Estimation and Minimization of Embodied Carbon of Buildings: A Review

Abstract

:1. Introduction

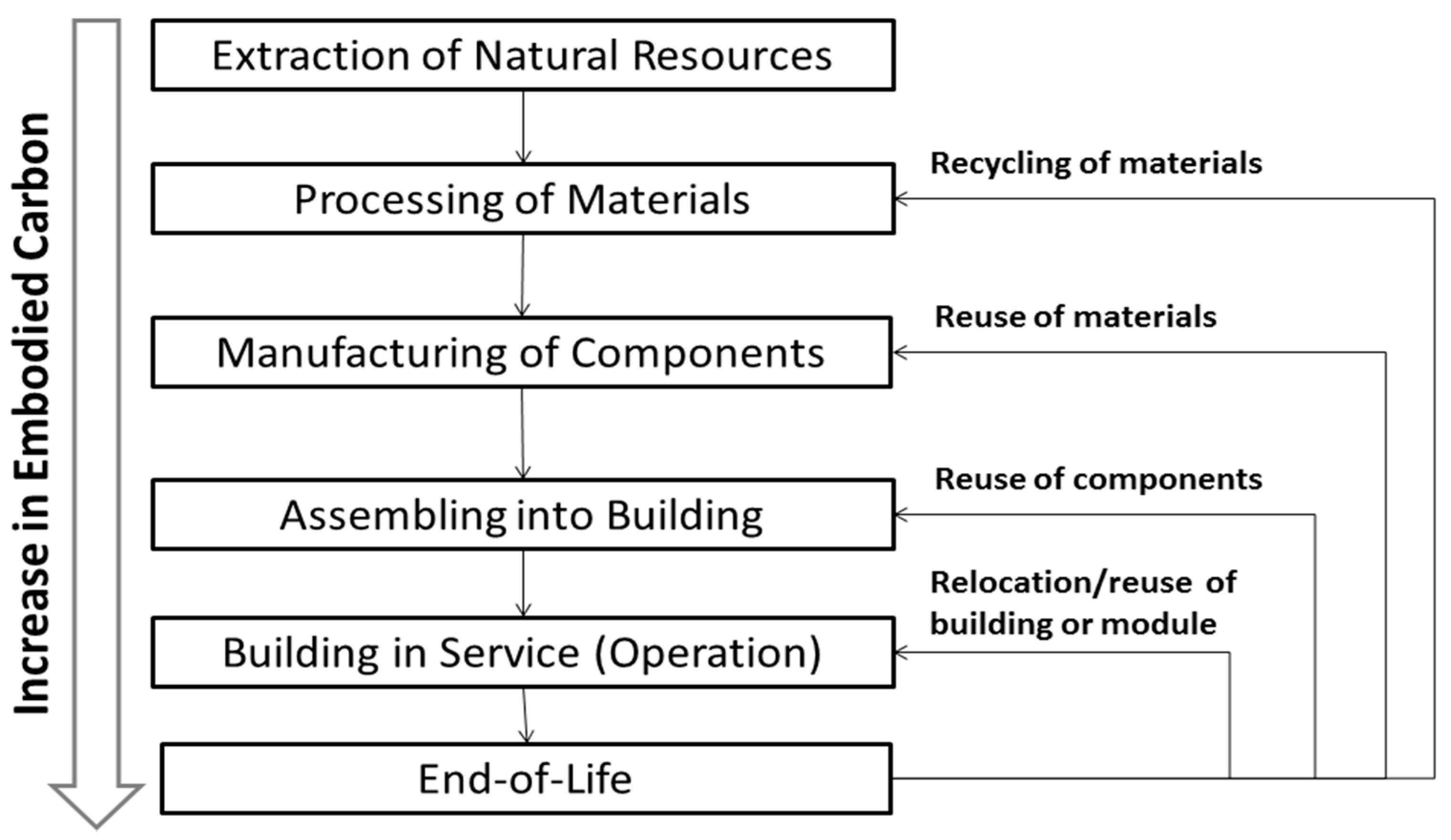

2. Embodied Carbon Reduction Strategies

2.1. Low-Carbon Materials

2.2. Material Minimization

2.3. Material Reuse and Recycling

2.4. Local Sourcing of Materials and Components

2.5. Construction Optimization Strategies

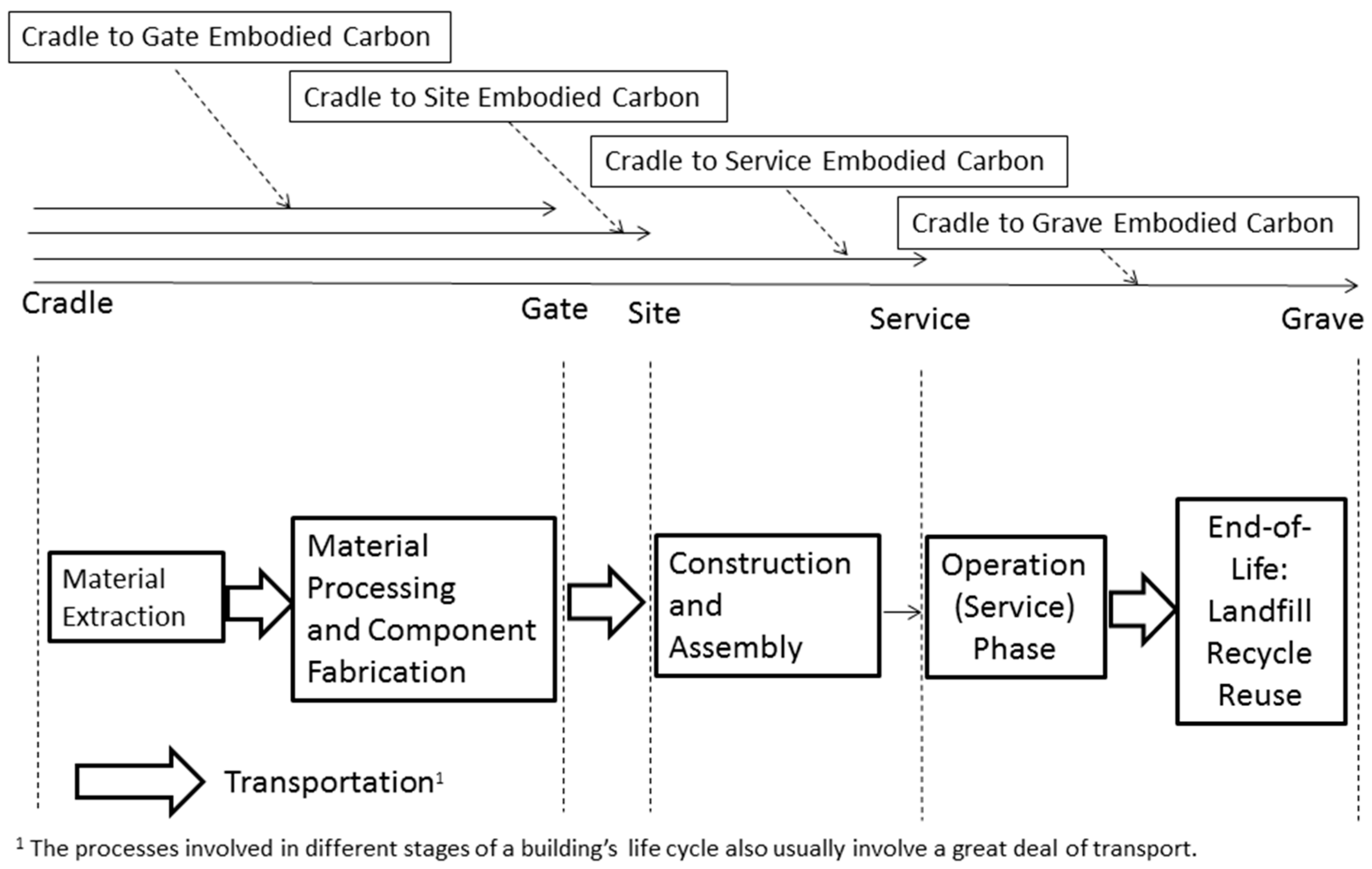

3. Estimation of Carbon Emissions

3.1. Cradle to Gate Embodied Carbon of Materials

3.2. Cradle to Site Embodied Carbon—Impact of Transportation

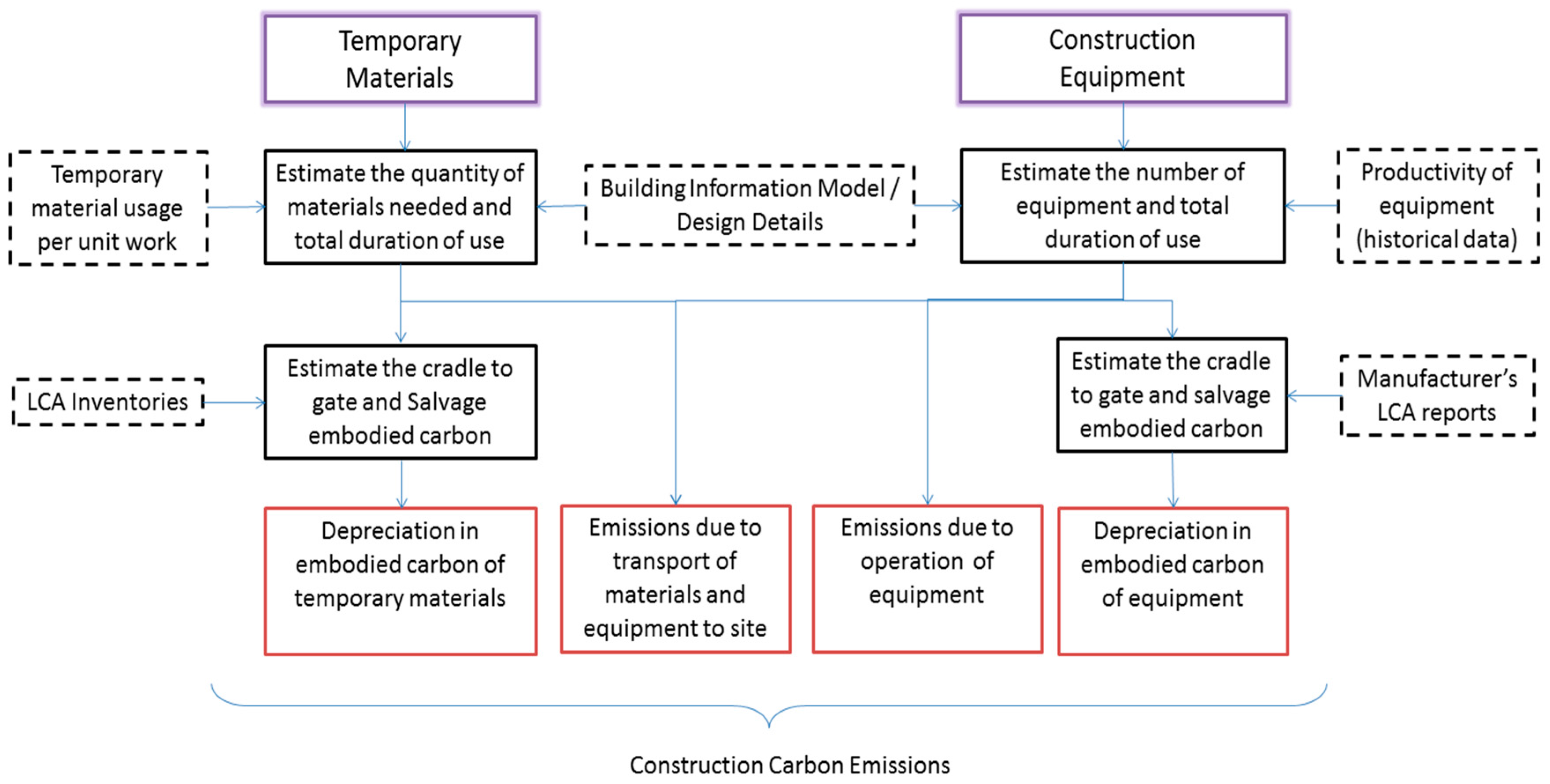

3.3. Cradle to Service Embodied Carbon—Impact of Construction Operations

3.3.1. Construction Carbon Emissions Due to Depreciation

3.3.2. Construction Carbon Due to Equipment Operations

3.3.3. Accounting for Uncertainty and Site-Specific Conditions

3.3.4. Direct Measurement of Equipment Emissions

3.4 Cradle to Grave Embodied Carbon

4. Conclusions

Conflicts of Interest

References

- Intergovernmental Panel On Climate Change (IPCC). IPCC Fourth Assessment Report: Climate Change 2007 (AR4); IPCC: Cambridge, UK, 2007. [Google Scholar]

- United Nations Environment Programme (UNEP). Building and Climte Change: Summary of Desicion-Makers; UNEP: Washington, DC, USA, 2009. [Google Scholar]

- United Nations. Kyoto Protocol to the United Nations Framework Convention on Climate Change; United Nations: New York, NY, USA, 1997. [Google Scholar]

- U.S. Environmental Protection Agency (EPA). Inventory of U.S. Greenhouse Gas Emissions and Sinks: 1990–2008; EPA: Washington, DC, USA, 2010.

