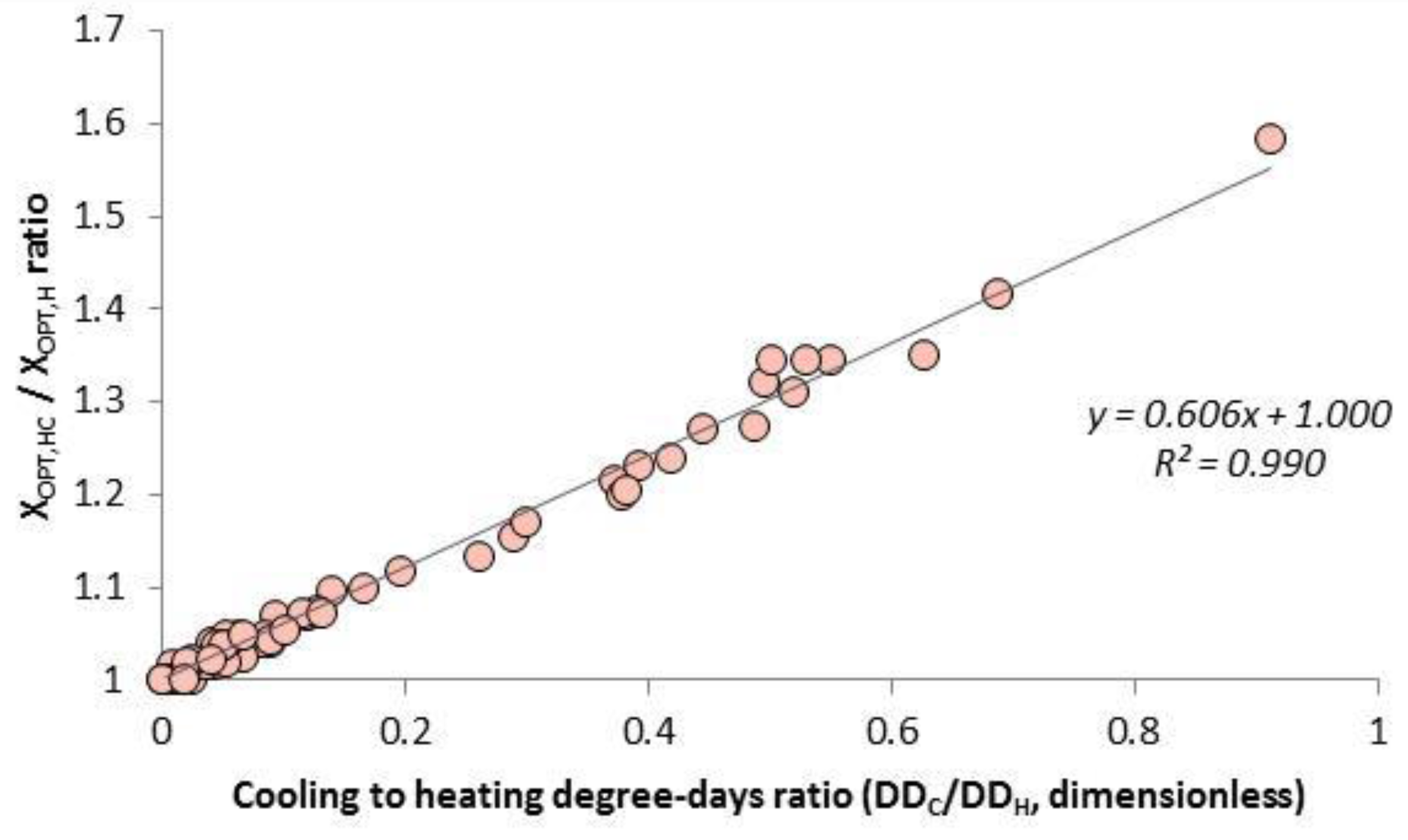

Cooling degree-days: The

DDC also affect optimum insulation thickness. In colder climates the

OITH for heating does not significantly differ from the value

OITY regarding the heating and cooling operation, as it is depicted in

Figure 4, which is based on published data [

13]. A linear relation between these quantities:

is apparently valid The coefficient in front of the degree-days ratio (value 0.6) results from the division of costs for cooling and heating, correspondingly:

Indeed, by introducing

HU = 34,485 kJ/m

3,

n = 0.90,

CF = 0.385 $/m

3 from [

12],

CE = 0.07 $/kWh [

8] and

COP = 2.5 [

12,

27] we estimate indeed

b = 0.6. As a consequence, a more general relation may arise:

An amended value of DDC can be introduced in Equation (5), when adopting a different scenario of operation during the cooling period (e.g., unoccupied period due to summer holidays, intermittent operation etc.). For instance, in Greece it is assumed in the energy classification of buildings (based on ISO 13790) that the actual cooling energy needs are only 50% of the total cooling energy demand, hence the half value of DDC should be respectively inserted in the above equation etc. thus causing a limited effect on OITY. By taking into consideration that: (a) cooling degree-days affect OIT at a lesser degree than heating degree-days (b is generally much lower than unit) (b) for the weather conditions prevailing in the European Countries and more general in Countries with continental climates, heating accounts for a significant part of the total energy consumption (c) cooling load is only partly due to transmission gains through opaque surfaces (d) according to regulations, cooling may be considered covering part of the demand (e) optimum insulation thickness for year around operation can be easily extracted, by applying Equation (5) from optimum thickness for heating, we further consider in this work the determination of optimum insulation for heating operation only.

Existing insulation: The higher the existing insulation is, the lesser the room for further savings. Hence, preexistence of any insulation on the wall leads to a lower optimum insulation thickness. It is easily proved that the total insulation thickness should be anyway the same between pre-insulated and non-insulated walls, when pre-existing insulation (e.g., of thickness

XPI) is also accounted for in the total insulation thickness (provided that the same insulation material is considered). This is mathematically expressed by the relation:

Such an issue is expected to arise when passing from already satisfactorily performing buildings to nearly zero energy buildings. Indeed, at an already insulated building, with

XPI, the

XOPT(

XPI) is expected to be much smaller and the question arising will be if it is worth proceeding with any additional insulation. In that case (but even more generally as well) the application of optimizing insulation thickness will not be enough but someone has to examine at first the profitability of the measure. If so, the fixed expenses should also be considered, and the following condition arises:

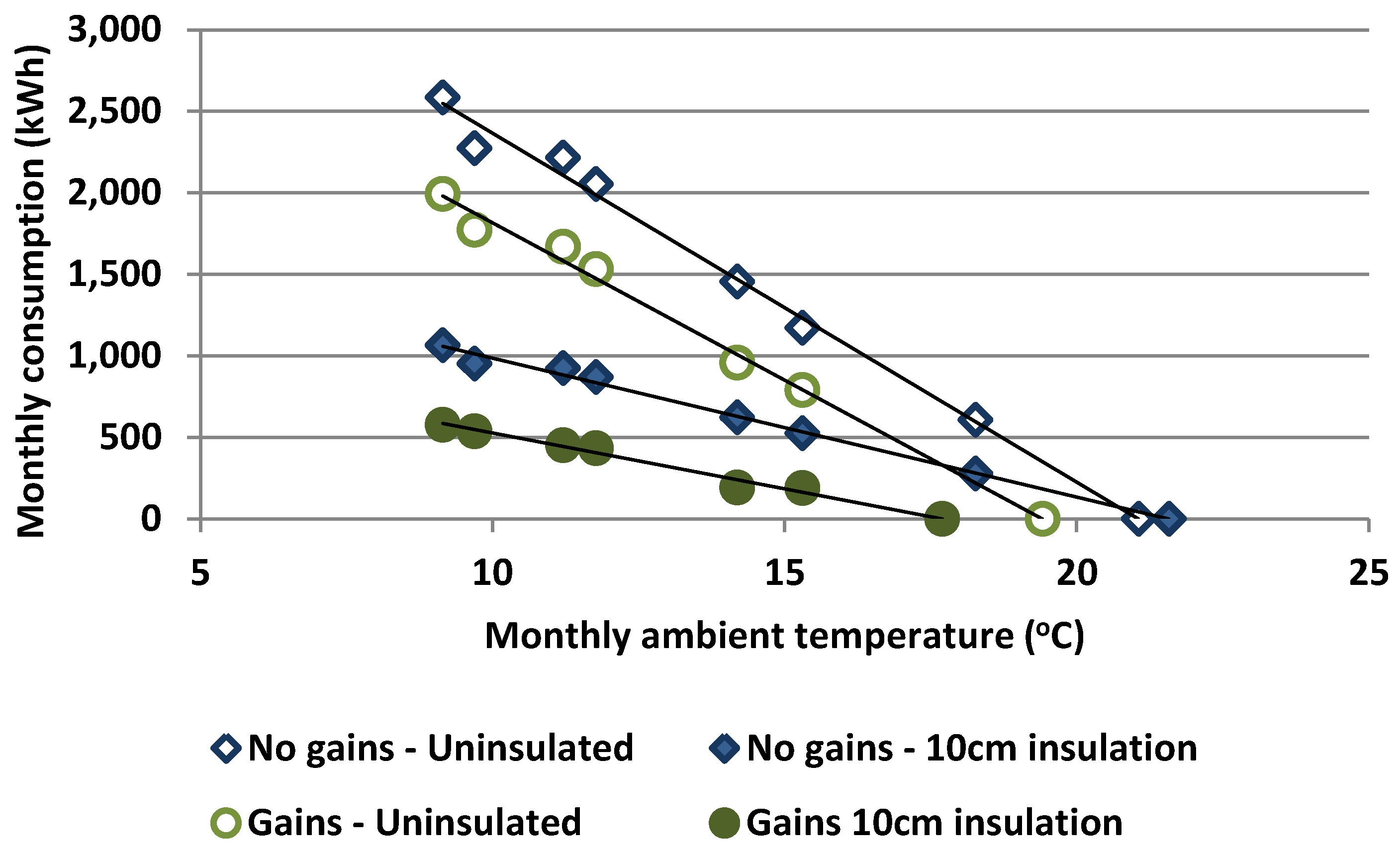

Heat and Solar gains: Heat and solar gains result in a lower base temperature, then in reduced heating degree-days, in lower energy needs and in the end in a smaller OITH value. The heat gains are more or less constant all through the year, while the solar gains vary. The application of insulation may reduce the solar gains through the opaque surface of the insulated wall, which constitutes however a minor part of solar gains in cases where the wall has some glazing surface on it.

Intermittency of operation: Intermittent heating is probably the rule in space heating. A night set-back temperature, and application of heating during occupancy hours only, lead to a lower mean temperature in the heated space and consequently to a reduced heating energy demand. The last fact has an impact on the economy of insulating, and reduces the OITH, since the achievable energy cost savings in intermittent heating operation (for the same insulation thicknesses) will be less. At the same time, however, the mean internal temperature is also reduced, in a way probably affecting the thermal comfort of the occupants. A compromise is finally desirable between the insulation cost and the thermal comfort, but such an approach is beyond the scope of the present work, where continuous heating is the main consideration.

Absorptance: The solar radiation incident on the external surface of the fabric element affects heat exchange with the environment. This is expressed via the sol-air temperature, which is strongly related to the absorptance and emittance of the surface:

where

TA is the outdoor air temperature (°C),

F is the shading reduction factor for external obstacles on the surface,

αES is the solar absorptance of the external surface,

IT is total solar irradiance incident on the surface (W/m

2),

hES is the combined convective and radiative heat transfer coefficient on the external surface (W/m

2 K),

εES is the hemispherical emittance of the surface and

ΔR is the difference between the long-wave radiation incident on the surface from the sky and surroundings and the radiation emitted by a blackbody at outdoor air temperature (W/m

2). The value of

ΔR can be considered zero for vertical surfaces, because the radiant heat loss to the sky compensates the heat. Hence, solar gains through the opaque surface

A* are equivalently expressed by the relation:

where

U* is the thermal transmittance of the considered fabric element. The higher the absorptance is, the higher the solar gains get, leading to respectively lower heating energy needs and in turn to lower values for

OITH.