- Hong, T.; Ji, C.; Jang, M.; Park, H. Assessment Model for Energy Consumption and Greenhouse Gas Emissions during Building Construction. J. Manag. Eng. 2014, 30, 226–235. [Google Scholar] [CrossRef]

- Ramesh, T.; Prakash, R.; Shukla, K.K. Life cycle energy analysis of buildings: An overview. Energy Build. 2010, 42, 1592–1600. [Google Scholar] [CrossRef]

- Dixit, M.K.; Fernandez-Solis, J.L.; Lavy, S.; Culp, C.H. Need for an embodied energy measurement protocol for buildings: A review paper. Renew. Sustain. Energy Rev. 2012, 16, 3730–3743. [Google Scholar] [CrossRef]

- Methodology to Calculate Embodied Carbon of Materials; RICS Information Paper, IP 32/2012; RICS, Surveyor Court, Westwood Business Park: Coventry, UK, 2012.

- Nebel, B.; Alcorn, A.; Wittstock, B. Life Cycle Assessment: Adopting and Adapting Overseas LCA Data and Methodologies for Building Materials in New Zealand; Fraunhofer: Rotorua, New Zealand, 2008. [Google Scholar]

- Thormark, C. The effect of material choice on the total energy need and recycling potential of a building. Build. Environ. 2006, 41, 1019–1026. [Google Scholar] [CrossRef]

- Thormark, C. A low energy building in a life cycle—Its embodied energy, energy need for operation and recycling potential. Build. Environ. 2002, 37, 429–435. [Google Scholar] [CrossRef]

- Nemry, F.; Uihlein, A.; Colodel, C.M.; Wetzel, C.; Braune, A.; Wittstock, B.; Hasan, I.; Kreißig, J.; Gallon, N.; Niemeier, S.; et al. Options to reduce the environmental impacts of residential buildings in the European Union—Potential and costs. Energy Build. 2010, 42, 976–984. [Google Scholar] [CrossRef]

- Bastos, J.; Batterman, S.A.; Freire, F. Life-cycle energy and greenhouse gas analysis of three building types in a residential area in Lisbon. Energy Build. 2014, 69, 344–353. [Google Scholar] [CrossRef]

- Plank, R. The principles of sustainable construciton. IES J. Part A Civ. Struct. Eng. 2008, 1, 301–307. [Google Scholar] [CrossRef]

- Sartori, I.; Hestnes, A.G. Energy use in the life cycle of conventional and low-energy buildings: A review article. Energy Build. 2007, 39, 249–257. [Google Scholar] [CrossRef]

- Thormark, C. CIB Conference: Energy and Resources, Material Choice and Recycling Potential in Low Energy Buildings. In SB 07 Sustainable Construction Materials & Practices; IOS Press: Amsterdam, The Netherlands, 2007. [Google Scholar]

- Ibn-Mohammed, T.; Greenough, R.; Taylor, S.; Ozawa-Meida, L.; Acquaye, A. Operational vs. embodied emissions in buildings—A review of current trends. Energy Build. 2013, 66, 232–245. [Google Scholar] [CrossRef]

- Dixit, M.K.; Fernandez-Solis, J.L.; Lavy, S.; Culp, C.H. Identification of parameters for embodied energy measurement: A literature review. Energy Build. 2010, 42, 1238–1247. [Google Scholar] [CrossRef]

- Reddy, B.V.V.; Jagadish, K.S. Embodied energy of common and alternative building materials and technologies. Energy Build. 2003, 35, 129–137. [Google Scholar] [CrossRef]

- Akbarnezhad, A.; Moussavi Nadoushani, Z.S. A computational method for selection of optimal concrete recycling strategy. Mag. Concr. Res. 2015, 67, 543–558. [Google Scholar] [CrossRef]

- Yeo, D.; Gabbai, R.D. Sustainable design of reinforced concrete structures through embodied energy optimization. Energy Build. 2011, 43, 2028–2033. [Google Scholar] [CrossRef]

- Crowther, P. Design for disassembly to recover embodied energy. In Proceedings of the 16th Annual Conference on Passive and Low Energy Architecture, Melbourne/Brisbane/Cairns, Australia, 22–24 September 1999.

- Ahmadian Fard Fini, A.; Akbarnezhad, A.; Rashidi, T.; Waller, T. BIM-enabled Sustainability Assessment of Material Supply Decisions. Eng. Constr. Archit. Manag. 2016, in press. [Google Scholar]

- Hammond, G.; Jones, C.I. Inventory of Carbon and Energy (ICE), 1.5a Beta ed.; United Overseas Bank Ltd.: London, UK, 2006. [Google Scholar]

- Hammond, G.P.; Jones, C.I. Embodied energy and carbon in construction materials. Proc. Inst. Civ. Eng. Energy 2008, 161, 87–98. [Google Scholar] [CrossRef] [Green Version]

- Reddy, B. Sustainable materials for low carbon buildings. Int. J. Low Carbon Technol. 2009, 4, 175–181. [Google Scholar] [CrossRef]

- Gonzalez, M.J.; Navarro, J.G. Assessment of the decrease of CO2 emissions in the construction field through the selection of materials: Practical case study of three houses of low environmental impact. Build. Environ. 2006, 41, 902–909. [Google Scholar] [CrossRef]

- Sandanayake, M.; Zhang, G.M.; Setunge, S.; Li, C.Q.; Fang, J. Models and method for estimation and comparison of direct emissions in building construction in Australia and a case study. Energy Build. 2016, 126, 128–138. [Google Scholar] [CrossRef]

- Moussavi Nadoushani, Z.S.; Akbarnezhad, A. Effects of structural system on the life cycle carbon footprint of buildings. Energy Build. 2015, 102, 337–346. [Google Scholar] [CrossRef]

- Cabeza, L.F.; Barreneche, C.; Miro, L.; Morera, J.M.; Bartoli, E.; Fernandez, A.I. Low carbon and low embodied energy materials in buildings: A review. Renew. Sustain. Energy Rev. 2013, 23, 536–542. [Google Scholar] [CrossRef]

- Dimoudi, A.; Tompa, C. Energy and environmental indicators related to construction of office buildings. Resour. Conserv. Recycl. 2008, 53, 86–95. [Google Scholar] [CrossRef]

- Ji, C.; Hong, T.; Park, H.S. Comparative analysis of decision-making methods for integrating cost and CO2 emission—Focus on building structural design. Energy Build. 2014, 72, 186–194. [Google Scholar] [CrossRef]

- Cole, R.J. Energy and greenhouse gas emissions associated with the construction of alternative structural systems. Build. Environ. 1999, 34, 335–348. [Google Scholar] [CrossRef]

- Buchanan, A.; Levine, S. Wood-based building materials and atmospheric carbon emissions. Environ. Sci. Policy 1999, 2, 427–437. [Google Scholar] [CrossRef]

- Nassen, J.; Hedenus, F.; Karlsson, S.; Holmberg, J. Concrete vs. wood in buildings—An energy system approach. Build. Environ. 2012, 51, 361–369. [Google Scholar] [CrossRef]

- Gerilla, G.P.; Teknomo, K.; Hokao, K. An environmental assessment of wood and steel reinforced concrete housing construction. Build. Environ. 2007, 42, 2778–2784. [Google Scholar] [CrossRef]

- Habert, G.; Roussel, N. Study of two concrete mix-design strategies to reach carbon mitigation objectives. Cem. Concr. Compos. 2009, 31, 397–402. [Google Scholar] [CrossRef]

- Davidovits, J.; Davidovics, M. Geopolymer—Ultra-High Temperature Tooling Material for the Manufacture of Advanced Composites. In Proceedings of the 36th International Sampe Symposium and Exhibition, Book 1 and 2, San Diego, CA, USA, 15–18 April 1991; Volume 36, pp. 1939–1949.

- Provis, J.L.; van Deventer, J.S.J. Geopolymers: Structures, Processing, Properties and Industrial Applications; Woodhead Publishing: Cambridge, UK, 2009. [Google Scholar]

- Sustainable Buildings & Climate Initiative. In Buildings and Climate Change: Summary for Decision-Makers; United Nations Environment Programme: Washington, DC, USA, 2009.

- Ong, K.C.G.; Akbarnezhad, A. Microwave-Assisted Concrete Technology Production, Demolition and Recycling Introduction. In Microwave-Assisted Concrete Technology: Production, Demolition and Recycling; CRC Press: Boca Raton, FL, USA, 2015; pp. 1–38. [Google Scholar]

- Flower, D.J.M.; Sanjayan, J.G. Green house gas emissions due to concrete manufacture. Int. J. Life Cycle Assess. 2007, 12, 282–288. [Google Scholar] [CrossRef]

- O’brien, K.R.; Menache, J.; O’moore, L.M. Impact of fly ash content and fly ash transportation distance on embodied greenhouse gas emissions and water consumption in concrete. Int. J. Life Cycle Assess. 2009, 14, 621–629. [Google Scholar] [CrossRef] [Green Version]

- Gharehchaei, M.; Akbarnezhad, A.; Lazenby, H.; Castel, A.; Lloyd, R.; Foster, S.J. Precision of Existing Hydration Heat Models for Portland Cement in Capturing the Effects of Supplementary Cementitious Materials and Retarders. In Proceedings of the 24th Australasian Conference on the Mechanics of Structures and Materials (ACMSM24), Curtin University of Technology, Perth, Australia, 6–9 December 2016.

- Thomas, M. Optimizing the Use of Fly Ash in Concrete; The Portland Cement Association: Skokie, IL, USA, 2007; Volume 24. [Google Scholar]

- Gartner, E. Industrially interesting approaches to “low-CO2” cements. Cem. Concr. Res. 2004, 34, 1489–1498. [Google Scholar] [CrossRef]

- Duxson, P.; Fernandez-Jimenez, A.; Provis, J.L.; Lukey, G.C.; Palomo, A.; van Deventer, J.S.J. Geopolymer technology: The current state of the art. J. Mater. Sci. 2007, 42, 2917–2933. [Google Scholar] [CrossRef]

- Davidovits, J. Properties of geopolymer cements. In Proceedings of the First international Conference on Alkaline Cements and Concretes, Kiev, Ukraine, 11–14 October 1994.

- Khan, M.; Castel, A.; Akbarnezhad, A.; Foster, S.; Smith, M. Utilisation of steel furnace slag coarse aggregate in a low calcium fly ash geopolymer concrete. Cem. Concr. Res. 2016, 89, 220–229. [Google Scholar] [CrossRef]

- Akbarnezhad, A.; Huan, M.; Mesgari, S.; Castel, A. Recycling of geopolymer concrete. Constr. Build. Mater. 2015, 101, 152–158. [Google Scholar] [CrossRef]

- Pan, Z.; Sanjayan, J.G.; Rangan, B.V. Fracture properties of geopolymer paste and concrete. Mag. Concr. Res. 2011, 63, 763–771. [Google Scholar] [CrossRef]

- Pan, Z.; Sanjayan, J.G.; Rangan, B.V. An investigation of the mechanisms for strength gain or loss of geopolymer mortar after exposure to elevated temperature. J. Mater. Sci. 2009, 44, 1873–1880. [Google Scholar] [CrossRef]

- Rangan, B.V. Engineering properties of geopolymer concrete. In Geopolymers: Structure, Processing, Properties and Industrial Applications; Woodhead Publishing: Cambridge, UK, 2009; pp. 211–226. [Google Scholar]

- Rangan, B.V. Design, Properties, and Applications of Low-Calcium Fly Ash-Based Geopolymer Concrete. Dev. Porous Biol. Geopolym. Ceram. 2008, 28, 347–361. [Google Scholar]

- Hardjito, D.; Wallah, S.E.; Sumajouw, D.M.J.; Rangan, B.V. On the development of fly ash-based geopolymer concrete. ACI Mater. J. 2004, 101, 467–472. [Google Scholar]

- Shi, X.S.; Collins, E.G.; Zhao, X.L.; Wang, Q.Y. Mechanical properties and microstructure analysis of fly ash geopolymeric recycled concrete. J. Hazard. Mater. 2012, 237, 20–29. [Google Scholar] [CrossRef] [PubMed]

- Ryu, G.S.; Lee, Y.B.; Koh, K.T.; Chung, Y.S. The mechanical properties of fly ash-based geopolymer concrete with alkaline activators. Constr. Build. Mater. 2013, 47, 409–418. [Google Scholar] [CrossRef]

- Castel, A.; Foster, S.J.; Ng, T.; Sanjayan, J.G.; Gilbert, I.R. Creep and drying shrinkage of a blended slag and low calcium fly ash geopolymer Concrete. Mater. Struct. 2015. [Google Scholar] [CrossRef]