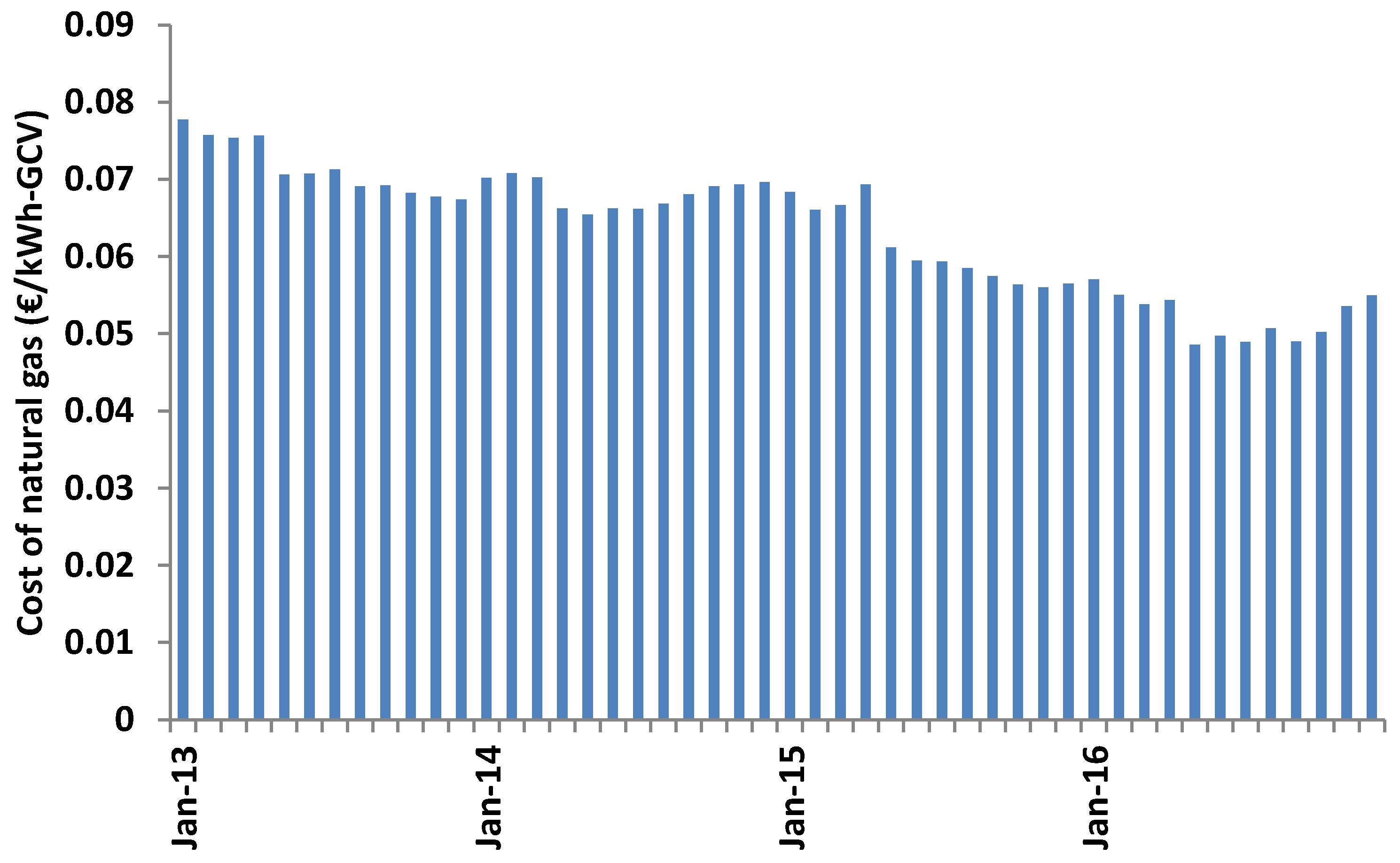

Economic factors: We distinguish cost factors (cost of insulation, cost of fuel) and financial factors (discount rate, life-time). All quantities are expressed in present values. The application of any loan can also be easily accounted for by converting all future installments on the debt to present values and adding them to the insulation cost.

The fact that the issue of specifying a suitable insulation thickness is multi-parametric arises as a conclusion of the above analysis of the factors affecting OIT. In addition, the wall should not be considered as isolated but as a constituent of the whole heated space.