- Bakharev, T. Durability of geopolymer materials in sodium and magnesium sulfate solutions. Cem. Concr. Res. 2005, 35, 1233–1246. [Google Scholar] [CrossRef]

- Wallah, S.; Rangan, B.V. Low-Calcium Fly Ash-Based Geopolymer Concrete: Long-Term Properties; Res. Report-GC2; Curtin University: Bentley, Australia, 2006. [Google Scholar]

- Fernandez-Jimenez, A.; Palomo, A. Nanostructure/microstructure of fly ash geopolymers. In Geopolymers: Structure, Processing, Properties and Industrial Applications; Woodhead Publishing: Cambridge, UK, 2009; pp. 89–117. [Google Scholar]

- Sun, P.J.; Wu, H.C. Chemical and freeze-thaw resistance of fly ash-based inorganic mortars. Fuel 2013, 111, 740–745. [Google Scholar] [CrossRef]

- Chindaprasirt, P.; Chalee, W. Effect of sodium hydroxide concentration on chloride penetration and steel corrosion of fly ash-based geopolymer concrete under marine site. Constr. Build. Mater. 2014, 63, 303–310. [Google Scholar] [CrossRef]

- Ariffin, M.A.M.; Bhutta, M.A.R.; Hussin, M.W.; Tahir, M.M.; Aziah, N. Sulfuric acid resistance of blended ash geopolymer concrete. Constr. Build. Mater. 2013, 43, 80–86. [Google Scholar] [CrossRef]

- Sarker, P.K.; Kelly, S.; Yao, Z.T. Effect of fire exposure on cracking, spalling and residual strength of fly ash geopolymer concrete. Mater. Des. 2014, 63, 584–592. [Google Scholar] [CrossRef]

- Babaee, M.; Castel, A.; Akbarnezhad, A. Active steel corrosion in blended slag and fly ash geopolymer concrete. In Proceedings of the 34th Cement and Concrete Science Conference, Sheffield, UK, 14–17 September 2014.

- Reddy, B.V.V.; Kumar, P.P. Embodied energy in cement stabilised rammed earth walls. Energy Build. 2010, 42, 380–385. [Google Scholar] [CrossRef]

- Serrano, S.; Barreneche, C.; Rincon, L.; Boer, D.; Cabeza, L.F. Optimization of three new compositions of stabilized rammed earth incorporating PCM: Thermal properties characterization and LCA. Constr. Build. Mater. 2013, 47, 872–878. [Google Scholar] [CrossRef]

- Jiao, S.; Cao, M.; Li, Y. Impact research of solid waste on the strength of low carbon building materials. In Proceedings of the 2nd Annual Conference on Electrical and Control Engineering, Yichang, China, 16–18 September 2011.

- Kinuthia, J.M.; Oti, J.E. Designed non-fired clay mixes for sustainable and low carbon use. Appl. Clay Sci. 2012, 59–60, 131–139. [Google Scholar] [CrossRef]

- Zavadskas, E.K.; Antucheviciene, J.; Saparauskas, J.; Turskis, Z. Multi-criteria Assessment of Facades’ Alternatives: Peculiarities of Ranking Methodology. Mod. Build. Mater. Struct. Tech. 2013, 57, 107–112. [Google Scholar] [CrossRef]

- Zavadskas, E.K.; Kaklauskas, A.; Turskis, Z.; Tamosaitiene, J. Selection of the Effective Dwelling House Walls by Applying Attributes Values Determined at Intervals. J. Civ. Eng. Manag. 2008, 14, 85–93. [Google Scholar] [CrossRef]

- Reza, B.; Sadiq, R.; Hewage, K. Sustainability assessment of flooring systems in the city of Tehran: An AHP-based life cycle analysis. Constr. Build. Mater. 2011, 25, 2053–2066. [Google Scholar] [CrossRef]

- Wong, J.K.W.; Li, H. Application of the analytic hierarchy process (AHP) in multi-criteria analysis of the selection of intelligent building systems. Build. Environ. 2008, 43, 108–125. [Google Scholar] [CrossRef]

- Akbarnezhad, A.; Moussavi Nadoushani, Z.S. Estimating the costs, energy use and carbon emissions of concrete recycling using building information modelling. In Proceedings of the 31st International Symposium on Automation and Robotics in Construction and Mining (ISARC 2014), Sydney, Australia, 9–11 July 2014; pp. 385–392.

- Moussavi Nadoushani, Z.S.; Hammad, A.W.; Akbarnezhad, A. A Framework for Optimizing Lap Splice Positions within Concrete Elements to Minimize Cutting Waste of Steel Bars. In Proceedings of the 33rd International Symposium on Automation and Robotics in Construction (ISARC), Auburn, AL, USA, 18–21 July 2016; pp. 444–451.

- Poon, C.S.; Yu, A.T.W.; Jaillon, L. Reducing building waste at construction sites in Hong Kong. Constr. Manag. Econ. 2004, 22, 461–470. [Google Scholar] [CrossRef]

- Akbarnezhad, A.; Ong, K.; Chandra, L.; Lin, Z. Economic and Environmental Assessment of Deconstruction Strategies Using Building Information Modeling. In Proceedings of the Construction Research Congress 2012, Purdue University, West Lafayette, IN, USA, 21–23 May 2012; pp. 1730–1739.

- Xiao, J.; Ma, Z.M.; Ding, T. Reclamation chain of waste concrete: A case study of Shanghai. Waste Manag. 2016, 48, 334–343. [Google Scholar] [CrossRef] [PubMed]

- Akbarnezhad, A.; Ong, K.C.G.; Zhang, M.H.; Tam, C.T. Acid Treatment Technique for Determining the Mortar Content of Recycled Concrete Aggregates. J. Test. Eval. 2013, 41, 441–450. [Google Scholar] [CrossRef]

- Akbarnezhad, A.; Ong, K.C.G.; Tam, C.T.; Zhang, M.H. Effects of the Parent Concrete Properties and Crushing Procedure on the Properties of Coarse Recycled Concrete Aggregates. J. Mater. Civ. Eng. 2013, 25, 1795–1802. [Google Scholar] [CrossRef]

- Akbarnezhad, A.; Ong, K.C.G.; Zhang, M.H.; Tam, C.T.; Foo, T.W.J. Microwave-assisted beneficiation of recycled concrete aggregates. Constr. Build. Mater. 2011, 25, 3469–3479. [Google Scholar] [CrossRef]

- Xiao, J.; Falkner, H. Bond behaviour between recycled aggregate concrete and steel rebars. Constr. Build. Mater. 2007, 21, 395–401. [Google Scholar] [CrossRef]

- Xiao, J.; Li, J.; Zhang, C. Mechanical properties of recycled aggregate concrete under uniaxial loading. Cem. Concr. Res. 2005, 35, 1187–1194. [Google Scholar] [CrossRef]

- Xiao, J.; Li, J.; Zhang, C. On statistical characteristics of the compressive strength of recycled aggregate concrete. Struct. Concr. 2005, 6, 149–153. [Google Scholar] [CrossRef]

- Xiao, J.; Liu, Q.; Wu, Y.C. Numerical and experimental studies on fracture process of recycled concrete. Fatigue Fract. Eng. Mater. Struct. 2012, 35, 801–808. [Google Scholar] [CrossRef]

- Xiao, J.; Fan, Y.H.; Tawana, M.M. Residual compressive and flexural strength of a recycled aggregate concrete following elevated temperatures. Struct. Concr. 2013, 14, 168–175. [Google Scholar] [CrossRef]

- Chowdhury, R.; Apul, D.; Fry, T. A life cycle based environmental impacts assessment of construction materials used in road construction. Resour. Conserv. Recycl. 2010, 54, 250–255. [Google Scholar] [CrossRef]

- Marinkovic, S.; Radonjanin, V.; Malesev, M.; Ignjatovic, I. Comparative environmental assessment of natural and recycled aggregate concrete. Waste Manag. 2010, 30, 2255–2264. [Google Scholar] [CrossRef] [PubMed]

- Akbarnezhad, A.; Ong, K.C.G. Chapter 10: Separation processes to improve the quality of recycled concrete aggregates. In Handbook of Recycled Concrete and Demolition Waste; Woodhead Publishing: Cambridge, UK, 2013. [Google Scholar]

- Akbarnezhad, A.; Ong, K.C.G.; Chandra, L.R. Economic and environmental assessment of deconstruction strategies using building information modeling. Autom. Constr. 2014, 37, 131–144. [Google Scholar] [CrossRef]

- Rios, F.C.; Chong, W.K.; Grau, D. Design for Disassembly and Deconstruction—Challenges and Opportunities. Defin. Future Sustain. Resil. Des. Eng. Constr. 2015, 118, 1296–1304. [Google Scholar] [CrossRef]

- Tingley, D.D.; Davison, B. Developing an LCA methodology to account for the environmental benefits of design for deconstruction. Build. Environ. 2012, 57, 387–395. [Google Scholar] [CrossRef]

- Tingley, D.D.; Davison, B. Design for deconstruction and material reuse. Proc. Inst. Civ. Eng. Energy 2011, 164, 195–204. [Google Scholar] [CrossRef]

- Burak, R.; Hall, B.; Parker, K. Designing for adaptability, disassembly, and deconstruction. Procedia J. 2010, 55, 40–43. [Google Scholar]

- Xiao, J.; Ding, T.; Zhang, Q. Structural Behavior of a New Moment-Resisting DfD Concrete Connection. Eng. Struct. 2017, 132, 1–13. [Google Scholar] [CrossRef]

- Yan, H.; Shen, Q.P.; Fan, L.C.H.; Wang, Y.W.; Zhang, L. Greenhouse gas emissions in building construction: A case study of One Peking in Hong Kong. Build. Environ. 2010, 45, 949–955. [Google Scholar] [CrossRef]

- Ahmadian, F.F.A.; Akbarnezhad, A.; Rashidi, T.H.; Waller, S.T. Accounting for Transport Times in Planning Off-Site Shipment of Construction Materials. J. Constr. Eng. Manag. 2016, 142. [Google Scholar] [CrossRef]

- Ahmadian, F.F.A.; Akbarnezhad, A.; Rashidi, T.; Waller, S. Importance of planning for the transport stage in procurement of construction materials’. In Proceedings of the 31st International Symposium on Automation and Robotics in Construction and Mining (ISARC 2014), Sydney, Australia, 9–11 July 2014; pp. 466–473.

- Olhager, J. Strategic positioning of the order penetration point. Int. J. Prod. Econ. 2003, 85, 319–329. [Google Scholar] [CrossRef]

- Moussavi Nadoushani, Z.S.; Akbarnezhad, A. A Computational Framework for Estimating the Carbon Footprint of Construction. In Proceedings of the 31st International Symposium on Automation and Robotics in Construction and Mining (ISARC), Sydney, Australia, 9–11 July 2014; pp. 714–721.

- Junnila, S.; Horvath, A. Life-Cycle Environmental Effects of an Office Building. J. Infrastruct. Syst. 2003, 9, 157–166. [Google Scholar] [CrossRef]

- Junnila, S.; Horvath, A.; Guggemos, A.A. Life-Cycle Assessment of Office Buildings in Europe and the United States. J. Infrastruct. Syst. 2006, 12, 10–17. [Google Scholar] [CrossRef]

- Guggemos, A.; Horvath, A. Comparison of Environmental Effects of Steel- and Concrete-Framed Buildings. J. Infrastruct. Syst. 2005, 11, 93–101. [Google Scholar] [CrossRef]

- Lewis, P.; Leming, M.; Rasdorf, W. Impact of Engine Idling on Fuel Use and CO2 Emissions of Nonroad Diesel Construction Equipment. J. Manag. Eng. 2012, 28, 31–38. [Google Scholar] [CrossRef]

- Lewis, P.; Rasdorf, W.; Frey, H.C.; Pang, S.H.; Kim, K. Requirements and Incentives for Reducing Construction Vehicle Emissions and Comparison of Nonroad Diesel Engine Emissions Data Sources. J. Constr. Eng. Manag. 2009, 135, 341–351. [Google Scholar] [CrossRef]

- Ahn, C.R.; Lee, S. Importance of Operational Efficiency to Achieve Energy Efficiency and Exhaust Emission Reduction of Construction Operations. J. Constr. Eng. Manag. 2013, 139, 404–413. [Google Scholar] [CrossRef]

- Avetisyan, H.G.; Miller-Hooks, E.; Melanta, S. Decision Models to Support Greenhouse Gas Emissions Reduction from Transportation Construction Projects. J. Constr. Eng. Manag. 2012, 138, 631–641. [Google Scholar] [CrossRef]

- Hammad, A.W.A.; Akbarnezhad, A.; Rey, D.; Waller, S.T. A Computational Method for Estimating Travel Frequencies in Site Layout Planning. J. Constr. Eng. Manag. 2016, 142. [Google Scholar] [CrossRef]