6. Conclusions

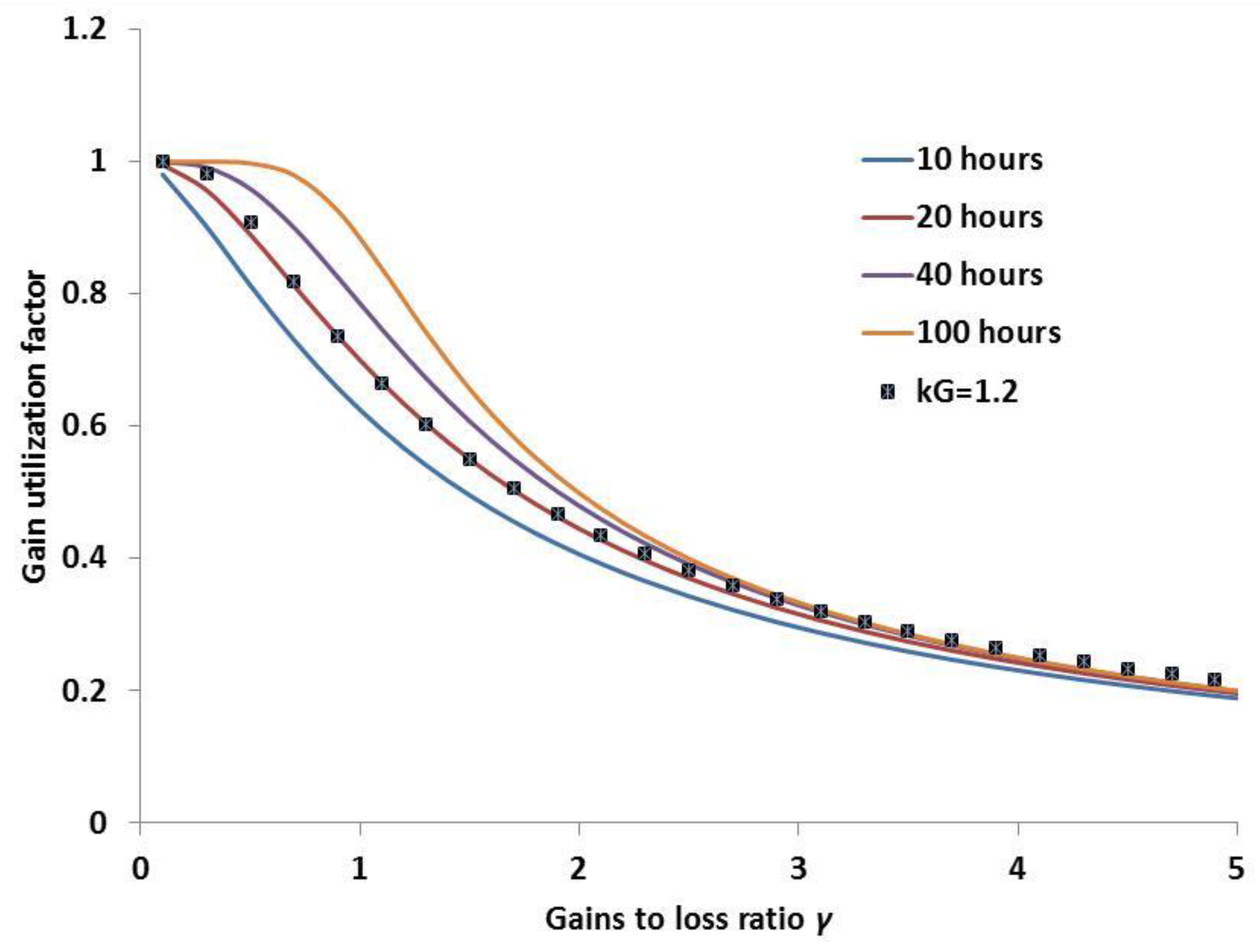

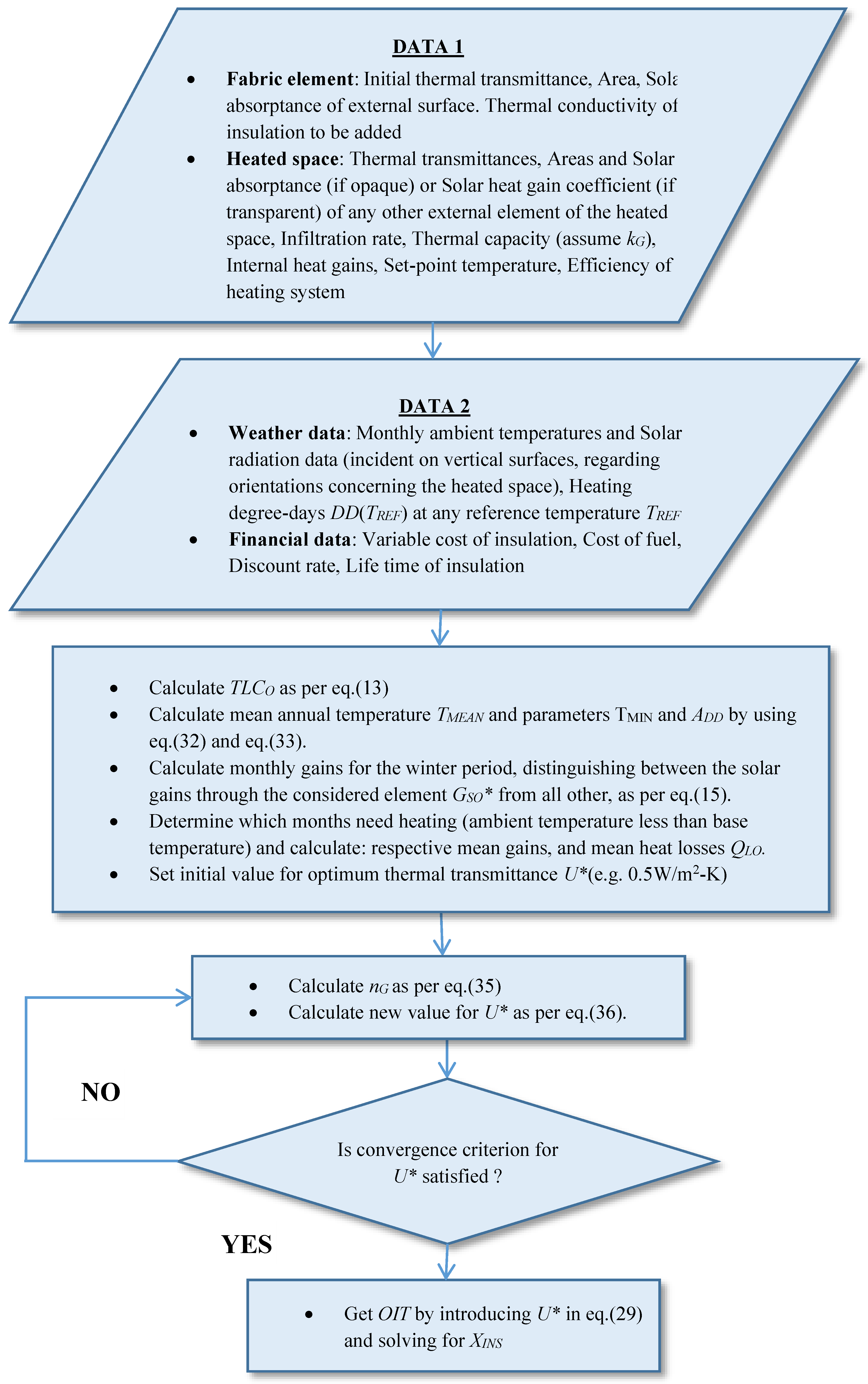

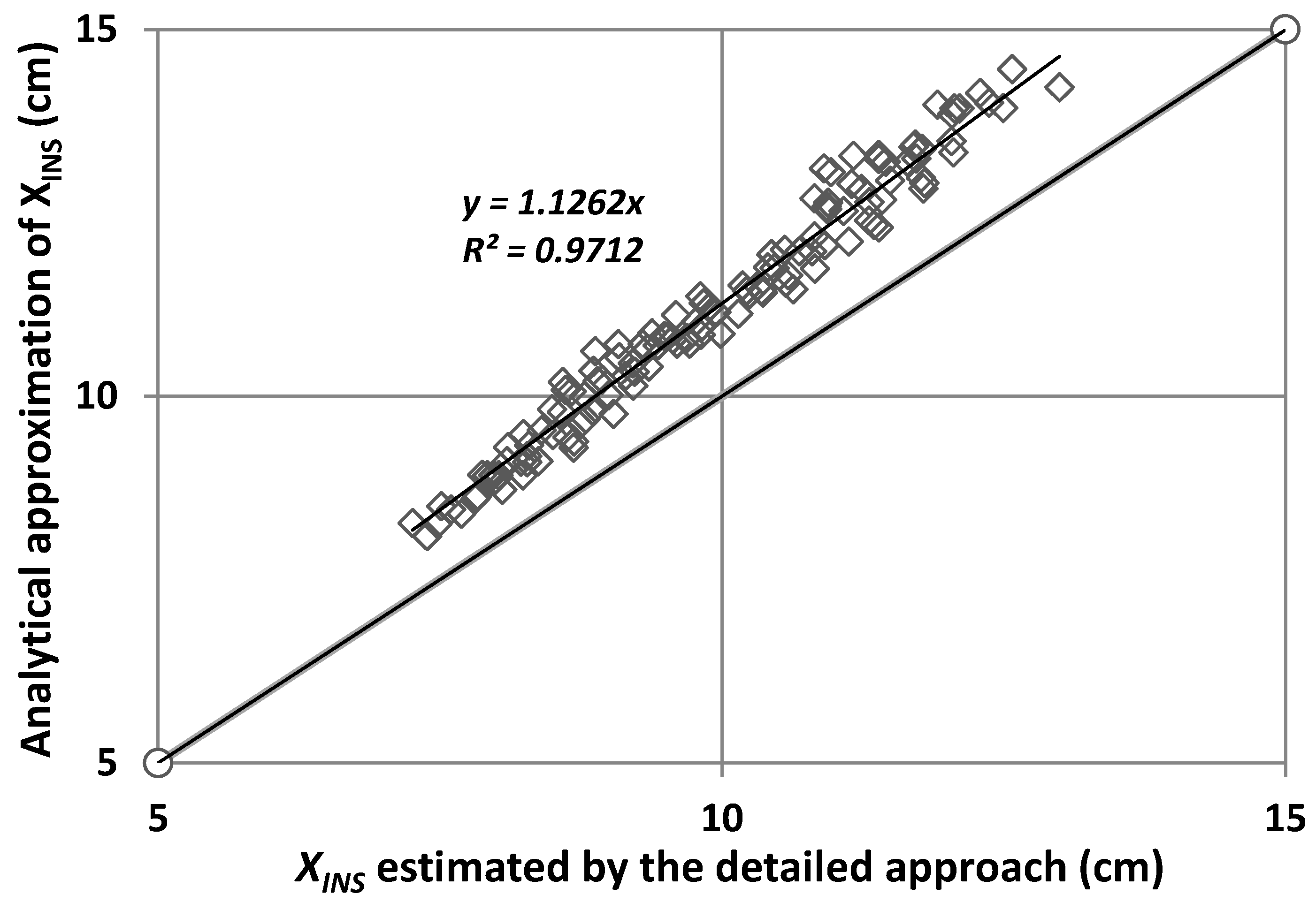

The accuracy in using the degree-days method to estimate optimum insulation thickness OIT of an opaque fabric element can be further improved, by taking into consideration the base temperature variation with insulation. In this framework, all factors affecting the above base temperature are also accounted for, such as heat generation within the heated space (including the heat gains utilization factor and the thermal capacity of the space), solar gains through the transparent and opaque surfaces of the space (including the solar absorptance of the considered fabric element) and the total heat losses coefficient of the heated space (including thermal transmittances and areas of the rest of the elements, as well as infiltration). In this sense, optimization does not focus solely on the fabric element but regards it as an interfering part of the whole heated space to which it belongs. In this way a system of two implicit equations arises, which is easily solvable however, with or without using a solver (e.g., either graphically or by applying successive substitutions), to get the optimum thermal transmittance of the considered fabric element and the respective OIT.