- Hammad, A.W.A.; Akbarnezhad, A.; Rey, D. A multi-objective mixed integer nonlinear programming model for construction site layout planning to minimise noise pollution and transport costs. Autom. Constr. 2016, 61, 73–85. [Google Scholar] [CrossRef]

- Moussavi Nadoushani, Z.S.; Hammad, A.W.A.; Akbarnezhad, A. Location Optimization of Tower Crane and Allocation of Material Supply Points in a Construction Site Considering Operating and Rental Costs. J. Constr. Eng. Manag. 2016. [Google Scholar] [CrossRef]

- Frey, H.C.; Rasdorf, W.; Lewis, P. Comprehensive Field Study of Fuel Use and Emissions of Nonroad Diesel Construction Equipment. Transp. Res. Rec. 2010, 2158, 69–76. [Google Scholar] [CrossRef]

- Guggemos, A.; Horvath, A. Decision-Support Tool for Assessing the Environmental Effects of Constructing Commercial Buildings. J. Archit. Eng. 2006, 12, 187–195. [Google Scholar] [CrossRef]

- Liu, C.N.; An, X.H.; Ahn, C.R.; Lee, S. Integrated Evaluation of Cost, Schedule and Emission Performance on Rock-Filled Concrete Dam Construction Operation Using Discrete Event Simulation. In Proceedings of the 2013 Winter Simulation Conference (WSC), Washington, DC, USA, 8–11 December 2013; pp. 3109–3120.

- Ahn, C.; Pan, W.J.; Lee, S.; Pena-Mora, F.A. Lessons Learned from Utilizing Discrete-Event Simulation Modeling for Quantifying Construction Emissions in Pre-Planning Phase. In Proceedings of the 2010 Winter Simulation Conference, Baltimore, MD, USA, 5–8 December 2010; pp. 3170–3176.

- Kaboli, A.S.; Carmichael, D.G. An examination of the DRET model and the influence of payload, haul grade and truck type on earthmoving emissions. Int. J. Constr. Manag. 2016, 16, 95–108. [Google Scholar] [CrossRef]

- Carmichael, D.G.; Williams, E.H.; Kaboli, A.S. Minimum Operational Emissions in Earthmoving. In Proceedings of the Construction Research Congress 2012, West Lafayette, IN, USA, 21–23 May 2012; American Society of Civil Engineers: New York, NY, USA, 2012; pp. 1869–1878. [Google Scholar]

- Mao, C.; Shen, Q.P.; Shen, L.Y.; Tang, L.Y.N. Comparative study of greenhouse gas emissions between off-site prefabrication and conventional construction methods: Two case studies of residential projects. Energy Build. 2013, 66, 165–176. [Google Scholar] [CrossRef]

- Suh, S.; Lenzen, M.; Treloar, G.J.; Hondo, H.; Horvath, A.; Huppes, G.; Jolliet, O.; Klann, U.; Krewitt, W.; Moriguchi, Y.; et al. System boundary selection in life-cycle inventories using hybrid approaches. Environ. Sci. Technol. 2004, 38, 657–664. [Google Scholar] [CrossRef] [PubMed]

- Luo, L.; van der Voet, E.; Huppes, G.; Udo de Haes, H.A. Allocation issues in LCA methodology: A case study of corn stover-based fuel ethanol. Int. J. Life Cycle Assess. 2009, 14, 529. [Google Scholar] [CrossRef]

- Rabl, A.; Benoist, A.; Dron, D.; Peuportier, B.; Spadaro, J.V.; Zoughaib, A. How to account for CO2 emissions from biomass in an LCA. Int. J. Life Cycle Assess. 2007, 12, 281. [Google Scholar] [CrossRef]

- Hammond, G.P.; Jones, C.I. Embodied carbon: The concealed impact of residential construction. In Proceedings of the Global Conference on Global Warming, Istanbul, Turkey, 6–10 July 2009; pp. 367–384.

- Langston, Y.L.; Ca, L. Reliability of building embodied energy modeling: An analysis of 30 Melbourne case studies. Constr. Manag. Econ. 2008, 26, 147–160. [Google Scholar] [CrossRef]

- Andrew, A. Embodied Energy and CO2 Coefficients for NZ Building Materials; Centre for Building Performance Research Report; Centre for Building Performance Research: Wellington, New Zealand, 2003. [Google Scholar]

- EPA. Quantifying Greenhouse Gas Emissions in Key Industrial Sectors; Sector Strategies Div: Washington, DC, USA, 2008. Available online: http://www.epa.gov/sectors/pdf/2008/2008-sector-report-508-full.pdf (accessed on 15 September 2016).

- EPA. Sources of Greenhouse Gas Emissions. 2012. Available online: http://www.epa.gov/climatechange/ghgemissions/sources/transportation.html (accessed on 15 September 2016). [Google Scholar]

- MOBILE Model (on-Road Vehicles). Environmental Protection Agency: Washington, DC, USA, 2016. Available online: http://www.epa.gov/otaq/mobile.htm (accessed on 15 September 2016).

- MOVES (Motor Vehicle Emission Simulator). Environmental Protection Agency: Washington, DC, USA, 2016. Available online: http://www.epa.gov/otaq/models/moves/index.htm (accessed on 15 September 2016).

- Bai, S.; Eisinger, D.; Niemeier, D. MOVES vs. EMFAC: A Comparison of Greenhouse Gas Emissions Using Los Angeles County. In Proceedings of the Transportation Research Board 88th Annual Meeting, Washington, DC, USA, 11–15 January 2009.

- EMFAC. EMFAC2011 Overview. 2013. Available online: http://www.arb.ca.gov/msei/emfac2011-release-document-final-updated-0712v03.pdf (accessed on 15 September 2016). [Google Scholar]

- Wong, J.K.W.; Li, H.; Wang, H.R.; Huang, T.; Luo, E.; Li, V. Toward low-carbon construction processes: The visualisation of predicted emission via virtual prototyping technology. Autom. Constr. 2013, 33, 72–78. [Google Scholar] [CrossRef]

- Memarzadeh, M.; Golparvar-Fard, M. Monitoring and Visualization of Building Construction Embodied Carbon Footprint Using DnAR-N-Dimensional Augmented Reality Models. In Proceedings of the Construction Research Congress 2012, West Lafayette, IN, USA, 21–23 May 2012; American Society of Civil Engineers: New York, NY, USA, 2012. [Google Scholar]

- Ahn, C.R.; Lewis, P.; Golparvar-Fard, M.; Lee, S. Integrated Framework for Estimating, Benchmarking, and Monitoring Pollutant Emissions of Construction Operations. J. Constr. Eng. Manag. 2013, 139, A4013003. [Google Scholar] [CrossRef]

- Tang, P.; Cass, D.; Mukherjee, A. Using schedule simulation approaches to reduce greenhouse gas emissions in highway construction project. In Proceedings of the IEEE 2011 Winter Simulation Conference (WSC), Phoenix, AZ, USA, 11–14 December 2011.

- Tang, P.; Cass, D.; Mukherjee, A. Investigating the effect of construction management strategies on project greenhouse gas emissions using interactive simulation. J. Clean. Prod. 2013, 54, 78–88. [Google Scholar] [CrossRef]

- Lewis, P. Estimating Fuel Use and Emission Rates of Nonroad Diesel Construction Equipment Performing Representative Duty Cycles. Ph.D. Thesis, North Carolina State University, Raleigh, NC, USA, 2009. [Google Scholar]

- Nonroad Model (Nonroad Engines, Equipment, and Vehicles). Environmental Protection Agency: Washington, DC, USA, 2016. Available online: http://www.epa.gov/otaq/nonrdmdl.htm (accessed on 15 September 2016).

- Zhang, H. Discrete-Event Simulation for Estimating Emissions from Construction Processes. J. Manag. Eng. 2015, 31. [Google Scholar] [CrossRef]

- Lewis, P.; Leming, M.; Frey, H.C.; Rasdorf, W. Assessing Effects of Operational Efficiency on Pollutant Emissions of Nonroad Diesel Construction Equipment. Transp. Res. Rec. 2011, 2233, 11–18. [Google Scholar] [CrossRef]

- Offroad, A. Off-Road Motor Vehicles; California Air Resources Board (CARB): Sacramento, CA, USA, 2016. Available online: http://www.arb.ca.gov/msei/categories.htm#offroad_motor_vehicles (accessed on 15 September 2016).

- Urbemis. Software User’s Guide: Urbemis 2007 for Windows; Urbemis: Sacramento, CA, USA, 2007. [Google Scholar]

- Road Construction Emissions Model (RCEM), version 6.3.1; Sacramento, CA, USA, 2007.

- Smith, S. Concrete placing analysis using discrete-event simulation. Proc. Inst. Civ. Eng. Struct. Build. 1998, 128, 351–358. [Google Scholar] [CrossRef]

- Pantouvakis, J.P.; Panas, A. Computer simulation and analysis framework for floating caisson construction operations. Autom. Constr. 2013, 36, 196–207. [Google Scholar] [CrossRef]

- Feng, C.W.; Cheng, T.M.; Wu, H.T. Optimizing the schedule of dispatching RMC trucks through genetic algorithms. Autom. Constr. 2004, 13, 327–340. [Google Scholar] [CrossRef]

- Alanjari, P.; Razavialavi, S.; Abourizk, S. A simulation-based approach for material yard laydown planning. Autom. Constr. 2014, 40, 1–8. [Google Scholar] [CrossRef]

- Lu, W.Z.; Olofsson, T. Building information modeling and discrete event simulation: Towards an integrated framework. Autom. Constr. 2014, 44, 73–83. [Google Scholar] [CrossRef]

- Abourizk, S.; Halpin, D.; Mohamed, Y.; Hermann, U. Research in Modeling and Simulation for Improving Construction Engineering Operations. J. Constr. Eng. Manag. 2011, 137, 843–852. [Google Scholar] [CrossRef]

- Lee, D.E.; Yi, C.Y.; Lim, T.K.; Arditi, D. Integrated Simulation System for Construction Operation and Project Scheduling. J. Comput. Civ. Eng. 2010, 24, 557–569. [Google Scholar] [CrossRef]

- Zhang, H.; Zhai, D.; Yang, Y.N. Simulation-based estimation of environmental pollutions from construction processes. J. Clean. Prod. 2014, 76, 85–94. [Google Scholar] [CrossRef]

- Zhang, H. Simulation-Based Estimation of Fuel Consumption and Emissions of Asphalt Paving Operations. J. Comput. Civ. Eng. 2015, 29. [Google Scholar] [CrossRef]

- Hasan, S.; Bouferguene, A.; Al-Hussein, M.; Gillis, P.; Telyas, A. Productivity and CO2 emission analysis for tower crane utilization on high-rise building projects. Autom. Constr. 2013, 31, 255–264. [Google Scholar] [CrossRef]

- Hajjar, D.; Abourizk, S. Simphony: An environment for building special purpose construction simulation tools. Simul. Conf. Proc. 1999, 2, 998–1006. [Google Scholar]

- Martinez, J.C. Stroboscope: State and Resource Based Simulation of Construction Processes; University of Michigan: Ann Arbor, MI, USA, 1996. [Google Scholar]

- Golparvar-Fard, M.; Heydarian, A.; Niebles, J.C. Vision-based action recognition of earthmoving equipment using spatio-temporal features and support vector machine classifiers. Adv. Eng. Inform. 2013, 27, 652–663. [Google Scholar] [CrossRef]

- Vitale, P.; Arena, N.; Crisostomo, F.; Arena, U. Life cycle assessment of the end-of-life phase of a residential building. Waste Manag. 2016, in press. [Google Scholar] [CrossRef] [PubMed]

| Concrete Grade | Embodied Carbon (kg CO2-e/kg) | ||

|---|---|---|---|

| Cement Replacement with Fly Ash (%) | |||

| 0% | 15% | 30% | |

| RC 20/25 (20/25 MPa) | 0.132 | 0.122 | 0.108 |

| RC 25/30 (25/30 MPa) | 0.140 | 0.130 | 0.115 |

| RC 28/35 (28/35 MPa) | 0.148 | 0.138 | 0.124 |

| RC 32/40 (32/40 MPa) | 0.163 | 0.152 | 0.136 |

| RC 40/50 (40/50 MPa) | 0.188 | 0.174 | 0.155 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license ( http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Akbarnezhad, A.; Xiao, J. Estimation and Minimization of Embodied Carbon of Buildings: A Review. Buildings 2017, 7, 5. https://doi.org/10.3390/buildings7010005

Akbarnezhad A, Xiao J. Estimation and Minimization of Embodied Carbon of Buildings: A Review. Buildings. 2017; 7(1):5. https://doi.org/10.3390/buildings7010005

Chicago/Turabian StyleAkbarnezhad, Ali, and Jianzhuang Xiao. 2017. "Estimation and Minimization of Embodied Carbon of Buildings: A Review" Buildings 7, no. 1: 5. https://doi.org/10.3390/buildings7010005