The optimum insulation thickness for heating and cooling operation OITY is linearly correlated with the optimum thickness for heating only OITH. The regression coefficient depends on the ratio between cooling and heating degree-days and the relative cost of heating and cooling, respectively. In this context, the optimum insulation thickness for heating application can be firstly estimated followed by the optimum insulation thickness for the whole year operation being concluded, taking additionally into consideration any limitations set by the designer or the standards (e.g., consideration of summer holidays, partial application of cooling etc.).

The optimum insulation thickness (OITH) is estimated by equalizing the marginal insulation cost with the marginal induced benefits. In this sense, OITH is practically the insulation thickness, which leads economically to the maximum achievable energy savings.

Optimum insulation thickness is strongly correlated (positively) to the initial thermal transmittance of the wall; this may vary significantly (e.g., from 0.5 to 2.0 W/m2-K), as addition of insulation may be attempted to non-insulated buildings or even to well performing buildings which undergo retrofitting to n-ZEBs. For all these cases however a roughly equal optimum thermal transmittance arises, rendering the results of such an approach (optimization of thermal transmittance) of more general interest and simultaneously in agreement with the requirements set by the regulations regarding transmittance maximum values.

Several parameters affect optimum transmittance (and in turn optimum insulation thickness) in an area, like financial parameters and the thermal conductivity of the insulation material (the principal ones), but also other less important ones such as the incident solar radiation, the total heat loss coefficient of the heated space, the solar heat gain coefficient through any openings existing in the heated space, the heat gains of the space etc. The combined effect of these secondary parameters proved they can be of equal importance to the principal ones. In this sense, the insulation of a fabric element should not be considered as an isolated issue, but as part of the heated space.

The optimum insulation thickness depends on the base temperature of the heated space, which in turn decreases by the addition of insulation. This induced variation should be taken into consideration when estimating optimum insulation thickness, otherwise errors up to 20% may arise. The analytical approach proposed here, although implicit, is easily solvable e.g., via a successive substitution or in a graphic, to rapidly lead to a more accurate estimation of the optimum insulation thicknesses rather than the previously suggested analytical relations.

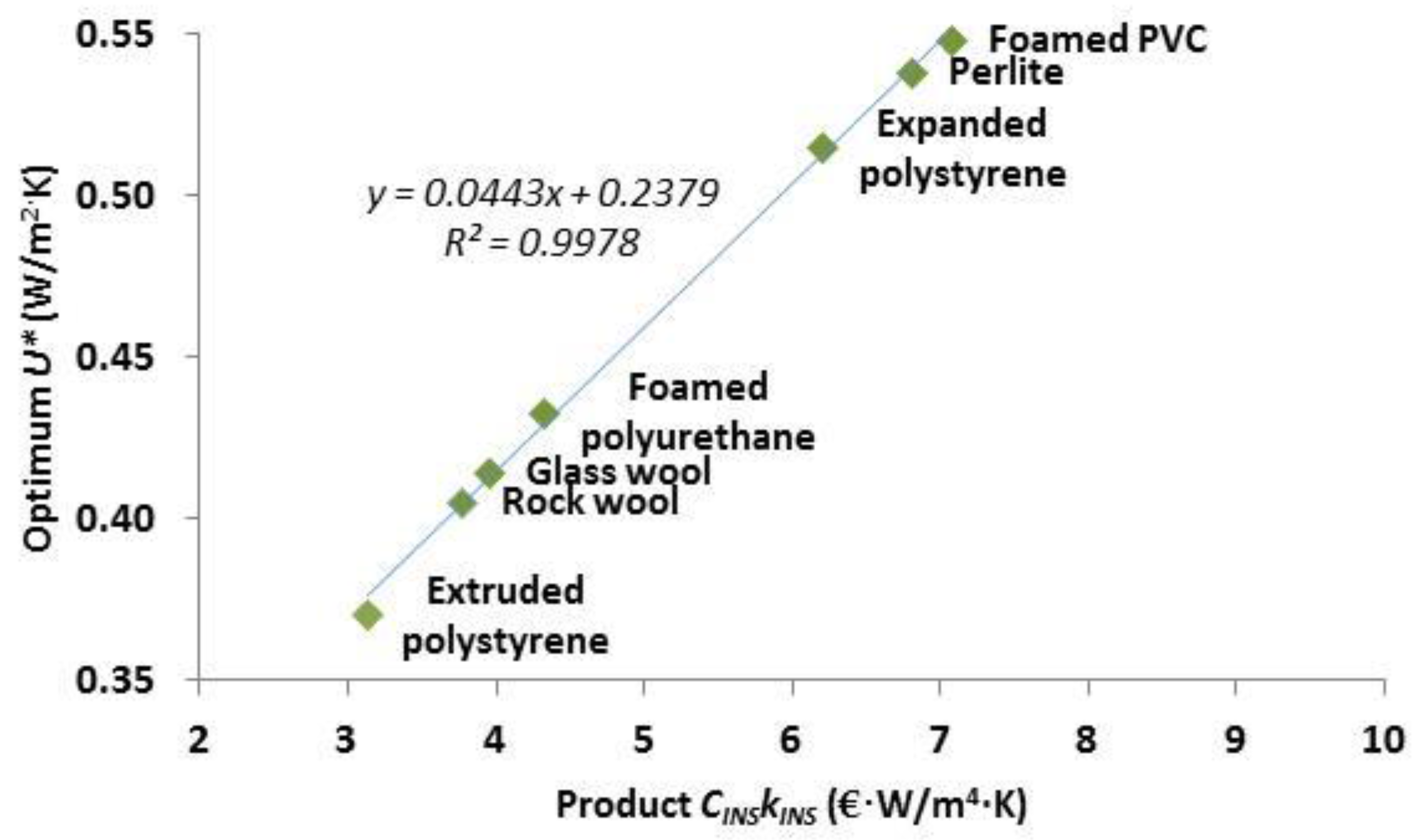

When selecting among alternative insulation materials, the most cost-effective is the one with the lower product when multiplying its cost by its thermal conductivity, CINS·kINS.